| [1] |

卢秋虹, 王宁, 范诚, 等. 壁厚对HR2钢柱壳爆轰加载下膨胀断裂行为的影响 [J]. 材料研究学报, 2020, 34(4): 241–246.LU Q H, WANG N, FAN C, et al. Effect of shell thickness on expanding fracture behavior of HR2 steel cylinders under explosive loading [J]. Chinese Journal of Materials Research, 2020, 34(4): 241–246.

|

| [2] |

禹富有, 董新龙, 俞鑫炉, 等. 不同填塞装药下金属柱壳断裂特性的实验研究 [J]. 兵工学报, 2019, 40(7): 1418−1424.YU F Y, DONG X L, YU X L, et al. Fracture characteristics of metal cylinder shells with different charges [J]. Acta Armamentarii, 2019, 40(7): 1418−1424.

|

| [3] |

HIROE T, FUJIWARA K, HATA H, et al. Explosively driven expansion and fragmentation behavior for cylinders, spheres and rings of 304 stainless steel [J]. Materials Science Forum, 2010: 638–642.

|

| [4] |

HIROE T, FUJIWARA K, HATA H, et al. Deformation and fragmentation behaviour of exploded metal cylinders and the effects of wall materials, configuration, explosive energy and initiated locations [J]. International Journal of Impact Engineering, 2008, 35(12): 1578–1586. doi: 10.1016/j.ijimpeng.2008.07.002

|

| [5] |

汤铁钢, 李庆忠, 孙学林, 等. 45钢柱壳膨胀断裂的应变率效应 [J]. 爆炸与冲击, 2006, 26(2): 129–133. doi: 10.11883/1001-1455(2006)02-0129-05TANG T G, LI Q Z, SUN X L, et al. Strain-rate effects of expanding fracture of 45 steel cylinder shells driven by detonation [J]. Explosion and Shock Waves, 2006, 26(2): 129–133. doi: 10.11883/1001-1455(2006)02-0129-05

|

| [6] |

胡八一, 董庆东, 韩长生, 等. TC4钛合金自然破片的引燃机理 [J]. 爆炸与冲击, 1995, 12(3): 254–258.HU B Y, DONG Q D, HAN C S, et al. Analysis of the firing mechanics for Ti-6Al-4V natural fragments [J]. Explosion and Shock Waves, 1995, 12(3): 254–258.

|

| [7] |

MOTT N F. A theory of the fragmentation of shells and bomb [C]//Fragmentation of Rings and Shells. Shock Wave and High Pressure Phenomena. Berlin, Heidelberg: Springer, 1943.

|

| [8] |

MOTT N F. Fragmentation of shells cases [J]. Proceedings of the Royal Society of London A, 1947, 189: 300–308.

|

| [9] |

GRADY D. Investigation of explosively driven fragmentation of metals-two-dimensional fracture and fragmentation of metal shells: UCRL-CR-152264 [R]. Livermore, CA: Lawrence Livermore National Laboratory, 2003.

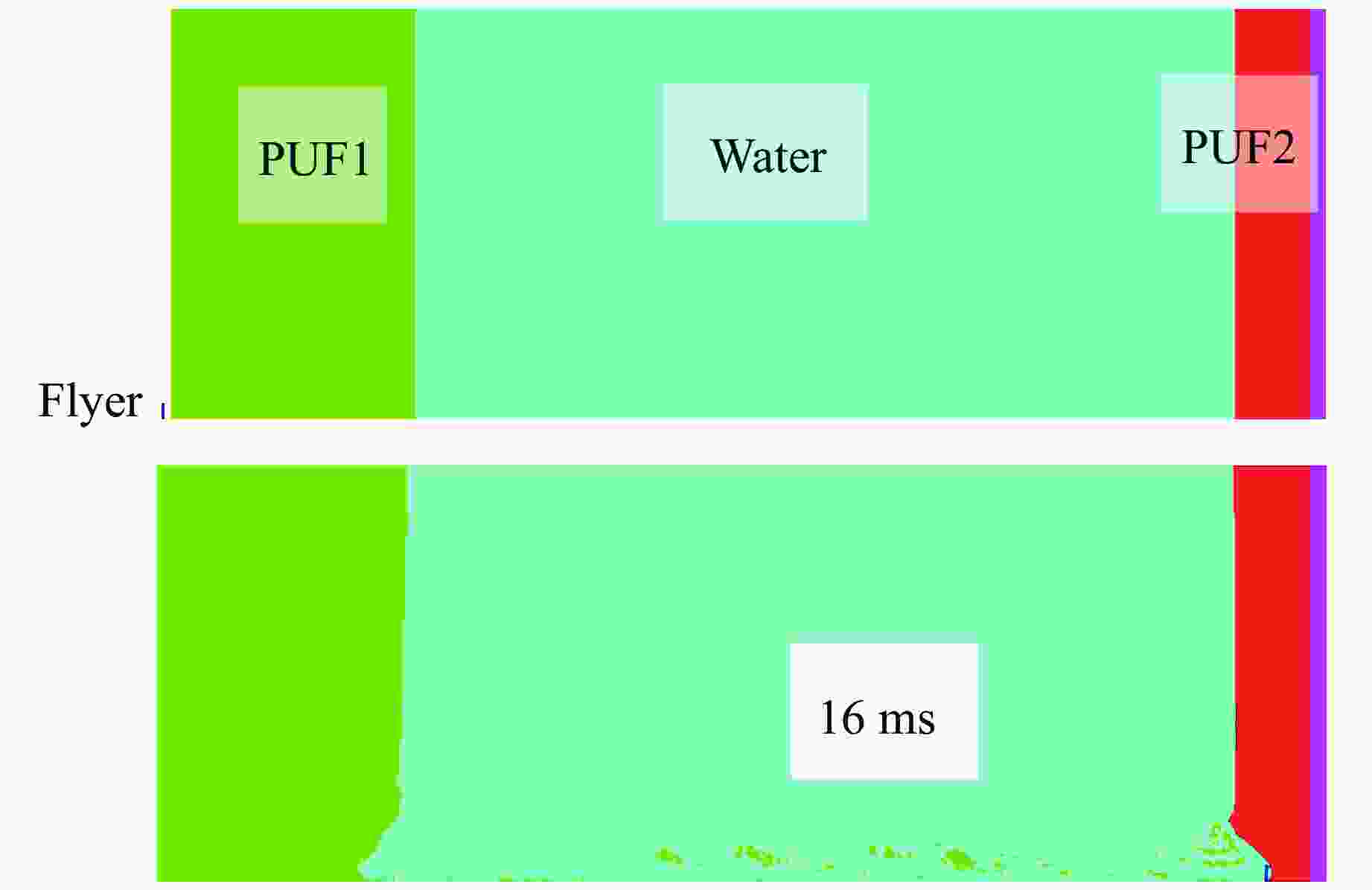

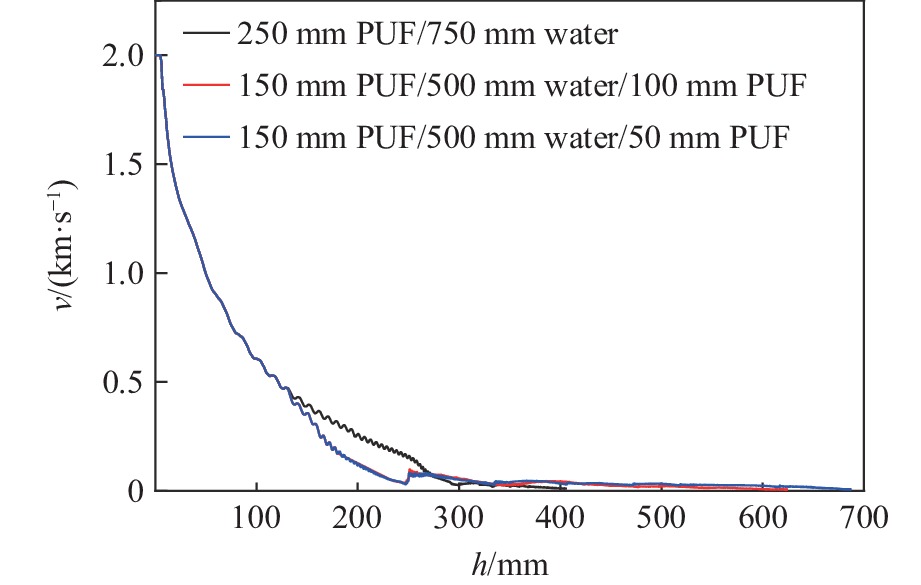

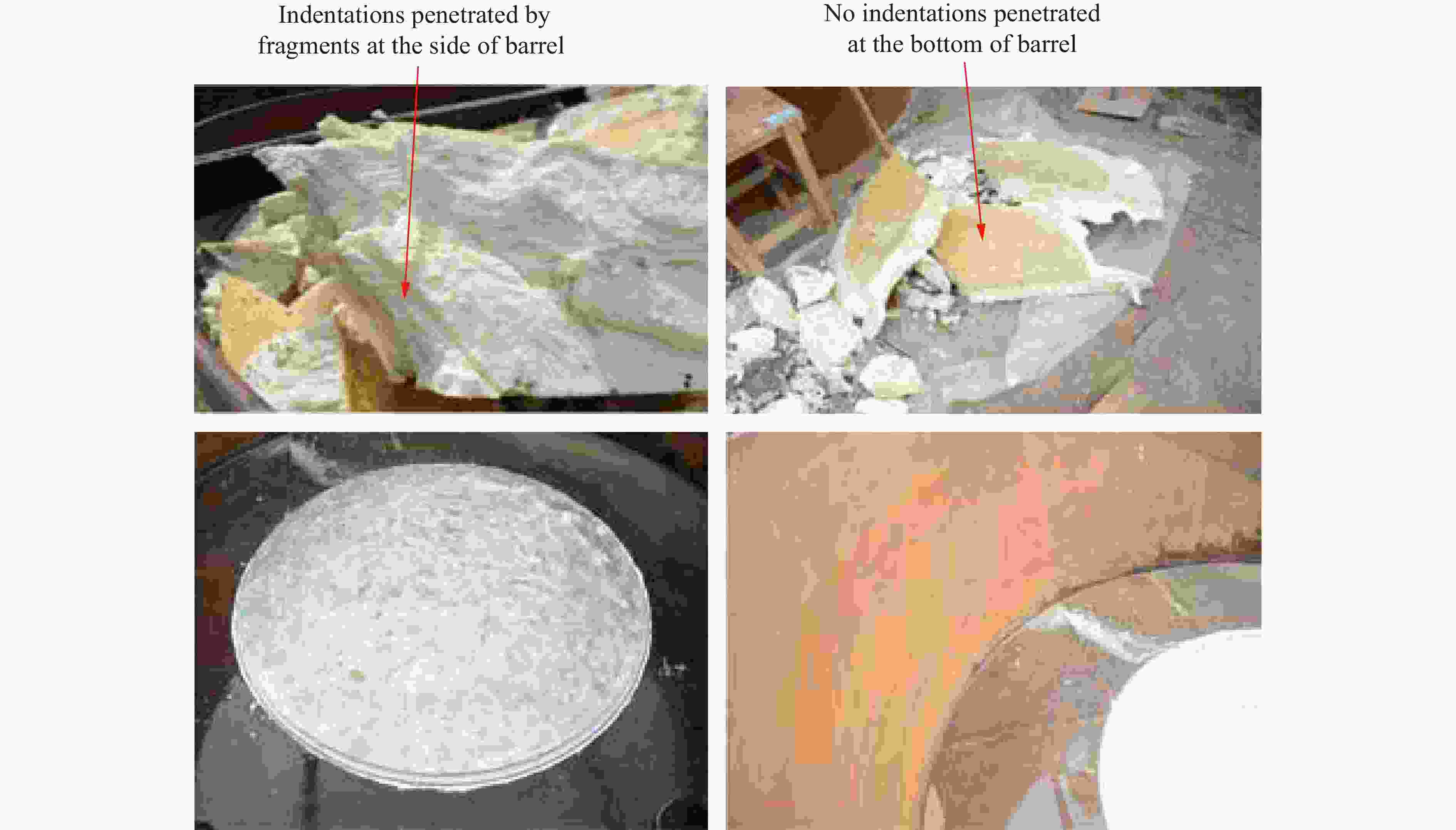

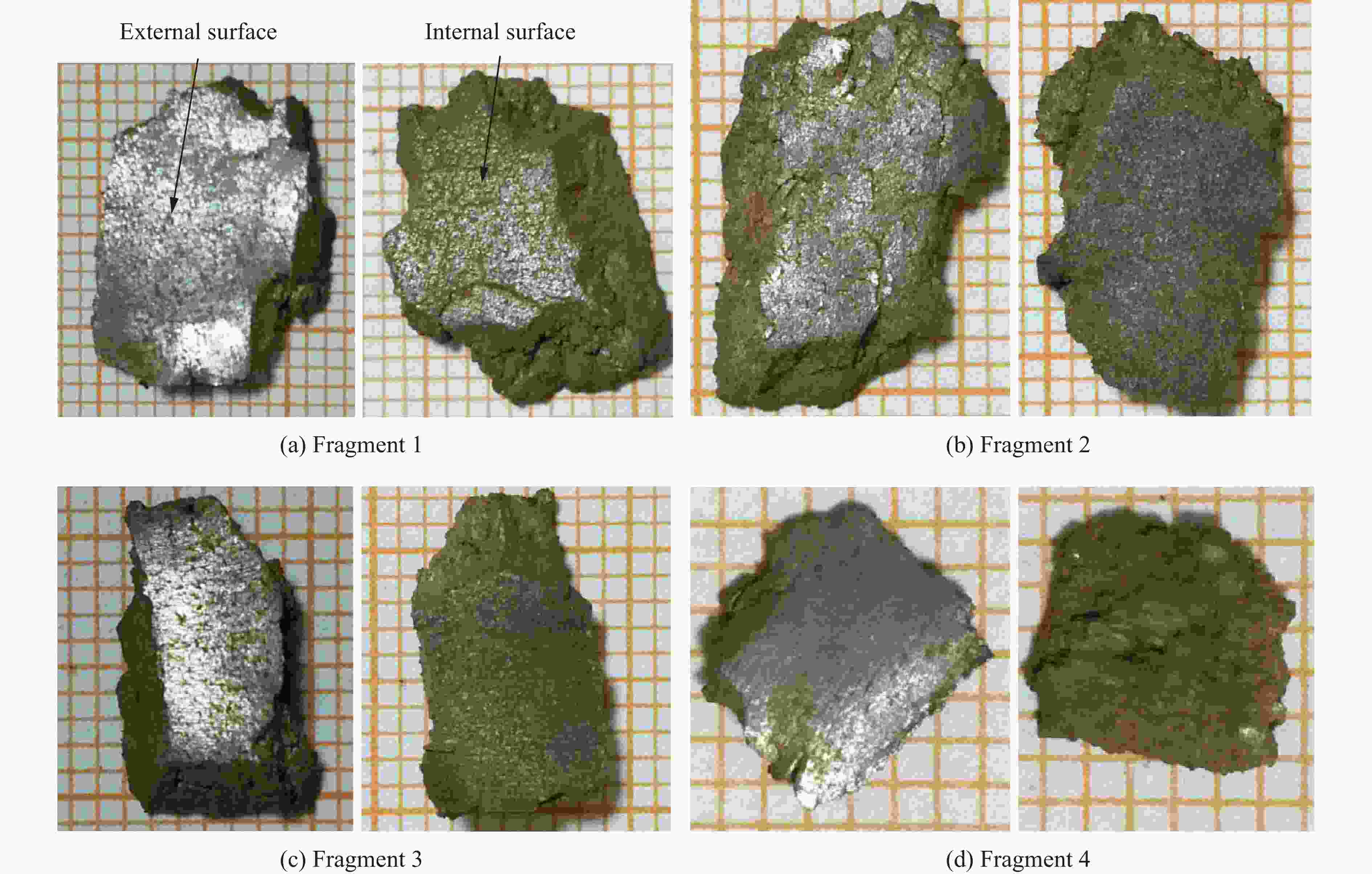

|

| [10] |

GURNEY R W. The initial velocity of fragments from bombs, shells and grenades: BRL Report 450 [R]. MaryLand, USA: Ballistic Research Laboratory, 1943.

|

| [11] |

金山, 汤铁钢, 孙学林, 等. 不同热处理下45钢柱壳的动态性能 [J]. 爆炸与冲击, 2006, 26(5): 423–428. doi: 10.3321/j.issn:1001-1455.2006.05.006JIN S, TANG T G, SUN X L, et al. Dynamic characteristics of 45 steel cylinder shell by different heat treatment conditions [J]. Explosion and Shock Waves, 2006, 26(5): 423–428. doi: 10.3321/j.issn:1001-1455.2006.05.006

|

| [12] |

何辉, 禹海军, 王毅, 等. 4 MeV闪光X光机轫致辐射靶设计 [J]. 强激光与粒子束, 2019, 31(12): 125102. doi: 10.11884/HPLPB201931.190273HE H, YU H J, WANG Y, et al. Design of bremsstrahlung target of 4 MeV flash X-ray machine [J]. High Power Laser and Particle Beams, 2019, 31(12): 125102. doi: 10.11884/HPLPB201931.190273

|

| [13] |

施将君, 刘进, 刘军. 闪光照相中X光能谱对有效吸收系数的影响 [J]. 强激光与粒子束, 2004, 16(6): 809–812.SHI J J, LIU J, LIU J. Effect of X-ray penetration spectrum on attenuation coefficient in flash radiography [J]. High Power Laser and Particle Beams, 2004, 16(6): 809–812.

|

| [14] |

BOLIS C, COUNILH D, LAGRANGE J M, et al. Fragmentation of a titanium alloy shell in expansion: from experiment to simulation [J]. Procedia Engineering, 2013, 58: 672-677.

|

| [15] |

刘明涛, 汤铁钢. 爆炸加载下金属壳体膨胀断裂过程中的关键物理问题 [J]. 爆炸与冲击, 2021, 41(1): 011402. doi: 10.11883/bzycj-2020-0351LIU M T, TANG T G. Key physical problems in the expanding fracture of explosively driven metallic shells [J]. Explosion and Shock Waves, 2021, 41(1): 011402. doi: 10.11883/bzycj-2020-0351

|

| [16] |

ZHANG Z B, HUANG F L, CAO Y, et al. A fragments mass distribution scaling relations for fragmenting shells with variable thickness subjected to internal explosive loading [J]. International Journal of Impact Engineering, 2018, 120: 79–94. doi: 10.1016/j.ijimpeng.2018.05.013

|

| [17] |

汤铁钢, 谷岩, 李庆忠, 等. 爆轰加载下金属柱壳膨胀破裂过程研究 [J]. 爆炸与冲击, 2003, 23(6): 529–533. doi: 10.3321/j.issn:1001-1455.2003.06.008TANG T G, GU Y, LI Q Z, et al. Expanding fracture of steel cylinder shell by detonation driving [J]. Explosion and Shock Waves, 2003, 23(6): 529–533. doi: 10.3321/j.issn:1001-1455.2003.06.008

|

| [18] |

张绍兴, 李翔宇, 丁亮亮, 等. 聚焦式战斗部破片轴向飞散控制技术 [J]. 高压物理学报, 2018, 32(1): 015103. doi: 10.11858/gywlxb.20170512ZHANG S X, LI X Y, DING L L, et al. Axial dispersion control of focusing fragment warhead [J]. Chinese Journal of High Pressure Physics, 2018, 32(1): 015103. doi: 10.11858/gywlxb.20170512

|

| [19] |

史志鑫, 尹建平, 王志军, 等. 预制破片的形状对破片飞散性能影响的数值模拟研究 [J]. 兵器装备工程学报, 2017, 38(12): 31–35. doi: 10.11809/scbgxb2017.12.008SHI Z X, YIN J P, WANG Z J, et al. Numerical simulation of the influence of prefabricated fragments shape on fragment scattering performance [J]. Journal of Ordnance Equipment Engineering, 2017, 38(12): 31–35. doi: 10.11809/scbgxb2017.12.008

|

| [20] |

李翔宇, 卢芳云, 王志兵, 等. 可变形定向破片战斗部模型试验和数值模拟研究 [J]. 国防科技大学学报, 2006, 28(1): 121–124. doi: 10.3969/j.issn.1001-2486.2006.01.027LI X Y, LU F Y, WANG Z B, et al. A study of simulation and experiment of target-directed deformable warhead model [J]. Journal of National University of Defense Technology, 2006, 28(1): 121–124. doi: 10.3969/j.issn.1001-2486.2006.01.027

|

| [21] |

宋桂飞, 李成国, 夏福君, 等. 回收战斗部破片的新型爆炸容器及应用 [J]. 爆炸与冲击, 2008, 28(4): 372–377. doi: 10.3321/j.issn:1001-1455.2008.04.015SONG G F, LI C G, XIA F J, et al. A new explosion vessel used to recover warhead fragments and its application [J]. Explosion and Shock Waves, 2008, 28(4): 372–377. doi: 10.3321/j.issn:1001-1455.2008.04.015

|

| [22] |

柏劲松, 刘坤, 张红平, 等. 基于MVPPM的流固耦合方法在爆炸容器数值计算中的应用 [J]. 高压物理学报, 2013, 27(3): 343–351. doi: 10.11858/gywlxb.2013.03.005BAI J S, LIU K, ZHANG H P, et al. Application of the MVPPM-based fliud-solid coupling method [J]. Chinese Journal of High Pressure Physics, 2013, 27(3): 343–351. doi: 10.11858/gywlxb.2013.03.005

|

| [23] |

陈志闯, 李伟兵, 朱建军, 等. 40CrMnSiB钢圆柱壳体膨胀断裂中间状态回收试验研究 [J]. 兵工学报, 2018, 39(11): 2137–2144. doi: 10.3969/j.issn.1000-1093.2018.11.007CHEN Z C, LI W B, ZHU J J, et al. Recovery experiment study of cylindrical 40CrMnSiB steel shell in intermediate phase of expanding fracture processes [J]. Acta Armamentarii, 2018, 39(11): 2137–2144. doi: 10.3969/j.issn.1000-1093.2018.11.007

|

| [24] |

罗渝松, 李伟兵, 陈志闯, 等. 内爆加载下金属柱壳的冻结回收方法 [J]. 爆炸与冲击, 2020, 40(10): 104101. doi: 10.11883/bzycj-2020-0041LUO Y S, LI W B, CHEN Z C, et al. A freezing recovery method for metallic cylinder shells under internal explosive loading [J]. Explosion and Shock Waves, 2020, 40(10): 104101. doi: 10.11883/bzycj-2020-0041

|

| [25] |

GOTO D M, BECKER R, ORZECHOWSKI T J, et al. Investigation of the fracture and fragmentation of explosively driven rings and cylinders [J]. International Journal of Impact Engineering, 2008, 35: 1547–1556. doi: 10.1016/j.ijimpeng.2008.07.081

|

| [26] |

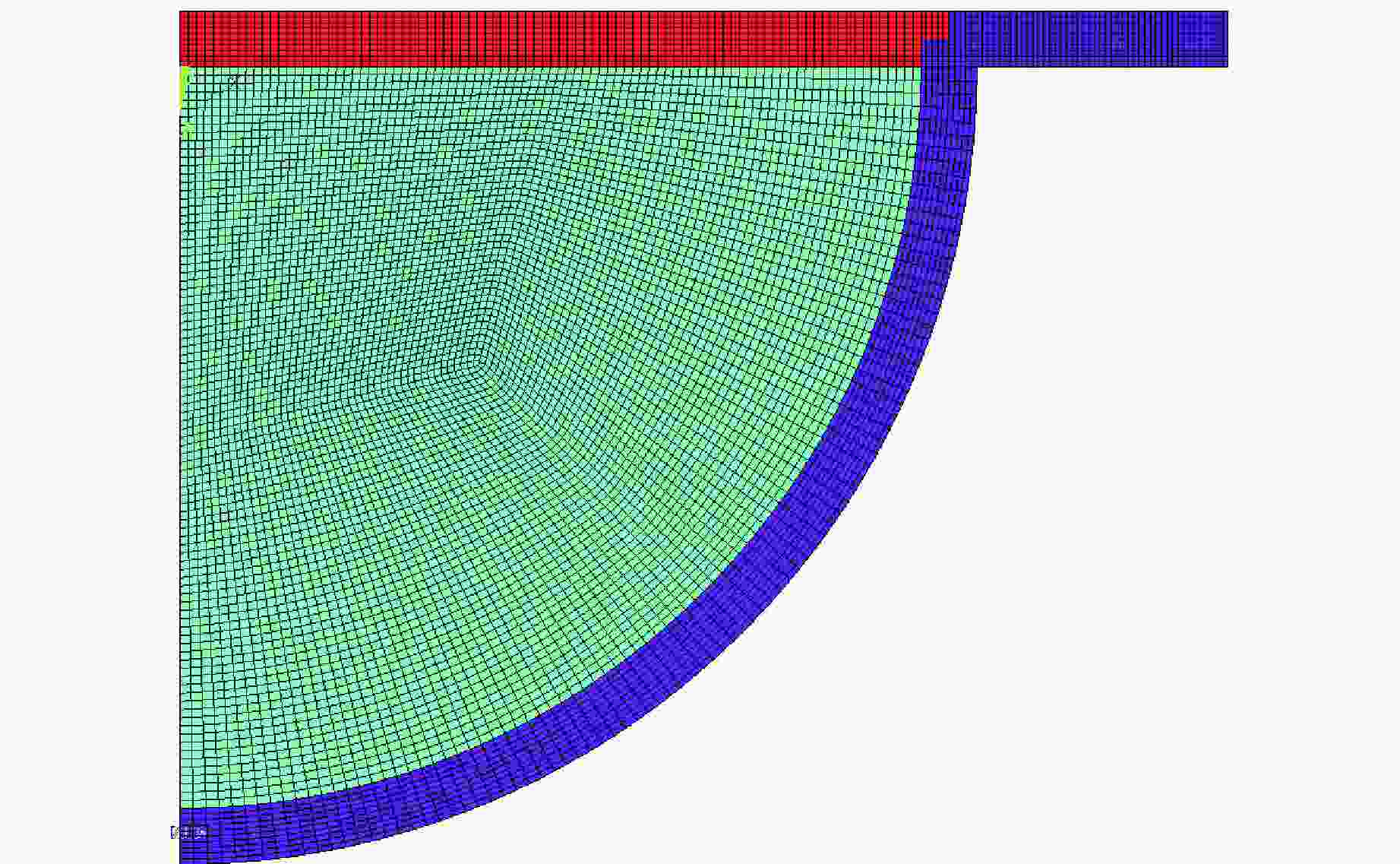

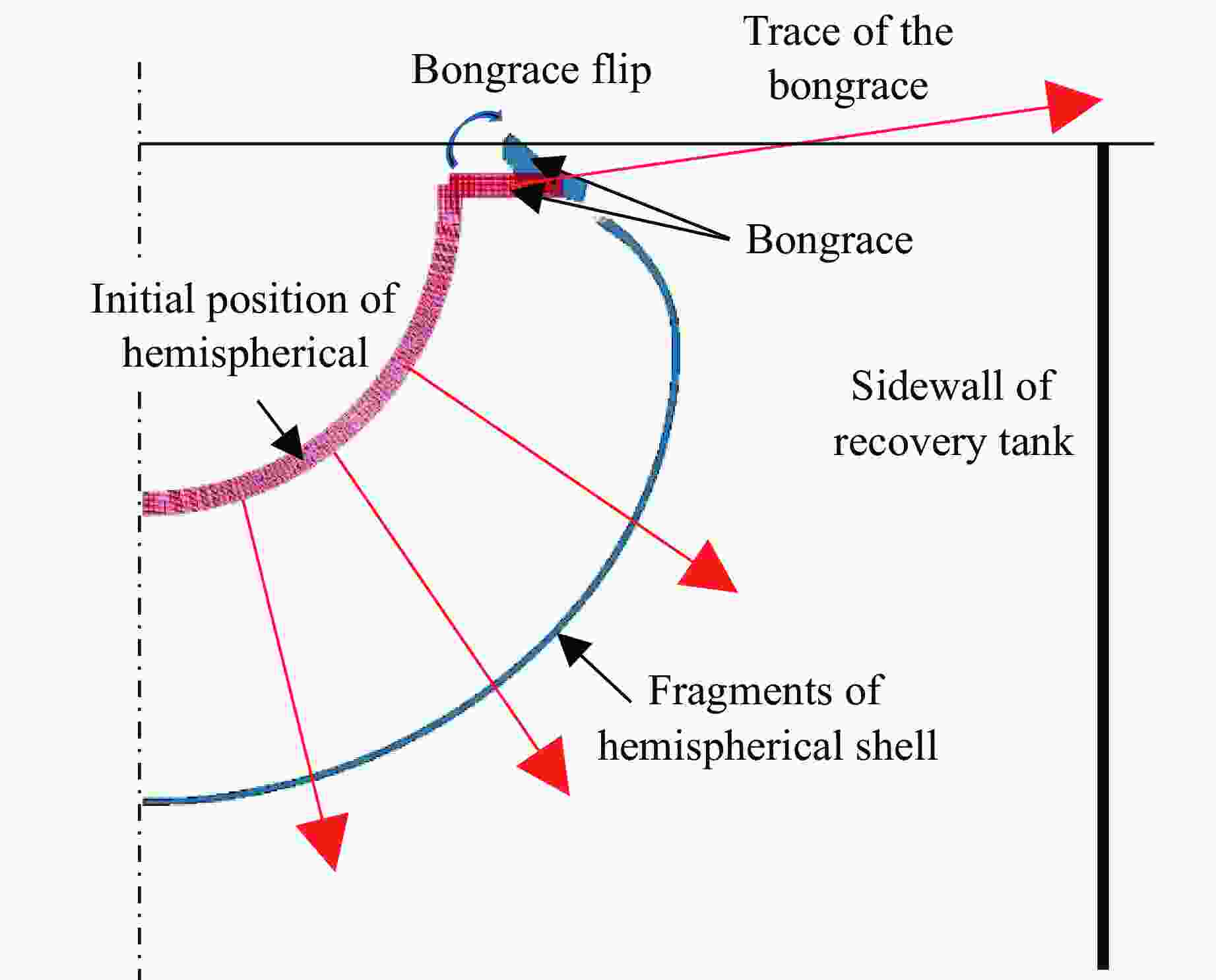

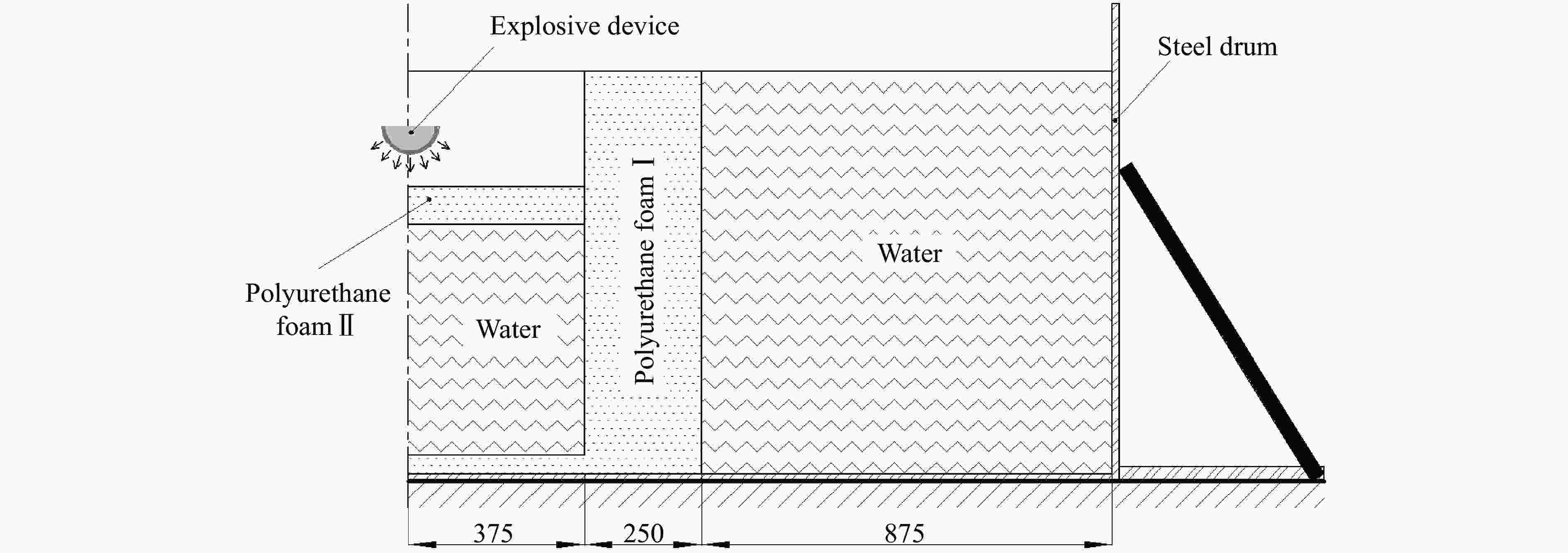

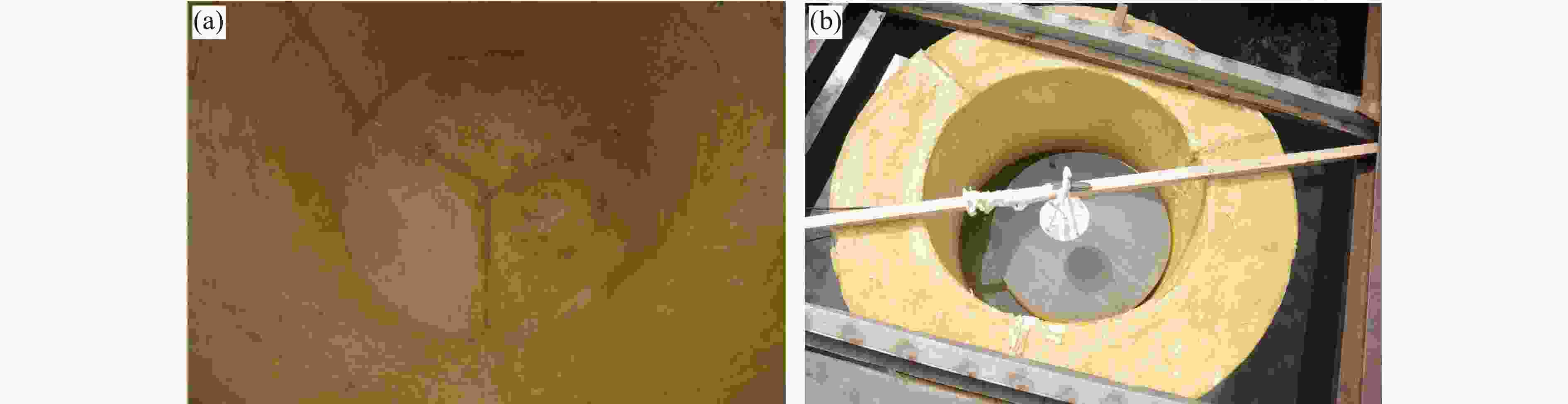

张世文, 李英雷, 陈艳, 等. 爆炸加载下金属柱壳破片软回收技术研究 [J]. 爆炸与冲击, 2021, 41(11): 114102. doi: 10.11883/bzycj-2020-0449ZHANG S W, LI Y L, CHEN Y, et al. Investigation on the technology of soft recovery of fragment produced by metal cylindrical shell subjected to explosive loading [J]. Explosion and Shock Waves, 2021, 41(11): 114102. doi: 10.11883/bzycj-2020-0449

|

| [27] |

吴文苍, 董新龙, 庞振, 等. TA2钛合金开口柱壳外爆碎片分布研究 [J]. 力学学报, 2021, 53(6): 1795–1806. doi: 10.6052/0459-1879-21-017WU W C, DONG X L, PANG Z, et al. Study on fragments distribution of explosively driven cylinders for TA2 titanium alloy [J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(6): 1795–1806. doi: 10.6052/0459-1879-21-017

|

| [28] |

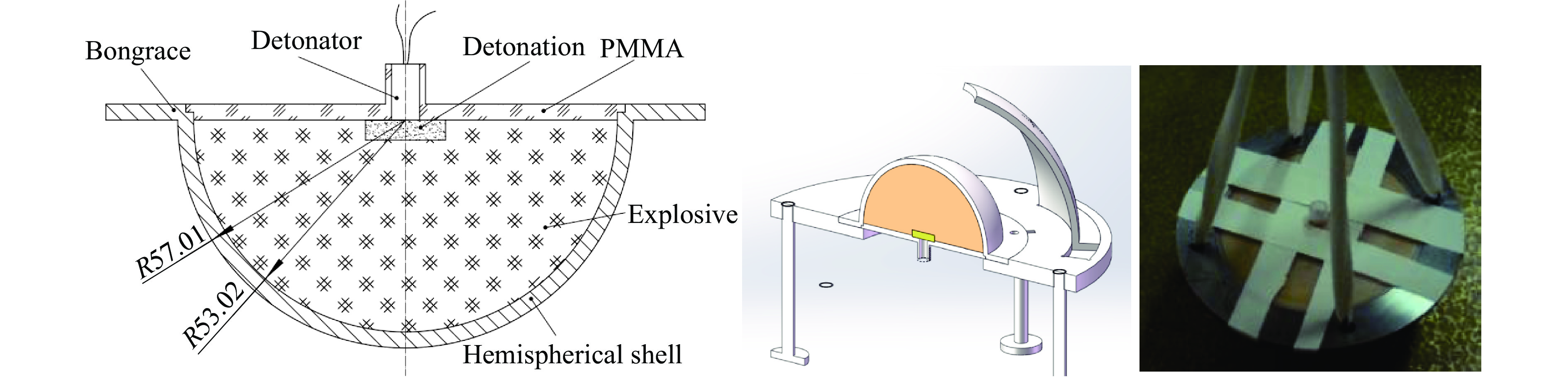

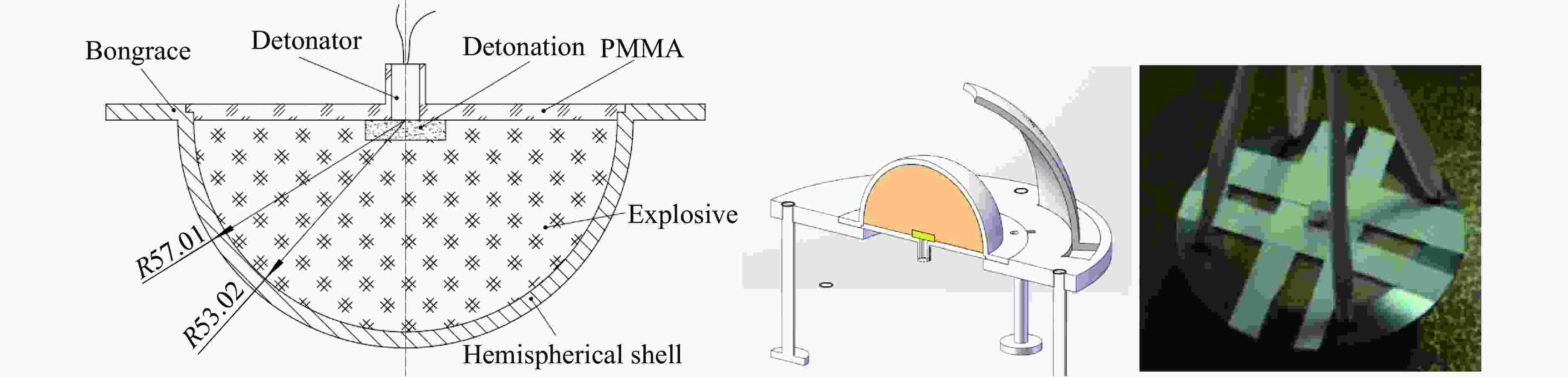

MERCIER S, GRANIER N, MOLINARI A, et al. Multiple necking during the dynamic expansion of hemispherical metallic shells, from experiments to modelling [J]. Journal of the Mechanics and Physics of Solids, 2010, 58: 955–982. doi: 10.1016/j.jmps.2010.05.001

|

| [29] |

张世文, 龙建华, 贾宏志, 等. 平面冲击波在有机玻璃中的衰减测试与数值模拟 [J]. 兵工学报, 2016, 37(7): 1214–1219.ZHANG S W, LONG J H, JIA H Z, et al. Measuring and numerical simulation of attenuation of planar shock wave in PMMA [J]. Acta Armamentarii, 2016, 37(7): 1214–1219.

|

| [30] |

李英雷, 刘明涛, 陈艳, 等. 线起爆膨胀柱壳实验加载及诊断技术 [J]. 爆炸与冲击, 2022, 42(12): 124101. LI Y L, LIU M T, CHEN Y, et al. A loading and diagnosis technology of expanding cylinder experiment with linear initiated explosives [J]. Explosion and Shock Waves, 2022, 42(12): 124101.

|

下载:

下载: