Experimental Study on the Penetration of Zr-Based Amorphous Fragment into Carbon Fiber Composite Target and Post-Effect Aluminum Target

-

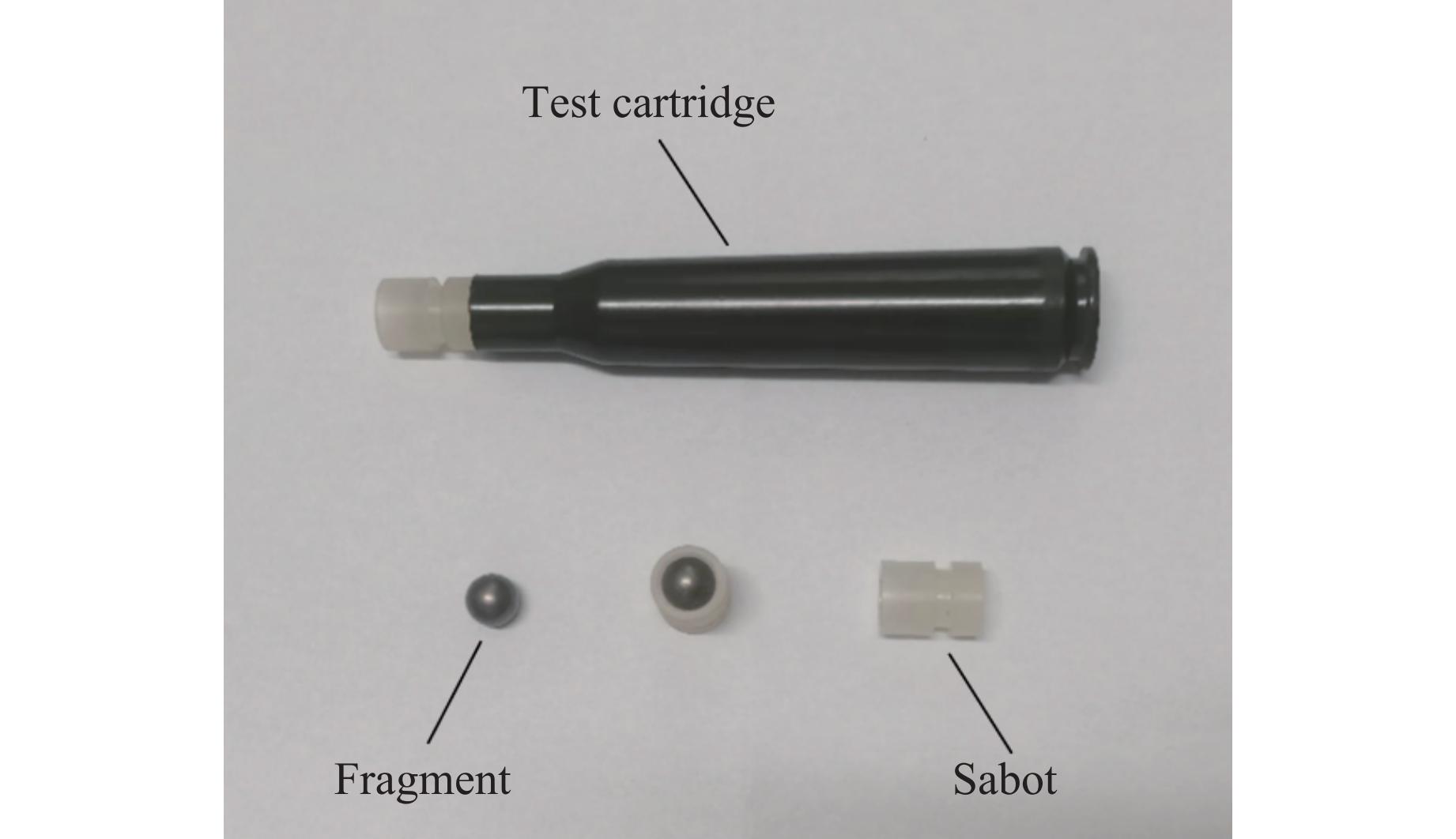

摘要: Zr基非晶破片是一种新兴的活性高效毁伤元,其着靶速度达到一定阈值时会发生燃烧反应并破碎,从而大幅提高其后效毁伤能力。为研究Zr基非晶破片对碳纤维增强复合材料的侵彻破坏机理及后效毁伤能力,利用弹道枪加载球形破片,分别以496.4~1085.8 m/s、571.4~1103.9 m/s的速度范围撞击8和6 mm厚的碳纤维复合靶,并布置2 mm厚LY12铝靶板作为后效靶,以比较破片在不同工况下的后效毁伤能力。实验结果表明:碳纤维靶受活性破片冲击时,其迎弹面的破坏形式主要是压缩失效与剪切失效的耦合破坏,其背弹面的破坏形式主要是拉伸失效破坏与层间的脱粘分裂;随着破片着靶速度的提高,碳纤维靶板的压剪耦合破坏比例逐渐增加,拉伸断裂与分层现象逐渐减弱;破片对于8和6 mm厚碳纤维靶的弹道极限速度分别为351.9、264.6 m/s;相同着靶速度下,8 mm厚碳纤维靶的后效毁伤面积大于6 mm厚碳纤维靶的后效毁伤面积,两者之间的差异随着着靶速度的提高而逐渐减小;破片冲击等厚度碳纤维靶时,破片的后效毁伤能力随着靶速度的提高而增强。Abstract: Zr-based amorphous fragment is an emerging active and efficient destructive element, which will undergo a deflagration reaction and fragmentation when its impact velocity reaches its threshold. The deflagration reaction and fragmentation could greatly increase its behind-armor destructive capability. In order to study the penetration damage mechanism and behind-armor destructive capability of Zr-based amorphous fragments on carbon fiber reinforced composites, a ballistic gun was used to load the spherical fragments to impact 8 and 6 mm thick carbon fiber composite targets at velocities ranging from 496.4 m/s to 1085.8 m/s and 571.4 m/s to 1103.9 m/s, respectively. Then a 2 mm thick LY12 aluminum target plate was arranged behind the target to measure the damage capability under different working conditions. The test results showed that the mainly failure mode of strike face was a coupling failure mode of compression failure and shear failure, and the main failure mode of its back face was a coupling failure mode of tensile failure and the de-sticky splitting of the layer. With the increase of the impact velocity, the proportion of the compression and shear coupling damage of the carbon fiber composite target plate was gradually increased, and the phenomenon of tensile breakage and delamination was gradually decreased. The ballistic ultimate velocities of the fragment for 8 and 6 mm thick carbon fiber composite target were 351.9 and 264.6 m/s, respectively. Behind-armor damage area of the fragment impacted on the 8 mm thick carbon fiber composite target was larger than that of the 6 mm thick carbon fiber target under the same impact velocity. The difference of behind-armor damage area impacted on 8 and 6 mm thick carbon fiber composite targets decreased with the increase of the impact velocity. The behind-armor damage ability of the fragment impacting on the carbon fiber composite target increased with the increase of the impact velocity.

-

表 1 碳纤维复合材料性能参数

Table 1. Performance parameters of carbon fiber composites

E1/GPa E2/GPa G/GPa XT/GPa XC/GPa YT/MPa YC/MPa SC/MPa ν ρ/(kg∙m−3) 125 7.8 5.6 2.5 1.1 72 220 92 0.316 1600 表 2 试验数据

Table 2. Test data

Target plate thickness/mm Test No. Impact

velocity/(m∙s−1)Residual

velocity/(m∙s−1)Perforation

diameter/mm8 1 1085.8 764.9 10.17 2 1008.9 688.3 9.89 3 904.3 530.6 9.68 4 790.3 515.7 9.80 5 691.1 443.2 9.64 6 679.7 411.6 9.75 7 496.4 123.1 9.56 6 8 1103.9 931.5 10.14 9 936.6 724.6 10.07 10 767.5 590.7 9.85 11 695.3 537.1 9.67 12 571.4 442.6 9.57 表 3 Zr基非晶破片对碳纤维靶板的弹道极限速度及拟合参数

Table 3. Ballistic limits and fitting parameters of zirconium-based amorphous fragments on carbon fiber composite targets

Target plate thickness/mm a v50/(m·s−1) 8 0.69 351.9 6 0.84 264.6 表 4 计算得出的后效靶破孔面积

Table 4. Calculated area of broken holes in the post-effect target

Target plate thickness/mm No. Shole/mm2 Target plate thickness/mm No. Shole/mm2 8 1 528.1 6 8 439.2 2 493.9 9 312.4 3 457.5 10 156.0 4 432.2 11 89.5 5 367.6 12 80.7 6 213.8 7 0 -

[1] TOGO H, ZHANG Y, KAWAMURA Y, et al. Properties of Zr-based bulk metallic glass under shock compression [J]. Materials Science and Engineering: A, 2007, 449: 264–268. [2] MATTERN N, KUEHN U, HERMANN H, et al. Thermal behavior and glass transition of Zr-based bulk metallic glasses [J]. Materials Science and Engineering: A, 2004, 375: 351–354. [3] QIAO J W, ZHANG Y, LI J H, et al. Strain rate response of a Zr-based composite fabricated by Bridgman solidification [J]. International Journal of Minerals Metallurgy and Materials, 2010, 17(2): 214–219. doi: 10.1007/s12613-010-0216-9 [4] CHEN X, DU C X, CHENG C, et al. Impact-induced chemical reaction behavior of ZrTiNiCuBe bulk metallic glass fragments impacting on thin plates [J]. Materiali in Tehnologije, 2018, 52(6): 737–743. [5] WEI H Y, YOO C S. Kinetics of small single particlecombustion of zirconium alloy [J]. Journal of Applied Physics, 2012, 111(2): 1–13. [6] WEI H Y, YOO C S. Dynamic responses of reactive metallic structures under thermal and mechanical ignitions [J]. Journal of Materials Research, 2012, 27(21): 2705–2717. doi: 10.1557/jmr.2012.302 [7] 张云峰, 罗兴柏, 刘国庆, 等. W/ZrNiAlCu亚稳态合金复合材料破片对RHA靶的侵彻释能特性 [J]. 爆炸与冲击, 2020, 40(2): 023301.ZHANG Y F, LUO X B, LIU G Q, et al. Penetration and energy release effect of W/ZrNiAlCu metastable reactive alloy composite rragment against RHA target [J]. Explosion and Shock Waves, 2020, 40(2): 023301. [8] 郭磊, 王传婷, 何勇, 等. Zr55Cu30Ni5Al10活性破片对间隔防护结构破坏特性研究 [J]. 航天器环境工程, 2020, 37(6): 582–588.GUO L, WANG C T, HE Y, et al. The failure characteristics of spacing protective structures impacted by Zr55Cu30Ni5Al10 active fragments [J]. Spacecraft Environment Engineering, 2020, 37(6): 582–588. [9] 罗普光, 毛亮, 李国杰, 等. 锆基非晶活性破片侵靶特性研究 [J]. 兵器装备工程学报, 2022, 43(3): 42–46.LUO P G, MAO L, LI G J, et al. Research on damage characteristics of Zr-base amorphous reactive fragment after impact target [J].Journal of Ordnance Equipment Engineering, 2022, 43(3): 42–46. [10] 杨林, 于述贤, 范群波. Zr77.1Cu13Ni9.9非晶合金破片侵彻LY12铝合金及TC4钛合金靶板毁伤后效及机理对比研究 [J]. 北京理工大学学报自然版, 2023, 43(4): 417–428.YANG L, YU S X, FAN Q B. Damage effect and mechanism of Zr77.1Cu13Ni9.9 bulk metallic glasses fragment penetrating LY12 aluminum alloy and TC4 titanium alloy target plate [J]. Transactions of Beijing Institute of Technology, 2023, 43(4): 417–428. [11] 张佐光, 霍刚, 张大兴. 纤维复合材料的弹道吸能研究 [J]. 复合材料学报, 1998, 15(2): 74–81.ZHANG Z G, HUO G, ZHANG D X. Ballistic energy absorption study of fiber composites [J]. Acta Materiae Compositae Sinica, 1998, 15(2): 74–81. [12] 黄晨光, 施媚梧, 段祝平. 头盔用复合材料抗侵彻性能研究进展 [J]. 力学进展, 2000, 30(2): 239–251.HUANG C G, SHI M W, DUAN Z P. Review on the dynamic behaviors and penetration of the composite shelmet under impact loading [J]. Advances in Mechanics, 2000, 30(2): 239–251. [13] 孙浩伟, 李涛. 碳纤维及其复合材料在国外军民领域的应用 [J]. 纤维复合材料, 2005, 22(3): 65−67.SUN H W, LI T. Application of carbon fiber and its composites in overseas military and civil fields [J]. Fiber Composites, 2005, 22(3): 65−67. [14] 黄涛, 陈威, 彭帅,等. 典型舱室在战斗部内爆下的载荷及毁伤特性试验研究 [J]. 中国舰船研究,2023, 18(6): 167–176.HUANG T, CHEN W, PENG S, et al. Testing investigation on load and damage characteristic of typical cabins under warhead internal blast [J]. Chinese Journal of Ship Research, 2023, 18(6): 167–176. [15] 王兆纶. 大型舰船功能毁伤评估方法研究[D]. 北京: 军事科学院, 2023.WANG Z L. Research on evaluation methods for functional damage of large warships [D]. Beijing: Academy of Military Sciences, 2023. [16] RECHT R F, IPSON T W. Ballistic perforation dynamics [J]. ASME Journal of Applied Mechanics, 1963, 30(3): 384–390. [17] 张猛, 王金华, 俞森彬, 等. 自适应阈值二值法提取湍流火焰前锋面结构 [J]. 燃烧科学与技术, 2016, 22(3): 212–217.ZHANG M, WANG J H, YU S B, et al. Flame front tracking of turbulent premixed flames using adaptive threshold binarization [J]. Journal of Combustion Science and Technology, 2016, 22(3): 212–217. -

下载:

下载: