Discrete Element Simulation of Splitting Failure of Ceramic Disk with Prefabricated Crack

-

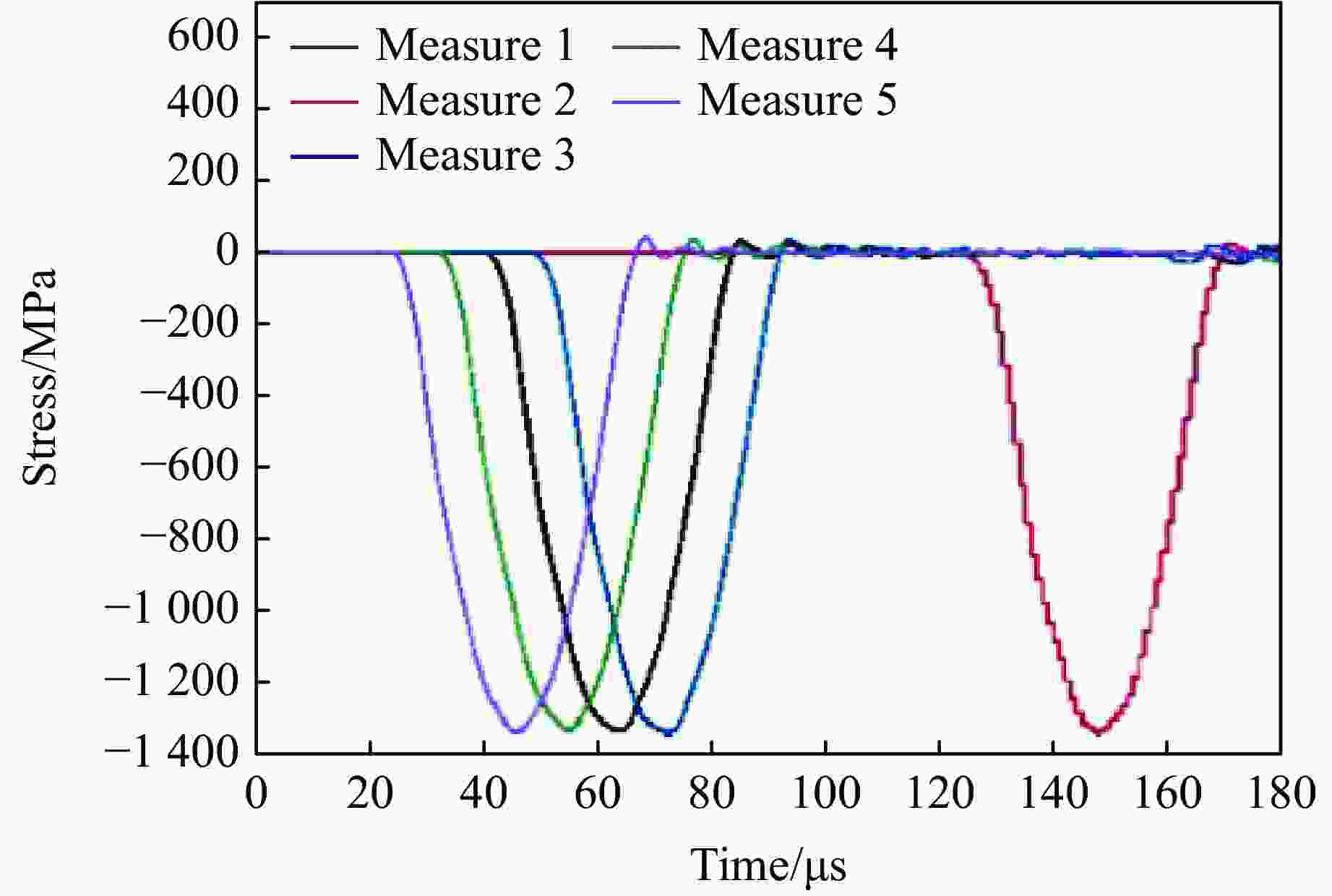

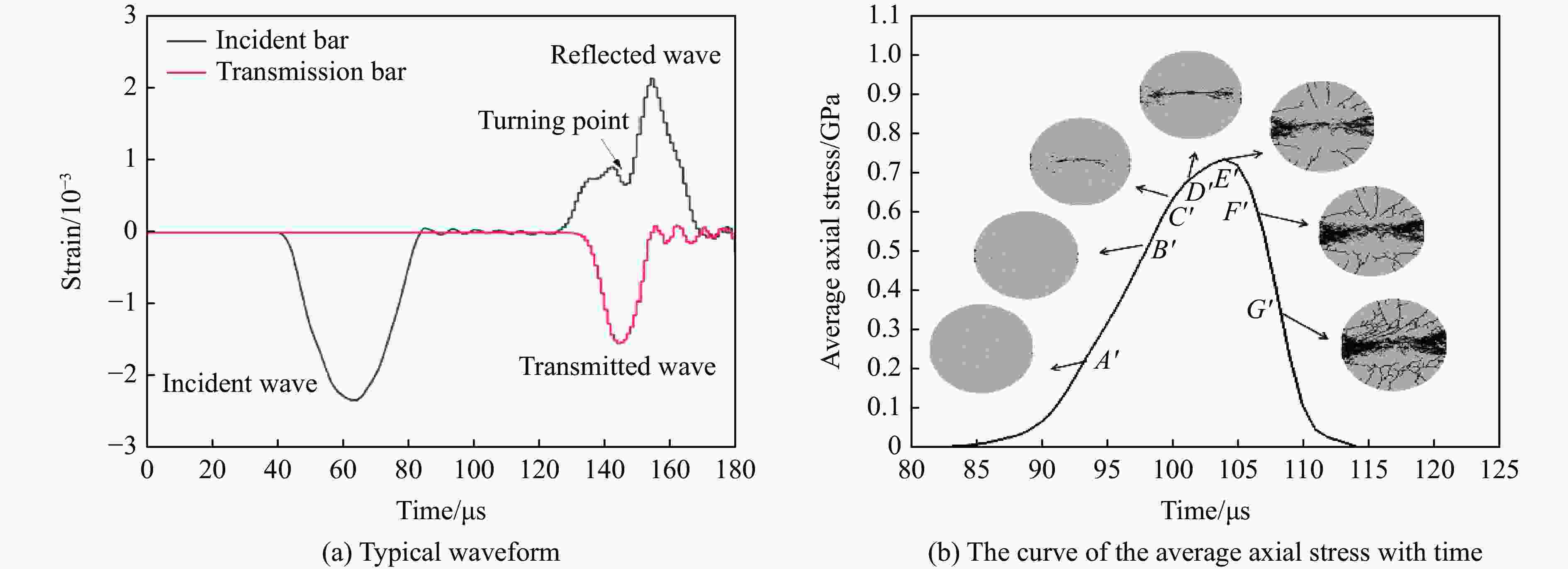

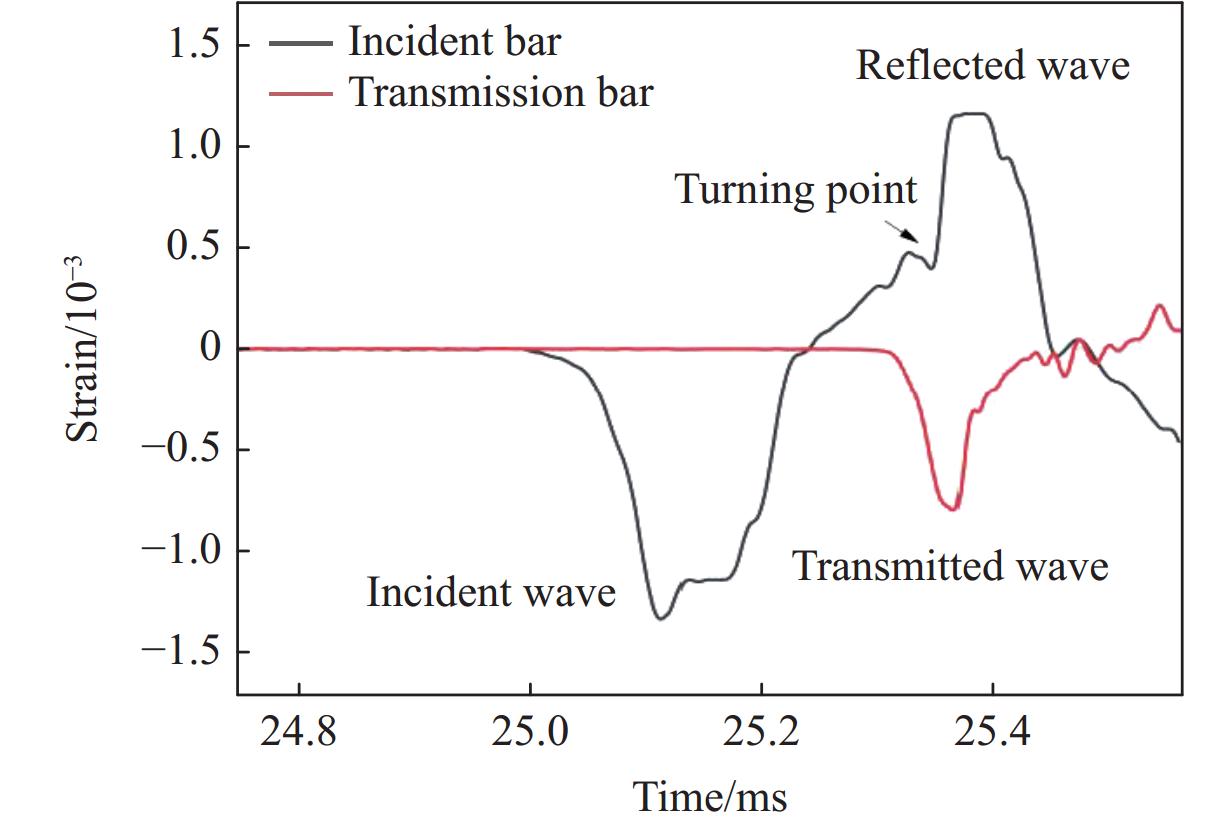

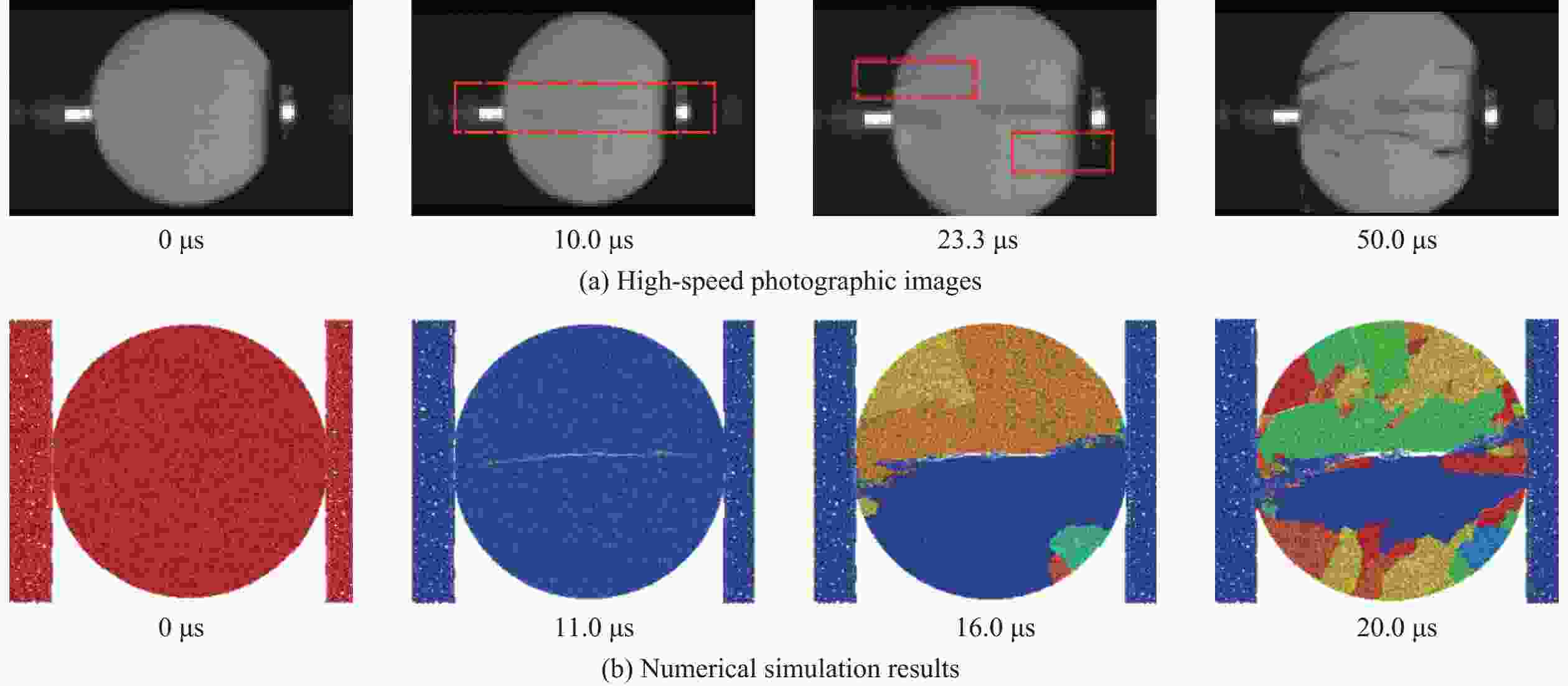

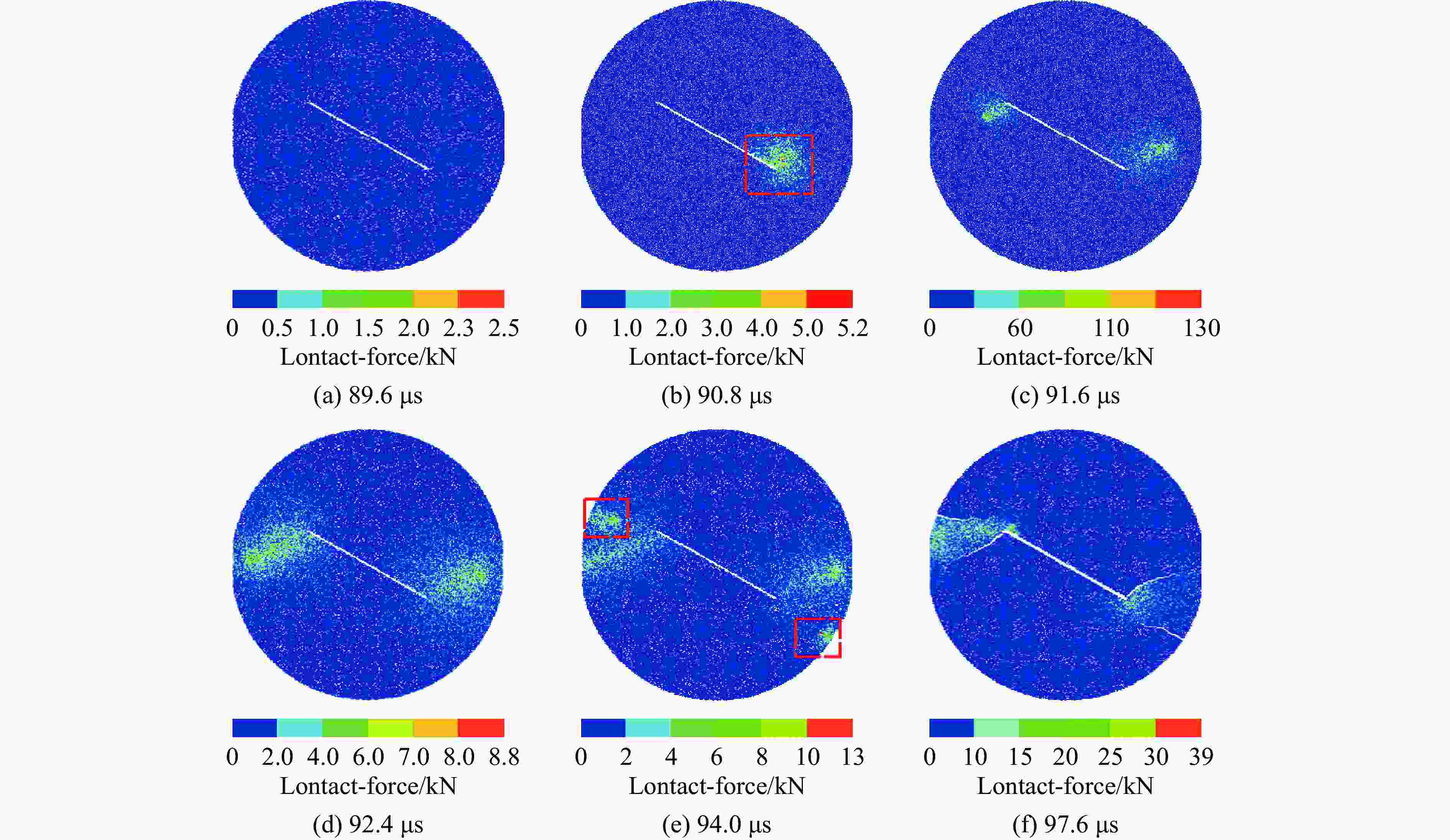

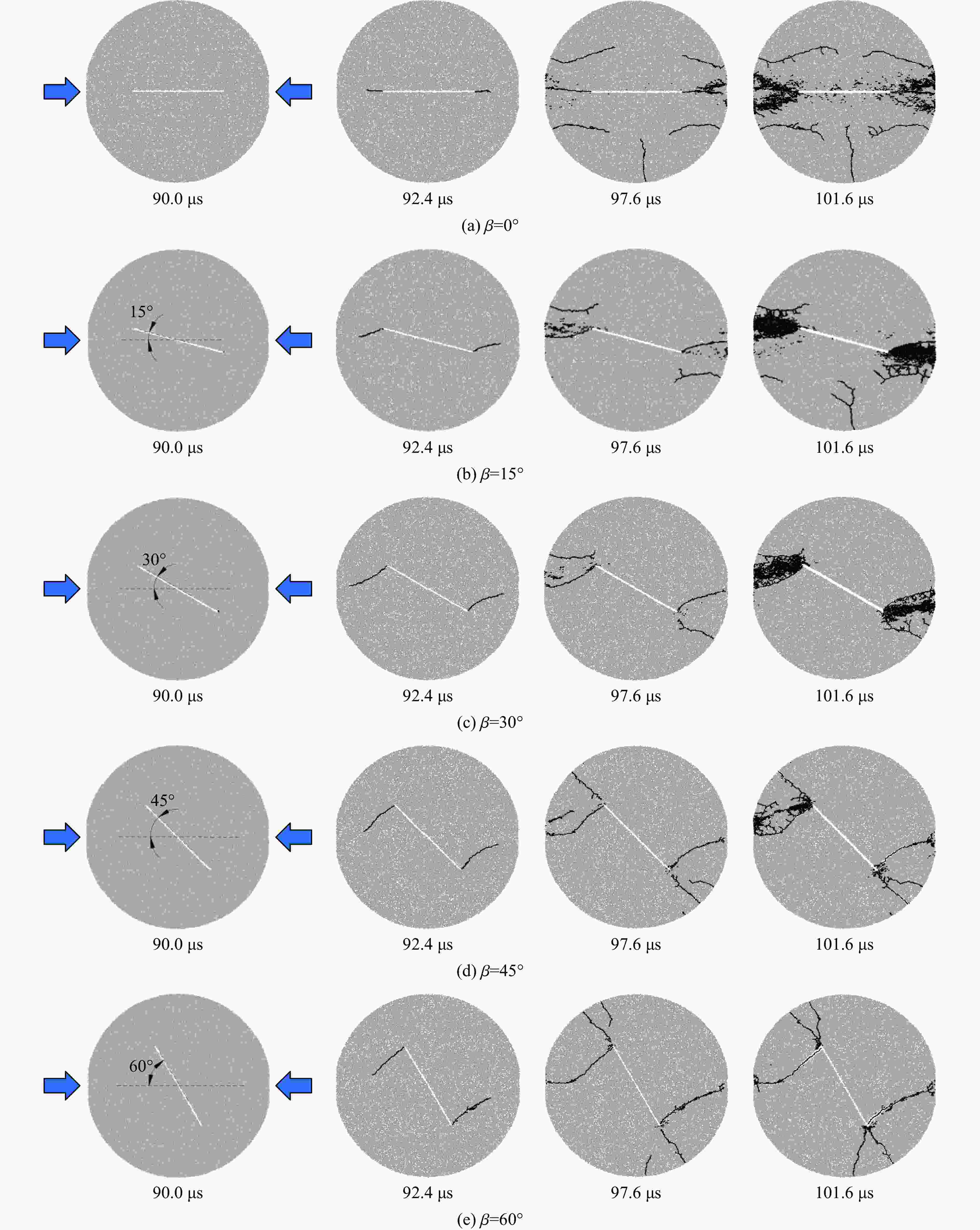

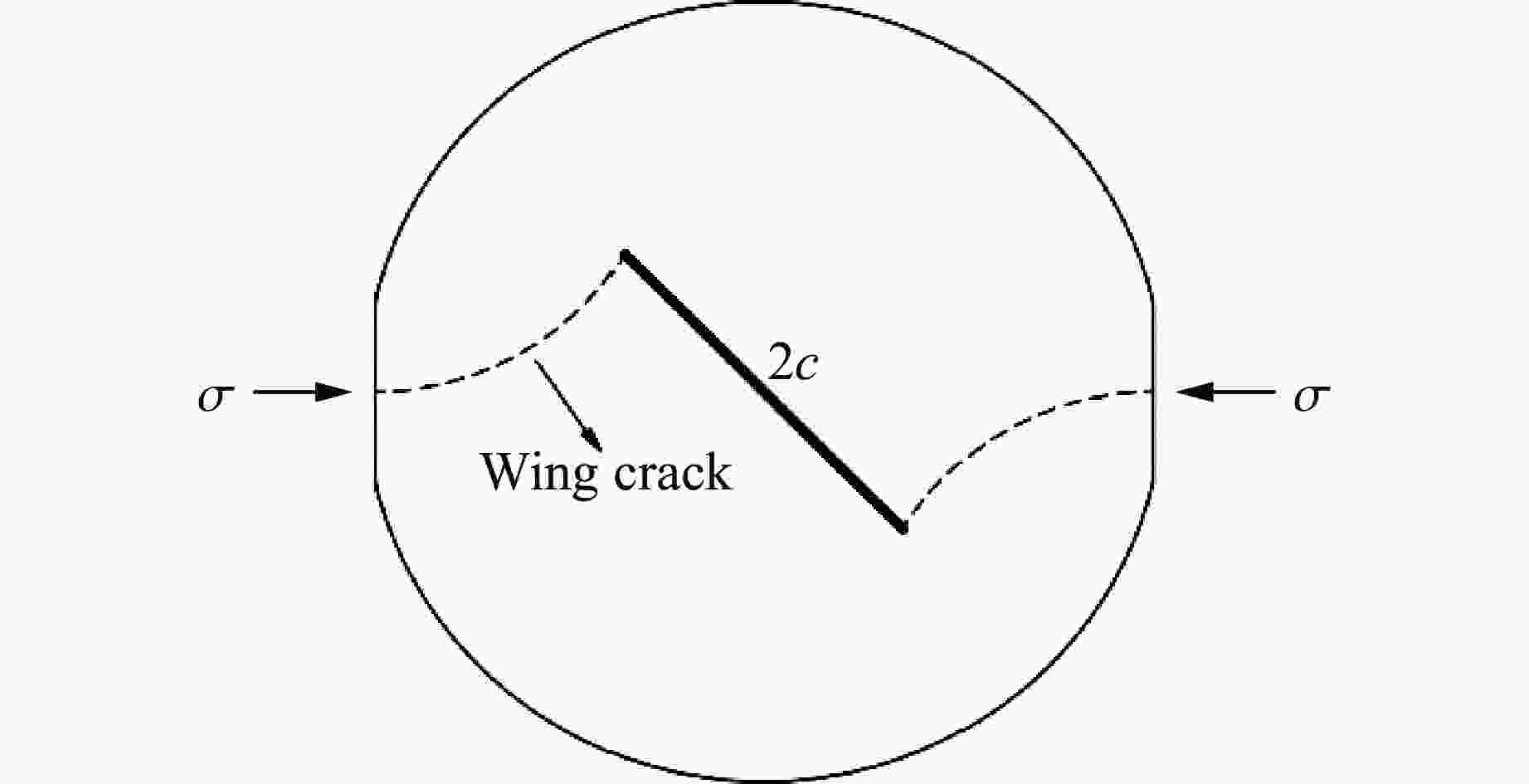

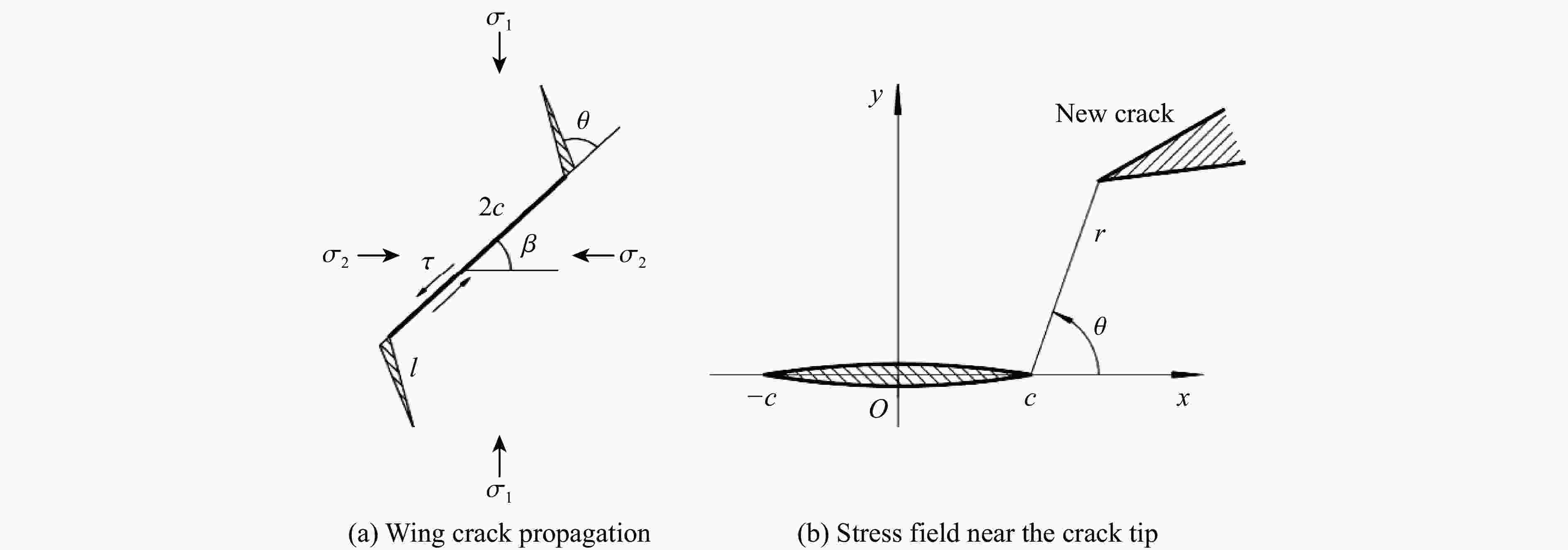

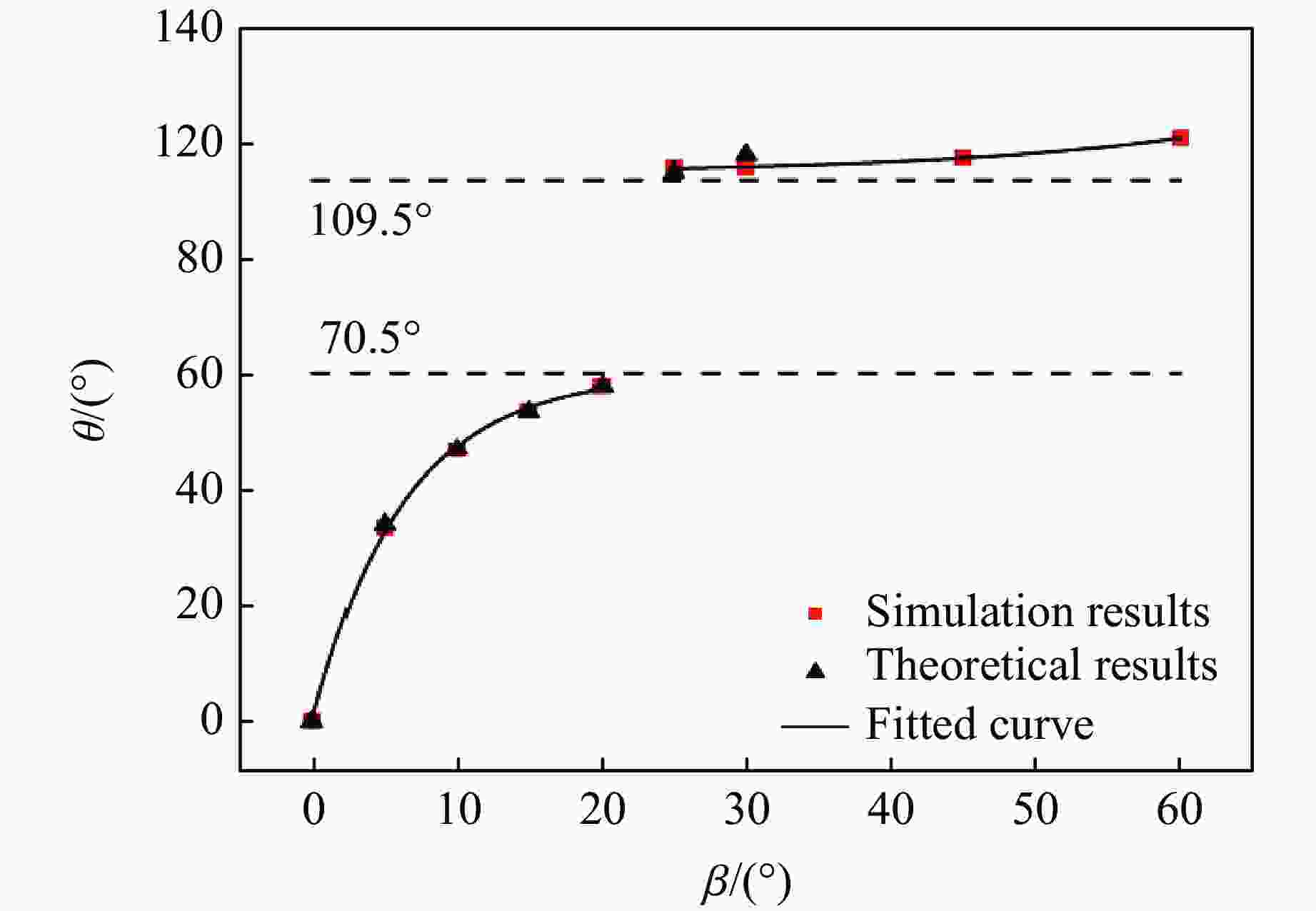

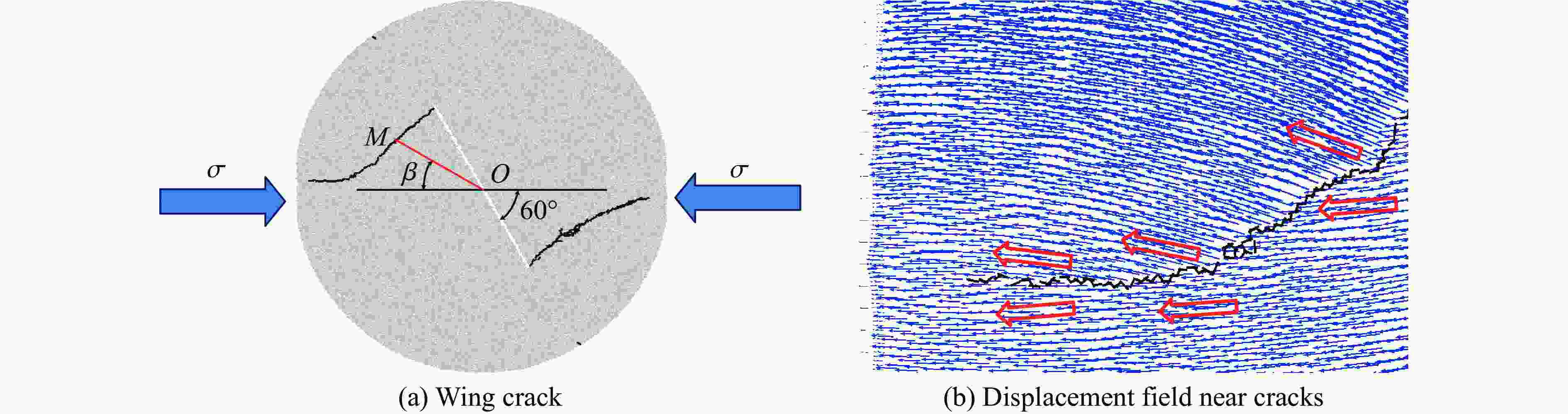

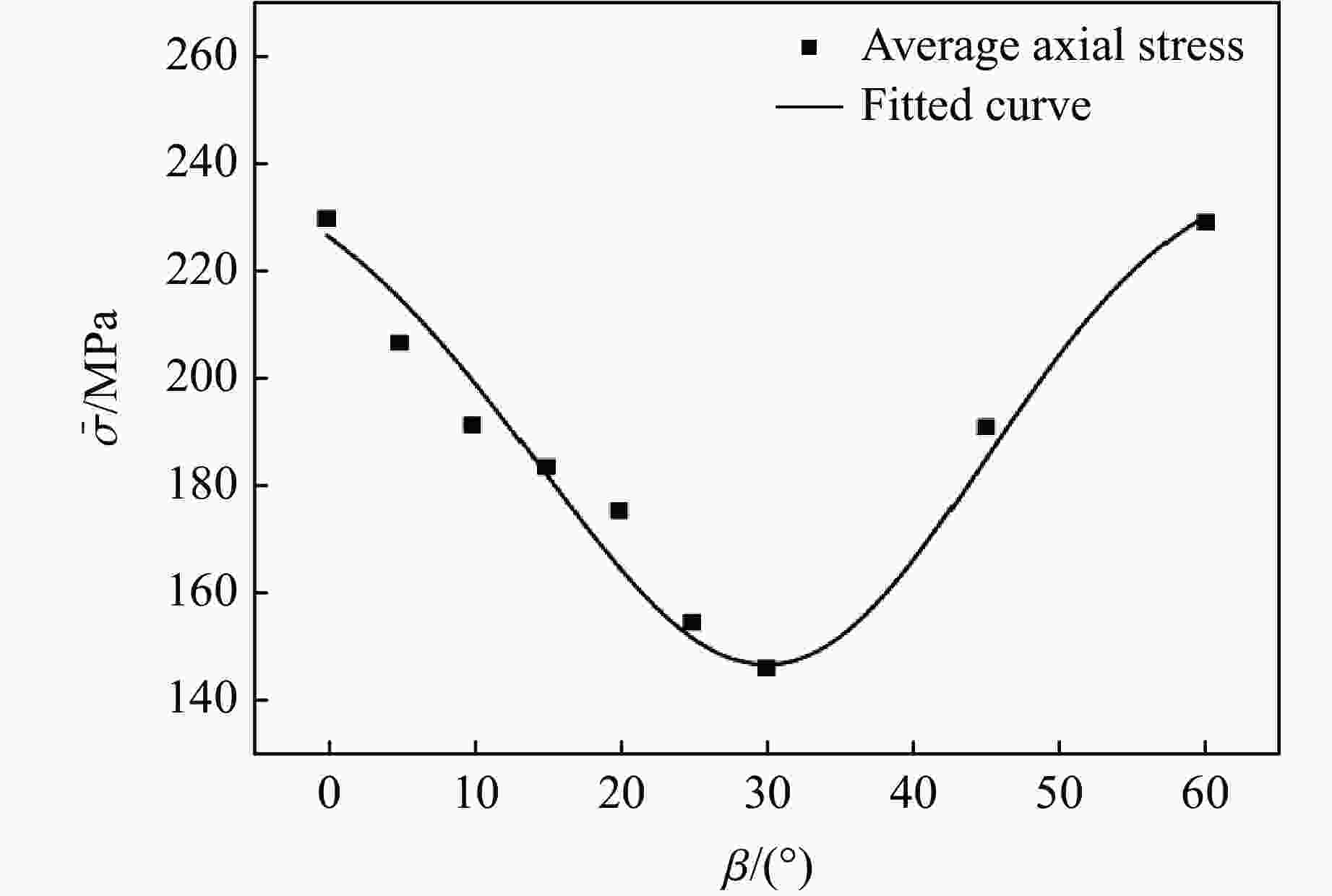

摘要: 为研究氧化铝陶瓷在冲击载荷作用下的裂纹演化过程,对平台圆盘陶瓷开展动态巴西劈裂的离散元数值计算研究。利用离散元颗粒流软件建立陶瓷试件冲击加载实验的数值计算模型,分析了不同倾角(预制裂纹与加载方向的夹角)的试件在冲击载荷下的裂纹演化过程和破坏形式,并结合复合型裂纹尖端的应力场分布分析了翼型裂纹起裂和扩展规律。研究结果表明:平台圆盘试件的裂纹首先产生于中心部位,之后次生裂纹从圆盘边缘处萌生扩展,试件最终呈现拉伸破坏模式;离散元模拟结果与基于分离式霍普金森压杆装置的动态巴西劈裂的实验现象吻合;预制裂纹倾角为0°~60°时,改变倾角可以产生介于Ⅰ型与Ⅱ型裂纹之间的复合型裂纹,试件上主裂纹从预制裂纹尖端处成核扩展,表现为翼型裂纹扩展类型(扩展的曲率逐渐趋于零);试件裂纹的起裂角度随着预制裂纹倾角的增加而增大,起裂应力呈现先降低后升高的趋势;当预制裂纹倾角为30°时,试件最易发生开裂。Abstract: To investigate the alumina ceramics’ crack evolution process under impact loading, a numerical simulation of dynamic Brazilian splitting for platform disc ceramics was carried out by the discrete element method. The discrete element particle flow software was adopted to establish the numerical simulation model of ceramic specimens in impact loading experiments. The crack evolution process and failure mode of specimens with different inclination angles (the angle between the prefabricated crack and the loading direction) under impact loading were analyzed. Combined with the stress field distribution at the tip of mixed mode crack, the initiation and propagation laws of wing crack were analyzed. The results show that the cracks in the platform disc specimen are produced in the center firstly, then the secondary cracks sprouted and expanded from the disc edge. The specimen finally shows a tensile damage pattern. The results of the discrete element simulations are consistent with the experimental phenomena of dynamic Brazilian splitting based on the SHPB device. When the inclination angle of the prefabricated crack is 0°~60°, changing the inclination angle can produce a mixed crack mode between type Ⅰ crack and type Ⅱ crack. And the main crack on the specimen is nucleated from the tip of the prefabricated crack and exhibits a winged crack extension type (the curvature of the extension tapers to zero). With the increase of the inclination angle of the prefabricated crack, the crack initiation angle increases, and the crack initiation stress shows a trend of decreasing firstly and then increasing. The specimens are most susceptible to cracking when the prefabricated crack inclination is 30°.

-

Key words:

- alumina ceramics /

- dynamic response /

- prefabricated crack /

- discrete element /

- wing crack

-

表 1 材料Flat-joint模型的细观参数

Table 1. Micro parameters of the Flat-joint model for materials

Material Minimum particle diameter/mm Maximum particle diameter/mm Effective modulus of

linear contact/GPaNormal shear stiffness

ratio of linear contactPorosity Steel bar 0.20 0.300 218.0 6.0 0.1 Ceramics 0.05 0.075 346.5 1.9 0.1 Material Effective modulus of

Flat-joint contact/GPaShear strength of

Flat-joint contact/GPaTensile strength of

Flat-joint contact/GPaNormal shear stiffness

ratio of Flat-joint contactSteel bar 218.0 100 100 6.0 Ceramics 346.5 390 1760 1.9 表 2 陶瓷力学性能的数值模拟与实验结果

Table 2. Numerical simulation and experimental results of mechanical properties of the ceramics

Method Modulus of elasticity/GPa Compressive strength/MPa Tensile strength/MPa Bending strength/MPa Fracture toughness/

(MPa·m1/2)Experimental results 360 2942 343.0 4 Simulation results 360 2940 200 337.5 4 表 3 理论和数值计算的起裂角对比

Table 3. Comparison of the crack initiation angles between theoretical and simulation results

β/(°) θ/(°) Simulation results Theoretical results 0 0 0 5 39 39.8 10 55 55.1 15 63 62.8 20 68 68.0 25 112 111.1 30 112 114.7 45 114 60 118 -

[1] 吴燕平, 燕青芝. 防弹装甲中的陶瓷材料 [J]. 兵器材料科学与工程, 2017, 40(4): 135–140. doi: 10.14024/j.cnki.1004-244x.20170630.001WU Y P, YAN Q Z. Application of ceramics in armor protection [J]. Ordnance Material Science and Engineering, 2017, 40(4): 135–140. doi: 10.14024/j.cnki.1004-244x.20170630.001 [2] STRAßBURGER E. Ballistic testing of transparent armour ceramics [J]. Journal of the European Ceramic Society, 2009, 29(2): 267–273. doi: 10.1016/j.jeurceramsoc.2008.03.049 [3] WANG Q Z, JIA X M, KOU S Q, et al. The flattened Brazilian disc specimen used for testing elastic modulus, tensile strength and fracture toughness of brittle rocks: analytical and numerical results [J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(2): 245–253. doi: 10.1016/S1365-1609(03)00093-5 [4] 王启智, 贾学明. 用平台巴西圆盘试样确定脆性岩石的弹性模量、拉伸强度和断裂韧度——第一部分: 解析和数值结果 [J]. [J]. 岩石力学与工程学报, 2002, 21(9): 1285–1289. doi: 10.3321/j.issn:1000-6915.2002.09.001WANG Q Z, JIA X M. Determination of elastic modulus, tensile strength and fracture toughness of brittle rocks by using flattened Brazilian disk specimen—partⅠ: analytical and numerical results [J]. Chinese Journal of Rock Mechanics and Engineering, 2002, 21(9): 1285–1289. doi: 10.3321/j.issn:1000-6915.2002.09.001 [5] 王启智, 吴礼舟. 用平台巴西圆盘试样确定脆性岩石的弹性模量、拉伸强度和断裂韧度——第二部分: 试验结果 [J]. 岩石力学与工程学报, 2004, 23(2): 199–204. doi: 10.3321/j.issn:1000-6915.2004.02.004WANG Q Z, WU L Z. Determination of elastic modulus, tensile strength and fracture toughness of britle rocks by using flattened Brazilian disk specimen—partⅡ: experimental results [J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(2): 199–204. doi: 10.3321/j.issn:1000-6915.2004.02.004 [6] 王启智, 戴峰, 贾学明. 对“平台圆盘劈裂的理论和试验”一文的回复 [J]. 岩石力学与工程学报, 2004, 23(1): 175–178. doi: 10.3321/j.issn:1000-6915.2004.01.033WANG Q Z, DAI F, JIA X M. Reply to the paper ‘split test of flattened rock disc and related theory’ [J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(1): 175–178. doi: 10.3321/j.issn:1000-6915.2004.01.033 [7] 牛欢欢, 闫晓鹏, 罗浩舜, 等. 不同应变率下蓝宝石透明陶瓷玻璃的力学响应 [J]. 爆炸与冲击, 2022, 42(7): 073105. doi: 10.11883/bzycj-2021-0434NIU H H, YAN X P, LUO H S, et al. Mechanical response of sapphire transparent ceramic glass at different strain rates [J]. Explosion and Shock Waves, 2022, 42(7): 073105. doi: 10.11883/bzycj-2021-0434 [8] 赵翰卿, 任会兰. 陶瓷巴西圆盘动态劈裂的离散元模拟 [J]. 兵器装备工程学报, 2021, 42(3): 119–124. doi: 10.11809/bqzbgcxb2021.03.023ZHAO H Q, REN H L. Discrete element simulation of dynamic splitting of ceramic Brazilian disc [J]. Journal of Ordnance Equipment Engineering, 2021, 42(3): 119–124. doi: 10.11809/bqzbgcxb2021.03.023 [9] HORII H, NEMAT-NASSER S. Compression-induced microcrack growth in brittle solids: axial splitting and shear failure [J]. Journal of Geophysical Research: Solid Earth, 1985, 90(B4): 3105–3125. doi: 10.1029/JB090iB04p03105 [10] NEMAT-NASSER S, HORII H. Compression-induced nonplanar crack extension with application to splitting, exfoliation, and rockburst [J]. Journal of Geophysical Research: Solid Earth, 1982, 87(B8): 6805–6821. doi: 10.1029/JB087iB08p06805 [11] 方敏杰, 任会兰, 宁建国. 准脆性材料中椭圆形微裂纹的生长与演化 [J]. 材料工程, 2013(2): 35–39. doi: 10.3969/j.issn.1001-4381.2013.02.007FANG M J, REN H L, NING J G. The growth and evolution of elliptical micro-cracks in quasi-brittle materials [J]. Journal of Materials Engineering, 2013(2): 35–39. doi: 10.3969/j.issn.1001-4381.2013.02.007 [12] 宁建国, 任会兰, 方敏杰. 基于椭圆形微裂纹演化与汇合的准脆性材料本构模型 [J]. 科学通报, 2012, 57(21): 1978–1986. doi: 10.1007/s11434-012基于椭圆形微裂纹演化与汇合的准脆性材料本构模型-5319-4NING J G, REN H L, FANG M J. A constitutive model based on the evolution and coalescence of elliptical micro-cracks for quasi-brittle materials [J]. Chinese Science Bulletin, 2012, 57(21): 1978–1986. doi: 10.1007/s11434-012基于椭圆形微裂纹演化与汇合的准脆性材料本构模型-5319-4 [13] 朱万成, 黄志平, 唐春安, 等. 含预制裂纹巴西盘试样破裂模式的数值模拟 [J]. 岩土力学, 2004, 25(10): 1609–1612. doi: 10.3969/j.issn.1000-7598.2004.10.019ZHU W C, HUANG Z P, TANG C A, et al. Numerical simulation on failure process of pre-cracked Brazilian disk specimen of rock [J]. Rock and Soil Mechanics, 2004, 25(10): 1609–1612. doi: 10.3969/j.issn.1000-7598.2004.10.019 [14] 杨庆, 李强, 赵维, 等. 翼型裂纹扩展特性的试验和数值分析 [J]. 水利学报, 2009, 40(8): 934–940. doi: 10.3321/j.issn:0559-9350.2009.08.006YANG Q, LI Q, ZHAO W, et al. Experimental study and numerical simulation on propagation characteristics of wing type cracks under compression [J]. Journal of Hydraulic Engineering, 2009, 40(8): 934–940. doi: 10.3321/j.issn:0559-9350.2009.08.006 [15] 胡荣, 朱哲明, 胡哲源, 等. 爆炸动载荷下裂纹扩展规律的实验研究 [J]. 岩石力学与工程学报, 2013, 32(7): 1476–1481. doi: 10.3969/j.issn.1000-6915.2013.07.024HU R, ZHU Z M, HU Z Y, et al. Experimental study of regularity of crack propagation under blasting dynamic loads [J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(7): 1476–1481. doi: 10.3969/j.issn.1000-6915.2013.07.024 [16] 赵永, 杨天鸿, 于庆磊, 等. 基于离散元方法的预制裂纹扩展过程分析 [J]. 东北大学学报(自然科学版), 2018, 39(7): 1038–1043. doi: 10.12068/j.issn.1005-3026.2018.07.025ZHAO Y, YANG T H, YU Q L, et al. Analysis of pre-existing crack propagation process based on discrete element method [J]. Journal of Northeastern University (Natural Science), 2018, 39(7): 1038–1043. doi: 10.12068/j.issn.1005-3026.2018.07.025 [17] 马棋棋, 熊迅, 郑宇轩, 等. 无机玻璃动态压缩破坏的离散元模拟 [J]. 高压物理学报, 2019, 33(4): 044101. doi: 10.11858/gywlxb.20190719MA Q Q, XIONG X, ZHENG Y X, et al. Discrete element simulations of dynamic compression failure of inorganic glass in SHPB tests [J]. Chinese Journal of High Pressure Physics, 2019, 33(4): 044101. doi: 10.11858/gywlxb.20190719 [18] POTYONDY D O, CUNDALL P A. A bonded-particle model for rock [J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1329–1364. doi: 10.1016/j.ijrmms.2004.09.011 [19] 倪敏, 汪坤, 王启智. SHPB冲击加载下四种岩石的复合型动态断裂实验研究 [J]. 应用力学学报, 2010, 27(4): 697–702.NI M, WANG K, WANG Q Z. Experimental study on mixed-mode dynamic fracture of four rocks under impact loading using split hopkinson pressure bar [J]. Chinese Journal of Applied Mechanics, 2010, 27(4): 697–702. [20] RAVICHANDRAN G, SUBHASH G. A micromechanical model for high strain rate behavior of ceramics [J]. International Journal of Solids and Structures, 1995, 32(17/18): 2627–2646. doi: 10.1016/0020-7683(94)00286-6 [21] DENG H, NEMAT-NASSER S. Dynamic damage evolution in brittle solids [J]. Mechanics of Materials, 1992, 14(2): 83–103. doi: 10.1016/0167-6636(92)90008-2 [22] 李世愚, 和泰名, 尹祥础. 岩石断裂力学导论 [M]. 合肥: 中国科学技术大学出版社, 2010: 99−107.LI S Y, HE T M, YIN X C. Introduction of rock fracture mechanics [M]. Hefei: University of Science and Technology of China Press, 2010: 99−107. [23] 董世明, 汪洋, 夏源明. 中心裂纹圆盘集中载荷作用下的应力强度因子 [J]. 中国科学技术大学学报, 2003, 33(3): 310–317. doi: 10.3969/j.issn.0253-2778.2003.03.009DONG S M, WANG Y, XIA Y M. Stress intensity factors of the central cracked disk subjected to concentrated load [J]. Journal of University of Science and Technology of China, 2003, 33(3): 310–317. doi: 10.3969/j.issn.0253-2778.2003.03.009 [24] 李银平, 王元汉, 陈龙珠, 等. 含预制裂纹大理岩的压剪试验分析 [J]. 岩土工程学报, 2004, 26(1): 120–124. doi: 10.3321/j.issn:1000-4548.2004.01.023LI Y P, WANG Y H, CHEN L Z, et al. Experimental research on pre-existing cracks in marble under compression [J]. Chinese Journal of Geotechnical Engineering, 2004, 26(1): 120–124. doi: 10.3321/j.issn:1000-4548.2004.01.023 [25] 张杰, 席迅, 郭奇峰, 等. 含预制裂隙花岗岩破坏的细观多相颗粒流模拟 [J]. 华中科技大学学报(自然科学版), 2021, 49(4): 79–85. doi: 10.13245/j.hust.210413ZHANG J, XI X, GUO Q F, et al. Meso multi-phase particle flow simulation of granite failure with preexisting crack [J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2021, 49(4): 79–85. doi: 10.13245/j.hust.210413 -

下载:

下载: