Fracturing Failure Mechanism of Porous Cement Sheath under Triaxial Stress

-

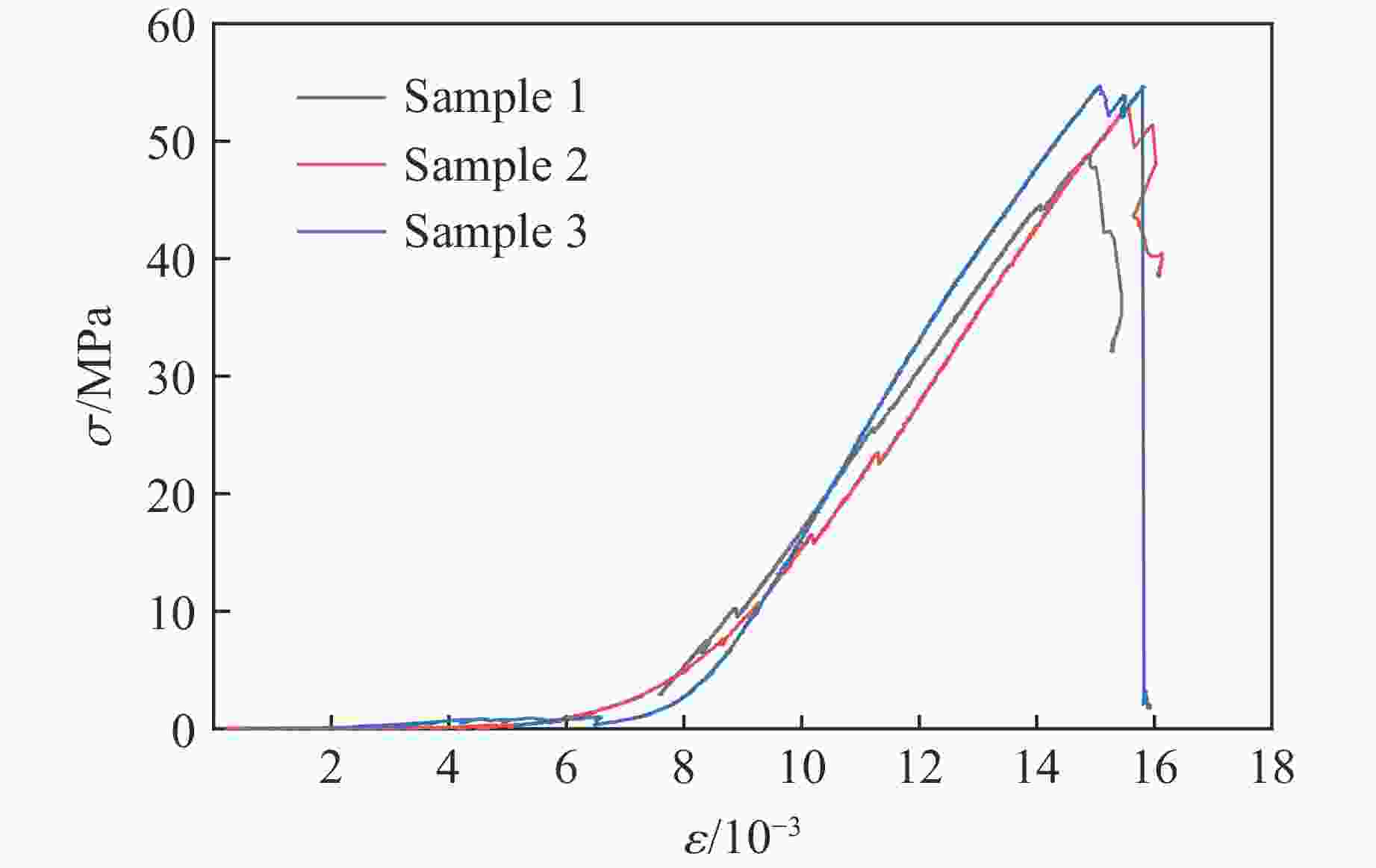

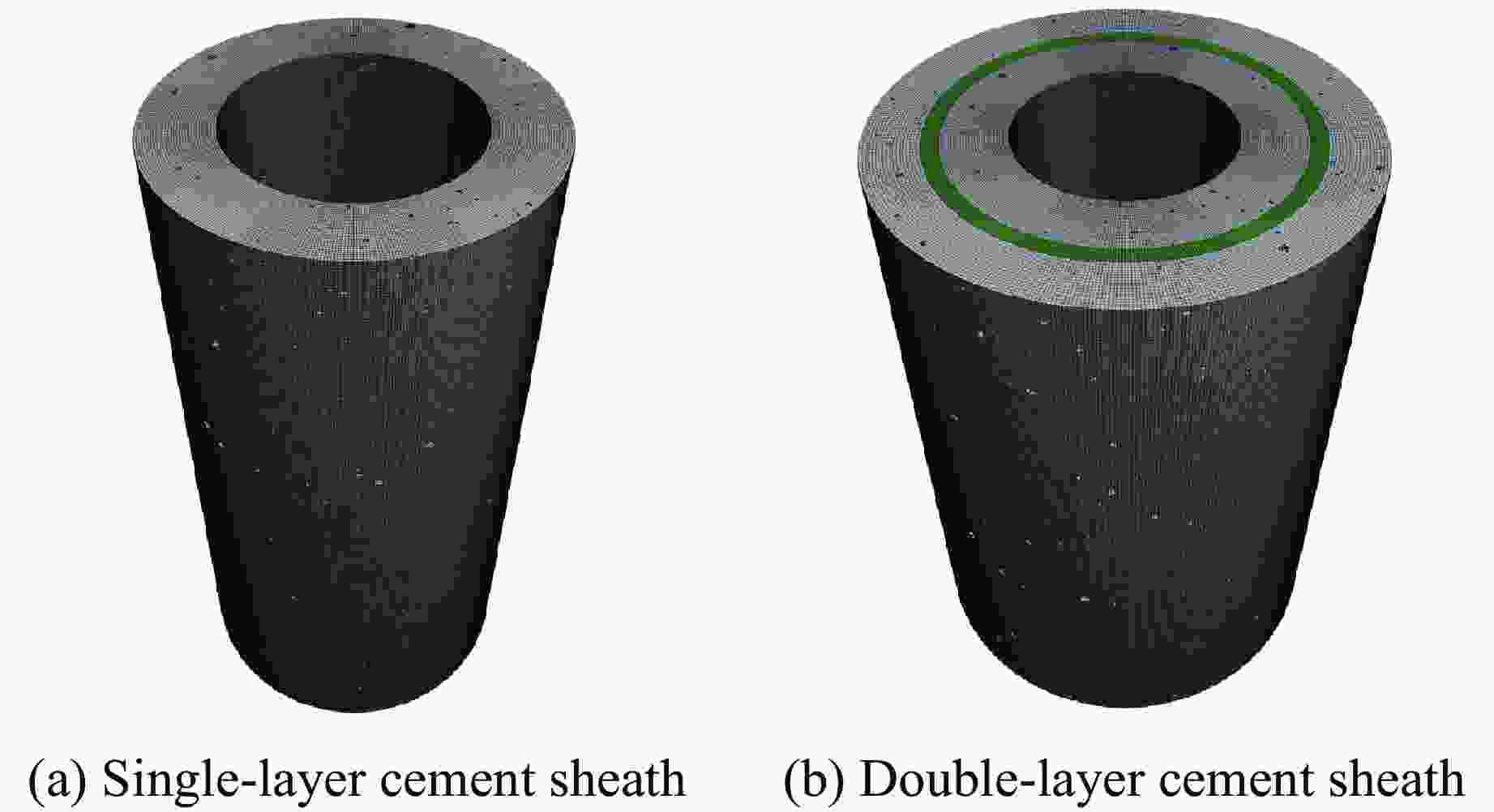

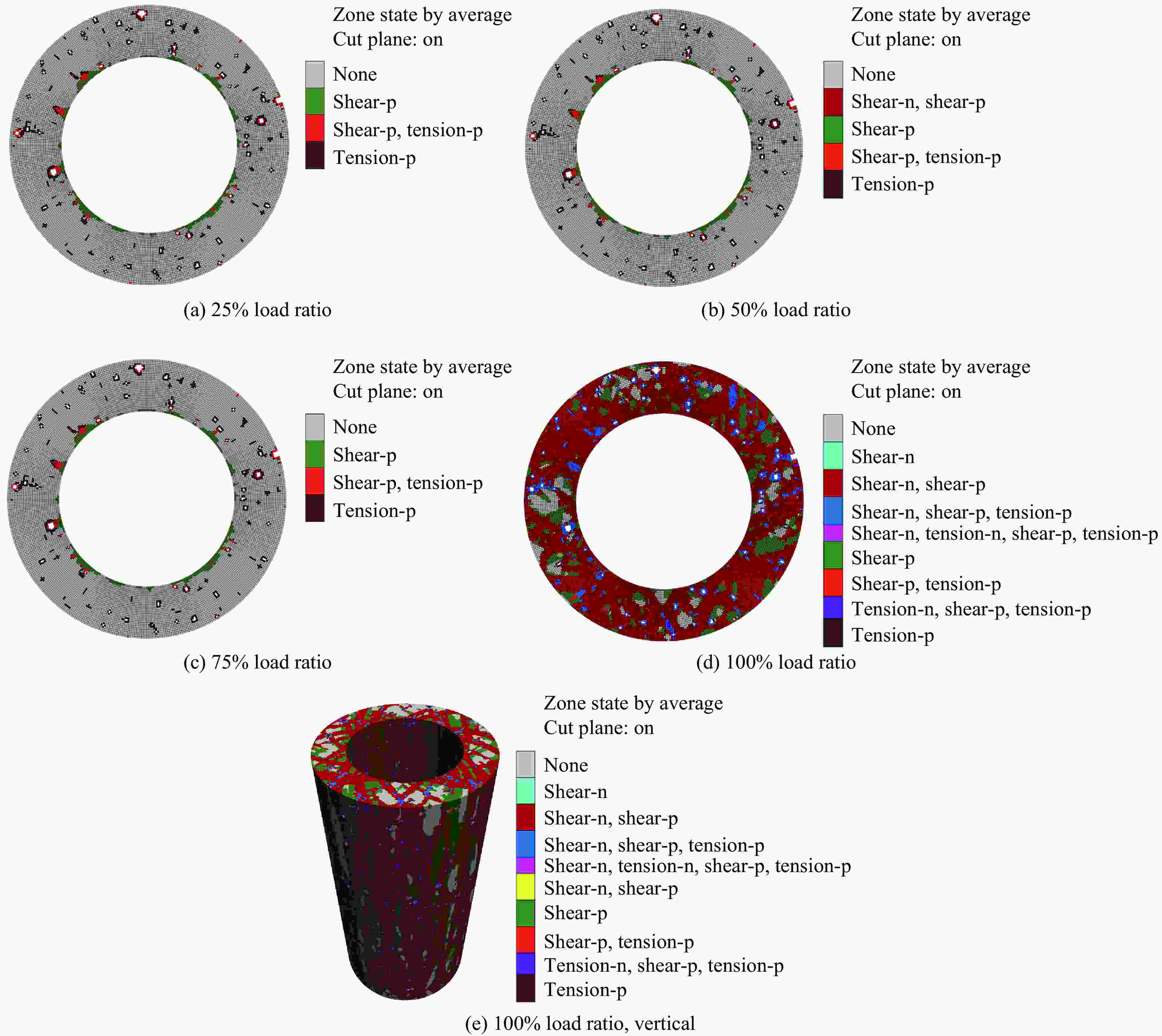

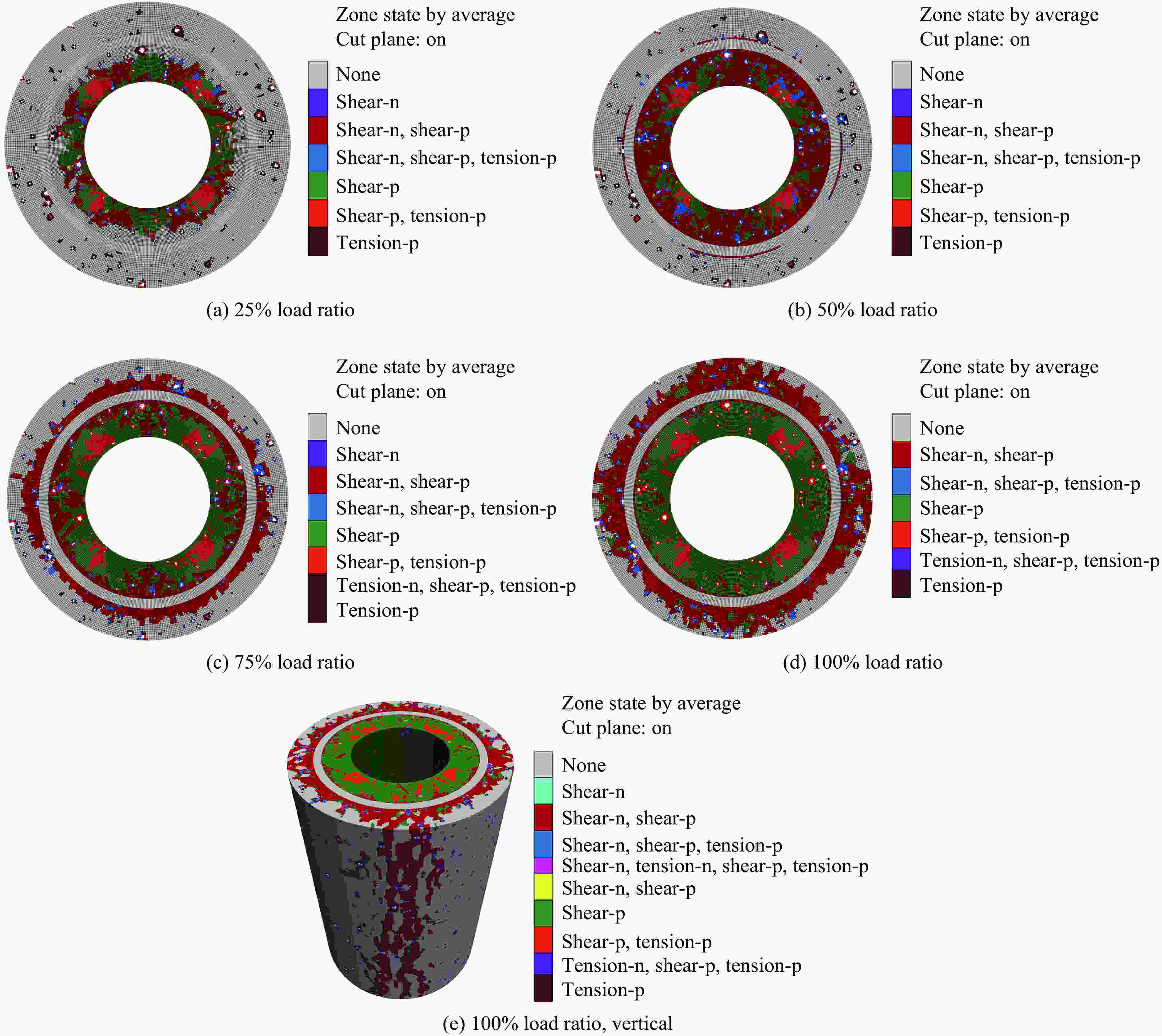

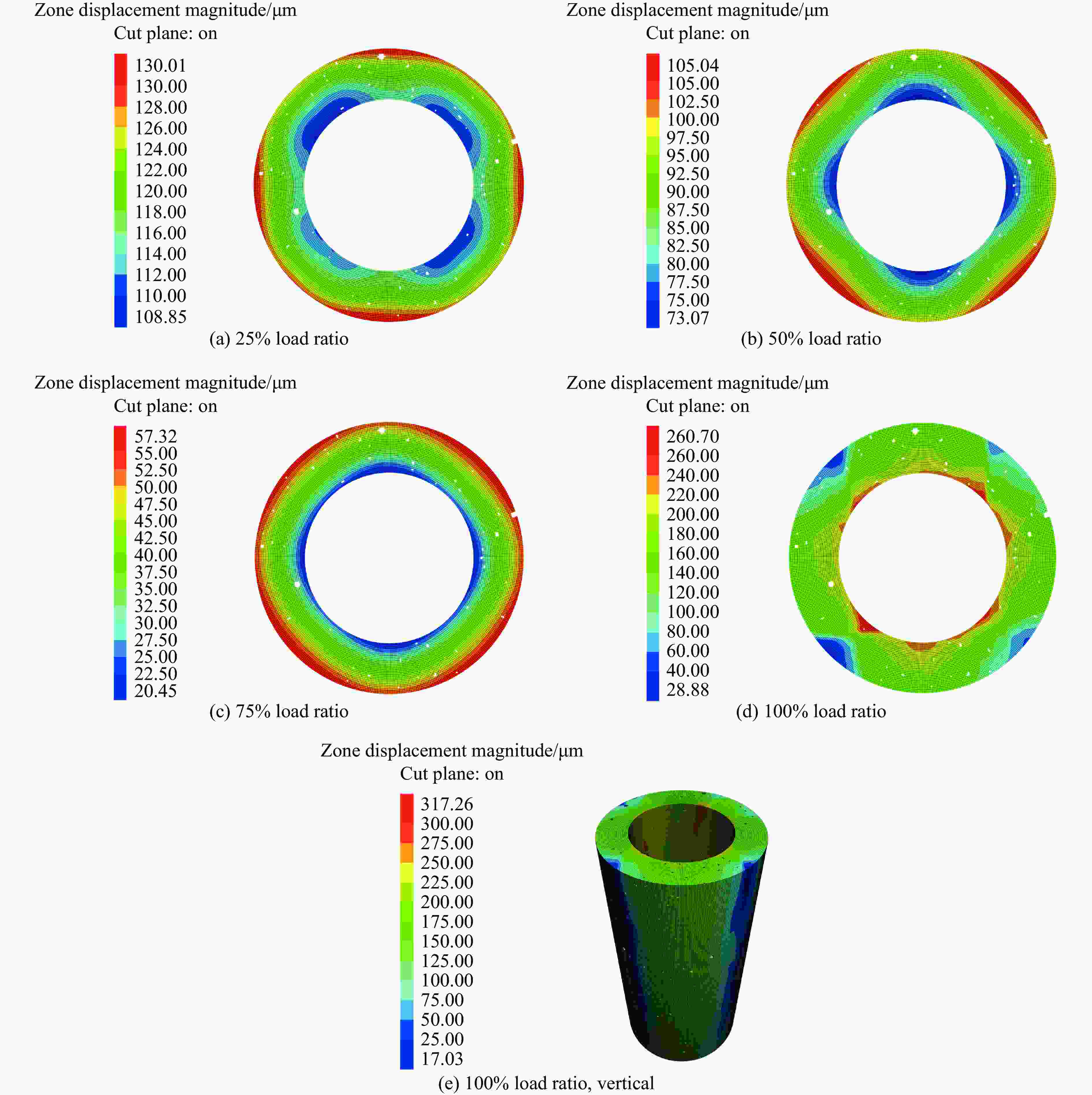

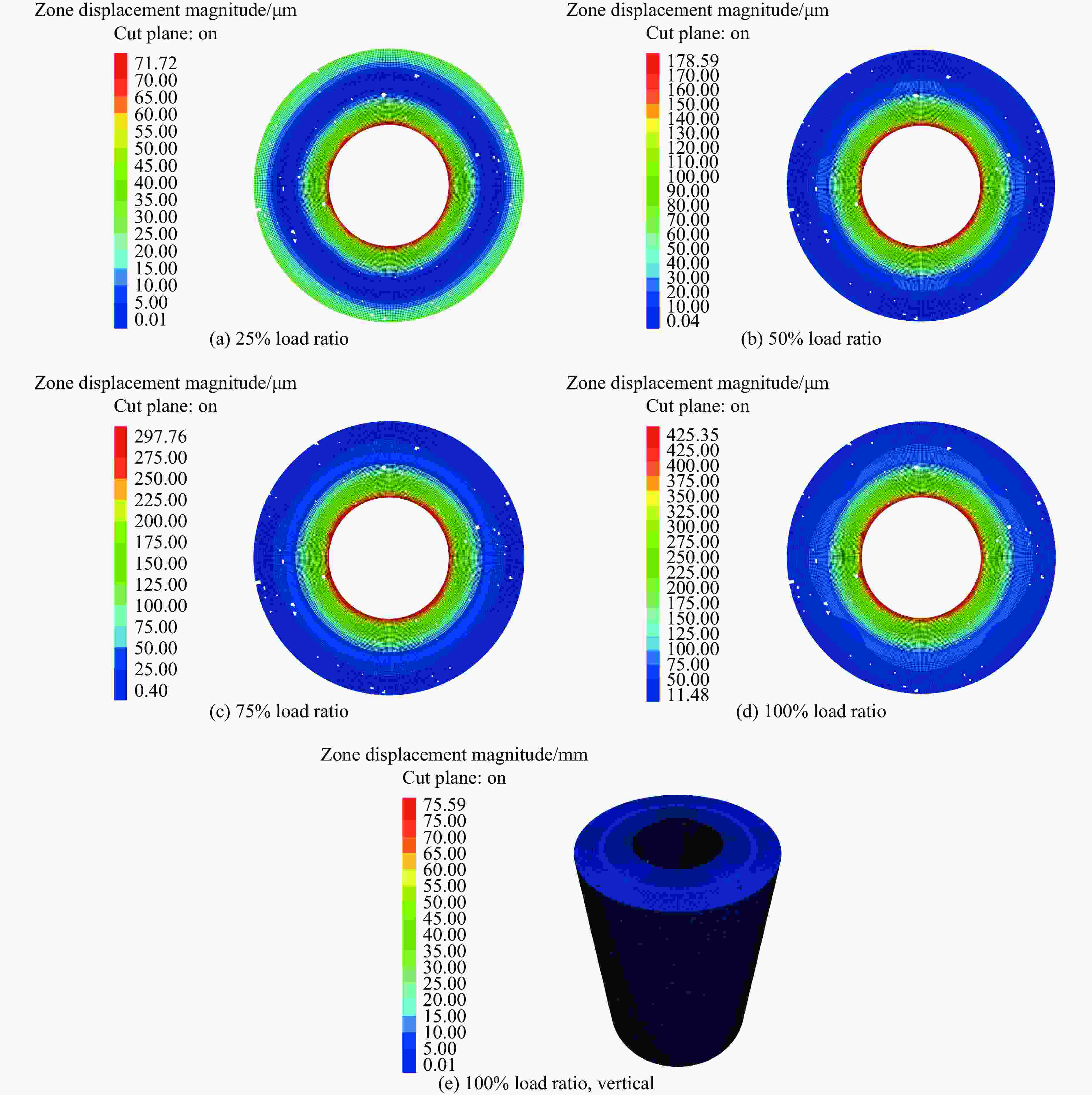

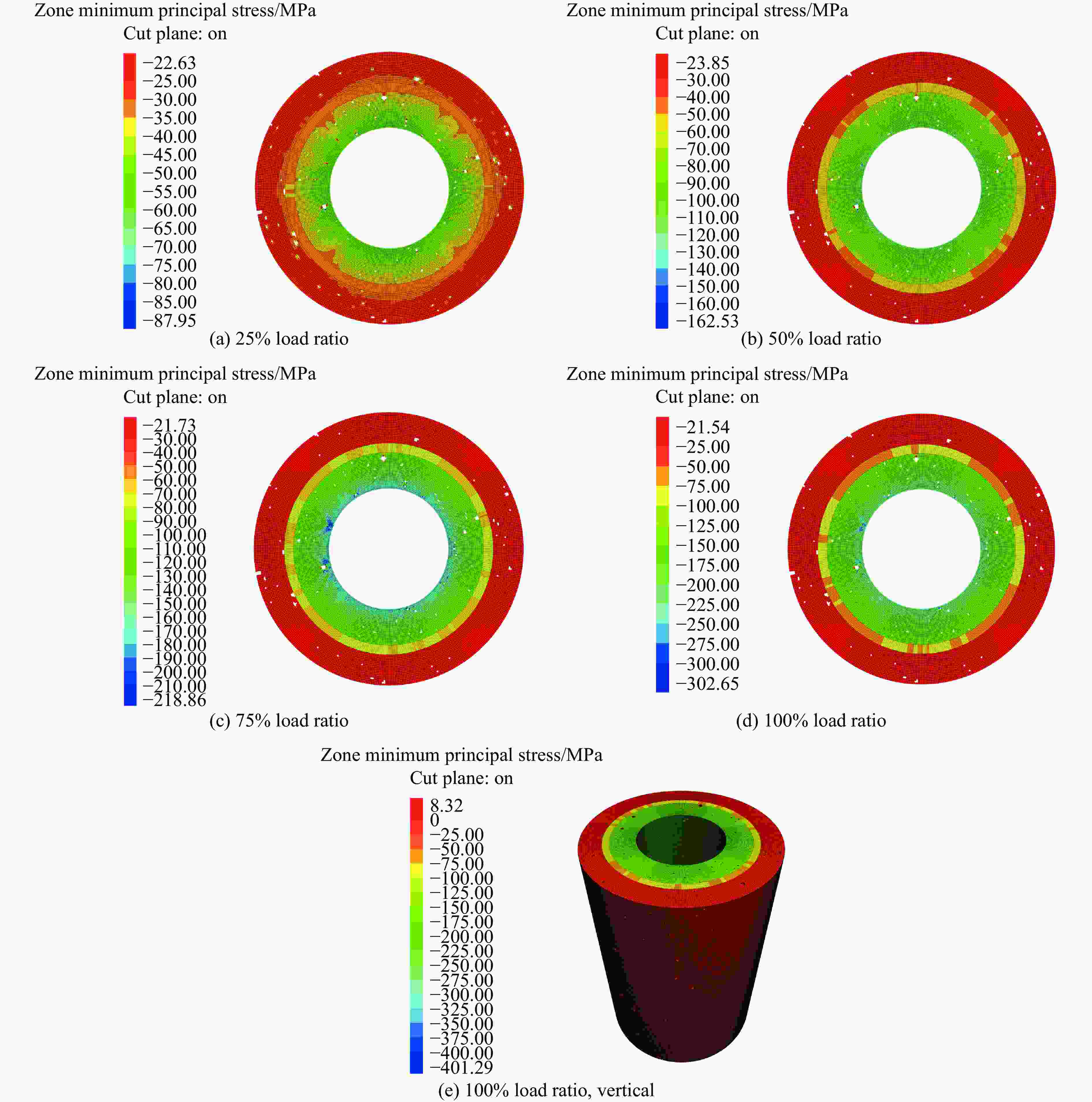

摘要: 针对多孔水泥环的井下失效问题,制备了液硅水泥环岩心试样,开展了力学性能测试试验,同时利用Flac 3D自编程序构建了多孔“单层水泥环”和“水泥环/套管/水泥环”模型,模拟深部地应力作用下水泥环的压裂过程,探明在水压和地应力耦合作用下水泥环的变形破坏机制。研究表明:单层水泥环在应力作用下表现为脆性破坏,外层套管和水泥环的保护能有效提高水泥环的峰值载荷。研究结果为揭示水泥环密封失效的破坏机理提供了理论基础。Abstract: The liquid silicon cement sheath samples were prepared, and the mechanical property testing experiments were carried out. Aiming at the problem of downhole failure of porous cement sheath, the porous “single-layer cement sheath” and “cement sheath-casing-cement sheath” models were established by using Flac 3D self-programming program to simulate the cement sheath fracturing process under the action of deep in-situ stress, and the deformation and failure laws of cement sheath under the coupling action of hydraulic pressure and in-situ stress were proved. The research shows that the single-layer cement sheath exhibits brittle failure under the action of stress, while under the protection of the outer casing and the cement sheath, the peak load of the cement sheath can be effectively increased. The research results provide a theoretical basis for revealing the failure mechanism of cement ring seal failure.

-

表 1 液硅水泥环的物理力学参数

Table 1. Physical and mechanical parameters of liquid silica cement sheath

Tensile strength/

MPaUniaxial compressive strength/MPa Modulus of elasticity/GPa Poisson’s ratio Cohesion/

MPaInternal friction angle/(°) 4.8 54.31 3.56 0.15 7.8 35 -

[1] BECKWITH R. Hydraulic fracturing: the fuss, the facts, the future [J]. Journal of Petroleum Technology, 2010, 62(12): 34–40. doi: 10.2118/1210-0034-JPT [2] ALLOUCHE E N, ARIARATNAM S T, LUEKE J S. Horizontal directional drilling: profile of an emerging industry [J]. Journal of Construction Engineering and Management, 2000, 126(1): 68–76. doi: 10.1061/(ASCE)0733-9364(2000)126:1(68 [3] MONTGOMERY C T, SMITH M B. Hydraulic fracturing: history of an enduring technology [J]. Journal of Petroleum Technology, 2010, 62(12): 26–40. doi: 10.2118/1210-0026-JPT [4] 王昌辉, 张红杰, 赵俊, 等. 弹塑性储层水力压裂裂缝扩展研究 [J]. 石油机械, 2022, 50(2): 80–88. doi: 10.16082/j.cnki.issn.1001-4578.2022.02.012WANG C H, ZHANG H J, ZHAO J, et al. Study on hydraulic fracture propagation in elastoplastic reservoir [J]. China Petroleum Machinery, 2022, 50(2): 80–88. doi: 10.16082/j.cnki.issn.1001-4578.2022.02.012 [5] 徐瑞. 倾斜松软煤层梳状钻孔水力压裂治理条带瓦斯技术研究与应用 [J]. 煤炭技术, 2021, 40(6): 106–109. doi: 10.13301/j.cnki.ct.2021.06.030XU R. Study and application of comb type borehole and hydraulic fracturing technology for inclined and soft seam gas pre-drainaging at coal lane band [J]. Coal Technology, 2021, 40(6): 106–109. doi: 10.13301/j.cnki.ct.2021.06.030 [6] 华苏东, 姚晓. 高韧性水泥环降低油气井套损作用机制分析 [J]. 油气田地面工程, 2009, 28(11): 34–35. doi: 10.3969/j.issn.1006-6896.2009.11.018HUA S D, YAO X. Mechanism analysis of reducing casing damage for gas and oil wells of high toughness cement sheath [J]. Oil-Gasfield Surface Engineering, 2009, 28(11): 34–35. doi: 10.3969/j.issn.1006-6896.2009.11.018 [7] 姚晓, 樊松林, 吴叶成, 等. 油井水泥纤维增韧材料的研究与应用 [J]. 西安石油大学学报(自然科学版), 2005, 20(2): 39–42. doi: 10.3969/j.issn.1673-064X.2005.02.010YAO X, FAN S L, WU Y C, et al. Study and application of toughness-enhancing fiber material for the cement used for well-cementing [J]. Journal of Xi’an Shiyou University (Natural Science Edition), 2005, 20(2): 39–42. doi: 10.3969/j.issn.1673-064X.2005.02.010 [8] 李军, 陈勉, 张辉, 等. 水泥环弹性模量对套管外挤载荷的影响分析 [J]. 石油大学学报(自然科学版), 2005, 29(6): 41–44. doi: 10.3321/j.issn:1000-5870.2005.06.010LI J, CHEN M, ZHANG H, et al. Effects of cement sheath elastic modulus on casing external collapse load [J]. Journal of the University of Petroleum (Natural Science Edition), 2005, 29(6): 41–44. doi: 10.3321/j.issn:1000-5870.2005.06.010 [9] 陈朝伟, 曹虎, 周小金, 等. 四川盆地长宁区块页岩气井套管变形和裂缝带相关性 [J]. 天然气勘探与开发, 2020, 43(4): 123–130. doi: 10.12055/gaskk.issn.1673-3177.2020.04.015CHEN Z W, CAO H, ZHOU X J, et al. Correlation between casing deformation and fracture zones in Changning shale gas block, Sichuan Basin [J]. Natural Gas Exploration and Development, 2020, 43(4): 123–130. doi: 10.12055/gaskk.issn.1673-3177.2020.04.015 [10] 童亨茂, 张平, 张宏祥, 等. 页岩气水平井开发套管变形的地质力学机理及其防治对策 [J]. 天然气工业, 2021, 41(1): 189–197. doi: 10.3787/j.issn.1000-0976.2021.01.017TONG H M, ZHANG P, ZHANG H X, et al. Geomechanical mechanisms and prevention countermeasures of casing deformation in shale gas horizontal wells [J]. Natural Gas Industry, 2021, 41(1): 189–197. doi: 10.3787/j.issn.1000-0976.2021.01.017 [11] 范宇, 黄锐, 曾波, 等. 四川页岩气水力压裂诱发断层滑动和套管变形风险评估 [J]. 石油科学通报, 2020, 5(3): 366–375. doi: 10.3969/j.issn.2096-1693.2020.03.031FAN Y, HUANG R, ZENG B, et al. Fault slip induced by hydraulic fracturing and risk assessment of casing deformation in the Sichuan Basin [J]. Petroleum Science Bulletin, 2020, 5(3): 366–375. doi: 10.3969/j.issn.2096-1693.2020.03.031 [12] 张景富, 公海峰, 靳建州, 等. 地层类型对水泥环的力学作用及影响 [J]. 东北石油大学学报, 2020, 44(4): 30–39. doi: 10.3969/j.issn.2095-4107.2020.04.005ZHANG J F, GONG H F, JIN J Z, et al. Mechanical action and effect of the stratum types on cement sheath [J]. Journal of Northeast Petroleum University, 2020, 44(4): 30–39. doi: 10.3969/j.issn.2095-4107.2020.04.005 [13] 于浩, 练章华, 林铁军, 等. 页岩气体积压裂过程中套管失效机理研究 [J]. 中国安全生产科学技术, 2016, 12(10): 37–43. doi: 10.11731/j.issn.1673-193x.2016.10.006YU H, LIAN Z H, LIN T J, et al. Study on failure mechanism of casing in stimulated reservoir volume fracturing of shale gas [J]. Journal of Safety Science and Technology, 2016, 12(10): 37–43. doi: 10.11731/j.issn.1673-193x.2016.10.006 [14] 于浩, 练章华, 林铁军. 页岩气压裂过程套管失效机理有限元分析 [J]. 石油机械, 2014, 42(8): 84–88,93. doi: 10.3969/j.issn.1001-4578.2014.08.020YU H, LIAN Z H, LIN T J. Finite element analysis of failure mechanism of casing during shale gas fracturing [J]. China Petroleum Machinery, 2014, 42(8): 84–88,93. doi: 10.3969/j.issn.1001-4578.2014.08.020 [15] 刘奎, 高德利, 王宴滨, 等. 局部载荷对页岩气井套管变形的影响 [J]. 天然气工业, 2016, 36(11): 76–82. doi: 10.3787/j.issn.1000-0976.2016.11.010LIN K, GAO D L, WANG Y B, et al. Effects of local load on shale gas well casing deformation [J]. Natural Gas Industry, 2016, 36(11): 76–82. doi: 10.3787/j.issn.1000-0976.2016.11.010 [16] 陈朝伟, 石林, 项德贵. 长宁-威远页岩气示范区套管变形机理及对策 [J]. 天然气工业, 2016, 36(11): 70–75. doi: 10.3787/j.issn.1000-0976.2016.11.009CHEN Z W, SHI L, XIANG D G. Mechanism of casing deformation in the Changning-Weiyuan national shale gas project demonstration area and countermeasures [J]. Natural Gas Industry, 2016, 36(11): 70–75. doi: 10.3787/j.issn.1000-0976.2016.11.009 [17] 陈勇, 练章华, 乐彬, 等. 考虑地应力耦合的热采井套管损坏分析 [J]. 钻采工艺, 2007, 30(5): 13–16. doi: 10.3969/j.issn.1006-768X.2007.05.005CHEN Y, LIAN Z H, YUE B, et al. Analysis of casing failure in thermal production well when earth stress considered [J]. Drilling & Production Technology, 2007, 30(5): 13–16. doi: 10.3969/j.issn.1006-768X.2007.05.005 [18] 马绰, 康志勤. 新型矿井套管-水泥环变形与渗漏试验研究 [J]. 煤炭技术, 2016, 35(6): 48–50. doi: 10.13301/j.cnki.ct.2016.06.020MA C, KANG Z Q. Experimental study on deformation and seepage of new type of mine casing-cement sheath [J]. Coal Technology, 2016, 35(6): 48–50. doi: 10.13301/j.cnki.ct.2016.06.020 [19] 李军, 丁士东, 韩礼红, 等. 页岩气多级压裂井筒完整性失效机理及控制方法研究进展 [J]. 石油管材与仪器, 2020, 6(4): 10–15. doi: 10.19459/j.cnki.61-1500/te.2020.04.002LI J, DING S D, HAN L H, et al. Research progress on failure mechanism and control methods of wellbore integrity during multi-stage fracturing of shale gas [J]. Petroleum Tubular Goods & Instruments, 2020, 6(4): 10–15. doi: 10.19459/j.cnki.61-1500/te.2020.04.002 [20] GOODWIN K J, CROOK R J. Cement sheath stress failure [J]. SPE Drilling Engineering, 1992, 7(4): 291–296. doi: 10.2118/20453-PA [21] BOUKHELIFA L, MORONI N, JAMES S G, et al. Evaluation of cement systems for oil and gas well zonal isolation in a full-scale annular geometry [J]. SPE Drilling & Completion, 2005, 20(1): 44–53. doi: 10.2118/87195-PA [22] THIERCELIN M J, DARGAUD B, BARET J F, et al. Cement design based on cement mechanical response [J]. SPE Drilling & Completion, 1998, 13(4): 266–273. doi: 10.2118/52890-PA [23] 李军, 陈勉, 柳贡慧, 等. 套管、水泥环及井壁围岩组合体的弹塑性分析 [J]. 石油学报, 2005, 26(6): 99–103. doi: 10.7623/syxb200506023LI J, CHEN M, LIU G H, et al. Elastic-plastic analysis of casing-concrete sheath-rock combination [J]. Acta Petrolei Sinica, 2005, 26(6): 99–103. doi: 10.7623/syxb200506023 [24] 卢亚锋, 郑友志, 佘朝毅, 等. 基于水泥石实验数据的水泥环力学完整性分析 [J]. 天然气工业, 2013, 33(5): 77–81. doi: 10.3787/j.issn.1000-0976.2013.05.014LU Y F, ZHENG Y F, SHE C Y, et al. Analysis of cement-sheath mechanical integrity based on the experiment data of cement paste [J]. Natural Gas Industry, 2013, 33(5): 77–81. doi: 10.3787/j.issn.1000-0976.2013.05.014 [25] 沈吉云, 石林, 李勇, 等. 大压差条件下水泥环密封完整性分析及展望 [J]. 天然气工业, 2017, 37(4): 98–108. doi: 10.3787/j.issn.1000-0976.2017.04.012SHEN J Y, SHI L, LI Y, et al. Analysis and perspective of cement sheath integrity under a high differential pressure [J]. Natural Gas Industry, 2017, 37(4): 98–108. doi: 10.3787/j.issn.1000-0976.2017.04.012 [26] 楼晨阳, 姚晓, 顾光伟, 等. 镁质晶须对油井水泥石力学性能的影响 [J]. 钻井液与完井液, 2015, 32(1): 77–80. doi: 10.3969/j.issn.1001-5620.2015.01.20LOU C Y, YAO X, GU G W, et al. Effect of magnesia whisker on mechanical property of set cement [J]. Drilling Fluid & Completion Fluid, 2015, 32(1): 77–80. doi: 10.3969/j.issn.1001-5620.2015.01.20 -

下载:

下载: