Discrete Element Simulation of Blasting Damage Characteristics of Granite under Different Decoupling Coefficients

-

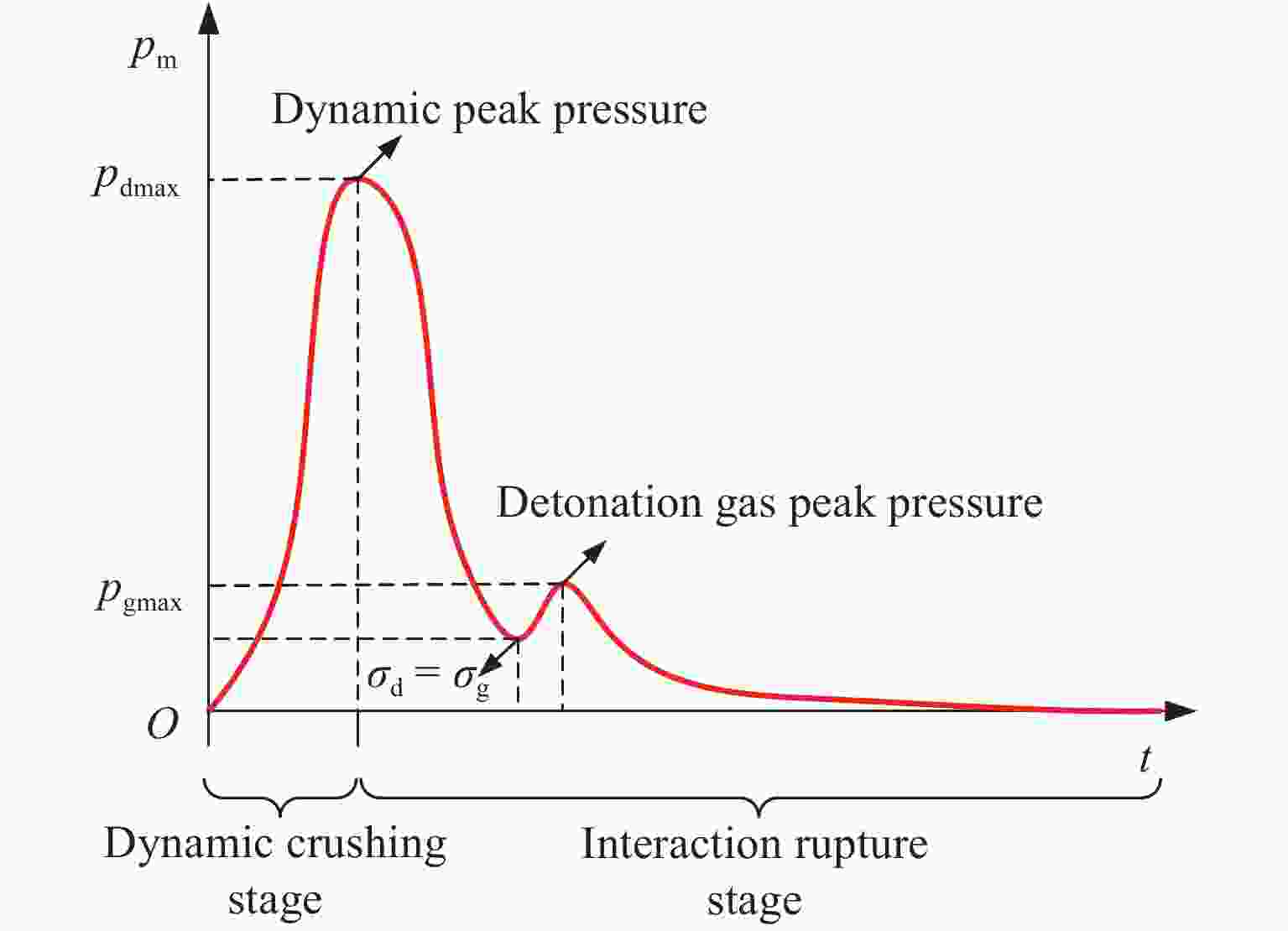

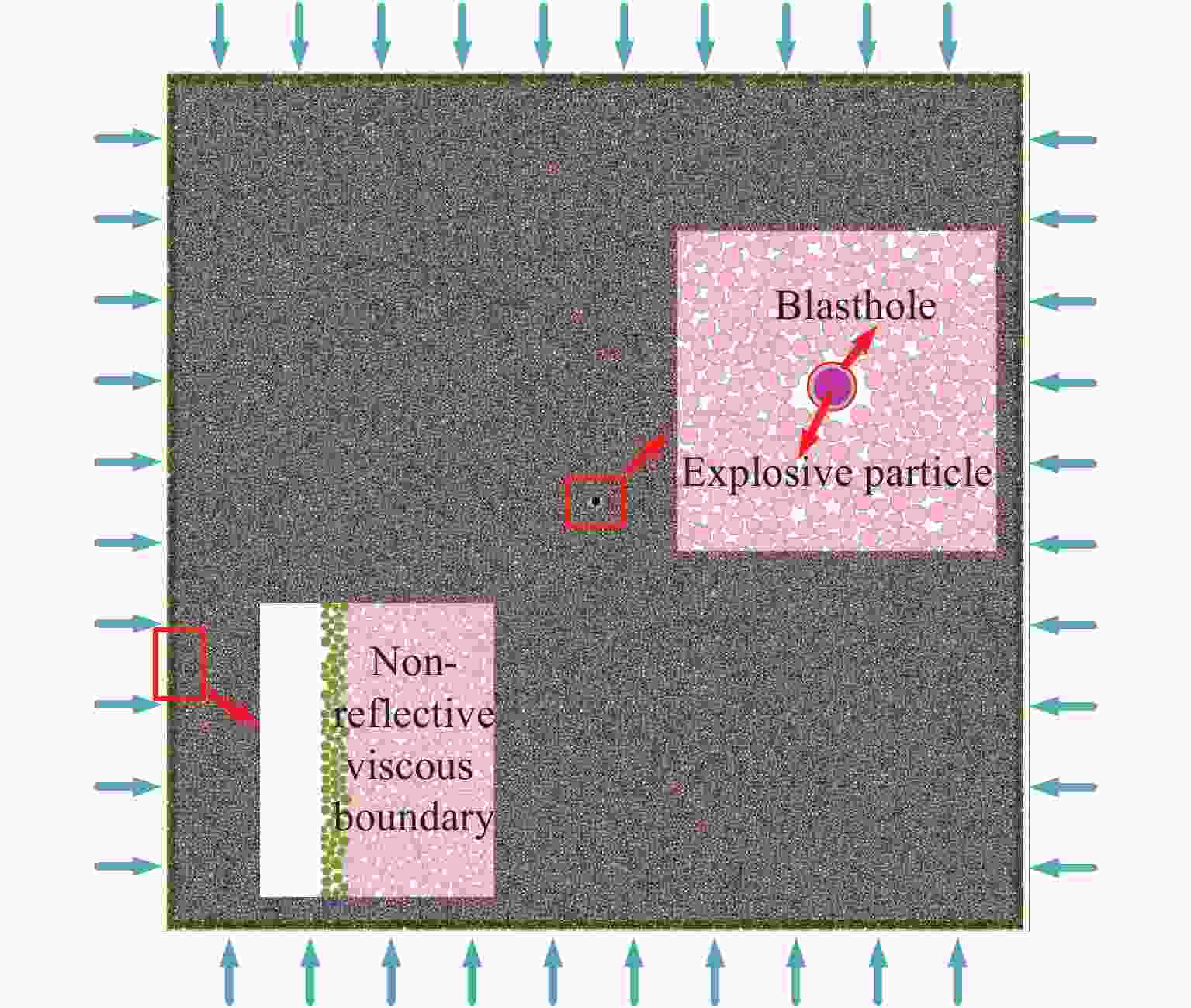

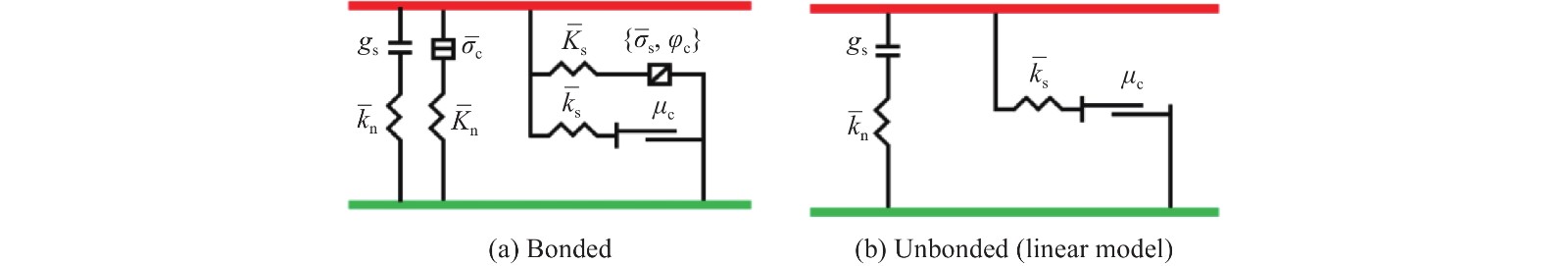

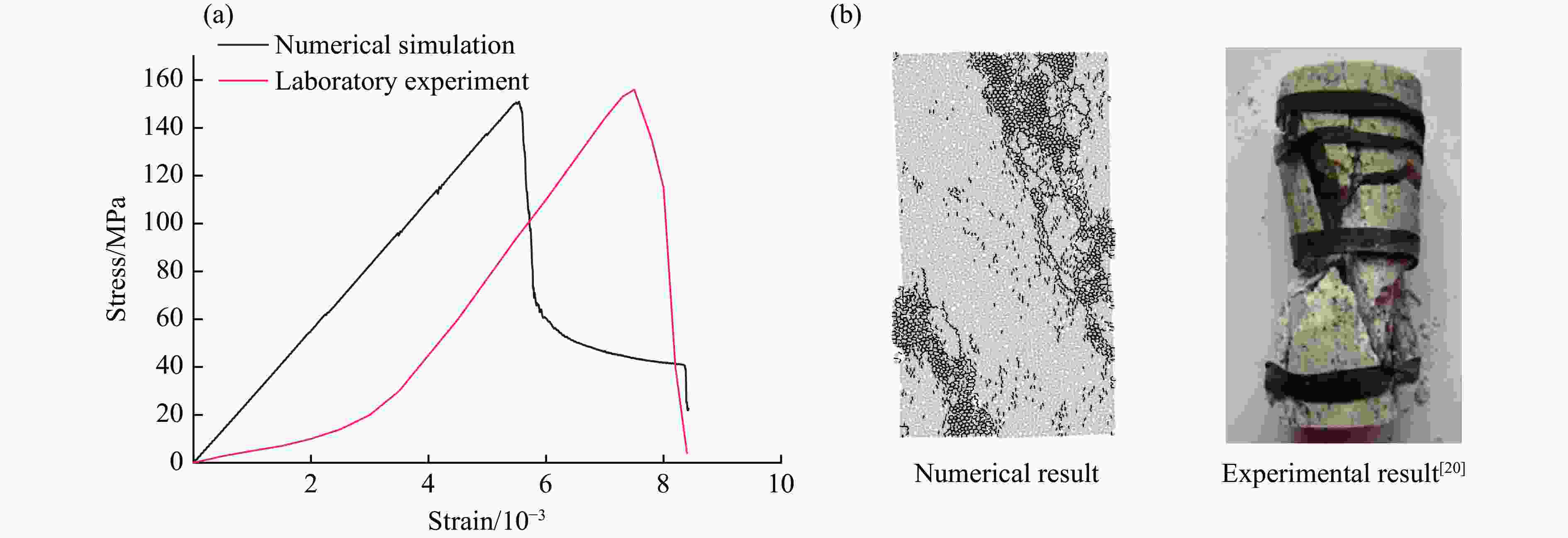

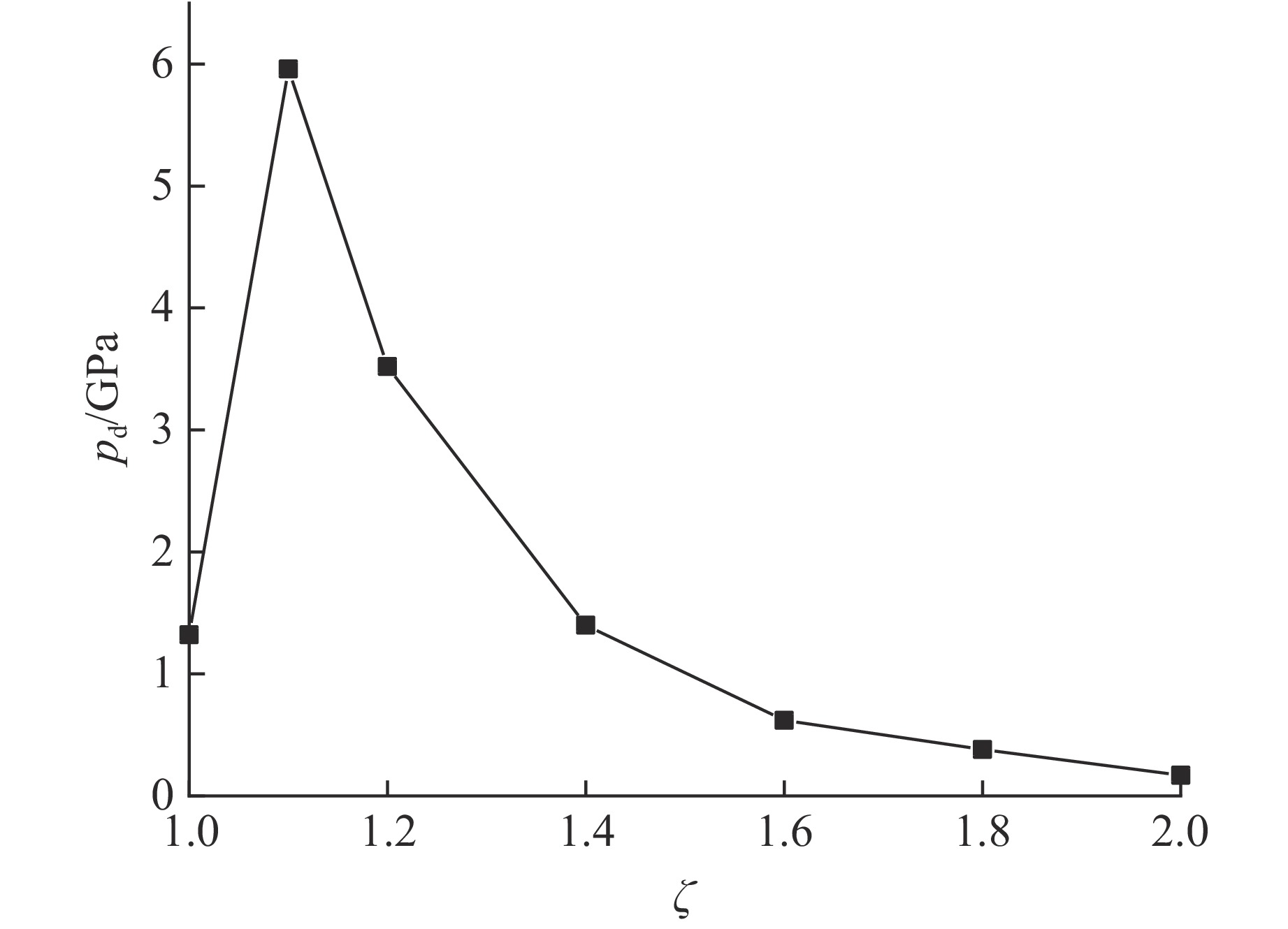

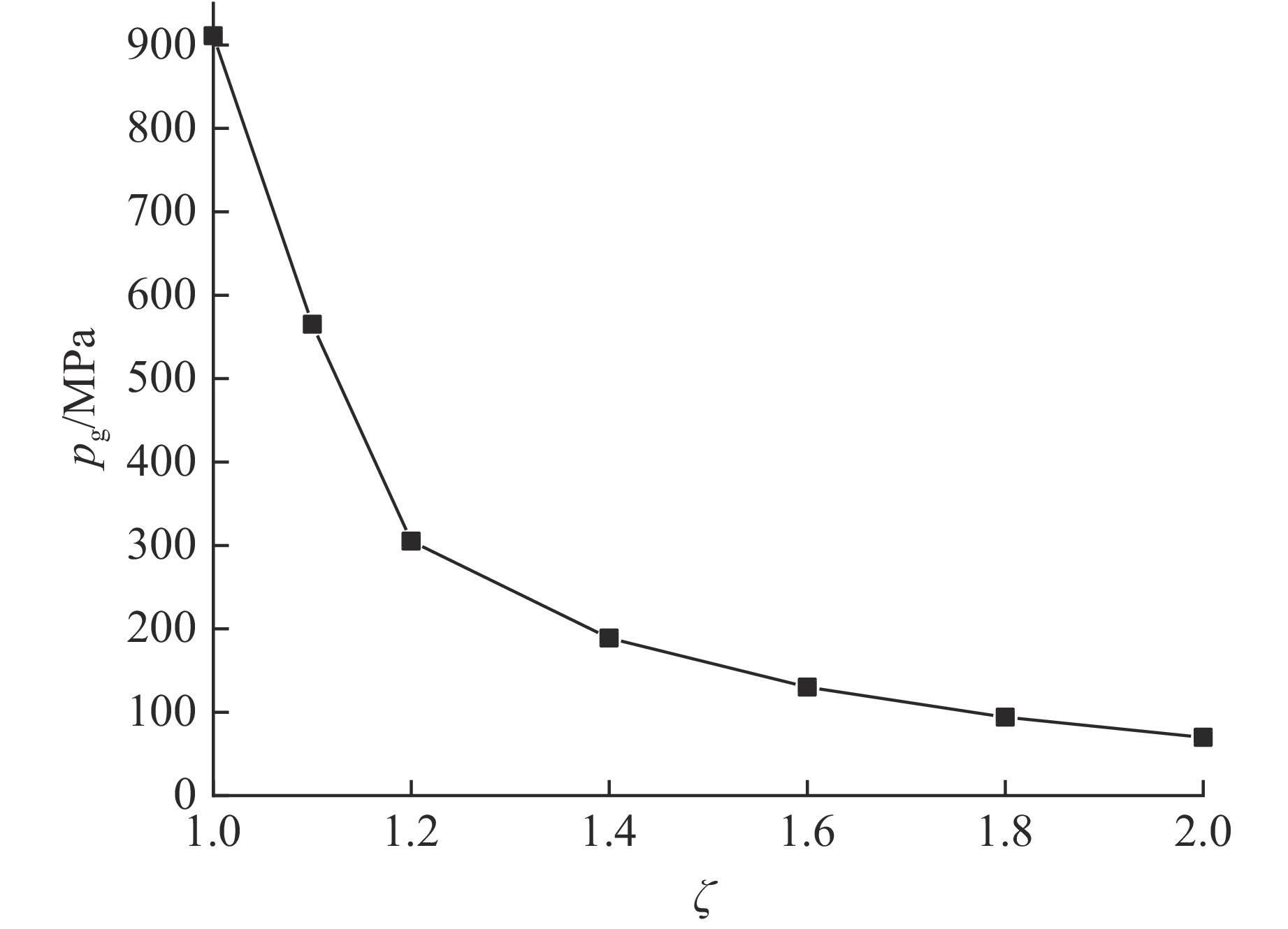

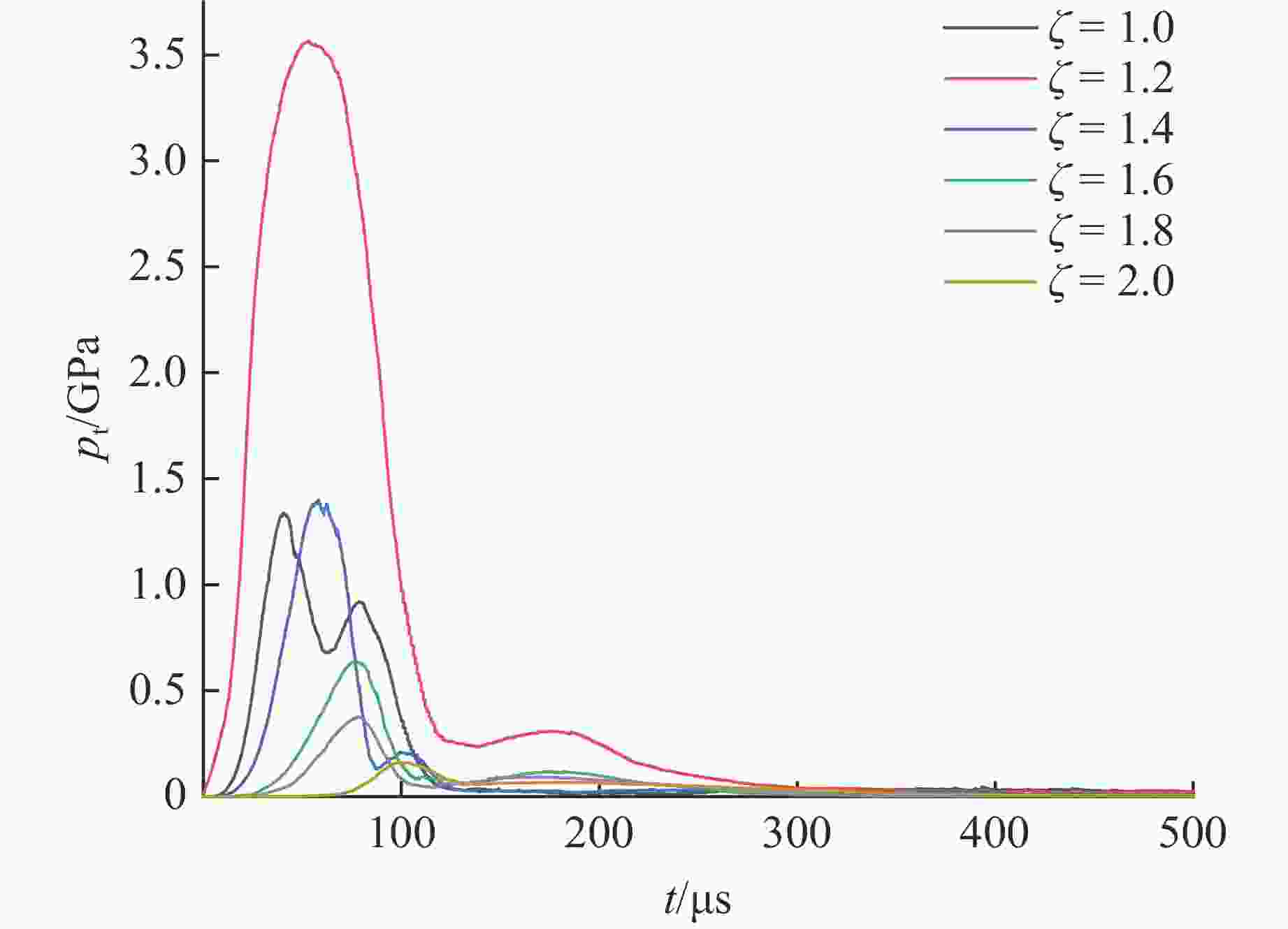

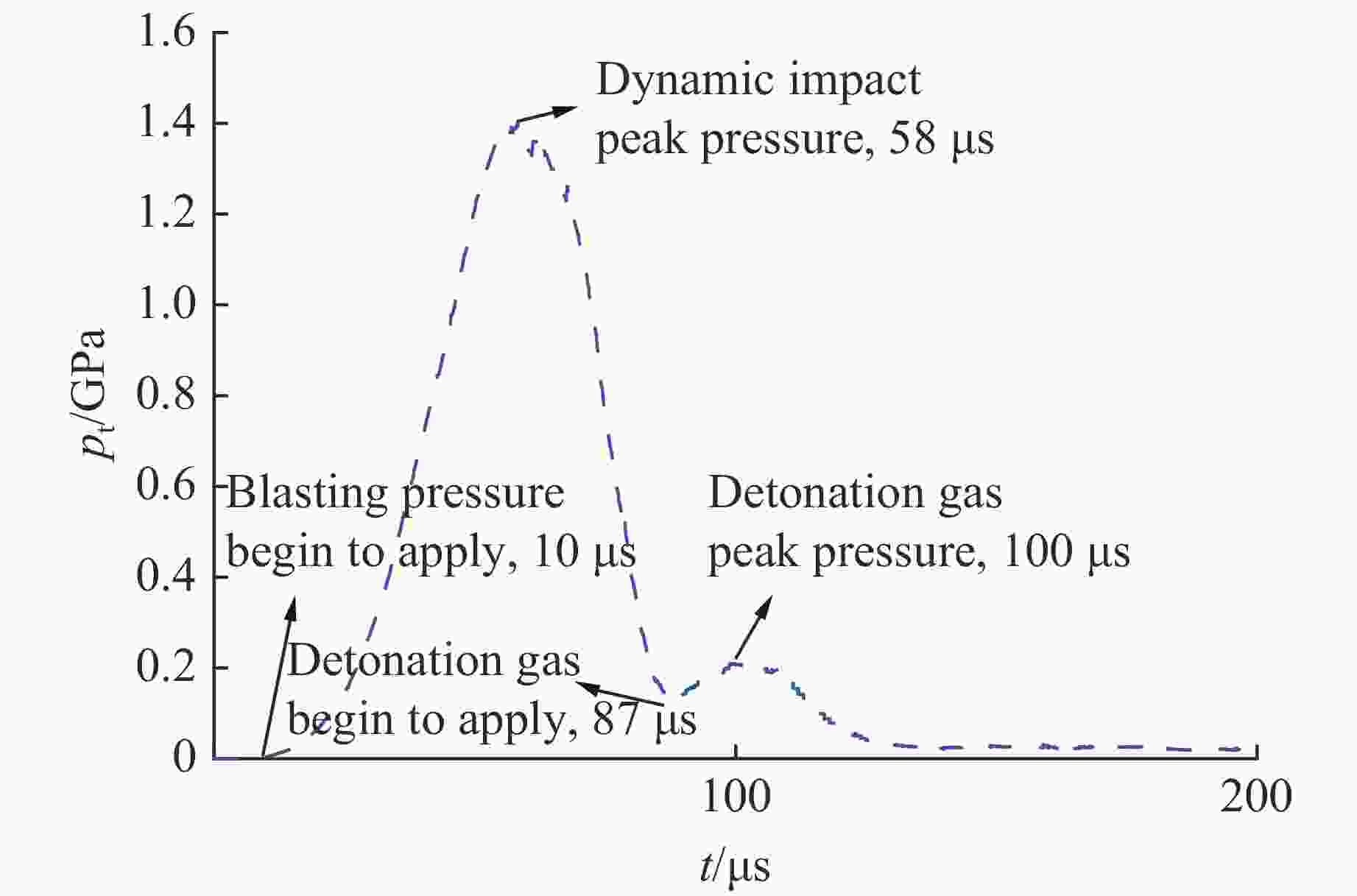

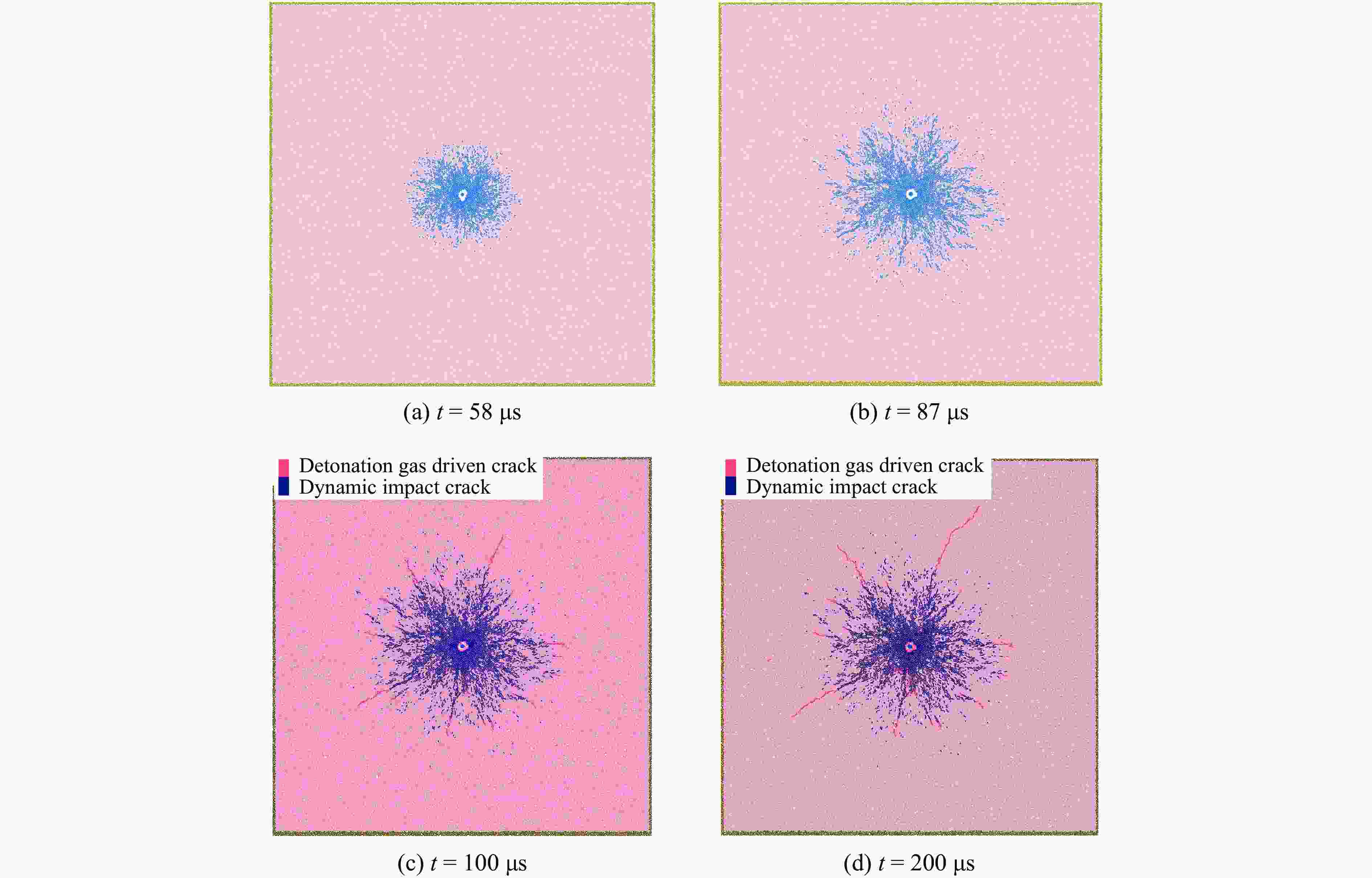

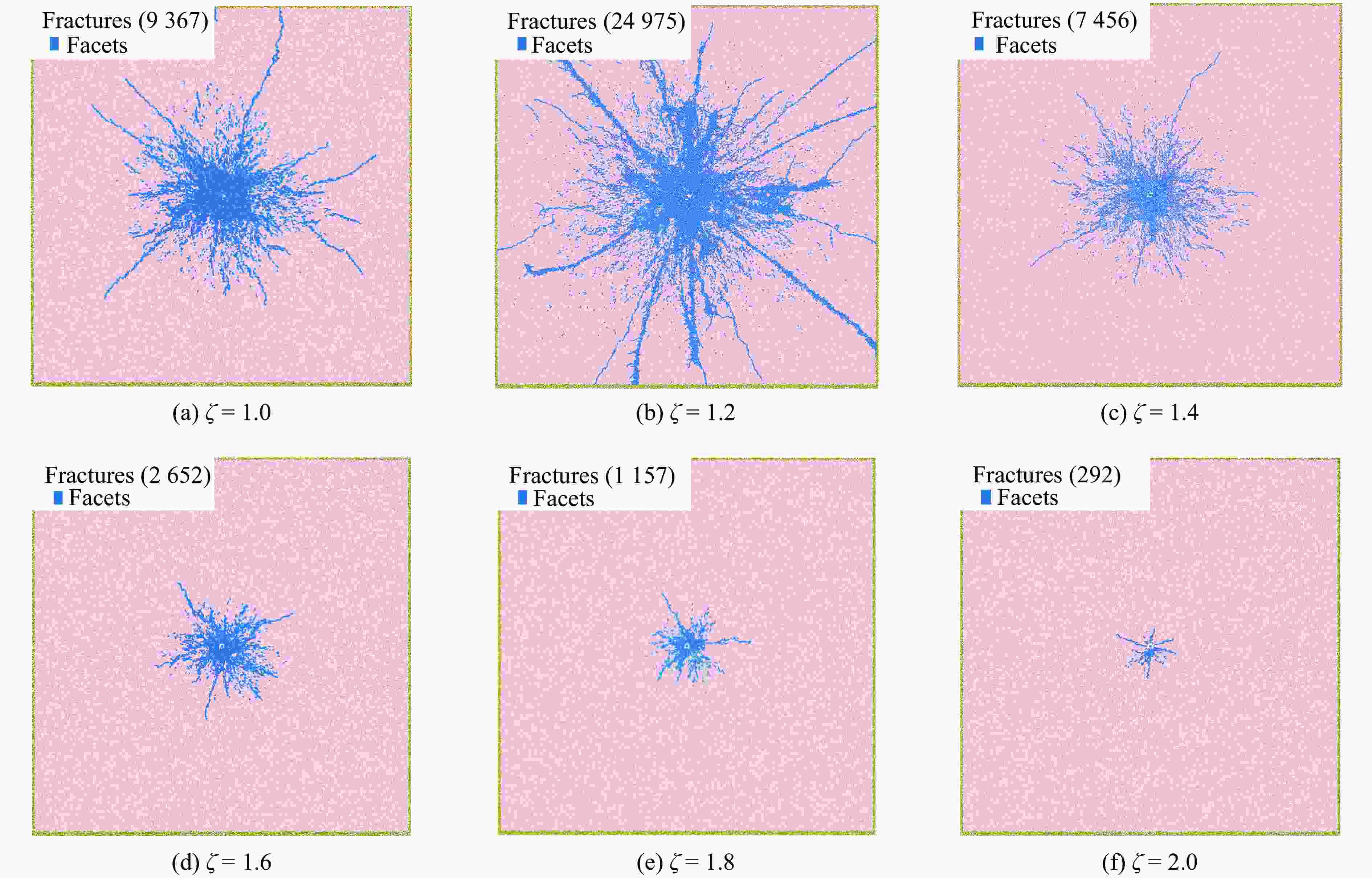

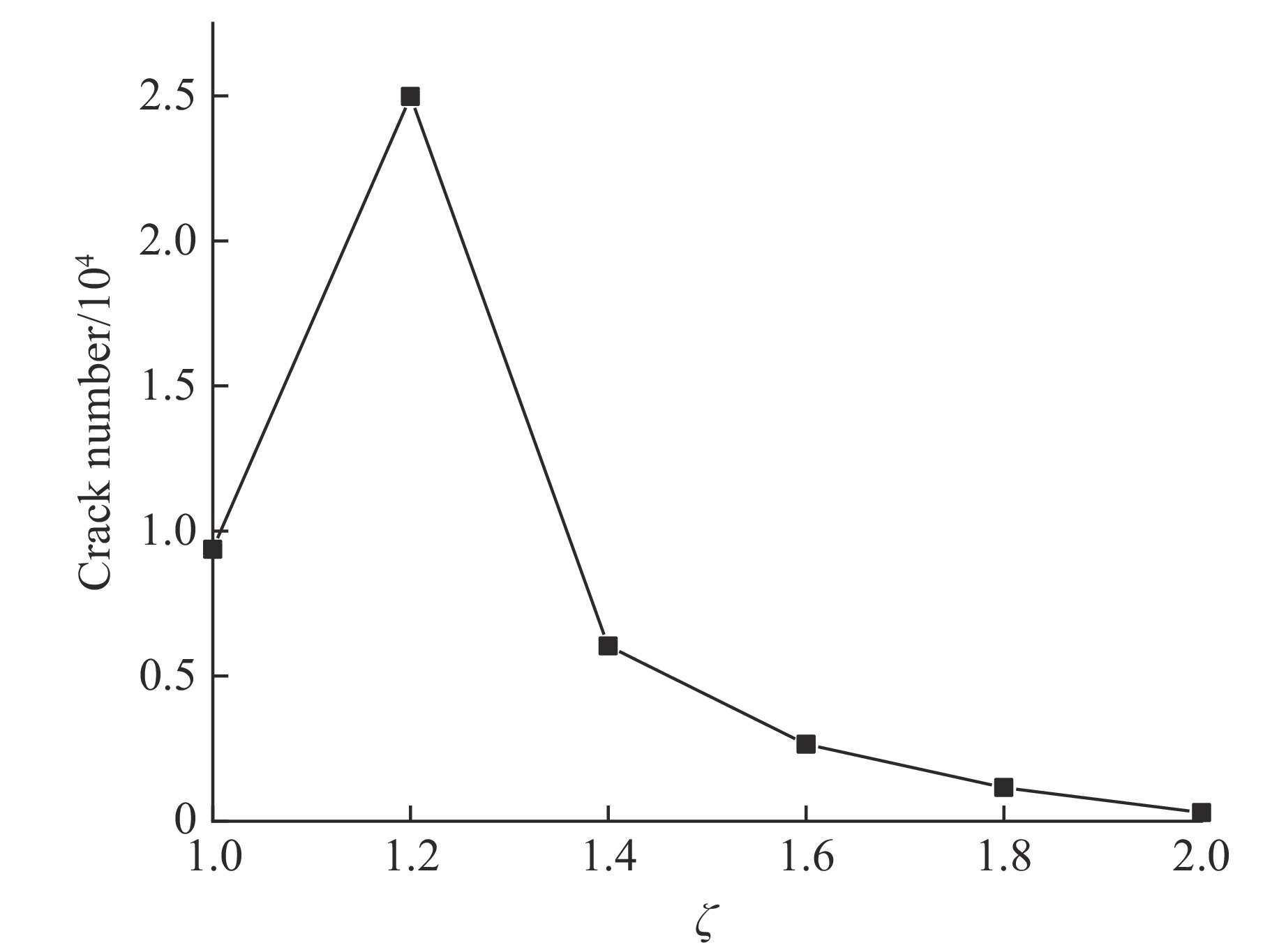

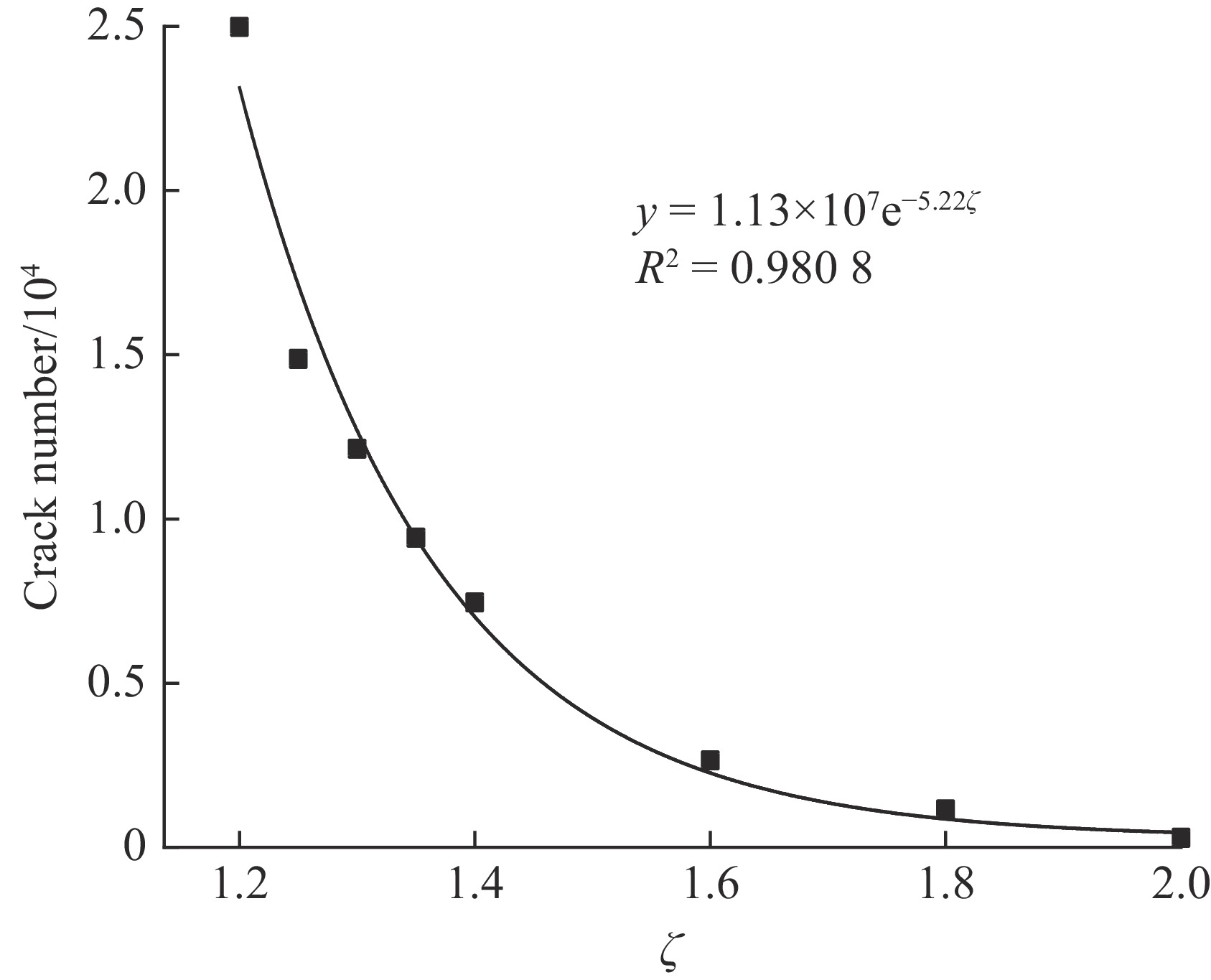

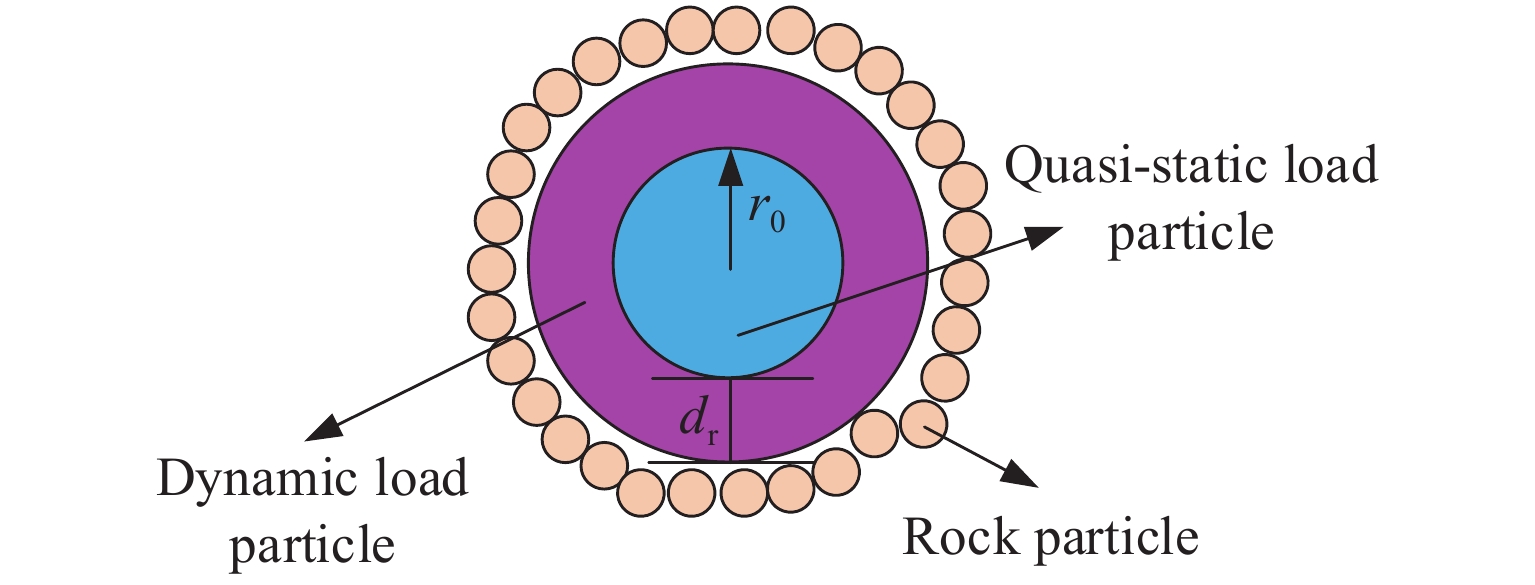

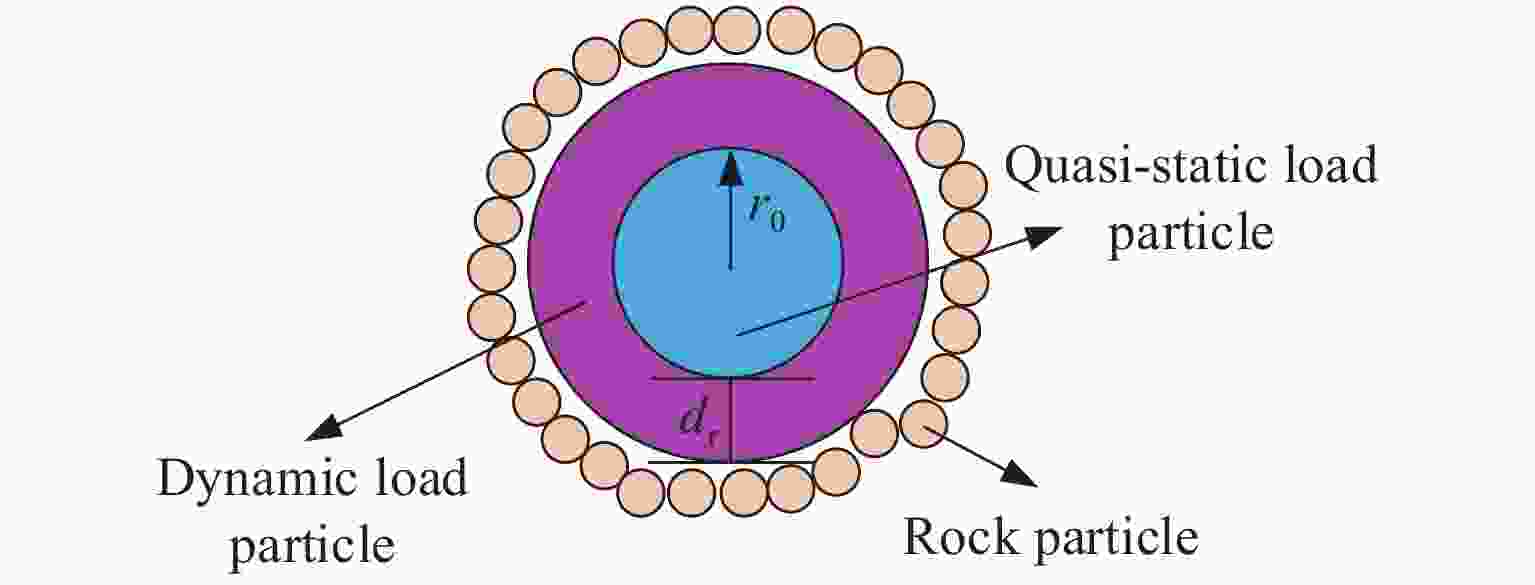

摘要: 为研究径向装药不耦合系数对花岗岩爆破损伤程度的影响,在考虑爆炸冲击波和爆生气体共同作用的基础上,提出了一种“动”、“静”荷载混合施加的PFC爆破模拟方法,采用该方法分别进行了6种不耦合系数下花岗岩爆破过程的数值模拟。模拟结果显示,随着装药不耦合系数的增大,花岗岩爆破损伤程度先增强后减弱。耦合装药下,爆生裂纹数量为9367;不耦合系数为1.2时,裂纹数量增加至最多,为24975;不耦合系数为2.0时,裂纹数量减少为292。对比耦合装药和不耦合系数为1.4时的花岗岩损伤模式发现,爆生气体的准静态压力对爆生裂纹的扩展具有重要作用。根据不同不耦合系数下的爆生裂纹数量,建立了不耦合系数大于或等于1.2时的岩石爆破损伤程度预测模型,拟合度达0.9808。该预测模型对爆破施工设计等工作具有一定的参考意义。Abstract: In order to study the effect of charge decoupling coefficients on the extent of granite blasting damage, a particle flow code (PFC) blasting simulation method with mixed “dynamic” and “quasi-static” loads is proposed based on the joint action of blast shock wave and detonation gas, and then the numerical simulation of granite blasting process under six decoupling coefficients was carried out. The results show that the extent of granite blasting damage increases and then decreases as the decoupling coefficients increases; the number of blasting induced cracks under coupled charge is 9367, which increases to 24975 when the decoupling coefficient is 1.2, and then decreases to 292 when the decoupling coefficient is 2.0. Comparing to the damage pattern under coupled charge, the extension distance of blasting induced crack is obviously shorter when the decoupling coefficient is 1.4, which indicates that the quasi-static pressure of blast gas plays an important role in crack extension. According to the number of blasting cracks, the prediction model of rock blasting damage under different decoupling coefficients greater than or equal to 1.2 was established, and the fitting degree reaches 0.9808. The prediction model presented in this paper is of certain reference significance for practical blasting design.

-

Key words:

- granite /

- decoupling coefficient /

- explosion damage /

- crack /

- particle flow code

-

表 1 主要细观参数

Table 1. Main microscopic parameters

Linear contact parameters Rmin/m Rmax/Rmin ${\bar E{_{\rm l}} }$/GPa ${\bar k{_{\text{n} }} }$/${\bar k{_{\text{s}} } }$ ${\mu {_{\text{c} }} }$ 0.028 1.66 45 2.5 1.0 Parallel bond parameters ${\bar \sigma {_{\text{n} }} }$/MPa ${\bar \sigma {_{\text{s} } }}$/MPa ${\bar E{_{\rm p}} }$/GPa ${\bar K{_{\text{n} } } }$/${\bar K{_{\text{s} } } }$ ${\varphi {_{\text{c} } } }$/(°) 72 150 45 2.5 30 表 2 试样的主要力学参数

Table 2. Main mechanical parameters of the sample

Method ${E{_{\text{t} } } }$/GPa ${\sigma {_{\text{t} } } }$/MPa ${v{_{\text{t} } } }$ $\,\rho $/(kg·m−3) Experiment 21.4 – 63.7 137.7 – 163.8 0.23 – 0.26 2650 – 2740 Numerical simulation 27.2 150.93 0.24 2700 表 3 不同不耦合系数对应的炮孔半径

Table 3. Blasthole radius vs. decoupling coefficient

$\zeta $ rp $\zeta $ rp 1.0 0.060 1.6 0.096 1.2 0.072 1.8 0.108 1.4 0.084 2.0 0.120 -

[1] 宗琦, 孟德君. 炮孔不同装药结构对爆破能量影响的理论探讨 [J]. 岩石力学与工程学报, 2003, 22(4): 641–645. doi: 10.3321/j.issn:1000-6915.2003.04.027ZONG Q, MENG D J. Influence of different kinds of hole charging structue on explosion energy transmission [J]. Chinese Journal of Rock Mechanics and Engineering, 2003, 22(4): 641–645. doi: 10.3321/j.issn:1000-6915.2003.04.027 [2] 岳中文, 胡晓冰, 陈志远, 等. 不耦合装药对炸药能量利用率影响的实验研究 [J]. 爆破, 2020, 37(3): 34–39. doi: 10.3963/j.issn.1001-487X.2020.03.006YUE Z W, HU X B, CHEN Z Y, et al. Experimental study of effect of uncoupled charge on energy utilization efficiency of explosives [J]. Blasting, 2020, 37(3): 34–39. doi: 10.3963/j.issn.1001-487X.2020.03.006 [3] WANG Y B. Study of the dynamic fracture effect using slotted cartridge decoupling charge blasting [J]. International Journal of Rock Mechanics and Mining Sciences, 2017, 96: 34–46. doi: 10.1016/j.ijrmms.2017.04.015 [4] 汪旭光. 爆破设计与施工 [M]. 北京: 冶金工业出版社, 2011.WANG X G. Blasting design and construction [M]. Beijing: Metallurgical Industry Press, 2011. [5] 叶志伟, 陈明, 李桐, 等. 小不耦合系数装药爆破孔壁压力峰值计算方法 [J]. 爆炸与冲击, 2021, 41(6): 064901. doi: 10.11883/bzcyj-2020-0185YE Z W, CHEN M, LI T, et al. A calculation method of the peak pressure on borehole wall for low decoupling coefficient charge blasting [J]. Explosion and Shock Waves, 2021, 41(6): 064901. doi: 10.11883/bzcyj-2020-0185 [6] 徐颖, 孟益平, 程玉生. 装药不耦合系数对爆破裂纹控制的试验研究 [J]. 岩石力学与工程学报, 2002, 21(12): 1843–1847. doi: 10.3321/j.issn:1000-6915.2002.12.020XU Y, MENG Y P, CHENG Y S. Study on control of blast crack by decoupling charge index [J]. Chinese Journal of Rock Mechanics and Engineering, 2002, 21(12): 1843–1847. doi: 10.3321/j.issn:1000-6915.2002.12.020 [7] 费鸿禄, 李守巨, 何庆志. 光面爆破装药不偶合系数的计算 [J]. 爆炸与冲击, 1992, 12(3): 270–274.FEI H L, LI S J, HE Q Z. Determintion of decouple coefficient and analysis of decouple action in the smooth blasting [J]. Explosion and Shock Waves, 1992, 12(3): 270–274. [8] 杨仁树, 肖成龙, 李永亮, 等. 不耦合偏心装药结构爆破损伤破坏的分形研究 [J]. 振动与冲击, 2020, 39(12): 129–134. doi: 10.13465/j.cnki.jvs.2020.12.017YANG R S, XIAO C L, LI Y L, et al. A fractal study on blasting damage of an eccentric decouple charge structure [J]. Journal of Vibration and Shock, 2020, 39(12): 129–134. doi: 10.13465/j.cnki.jvs.2020.12.017 [9] YUAN W, WANG W, SU X B, et al. Numerical study of the impact mechanism of decoupling charge on blasting-enhanced permeability in low-permeability sandstones [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 106: 300–310. doi: 10.1016/j.ijrmms.2018.04.029 [10] 杜俊林, 罗强, 宗琦. 空气不耦合装药爆破孔壁冲击压力分析 [J]. 西安科技大学学报, 2005, 25(3): 306–310. doi: 10.3969/j.issn.1672-9315.2005.03.009DU J L, LUO Q, ZONG Q. Analysis on preliminary shock pressure on borehole of air-de-coupling charging [J]. Journal of Xi’an University of Science and Technology, 2005, 25(3): 306–310. doi: 10.3969/j.issn.1672-9315.2005.03.009 [11] PARK D, JEON B, JEON S. A numerical study on the screening of blast-induced waves for reducing ground vibration [J]. Rock Mechanics and Rock Engineering, 2009, 42(3): 449–473. doi: 10.1007/s00603-008-0016-y [12] 吴再海, 安龙, 齐兆军, 等. 基于LS-DYNA与PFC联合的岩体爆破数值模拟方法分析 [J]. 采矿与安全工程学报, 2021, 38(3): 609–614. doi: 10.13545/j.cnki.jmse.2020.0133WU Z H, AN L, QI Z J, et al. The numerical simulation method of rock mass blasting based on PFC combined with LS-DYNA [J]. Journal of Mining & Safety Engineering, 2021, 38(3): 609–614. doi: 10.13545/j.cnki.jmse.2020.0133 [13] 许彪. 基于PFC的岩石控制爆破技术研究 [D]. 淮南: 安徽理工大学, 2018.XU B. Research on controlled blasting technology of rock based on PFC [D]. Huainan: Anhui University of Science and Technology, 2018. [14] ZHAO J J, ZHANG Y, RANJITH P G. Numerical modelling of blast-induced fractures in coal masses under high in-situ stresses [J]. Engineering Fracture Mechanics, 2019, 225: 106749. doi: 10.1016/j.engfracmech.2019.106749 [15] 孙宁新, 雷明锋, 张运良, 等. 软弱夹层对爆炸应力波传播过程的影响研究 [J]. 振动与冲击, 2020, 39(16): 112–119, 147. doi: 10.13465/j.cnki.jvs.2020.16.016SUN N X, LEI M F, ZHANG Y L, et al. A study on the influence of weak interlayer on the propagation process of explosion stress wave [J]. Journal of Vibration and Shock, 2020, 39(16): 112–119, 147. doi: 10.13465/j.cnki.jvs.2020.16.016 [16] 张玉磊, 苏健军, 李芝绒, 等. TNT内爆炸准静态压力特性 [J]. 爆炸与冲击, 2018, 38(6): 1429–1434. doi: 10.11883/bzycj-2017-0170ZHANG Y L, SU J J, LI Z R, et al. Quasi-static pressure characteristic of TNT’s internal explosion [J]. Explosion and Shock Waves, 2018, 38(6): 1429–1434. doi: 10.11883/bzycj-2017-0170 [17] 石崇, 张强, 王盛年. 颗粒流(PFC5.0)数值模拟技术及应用 [J]. 岩土力学, 2018, 39(Suppl 2): 36.SHI C, ZHANG Q, WANG S N. Numerical simulation technology and application with particle flow code (PFC 5.0) [J]. Rock and Soil Mechanics, 2018, 39(Suppl 2): 36. [18] POTYONDY D O. Simulating stress corrosion with a bonded-particle model for rock [J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(5): 677–691. doi: 10.1016/j.ijrmms.2006.10.002 [19] 张学朋, 王刚, 蒋宇静, 等. 基于颗粒离散元模型的花岗岩压缩试验模拟研究 [J]. 岩土力学, 2014, 35(Suppl 1): 99–105.ZHANG X P, WANG G, JIANG Y J, et al. Simulation research on granite compression test based on particle discrete element model [J]. Rock and Soil Mechanics, 2014, 35(Suppl 1): 99–105. [20] QIU J D, LI D Y, LI X B, et al. Numerical investigation on the stress evolution and failure behavior for deep roadway under blasting disturbance [J]. Soil Dynamics and Earthquake Engineering, 2020, 137: 106278. doi: 10.1016/j.soildyn.2020.106278 [21] 孙闯, 敖云鹤, 张家鸣, 等. 花岗岩细观破裂特征及宏观尺度效应的颗粒流研究 [J]. 岩土工程学报, 2020, 42(9): 1687–1695. doi: 10.11779/CJGE202009013SUN C, AO Y H, ZHANG J M, et al. Particle flow of meso-fracture characteristics and macro-scale effect of granites [J]. Chinese Journal of Geotechnical Engineering, 2020, 42(9): 1687–1695. doi: 10.11779/CJGE202009013 [22] 李夕兵. 岩石动力学基础与应用 [M]. 北京: 科学出版社, 2014: 258–287.LI X B. Rock dynamics fundamentals and applications [M]. Beijing: Science Press, 2014: 258–287. -

下载:

下载: