Impact Damage Localization of Composite Laminates by In-Situ Measurement

-

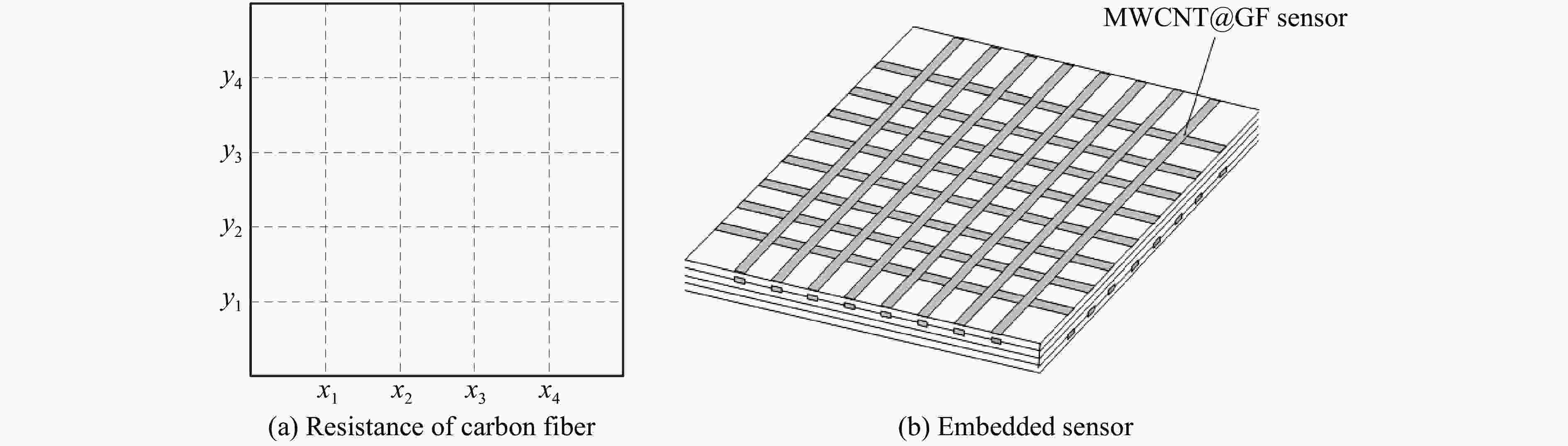

摘要: 针对连续碳纤维增强环氧树脂基复合材料层合板和玻璃纤维(GF)增强环氧树脂基复合材料层合板两类典型结构,开展了基于原位测量的冲击损伤定位研究。利用碳纤维/环氧树脂基复合材料层合板自身的导电性,设计了电极阵列,考察了板厚对定位结果的影响;对于不导电玻璃纤维/环氧树脂基复合材料层合板,设计并制备了多壁碳纳米管涂覆的玻璃纤维束(MWCNT@GF)传感器,并将MWCNT@GF嵌入层合板中形成传感网络,考察了不同入射角度对定位结果的影响。对于上述两种方法,编制了冲击损伤成像算法。结果表明:利用冲击前后碳纤维自身电阻和嵌入MWCNT@GF传感器的方法,可准确定位碳纤维/环氧树脂基复合材料层合板和玻璃纤维/环氧树脂基复合材料层合板的冲击损伤。

-

关键词:

- 低速冲击 /

- 损伤定位 /

- 多壁碳纳米管涂覆的玻璃纤维束传感器 /

- 碳纤维电阻

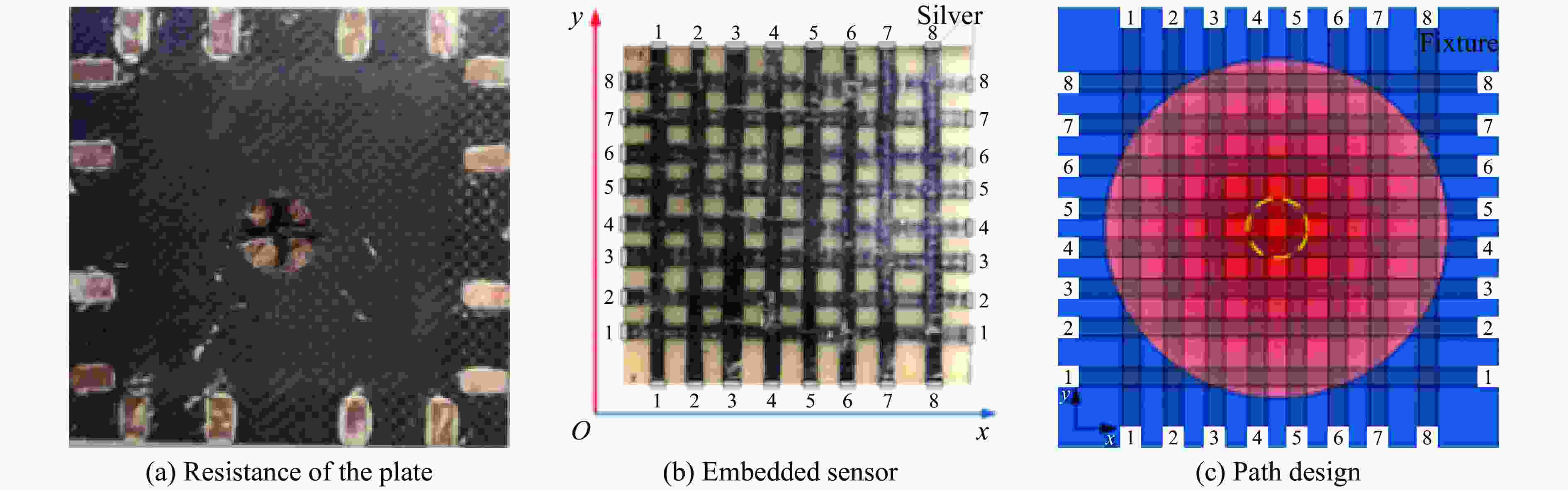

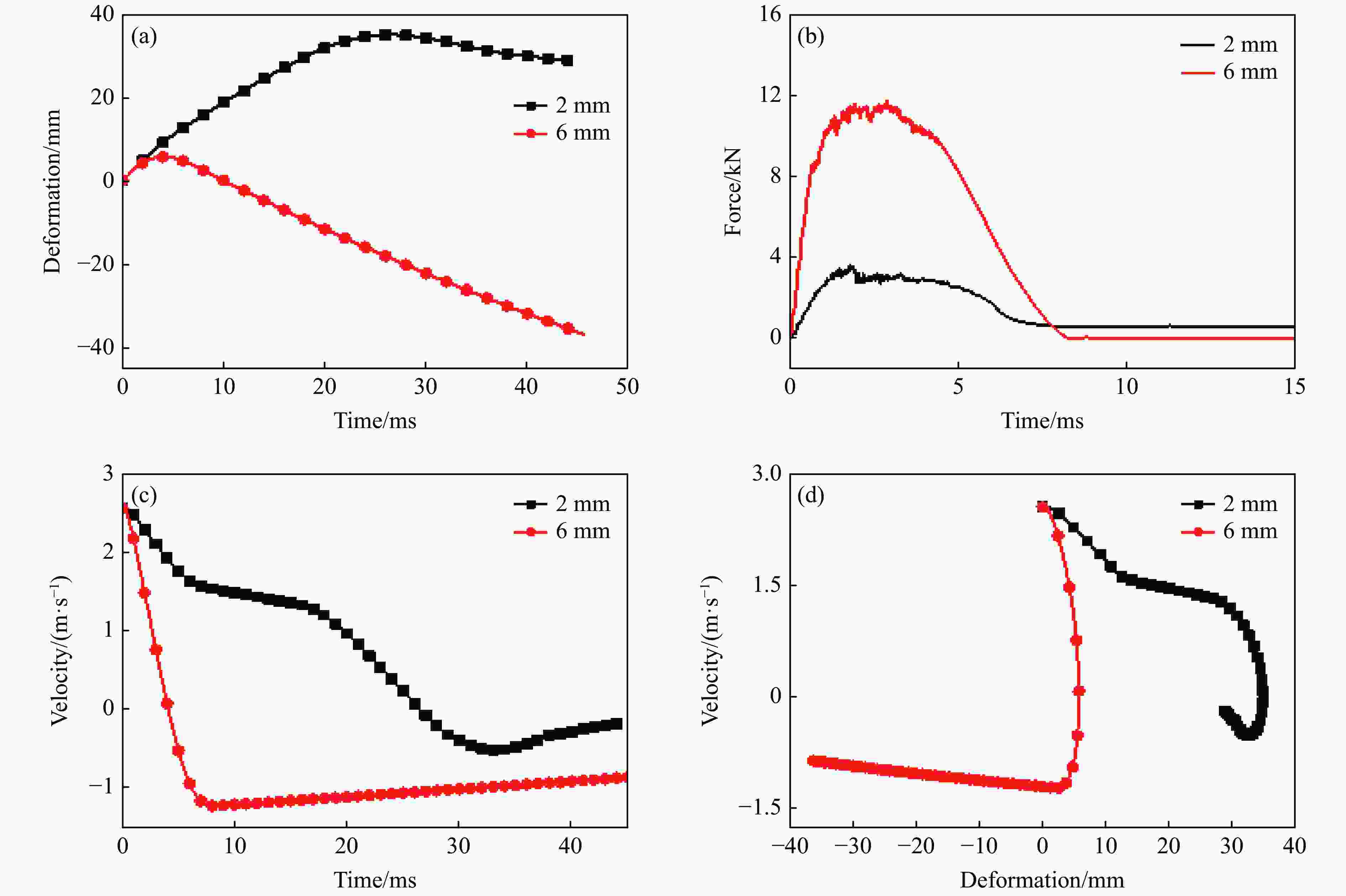

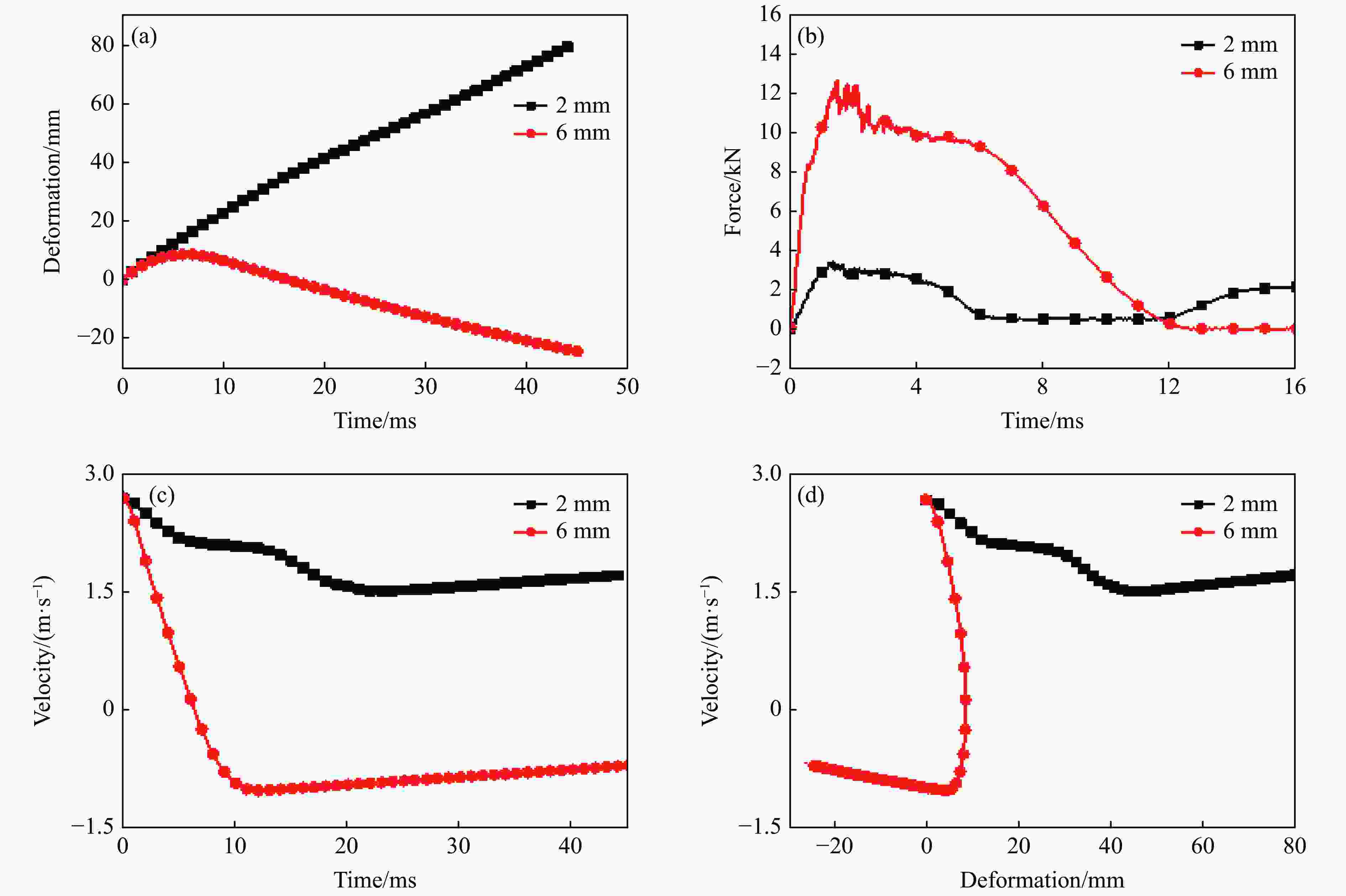

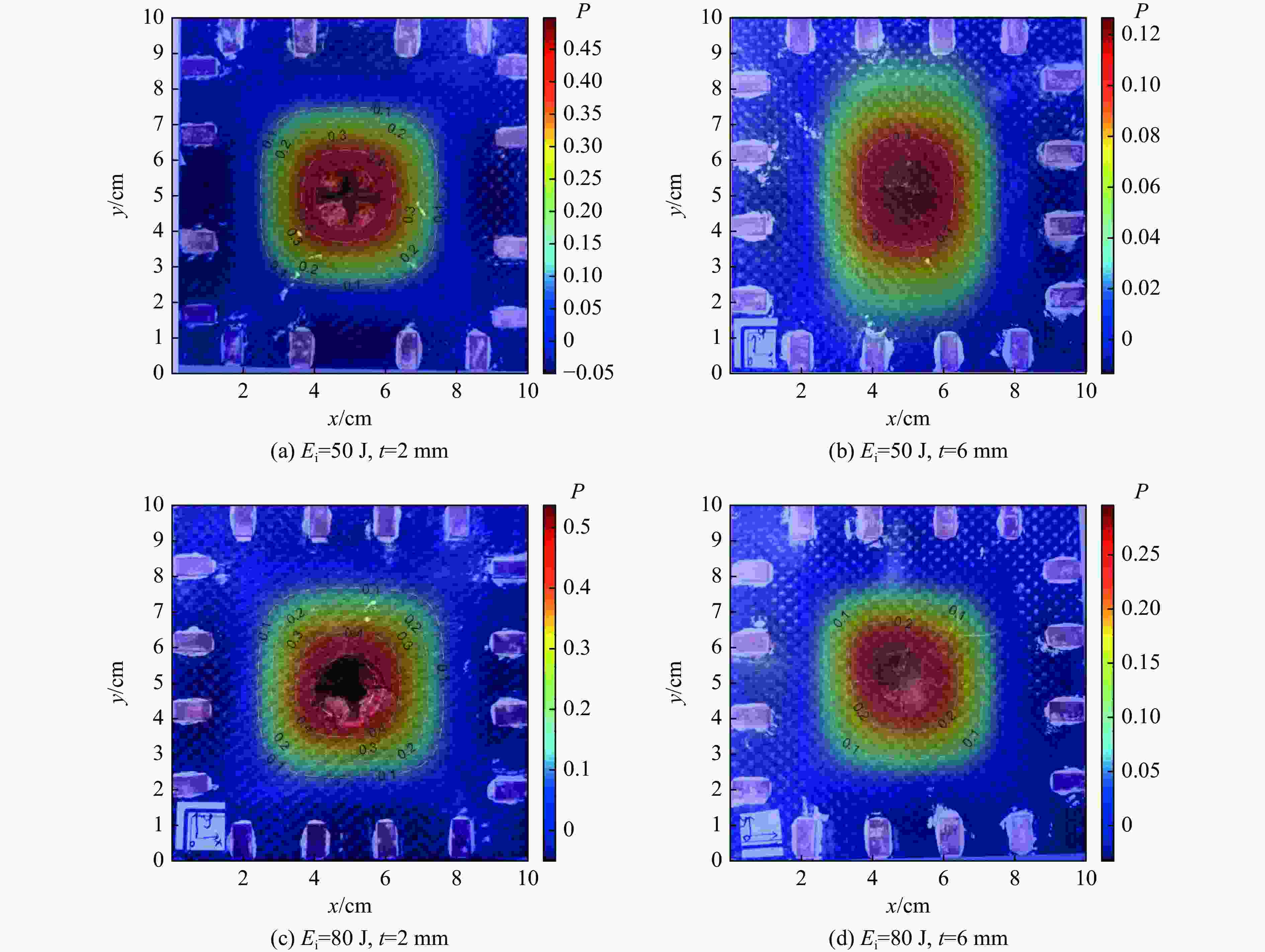

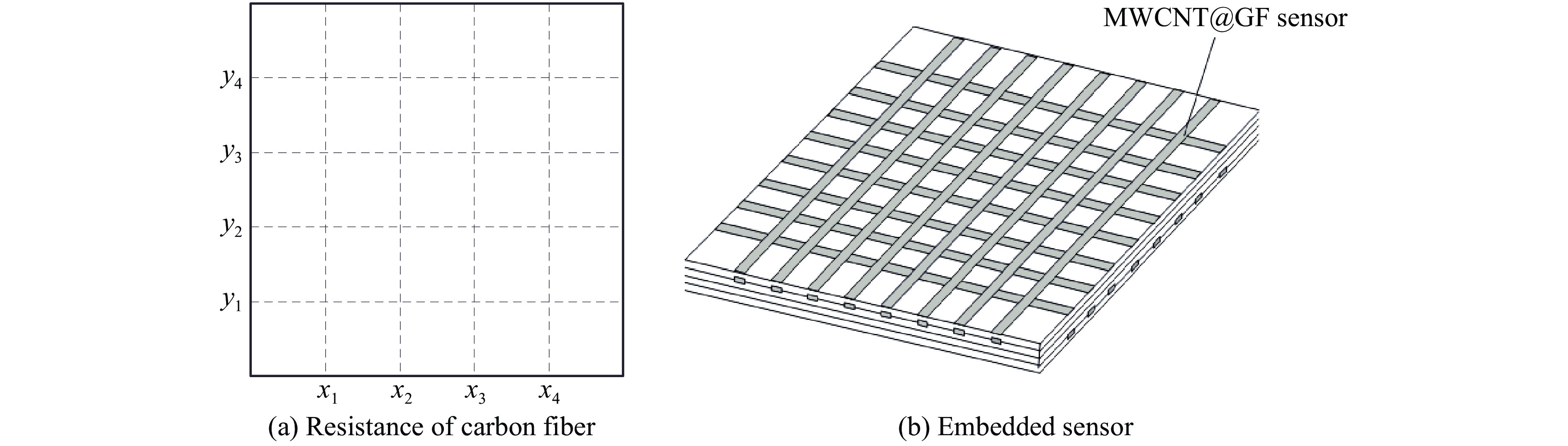

Abstract: Damage localization was performed for the typical carbon fiber (CF) and glass fiber (GF) reinforced epoxy composite laminates through in-situ measurement technology. The electrode array was developed by utilizing the conductivity of CF reinforced epoxy composite laminates. The influence of plate thickness on the damage localization was investigated. For non-conductive GF reinforced epoxy composite laminates, multi-walled carbon nanotubes coated GF bundles sensors (MWCNT@GF) were fabricated, and the sensors were embedded into the laminates to form the sensor network. The influence of different incident angles on the localization was investigated. For the above two methods, an impact damage localization algorithm was developed and compiled. The results show that the damage position of CF/epoxy and GF/epoxy composite laminates can be located with high accuracy by using the self-resistance of CF and embedding MWCNT@GF sensors.-

Key words:

- low-velocity impact /

- damage localization /

- MWCNT@GF sensor /

- carbon fiber resistance

-

表 1 利用碳纤维自身电阻得到的实际损伤与预测损伤位置的比较

Table 1. Comparison between the damage localizations in the real and predicted results by the carbon fibers themselves

Case No. Thickness/mm Impact energy/J Real localization/mm Predicted localization/mm Relative error/% x y x y $\delta $x $\delta $y 1 2 50 47.5 48.5 49.0 50.0 −3.16 −3.09 2 6 50 51.5 51.5 49.0 52.0 4.85 −0.97 3 2 80 49.5 47.0 49.0 48.0 1.01 −2.13 4 6 80 47.5 53.0 46.0 55.0 3.16 −3.77 表 2 利用埋入式MWCNT@GF得到的实际损伤与预测损伤位置的比较

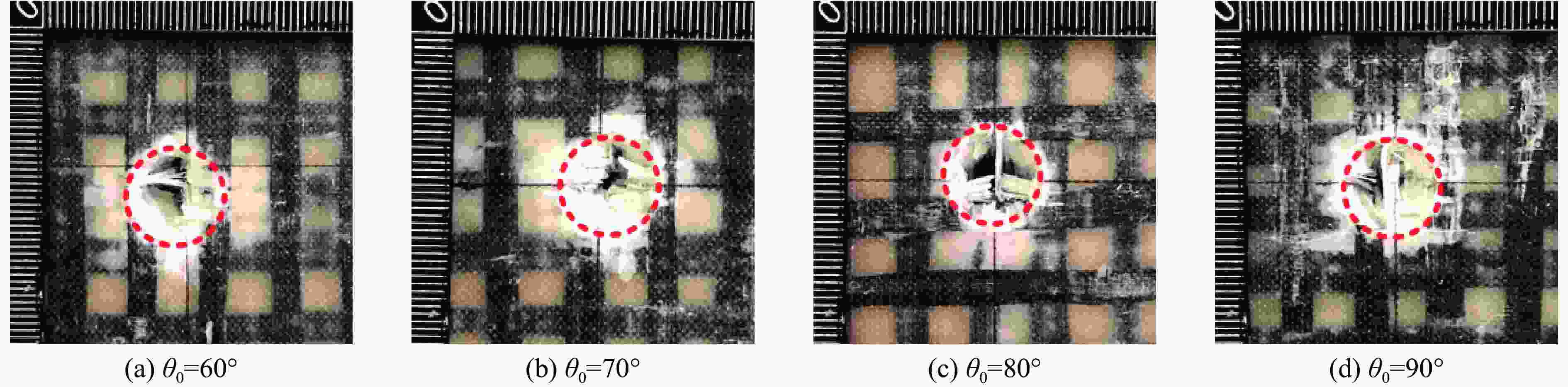

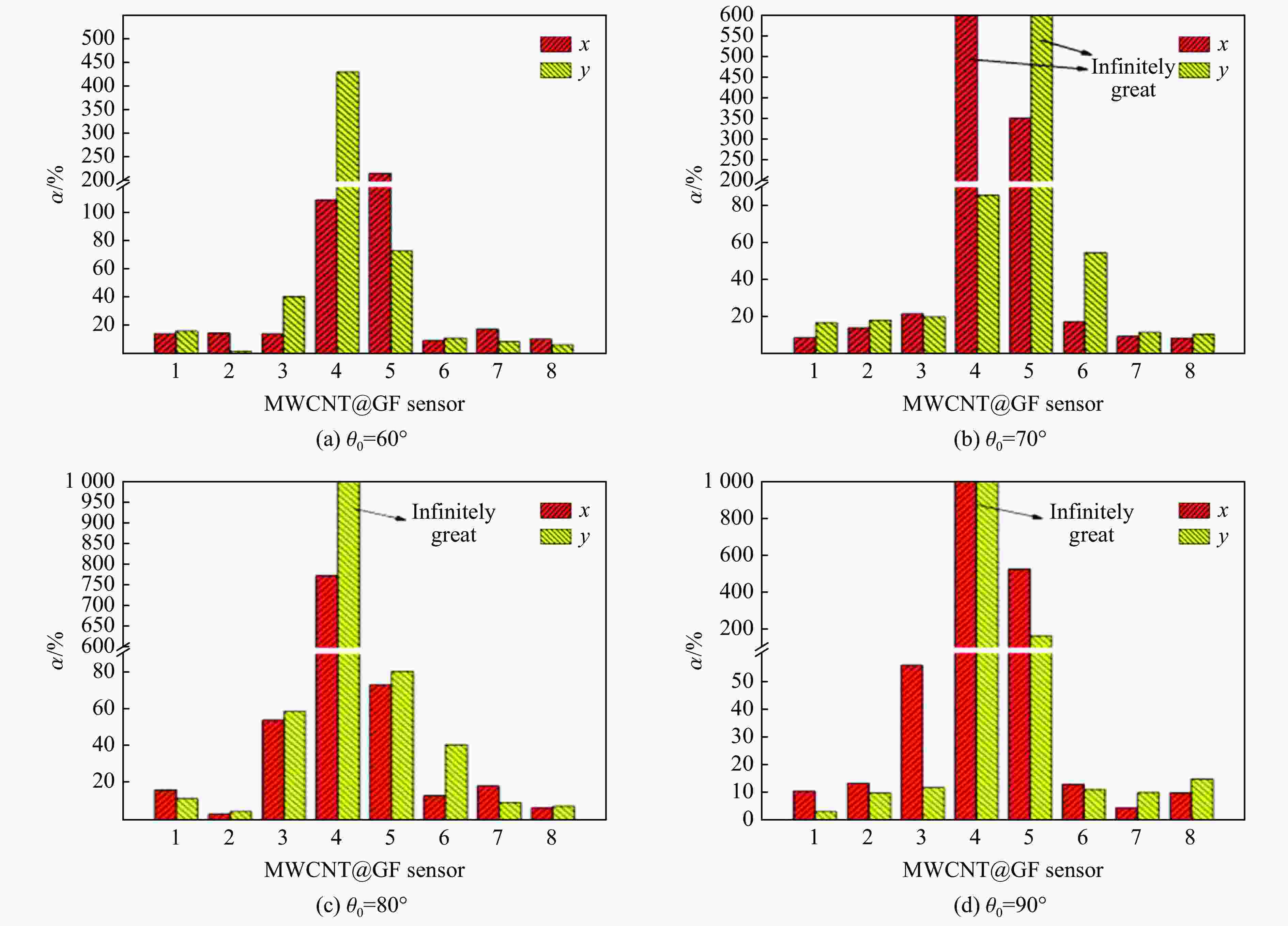

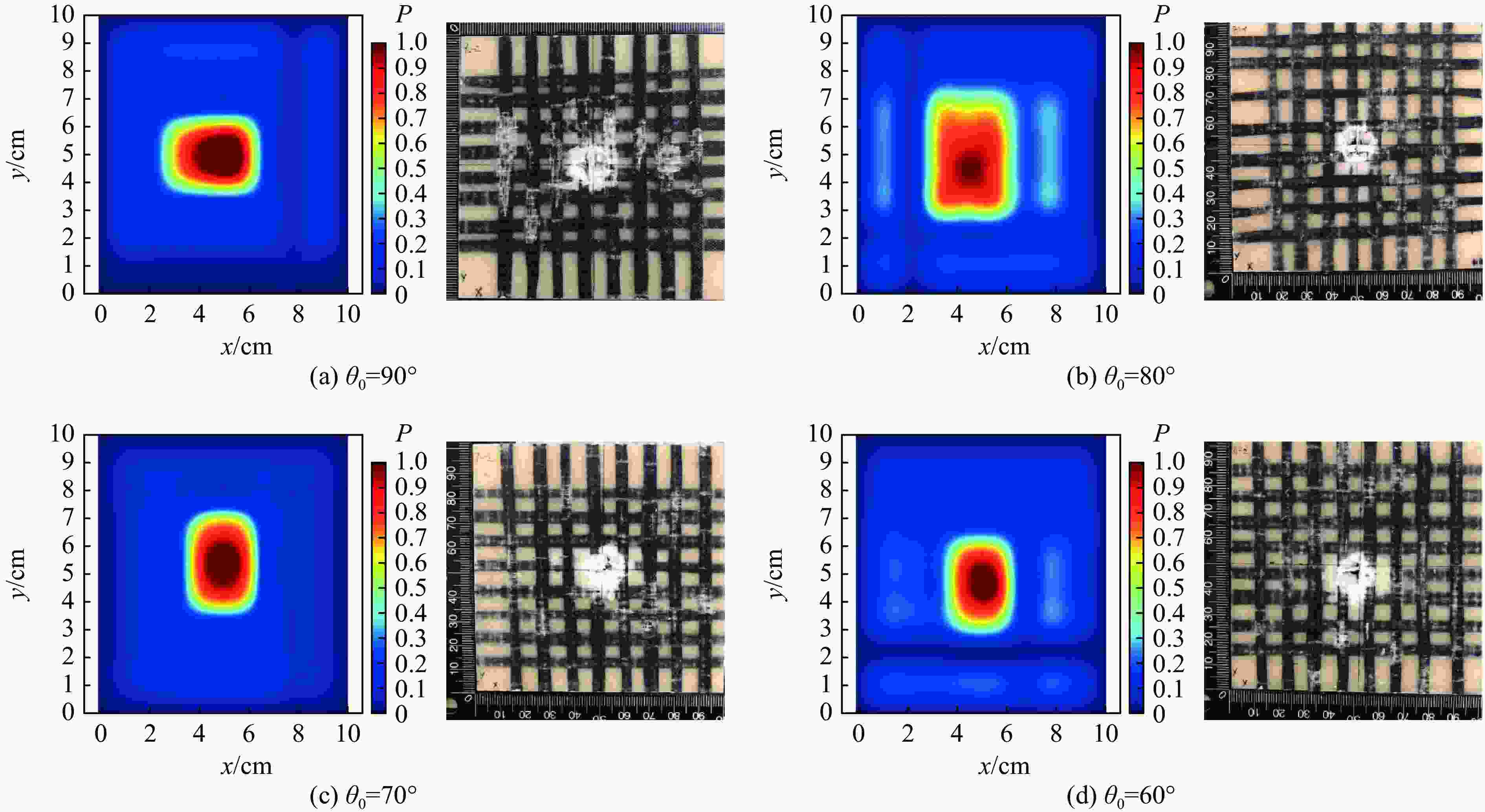

Table 2. Comparison between the damage localizations in the real and predicted results monitored by the embedded MWCNT@GF sensor

Case No. Thickness/mm Incident angle/(°) Real localization/mm Predicted localization/mm Relative error/% x y x y $\delta $x $\delta $y 1 1 60 48.0 47.5 50.0 48.0 −4.16 −1.05 2 1 70 52.0 50.0 50.0 52.0 3.84 −4.00 3 1 80 50.0 51.5 47.0 48.0 6.00 6.79 4 1 90 50.0 51.0 50.0 50.0 0 1.96 -

[1] LIU P F, LIAO B B, JIA L Y, et al. Finite element analysis of dynamic progressive failure of carbon fiber composite laminates under low velocity impact [J]. Composite Structures, 2016, 149: 408–422. doi: 10.1016/j.compstruct.2016.04.012 [2] DUBARY N, BOUVET C, RIVALLANT S, et al. Damage tolerance of an impacted composite laminate [J]. Composite Structures, 2018, 206: 261–271. doi: 10.1016/j.compstruct.2018.08.045 [3] 武海鹏, 王威力. 复合材料层合板低速冲击下剩余强度的评价 [J]. 材料导报, 2020, 34(Suppl 2): 598–602.WU H P, WANG W L. Research on composite laminates damage tolerance under low-velocity impact [J]. Materials Review, 2020, 34(Suppl 2): 598–602. [4] HAIDER M F, MIGOT A, BHUIYAN M Y, et al. Experimental investigation of impact localization in composite plate using newly developed imaging method [J]. Inventions, 2018, 3(3): 59. doi: 10.3390/inventions3030059 [5] 陆观, 马鑫勇, 徐一鸣, 等. 基于FBG单传感器的复合材料板低速冲击定位研究 [J]. 传感技术学报, 2019, 32(2): 206–211. doi: 10.3969/j.issn.1004-1699.2019.02.009LU G, MA X Y, XU Y M, et al. Low velocity impact localization system of composite laminates with single fiber Bragg grating sensor [J]. Chinese Journal of Sensors and Actuators, 2019, 32(2): 206–211. doi: 10.3969/j.issn.1004-1699.2019.02.009 [6] NUCERA C, WHITE S, CHEN Z M, et al. Impact monitoring in stiffened composite aerospace panels by wave propagation [J]. Structural Health Monitoring, 2015, 14(6): 547–557. doi: 10.1177/1475921715599600 [7] 常琦, 孟瑶, 杨维希, 等. 基于二维波束聚焦算法的低速冲击监测研究 [J]. 振动与冲击, 2021, 40(3): 28–34. doi: 10.13465/j.cnki.jvs.2021.03.004CHANG Q, MENG Y, YANG W X, et al. Low speed impact monitoring based on 2-D beam focusing algorithm [J]. Journal of Vibration and Shock, 2021, 40(3): 28–34. doi: 10.13465/j.cnki.jvs.2021.03.004 [8] ZHAO G, LI S X, HU H X, et al. Impact localization on composite laminates using fiber Bragg grating sensors and a novel technique based on strain amplitude [J]. Optical Fiber Technology, 2018, 40: 172–179. doi: 10.1016/j.yofte.2017.12.001 [9] 喻俊松, 梁大开. 基于偏斜度、陡峭度特征的光纤布拉格光栅冲击载荷定位 [J]. 光学学报, 2018, 38(3): 0328019. doi: 10.3788/AOS201838.0328019YU J S, LIANG D K. Impact load localization by using fiber Bragg gratings based on characteristics of skewness and kurtosis [J]. Acta Optica Sinica, 2018, 38(3): 0328019. doi: 10.3788/AOS201838.0328019 [10] KIM J H, KIM Y Y, PARK Y, et al. Low-velocity impact localization in a stiffened composite panel using a normalized cross-correlation method [J]. Smart Materials and Structures, 2015, 24(4): 045036. doi: 10.1088/0964-1726/24/4/045036 [11] HIRANO Y, YAMANE T, TODOROKI A. Through-thickness electric conductivity of toughened carbon-fibre-reinforced polymer laminates with resin-rich layers [J]. Composites Science and Technology, 2016, 122: 67–72. doi: 10.1016/j.compscitech.2015.11.018 [12] GARCEA S C, SINCLAIR I, SPEARING S M. Fibre failure assessment in carbon fibre reinforced polymers under fatigue loading by synchrotron X-ray computed tomography [J]. Composites Science and Technology, 2016, 133: 157–164. doi: 10.1016/j.compscitech.2016.07.030 [13] 周文松, 李惠, 欧进萍. 无环氧树脂基碳纤维束自监测功能 [J]. 复合材料学报, 2005, 22(2): 63–66. doi: 10.3321/j.issn:1000-3851.2005.02.012ZHOU W S, LI H, OU J P. Self-monitoring performance of the carbon fiber sheet without epoxy resin matrix [J]. Acta Materiae Compositae Sinica, 2005, 22(2): 63–66. doi: 10.3321/j.issn:1000-3851.2005.02.012 [14] ALY K, LI A, BRADFORD P D. In-situ monitoring of woven glass fiber reinforced composites under flexural loading through embedded aligned carbon nanotube sheets [J]. Journal of Composite Materials, 2018, 52(20): 2777–2788. doi: 10.1177/0021998317754128 [15] LIU P, LIU J, ZHU X, et al. A highly adhesive flexible strain sensor based on ultra-violet adhesive filled by graphene and carbon black for wearable monitoring [J]. Composites Science and Technology, 2019, 182: 107771. doi: 10.1016/j.compscitech.2019.107771 [16] KHAN N I, HALDER S, DAS S, et al. Exfoliation level of aggregated graphitic nanoplatelets by oxidation followed by silanization on controlling mechanical and nanomechanical performance of hybrid CFRP composites [J]. Composites Part B: Engineering, 2019, 173: 106855. doi: 10.1016/j.compositesb.2019.05.066 [17] LUO S D, WANG G T, WANG Y, et al. Carbon nanomaterials enabled fiber sensors: a structure-oriented strategy for highly sensitive and versatile in situ monitoring of composite curing process [J]. Composites Part B: Engineering, 2019, 166: 645–652. doi: 10.1016/j.compositesb.2019.02.067 [18] 杨斌, 胡超杰, 轩福贞, 等. 多壁碳纳米管界面传感器及其在纤维缠绕压力容器原位监测中的应用 [J]. 复合材料学报, 2020, 37(2): 336–344. doi: 10.13801/j.cnki.fhclxb.20190417.004YANG B, HU C J, XUAN F Z, et al. Multi-walled carbon nanotube interfacial sensor and its application in in-situ monitoring of the filament wound pressure vessel [J]. Acta Materiae Compositae Sinica, 2020, 37(2): 336–344. doi: 10.13801/j.cnki.fhclxb.20190417.004 [19] YANG B, XUAN F Z, LEI H S, et al. Simultaneously enhancing the IFSS and monitoring the interfacial stress state of GF/epoxy composites via building in the MWCNT interface sensor [J]. Composites Part A: Applied Science and Manufacturing, 2018, 112: 161–167. doi: 10.1016/j.compositesa.2018.06.006 [20] 谭志中, 谭震. 一类任意m×n阶矩形网络的电特性 [J]. 物理学报, 2020, 69(2): 020502.TAN Z Z, TAN Z. Electrical properties of an arbitrary m×n rectangular network [J]. Acta Physica Sinica, 2020, 69(2): 020502. [21] TAN Z Z. Two-point resistance of an n×m resistor network with an arbitrary boundary and its application in RLC network [J]. Chinese Physics B, 2016, 25(5): 050504. -

下载:

下载: