Brief Review of Research Progress on the Deformation, Damage and Failure of Silicon Carbide under Extreme Conditions

-

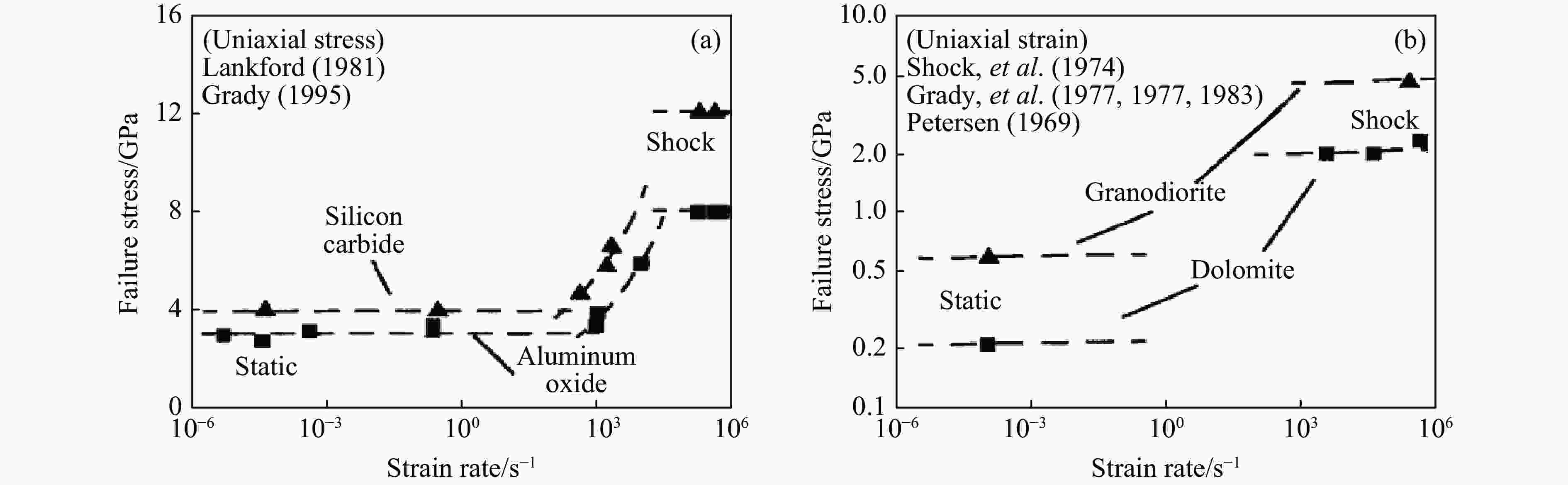

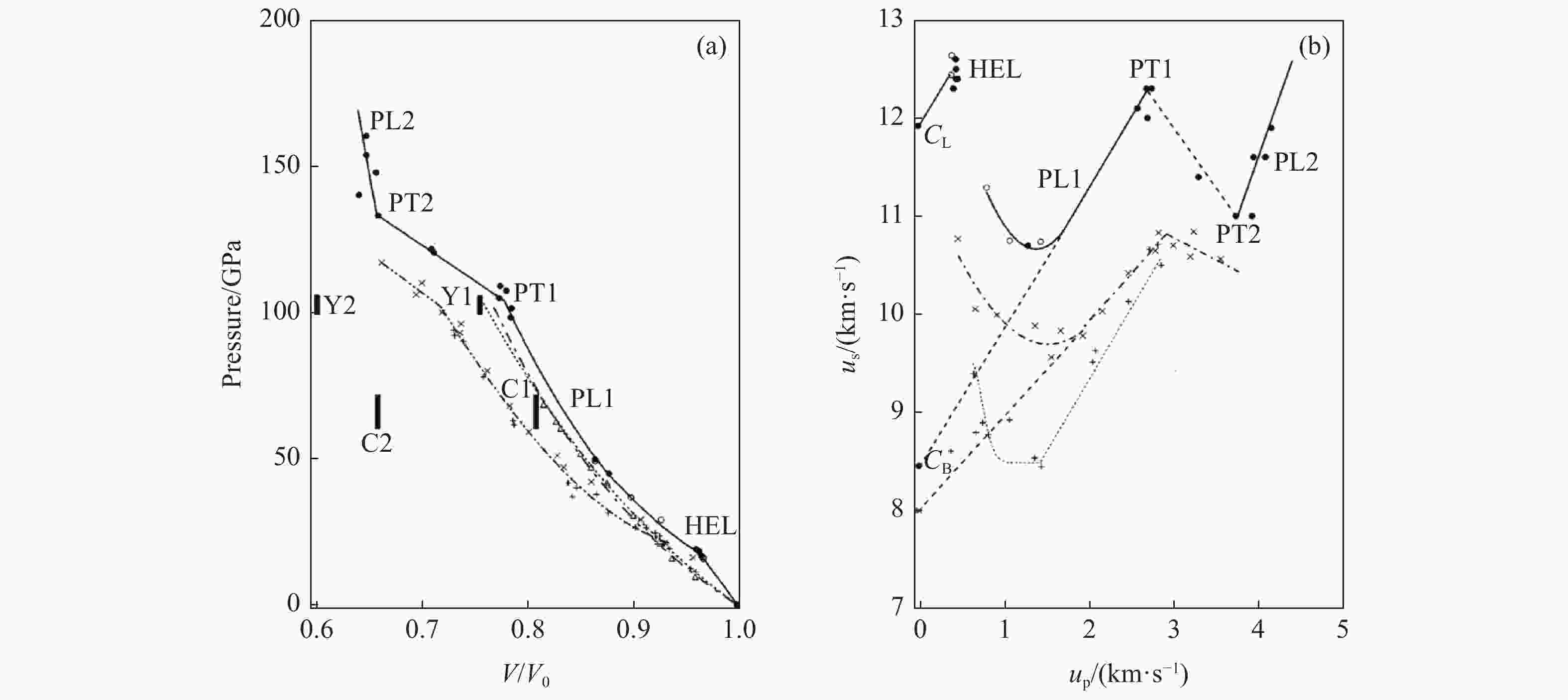

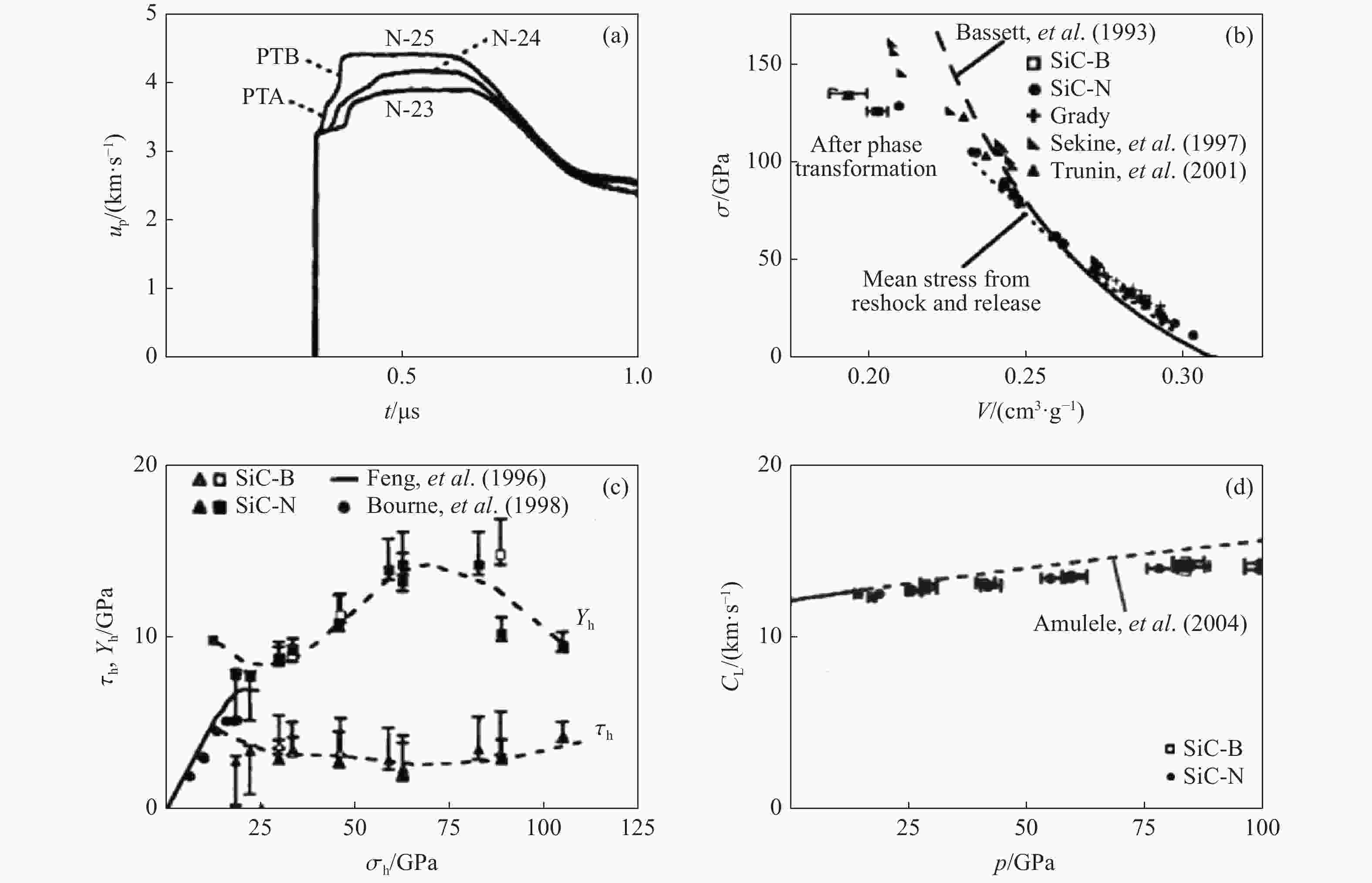

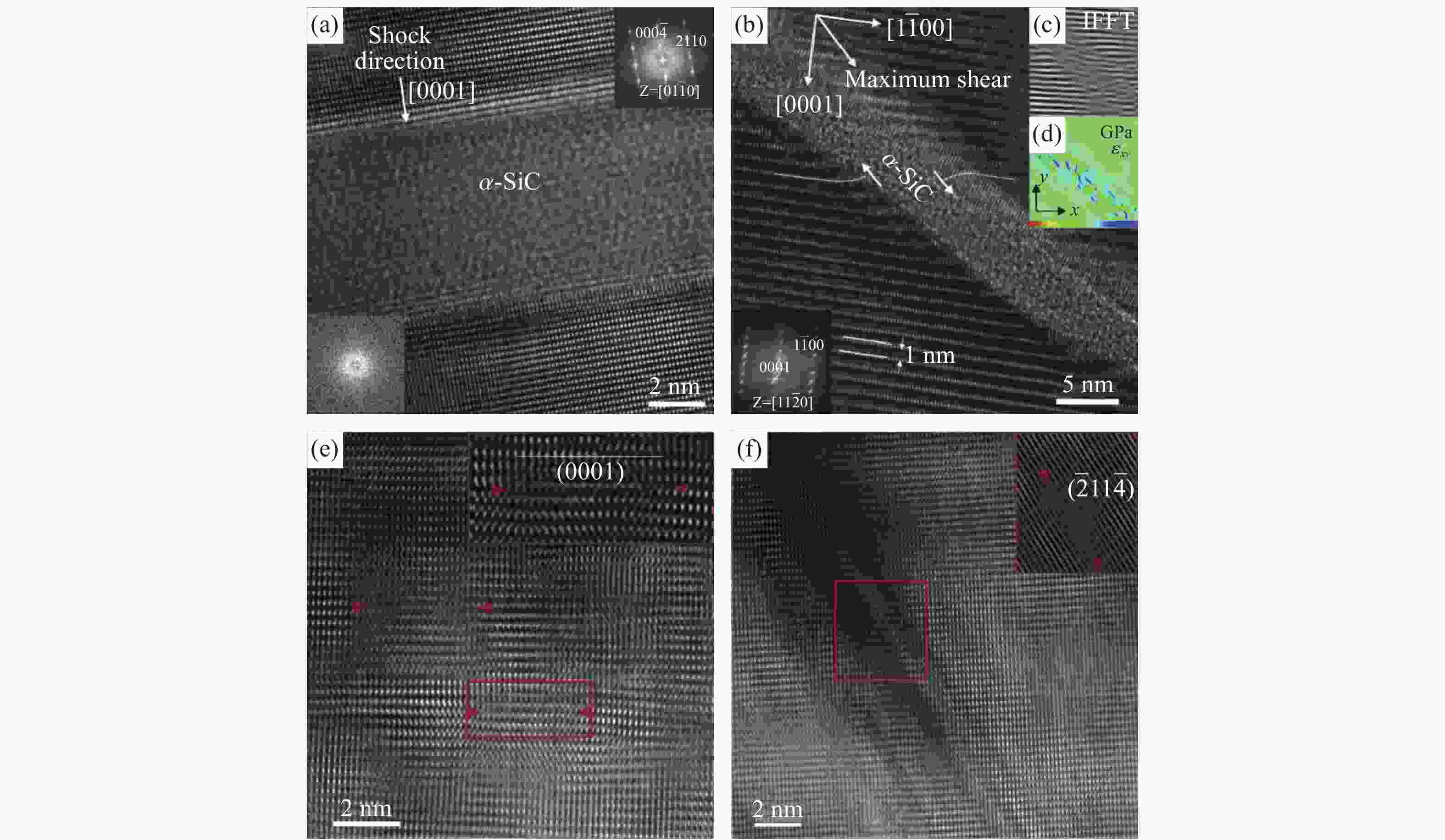

摘要: 碳化硅作为重要的陶瓷和半导体材料,在国防军工、航空航天等应用领域和高压物质科学等方面具有重要的应用研究和科学价值。本文对动加载下碳化硅的变形、损伤和破坏等物理力学行为和特性研究进行了梳理,分别从实验研究和计算模拟角度概述了碳化硅在不同加载条件和微结构下的变形与破坏行为研究进展,总结归纳了碳化硅材料动态响应相关研究的若干现存问题,并展望了该领域内几个重要的发展方向,以期为相关群体的研究工作提供有益参考。Abstract: As an important ceramic and semiconductor material, silicon carbide has important engineering and scientific value in application fields such as national defense, military, aerospace, and high-pressure material science. This paper summarized the physical and mechanical behaviors, and characteristics of silicon carbide under dynamic loading, such as deformation, damage and failure, providing a research progress in the deformation and failure of silicon carbide under different loading conditions and microstructures from both the experimental studies and computational simulations. Then the paper summarized some existing problems related to the dynamic response of silicon carbide materials, and proposed several important development directions in this field, in order to provide a useful reference for the research of related research groups.

-

Key words:

- silicon carbide /

- multiscale /

- dynamic loading /

- dynamic behavior

-

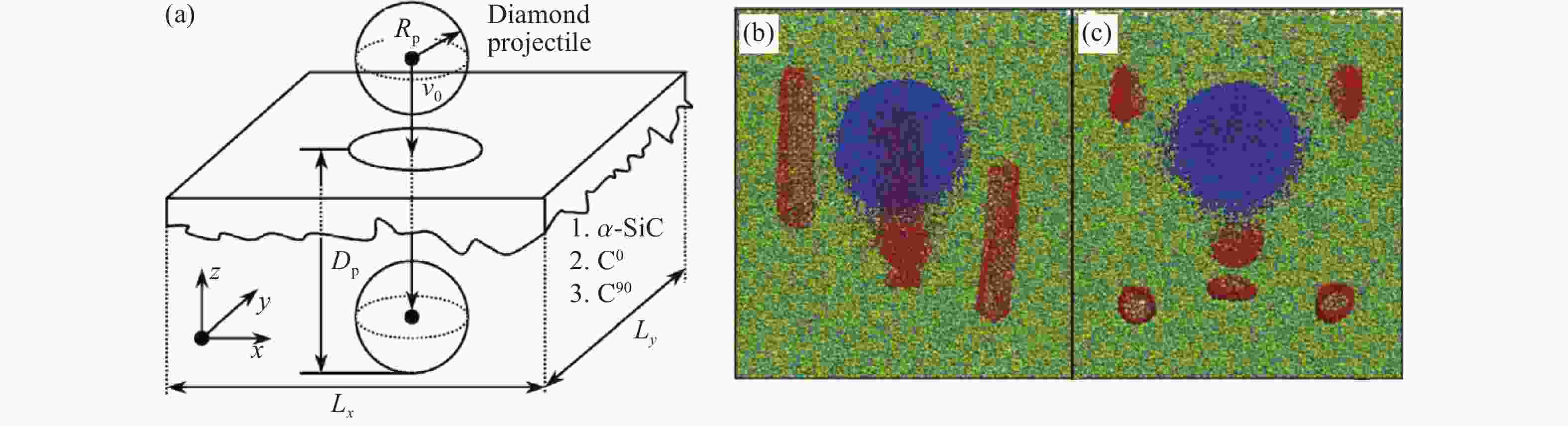

图 21 金刚石弹丸撞击原始无定形SiC和CNT/无定形SiC复合靶示意图: (a) 半径为2.5 nm的球形金刚石弹丸沿z轴反方向冲击目标,(b)~(c) 由弹丸冲击而造成的碳纳米管损伤[140]

Figure 21. Schematic diagram of diamond projectile impacting original amorphous SiC and CNT/amorphous SiC composite targets: (a) diamond projectile with a radius of 2.5 nm impacting on target along negative z axis; (b)–(c) projectile impact induced damage of CNT[140]

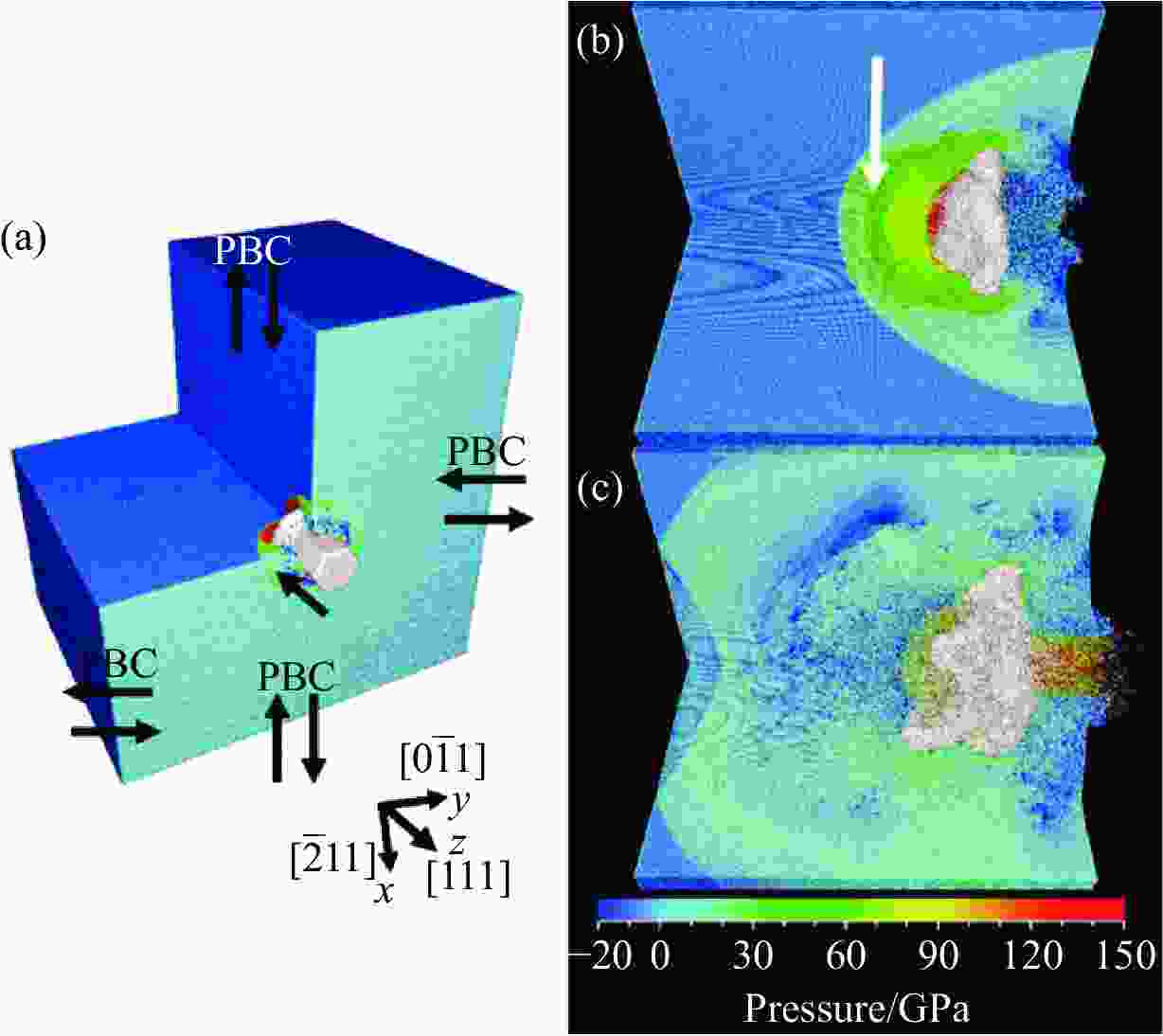

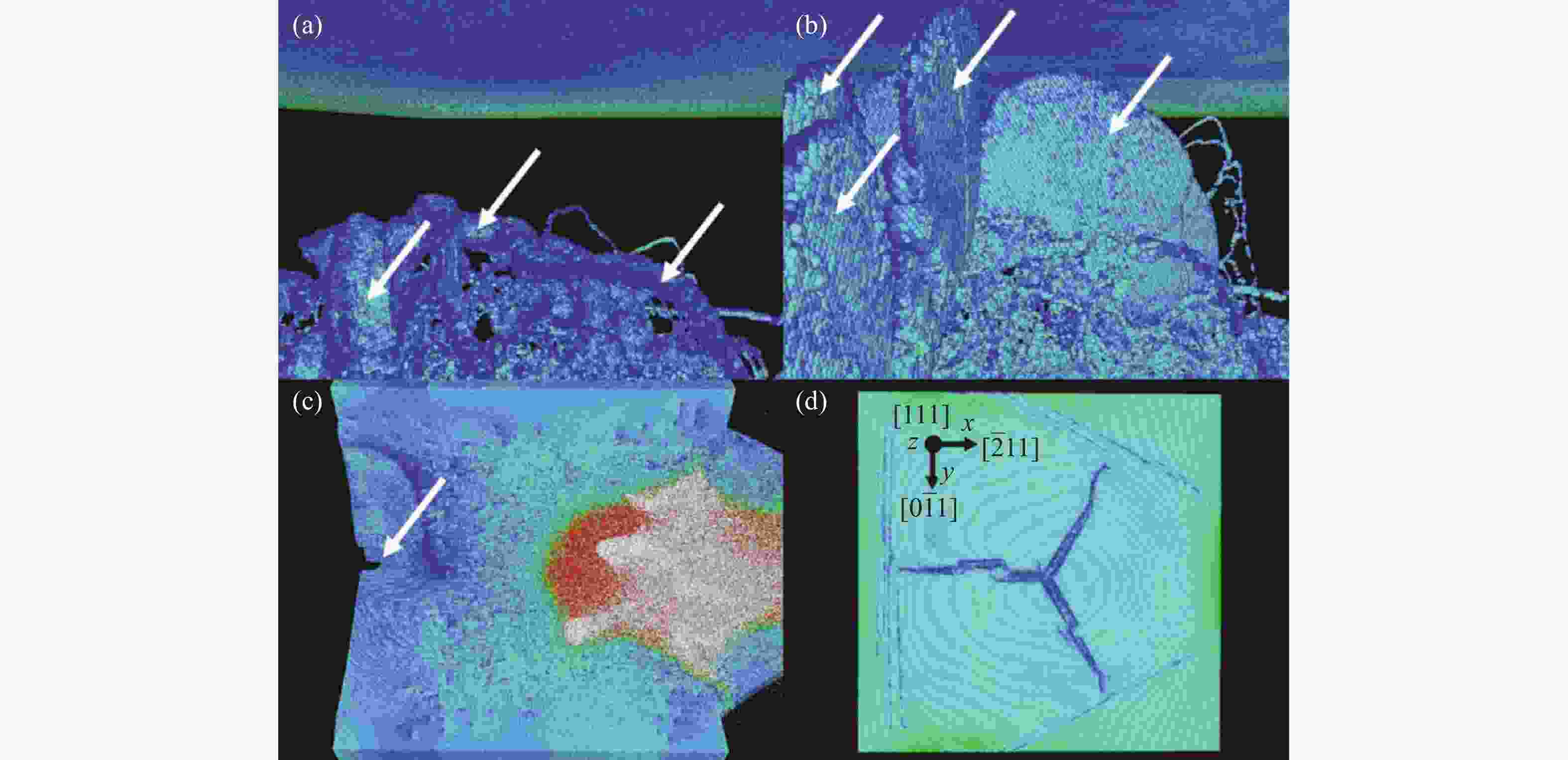

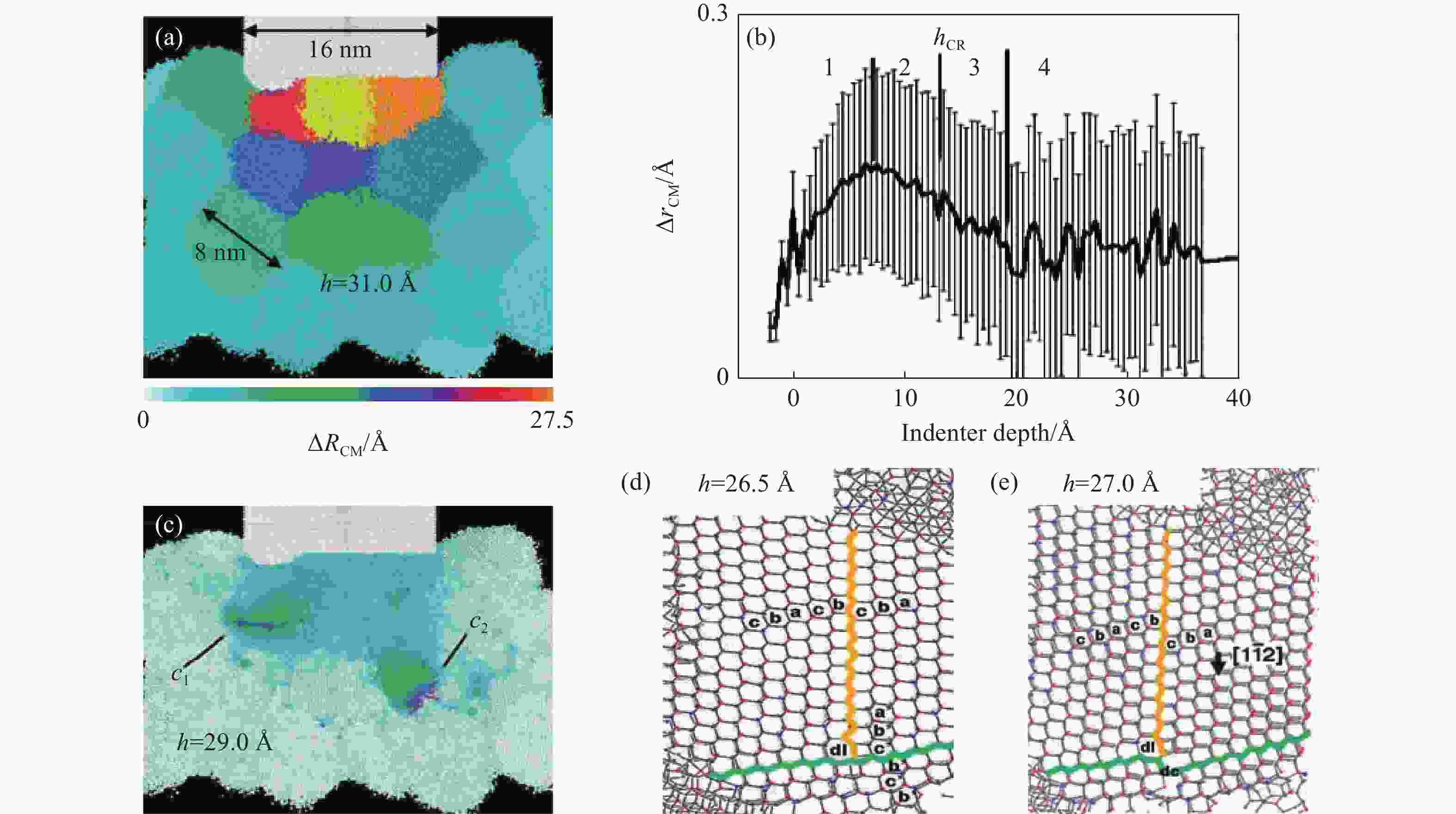

图 23 冲击碳化硅中位错、脆性裂纹引起的形核和生长: (a) 13.05 ps时位错线上形成的脆性裂纹(白色箭头处); (b) 闪锌晶型在{110}平面形成的裂纹扩展; (c) 27 ps 时材料裂纹扩展; (d) 31.2 ps时材料后表面开裂[133]

Figure 23. Nucleation and growth of brittle cracks from dislocations in shocked SiC: (a) white arrows indicate brittle cracks nucleating directly from dislocation lines at 13.05 ps; (b) cracks cleaving {110} planes of the zinc blende crystal in the direction of the back surface; (c) cracked configuration at 27 ps; (d) cracked back surface at 31.2 ps[133]

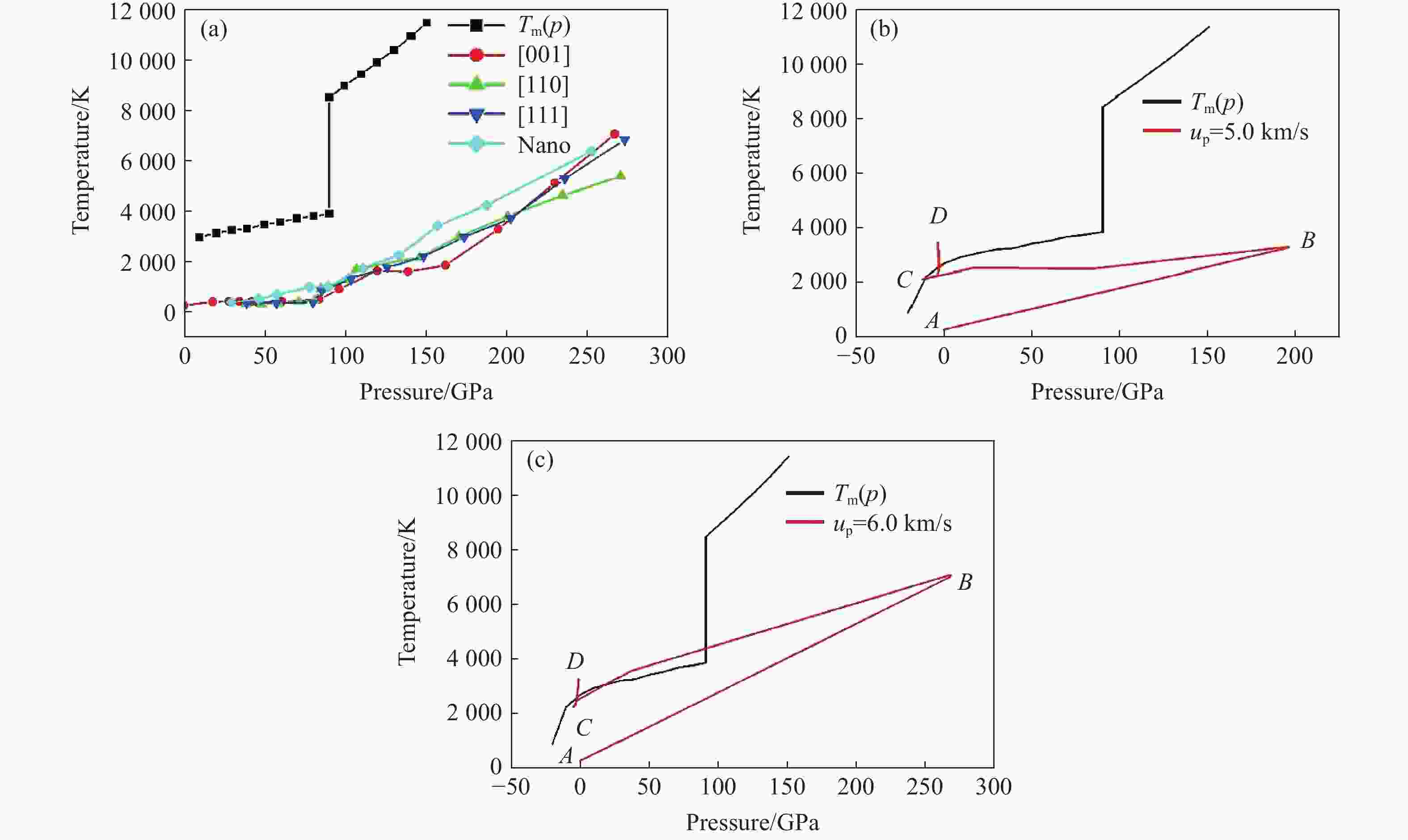

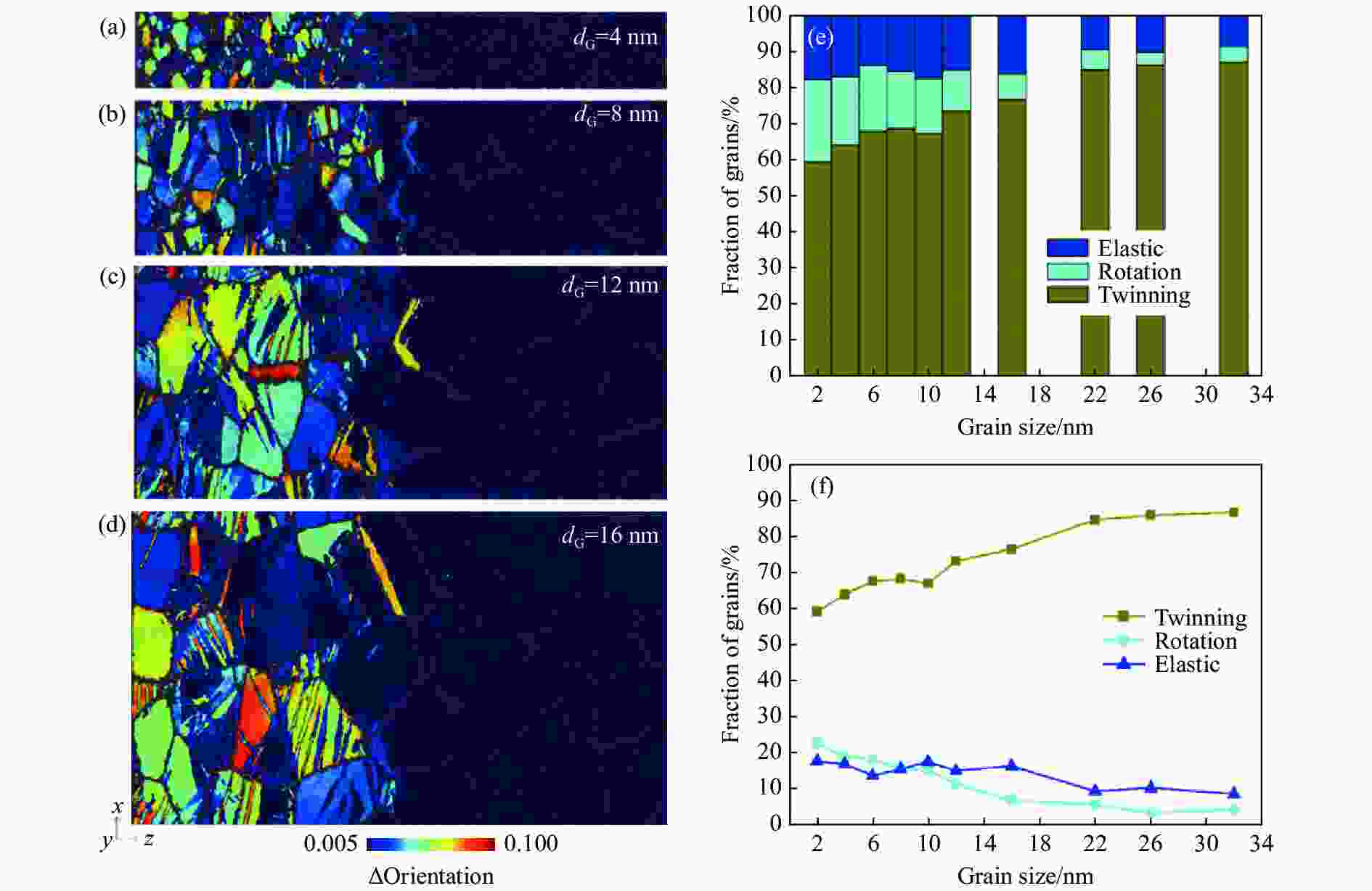

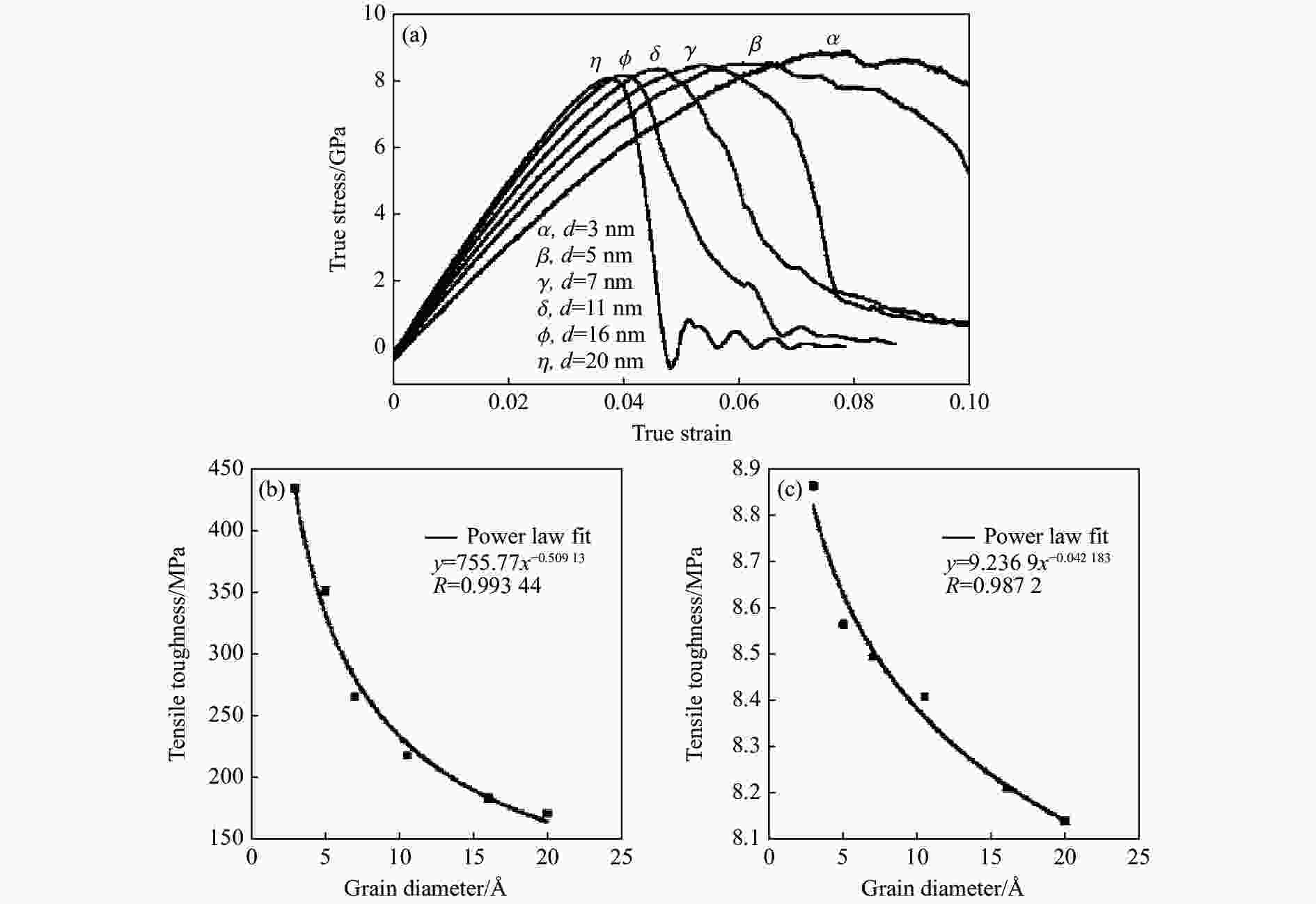

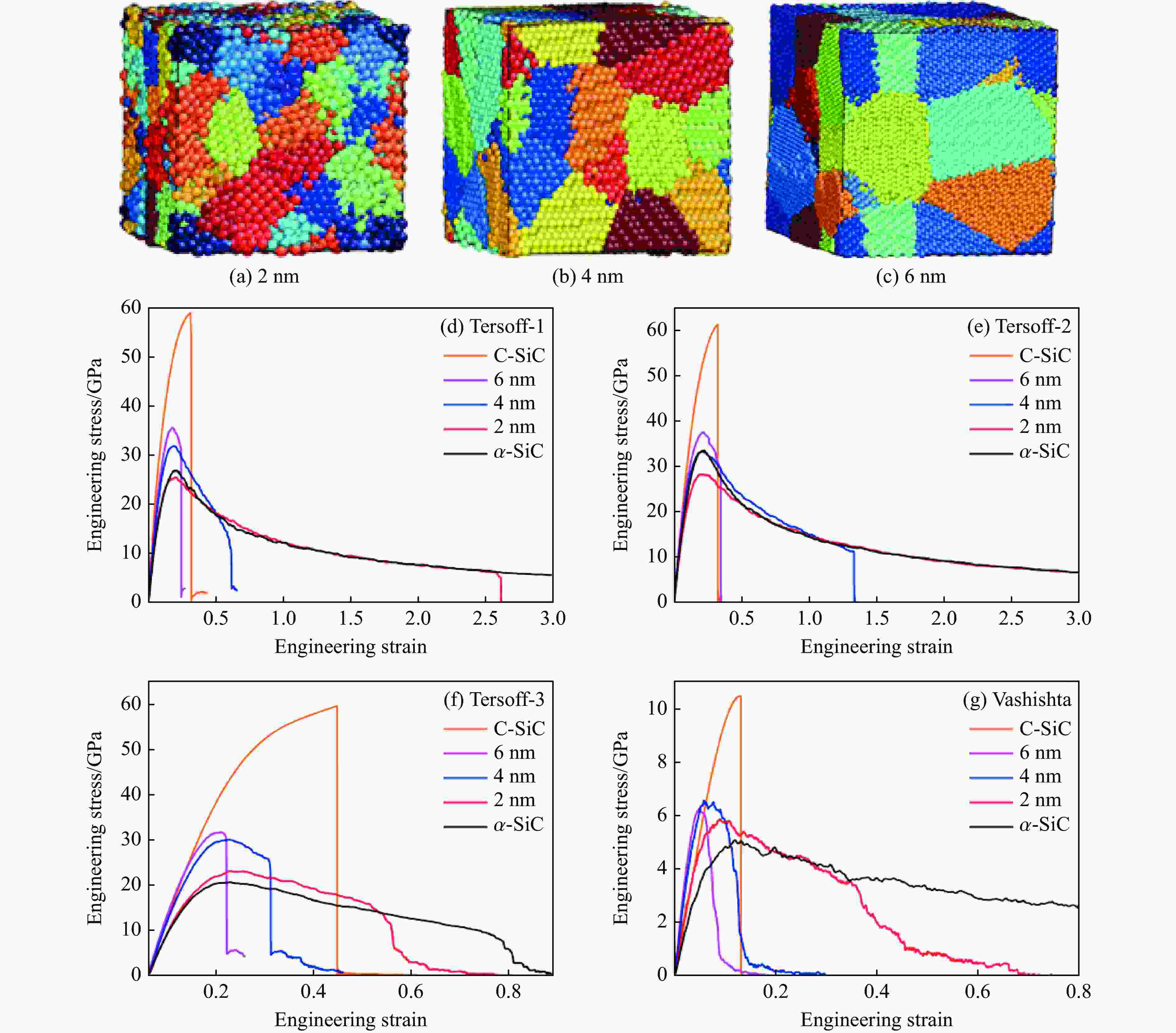

图 28 (a) 样品中原子数-晶粒尺寸关系,(b) 密度和单位原子能量与晶粒尺寸的关系,(c) 晶粒或晶界中原子的比例作为晶粒大小的函数(黑色和红线分别为颗粒原子和晶界原子比例的理论预测)[143]

Figure 28. (a) The number of atoms in samples as a function of grain size, (b) the density and per-atom energy as functions of grain size, (c) the fraction of atoms in grains or grain boundaries as functions of grain size (The black and red lines are the theoretical predictions of the fraction of grains and grain boundaries atoms, respectively.)[143]

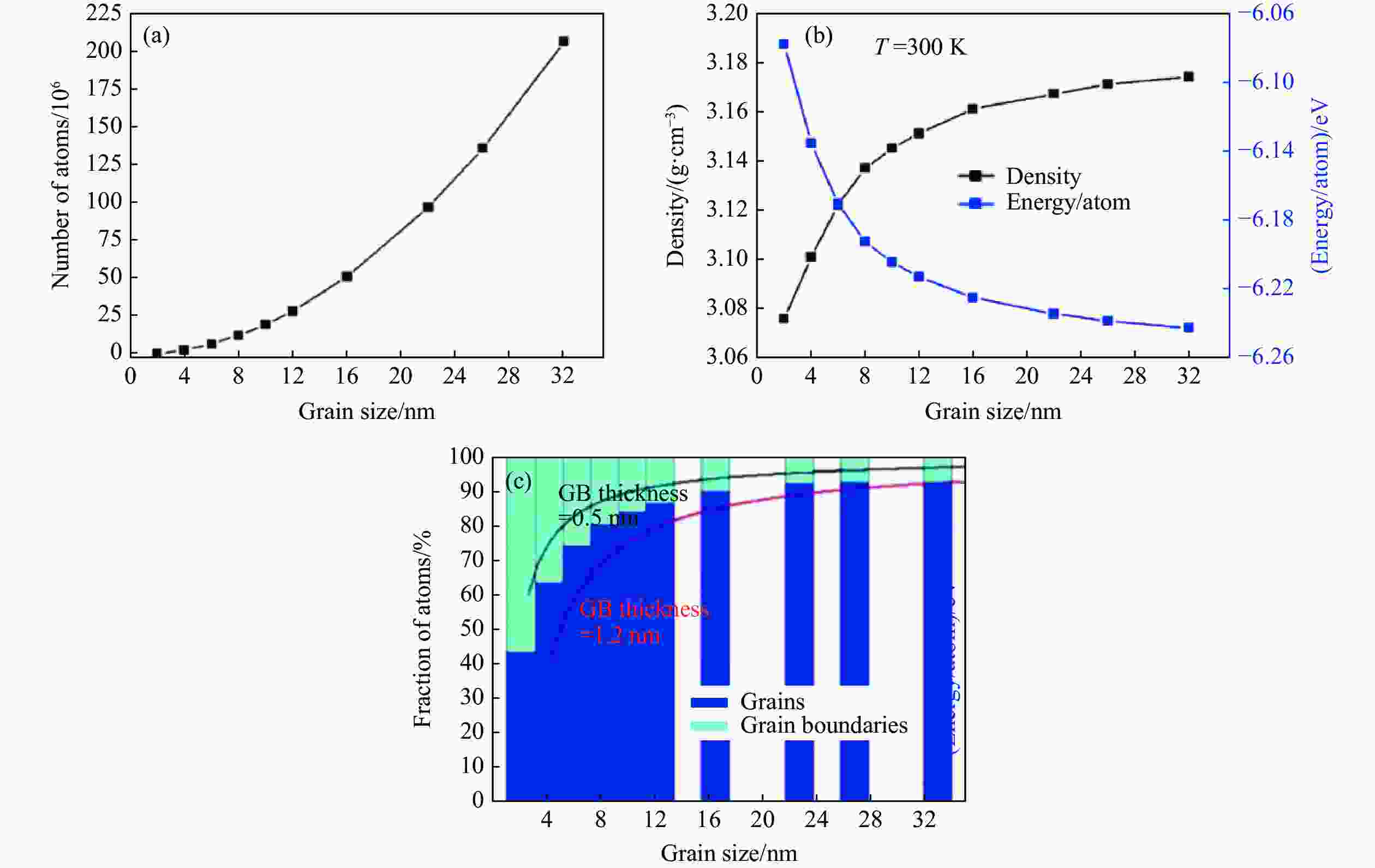

图 29 (a)~(d)纳米多晶在不同晶粒尺寸下的冲击引起的晶体塑性变形,(e)~(f)不同晶粒尺寸的纳米碳化硅在up = 2 km/s时的冲击塑性统计[143]

Figure 29. (a)–(d) Shock induced plasticity in nanocrystalline SiC with different grain size; (e)–(f) the statistics of shock induced plasticity at up = 2 km/s including twinning, rotation in nanocrystalline SiC with different grain sizes[143]

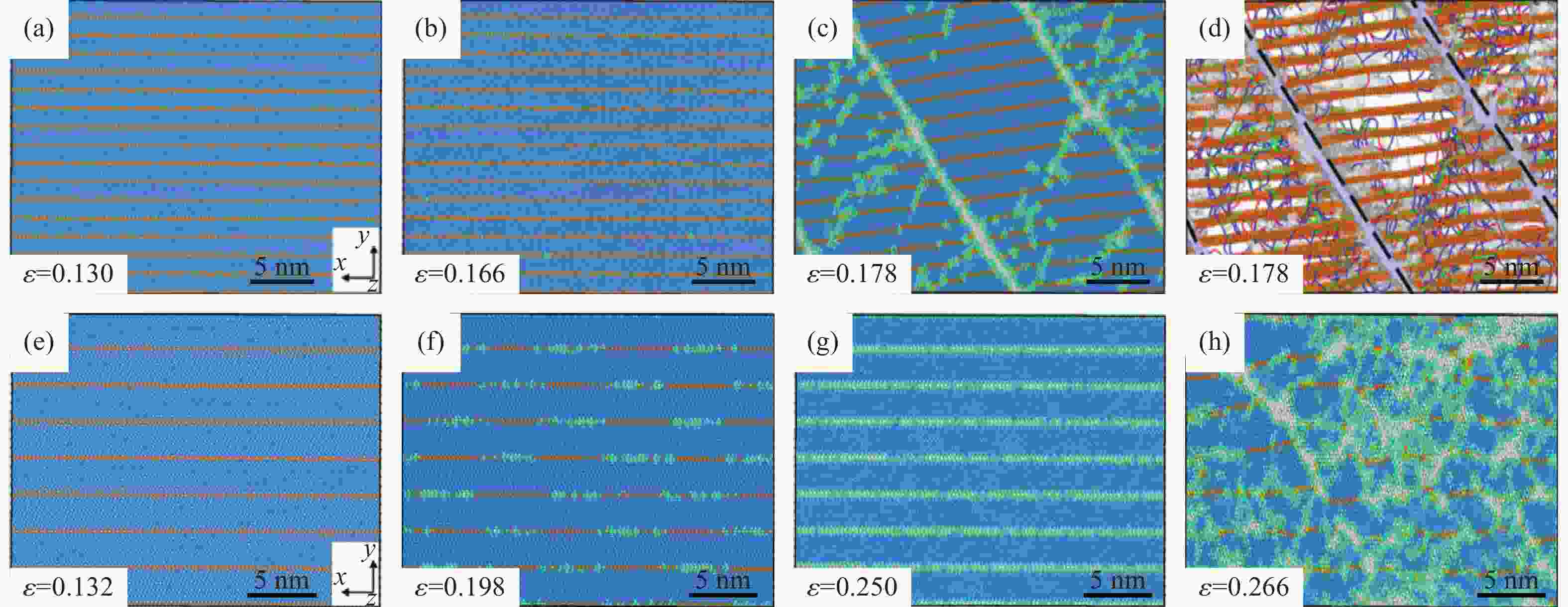

图 39 (a)~(d) λ= 1.5 nm时样品在剪切诱导下的结构演化;(e)~(h) λ= 3 nm时样品在单轴压缩下的微观结构演化[216]

Figure 39. (a)–(d) Shear-induced fracture in the nanotwinned sample with λ = 1.5 nm subjected to uniaxial compressive loading; (e)–(h) microstructural evolution of the nanotwinned sample with λ = 3 nm subjected to uniaxial compressive loading[216]

-

[1] GOOCH JR W A. An overview of ceramic armor applications [J]. Ceramic Transactions, 2002, 134: 3–21. [2] HOGG P J. Composites in armor [J]. Science, 2006, 314(5802): 1100–1101. doi: 10.1126/science.1131118 [3] HELVAJIAN H. Microengineering aerospace systems [M]. El Segundo, CA: The Aerospace Press, 1999. [4] DROLSHAGEN G. Impact effects from small size meteoroids and space debris [J]. Advances in Space Research, 2008, 41(7): 1123–1131. doi: 10.1016/j.asr.2007.09.007 [5] MCBRIDE N, MCDONNELL J A M. Meteoroid impacts on spacecraft: sporadics, streams, and the 1999 Leonids [J]. Planetary and Space Science, 1999, 47(8/9): 1005–1013. doi: 10.1016/S0032-0633(99)00023-9 [6] CHRISTIANSEN E L, HYDE J L, BERNHARD R P. Space shuttle debris and meteoroid impacts [J]. Advances in Space Research, 2004, 34(5): 1097–1103. doi: 10.1016/j.asr.2003.12.008 [7] 王东方, 肖伟科, 庞宝君. NASA二级轻气炮设备简介 [J]. 实验流体力学, 2014, 28(4): 99–104. doi: 10.11729/syltlx2014pz02WANG D F, XIAO W K, PANG B J. A brief introduction on NASA’s two stage light gas guns [J]. Journal of Experiments in Fluid Mechanics, 2014, 28(4): 99–104. doi: 10.11729/syltlx2014pz02 [8] 王青松, 王翔, 郝龙, 等. 三级炮超高速发射技术研究进展 [J]. 高压物理学报, 2014, 28(3): 339–345. doi: 10.11858/gywlxb.2014.03.012WANG Q S, WANG X, HAO L, et al. Progress on hypervelocity launcher techniques using a three-stage gun [J]. Chinese Journal of High Pressure Physics, 2014, 28(3): 339–345. doi: 10.11858/gywlxb.2014.03.012 [9] 曹落霞, 胡海波, 陈永涛, 等. 磁驱动飞片加载下纯铁的冲击相变和层裂特性 [J]. 高压物理学报, 2015, 29(4): 248–254. doi: 10.11858/gywlxb.2015.04.002CAO L X, HU H B, CHEN Y T, et al. Shock-induced phase transition and spallation in pure iron under magnetically driven flyer plate loading [J]. Chinese Journal of High Pressure Physics, 2015, 29(4): 248–254. doi: 10.11858/gywlxb.2015.04.002 [10] 牛锦超, 龚自正, 曹燕, 等. 8 km/s激光驱动飞片发射技术实验研究 [J]. 爆炸与冲击, 2014, 34(2): 129–136. doi: 10.11883/1001-1455(2014)02-0129-08NIU J C, GONG Z Z, CAO Y, et al. Experimental research on laser-driven flyer plates up to 8 km/s [J]. Explosion and Shock Waves, 2014, 34(2): 129–136. doi: 10.11883/1001-1455(2014)02-0129-08 [11] 王志昊, 李勇, 覃文志, 等. 激光驱动飞片飞行特征研究进展 [J]. 含能材料, 2019, 27(3): 255–264. doi: 10.11943/CJEM2018235WANG Z H, LI Y, QIN W Z, et al. Research progress in the flight characteristics of laser-driven flyer [J]. Chinese Journal of Energetic Materials, 2019, 27(3): 255–264. doi: 10.11943/CJEM2018235 [12] 税敏, 储根柏, 席涛, 等. 神光Ⅲ原型装置激光驱动高速飞片实验研究进展 [J]. 物理学报, 2017, 66(6): 064703. doi: 10.7498/aps.66.064703SHUI M, CHU G B, XI T, et al. Experimental progress of laser-driven flyers at the SG-Ⅲ prototype laser facility [J]. Acta Physica Sinica, 2017, 66(6): 064703. doi: 10.7498/aps.66.064703 [13] 单连强, 高宇林, 辛建婷, 等. 激光驱动气库靶对铝的准等熵压缩实验研究 [J]. 物理学报, 2012, 61(13): 135204. doi: 10.7498/aps.61.135204SHAN L Q, GAO Y L, XIN J T, et al. Laser-driven reservoir target for quasi-isentropic compression in aluminum [J]. Acta Physica Sinica, 2012, 61(13): 135204. doi: 10.7498/aps.61.135204 [14] SAVAGE M E, ATHERTON B W, BLISS D E, et al. The Z pulsed power driver since refurbishment [R]. Albuquerque: Sandia National Laboratories, 2010. [15] 王桂吉, 赵剑衡, 孙承纬, 等. 磁驱动准等熵加载装置CQ-4的加载能力及主要应用 [J]. 实验力学, 2015, 30(2): 252–262. doi: 10.7520/1001-4888-15-001WANG G J, ZHAO J H, SUN C W, et al. On the loading capability and main application of magnetically driven quasi-isentropic compression device CQ-4 [J]. Journal of Experimental Mechanics, 2015, 30(2): 252–262. doi: 10.7520/1001-4888-15-001 [16] LANE J M D, FOILES S M, LIM H, et al. Strain-rate dependence of ramp-wave evolution and strength in tantalum [J]. Physical Review B, 2016, 94(6): 064301. doi: 10.1103/PhysRevB.94.064301 [17] 王贵林, 郭帅, 沈兆武, 等. 基于聚龙一号装置的超高速飞片发射实验研究进展 [J]. 物理学报, 2014, 63(19): 196201–280. doi: 10.7498/aps.63.196201WANG G L, GUO S, SHEN Z W, et al. Recent advances in hyper-velocity flyer launch experiments on PTS [J]. Acta Physica Sinica, 2014, 63(19): 196201–280. doi: 10.7498/aps.63.196201 [18] REMINGTON B A, ALLEN P, BRINGA E M, et al. Material dynamics under extreme conditions of pressure and strain rate [J]. Materials Science and Technology, 2006, 22(4): 474–488. doi: 10.1179/174328406X91069 [19] REMINGTON T P, REMINGTON B A, HAHN E N, et al. Deformation and failure in extreme regimes by high-energy pulsed lasers: a review [J]. Materials Science and Engineering: A, 2017, 688: 429–458. doi: 10.1016/j.msea.2017.01.114 [20] ZHANG F C, CUI H W, RUAN X X, et al. The study of electronic structure and optical properties of 2H-SiC [J]. Applied Mechanics and Materials, 2014, 556: 535–538. doi: 10.4028/WWW.SCIENTIFIC.NET/AMM.556-562.535 [21] 孙晓波, 高玉波, 徐鹏. 冲击载荷下Al2O3陶瓷的失效与破碎特性 [J]. 高压物理学报, 2019, 33(5): 054202. doi: 10.11858/gywlxb.20180695SUN X B, GAO Y B, XU P. Failure and fracture characteristics of Al2O3 ceramics under impact loading [J]. Chinese Journal of High Pressure Physics, 2019, 33(5): 054202. doi: 10.11858/gywlxb.20180695 [22] 刘占芳, 冯晓伟, 张凯, 等. 氧化铝陶瓷动态压缩强度的高压和高应变率效应 [J]. 功能材料, 2010, 41(12): 2087–2090.LIU Z F, FENG X W, ZHANG K, et al. Effects of high pressure and high strain rate on dynamic compressive strength of alumina [J]. Journal of Functional Materials, 2010, 41(12): 2087–2090. [23] 王永刚, 周风华. 径向膨胀Al2O3陶瓷环动态拉伸破碎的实验研究 [J]. 固体力学学报, 2008, 29(3): 245–249. doi: 10.19636/j.cnki.cjsm42-1250/o3.2008.03.005WANG Y G, ZHOU F H. Experimental study on the dynamic tensile framentations of Al2O3 rings under radial expansion [J]. Chinese Journal of Solid Mechanics, 2008, 29(3): 245–249. doi: 10.19636/j.cnki.cjsm42-1250/o3.2008.03.005 [24] 孙占峰, 贺红亮, 李平, 等. AD95陶瓷破坏波问题的实验研究 [J]. 高压物理学报, 2014, 28(2): 129–136. doi: 10.11858/gywlxb.2014.02.001SUN Z F, HE H L, LI P, et al. Experimental study on the problem of failure wave in AD95 ceramics [J]. Chinese Journal of High Pressure Physics, 2014, 28(2): 129–136. doi: 10.11858/gywlxb.2014.02.001 [25] 包阔, 张先锋, 谈梦婷, 等. 子弹撞击碳化硼陶瓷复合靶试验与数值模拟研究 [J]. 爆炸与冲击, 2019, 39(12): 123102. doi: 10.11883/bzycj-2018-0462BAO K, ZHANG X F, TAN M T, et al. Ballistic test and numerical simulation on penetration of a boron-carbide-ceramic composite target by a bullet [J]. Explosion and Shock Waves, 2019, 39(12): 123102. doi: 10.11883/bzycj-2018-0462 [26] 段士伟, 李永池, 李平. 陶瓷材料SHPB实验的改进垫块法 [J]. 实验力学, 2013, 28(5): 607–613. doi: 10.7520/1001-4888-13-025DUAN S W, LI Y C, LI P. An improved inserts form in SHPB experiment for ceramic material [J]. Journal of Experimental Mechanics, 2013, 28(5): 607–613. doi: 10.7520/1001-4888-13-025 [27] 段士伟, 李永池, 高光发, 等. 陶瓷的平板撞击拉伸损伤演化表征研究 [J]. 弹道学报, 2013, 25(1): 59–61, 76. doi: 10.3969/j.issn.1004-499X.2013.01.012DUAN S W, LI Y C, GAO G F, et al. Characterization and tensile evaluation of ceramics under plate-impact conditions [J]. Journal of Ballistics, 2013, 25(1): 59–61, 76. doi: 10.3969/j.issn.1004-499X.2013.01.012 [28] 任文科, 高光发, 朴春华, 等. 碳化硼陶瓷复合靶板抗侵彻性能实验研究 [J]. 高压物理学报, 2019, 33(4): 045104. doi: 10.11858/gywlxb.20180657REN W K, GAO G F, PIAO C H, et al. Experimental study of ballistic performance for boron carbide ceramic composite targets [J]. Chinese Journal of High Pressure Physics, 2019, 33(4): 045104. doi: 10.11858/gywlxb.20180657 [29] 张先锋, 李永池. 约束及增韧对氧化铝陶瓷抗射流侵彻性能的影响 [J]. 爆炸与冲击, 2009, 29(2): 149–154. doi: 10.11883/1001-1455(2009)02-0149-06ZHANG X F, LI Y C. Constraining and toughening effects alumina ceramic targets on anti-penetration properties of to shaped charge jets [J]. Explosion and Shock Waves, 2009, 29(2): 149–154. doi: 10.11883/1001-1455(2009)02-0149-06 [30] 李永池, 王道荣, 姚磊, 等. 陶瓷材料的抗侵彻机理和陶瓷锥演化的数值模拟 [J]. 弹道学报, 2004, 16(4): 12–17. doi: 10.3969/j.issn.1004-499X.2004.04.003LI Y C, WANG D R, YAO L, et al. A numerical simulation on anti-penetration mechanism and ceramic cone evolution of ceramic targets [J]. Journal of Ballistics, 2004, 16(4): 12–17. doi: 10.3969/j.issn.1004-499X.2004.04.003 [31] 谈梦婷, 张先锋, 何勇, 等. 长杆弹撞击装甲陶瓷的界面击溃效应数值模拟 [J]. 兵工学报, 2016, 37(4): 627–634. doi: 10.3969/j.issn.1000-1093.2016.04.008TAN M T, ZHANG X F, HE Y, et al. Numerical simulation on interface defeat of ceramic armor impacted by long-rod projectile [J]. Acta Armamentarii, 2016, 37(4): 627–634. doi: 10.3969/j.issn.1000-1093.2016.04.008 [32] 王长利, 周刚, 马坤, 等. 爆炸成型弹丸对陶瓷材料的侵彻实验研究 [J]. 兵器材料科学与工程, 2017, 40(3): 94–98. doi: 10.14024/j.cnki.1004-244x.20170427.007WANG C L, ZHOU G, MA K, et al. Experimental study of EFP penetrating ceramic armor [J]. Ordnance Material Science and Engineering, 2017, 40(3): 94–98. doi: 10.14024/j.cnki.1004-244x.20170427.007 [33] SUBHASH G, MAITI S, GEUBELLE P H, et al. Recent advances in dynamic indentation fracture, impact damage and fragmentation of ceramics [J]. Journal of the American Ceramic Society, 2008, 91(9): 2777–2791. doi: 10.1111/j.1551-2916.2008.02624.x [34] NORMANDIA M J. Impact response and analysis of several silicon carbides [J]. International Journal of Applied Ceramic Technology, 2004, 1(3): 226–234. doi: 10.1111/j.1744-7402.2004.tb00174.x [35] LI T, YANG Y, YU X, et al. Micro-structure response and fracture mechanisms of C/SiC composites subjected to low-velocity ballistic penetration [J]. Ceramics International, 2017, 43(9): 6910–6918. doi: 10.1016/j.ceramint.2017.02.113 [36] 王鹏. 碳化硅陶瓷抗弹性能研究[D]. 南京: 南京理工大学, 2012.WANG P. Research of capacity for penetrating resistance of SiC ceramic [D]. Nanjing: Nanjing University of Science andTechnology, 2012. [37] ZINSZNER J L, FORQUIN P, ROSSIQUET G. Experimental and numerical analysis of the dynamic fragmentation in a SiC ceramic under impact [J]. International Journal of Impact Engineering, 2015, 76: 9–19. doi: 10.1016/j.ijimpeng.2014.07.007 [38] FORQUIN P, ROSSIQUET G, ZINSZNER J L, et al. Microstructure influence on the fragmentation properties of dense silicon carbides under impact [J]. Mechanics of Materials, 2018, 123: 59–76. doi: 10.1016/J.MECHMAT.2018.03.007 [39] GAMA B A, LOPATNIKOV S L, GILLESPIE JR J W. Hopkinson bar experimental technique: a critical review [J]. Applied Mechanics Reviews, 2004, 57(4): 223–250. doi: 10.1115/1.1704626 [40] FOLLANSBEE P S. The hopkinson bar [M]//BOYER H E, GALL T L. Metals Handbook. Metals Park: American Society for Metals, 1985: 198−217. [41] HUH H, KANG W J, HAN S S. A tension split Hopkinson bar for investigating the dynamic behavior of sheet metals [J]. Experimental Mechanics, 2002, 42(1): 8–17. doi: 10.1007/BF02411046 [42] 胡时胜, 王礼立, 宋力, 等. Hopkinson压杆技术在中国的发展回顾 [J]. 爆炸与冲击, 2014, 34(6): 641–657. doi: 10.11883/1001-1455(2014)06-0641-17HU S S, WANG L L, SONG L, et al. Review of the development of Hopkinson pressure bar technique in China [J]. Explosion and Shock Waves, 2014, 34(6): 641–657. doi: 10.11883/1001-1455(2014)06-0641-17 [43] RAVICHANDRAN G, SUBHASH G. Critical appraisal of limiting strain rates for compression testing of ceramics in a split Hopkinson pressure bar [J]. Journal of the American Ceramic Society, 1994, 77(1): 263–267. doi: 10.1111/j.1151-2916.1994.tb06987.x [44] SHIH C J, MEYERS M A, NESTERENKO V F, et al. Damage evolution in dynamic deformation of silicon carbide [J]. Acta Materialia, 2000, 48(9): 2399–2420. doi: 10.1016/S1359-6454(99)00409-7 [45] SARVA S, NEMAT-NASSER S. Dynamic compressive strength of silicon carbide under uniaxial compression [J]. Materials Science and Engineering: A, 2001, 317(1/2): 140–144. doi: 10.1016/S0921-5093(01)01172-8 [46] BOURNE N, MILLETT J, PICKUP I. Delayed failure in shocked silicon carbide [J]. Journal of Applied Physics, 1997, 81(9): 6019–6023. doi: 10.1063/1.364450 [47] PICKUP I M, BARKER A K. Damage kinetics in silicon carbide [J]. AIP Conference Proceedings, 1998, 429(1): 513–516. doi: 10.1063/1.55698 [48] WANG H, RAMESH K T. Dynamic strength and fragmentation of hot-pressed silicon carbide under uniaxial compression [J]. Acta Materialia, 2004, 52(2): 355–367. doi: 10.1016/j.actamat.2003.09.036 [49] 靳晓庆. 陶瓷材料在准静态和冲击压缩载荷作用下的动态碎裂过程[D]. 宁波: 宁波大学, 2014.JIN X Q. Dynamic fragmentation processes of ceramic cylinders under quasi-static and dynamic compression [D]. Ningbo: Ningbo University, 2014 [50] 孙红婵, 胡冰, 李晨辉, 等. 钨丝掺杂碳化硅的高速冲击力学性能研究 [J]. 中国陶瓷, 2014, 50(12): 49–51. doi: 10.16521/j.cnki.issn.1001-9642.2014.12.007SUN H C, HU B, LI C H, et al. The research on high speed impact mechanical properties of W mix SiC [J]. China Ceramics, 2014, 50(12): 49–51. doi: 10.16521/j.cnki.issn.1001-9642.2014.12.007 [51] 高远飞. 氧化铝、碳化硅及Al2O3/SiC复相陶瓷高应变率形变研究[D]. 北京: 中国地质大学(北京), 2014.GAO Y F. Study on high strain rate deformation of alumina, silicon carbide ceramics and Al2O3/SiC nanocomposites [D]. Beijing: China University of Geosciences, 2014. [52] WANG Z Y, LI P F, SONG W D. Inelastic deformation micromechanism and modified fragmentation model for silicon carbide under dynamic compression [J]. Materials & Design, 2018, 157: 244–250. doi: 10.1016/j.matdes.2018.07.032 [53] LI X, ZHANG K, KONIETZKY H, et al. Experimental study on the dynamic mechanical behaviors of silicon carbide ceramic after thermal shock [J]. Nuclear Materials and Energy, 2020, 24: 100774. doi: 10.1016/j.nme.2020.100774 [54] AHRENS T J, GREGSON JR V G. Shock compression of crustal rocks: data for quartz, calcite, and plagioclase rocks [J]. Journal of Geophysical Research, 1964, 69(22): 4839–4874. doi: 10.1029/JZ069i022p04839 [55] KINSLOW R. High-velocity impact phenomena [M]. New York: Academic Press, 1970. [56] GUST W H, ROYCE E B. Axial yield strengths and two successive phase transition stresses for crystalline silicon [J]. Journal of Applied Physics, 1971, 42(5): 1897–1905. doi: 10.1063/1.1660465 [57] GUST W H, HOLT A C, ROYCE E B. Dynamic yield, compressional, and elastic parameters for several lightweight intermetallic compounds [J]. Journal of Applied Physics, 1973, 44(2): 550–560. doi: 10.1063/1.1662224 [58] KIPP M E, GRADY D E. Shock compression and release in high-strength ceramics [R]. Albuquerque: Sandia National Laboratories, 1989. [59] GRADY D E. Shock-wave properties of brittle solids [J]. AIP Conference Proceedings, 1996, 370(1): 9–20. doi: 10.1063/1.50579 [60] FENG R, RAISER G F, GUPTA Y M. Shock response of polycrystalline silicon carbide undergoing inelastic deformation [J]. Journal of Applied Physics, 1996, 79(3): 1378–1387. doi: 10.1063/1.361036 [61] FENG R, RAISER G F, GUPTA Y M. Material strength and inelastic deformation of silicon carbide under shock wave compression [J]. Journal of Applied Physics, 1998, 83(1): 79–86. doi: 10.1063/1.366704 [62] YUAN G, FENG R, GUPTA Y M. Compression and shear wave measurements to characterize the shocked state in silicon carbide [J]. Journal of Applied Physics, 2001, 89(10): 5372–5380. doi: 10.1063/1.1365438 [63] SEKINE T, KOBAYASHI T. Shock compression of 6H polytype SiC to 160 GPa [J]. Physical Review B, 1997, 55(13): 8034–8037. doi: 10.1103/PhysRevB.55.8034 [64] ZHU Y Q, SEKINE T, KOBAYASHI T, et al. Shock-induced phase transitions among SiC polytypes [J]. Journal of Materials Science, 1998, 33(24): 5883–5890. doi: 10.1023/A:1004482922441 [65] VOGLER T J, REINHART W D, CHHABILDAS L C, et al. Hugoniot and strength behavior of silicon carbide [J]. Journal of Applied Physics, 2006, 99(2): 023512. doi: 10.1063/1.2159084 [66] PARIS V, FRAGE N, DARIEL M P, et al. Divergent impact study of the compressive failure threshold in SiC and B4C [J]. International Journal of Impact Engineering, 2011, 38(4): 228–237. doi: 10.1016/j.ijimpeng.2010.10.027 [67] GAUTAM P C, GUPTA R, SHARMA A C, et al. Determination of Hugoniot elastic limit (HEL) and equation of state (EOS) of ceramic materials in the pressure region 20 GPa to 100 GPa [J]. Procedia Engineering, 2017, 173: 198–205. doi: 10.1016/j.proeng.2016.12.058 [68] MILLETT J C F, BOURNE N K, DANDEKAR D P. Delayed failure in a shock-loaded silicon carbide [J]. Journal of Applied Physics, 2005, 97(11): 113513. doi: 10.1063/1.1923161 [69] WINKLER W D, STILP A J. Spallation behavior of TiB2, SiC, and B4C under planar impact tensile stresses [M]//SCHMIDT S C, DICK R D, FORBES J W, et al. Shock Compression of Condensed Matter–1991. Amsterdam: Elsevier, 1992: 475–478. [70] BARTKOWSKI P, DANDEKAR D P. Spall strengths of sintered and hot pressed silicon carbide [J]. AIP Conference Proceedings, 1996, 370(1): 535–538. doi: 10.1063/1.50654 [71] DANDEKAR D P, BARTKOWSKI P T. Tensile strengths of silicon carbide (SiC) under shock loading [R]. Army Research Laboratories, 2001. [72] DANDEKAR D P. Spall strength of silicon carbide under normal and simultaneous compression-shear shock wave loading [J]. International Journal of Applied Ceramic Technology, 2004, 1(3): 261–268. doi: 10.1111/j.1744-7402.2004.tb00178.x [73] PARIS V, FRAGE N, DARIEL M P, et al. The spall strength of silicon carbide and boron carbide ceramics processed by spark plasma sintering [J]. International Journal of Impact Engineering, 2010, 37(11): 1092–1099. doi: 10.1016/j.ijimpeng.2010.06.008 [74] SAVINYKH A S, KANEL G I, RAZORENOV S V, et al. Evolution of shock waves in SiC ceramic [J]. Technical Physics, 2013, 58(7): 973–977. doi: 10.1134/S1063784213070207 [75] GARKUSHIN G V, RAZORENOV S V, RUMYANTSEV V I, et al. Dynamic strength of reaction-sintered silicon carbide ceramics [J]. Mechanics of Solids, 2014, 49(6): 616–622. doi: 10.3103/S0025654414060028 [76] PAISLEY D L, LUO S N, GREENFIELD S R, et al. Laser-launched flyer plate and confined laser ablation for shock wave loading: validation and applications [J]. Review of Scientific Instruments, 2008, 79(2): 023902. doi: 10.1063/1.2839399 [77] ZHAO S T, KAD B, REMINGTON B A, et al. Directional amorphization of boron carbide subjected to laser shock compression [J]. Proceedings of the National Academy of Sciences of the United States of America, 2016, 113(43): 12088–12093. doi: 10.1073/pnas.1604613113 [78] ZHAO S, HAHN E N, KAD B, et al. Amorphization and nanocrystallization of silicon under shock compression [J]. Acta Materialia, 2016, 103: 519–533. doi: 10.1016/j.actamat.2015.09.022 [79] ZHAO S T, KAD B, WEHRENBERG C E, et al. Generating gradient germanium nanostructures by shock-induced amorphization and crystallization [J]. Proceedings of the National Academy of Sciences of the United States of America, 2017, 114(37): 9791–9796. doi: 10.1073/pnas.1708853114 [80] ASHITKOV S I, AGRANAT M B, KANEL’G I, et al. Behavior of aluminum near an ultimate theoretical strength in experiments with femtosecond laser pulses [J]. JETP Letters, 2010, 92(8): 516–520. doi: 10.1134/S0021364010200051 [81] WHITLEY V, MCGRANE S, BOLME C, et al. The elastic-plastic response of metal films subjected to ultrafast laser-generated shocks [C]//Proceedings of the 17th Biennial International Conference of the APS Topical Group on Shock Compression of Condensed Matter. Washington DC, USA: American Physical Society, 2011. [82] ZHAO S, FLANAGAN R, HAHN E N, et al. Shock-induced amorphization in silicon carbide [J]. Acta Materialia, 2018, 158: 206–213. doi: 10.1016/j.actamat.2018.07.047 [83] TRACY S J, SMITH R F, WICKS J K, et al. In situ: observation of a phase transition in silicon carbide under shock compression using pulsed x-ray diffraction [J]. Physical Review B, 2019, 99(21): 214106. doi: 10.1103/PhysRevB.99.214106 [84] GRADY D E. Shock-wave strength properties of boron carbide and silicon carbide [J]. Journal de Physique IV, 1994, 4(C8): C8-385–C8-391. doi: 10.1051/jp4:1994859 [85] SMITH R F, MINICH R W, RUDD R E, et al. Orientation and rate dependence in high strain-rate compression of single-crystal silicon [J]. Physical Review B, 2012, 86(24): 245204. doi: 10.1103/PhysRevB.86.245204 [86] SMITH R F, EGGERT J H, RUDD R E, et al. High strain-rate plastic flow in Al and Fe [J]. Journal of Applied Physics, 2011, 110(12): 123515. doi: 10.1063/1.3670001 [87] BEHNER T, ORPHAL D L, HOHLER V, et al. Hypervelocity penetration of gold rods into SiC-N for impact velocities from 2.0 to 6.2 km/s [J]. International Journal of Impact Engineering, 2006, 33(1): 68–79. doi: 10.1016/j.ijimpeng.2006.09.082 [88] ANDERSON JR C E, BEHNER T, HOLMQUIST T J, et al. Penetration response of silicon carbide as a function of impact velocity [J]. International Journal of Impact Engineering, 2011, 38(11): 892–899. doi: 10.1016/j.ijimpeng.2011.06.002 [89] COX B N, GAO H J, GROSS D, et al. Modern topics and challenges in dynamic fracture [J]. Journal of the Mechanics and Physics of Solids, 2005, 53(3): 565–596. doi: 10.1016/j.jmps.2004.09.002 [90] FAHRENTHOLD E P. A continuum damage model for fracture of brittle solids under dynamic loading [J]. Journal of Applied Mechanics, 1991, 58(4): 904–909. doi: 10.1115/1.2897704 [91] RAJENDRAN A M. Modeling the impact behavior of AD85 ceramic under multiaxial loading [J]. International Journal of Impact Engineering, 1994, 15(6): 749–768. doi: 10.1016/0734-743X(94)90033-H [92] JOHNSON G R, HOLMQUIST T J. An improved computational constitutive model for brittle materials [J]. AIP Conference Proceedings, 1994, 309(1): 981–984. doi: 10.1063/1.46199 [93] SIMHA C H M, BLESS S J, BEDFORD A. Computational modeling of the penetration response of a high-purity ceramic [J]. International Journal of Impact Engineering, 2002, 27(1): 65–86. doi: 10.1016/S0734-743X(01)00036-7 [94] RAVICHANDRAN G, SUBHASH G. A micromechanical model for high strain rate behavior of ceramics [J]. International Journal of Solids and Structures, 1995, 32(17/18): 2627–2646. doi: 10.1016/0020-7683(94)00286-6 [95] ESPINOSA H D. On the dynamic shear resistance of ceramic composites and its dependence on applied multiaxial deformation [J]. International Journal of Solids and Structures, 1995, 32(21): 3105–3128. doi: 10.1016/0020-7683(94)00300-L [96] ESPINOSA H D, XU Y P, BRAR N S. Micromechanics of failure waves in glass: Ⅱ modeling [J]. Journal of the American Ceramic Society, 1997, 80(8): 2074–2085. doi: 10.1111/J.1151-2916.1997.TB03091.X [97] STEINBERG D J. Computer studies of the dynamic strength of ceramics [M]//TAKAYAMA K. Shock Waves. Berlin: Springer, 1992: 415–422. [98] 张晓晴, 姚小虎, 宁建国, 等. Al2O3陶瓷材料应变率相关的动态本构关系研究 [J]. 爆炸与冲击, 2004, 24(3): 226–232. doi: 10.3321/j.issn:1001-1455.2004.03.006ZHANG X Q, YAO X H, NING J G, et al. A study on the strain-rate dependent dynamic constitutive equation of Al2O3 ceramics [J]. Explosion and Shock Waves, 2004, 24(3): 226–232. doi: 10.3321/j.issn:1001-1455.2004.03.006 [99] RAJENDRAN A M, GROVE D J. Modeling the shock response of silicon carbide, boron carbide and titanium diboride [J]. International Journal of Impact Engineering, 1996, 18(6): 611–631. doi: 10.1016/0734-743X(96)89122-6 [100] 任会兰, 宁建国. 强冲击载荷下氧化铝陶瓷的力学特性及本构模型 [J]. 北京理工大学学报, 2007, 27(9): 761–764, 796. doi: 10.3969/j.issn.1001-0645.2007.09.003REN H L, NING J G. Mechanical characteristics and constitutive model of alumina ceramic subjected to shock loading [J]. Transactions of Beijing Institute of Technology, 2007, 27(9): 761–764, 796. doi: 10.3969/j.issn.1001-0645.2007.09.003 [101] HOLMQUIST T J, JOHNSON G R. Response of silicon carbide to high velocity impact [J]. Journal of Applied Physics, 2002, 91(9): 5858–5866. doi: 10.1063/1.1468903 [102] HOLMQUIST T J, JOHNSON G R. Characterization and evaluation of silicon carbide for high-velocity impact [J]. Journal of Applied Physics, 2005, 97(9): 093502. doi: 10.1063/1.1881798 [103] 唐瑞涛, 徐柳云, 文鹤鸣, 等. 陶瓷材料宏观动态新本构模型 [J]. 高压物理学报, 2020, 34(4): 044201. doi: 10.11858/gywlxb.20190863TANG R T, XU L Y, WEN H M, et al. A macroscopic dynamic constitutive model for ceramic materials [J]. Chinese Journal of High Pressure Physics, 2020, 34(4): 044201. doi: 10.11858/gywlxb.20190863 [104] ANDERSON JR C E. A review of computational ceramic armor modeling [M]//PROKURAT L, WERESZCZAK A, LARA-CURZIO E. Advances in ceramic armor Ⅱ: ceramic engineering and science proceedings. Hoboken: John Wiley & Sons Inc., 2006. . [105] WALLEY S M. Historical review of high strain rate and shock properties of ceramics relevant to their application in armour [J]. Advances in Applied Ceramics, 2010, 109(8): 446–466. doi: 10.1179/174367609X422180 [106] ZHU J B. Strength of polycrystalline ceramics under shock compression [D]. Nebraska: The University of Nebraska-Lincoln, 2011. [107] LEVY S, MOLINARI J F. Dynamic fragmentation of ceramics, signature of defects and scaling of fragment sizes [J]. Journal of the Mechanics and Physics of Solids, 2010, 58(1): 12–26. doi: 10.1016/j.jmps.2009.09.002 [108] 易洪昇, 徐松林, 单俊芳, 等. 不同加载速度下脆性颗粒的破坏特性 [J]. 爆炸与冲击, 2017, 37(5): 913–922. doi: 10.11883/1001-1455(2017)05-0913-10YI H S, XU S L, SHAN J F, et al. Fracture characteristics of brittle particles at different loading velocities [J]. Explosion and Shock Waves, 2017, 37(5): 913–922. doi: 10.11883/1001-1455(2017)05-0913-10 [109] 易荣成, 王坚茹, 印立魁, 等. 陶瓷易碎弹对铝板的冲击特性研究 [J]. 振动与冲击, 2017, 36(6): 163–167. doi: 10.13465/j.cnki.jvs.2017.06.025YI R C, WANG J R, YIN L K, et al. Characteristics of ceramic fragile projectiles impacting against aluminum plates [J]. Journal of Vibration and Shock, 2017, 36(6): 163–167. doi: 10.13465/j.cnki.jvs.2017.06.025 [110] CHAKRABORTY S, ISLAM M R I, SHAW A, et al. A computational framework for modelling impact induced damage in ceramic and ceramic-metal composite structures [J]. Composite Structures, 2017, 164: 263–276. doi: 10.1016/j.compstruct.2016.12.064 [111] COOPER I Z, RUBIN M B. Modeling damage in silicon carbide due to an impact stress below the HEL [J]. International Journal of Impact Engineering, 2014, 65: 174–184. doi: 10.1016/j.ijimpeng.2013.11.007 [112] MERZHIEVSKII L A. Deformation models under intense dynamic loading (review) [J]. Combustion, Explosion, and Shock Waves, 2015, 51(2): 269–283. doi: 10.1134/S0010508215020100 [113] CHI R Q, SERJOUEI A, SRIDHAR I, et al. Pre-stress effect on confined ceramic armor ballistic performance [J]. International Journal of Impact Engineering, 2015, 84: 159–170. doi: 10.1016/j.ijimpeng.2015.05.011 [114] TANG R T, WEN H M. Predicting the perforation of ceramic-faced light armors subjected to projectile impact [J]. International Journal of Impact Engineering, 2017, 102: 55–61. doi: 10.1016/j.ijimpeng.2016.11.008 [115] ZHANG D, ZHAO L G, ROY A. Mechanical behavior of silicon carbide under static and dynamic compression [J]. Journal of Engineering Materials and Technology, 2019, 141(1): 011007. doi: 10.1115/1.4040591 [116] KADAU K, GERMANN T C, LOMDAHL P S. Molecular dynamics comes of age: 320 billion atom simulation on BlueGene/L [J]. International Journal of Modern Physics C, 2006, 17(12): 1755–1761. doi: 10.1142/S0129183106010182 [117] KADAU K, GERMANN T C, LOMDAHL P S, et al. Atomistic simulations of shock-induced transformations and their orientation dependence in bcc Fe single crystals [J]. Physical Review B, 2005, 72(6): 064120. doi: 10.1103/PhysRevB.72.064120 [118] KADAU K, GERMANN T C, LOMDAHL P S, et al. Shock waves in polycrystalline iron [J]. Physical Review Letters, 2007, 98(13): 135701. doi: 10.1103/PhysRevLett.98.135701 [119] VASHISHTA P, KALIA R K, NAKANO A. Multimillion atom simulations of dynamics of wing cracks and nanoscale damage in glass, and hypervelocity impact damage in ceramics [J]. Computer Physics Communications, 2007, 177(1/2): 202–205. doi: 10.1016/j.cpc.2007.02.097 [120] TERSOFF J. Modeling solid-state chemistry: interatomic potentials for multicomponent systems [J]. Physical Review B, 1989, 39(8): 5566–5568. doi: 10.1103/PhysRevB.39.5566 [121] TERSOFF J. Carbon defects and defect reactions in silicon [J]. Physical Review Letters, 1990, 64(15): 1757–1760. doi: 10.1103/PhysRevLett.64.1757 [122] TERSOFF J. Chemical order in amorphous silicon carbide [J]. Physical Review B, 1994, 49(23): 16349–16352. doi: 10.1103/PhysRevB.49.16349 [123] ERHART P, ALBE K. Analytical potential for atomistic simulations of silicon, carbon, and silicon carbide [J]. Physical Review B, 2005, 71(3): 035211. doi: 10.1103/PHYSREVB.71.035211 [124] VASHISHTA P, KALIA R K, NAKANO A, et al. Interaction potential for silicon carbide: a molecular dynamics study of elastic constants and vibrational density of states for crystalline and amorphous silicon carbide [J]. Journal of Applied Physics, 2007, 101(10): 103515. doi: 10.1063/1.2724570 [125] LI W H, YAO X H, ZHANG X Q. Planar impacts on nanocrystalline SiC: a comparison of different potentials [J]. Journal of Materials Science, 2018, 53(9): 6637–6651. doi: 10.1007/s10853-018-1985-1 [126] BRANICIO P S, KALIA R K, NAKANO A, et al. Atomistic damage mechanisms during hypervelocity projectile impact on AlN: a large-scale parallel molecular dynamics simulation study [J]. Journal of the Mechanics and Physics of Solids, 2008, 56(5): 1955–1988. doi: 10.1016/j.jmps.2007.11.004 [127] BRANICIO P S, NAKANO A, KALIA R K, et al. Shock loading on AlN ceramics: a large scale molecular dynamics study [J]. International Journal of Plasticity, 2013, 51: 122–131. doi: 10.1016/j.ijplas.2013.06.002 [128] BRANICIO P S, KALIA R K, NAKANO A, et al. Shock-induced structural phase transition, plasticity, and brittle cracks in aluminum nitride ceramic [J]. Physical Review Letters, 2006, 96(6): 065502. doi: 10.1103/PhysRevLett.96.065502 [129] ZHANG C, KALIA R K, NAKANO A, et al. Hypervelocity impact induced deformation modes in α-alumina [J]. Applied Physics Letters, 2007, 91(7): 071906. doi: 10.1063/1.2753092 [130] ZHANG C, KALIA R K, NAKANO A, et al. Fracture initiation mechanisms in α-alumina under hypervelocity impact [J]. Applied Physics Letters, 2007, 91(12): 121911. doi: 10.1063/1.2786865 [131] ZHANG C, KALIA R K, NAKANO A, et al. Deformation mechanisms and damage in α-alumina under hypervelocity impact loading [J]. Journal of Applied Physics, 2008, 103(8): 083508. doi: 10.1063/1.2891797 [132] KUKSIN A Y, YANILKIN A V. Formation of twins in sapphire under shock wave loading: atomistic simulations [J]. Journal of Applied Physics, 2012, 111(3): 033513. doi: 10.1063/1.3681321 [133] BRANICIO P S, KALIA R K, NAKANO A, et al. Nanoductility induced brittle fracture in shocked high performance ceramics [J]. Applied Physics Letters, 2010, 97(11): 111903. doi: 10.1063/1.3478003 [134] ZHANG J Y, BRANICIO P S. Molecular dynamics simulations of plane shock loading in SiC [J]. Procedia Engineering, 2014, 75: 150–153. doi: 10.1016/j.proeng.2013.11.032 [135] BRANICIO P S, ZHANG J Y, RINO J P, et al. Plane shock loading on mono-and nano-crystalline silicon carbide [J]. Applied Physics Letters, 2018, 112(11): 111909. doi: 10.1063/1.5025583 [136] BRANICIO P S, ZHANG J Y, RINO J P, et al. Shock-induced microstructural response of mono-and nanocrystalline SiC ceramics [J]. Journal of Applied Physics, 2018, 123(14): 145902. doi: 10.1063/1.5023915 [137] LI W H, YAO X H, BRANICIO P S, et al. Shock-induced spall in single and nanocrystalline SiC [J]. Acta Materialia, 2017, 140: 274–289. doi: 10.1016/j.actamat.2017.08.036 [138] LEE W H, YAO X H. First principle investigation of phase transition and thermodynamic properties of SiC [J]. Computational Materials Science, 2015, 106: 76–82. doi: 10.1016/j.commatsci.2015.04.044 [139] MAKEEV M A, SRIVASTAVA D. Hypersonic velocity impact on α-SiC target: a diagram of damage characteristics via molecular dynamics simulations [J]. Applied Physics Letters, 2008, 92(15): 151909. doi: 10.1063/1.2894188 [140] MAKEEV M A, SRIVASTAVA D. Molecular dynamics simulations of hypersonic velocity impact protection properties of CNT/α-SiC composites [J]. Composites Science and Technology, 2008, 68(12): 2451–2455. doi: 10.1016/j.compscitech.2008.04.040 [141] MAKEEV M A, SUNDARESH S, SRIVASTAVA D. Shock-wave propagation through pristine α-SiC and carbon-nanotube-reinforced α-SiC matrix composites [J]. Journal of Applied Physics, 2009, 106(1): 014311. doi: 10.1063/1.3152587 [142] LI W H, HAHN E N, YAO X H, et al. Shock induced damage and fracture in SiC at elevated temperature and high strain rate [J]. Acta Materialia, 2019, 167: 51–70. doi: 10.1016/j.actamat.2018.12.035 [143] LI W H, HAHN E N, YAO X H, et al. On the grain size dependence of shock responses in nanocrystalline SiC ceramics at high strain rates [J]. Acta Materialia, 2020, 200: 632–651. doi: 10.1016/j.actamat.2020.09.044 [144] LI W H, HAHN E N, BRANICIO P S, et al. Rate dependence and anisotropy of SiC response to ramp and wave-free quasi-isentropic compression [J]. International Journal of Plasticity, 2021, 138: 102923. doi: 10.1016/j.ijplas.2020.102923 [145] DAVIAU K, LEE K K M. Zinc-blende to rocksalt transition in SiC in a laser-heated diamond-anvil cell [J]. Physical Review B, 2017, 95(13): 134108. doi: 10.1103/PHYSREVB.95.134108 [146] 李旺辉. 极端条件下碳化硅的变形、损伤与破坏研究[D]. 广州: 华南理工大学, 2018.LI W H. Investigation on the deformation, damage and fracture of SiC under extreme conditions [D]. Guangzhou: South China University of Technology, 2018. [147] PIZZAGALLI L. Stability and mobility of screw dislocations in 4H, 2H and 3C silicon carbide [J]. Acta Materialia, 2014, 78: 236–244. doi: 10.1016/j.actamat.2014.06.053 [148] LU Y P, HE D W, ZHU J, et al. First-principles study of pressure-induced phase transition in silicon carbide [J]. Physica B: Condensed Matter, 2008, 403(19/20): 3543–3546. doi: 10.1016/j.physb.2008.05.028 [149] PERDEW J P, WANG Y. Erratum: accurate and simple analytic representation of the electron-gas correlation energy [J]. Physical Review B, 2018, 98(7): 079904. doi: 10.1103/PhysRevB.98.079904 [150] PERDEW J P, BURKE K, ERNZERHOF M. Generalized gradient approximation made simple [J]. Physical Review Letters, 1997, 78(7): 1396. doi: 10.1103/PhysRevLett.78.1396 [151] PERDEW J P, RUZSINSZKY A, CSONKA G I, et al. Restoring the density-gradient expansion for exchange in solids and surfaces [J]. Physical Review Letters, 2008, 100(13): 136406. doi: 10.1103/PhysRevLett.100.136406 [152] GORAI S, BHATTACHARYA C. Shock induced phase transition in SiC polytypes [J]. Journal of Applied Physics, 2019, 125(18): 185903. doi: 10.1063/1.5090808 [153] CATTI M. Orthorhombic intermediate state in the zinc blende to rocksalt transformation path of SiC at high pressure [J]. Physical Review Letters, 2001, 87(3): 035504. doi: 10.1103/PhysRevLett.87.035504 [154] LU G, KAXIRAS E. An overview of multiscale simulations of materials [EB/OL]. (2004−01−07)[2021−04−25]. https://arxiv.org/abs/cond-mat/0401073. [155] TADMOR E B, ORTIZ M, PHILLIPS R. Quasicontinuum analysis of defects in solids [J]. Philosophical Magazine A, 1996, 73(6): 1529–1563. doi: 10.1080/01418619608243000 [156] LI J, YIP S. Atomistic measures of materials strength [J]. CMES-Computer Modeling in Engineering & Sciences, 2002, 3(2): 219–228. doi: 10.3970/cmes.2002.003.219 [157] CAI W, DE KONING M, BULATOV V V, et al. Minimizing boundary reflections in coupled-domain simulations [J]. Physical Review Letters, 2000, 85(15): 3213–3216. doi: 10.1103/PhysRevLett.85.3213 [158] CAI W, BULATOV V V, JUSTO J F, et al. Intrinsic mobility of a dissociated dislocation in silicon [J]. Physical Review Letters, 2000, 84(15): 3346–3349. doi: 10.1103/PhysRevLett.84.3346 [159] DONG X Y. Materials-genome-based multiscale modeling of ceramics and laser-assisted machining [D]. Silafaye: Purdue University, 2017. [160] YAMASHITA H, HART R, SHARMA T, et al. A review of multiscale methods and their applications in modeling and simulation of engineering problems [J]. International Journal on Recent Technologies in Mechanical and Electrical Engineering, 2016, 3(3): 42–47. [161] GUR S, SADAT M R, FRANTZISKONIS G N, et al. The effect of grain-size on fracture of polycrystalline silicon carbide: a multiscale analysis using a molecular dynamics-peridynamics framework [J]. Computational Materials Science, 2019, 159: 341–348. doi: 10.1016/j.commatsci.2018.12.038 [162] HANSEN N. Hall-Petch relation and boundary strengthening [J]. Scripta Materialia, 2004, 51(8): 801–806. doi: 10.1016/j.scriptamat.2004.06.002 [163] SZLUFARSKA I, RAMESH K T, WARNER D H. Simulating mechanical behavior of ceramics under extreme conditions [J]. Annual Review of Materials Research, 2013, 43: 131–156. doi: 10.1146/annurev-matsci-071312-121714 [164] FORQUIN P. Brittle materials at high-loading rates: an open area of research [J]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2017, 375(2085): 20160436. doi: 10.1098/RSTA.2016.0436 [165] BALINT D S, DESHPANDE V S, NEEDLEMAN A, et al. Discrete dislocation plasticity analysis of the grain size dependence of the flow strength of polycrystals [J]. International Journal of Plasticity, 2008, 24(12): 2149–2172. doi: 10.1016/j.ijplas.2007.08.005 [166] PANDE C S, COOPER K P. Nanomechanics of Hall-Petch relationship in nanocrystalline materials [J]. Progress in Materials Science, 2009, 54(6): 689–706. doi: 10.1016/j.pmatsci.2009.03.008 [167] ARMSTRONG R W. 60 years of Hall-Petch: past to present nano-scale connections [J]. Materials Transactions, 2014, 55(1): 2–12. doi: 10.2320/matertrans.MA201302 [168] HALL E O. The deformation and ageing of mild steel: Ⅲ discussion of results [J]. Proceedings of the Physical Society. Section B, 1951, 64(9): 747–753. doi: 10.1088/0370-1301/64/9/303 [169] PETCH N J. The cleavage strength of polycrystals [J]. Journal of the Iron and Steel Institute, 1953, 174: 25–28. [170] LEE W H, YAO X H, JIAN W R, et al. High-velocity shock compression of SiC via molecular dynamics simulation [J]. Computational Materials Science, 2015, 98: 297–303. doi: 10.1016/j.commatsci.2014.11.029 [171] YUAN W, PANIGRAHI S K, SU J Q, et al. Influence of grain size and texture on Hall-Petch relationship for a magnesium alloy [J]. Scripta Materialia, 2011, 65(11): 994–997. doi: 10.1016/j.scriptamat.2011.08.028 [172] CORDERO Z C, KNIGHT B E, SCHUH C A. Six decades of the Hall-Petch effect–a survey of grain-size strengthening studies on pure metals [J]. International Materials Reviews, 2016, 61(8): 495–512. doi: 10.1080/09506608.2016.1191808 [173] AIFANTIS K E, KONSTANTINIDIS A A. Hall-Petch revisited at the nanoscale [J]. Materials Science and Engineering: B, 2009, 163(3): 139–144. doi: 10.1016/j.mseb.2009.05.010 [174] HAHN E N, MEYERS M A. Grain-size dependent mechanical behavior of nanocrystalline metals [J]. Materials Science and Engineering: A, 2015, 646: 101–134. doi: 10.1016/j.msea.2015.07.075 [175] CARLTON C E, FERREIRA P J. What is behind the inverse Hall-Petch effect in nanocrystalline materials? [J]. Acta Materialia, 2007, 55(11): 3749–3756. doi: 10.1016/j.actamat.2007.02.021 [176] BARAI P, WENG G J. Mechanics of very fine-grained nanocrystalline materials with contributions from grain interior, GB zone, and grain-boundary sliding [J]. International Journal of Plasticity, 2009, 25(12): 2410–2434. doi: 10.1016/j.ijplas.2009.04.001 [177] QUEK S S, CHOOI Z H, WU Z X, et al. The inverse hall-petch relation in nanocrystalline metals: a discrete dislocation dynamics analysis [J]. Journal of the Mechanics and Physics of Solids, 2016, 88: 252–266. doi: 10.1016/j.jmps.2015.12.012 [178] TRELEWICZ J R, SCHUH C A. The Hall-Petch breakdown in nanocrystalline metals: a crossover to glass-like deformation [J]. Acta Materialia, 2007, 55(17): 5948–5958. doi: 10.1016/j.actamat.2007.07.020 [179] TRELEWICZ J R, SCHUH C A. The Hall-Petch breakdown at high strain rates: optimizing nanocrystalline grain size for impact applications [J]. Applied Physics Letters, 2008, 93(17): 171916. doi: 10.1063/1.3000655 [180] ZHOU K, LIU B, YAO Y J, et al. Effects of grain size and shape on mechanical properties of nanocrystalline copper investigated by molecular dynamics [J]. Materials Science and Engineering: A, 2014, 615: 92–97. doi: 10.1016/j.msea.2014.07.066 [181] FREY M H, PAYNE D A. Grain-size effect on structure and phase transformations for barium titanate [J]. Physical Review B, 1996, 54(5): 3158–3168. doi: 10.1103/PhysRevB.54.3158 [182] EHRE D, CHAIM R. Abnormal Hall-Petch behavior in nanocrystalline MgO ceramic [J]. Journal of Materials Science, 2008, 43(18): 6139–6143. doi: 10.1007/s10853-008-2936-z [183] SOKOL M, HALABI M, MORDEKOVITZ Y, et al. An inverse Hall-Petch relation in nanocrystalline MgAl2O4 spinel consolidated by high pressure spark plasma sintering (HPSPS) [J]. Scripta Materialia, 2017, 139: 159–161. doi: 10.1016/j.scriptamat.2017.06.049 [184] WOLLMERSHAUSER J A, FEIGELSON B N, GORZKOWSKI E P, et al. An extended hardness limit in bulk nanoceramics [J]. Acta Materialia, 2014, 69: 9–16. doi: 10.1016/j.actamat.2014.01.030 [185] MUCHE D N F, DRAZIN J W, MARDINLY J, et al. Colossal grain boundary strengthening in ultrafine nanocrystalline oxides [J]. Materials Letters, 2017, 186: 298–300. doi: 10.1016/j.matlet.2016.10.035 [186] RYOU H, DRAZIN J W, WAHL K J, et al. Below the hall-petch limit in nanocrystalline ceramics [J]. ACS Nano, 2018, 12(4): 3083–3094. doi: 10.1021/acsnano.7b07380 [187] BRINGA E M, CARO A, WANG Y M, et al. Ultrahigh strength in nanocrystalline materials under shock loading [J]. Science, 2005, 309(5742): 1838–1841. doi: 10.1126/science.1116723 [188] VO N Q, AVERBACK R S, BELLON P, et al. Yield strength in nanocrystalline Cu during high strain rate deformation [J]. Scripta Materialia, 2009, 61(1): 76–79. doi: 10.1016/j.scriptamat.2009.03.003 [189] WILKERSON J W, RAMESH K T. Unraveling the anomalous grain size dependence of cavitation [J]. Physical Review Letters, 2016, 117(21): 215503. doi: 10.1103/PhysRevLett.117.215503 [190] WILKERSON J W. On the micromechanics of void dynamics at extreme rates [J]. International Journal of Plasticity, 2017, 95: 21–42. doi: 10.1016/j.ijplas.2017.03.008 [191] SCHIØTZ J, DI TOLLA F D, JACOBSEN K W. Softening of nanocrystalline metals at very small grain sizes [J]. Nature, 1998, 391(6667): 561–563. doi: 10.1038/35328 [192] LIAO F, GIRSHICK S L, MOOK W M, et al. Superhard nanocrystalline silicon carbide films [J]. Applied Physics Letters, 2005, 86(17): 171913. doi: 10.1063/1.1920434 [193] SZLUFARSKA I, NAKANO A, VASHISHTA P. A crossover in the mechanical response of nanocrystalline ceramics [J]. Science, 2005, 309(5736): 911–914. doi: 10.1126/science.1114411 [194] MO Y F, SZLUFARSKA I. Simultaneous enhancement of toughness, ductility, and strength of nanocrystalline ceramics at high strain-rates [J]. Applied Physics Letters, 2007, 90(18): 181926. doi: 10.1063/1.2736652 [195] SHINODA Y, NAGANO T, GU H, et al. Superplasticity of silicon carbide [J]. Journal of the American Ceramic Society, 1999, 82(10): 2916–2918. doi: 10.1111/J.1151-2916.1999.TB02178.X [196] WANANURUKSAWONG R, SHINODA Y, AKATSU T, et al. High-strain-rate superplasticity in nanocrystalline silicon nitride ceramics under compression [J]. Scripta Materialia, 2015, 103: 22–25. doi: 10.1016/j.scriptamat.2015.02.028 [197] ZHANG J Y, SHA Z D, BRANICIO P S, et al. Superplastic nanocrystalline ceramics at room temperature and high strain rates [J]. Scripta Materialia, 2013, 69(7): 525–528. doi: 10.1016/j.scriptamat.2013.06.017 [198] NANDI P K, ANNAMAREDDY V A, EAPEN J. Role of CSL boundaries on displacement cascades in β-SiC [J]. MRS Online Proceedings Library, 2013, 1514: 43–48. doi: 10.1557/opl.2013.61 [199] SUN L G, HE X Q, LU J. Nanotwinned and hierarchical nanotwinned metals: a review of experimental, computational and theoretical efforts [J]. NJP Computational Materials, 2018, 4(1): 6. doi: 10.1038/s41524-018-0062-2 [200] LU K, LU L, SURESH S. Strengthening materials by engineering coherent internal boundaries at the nanoscale [J]. Science, 2009, 324(5925): 349–352. doi: 10.1126/science.1159610 [201] LU L, SHEN Y F, CHEN X H, et al. Ultrahigh strength and high electrical conductivity in copper [J]. Science, 2004, 304(5669): 422–426. doi: 10.1126/science.1092905 [202] LI X Y, YIN S, OH S H, et al. Hardening and toughening mechanisms in nanotwinned ceramics [J]. Scripta Materialia, 2017, 133: 105–112. doi: 10.1016/j.scriptamat.2017.02.003 [203] AN Q, GODDARD Ⅲ W A, XIE K Y, et al. Superstrength through nanotwinning [J]. Nano Letters, 2016, 16(12): 7573–7579. doi: 10.1021/acs.nanolett.6b03414 [204] AN Q, GODDARD Ⅲ W A. Nanotwins soften boron-rich boron carbide (B13C2) [J]. Applied Physics Letters, 2017, 110(11): 111902. doi: 10.1063/1.4978644 [205] KUNKA C, AN Q, RUDAWSKI N, et al. Nanotwinning and amorphization of boron suboxide [J]. Acta Materialia, 2018, 147: 195–202. doi: 10.1016/j.actamat.2018.01.048 [206] KUNKA C, YANG X K, AN Q, et al. Icosahedral superstrength at the nanoscale [J]. Physical Review Materials, 2018, 2(6): 063606. doi: 10.1103/PhysRevMaterials.2.063606 [207] LI G D, AYDEMIR U, MOROZOV S I, et al. Superstrengthening Bi2Te3 through Nanotwinning [J]. Physical Review Letters, 2017, 119(8): 085501. doi: 10.1103/PhysRevLett.119.085501 [208] LI G D, MOROZOV S I, ZHANG Q J, et al. Enhanced strength through nanotwinning in the thermoelectric semiconductor InSb [J]. Physical Review Letters, 2017, 119(21): 215503. doi: 10.1103/PhysRevLett.119.215503 [209] LI G D, AN Q, MOROZOV S I, et al. Mechanical softening of thermoelectric semiconductor Mg2Si from nanotwinning [J]. Scripta Materialia, 2018, 157: 90–94. doi: 10.1016/j.scriptamat.2018.08.002 [210] WU R B, ZHOU K, YUE C Y, et al. Recent progress in synthesis, properties and potential applications of SiC nanomaterials [J]. Progress in Materials Science, 2015, 72: 1–60. doi: 10.1016/j.pmatsci.2015.01.003 [211] LIN Z J, WANG L, ZHANG J Z, et al. Nanoscale twinning-induced elastic strengthening in silicon carbide nanowires [J]. Scripta Materialia, 2010, 63(10): 981–984. doi: 10.1016/j.scriptamat.2010.07.023 [212] WANG D H, XU D, WANG Q, et al. Periodically twinned SiC nanowires [J]. Nanotechnology, 2008, 19(21): 215602. doi: 10.1088/0957-4484/19/21/215602 [213] HUANG Q, YU D L, XU B, et al. Nanotwinned diamond with unprecedented hardness and stability [J]. Nature, 2014, 510(7504): 250–253. doi: 10.1038/nature13381 [214] HUANG C, PENG X H, YANG B, et al. Molecular dynamics simulations for responses of nanotwinned diamond films under nanoindentation [J]. Ceramics International, 2017, 43(18): 16888–16894. doi: 10.1016/j.ceramint.2017.09.089 [215] CHAVOSHI S Z, XU S Z. Twinning effects in the single/nanocrystalline cubic silicon carbide subjected to nanoindentation loading [J]. Materialia, 2018, 3: 304–325. doi: 10.1016/J.MTLA.2018.09.003 [216] CHAVOSHI S Z, TSCHOPP M A, BRANICIO P S. Transition of deformation mechanisms in nanotwinned single crystalline SiC [J]. Philosophical Magazine, 2019, 99(21): 2636–2660. doi: 10.1080/14786435.2019.1637033 [217] WANG G J, LUO B Q, ZHANG X P, et al. A 4 MA, 500 ns pulsed power generator CQ-4 for characterization of material behaviors under ramp wave loading [J]. Review of Scientific Instruments, 2013, 84(1): 015117. doi: 10.1063/1.4788935 [218] WANG G, ZHAO J, ZHANG H, et al. Advances in quasi-isentropic compression experiments at institute of fluid physics of CAEP [J]. The European Physical Journal Special Topics, 2012, 206(1): 163–172. doi: 10.1140/epjst/e2012-01597-y [219] 薛全喜, 江少恩, 王哲斌, 等. 基于神光Ⅲ原型装置开展的激光直接驱动准等熵压缩研究进展 [J]. 物理学报, 2018, 67(4): 045202. doi: 10.7498/aps.67.20172159XUE Q X, JIANG S E, WANG Z B, et al. Progress of laser-driven quasi-isentropic compression study performed on SHENGUANG Ⅲ prototype laser facility [J]. Acta Physica Sinica, 2018, 67(4): 045202. doi: 10.7498/aps.67.20172159 [220] SMITH R, ASAY J, COLLINS G. Laser driven quasi-isentropic compression experiments (ICE) for extracting EOS and phase transition information [C]//Proceedings of the 14th APS Topical Conference on Shock Compression of Condensed Matter. Baltimore, USA: American Physical Society, 2005. [221] AMADOU N, BRAMBRINK E, BENUZZI-MOUNAIX A, et al. Laser-driven quasi-isentropic compression experiments and numerical studies of the iron alpha-epsilon transition in the context of planetology [J]. AIP Conference Proceedings, 2012, 1426(1): 1525–1528. doi: 10.1063/1.3686573 [222] 种涛, 谭福利, 王桂吉, 等. 磁驱动斜波加载下铋的Ⅰ-Ⅱ-Ⅲ相变实验 [J]. 高压物理学报, 2018, 32(5): 051101. doi: 10.11858/gywlxb.20180511CHONG T, TAN F L, WANG G J, et al. Ⅰ-Ⅱ-Ⅲ phase transition of bismuth under magnetically driven ramp wave loading [J]. Chinese Journal of High Pressure Physics, 2018, 32(5): 051101. doi: 10.11858/gywlxb.20180511 [223] 种涛. 斜波加载下铋、锡等典型金属材料的相变动力学研究 [D]. 合肥: 中国科学技术大学, 2018.CHONG T. Study on kinetics of phase transition of metal under ramp wave loading [D]. Hefei: University of Science and Technology of China, 2018. [224] 种涛, 王桂吉, 谭福利, 等. 磁驱动准等熵压缩下铁的相变 [J]. 中国科学, 2014, 44(6): 630–636. doi: 10.1360/132013-378CHONG T, WANG G J, TAN F L, et al. Phase transition of iron under magnetically driven quasi-isentropic compression [J]. Scientia Sinica, 2014, 44(6): 630–636. doi: 10.1360/132013-378 [225] DAVIAU K, LEE K K M. Decomposition of silicon carbide at high pressures and temperatures [J]. Physical Review B, 2017, 96(17): 174102. doi: 10.1103/PhysRevB.96.174102 -

下载:

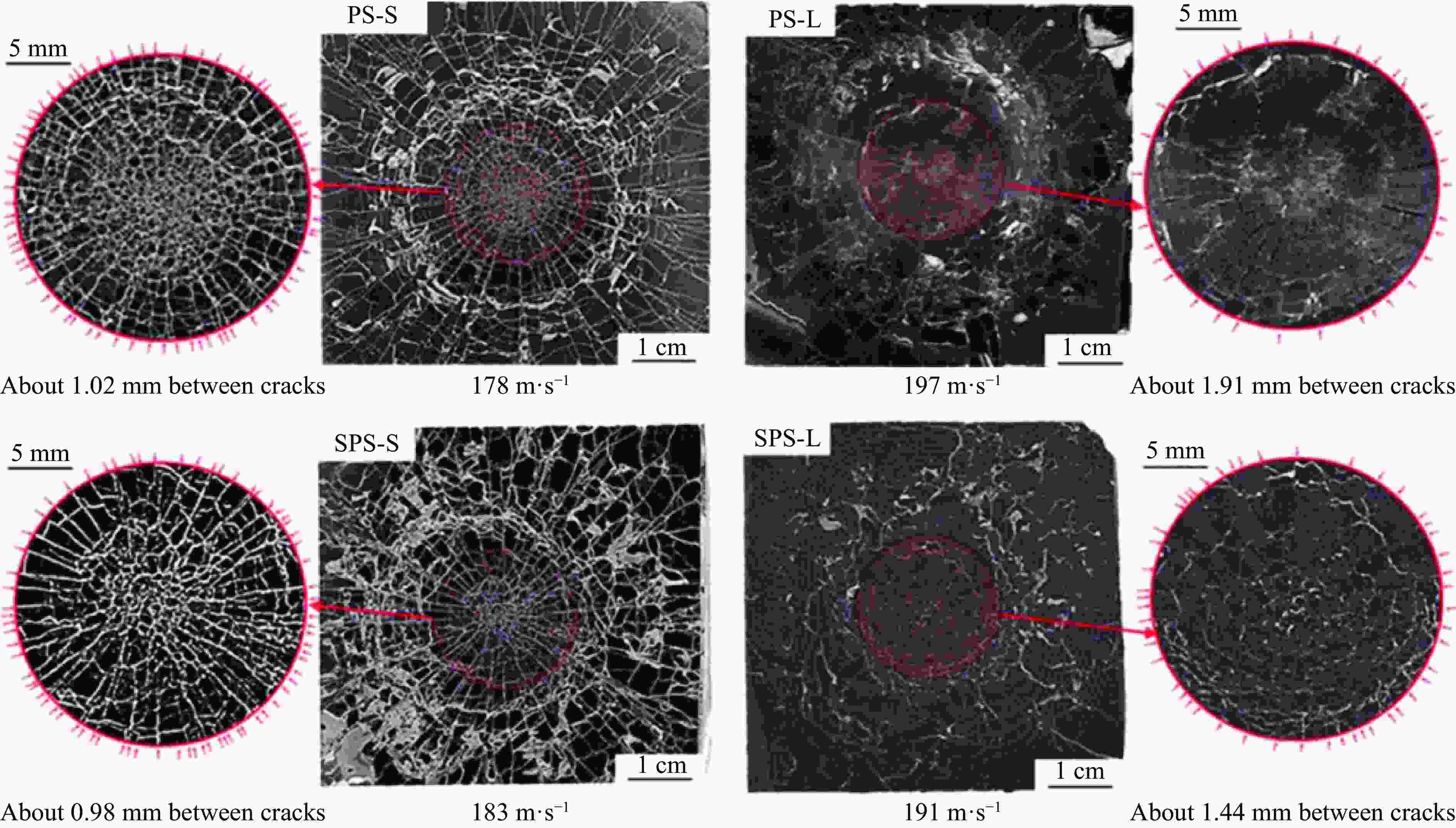

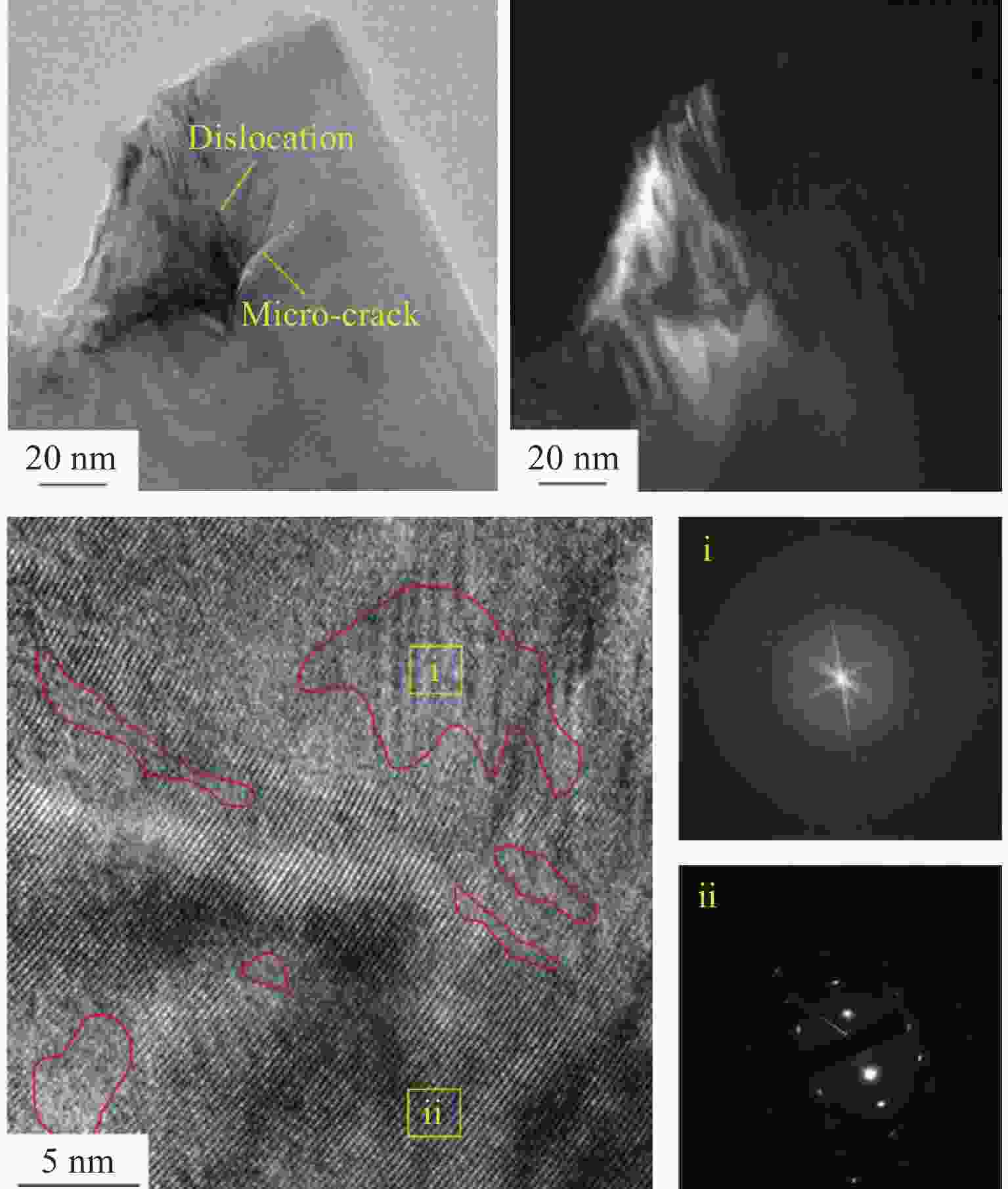

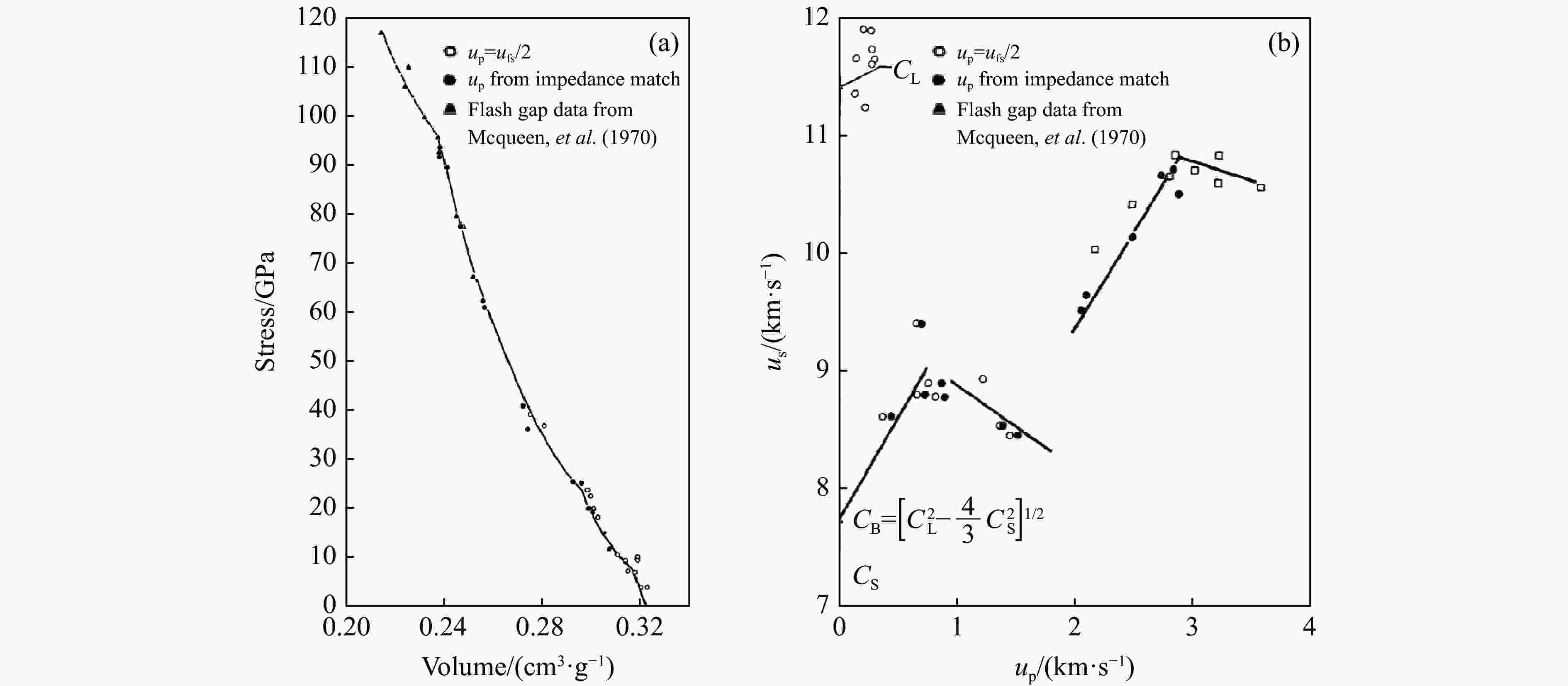

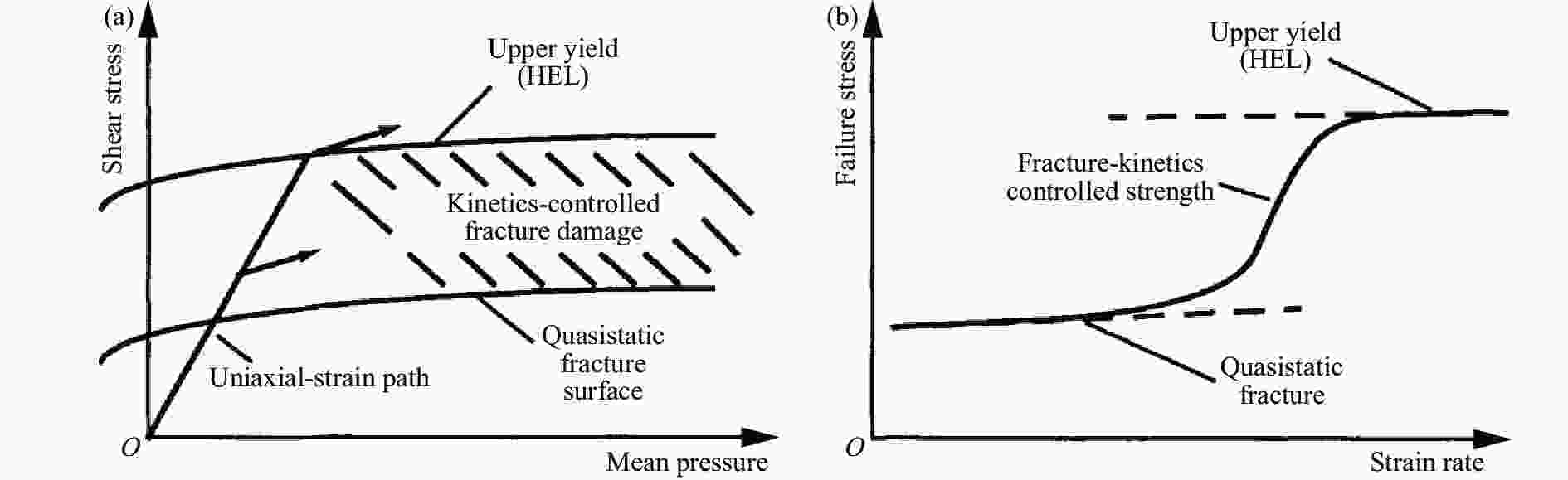

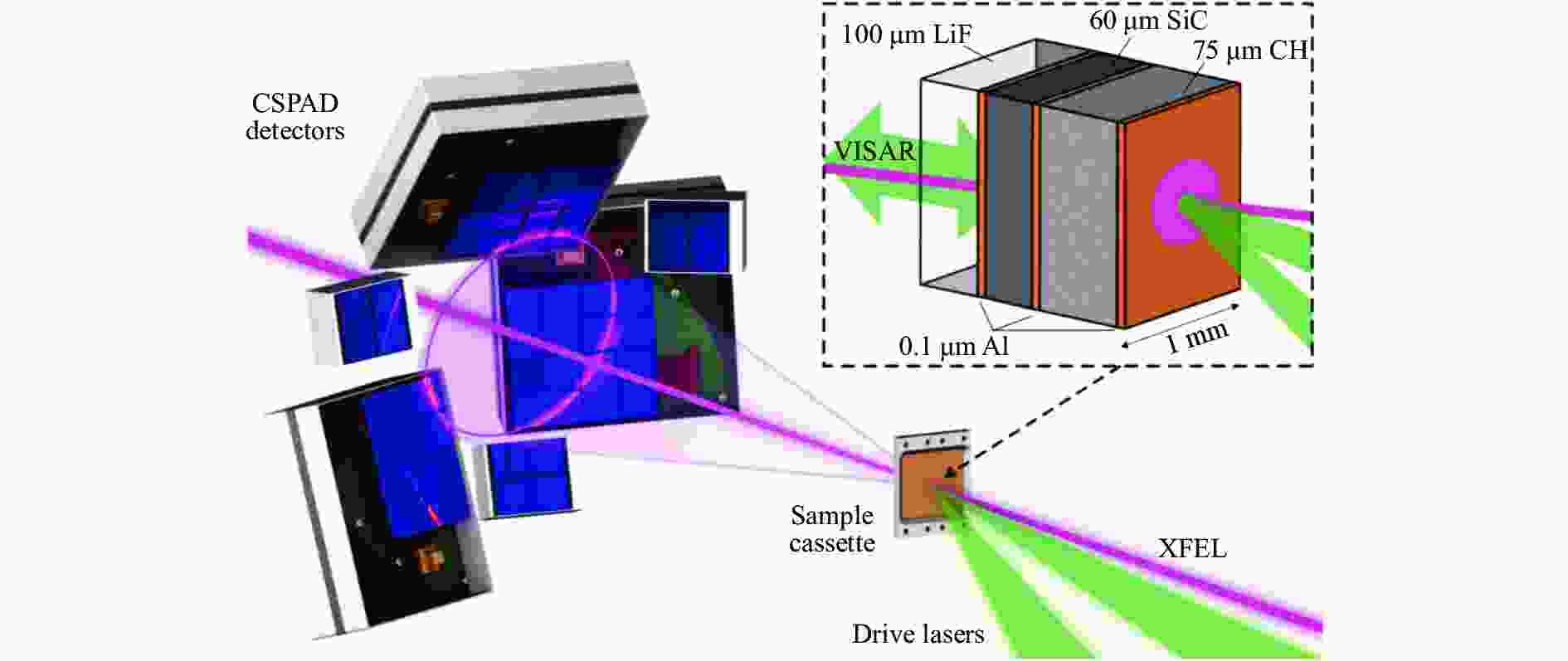

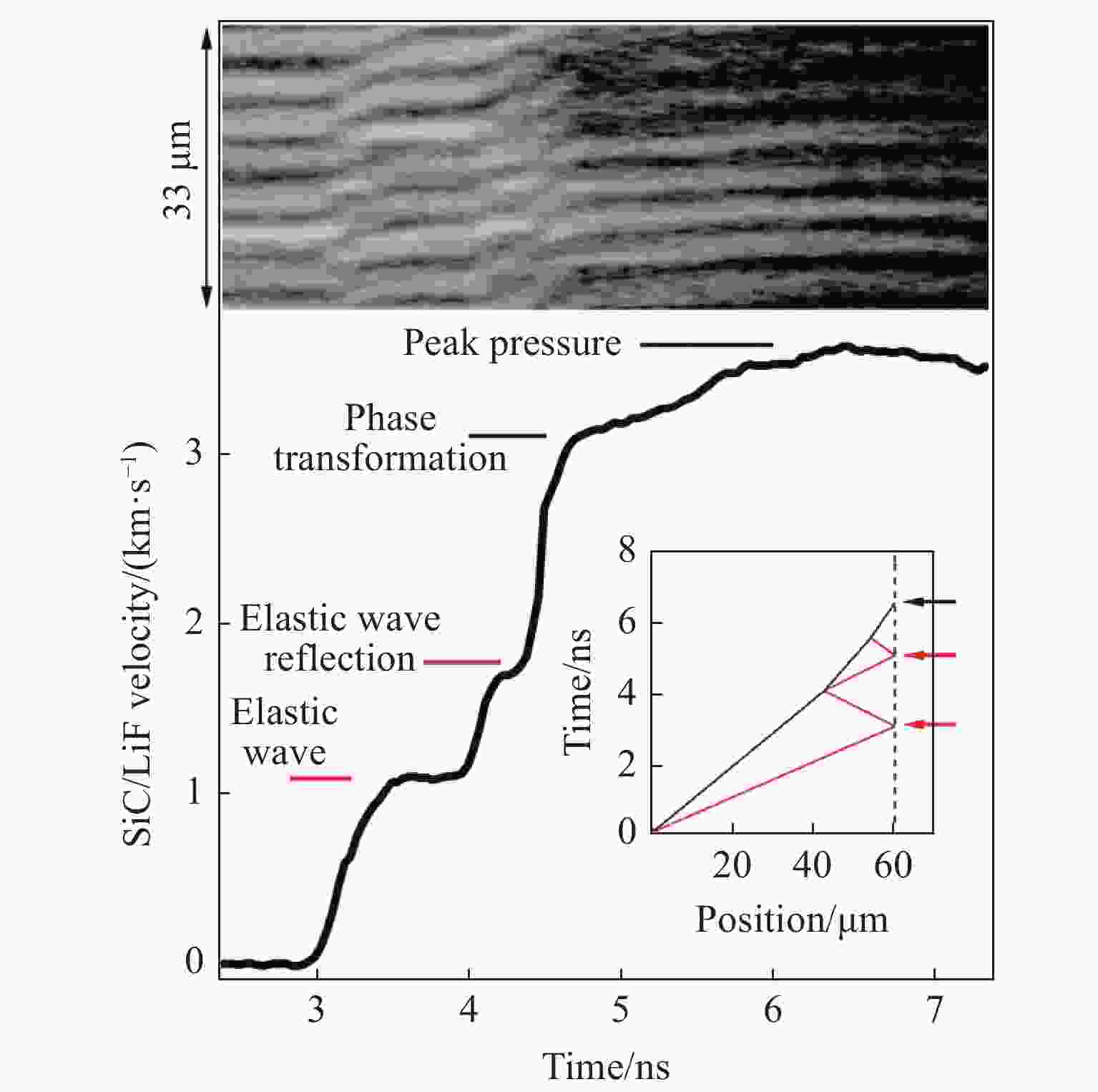

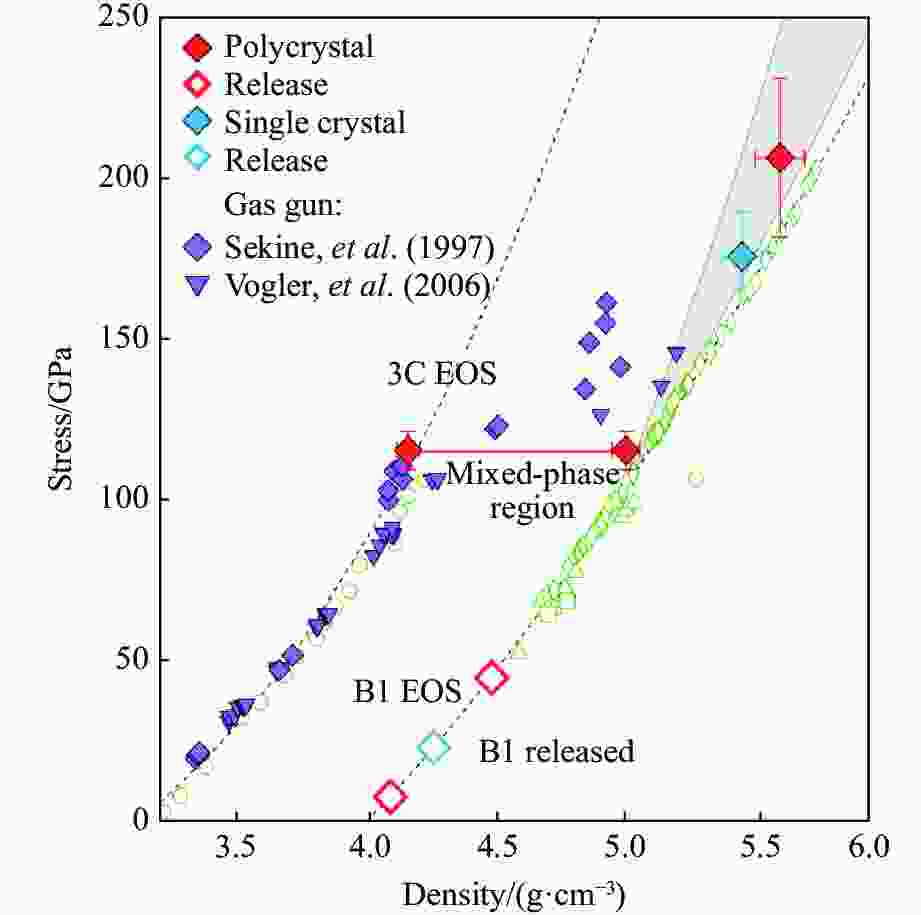

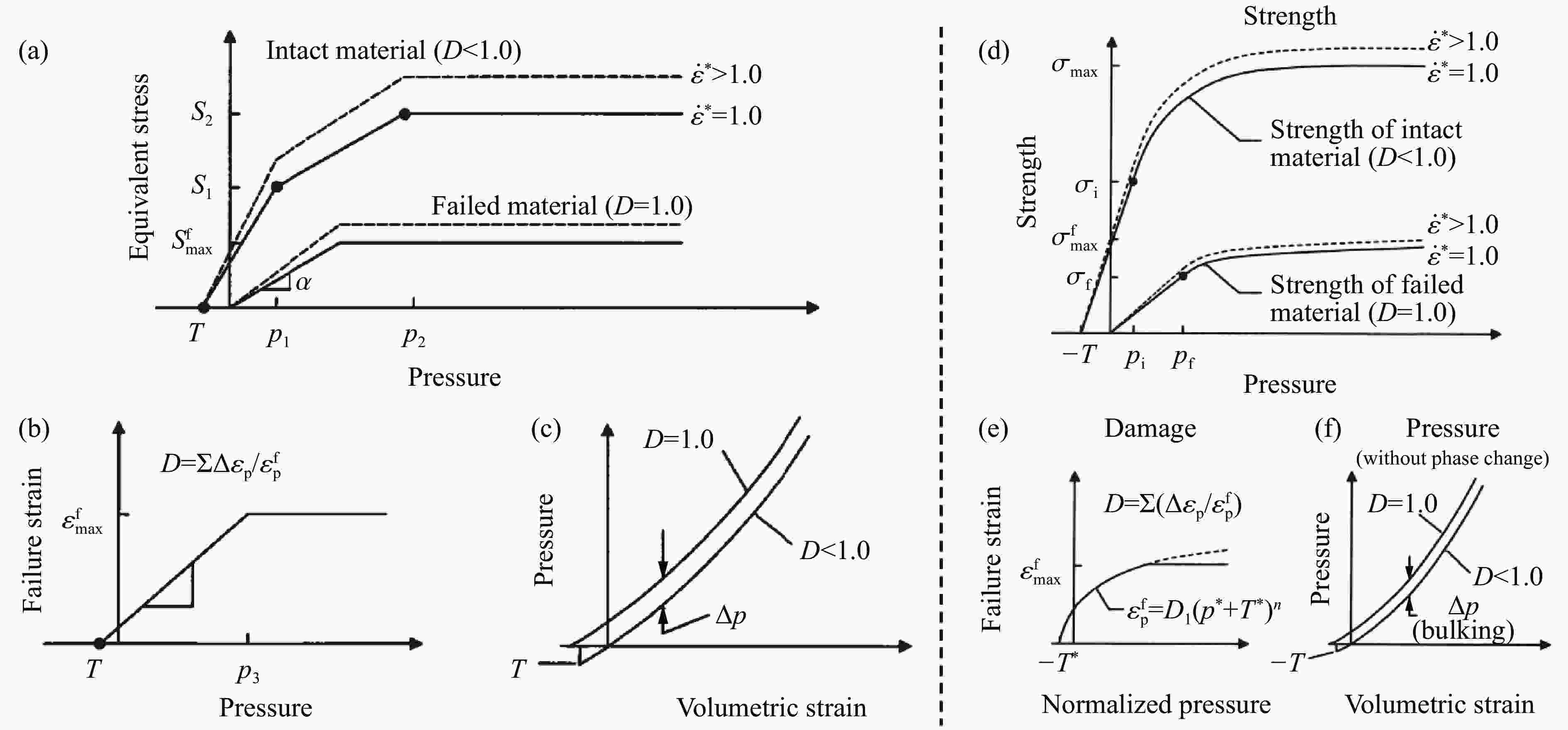

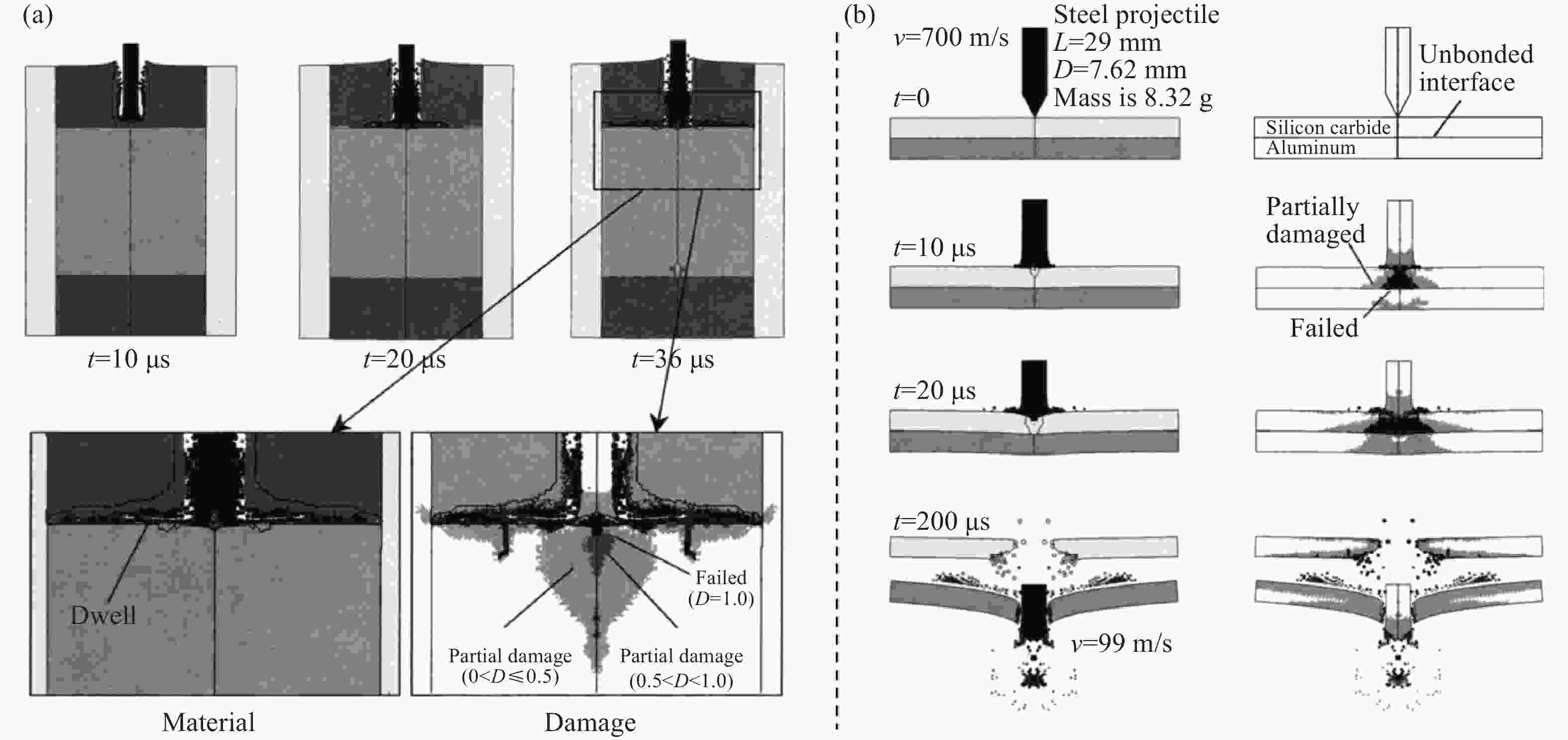

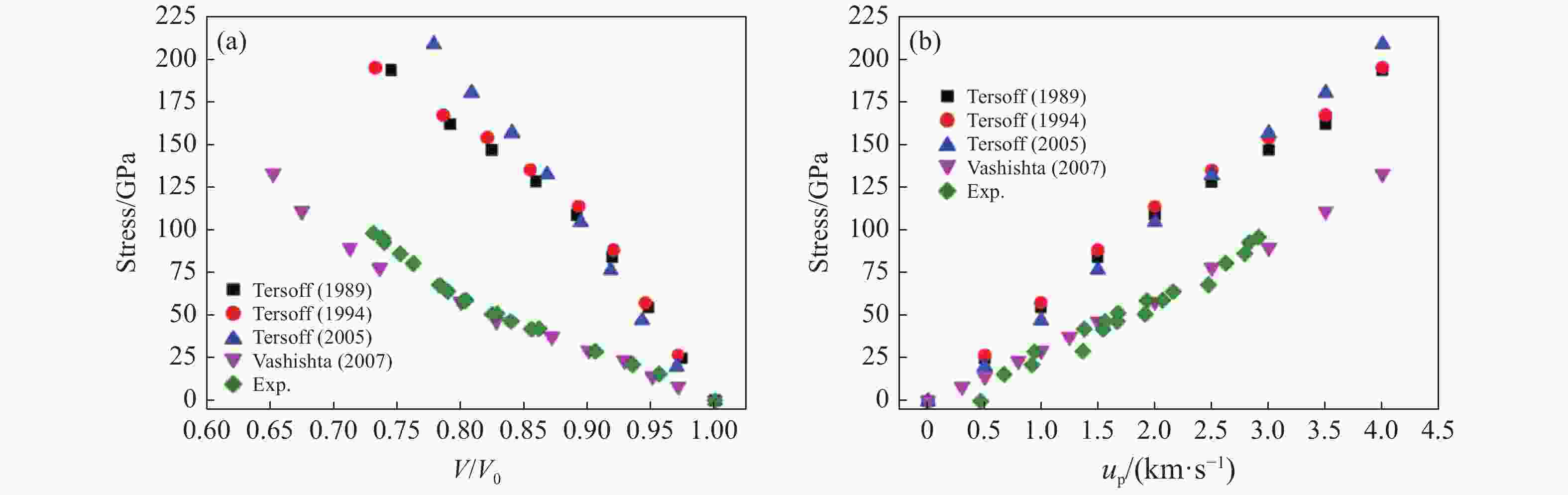

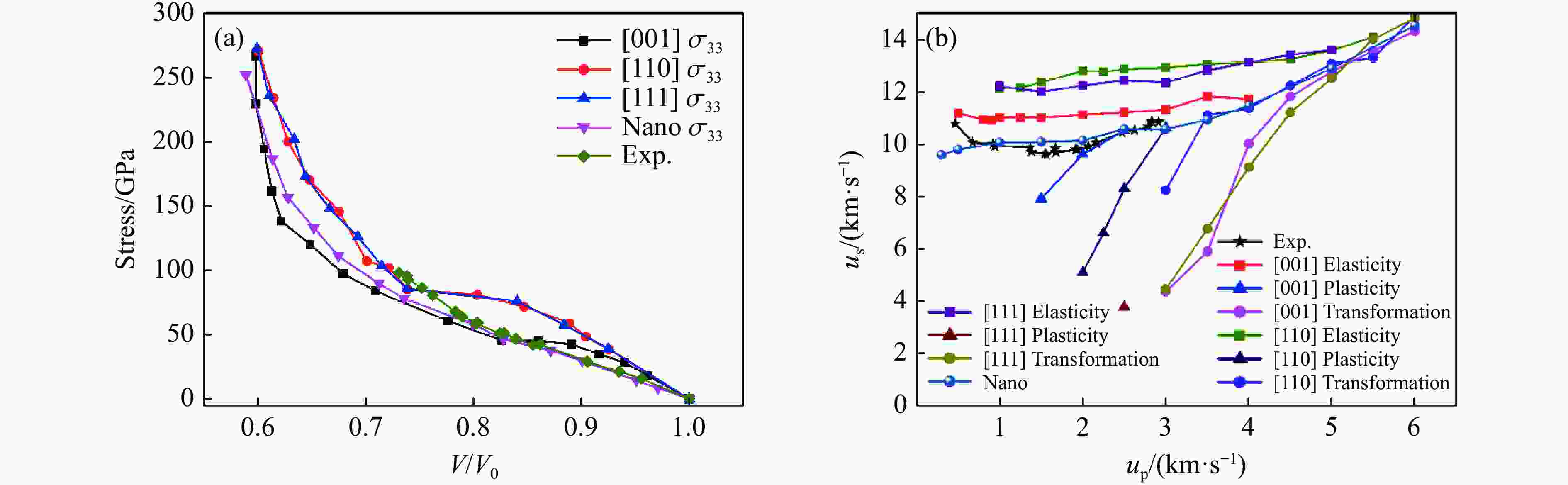

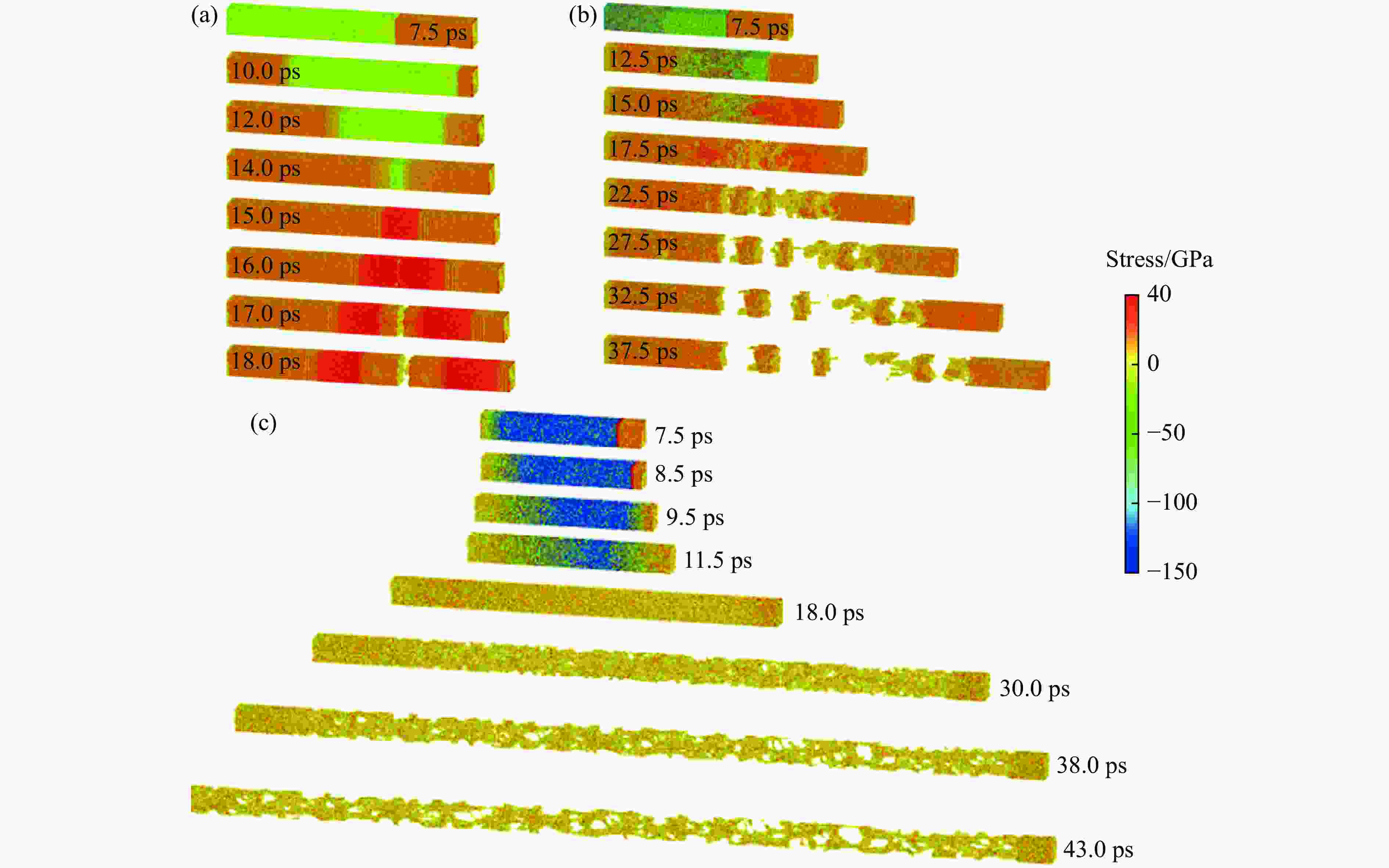

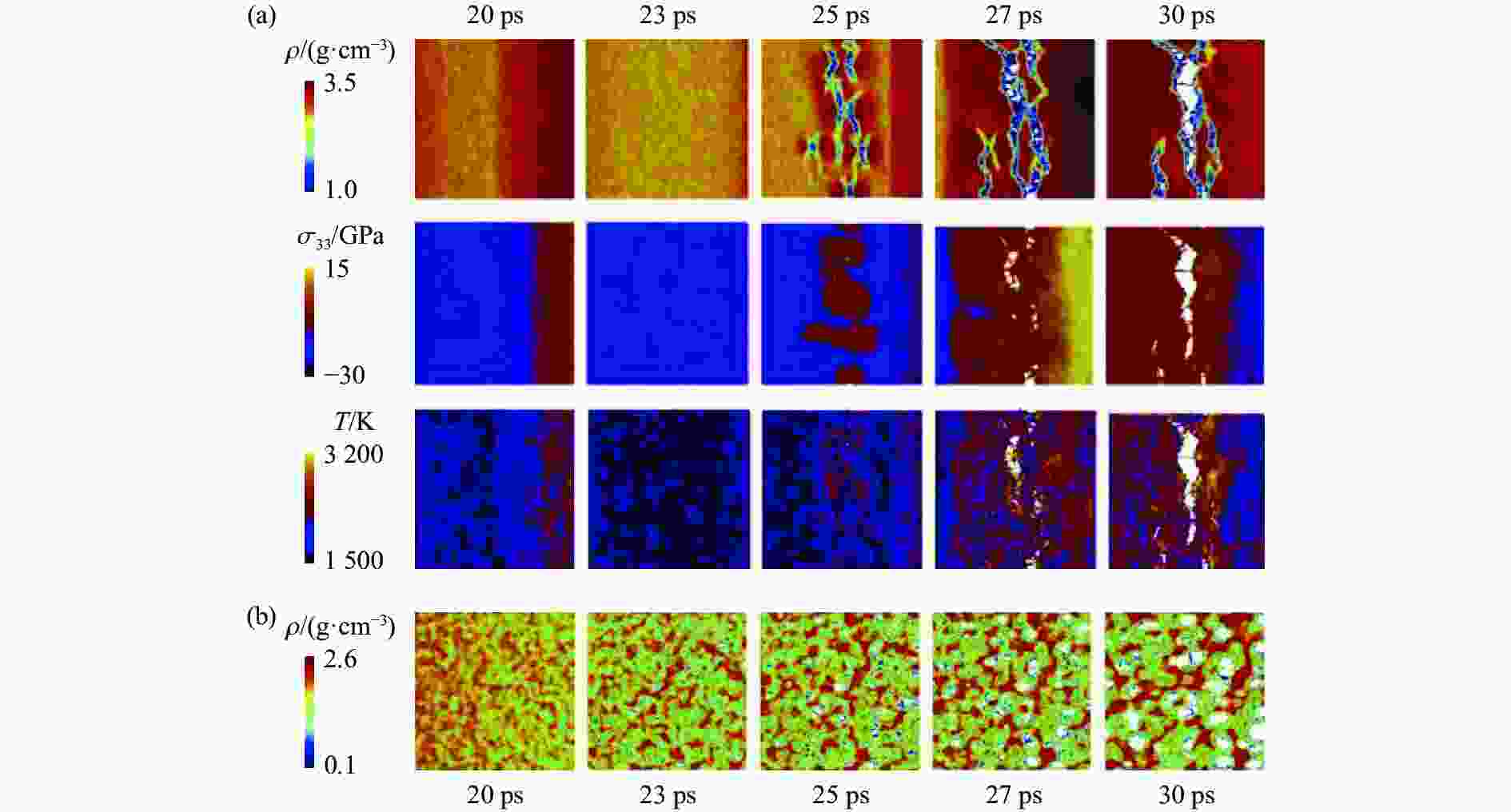

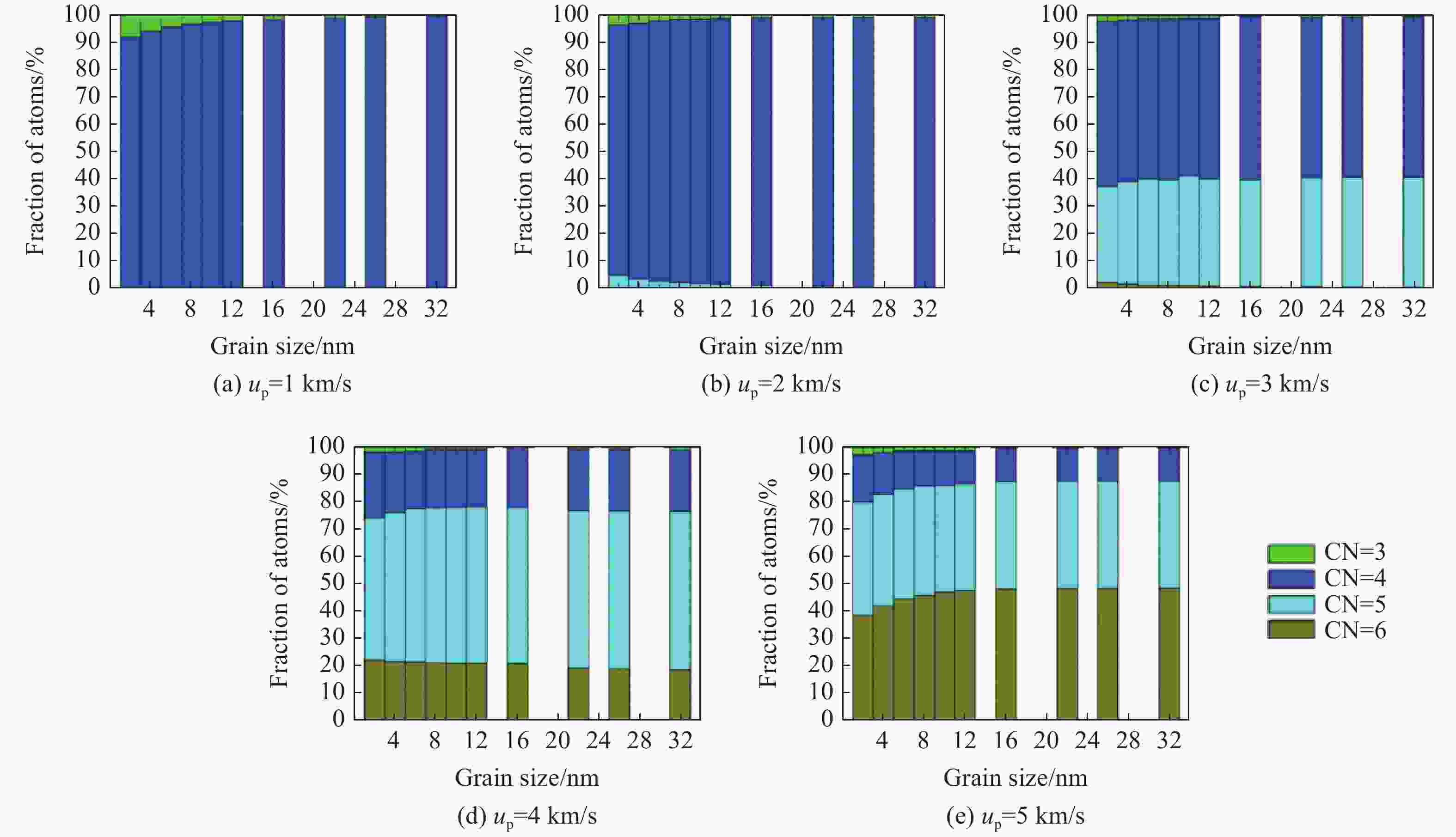

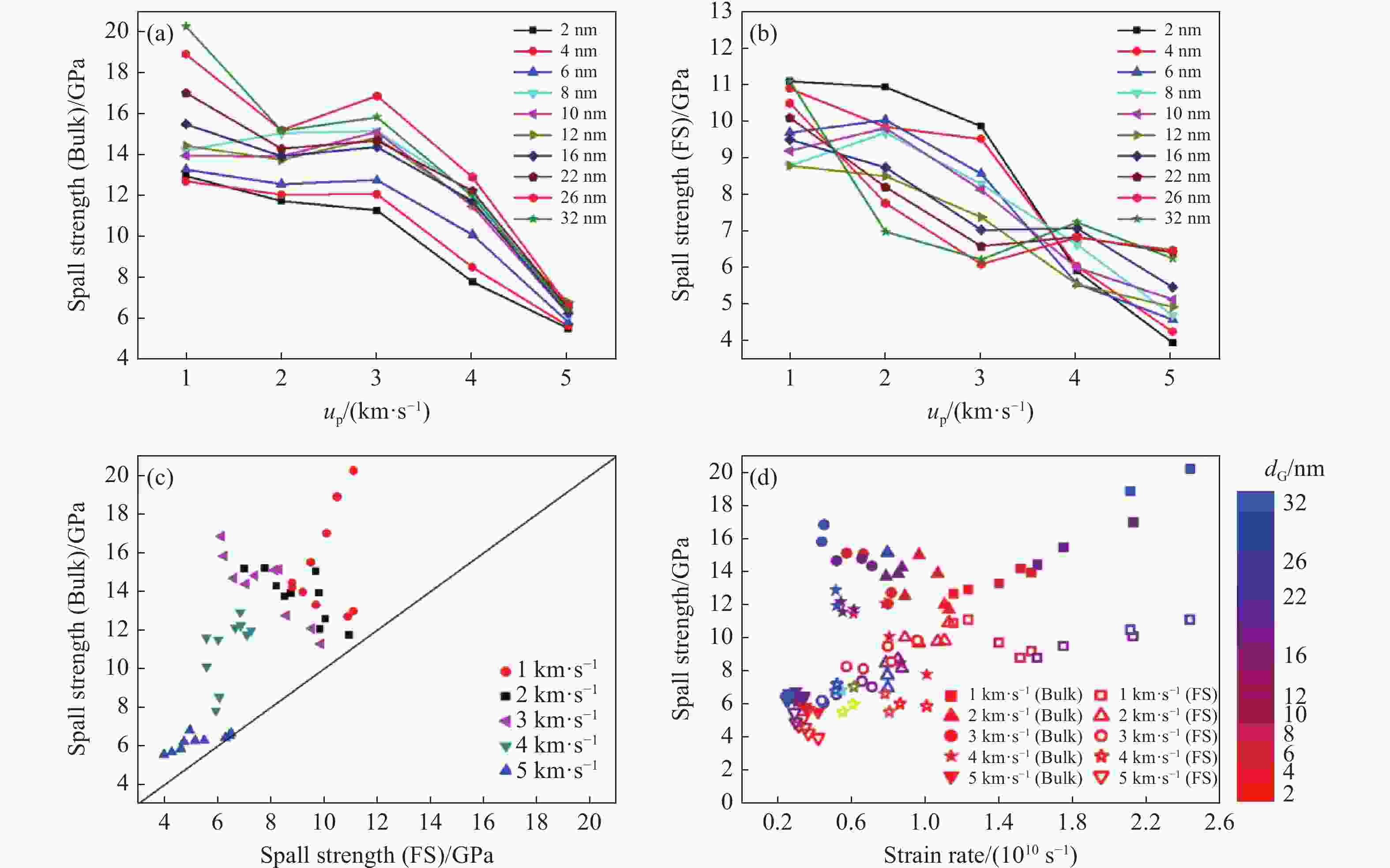

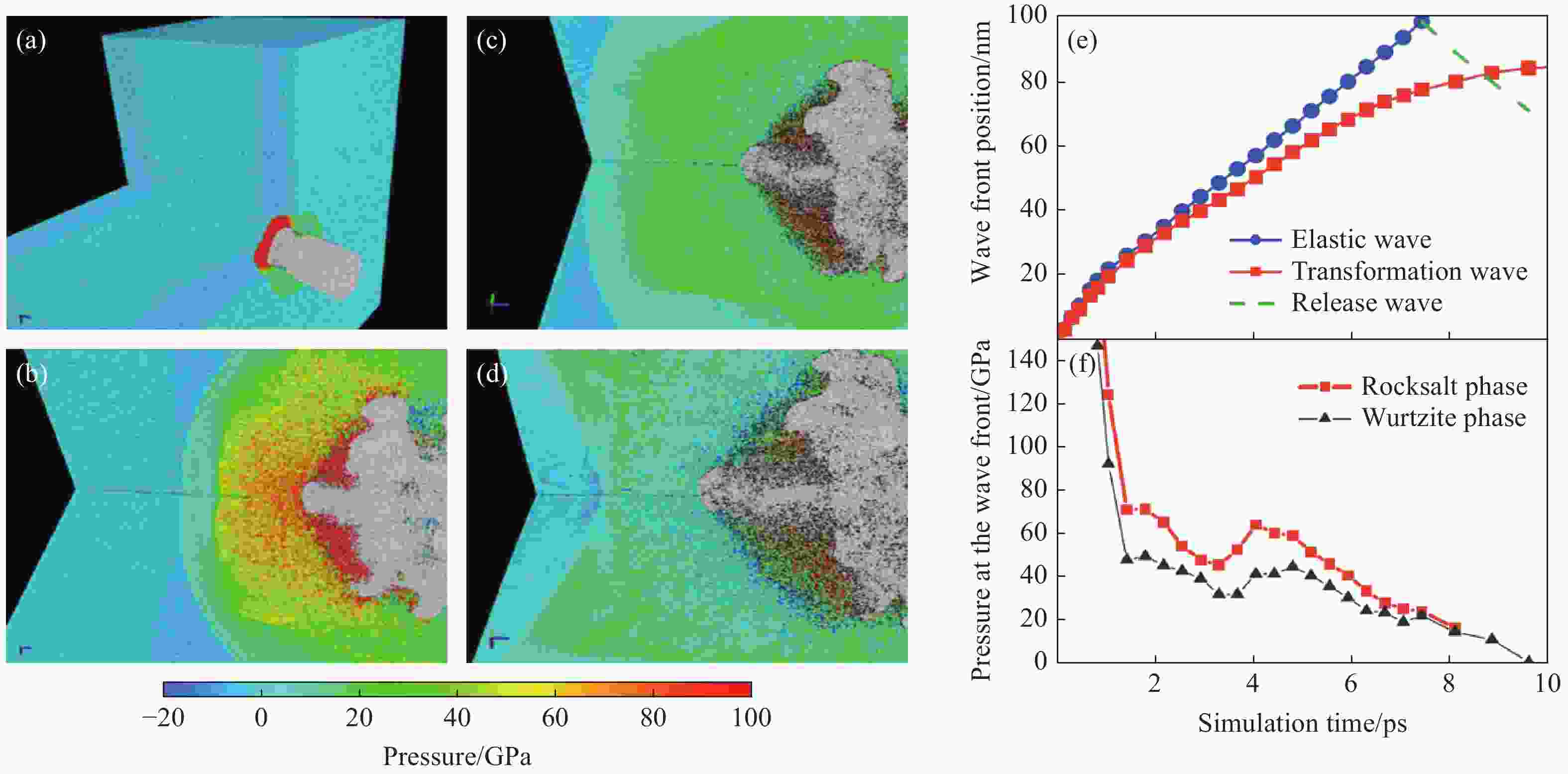

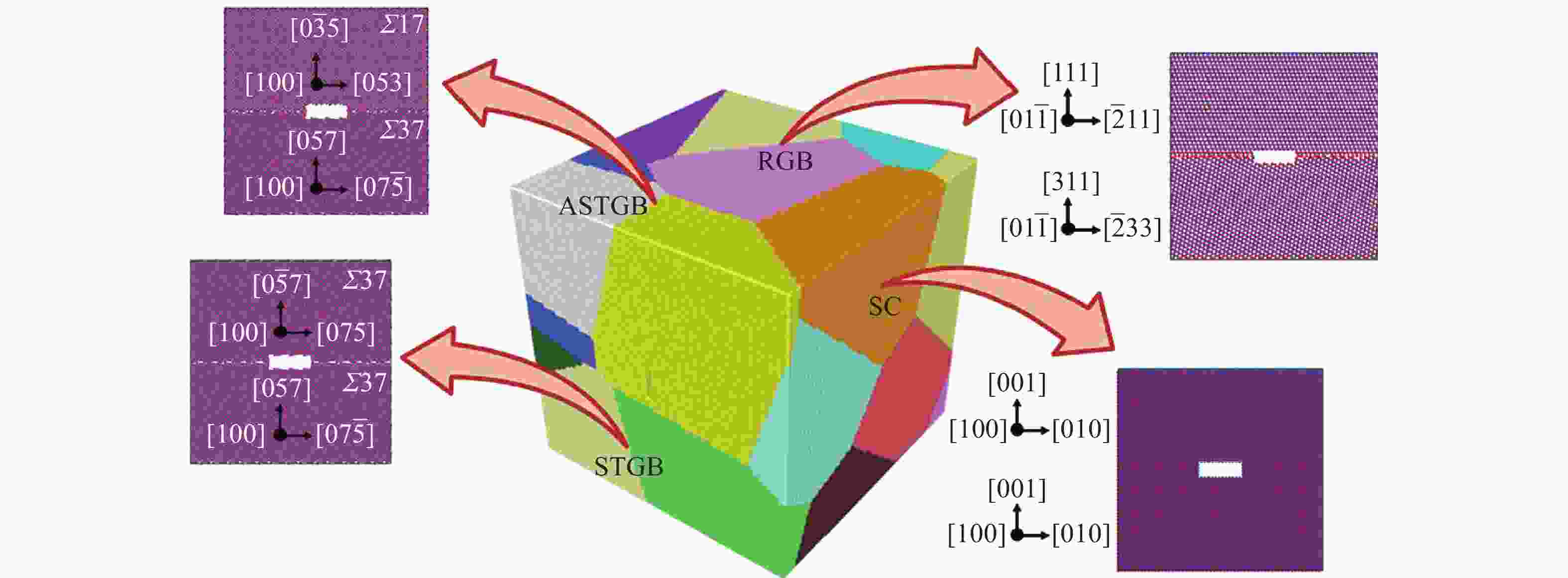

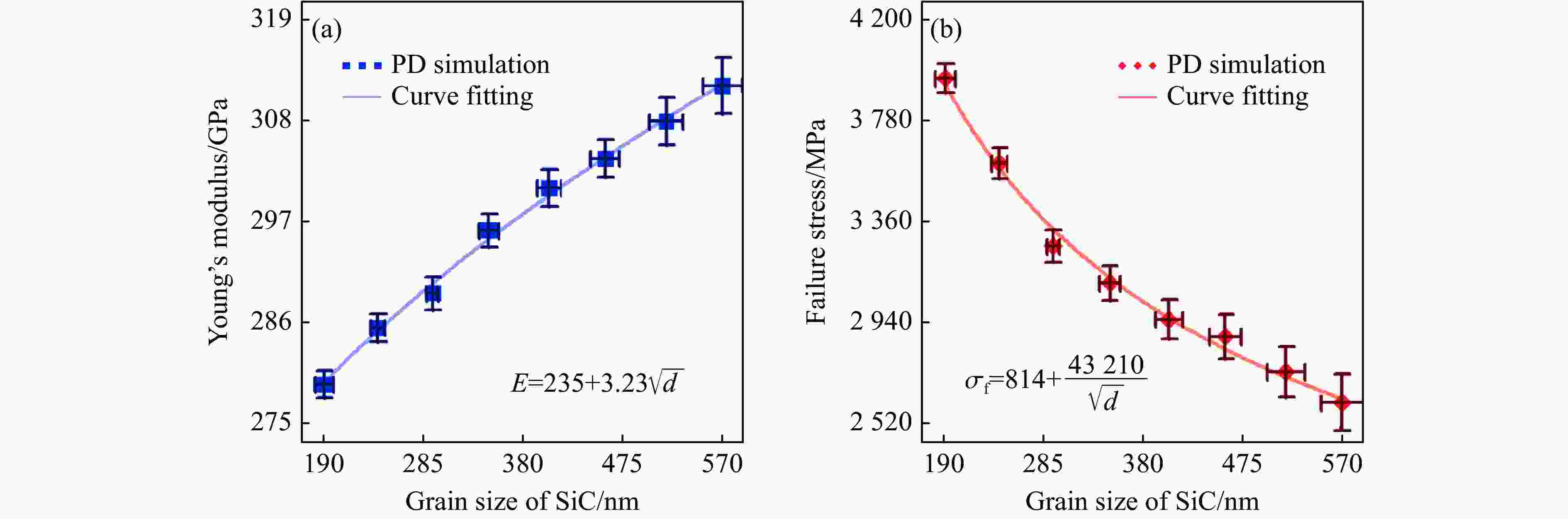

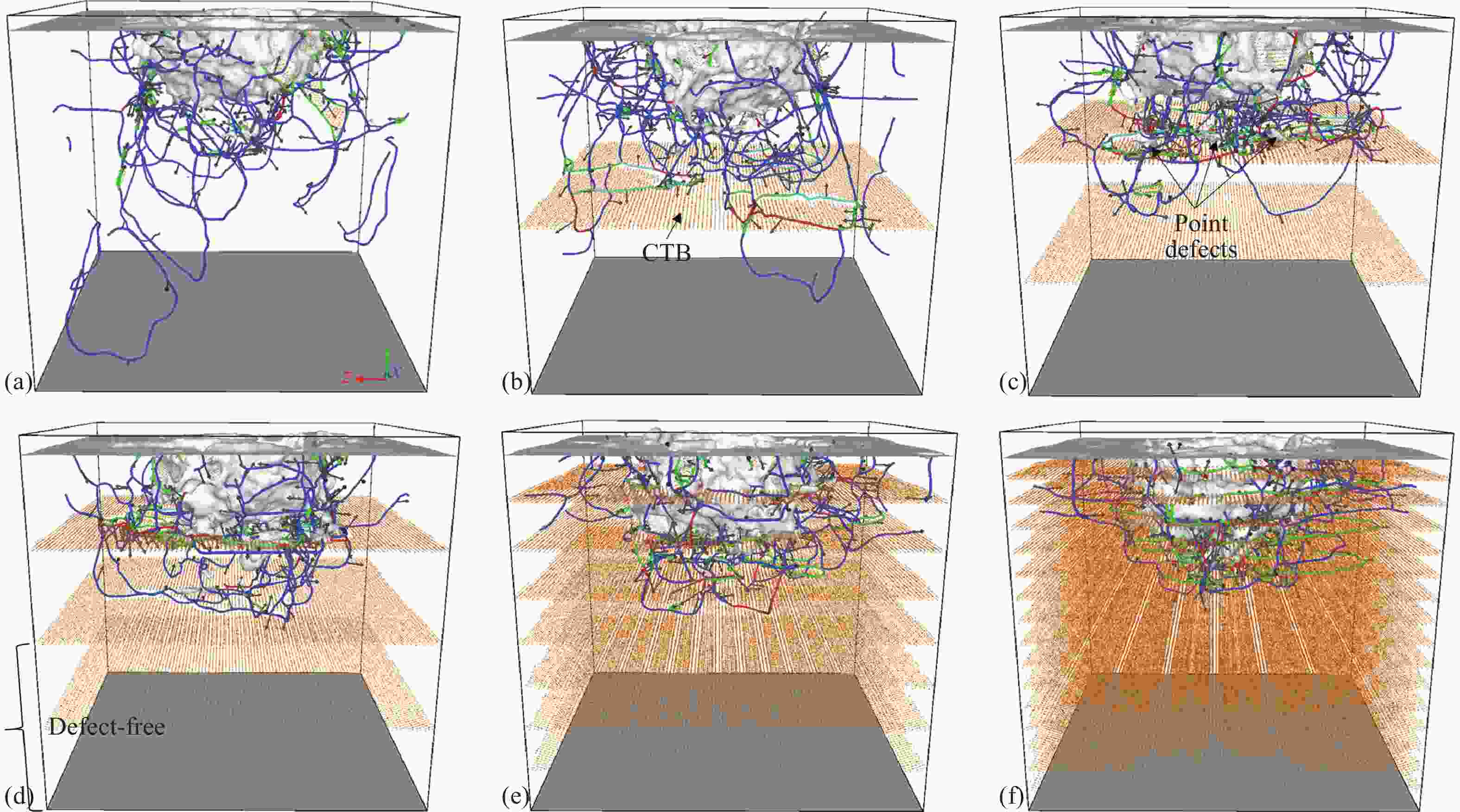

下载: