Progress in Dynamic Responses and Microstructure Evolution of the Additive Manufactured Alloys under Impact Load

-

摘要: 作为近20年来快速发展的制造技术,增材制造技术能够快速、直接制造形状复杂的零件,在工业领域得到越来越多的应用。在实际应用中,这些增材制造的零部件经常承受高速冲击载荷作用,因此其动态承载能力及破坏失效特征是人们关注的焦点,也给增材制造技术及其产品在国防军事、武器装备等领域的应用带来巨大挑战。首先综述增材制造技术的原理和特点;然后着重介绍在高速冲击等极端情况下增材制造金属零部件的宏/微观力学响应特征,探讨新的制造方法带来的金属材料动态性能的新变化;最后展望增材制造技术及产品在国防军事、武器装备等领域的发展前景。Abstract: As a rapidly developing technology in the past two decades, additive manufacturing has been widely used in industries due to its high-efficiently in manufacture, particularly for the components with complex geometry. Since these components usually subjected to high-speed impact in application, the issue of load-bearing capacity and failure characteristics becomes a major concern, also causes great challenges for the application of laser additive manufacturing technology and product development in national defense, military and weapons. In this study, the technical principles and characteristics of additive manufacturing was summarized, and then the macro/micro mechanical response of additive manufactured metallic components subjected to high-speed impact was introduced emphatically. The changes induced by the new manufacturing techniques in dynamic performance of metallic materials were explored. Lastly, the potential prospects of additive manufacturing techniques as well as the products were forecast in the field of national defense and military weapons.

-

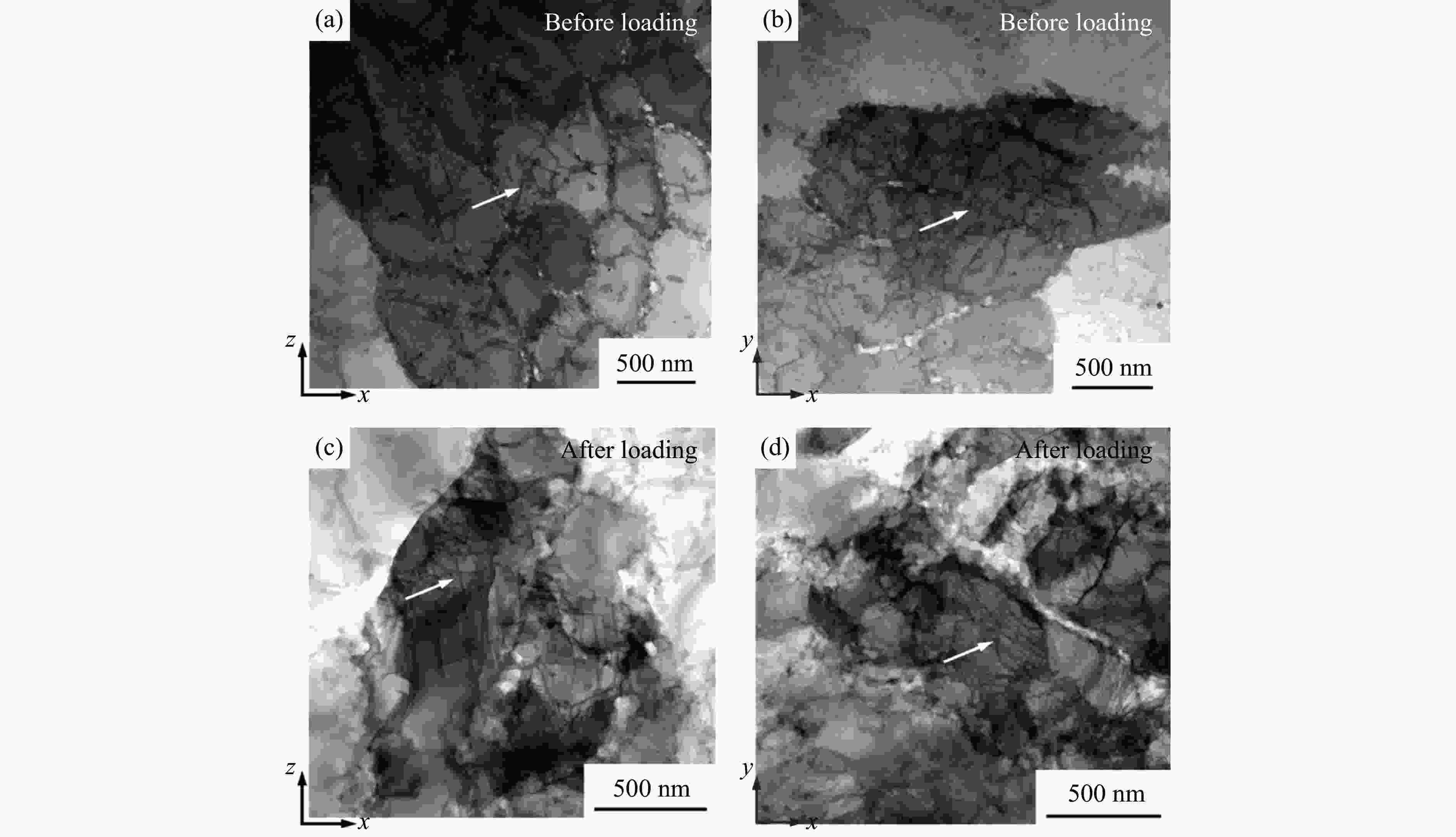

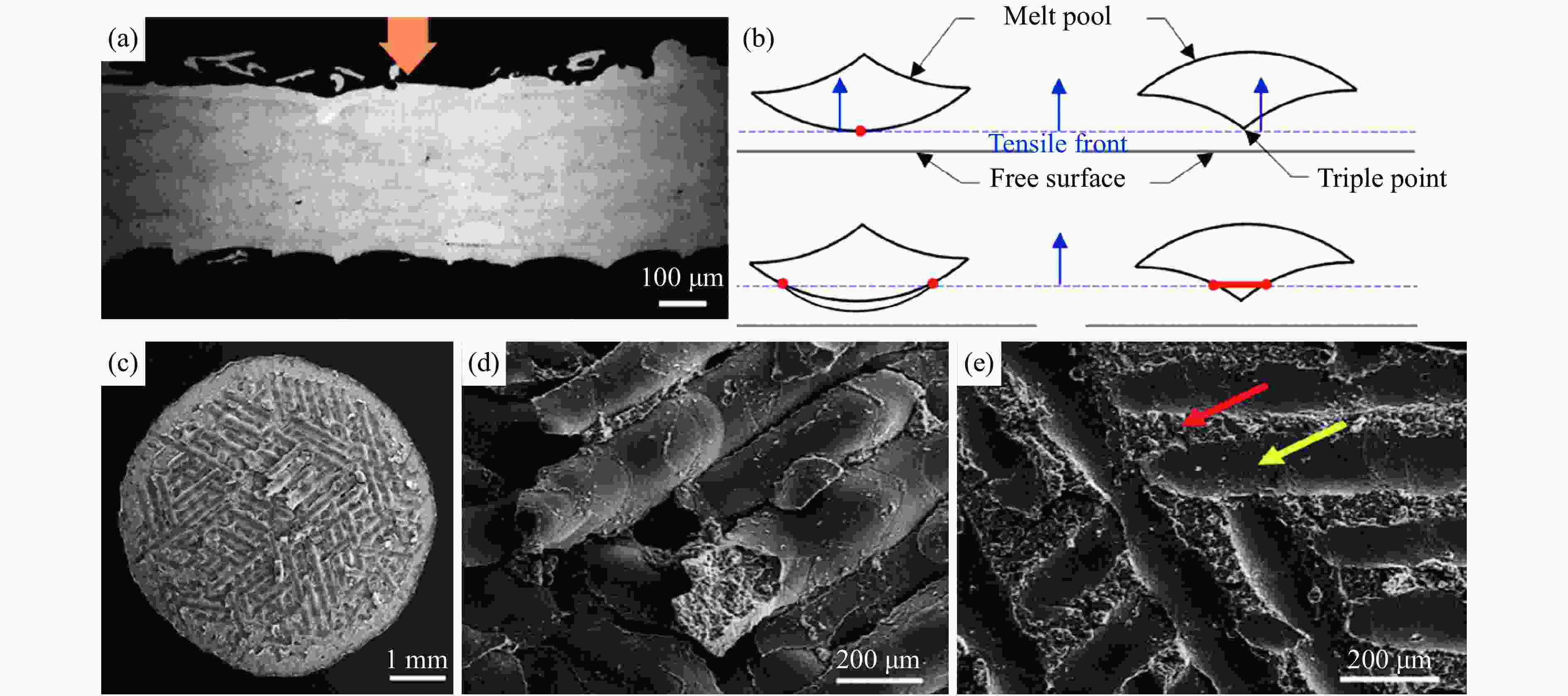

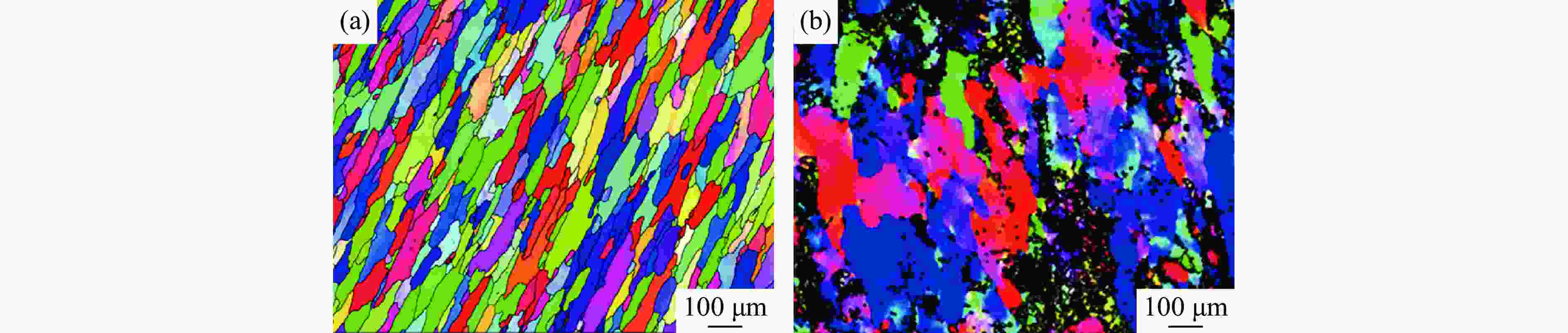

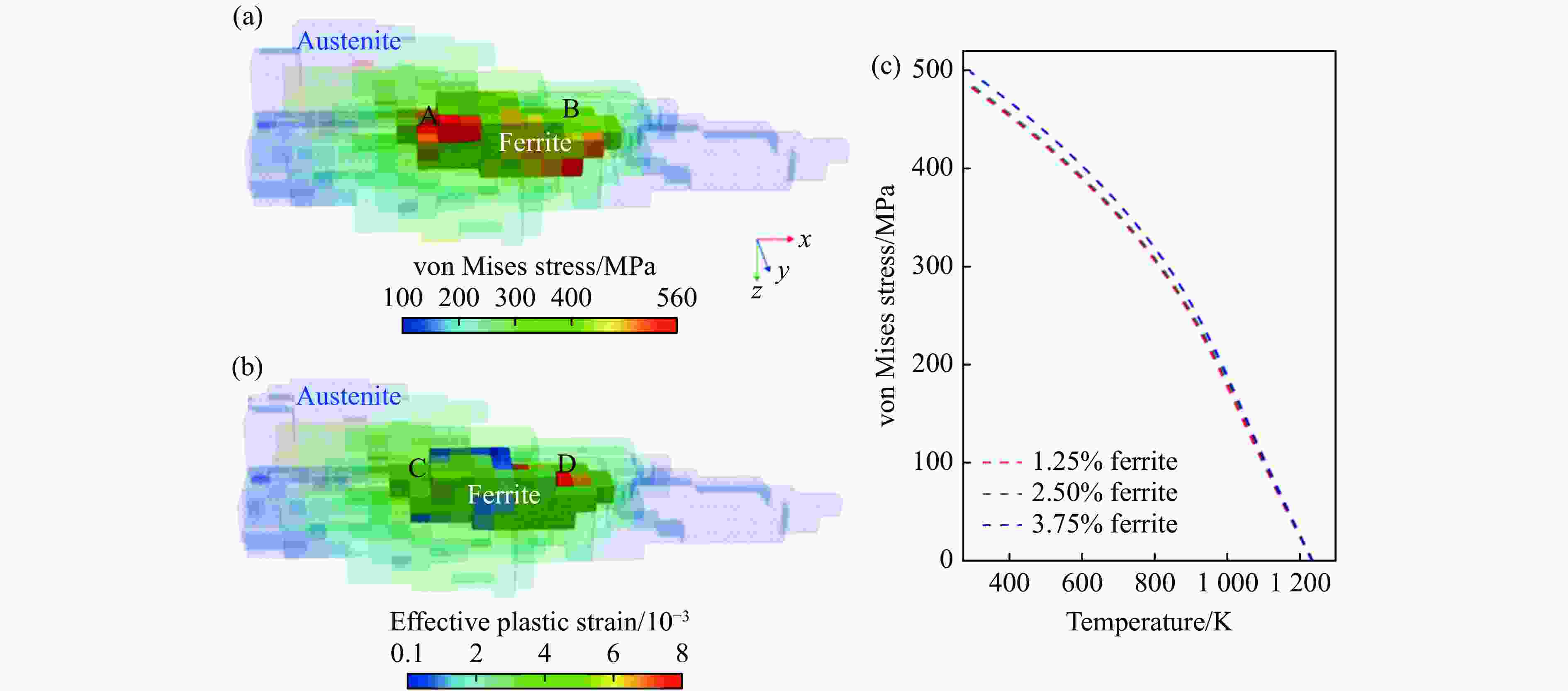

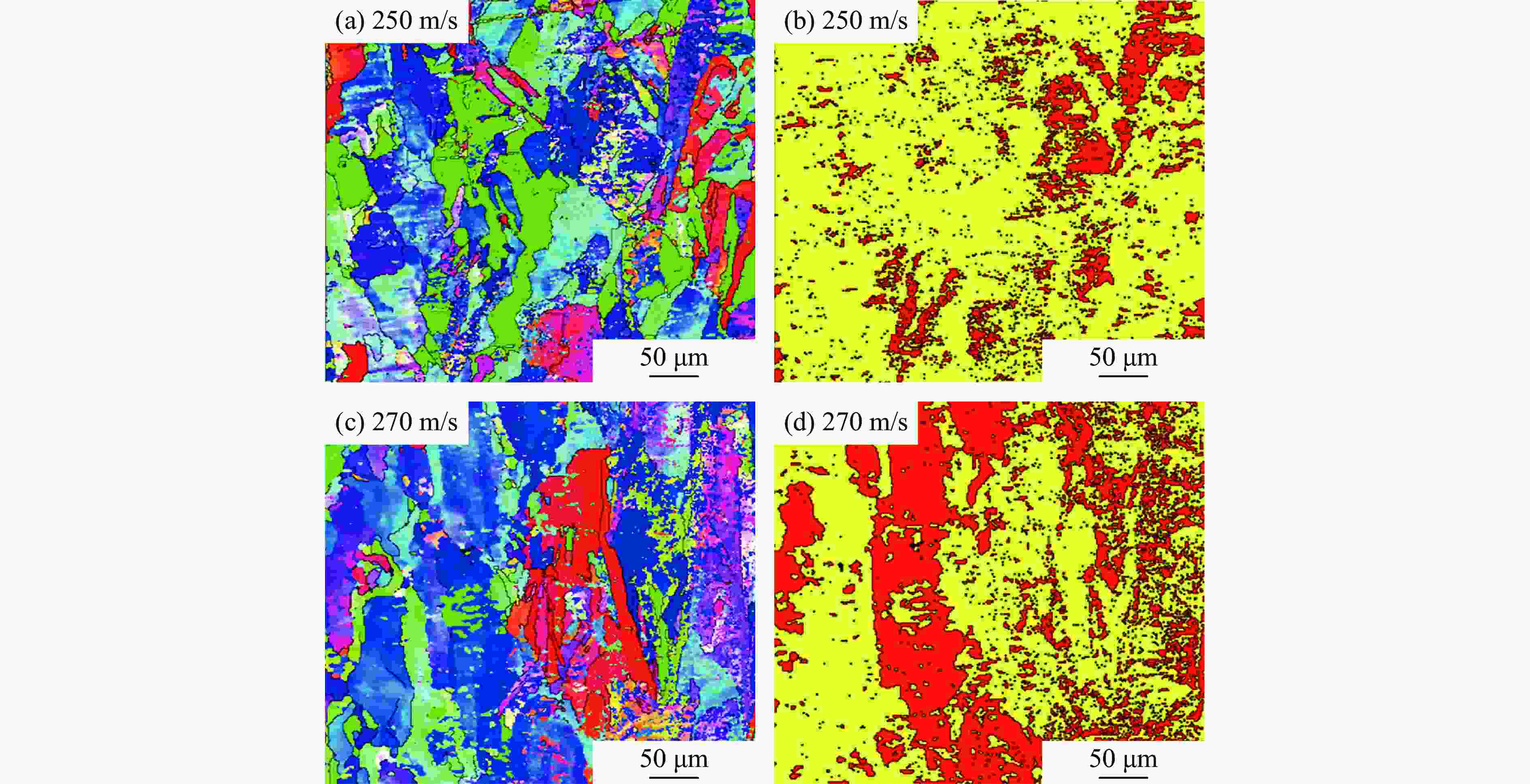

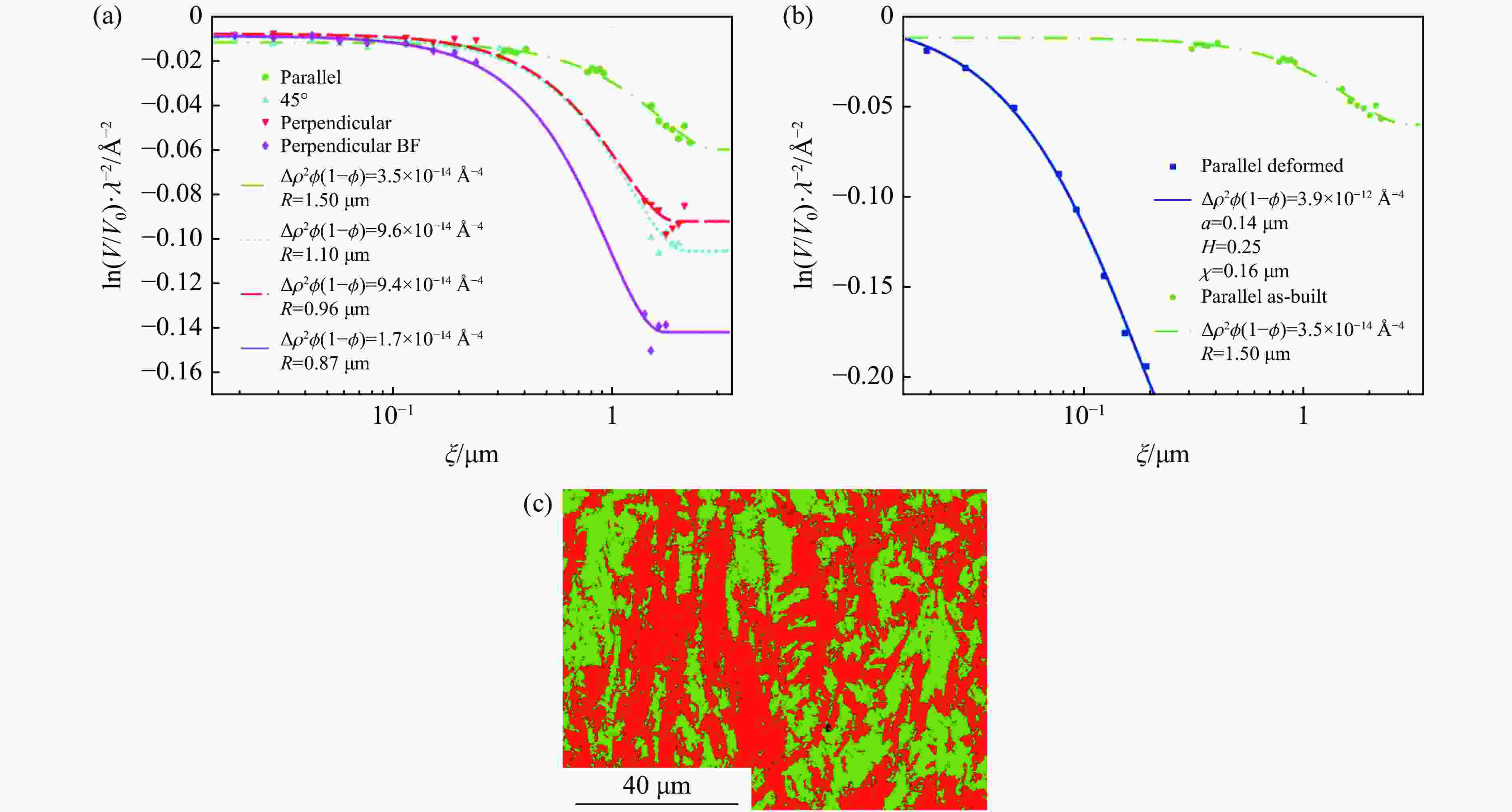

图 11 通过不同的波长组合和样品到探测器的距离获得原始样品(a)和变形样品(b)的暗场响应,以及加载后的相分布(c)(绿色代表马氏体,红色代表奥氏体)[82]

Figure 11. Measured data (points) and theoretical models (lines) assuming a random two phase medium model for the as-built (a) and deformed (b) samples, (c) phase image after impacting (Red represents austenitic phase, and green represents martensitic phase.)[82]

-

[1] SHIPLEY H, MCDONNELL D, CULLETON M, et al. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: a review [J]. International Journal of Machine Tools and Manufacture, 2018, 128: 1–20. doi: 10.1016/j.ijmachtools.2018.01.003 [2] HAN Q Q, SETCHI R, EVANS S L. Synthesis and characterisation of advanced ball-milled Al-Al2O3 nanocomposites for selective laser melting [J]. Powder Technology, 2016, 297: 183–192. doi: 10.1016/j.powtec.2016.04.015 [3] LIN K J, YUAN L H, GU D D. Influence of laser parameters and complex structural features on the bio-inspired complex thin-wall structures fabricated by selective laser melting [J]. Journal of Materials Processing Technology, 2019, 267: 34–43. doi: 10.1016/j.jmatprotec.2018.12.004 [4] LAKHDAR Y, TUCK C, BINNER J, et al. Additive manufacturing of advanced ceramic materials [J]. Progress in Materials Science, 2021, 116: 100736. doi: 10.1016/j.pmatsci.2020.100736 [5] WU H, FAHY W P, KIM S, et al. Recent developments in polymers/polymer nanocomposites for additive manufacturing [J]. Progress in Materials Science, 2020, 111: 100638. doi: 10.1016/j.pmatsci.2020.100638 [6] SONG C H, WANG A M, WU Z J, et al. The design and manufacturing of a titanium alloy beak for Grus japonensis using additive manufacturing [J]. Materials & Design, 2017, 117: 410–416. doi: 10.1016/j.matdes.2016.11.092 [7] CAI C, TEY W S, CHEN J Y, et al. Comparative study on 3D printing of polyamide 12 by selective laser sintering and multi jet fusion [J]. Journal of Materials Processing Technology, 2021, 288: 116882. doi: 10.1016/j.jmatprotec.2020.116882 [8] PUTRA N E, LEEFLANG M A, MINNEBOO M, et al. Extrusion-based 3D printed biodegradable porous iron [J]. Acta Biomaterialia, 2021, 121: 741–756. doi: 10.1016/j.actbio.2020.11.022 [9] BISWAS M C, CHAKRABORTY S, BHATTACHARJEE A, et al. 4D printing of shape memory materials for textiles: mechanism, mathematical modeling, and challenges [J]. Advanced Function Materials, 2021, 31(19): 2100257. doi: 10.1002/adfm.202100257 [10] ZHANG C, CAI D P, LIAO P, et al. 4D Printing of shape-memory polymeric scaffolds for adaptive biomedical implantation [J]. Acta Biomaterialia, 2021, 122(1): 101–110. [11] WANG J W, LUO Q, WANG H M, et al. Microstructure characteristics and failure mechanisms of Ti-48Al-2Nb-2Cr titanium aluminide intermetallic alloy fabricated by directed energy deposition technique [J]. Additive Manufacturing, 2020, 32: 101007. doi: 10.1016/j.addma.2019.101007 [12] LI J Q, LIN X, YANG Y, et al. Distinction in electrochemical behaviour of Ti6Al4V alloy produced by direct energy deposition and forging [J]. Journal of Alloys and Compounds, 2021, 860: 157912. doi: 10.1016/j.jallcom.2020.157912 [13] TANVIR A N M, AHSAN M R U, SEO G, et al. Phase stability and mechanical properties of wire+arc additively manufactured H13 tool steel at elevated temperatures [J]. Journal of Materials Science & Technology, 2021, 67: 80–94. doi: 10.1016/j.jmst.2020.04.085 [14] VRANCKEN B, THIJS L, KRUTH J P, et al. Heat treatment of Ti6Al4V produced by selective laser melting: microstructure and mechanical properties [J]. Journal of Alloys and Compounds, 2012, 541: 177–185. doi: 10.1016/j.jallcom.2012.07.022 [15] ZHANG J L, SONG B, WEI Q S, et al. A review of selective laser melting of aluminum alloys: processing, microstructure, property and developing trends [J]. Journal of Materials Science & Technology, 2109, 35(2): 270–284. doi: 10.1016/j.jmst.2018.09.004 [16] ZHAO D C, LIN F. Dual-detector electronic monitoring of electron beam selective melting [J]. Journal of Materials Processing Technology, 2021, 289: 116935. doi: 10.1016/j.jmatprotec.2020.116935 [17] LIU Y, PANG Z C, LI M, et al. Investigation into the dynamic mechanical properties of selective laser melted Ti-6Al-4V alloy at high strain rate tensile loading [J]. Materials Science and Engineering: A, 2019, 745: 440–449. doi: 10.1016/j.msea.2019.01.010 [18] ZHENG C, WANG F C, CHENG X W, et al. Effect of microstructures on ballistic impact property of Ti-6Al-4V targets [J]. Materials Science and Engineering: A, 2014, 608: 53–62. doi: 10.1016/j.msea.2014.04.032 [19] YANG B H, CAO Z Q, CHANG Z P, et al. The effect of the reflected shock wave on the foam material [J]. International Journal of Impact Engineering, 2021, 149: 103773. doi: 10.1016/j.ijimpeng.2020.103773 [20] WALSH J M, CHRISTIAN R H. Equation of state of metals from shock wave measurements [J]. Physical Review, 1955, 97(6): 1544–1556. doi: 10.1103/PhysRev.97.1544 [21] WALSH J M, RICE M H, MCQUEEN R G, et al. Shock-wave compressions of twenty-seven metals: equations of state of metals [J]. Physical Review, 1957, 108(2): 196–216. doi: 10.1103/PhysRev.108.196 [22] WANG Y G, HE H L, WANG L L, et al. Time-resolved dynamic tensile spall of pure aluminum under laser irradiation [J]. Journal of Applied Physics, 2006, 100(3): 033511. doi: 10.1063/1.2215074 [23] XIAO L J, SONG W D. Additively-manufactured functionally graded Ti-6Al-4V lattice structures with high strength under static and dynamic loading: experiments [J]. International Journal of Impact Engineering, 2018, 111: 255–272. doi: 10.1016/j.ijimpeng.2017.09.018 [24] KHOSRAVANI M R, WEINBERG K. A review on split Hopkinson bar experiments on the dynamic characterisation of concrete [J]. Construction and Building Materials, 2018, 190: 1264–1283. doi: 10.1016/j.conbuildmat.2018.09.187 [25] LI K B, LI X J, WANG X H, et al. A simple electrometric method for parametric determination of Jones-Wilkins-Lee equation of state from underwater explosion test [J]. Journal of Applied Physics, 2018, 124(21): 215906. doi: 10.1063/1.5049497 [26] JONES D R, FENSIN S J, NDEFRU B G, et al. Spall fracture in additive manufactured tantalum [J]. Journal of Applied Physics, 2018, 124(22): 225902. doi: 10.1063/1.5063930 [27] LU G X, TRDAN U, ZHANG Y K, et al. The distribution regularity of residual stress on a metal surface after laser shock marking [J]. Mechanics of Materials, 2020, 143: 103310. doi: 10.1016/j.mechmat.2020.103310 [28] DWAIKAT M B, KODUR V K R. Hydrothermal model for predicting fire-induced spalling in concrete structural systems [J]. Fire Safety Journal, 2009, 44(3): 425–434. doi: 10.1016/j.firesaf.2008.09.001 [29] LI K B, LI X J, YAN H H, et al. A velocity probe-based method for continuous detonation and shock measurement in near-field underwater explosion [J]. Review of Scientific Instruments, 2017, 88(12): 123905. doi: 10.1063/1.4999144 [30] JONES D R, FENSIN S J, MORROW B M, et al. Shock recompaction of spall damage [J]. Journal of Applied Physics, 2020, 127(24): 245901. doi: 10.1063/5.0011337 [31] LI C, LI B, HUANG J Y, et al. Spall damage of a mild carbon steel: effects of peak stress, strain rate and pulse duration [J]. Materials Science and Engineering: A, 2016, 660: 139–147. doi: 10.1016/j.msea.2016.02.080 [32] THOMPSON S M, ASPIN Z S, SHAMSAEI N, et al. Additive manufacturing of heat exchangers: a case study on a multi-layered Ti-6Al-4V oscillating heat pipe [J]. Additive Manufacturing, 2015, 8: 163–174. doi: 10.1016/j.addma.2015.09.003 [33] HAUBRICH J, GUSSONE J, BARRIOBERO-VILA P, et al. The role of lattice defects, element partitioning and intrinsic heat effects on the microstructure in selective laser melted Ti-6Al-4V [J]. Acta Materialia, 2019, 167: 136–148. doi: 10.1016/j.actamat.2019.01.039 [34] LI Z, LI J, LIU J, et al. Structure and formation mechanism of α/α interface in laser melting deposited α+β titanium alloy [J]. Journal of Alloys and Compounds, 2016, 657: 278–285. doi: 10.1016/j.jallcom.2015.09.236 [35] TAN H, GUO M L, CLARE A T, et al. Microstructure and properties of Ti-6Al-4V fabricated by low-power pulsed laser directed energy deposition [J]. Journal of Materials Science & Technology, 2019, 35(9): 2027–2037. doi: 10.1016/J.JMST.2019.05.008 [36] BISWAS N, DING J L, BALLA V K, et al. Deformation and fracture behavior of laser processed dense and porous Ti6Al4V alloy under static and dynamic loading [J]. Materials Science and Engineering: A, 2012, 549: 213–221. doi: 10.1016/j.msea.2012.04.036 [37] 傅华, 李涛, 吴廷烈, 等. 冲击作用下PBX炸药预制孔洞塌陷过程的实验探索 [J]. 高压物理学报, 2015, 29(4): 268–272. doi: 10.11858/gywlxb.2015.04.005FU H, LI T, WU T L, et al. Experiment of cavity collapse process in plastic-bonded explosives under shock loading [J]. Chinese Journal of High Pressure Physics, 2015, 29(4): 268–272. doi: 10.11858/gywlxb.2015.04.005 [38] LIU Y, XU H Z, ZHU L, et al. Investigation into the microstructure and dynamic compressive properties of selective laser melted Ti-6Al-4V alloy with different heating treatments [J]. Materials Science and Engineering: A, 2021, 805: 140561. doi: 10.1016/j.msea.2020.140561 [39] MOHAMMADHOSSEINI A, MASOOD S H, FRASER D, et al. Dynamic compressive behaviour of Ti-6Al-4V alloy processed by electron beam melting under high strain rate loading [J]. Advanced in Manufacturing, 2015, 3(3): 232–243. doi: 10.1007/s40436-015-0119-0 [40] ALAGHMANDFARD R, CHALASANI D, HADADZADEH A, et al. Dynamic compressive response of electron beam melted Ti-6Al-4V under elevated strain rates: microstructure and constitutive models [J]. Additive Manufacturing, 2020, 35: 101347. doi: 10.1016/j.addma.2020.101347 [41] ALAGHMANDFARD R, DHARMENDRA D, ODESHI A G, et al. Dynamic mechanical properties and failure characteristics of electron beam melted Ti-6Al-4V under high strain rate impact loadings [J]. Materials Science and Engineering: A, 2020, 793: 139794. doi: 10.1016/j.msea.2020.139794 [42] LI P H, GUO W G, HUANG W D, et al. Thermomechanical response of 3D laser-deposited Ti-6Al-4V alloy over a wide range of strain rates and temperatures [J]. Materials Science and Engineering: A, 2015, 647: 34–42. doi: 10.1016/j.msea.2015.08.043 [43] BROWN A D, AMERI A H, GREGG A, et al. Dynamic mechanical response of additive manufactured Ti-6Al-4V [C]//AIPConference Proceedings, 2018, 1979: 070008. [44] JONES D R, FENSIN S J, DIPPO O, et al. Spall fracture in additive manufactured Ti-6Al-4V [J]. Journal of Applied Physics, 2016, 120(13): 135902. doi: 10.1063/1.4963279 [45] RODRIGUEZ O L, ALLISON P G, WHITTINGTON W R, et al. Strain rate effect on the tension and compression stress-state asymmetry for electron beam additive manufactured Ti6Al4V [J]. Materials Science and Engineering: A, 2018, 713: 125–133. doi: 10.1016/J.MSEA.2017.12.062 [46] YANG D K, CIZEK P, HODGSON P D, et al. Microstructure evolution and nanograin formation during shear localization in cold-rolled titanium [J]. Acta Materialia, 2010, 58(13): 4536–4548. doi: 10.1016/j.actamat.2010.05.007 [47] YANG H L, WANG D D, ZHU X J, et al. Dynamic compression-induced twins and martensite and their combined effects on the adiabatic shear behavior in a Ti-8.5Cr-1.5Sn alloy [J]. Materials Science and Engineering: A, 2019, 759: 203–209. doi: 10.1016/J.MSEA.2019.05.040 [48] MING W W, CHEN J, AN Q L, et al. Dynamic mechanical properties and machinability characteristics of selective laser melted and forged Ti6Al4V [J]. Journal of Materials Processing Technology, 2019, 271: 284–292. doi: 10.1016/j.jmatprotec.2019.04.015 [49] SHI G Q, JIN S, XUE G, et al. A conducting polymer film stronger than aluminum [J]. Science, 1995, 267(5200): 994–996. doi: 10.1126/science.267.5200.994 [50] ZARETSKY E, STERN A, FRAGE N. Dynamic response of AlSi10Mg alloy fabricated by selective laser melting [J]. Materials Science and Engineering: A, 2017, 688: 364–370. doi: 10.1016/J.MSEA.2017.02.004 [51] HADADZADEH A, AMIRKHIZ S B, ODESHI A, et al. Dynamic loading of direct metal laser sintered AlSi10Mg alloy: strengthening behavior in different building directions [J]. Materials & Design, 2018, 159: 201–211. doi: 10.1016/j.matdes.2018.08.045 [52] NUREL B, NAHMANY M, FRAGE N, et al. Split Hopkinson pressure bar tests for investigating dynamic properties of additively manufactured AlSi10Mg alloy by selective laser melting [J]. Additive Manufacturing, 2018, 22: 823–833. doi: 10.1016/j.addma.2018.06.001 [53] PONNUSAM P, MASOOD S H, RUAN D, et al. Dynamic compressive behaviour of selective laser melted AlSi12 alloy: effect of elevated temperature and heat treatment [J]. Additive Manufacturing, 2020, 36: 101614. doi: 10.1016/j.addma.2020.101614 [54] PONNUSAM P, MASOOD S H, RUAN D, et al. High strain rate dynamic behaviour of AlSi12 alloy processed by selective laser melting [J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(1): 1023–1035. doi: 10.1007/S00170-018-1873-5 [55] ASGARI H, ODESHI A, HOSSEINKHANI K, et al. On dynamic mechanical behavior of additively manufactured AlSi10Mg_200C [J]. Materials Letters, 2018, 211: 187–190. doi: 10.1016/j.matlet.2017.10.001 [56] BAXTER C, CYR E, ODESHI A, et al. Constitutive models for the dynamic behaviour of direct metal laser sintered AlSi10Mg_200C under high strain rate shock loading [J]. Materials Science and Engineering: A, 2018, 731: 296–308. doi: 10.1016/J.MSEA.2018.06.040 [57] LAURENÇON M, RESSÉGUIER T, LOISON D, et al. Effects of additive manufacturing on the dynamic response of AlSi10Mg to laser shock loading [J]. Materials Science and Engineering: A, 2019, 748: 407–417. [58] LAURENÇON M, RESSÉGUIER T, LOISON D, et al. Dynamic behaviour and spall fracture of laser shock-loaded AlSi10Mg alloy obtained by selective laser melting [J]. AIP Conference Proceedings, 2020, 2272(1): 100018. [59] TIAMIYU A A, BASU R, ODESHI A G, et al. Plastic deformation in relation to microstructure and texture evolution in AA 2017-T451 and AA 2624-T351 aluminum alloys under dynamic impact loading [J]. Materials Science and Engineering: A, 2015, 636: 379–388. doi: 10.1016/J.MSEA.2015.03.113 [60] GU D D, MEINERS W, WISSENBACH K, et al. Laser additive manufacturing of metallic components: materials, processes and mechanisms [J]. International Materials Review, 2012, 57(2): 133–164. doi: 10.1179/1743280411Y.0000000014 [61] FELDHAUSEN T, RAGHAVAN N, SALEEBY K, et al. Mechanical properties and microstructure of 316L stainless steel produced by hybrid manufacturing [J]. Journal of Materials Processing Technology, 2021, 290: 116970. doi: 10.1016/j.jmatprotec.2020.116970 [62] WISE J L, ADAMS D P, NISHIDA E E, et al. Comparative shock response of additively manufactured versus conventionally wrought 304L stainless steel [J]. AIP Conference Proceedings, 2017, 1793: 100015. [63] POKHAREL R, PATRA A, BROWN D W, et al. An analysis of phase stresses in additively manufactured 304L stainless steel using neutron diffraction measurements and crystal plasticity finite element simulations [J]. International Journal of Plasticity, 2019, 121: 201–217. doi: 10.1016/j.ijplas.2019.06.005 [64] SONG B, NISHIDA E, SANBORN B, et al. Compressive and tensile stress-strain responses of additively manufactured (AM) 304L stainless steel at high strain rates [J]. Journal of Dynamic Behavior of Materials, 2017, 3(3): 412–425. doi: 10.1007/s40870-017-0122-6 [65] WANG X F, LIU Y, SHI T Y, et al. Strain rate dependence of mechanical property in a selective laser melted 17-4 PH stainless steel with different states [J]. Materials Science and Engineering: A, 2020, 792: 139776. doi: 10.1016/J.MSEA.2020.139776 [66] WANG X F, WANG G, SHI T Y, et al. Tensile mechanical behavior and spall response of a selective laser melted 17-4 PH stainless steel [J]. Metallurgical and Materials Transactions A, 2021, 52: 2369–2388. doi: 10.1007/s11661-021-06229-1 [67] 史同亚, 刘东升, 陈伟, 等. 激光选区熔化增材制造GP1不锈钢动态拉伸力学响应与层裂破坏 [J]. 爆炸与冲击, 2019, 39(7): 073101. doi: 10.11883/bzycj-2019-0015SHI T Y, LIU D S, CHEN W, et al. Dynamic tensile behavior and spall fracture of GP1 stainless steel processed by selective laser melting [J]. Explosion and Shock Waves, 2019, 39(7): 073101. doi: 10.11883/bzycj-2019-0015 [68] CLAUSEN B, BROWN D W, CARPENTER J S, et al. Deformation behavior of additively manufactured GP1 stainless steel [J]. Materials Science and Engineering: A, 2017, 696: 331–340. doi: 10.1016/j.msea.2017.04.081 [69] GRAY Ⅲ G T, LIVESCU V, RIGG P A, et al. Structure/property (constitutive and spallation response) of additively manufactured 316L stainless steel [J]. Acta Materialia, 2017, 138: 140–149. doi: 10.1016/j.actamat.2017.07.045 [70] CARLTON H D, HABOU A, GALLEGOS G F, et al. Damage evolution and failure mechanisms in additively manufactured stainless steel [J]. Materials Science and Engineering: A, 2016, 651: 406–414. doi: 10.1016/j.msea.2015.10.073 [71] RIZA S H, MASOOD S H, WEN C, et al. Dynamic behaviour of high strength steel parts developed through laser assisted direct metal deposition [J]. Materials & Design, 2014, 64: 650–659. doi: 10.1016/j.matdes.2014.08.026 [72] YANG Z, YU Y Y, WEI Y P, et al. Crushing behavior of a thin-walled circular tube with internal gradient grooves fabricated by SLM 3D printing [J]. Thin-Walled Structures, 2017, 111: 1–8. doi: 10.1016/j.tws.2016.11.004 [73] MONTERO-SISTIAGA M L, LIU Z Z, BAUTMANS L, et al. Effect of temperature on the microstructure and tensile properties of micro-crack free hastelloy X produced by selective laser melting [J]. Additive Manufacturing, 2020, 31: 100995. doi: 10.1016/J.ADDMA.2019.100995 [74] HAN Q Q, GU Y C, HUANG J, et al. Selective laser melting of Hastelloy X nanocomposite: effects of TiC reinforcement on crack elimination and strength improvement [J]. Composites Part B: Engineering, 2020, 202: 108442. doi: 10.1016/j.compositesb.2020.108442 [75] YUAN K B, LI X L, GUO W G, et al. Effect of microstructures and defects on dynamic compression and shear performance of laser metal-deposited GH4169 superalloy [J]. Journal of Aerospace Engineering, 2020, 33(3): 04020008. doi: 10.1061/(ASCE)AS.1943-5525.0001122 [76] YUAN K B, GUO W G, LI P H, et al. Thermomechanical behavior of laser metal deposited Inconel 718 superalloy over a wide range of temperature and strain rate: testing and constitutive modeling [J]. Mechanics of Materials, 2019, 135: 13–25. doi: 10.1016/j.mechmat.2019.04.024 [77] YUAN K B, GUO W G, LI P H, et al. Influence of process parameters and heat treatments on the microstructures and dynamic mechanical behaviors of Inconel 718 superalloy manufactured by laser metal deposition [J]. Materials Science and Engineering: A, 2018, 721: 215–225. doi: 10.1016/J.MSEA.2018.02.014 [78] BABAMIRI B B, INDECK J, DEMENEGHI G, et al. Quantification of porosity and microstructure and their effect on quasi-static and dynamic behavior of additively manufactured Inconel 718 [J]. Additive Manufacturing, 2020, 34: 101380. doi: 10.1016/j.addma.2020.101380 [79] LEE D G, LEE Y H, LEE S, et al. Dynamic deformation behavior and ballistic impact properties of Ti-6Al-4V alloy having equiaxed and bimodal microstructures [J]. Metallurgical and Materials Transactions A, 2004, 35(10): 3103–3112. doi: 10.1007/S11661-004-0055-2 [80] 刘静楠, 叶常青, 刘桂森, 等. 高温、高压、高应变速率动态过程晶体塑性有限元理论模型及其应用 [J]. 高压物理学报, 2020, 34(3): 030102. doi: 10.11858/gywlxb.20190874LIU J N, YE C Q, LIU G S, et al. Crystal plasticity finite element theoretical models and applications for high temperature, high pressure and high strain-rate dynamic process [J]. Chinese Journal of High Pressure Physics, 2020, 34(3): 030102. doi: 10.11858/gywlxb.20190874 [81] BUDIWANTORO B, KARIEM M A, FEBRINAWARTA B. The influence of shear angles on the split Hopkinson shear bar testing [J]. International Journal of Impact Engineering, 2021, 149: 103787. doi: 10.1016/j.ijimpeng.2020.103787 [82] BACAK M, VALSECCHI J, ČAPEK J, et al. Neutron dark-field imaging applied to porosity and deformation-induced phase transitions in additively manufactured steels [J]. Materials & Design, 2020, 195: 109009. doi: 10.1016/J.MATDES.2020.109009 [83] TONG Q C, LUO X S, ADELEKE A A, et al. Machine learning metadynamics simulation of reconstructive phase transition [J]. Physics Review B, 2021, 103(5): 054107. doi: 10.1103/PhysRevB.103.054107 [84] WANG L, ZHAO F, ZHAO F P, et al. Grain boundary orientation effects on deformation of Ta bicrystal nanopillars under high strain-rate compression [J]. Journal of Applied Physics, 2014, 115(5): 053528. doi: 10.1063/1.4864427 [85] SUN J L, TRIMBY P W, YAN F K, et al. Shear banding in commercial pure titanium deformed by dynamic compression [J]. Acta Materialia, 2014, 79: 47–58. doi: 10.1016/j.actamat.2014.07.011 [86] ZHOU Y, FAN Q B, LIU X, et al. Multi-scale crystal plasticity finite element simulations of the microstructural evolution and formation mechanism of adiabatic shear bands in dual-phase Ti20C alloy under complex dynamic loading [J]. Journal of Materials Science & Technology, 2020, 59: 138–148. doi: 10.1016/j.jmst.2020.03.079 [87] 唐长国, 陈文涛, 朱金华. 钨合金高应变率导致的塑性降低及微观机理 [J]. 西安交通大学学报, 1997, 31(3): 28–32.TANG C G, CHEN W T, ZHU J H. The plasticity decreasing induced by high strain rateof tungsten alloy [J]. Journal of Xi’an Jiaotong University, 1997, 31(3): 28–32. [88] 桂毓林, 刘仓理, 王彦平, 等. AF1410钢的层裂断裂特性研究 [J]. 高压物理学报, 2006, 20(1): 34–38. doi: 10.11858/gywlxb.2006.01.008GUI Y L, LIU C L, WANG Y P, et al. Spall fracture properties of AF1410 steel [J]. Chinese Journal of High Pressure Physics, 2006, 20(1): 34–38. doi: 10.11858/gywlxb.2006.01.008 [89] 祁美兰, 秦晓云, 张林, 等. HR2钢动态损伤与层裂的微观机理 [J]. 兵器材料科学与工程, 2006, 29(3): 29–32. doi: 10.3969/j.issn.1004-244X.2006.03.009QI M L, QIN X Y, ZHANG L, et al. Micromechanism of the dynamic damage and spallation of HR2 steel [J]. Ordnance Material Science and Engineering, 2006, 29(3): 29–32. doi: 10.3969/j.issn.1004-244X.2006.03.009 [90] FADIDA R, RITTEL D, SHIRIZLY A. Dynamic mechanical behavior of additively manufactured Ti6Al4V with controlled voids [J]. Journal of Applied Mechanics, 2015, 82(4): 041004. doi: 10.1115/1.4029745 [91] GENG R W, DU J, WEI Z Y, et al. Multiscale modelling of microstructure, micro-segregation, and local mechanical properties of Al-Cu alloys in wire and arc additive manufacturing [J]. Additive Manufacturing, 2020, 36: 101735. doi: 10.1016/j.addma.2020.101735 -

下载:

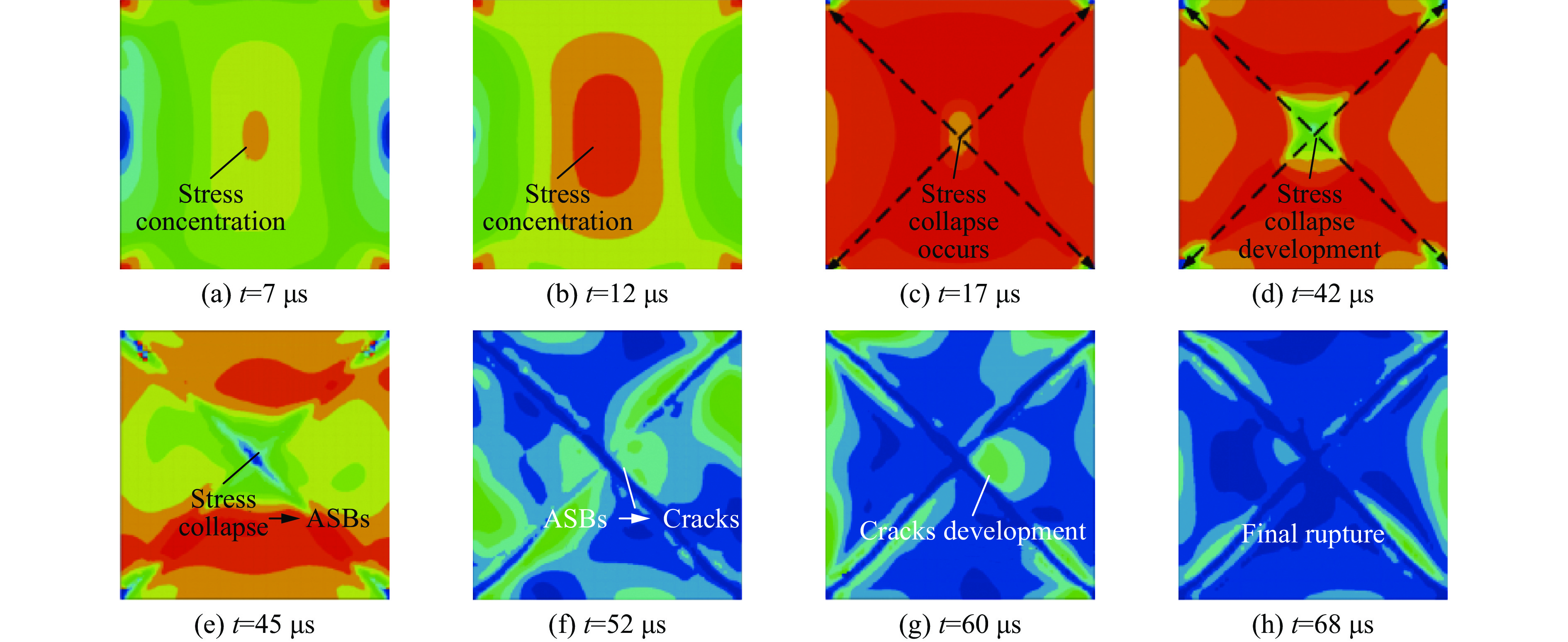

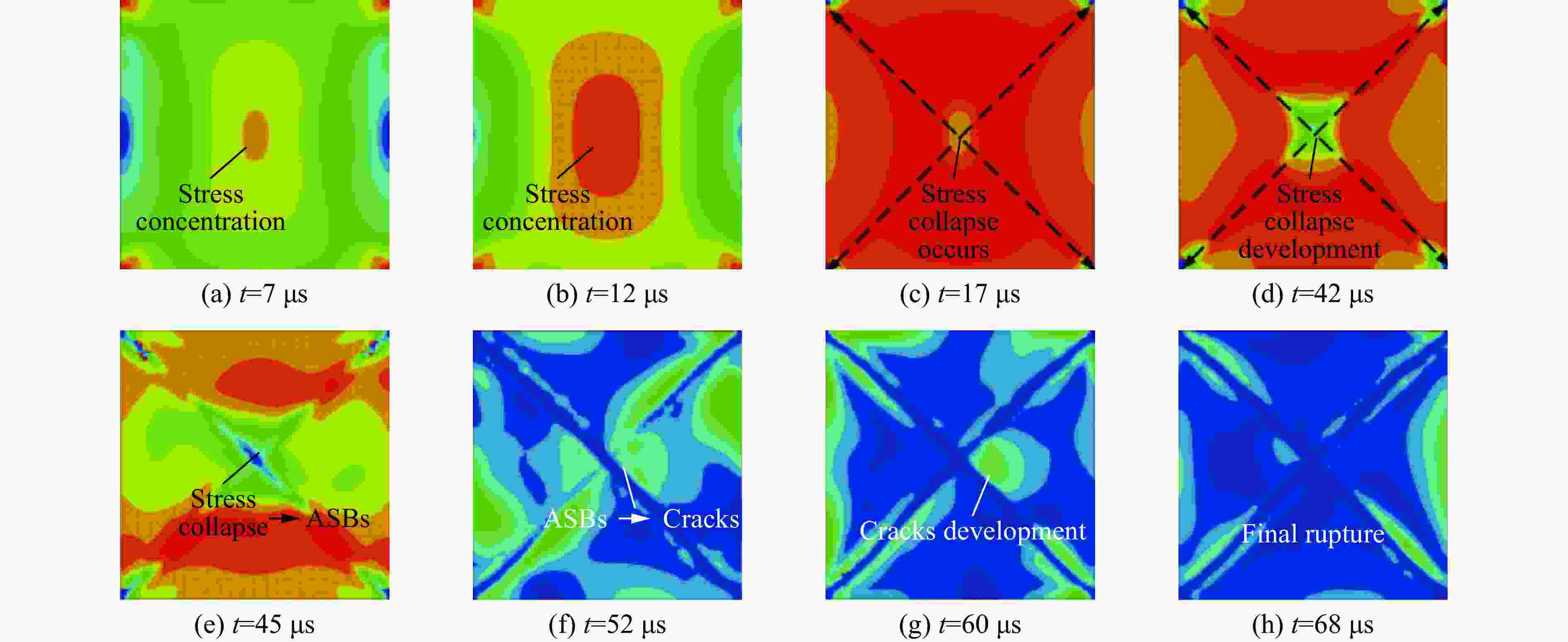

下载: