Mechanical Properties of AlxCoCrFeNi High-Entropy Alloy: A Molecular Dynamics Study

-

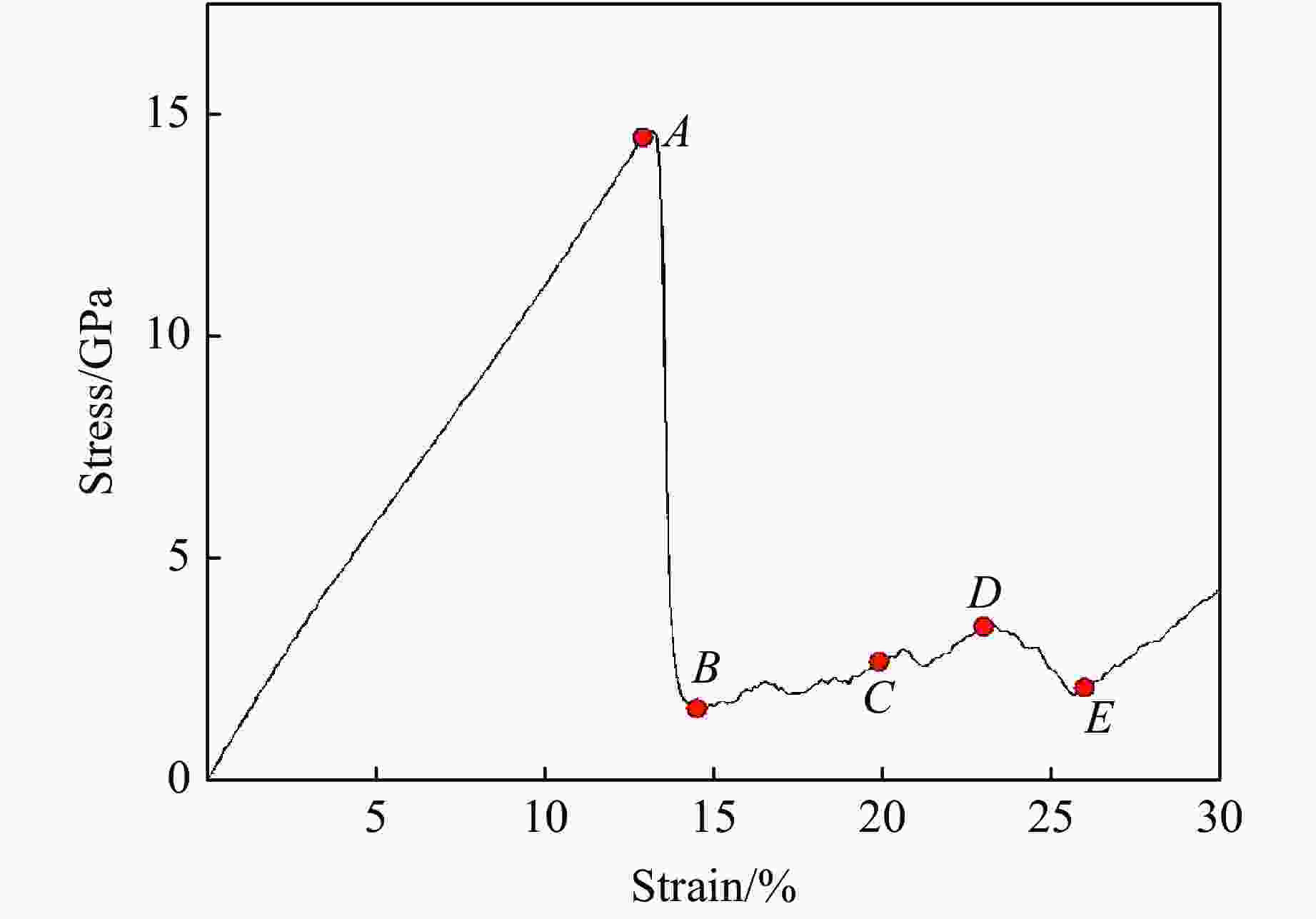

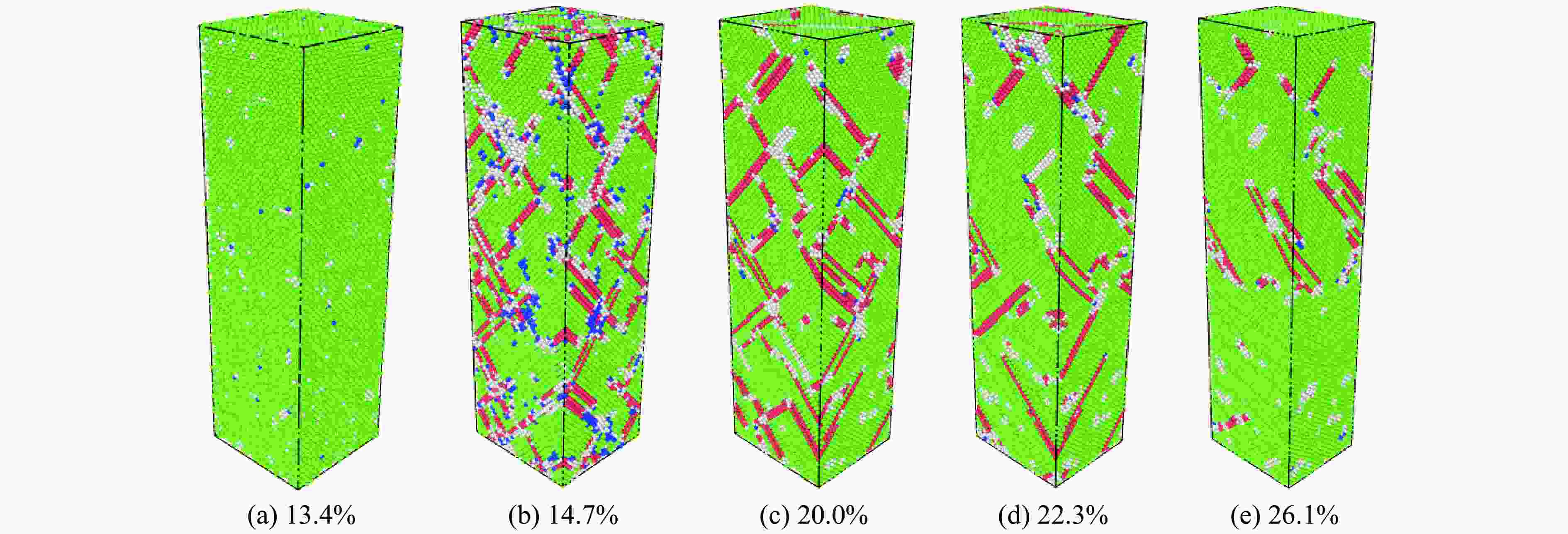

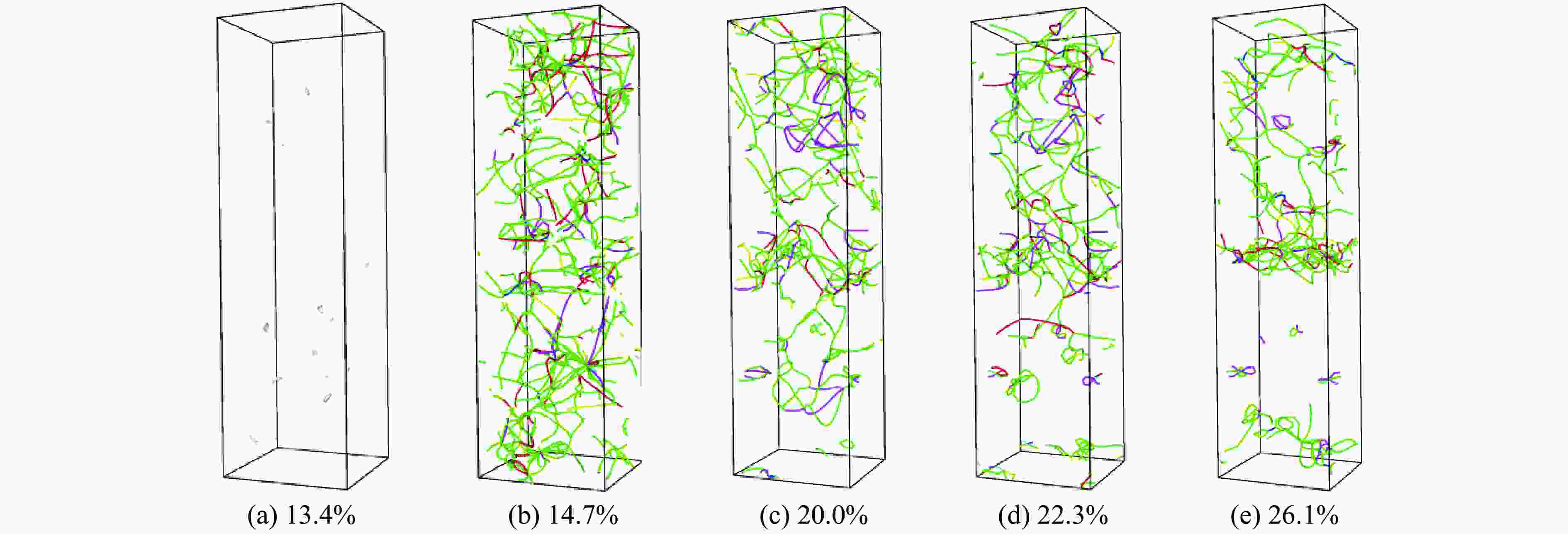

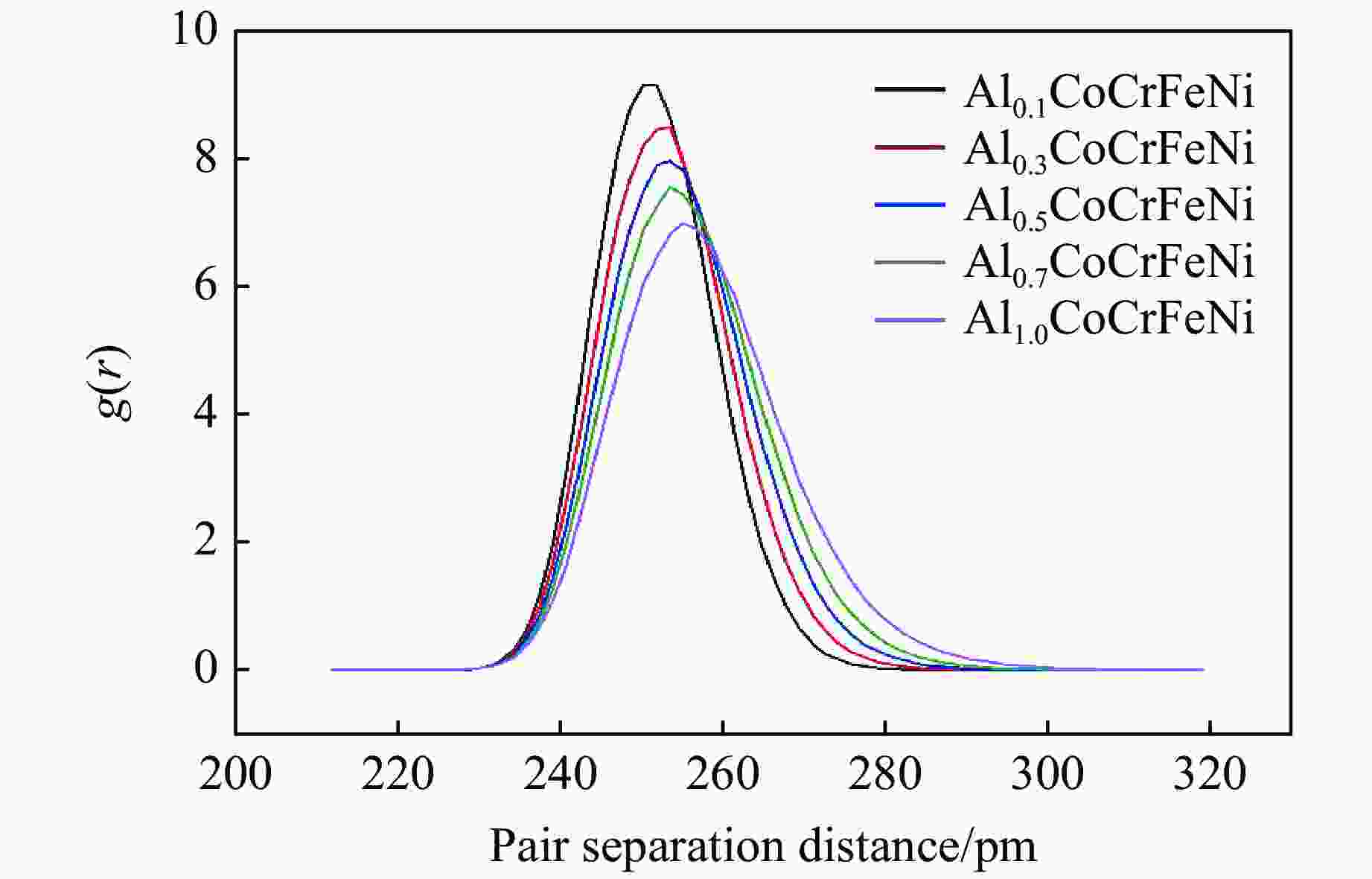

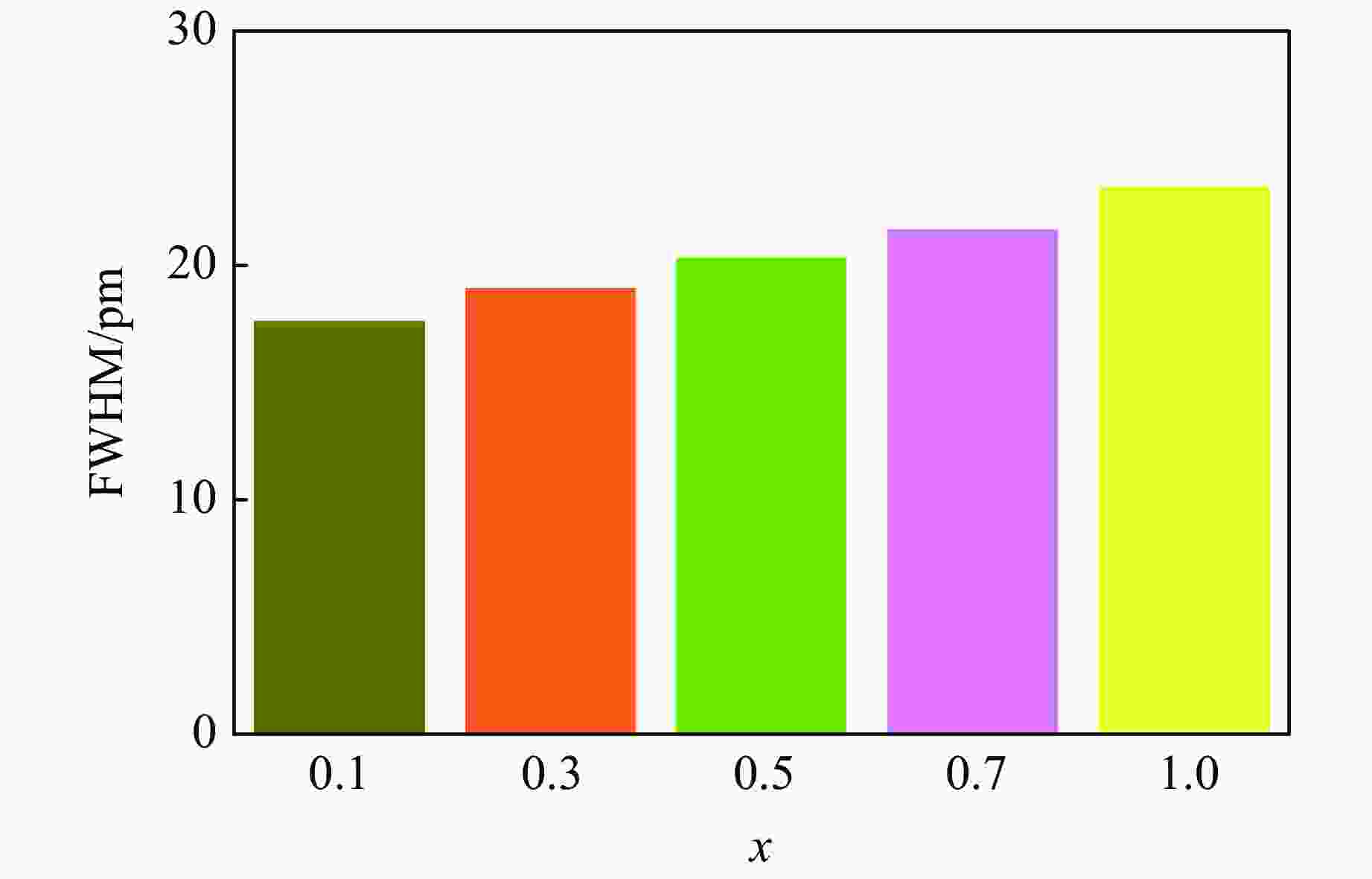

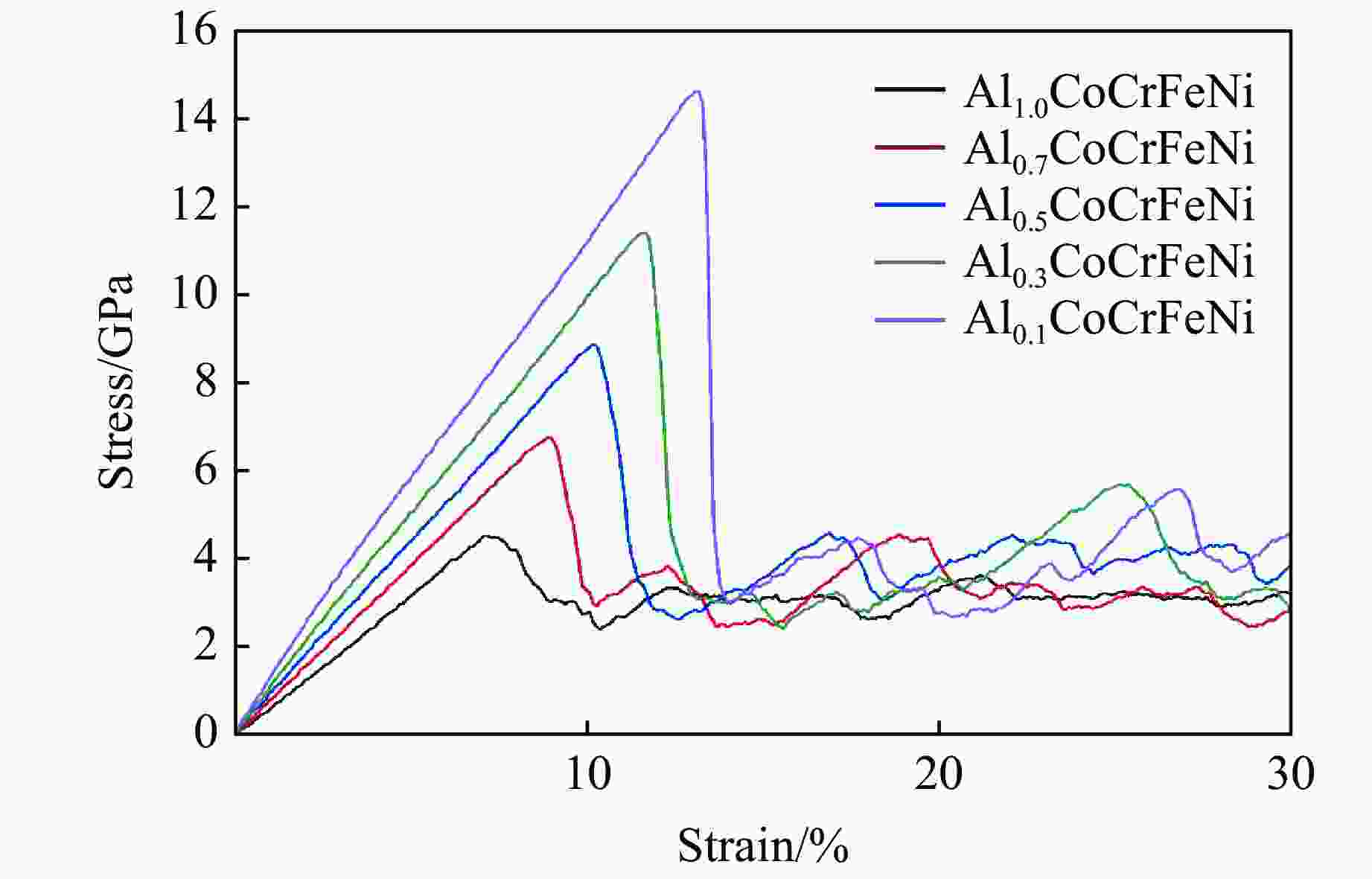

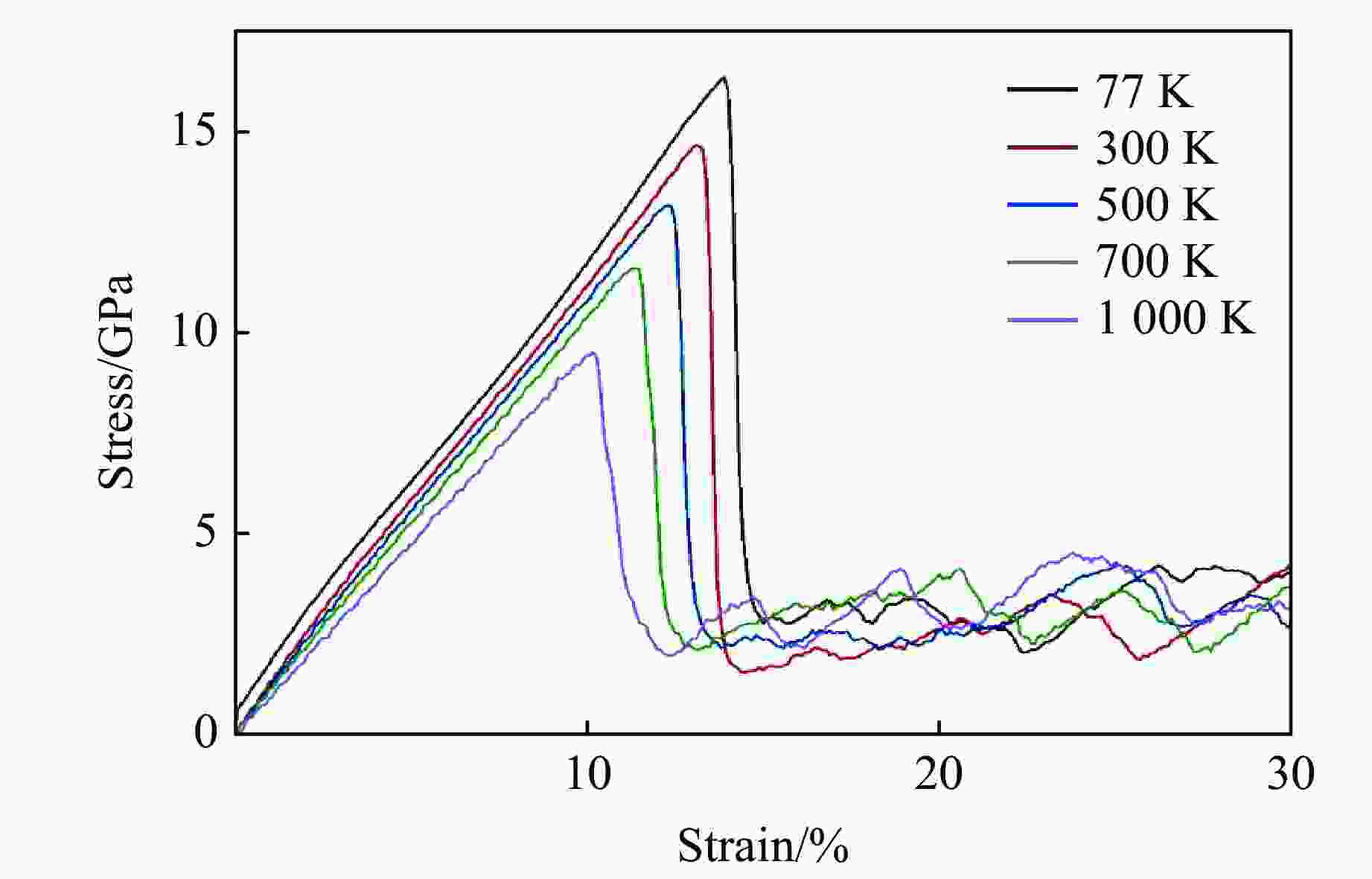

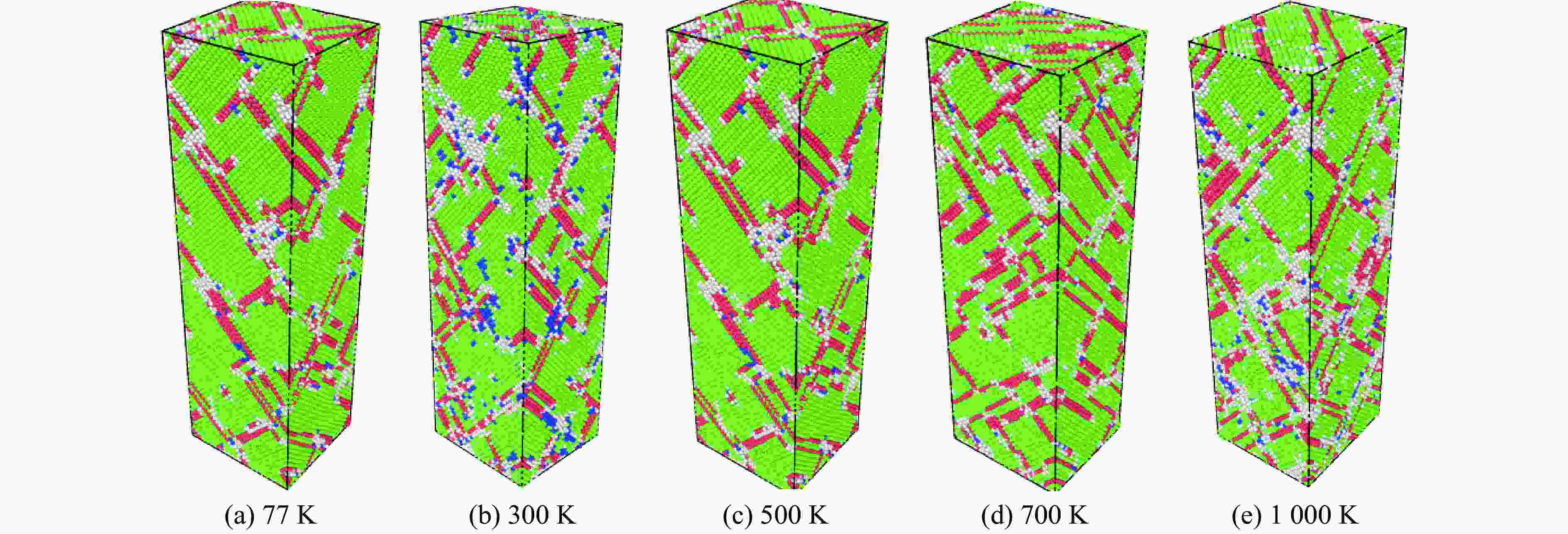

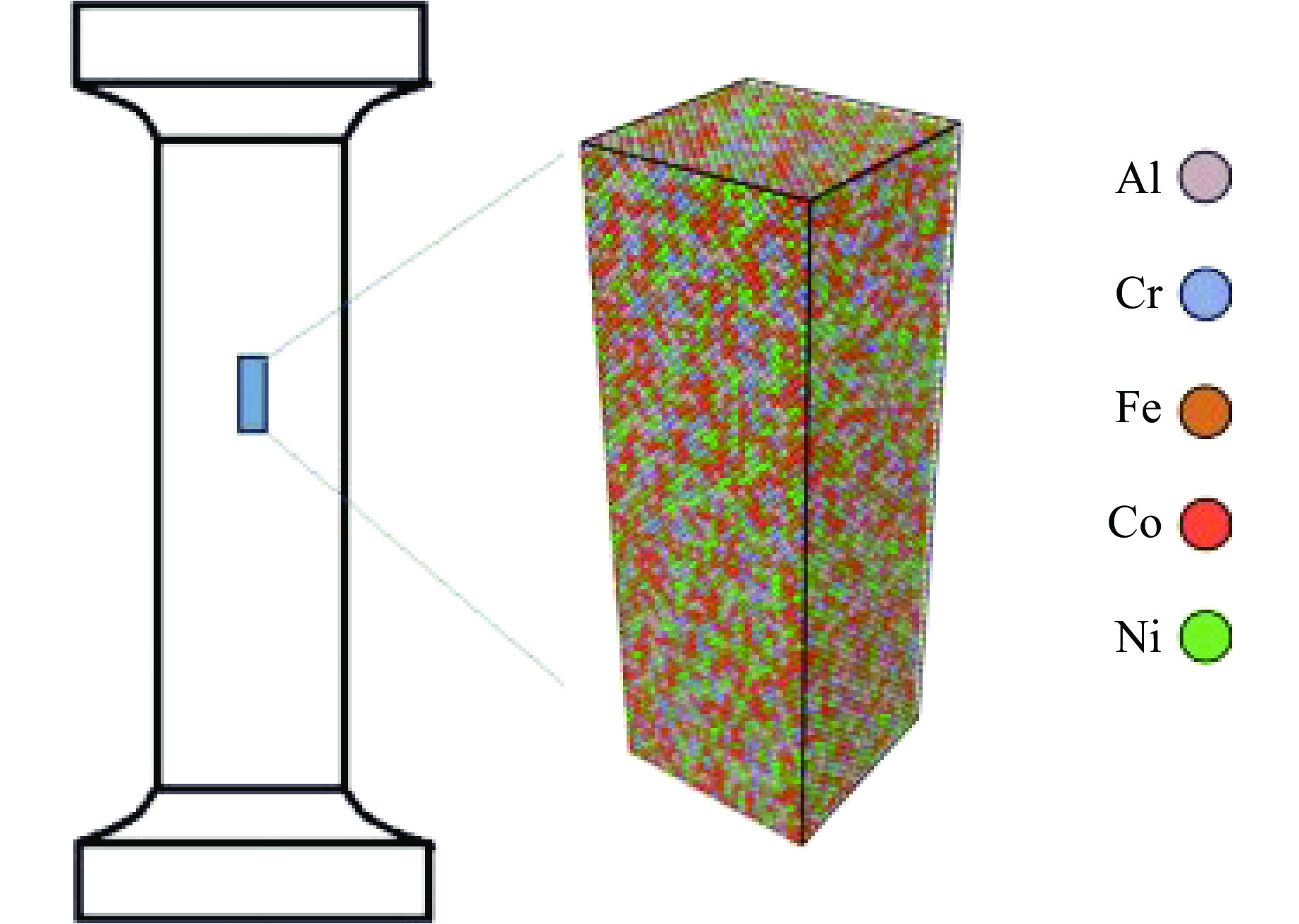

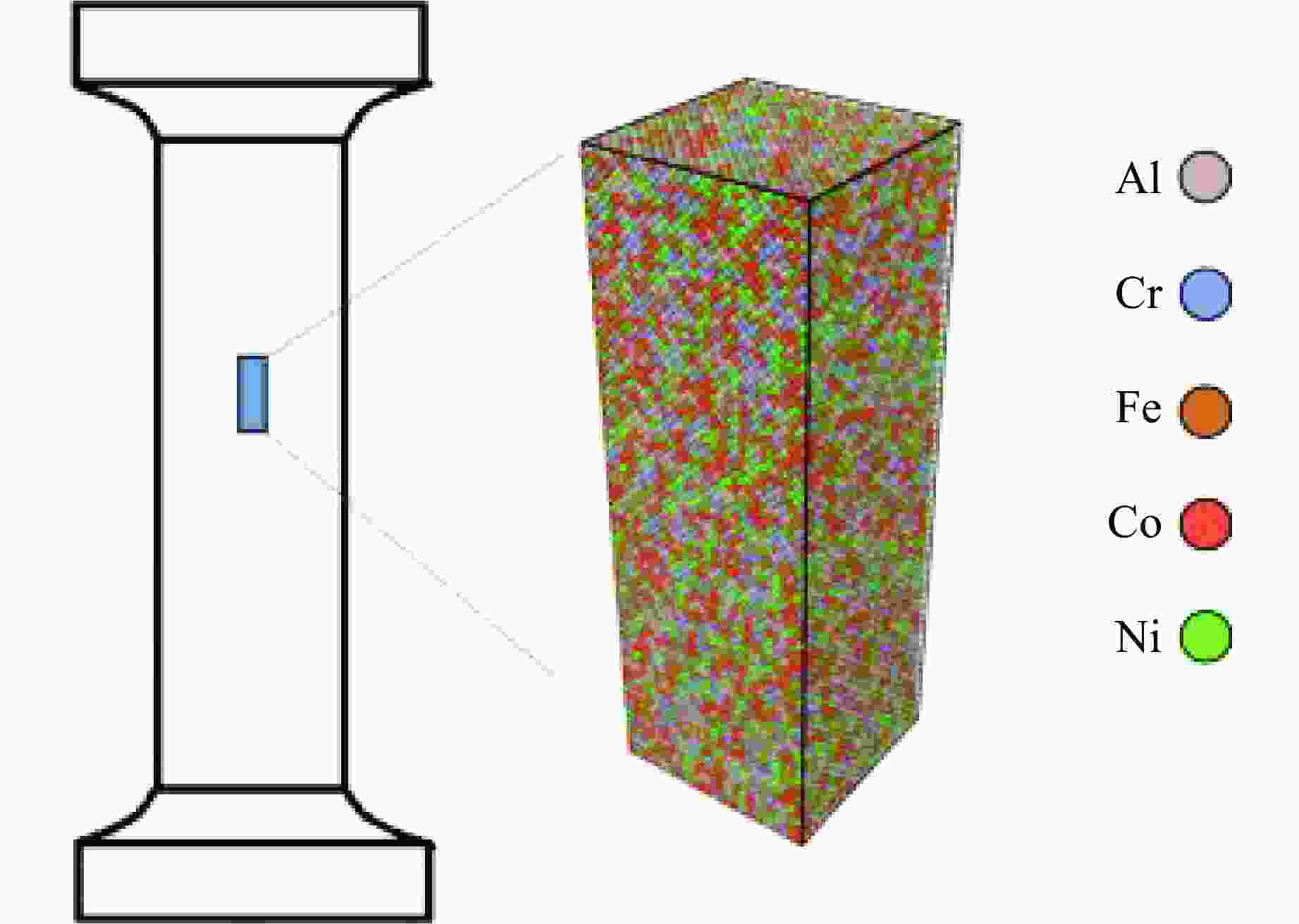

摘要: 通过分子动力学方法模拟了原子尺度下高熵合金的制备过程,对AlCoCrFeNi进行了微观组织分析,研究了温度和Al含量变化时AlCoCrFeNi高熵合金在轴向载荷作用下的力学性能。模拟结果显示:AlxCoCrFeNi高熵合金在拉伸过程中依次经历弹性—屈服—塑性阶段。屈服后,材料开始出现位错,随之出现层错和孪晶;随着位错的不断产生和湮灭,材料产生了不均匀塑性变形。分析显示:Al与其他元素的原子半径差产生的晶格畸变效应以及Al与其他原子的结合力影响了高熵合金的杨氏模量和屈服应力;温度升高导致金属原子间的热振动加剧,原子动能增加,原子间的距离增大,原子间的结合力下降,致使合金的弹性模量和屈服应力下降,温度的净效应类似于晶格畸变。Abstract: The fabrication process of the high-entropy alloys (HEAs) at the atomic scale was investigated numerically through molecular dynamics (MD) approach, with which the micro-structures of AlxCoCrFeNi were analyzed. The mechanical properties of the fabricated specimens with different Al contents subjected to axial loads were explored at different temperatures. Numerical results show that the high-entropy alloys AlxCoCrFeNi undergoes the elastic, yielding and plastic stages in order when subjected to tensile. After yielding, dislocation lines emerge in the material, followed by the stacking faults and twins. The material produces inhomogeneous plastic deformation with the continuous generation and disappearance of dislocations. This analysis suggest that the lattice distortion effect is induced by the radius difference between Al atoms and other atoms, additionally, the binding force between them affects the Young's modulus and yield stress of high-entropy alloys. Moreover, the increase of temperature leads to more severe thermal vibration between metal atoms, larger atomic dynamic energy, increasing distance between atoms, while decreasing binding force between atoms, thereby resulting in a decrease of alloy elastic modality and yield stress. The effect of temperature is similar to that of the lattice distortion.

-

Key words:

- high-entropy alloys /

- molecular dynamics /

- stretching /

- temperature /

- aluminum content

-

表 1 不同原子的半径

Table 1. Radius of different atoms

Å Al Co Cr Fe Ni 1.43 1.25 1.24 1.24 1.24 表 2 晶格常数、混合熵、混合焓、熔化相互作用参数及原子尺寸差

Table 2. Lattice constants, entropy of mixing, enthalpy of mixing, regular melt interaction parameter, and atomic-size difference

Alloy Lattice constant/nm ${\Delta }{S}{_{ {\rm{mix} }} }$/(J·mol−1·K−1) ${\Delta }{H}{_{\rm{mix} } }/(\mathrm{k}\mathrm{J} \cdot {\mathrm{m}\mathrm{o}\mathrm{l} }{^{-1}})$ $ \varOmega $ $\delta /\text{%}$ CoCrFeNi 0.3580 11.53 −3.75 5.71 1.06 Al0.25CoCrFeNi 0.3592 12.71 −6.25 3.40 3.25 Al0.50CoCrFeNi 0.3603, 0.2875 13.15 −9.09 2.55 4.22 Al0.75CoCrFeNi 0.3603, 0.2877 13.33 −10.90 2.09 4.83 AlCoCrFeNi 0.2879 13.38 −12.32 1.83 5.25 表 3 AlxCoCrFeNi高熵合金中Al含量、各元素原子个数及模型体积和密度

Table 3. Al concentration, atomic number of each element and bulk and density of the model in AlxCoCrFeNi HEA

x xAl/% Atomic number Volume/(10−30 m3) Density/(g·cm−3) Al Co Cr Fe Ni 0.1 2.4 2250 23703 23184 23439 23424 1088008.3 8.160 0.3 7.0 6948 21903 22902 22059 22188 1107889.7 7.799 0.5 11.1 10959 20898 21924 21123 21096 1126321.6 7.497 0.7 14.9 14616 19998 20895 20331 20160 1144551.1 7.222 1.0 20.0 19047 19092 19641 19035 18915 1170662.1 6.856 表 4 AlxCoCrFeNi在单轴拉伸加载下的力学性能

Table 4. Mechanical properties of AlxCoCrFeNi under uniaxial tensile loading

x E/GPa Y/GPa $\varepsilon $Y 0.1 115.29 14.638 0.131 0.3 97.65 11.372 0.117 0.5 86.95 8.809 0.103 0.7 76.88 6.738 0.089 1.0 64.18 4.510 0.071 表 5 不同温度下Al0.1CoCrFeNi在单轴拉伸载荷下的力学性能

Table 5. Mechanical properties of Al0.1CoCrFeNi under uniaxial tensile loading at different temperatures

T/K E/GPa Y/GPa $ \varepsilon$Y 77 116.74 16.098 0.140 300 115.29 14.638 0.131 500 110.92 13.169 0.123 700 104.71 11.596 0.113 1000 95.82 9.521 0.102 -

[1] CHEN W P, FU Z Q, FANG S C, et al. Alloying behavior, microstructure and mechanical properties in a FeNiCrCo0.3Al0.7 high entropy alloy [J]. Materials & Design, 2013, 51: 854–860. doi: 10.1016/J.MATDES.2013.04.061 [2] YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes [J]. Advanced Engineering Materials, 2004, 6(5): 299–303. doi: 10.1002/adem.200300567 [3] CHUANG M H, TSAI M H, WANG W R, et al. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys [J]. Acta Materialia, 2011, 59(16): 6308–6317. doi: 10.1016/j.actamat.2011.06.041 [4] 李天昕, 卢一平, 曹志强, 等. 难熔高熵合金在反应堆结构材料领域的机遇与挑战 [J]. 金属学报, 2021, 57(1): 42–54. doi: 10.11900/0412.1961.2020.00293LI T X, LU Y P, CAO Z Q, et al. Opportunity and challenge of refractory high-entropy alloys in the field of reactor structural materials [J]. Acta Metallurgica Sinica, 2021, 57(1): 42–54. doi: 10.11900/0412.1961.2020.00293 [5] LI J, FANG Q H, LIU B, et al. Mechanical behaviors of AlCrFeCuNi high-entropy alloys under uniaxial tension via molecular dynamics simulation [J]. RSC Advances, 2016, 6(80): 76409–76419. doi: 10.1039/C6RA16503F [6] SHARMA A, BALASUBRAMANIAN G. Dislocation dynamics in Al0.1CoCrFeNi high-entropy alloy under tensile loading [J]. Intermetallics, 2017, 91: 31–34. doi: 10.1016/j.intermet.2017.08.004 [7] AFKHAM Y, BAHRAMYAN M, TAHERZADEH R, et al. Tensile properties of AlCrCoFeCuNi glassy alloys: a molecular dynamics simulation study [J]. Materials Science and Engineering: A, 2017, 698: 143–151. doi: 10.1016/j.msea.2017.05.057 [8] LI J, CHEN H T, LI S X, et al. Tuning the mechanical behavior of high-entropy alloys via controlling cooling rates [J]. Materials Science and Engineering: A, 2019, 760: 359–365. doi: 10.1016/j.msea.2019.06.017 [9] JIAN W R, XIE Z C, XU S Z, et al. Effects of lattice distortion and chemical short-range order on the mechanisms of deformation in medium entropy alloy CoCrNi [J]. Acta Materialia, 2020, 199: 352–369. doi: 10.1016/j.actamat.2020.08.044 [10] 李春艳, 刘华, 刘波涛. 分子动力学模拟基本原理及研究进展 [J]. 广州化工, 2011, 39(4): 11–13. doi: 10.3969/j.issn.1001-9677.2011.04.004LI C Y, LIU H, LIU B T. Development and methods of molecular dynamics simulation [J]. Guangzhou Chemical Industry, 2011, 39(4): 11–13. doi: 10.3969/j.issn.1001-9677.2011.04.004 [11] 李健, 郭晓璇, 马胜国, 等. AlCrFeCuNi高熵合金力学性能的分子动力学模拟 [J]. 高压物理学报, 2020, 34(1): 011301. doi: 10.11858/gywlxb.20190762LI J, GUO X X, MA S G, et al. Mechanical properties of AlCrFeCuNi high entropy alloy: a molecular dynamics study [J]. Chinese Journal of High Pressure Physics, 2020, 34(1): 011301. doi: 10.11858/gywlxb.20190762 [12] FARKAS D, CARO A. Model interatomic potentials and lattice strain in a high-entropy alloy [J]. Journal of Materials Research, 2018, 33(19): 3218–3225. doi: 10.1557/jmr.2018.245 [13] 李健. 五边形石墨烯/高熵合金力学性能的分子动力学研究[D]. 太原: 太原理工大学, 2019.LI J. Mechanical properties of penta-graphene and high entropy alloy: a molecular dynamics study [D]. Taiyuan: Taiyuan University of Technology, 2019. [14] HONEYCUTT J D, ANDERSEN H C. Molecular dynamics study of melting and freezing of small Lennard-Jones clusters [J]. The Journal of Physical Chemistry, 1987, 91(19): 4950–4963. doi: 10.1021/j100303a014 [15] STUKOWSKI A, BULATOV V V, ARSENLIS A. Automated identification and indexing of dislocations in crystal interfaces [J]. Modelling and Simulation in Materials Science and Engineering, 2012, 20(8): 085007. doi: 10.1088/0965-0393/20/8/085007 [16] TAKEUCHI A, INOUE A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element [J]. Materials Transactions, 2005, 46(12): 2817–2829. doi: 10.2320/matertrans.46.2817 [17] MA S G, LIAW P K, GAO M C, et al. Damping behavior of AlxCoCrFeNi high-entropy alloys by a dynamic mechanical analyzer [J]. Journal of Alloys and Compounds, 2014, 604: 331–339. doi: 10.1016/j.jallcom.2014.03.050 -

下载:

下载: