Advances of Experimental and Theoretical Models of Magnesium Twin Deformation

-

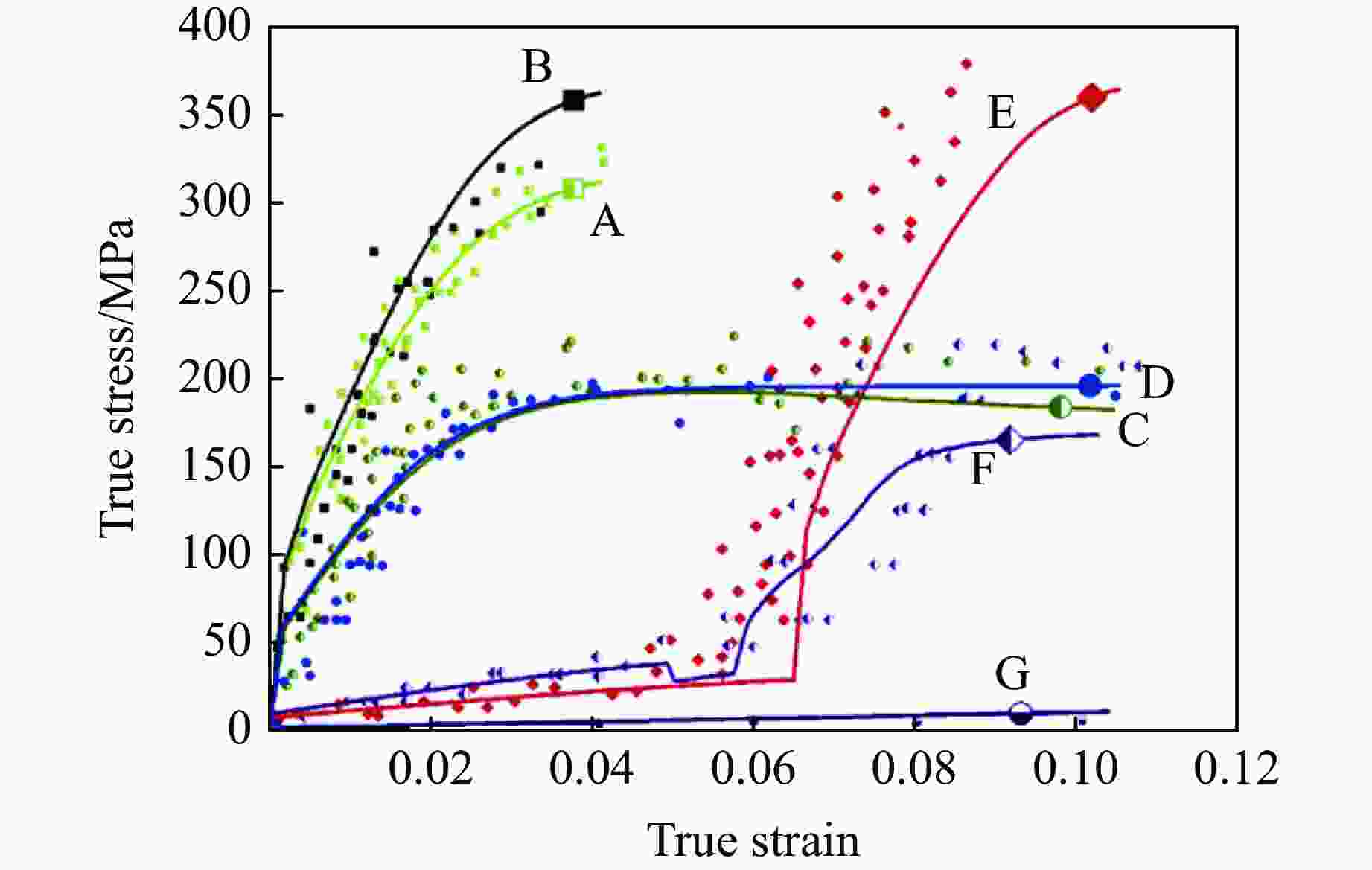

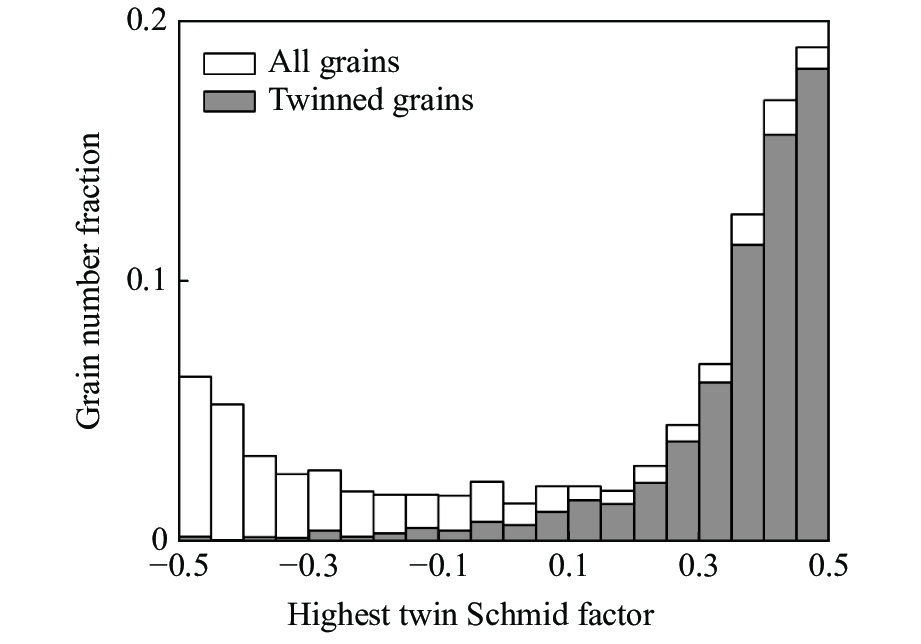

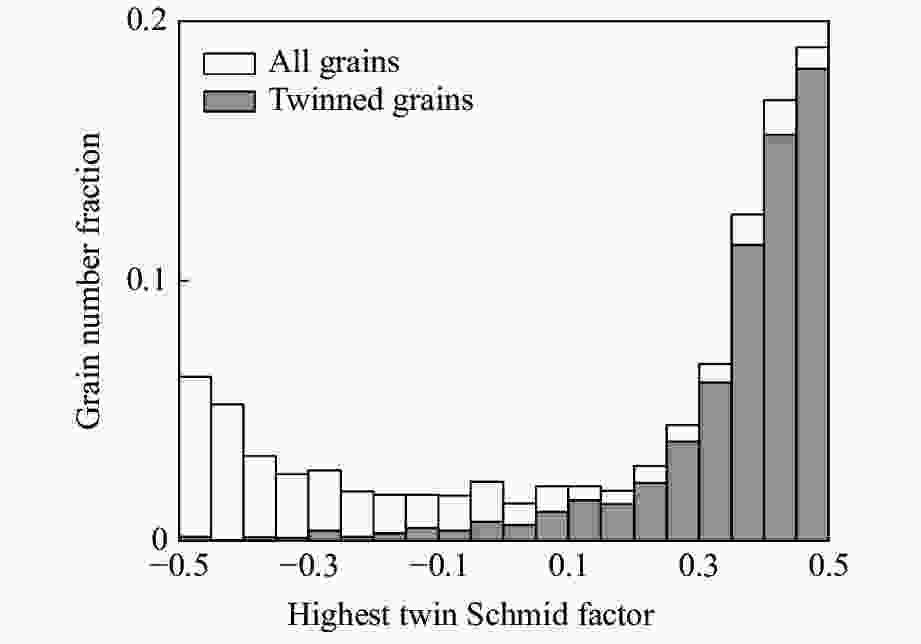

摘要: 孪晶变形作为密排六方(HCP)镁金属的重要变形机制,对镁金属的塑性硬化、破坏和织构演变等具有重要影响。影响孪晶变形的因素较多,有取向织构、晶粒尺寸、应变率、温度、晶界和应力状态等。首先重点介绍了前3种因素对镁金属孪晶变形的影响,孪晶的启动不再单一地考虑与取向相关的Schmid定律,需结合与临近晶粒间的应变兼容,晶粒尺寸对孪晶的影响同样可以采用Hall-Petch关系描述,只是关系式的斜率比滑移更大,提高应变率对孪晶成核和成长都有一定的促进作用;然后分析了现有常见的孪晶理论模型,最后展望了孪晶变形在实验和理论模型方面的发展方向。Abstract: Twin deformation is an important deformation mechanism of hexagonal close-packed (HCP) magnesium, and has a significant influence on the plastic hardening, failure and texture evolution of materials. There are many factors affecting twin deformation: orientation texture, grain size, strain rate, temperature, grain boundary and stress state, etc. Firstly, this paper focuses on the influence of the first three factors on the twin deformation. The activation of twins should consider the combination of the strain accommodation between adjacent grains and the orientation dependent Schmid’s law, instead of the later one solely. The effect of grain size on twinning can be described by Hall-Petch relation. However, the slope of Hall-Petch relation dominated by twin is larger than that of slip. And the twin nucleation and growth could be promoted by increasing the strain rate. Then, the common twin theory models are analyzed. Finally, the developments of twin deformation in experiment and theoretical models are prospected.

-

Key words:

- twinning /

- magnesium /

- deformation mechanism /

- theoretical model

-

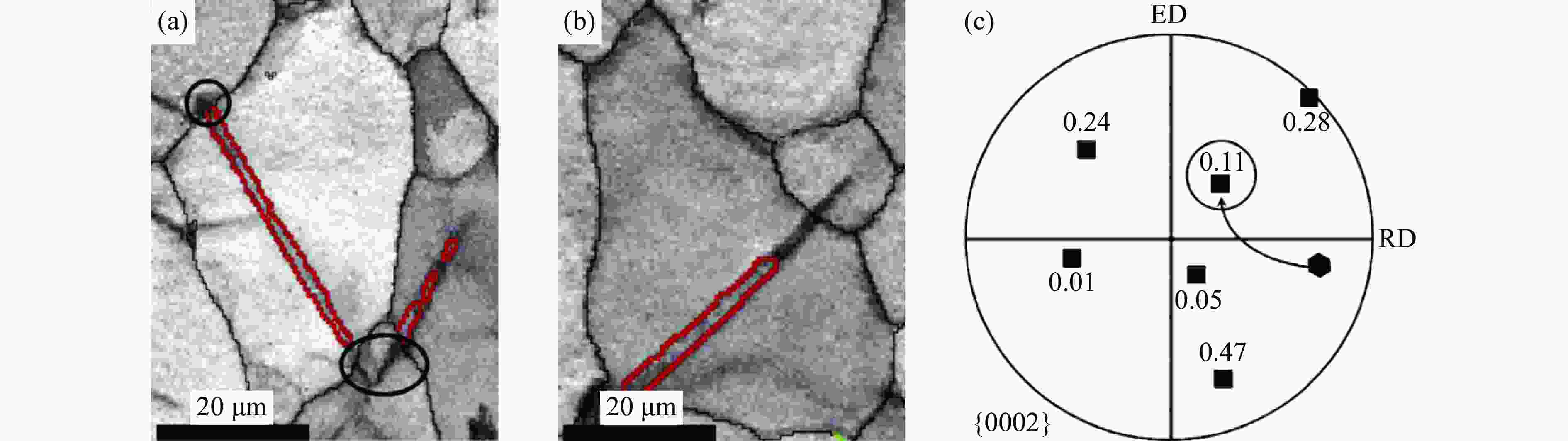

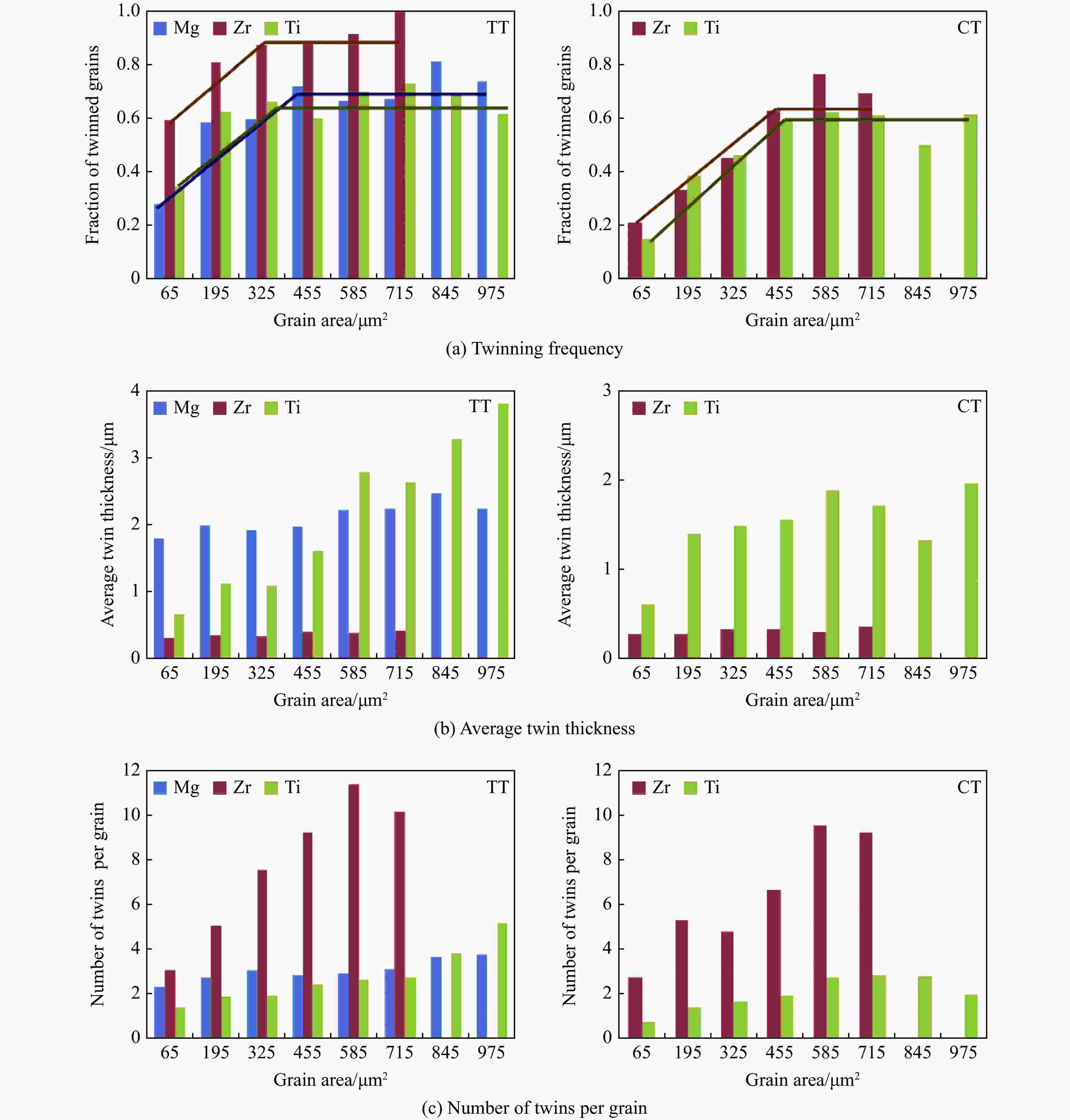

图 2 (a)应变为0.08时AM30样品2个压缩孪晶的EBSD图(黑色圆圈表示应变兼容);(b)临近轧制方向取向的晶粒内形成的{

$10\overline {1}1$ }压缩孪晶(红色)的EBSD图;(c) 2(b)图中基体的(0002)极图(黑色六边形)、6个孪晶取向(黑色正方形)和选择的临近晶粒孪晶取向(黑色圈内)以及它们的Schmid因子[9]Figure 2. (a) EBSD map of AM30 sample pulled to 0.08 strain showing two contraction twins (The black circles indicate strain compatibility.); (b) EBSD map of a {

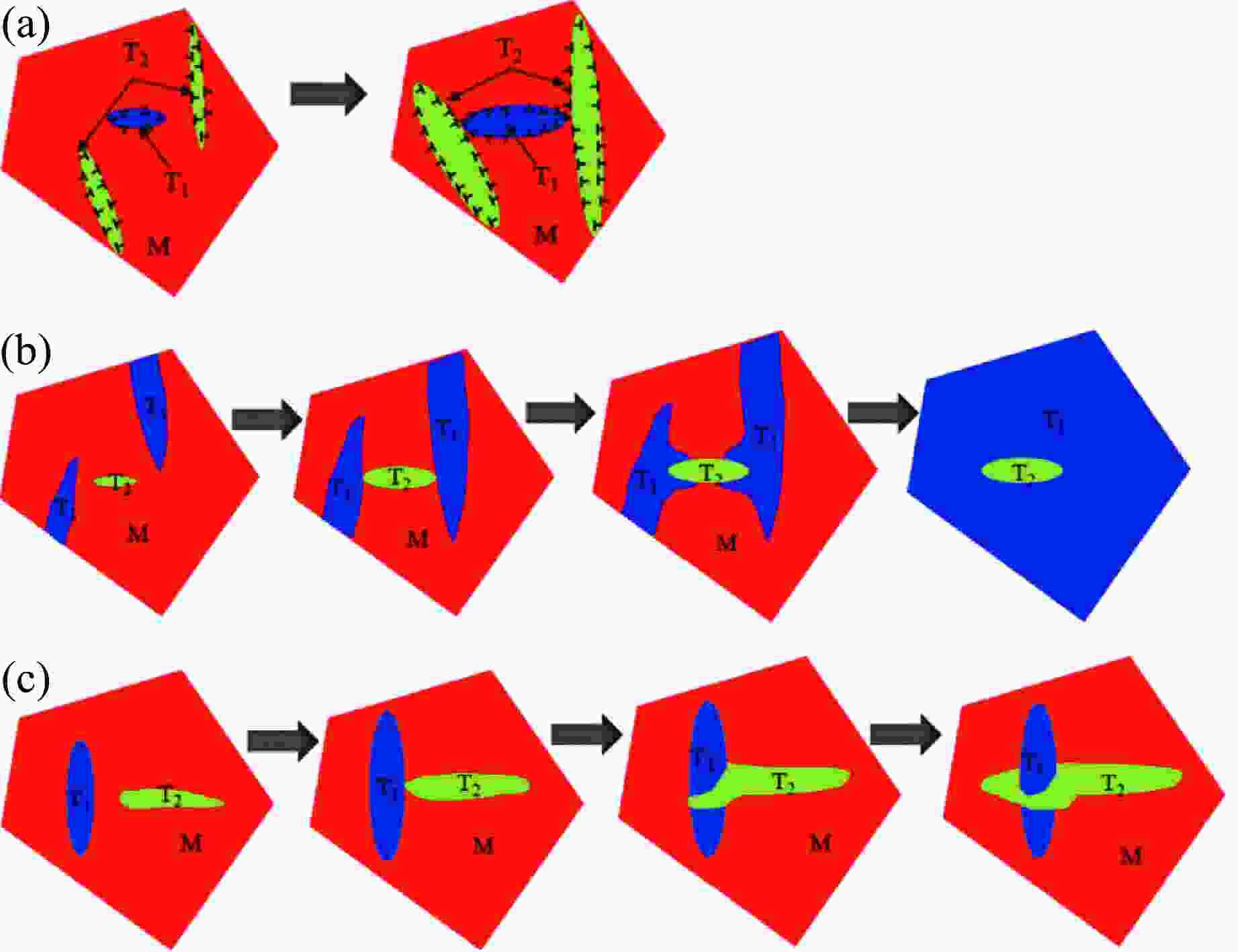

$10\overline {1}1$ } contraction twin (in red) formed within a near rolling direction orientation; (c) (0002) pole figure for the Fig.2 (b) matrix (black hexagon), the six twin variants (black squares), the selected variant (circled in black), and their respective Schmid factors[9]图 5 (a)基于传统孪晶理论的孪晶相互作用(由于孪晶位错不能穿透孪晶界,当两者相互靠近时将阻碍孪晶的增长);(b)非位错形式的孪晶增长(T1)(孪晶能够通过改变孪晶面产生分支而包围另一个孪晶);(c) 非位错形式的孪晶增长(T2)(孪晶通过侧向成长而绕过另一个孪晶)[45]

Figure 5. (a) Twin-twin interaction based on classical twinning theory (The growth of the twin variants will be impeded as the variants approach close to each other because the twinning dislocations are unable to penetrate the twin boundaries.); (b) non-dislocation mediated twin growth (T1) (A twin variant can branch out by changing the habit plane and surround the other variant.); (c) non-dislocation mediated twin growth (T2) (A twin variant can spread laterally and grow around the other variant.)[45]

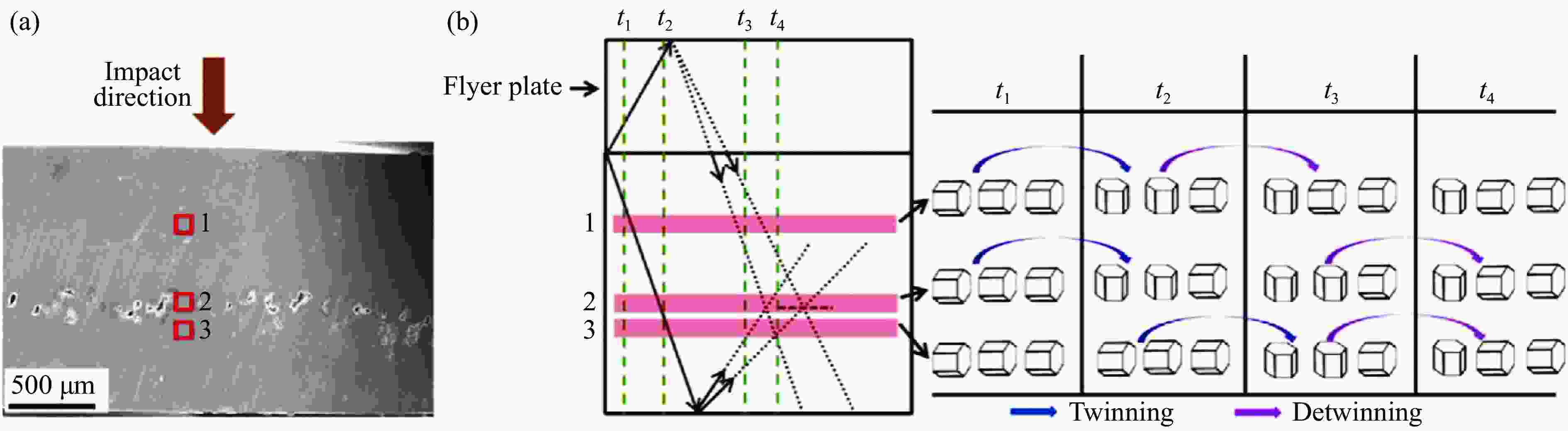

图 6 冲击波传播和材料微结构:(a)冲击示意图和3个观测点;(b)冲击波传播的时间-位置图和3个观测点在不同时刻(t)的微结构[1]

Figure 6. The propagation of shock wave and the microstructure of material: (a) The schematic diagram of shock and three observation point; (b) the time-distance diagram of the shock experiment and corresponding schematic diagrams of the microstructure at 3 location at different times (t)[1]

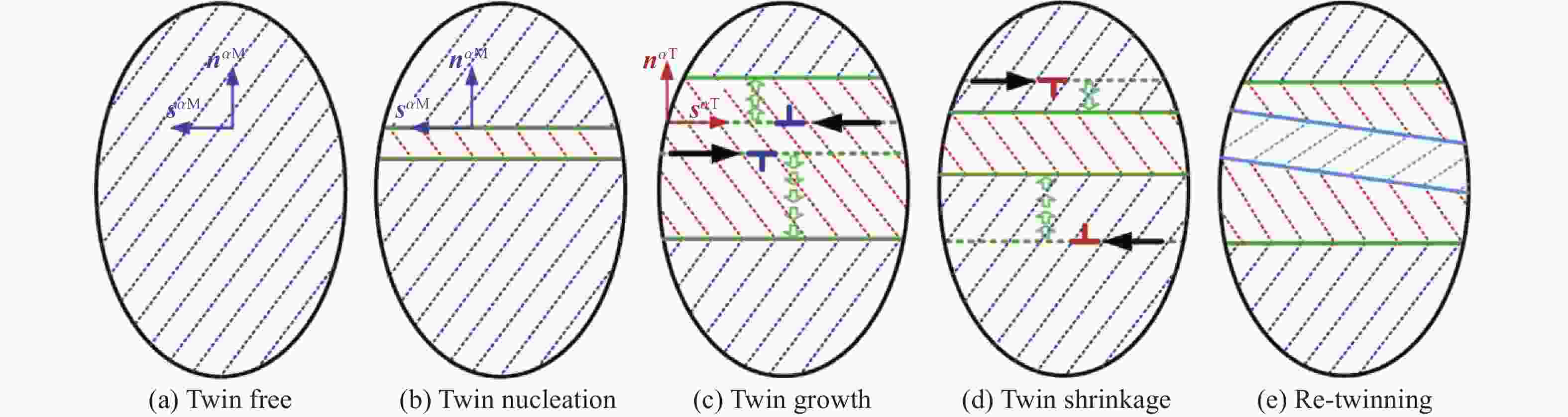

图 9 晶粒内的孪晶和退孪晶过程示意图(绿色实线为孪晶界,蓝色和红色点线代表晶格取向;

${s}^{\alpha {\mathrm{M}}}$ 和${n}^{\alpha {\mathrm{M}}}$ 分别表示基体中孪晶面和法线,${s}^{\alpha {\mathrm{T}}}$ 和${n}^{\alpha {\mathrm{T}}}$ 表示孪晶区域中孪晶面和法线方向)[91]Figure 9. Schematic representation of twinning and de-twinning in a grain (Solid green lines represent twinning boundaries; Lattices orientations are represented by dotted blue lines and dotted red lines;

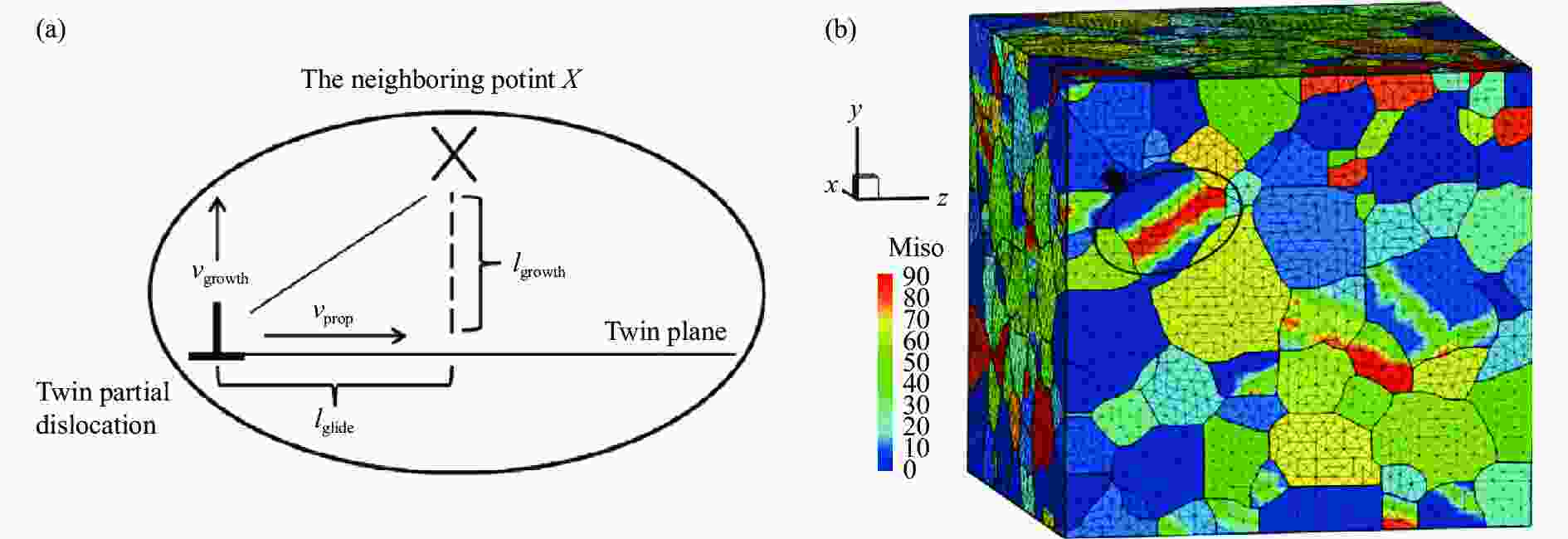

${{{s}}}^{\alpha {\mathrm{M}}}$ and${{{n}}}^{\alpha {\mathrm{M}}}$ are the twinning plane and normal direction in matrix;${{{s}}}^{\alpha {\mathrm{T}}}$ and${{{n}}}^{\alpha {\mathrm{T}}}$ are the twinning plane and normal direction in twin domain.)[91]图 10 (a)孪晶不全位错通过孪晶面滑动和垂直于孪晶面增长到临近点X的传播示意图(

$ {l}_{\mathrm{g}\mathrm{l}\mathrm{i}\mathrm{d}\mathrm{e}} $ 和$ {l}_{\mathrm{g}\mathrm{r}\mathrm{o}\mathrm{w}\mathrm{t}\mathrm{h}} $ 为孪晶成核点到增长点X的水平和垂直距离,$ {v}_{\mathrm{p}\mathrm{r}\mathrm{o}\mathrm{p}} $ 和$ {v}_{\mathrm{g}\mathrm{r}\mathrm{o}\mathrm{w}\mathrm{t}\mathrm{h}} $ 为孪晶沿孪晶面和孪晶面法线的增长速度);(b)包含孪晶的多晶微结构(晶粒内不同颜色代表不同取向)[95]Figure 10. (a) Sketch map of a twin partial dislocation propagation to a neighboring point X by respectively gliding on the twin plane and growing normal to it (

$ {l}_{\mathrm{g}\mathrm{l}\mathrm{i}\mathrm{d}\mathrm{e}} $ and$ {l}_{\mathrm{g}\mathrm{r}\mathrm{o}\mathrm{w}\mathrm{t}\mathrm{h}} $ are the horizontal and vertical distances from twin nucleation point to growth point X.$ {v}_{\mathrm{p}\mathrm{r}\mathrm{o}\mathrm{p}} $ and$ {v}_{\mathrm{g}\mathrm{r}\mathrm{o}\mathrm{w}\mathrm{t}\mathrm{h}} $ are the growth velocity of twins along the twin plane and its normal.); (b) polycrystalline microstructure with twins (Different colors in grains represent different orientations.)[95] -

[1] YU X, LI T, LI L, et al. Influence of initial texture on the shock property and spall behavior of magnesium alloy AZ31B [J]. Materials Science and Engineering: A, 2017, 700: 259–268. doi: 10.1016/j.msea.2017.06.015 [2] ZHANG F, HAO M, WANG F C, et al. Role of {10–12} twinning and detwinning in the shock-hardening behavior of rolled Mg-3Al-1Zn alloy [J]. Scripta Materialia, 2012, 67(12): 951–954. doi: 10.1016/j.scriptamat.2012.08.027 [3] PROUST G, TOMÉ C N, JAIN A, et al. Modeling the effect of twinning and detwinning during strain-path changes of magnesium alloy AZ31 [J]. International Journal of Plasticity, 2009, 25(5): 861–880. doi: 10.1016/j.ijplas.2008.05.005 [4] WANG H, WU P D, TOMÉ C N, et al. A constitutive model of twinning and detwinning for hexagonal close packed polycrystals [J]. Materials Science and Engineering: A, 2012, 555: 93–98. doi: 10.1016/j.msea.2012.06.038 [5] CHRISTIAN J W, MAHAJAN S. Deformation twinning [J]. Progress in Materials Science, 1995, 39(1/2): 1–157. doi: 10.1016/0079-6425(94)00007-7 [6] PARK S H, HONG S G, LEE J H, et al. Multiple twinning modes in rolled Mg-3Al-1Zn alloy and their selection mechanism [J]. Materials Science and Engineering: A, 2012, 532: 401–406. doi: 10.1016/j.msea.2011.11.003 [7] XU S, TYSON W R, EAGLESON R, et al. Dependence of flow strength and deformation mechanisms in common wrought and die cast magnesium alloys on orientation, strain rate and temperature [J]. Journal of Magnesium and Alloys, 2013, 1(4): 275–282. doi: 10.1016/j.jma.2013.11.003 [8] BEYERLEIN I J, CAPOLUNGO L, MARSHALL P E, et al. Statistical analyses of deformation twinning in magnesium [J]. Philosophical Magazine, 2010, 90(16): 2161–2190. doi: 10.1080/14786431003630835 [9] JONAS J J, MU S J, AL-SAMMAN T, et al. The role of strain accommodation during the variant selection of primary twins in magnesium [J]. Acta Materialia, 2011, 59(5): 2046–2056. doi: 10.1016/j.actamat.2010.12.005 [10] MU S J, JONAS J J, GOTTSTEIN G. Variant selection of primary, secondary and tertiary twins in a deformed Mg alloy [J]. Acta Materialia, 2012, 60(5): 2043–2053. doi: 10.1016/j.actamat.2012.01.014 [11] BARNETT M R, KESHAVARZ Z, BEER A G, et al. Non-Schmid behaviour during secondary twinning in a polycrystalline magnesium alloy [J]. Acta Materialia, 2008, 56(1): 5–15. doi: 10.1016/j.actamat.2007.08.034 [12] LOU C, ZHANG X Y, REN Y. Non-Schmid-based {10-12} twinning behavior in polycrystalline magnesium alloy [J]. Materials Characterization, 2015, 107: 249–254. doi: 10.1016/j.matchar.2015.07.022 [13] SONG B, XIN R L, LIANG Y C, et al. Twinning characteristic and variant selection in compression of a pre-side-rolled Mg alloy sheet [J]. Materials Science and Engineering: A, 2014, 614: 106–115. doi: 10.1016/j.msea.2014.07.026 [14] LUO J R, GODFREY A, LIU W, et al. Twinning behavior of a strongly basal textured AZ31 Mg alloy during warm rolling [J]. Acta Materialia, 2012, 60(5): 1986–1998. doi: 10.1016/j.actamat.2011.12.017 [15] BARNETT M R, KESHAVARZ Z, NAVE M D. Microstructural features of rolled Mg-3Al-1Zn [J]. Metallurgical and Materials Transactions A, 2005, 36(7): 1697–1704. doi: 10.1007/s11661-005-0033-3 [16] CHEN S F, SONG H W, ZHANG S H, et al. An effective Schmid factor in consideration of combined normal and shear stresses for slip/twin variant selection of Mg-3Al-1Zn alloy [J]. Scripta Materialia, 2019, 167: 51–55. doi: 10.1016/j.scriptamat.2019.03.026 [17] GUO C F, XIAO Y, XIN R L. Evaluation of twinning behavior in rolling of Mg alloys with three kinds of textures by a generalized schmid factor [J]. Metals and Materials International, 2020, 26(9): 1366–1372. doi: 10.1007/s12540-019-00378-0 [18] XIN R L, LIU Z, SUN Y J, et al. Understanding common grain boundary twins in Mg alloys by a composite Schmid factor [J]. International Journal of Plasticity, 2019, 123: 208–223. doi: 10.1016/j.ijplas.2019.07.018 [19] GUO C F, XIN R L, DING C H, et al. Understanding of variant selection and twin patterns in compressed Mg alloy sheets via combined analysis of Schmid factor and strain compatibility factor [J]. Materials Science and Engineering: A, 2014, 609: 92–101. doi: 10.1016/j.msea.2014.04.103 [20] LIU G D, XIN R L, SHU X G, et al. The mechanism of twinning activation and variant selection in magnesium alloys dominated by slip deformation [J]. Journal of Alloys and Compounds, 2016, 687: 352–359. doi: 10.1016/j.jallcom.2016.06.136 [21] SHI Z Z, ZHANG Y D, WAGNER F, et al. On the selection of extension twin variants with low Schmid factors in a deformed Mg alloy [J]. Acta Materialia, 2015, 83: 17–28. doi: 10.1016/j.actamat.2014.10.004 [22] HE W J, CHEN X, CHEN H, et al. Grain size effect on the thermally activated twin boundary migration in a zirconium alloy [J]. Materials Science and Engineering: A, 2018, 724: 576–585. doi: 10.1016/j.msea.2018.03.118 [23] KIM Y J, LEE J U, KIM S H, et al. Grain size effect on twinning and annealing behaviors of rolled magnesium alloy with bimodal structure [J]. Materials Science and Engineering: A, 2019, 754: 38–45. doi: 10.1016/j.msea.2019.03.041 [24] KIM Y J, LEE J U, KIM S H, et al. Variation in crystallographic orientation and twinning activation with size of individual grains in rolled magnesium alloy [J]. Metals and Materials International, 2019, 25(6): 1541–1547. doi: 10.1007/s12540-019-00321-3 [25] DOBROŇ P, CHMELÍK F, YI S B, et al. Grain size effects on deformation twinning in an extruded magnesium alloy tested in compression [J]. Scripta Materialia, 2011, 65(5): 424–427. doi: 10.1016/j.scriptamat.2011.05.027 [26] GHADERI A, BARNETT M R. Sensitivity of deformation twinning to grain size in titanium and magnesium [J]. Acta Materialia, 2011, 59(20): 7824–7839. doi: 10.1016/j.actamat.2011.09.018 [27] KUMAR M A, WROŃSKI M, MCCABE R J, et al. Role of microstructure on twin nucleation and growth in HCP titanium: a statistical study [J]. Acta Materialia, 2018, 148: 123–132. doi: 10.1016/j.actamat.2018.01.041 [28] ASGARI H, ODESHI A G, SZPUNAR J A, et al. Grain size dependence of dynamic mechanical behavior of AZ31B magnesium alloy sheet under compressive shock loading [J]. Materials Characterization, 2015, 106: 359–367. doi: 10.1016/j.matchar.2015.06.030 [29] MEYERS M A, VÖHRINGER O, LUBARDA V A. The onset of twinning in metals: a constitutive description [J]. Acta Materialia, 2001, 49(19): 4025–4039. doi: 10.1016/S1359-6454(01)00300-7 [30] CERRETA E, YABLINSKY C A, GRAY Ⅲ T G, et al. The influence of grain size and texture on the mechanical response of high purity hafnium [J]. Materials Science and Engineering: A, 2007, 456(1/2): 243–251. doi: 10.1016/j.msea.2006.11.111 [31] MARCINKOWSKI M J, LIPSITT H A. The plastic deformation of chromium at low temperatures [J]. Acta Metallurgica, 1962, 10(2): 95–111. doi: 10.1016/0001-6160(62)90055-X [32] ARMSTRONG R W, WORTHINGTON P J. A constitutive relation for deformation twinning in body centered cubic metals [M]//ROHDE R W, BUTCHER B M, HOLLAND J R, et al. Metallurgical Effects at High Strain Rates. Boston, MA: Springer, 1973: 401-414. [33] HONG S G, PARK S H, LEE C S. Role of {10–12} twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy [J]. Acta Materialia, 2010, 58(18): 5873–5885. doi: 10.1016/j.actamat.2010.07.002 [34] BOHLEN J, DOBROŇ P, SWIOSTEK J, et al. On the influence of the grain size and solute content on the AE response of magnesium alloys tested in tension and compression [J]. Materials Science and Engineering: A, 2007, 462(1/2): 302–306. doi: 10.1016/j.msea.2006.02.470 [35] YU H H, XIN Y C, WANG M Y, et al. Hall-petch relationship in Mg alloys: a review [J]. Journal of Materials Science & Technology, 2018, 34(2): 248–256. doi: 10.1016/j.jmst.2017.07.022 [36] YU H H, LI C Z, XIN Y C, et al. The mechanism for the high dependence of the Hall-Petch slope for twinning/slip on texture in Mg alloys [J]. Acta Materialia, 2017, 128: 313–326. doi: 10.1016/j.actamat.2017.02.044 [37] SOMEKAWA H, MUKAI T. Hall-Petch relation for deformation twinning in solid solution magnesium alloys [J]. Materials Science and Engineering: A, 2013, 561: 378–385. doi: 10.1016/j.msea.2012.10.040 [38] JIN Z Z, ZHA M, YU Z Y, et al. Exploring the Hall-Petch relation and strengthening mechanism of bimodal-grained Mg-Al-Zn alloys [J]. Journal of Alloys and Compounds, 2020, 833: 155004. doi: 10.1016/j.jallcom.2020.155004 [39] ZHOU P, XIAO D W, JIANG C L, et al. Twin interactions in pure Ti under high strain rate compression [J]. Metallurgical and Materials Transactions A, 2017, 48(1): 126–138. doi: 10.1007/s11661-016-3832-9 [40] WANG B S, XIN R L, HUANG G J, et al. Strain rate and texture effects on microstructural characteristics of Mg-3Al-1Zn alloy during compression [J]. Scripta Materialia, 2012, 66(5): 239–242. doi: 10.1016/j.scriptamat.2011.10.046 [41] DUDAMELL N V, ULACIA I, GÁLVEZ F, et al. Twinning and grain subdivision during dynamic deformation of a Mg AZ31 sheet alloy at room temperature [J]. Acta Materialia, 2011, 59(18): 6949–6962. doi: 10.1016/j.actamat.2011.07.047 [42] MAKSOUD I A, AHMED H, RÖDEL J. Investigation of the effect of strain rate and temperature on the deformability and microstructure evolution of AZ31 magnesium alloy [J]. Materials Science and Engineering: A, 2009, 504(1/2): 40–48. doi: 10.1016/j.msea.2008.10.033 [43] LI L, MURÁNSKY O, FLORES-JOHNSON E A, et al. Effects of strain rate on the microstructure evolution and mechanical response of magnesium alloy AZ31 [J]. Materials Science and Engineering: A, 2017, 684: 37–46. doi: 10.1016/j.msea.2016.12.015 [44] AHMAD I R, SHU D W. Compressive and constitutive analysis of AZ31B magnesium alloy over a wide range of strain rates [J]. Materials Science and Engineering: A, 2014, 592: 40–49. doi: 10.1016/j.msea.2013.10.056 [45] MAO B, LIAO Y L, LI B. Abnormal twin-twin interaction in an Mg-3Al-1Zn magnesium alloy processed by laser shock peening [J]. Scripta Materialia, 2019, 165: 89–93. doi: 10.1016/j.scriptamat.2019.02.028 [46] BERGE F, KRÜGER L, OUAZIZ H, et al. Influence of temperature and strain rate on flow stress behavior of twin-roll cast, rolled and heat-treated AZ31 magnesium alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 1–13. doi: 10.1016/S1003-6326(15)63572-5 [47] WANG M, LU L, LI C, et al. Deformation and spallation of a magnesium alloy under high strain rate loading [J]. Materials Science and Engineering: A, 2016, 661: 126–131. doi: 10.1016/j.msea.2016.03.009 [48] DIXIT N, XIE K Y, HEMKER K J, et al. Microstructural evolution of pure magnesium under high strain rate loading [J]. Acta Materialia, 2015, 87: 56–67. doi: 10.1016/j.actamat.2014.12.030 [49] YU J C, SONG B, XIA D B, et al. Dynamic tensile properties and microstructural evolution of extruded EW75 magnesium alloy at high strain rates [J]. Journal of Magnesium and Alloys, 2020, 8(3): 849–859. doi: 10.1016/j.jma.2020.02.013 [50] KURUKURI S, WORSWICK M J, TARI D G, et al. Rate sensitivity and tension-compression asymmetry in AZ31B magnesium alloy sheet [J]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2014, 372: 20130216. doi: 10.1098/rsta.2013.0216 [51] ULACIA I, DUDAMELL N V, GÁLVEZ F, et al. Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates [J]. Acta Materialia, 2010, 58(8): 2988–2998. doi: 10.1016/j.actamat.2010.01.029 [52] HAZELL P J, APPLEBY-THOMAS G J, WIELEWSKI E, et al. The influence of microstructure on the shock and spall behaviour of the magnesium alloy, Elektron 675 [J]. Acta Materialia, 2012, 60(17): 6042–6050. doi: 10.1016/j.actamat.2012.07.041 [53] DIXIT N, FARBANIEC L, RAMESH K T. Twinning in single crystal Mg under microsecond impact along the 〈a〉axis [J]. Materials Science and Engineering: A, 2017, 693(1): 22–25. doi: 10.1016/j.msea.2017.03.074 [54] WINEY J M, RENGANATHAN P, GUPTA Y M. Shock wave compression and release of hexagonal-close-packed metal single crystals: inelastic deformation of c-axis magnesium [J]. Journal of Applied Physics, 2015, 117(10): 105903. doi: 10.1063/1.4914525 [55] KANEL G I, GARKUSHIN G V, SAVINYKH A S, et al. Shock response of magnesium single crystals at normal and elevated temperatures [J]. Journal of Applied Physics, 2014, 116(14): 143504. doi: 10.1063/1.4897555 [56] RESSÉGUIER D T, HEMERY S, LESCOUTE E, et al. Spall fracture and twinning in laser shock-loaded single-crystal magnesium [J]. Journal of Applied Physics, 2017, 121(16): 165104. doi: 10.1063/1.4982352 [57] MILLETT J C F, STIRK S M, BOURNE N K, et al. On the behaviour of the magnesium alloy, AZ61 to one-dimensional shock loading [J]. Acta Materialia, 2010, 58(17): 5675–5682. doi: 10.1016/j.actamat.2010.06.042 [58] CEPEDA-JIMÉNEZ C M, MOLINA-ALDAREGUIA J M, PÉREZ-PRADO M T. Origin of the twinning to slip transition with grain size refinement, with decreasing strain rate and with increasing temperature in magnesium [J]. Acta Materialia, 2015, 88: 232–244. doi: 10.1016/j.actamat.2015.01.032 [59] MISHRA B, MUKHOPADHYAY A, SIVA KUMAR K, et al. Effect of test temperature on flow behavior and strain hardening of magnesium under high strain rate deformation conditions [J]. Materials Science and Engineering: A, 2020, 770: 138546. doi: 10.1016/j.msea.2019.138546 [60] KALIDINDI S R. Incorporation of deformation twinning in crystal plasticity models [J]. Journal of the Mechanics and Physics of Solids, 1998, 46(2): 267–271, 273–290. doi: 10.1016/S0022-5096(97)00051-3 [61] IZADBAKHSH A, INAL K, MISHRA R K, et al. New crystal plasticity constitutive model for large strain deformation in single crystals of magnesium [J]. Computational Materials Science, 2011, 50(7): 2185–2202. doi: 10.1016/j.commatsci.2011.02.030 [62] FAN H D, AUBRY S, ARSENLIS A, et al. The role of twinning deformation on the hardening response of polycrystalline magnesium from discrete dislocation dynamics simulations [J]. Acta Materialia, 2015, 92: 126–139. doi: 10.1016/j.actamat.2015.03.039 [63] NAMAKIAN R, VOYIADJIS G Z, KWAŚNIAK P. On the slip and twinning mechanisms on first order pyramidal plane of magnesium: molecular dynamics simulations and first principal studies [J]. Materials & Design, 2020, 191: 108648. doi: 10.1016/j.matdes.2020.108648 [64] HEO T W, WANG Y, BHATTACHARYA S, et al. A phase-field model for deformation twinning [J]. Philosophical Magazine Letters, 2011, 91(2): 110–121. doi: 10.1080/09500839.2010.537284 [65] TAYLOR G I. Plastic strain in metals [J]. Journal of the Institute of Metals, 1938, 62: 307–324. [66] HILL R. Generalized constitutive relations for incremental deformation of metal crystals by multislip [J]. Journal of the Mechanics and Physics of Solids, 1966, 14(2): 95–105. doi: 10.1016/0022-5096(66)90040-8 [67] ASARO R J, RICE J R. Strain localization in ductile single crystals [J]. Journal of the Mechanics and Physics of Solids, 1977, 25(5): 309–338. doi: 10.1016/0022-5096(77)90001-1 [68] SACHS G. Plasticity problems in metals [J]. Zeitschrift Verein Deutcher Ingenieur, 1928, 72: 734–736. [69] LEBENSOHN R A, TOMÉ C N. A self-consistent anisotropic approach for the simulation of plastic-deformation and texture development of polycrystals: application to zirconium alloys [J]. Acta Metallurgica et Materialia, 1993, 41(9): 2611–2624. doi: 10.1016/0956-7151(93)90130-K [70] LEBENSOHN R A, TOMÉ C N. A self-consistent viscoplastic model: prediction of rolling textures of anisotropic polycrystals [J]. Materials Science and Engineering: A, 1994, 175(1/2): 71–82. doi: 10.1016/0921-5093(94)91047-2 [71] ROTERS F, EISENLOHR P, HANTCHERLI L, et al. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: theory, experiments, applications [J]. Acta Materialia, 2010, 58(4): 1152–1211. doi: 10.1016/j.actamat.2009.10.058 [72] 郑松林. 晶体塑性有限元在材料动态响应研究中的应用进展 [J]. 高压物理学报, 2019, 33(3): 030108. doi: 10.11858/gywlxb.20190725ZHENG S L. Advances in the study of dynamic response of crystalline materials by crystal plasticity finite element modeling [J]. Chinese Journal of High Pressure Physics, 2019, 33(3): 030108. doi: 10.11858/gywlxb.20190725 [73] 刘静楠, 叶常青, 刘桂森, 等. 高温、高压、高应变速率动态过程晶体塑性有限元理论模型及其应用 [J]. 高压物理学报, 2020, 34(3): 030102. doi: 10.11858/gywlxb.20190874LIU J N, YE C Q, LIU G S, et al. Crystal plasticity finite element theoretical models and applications for high temperature, high pressure and high strain-rate dynamic process [J]. Chinese Journal of High Pressure Physics, 2020, 34(3): 030102. doi: 10.11858/gywlxb.20190874 [74] VANHOUTTE P. Simulation of the rolling and shear texture of brass by the Taylor theory adapted for mechanical twinning [J]. Acta Metallurgica, 1978, 26(4): 591–604. doi: 10.1016/0001-6160(78)90111-6 [75] TOMÉ C N, LEBENSOHN R A, KOCKS U F. A model for texture development dominated by deformation twinning: application to zirconium alloys [J]. Acta Metallurgica et Materialia, 1991, 39(11): 2667–2680. doi: 10.1016/0956-7151(91)90083-D [76] SALEM A A, KALIDINDI S R, SEMIATIN S L. Strain hardening due to deformation twinning in α-titanium: constitutive relations and crystal-plasticity modeling [J]. Acta Materialia, 2005, 53(12): 3495–3502. doi: 10.1016/j.actamat.2005.04.014 [77] ABDOLVAND H, DAYMOND M R, MAREAU C. Incorporation of twinning into a crystal plasticity finite element model: evolution of lattice strains and texture in Zircaloy-2 [J]. International Journal of Plasticity, 2011, 27(11): 1721–1738. doi: 10.1016/j.ijplas.2011.04.005 [78] TADANO Y, YOSHIHARA Y, HAGIHARA S. A crystal plasticity modeling considering volume fraction of deformation twinning [J]. International Journal of Plasticity, 2016, 84: 88–101. doi: 10.1016/j.ijplas.2016.05.002 [79] LIU Q, ROY A, SILBERSCHMIDT V V. Temperature-dependent crystal-plasticity model for magnesium: a bottom-up approach [J]. Mechanics of Materials, 2017, 113: 44–56. doi: 10.1016/j.mechmat.2017.07.008 [80] ZHANG J, JOSHI S P. Phenomenological crystal plasticity modeling and detailed micromechanical investigations of pure magnesium [J]. Journal of the Mechanics and Physics of Solids, 2012, 60(5): 945–972. doi: 10.1016/j.jmps.2012.01.005 [81] ARDELJAN M, MCCABE R J, BEYERLEIN I J, et al. Explicit incorporation of deformation twins into crystal plasticity finite element models [J]. Computer Methods in Applied Mechanics and Engineering, 2015, 295: 396–413. doi: 10.1016/j.cma.2015.07.003 [82] SUN C Y, GUO N, FU M W, et al. Modeling of slip, twinning and transformation induced plastic deformation for TWIP steel based on crystal plasticity [J]. International Journal of Plasticity, 2016, 76: 186–212. doi: 10.1016/j.ijplas.2015.08.003 [83] 潘昊, 王升涛, 吴子辉, 等. 孪晶对Be材料冲击加-卸载动力学影响的数值模拟研究 [J]. 物理学报, 2018, 67(16): 164601. doi: 10.7498/aps.67.20180451PAN H, WANG S T, WU Z H, et al. Effect of twining on dynamic behaviors of beryllium materials under impact loading and unloading [J]. Acta Physica Sinica, 2018, 67(16): 164601. doi: 10.7498/aps.67.20180451 [84] 郑华雷, 杨合, 李宏伟. 纯钛压缩变形下的晶体塑性有限元分析 [J]. 塑性工程学报, 2013, 20(1): 95–99. doi: 10.3969/j.issn.1007-2012.2013.01.020ZHENG H L, YANG H, LI H W. Crystal plasticity finite element modeling for uniaxial compression of commercially pure titanium [J]. Journal of Plasticity Engineering, 2013, 20(1): 95–99. doi: 10.3969/j.issn.1007-2012.2013.01.020 [85] STAROSELSKY A, ANAND L. Inelastic deformation of polycrystalline face centered cubic materials by slip and twinning [J]. Journal of the Mechanics and Physics of Solids, 1998, 46(4): 671–673, 675–696. doi: 10.1016/S0022-5096(97)00071-9 [86] STAROSELSKY A, ANAND L. A constitutive model for hcp materials deforming by slip and twinning: application to magnesium alloy AZ31B [J]. International Journal of Plasticity, 2003, 19(10): 1843–1864. doi: 10.1016/S0749-6419(03)00039-1 [87] STEINMETZ D R, JÄPEL T, WIETBROCK B, et al. Revealing the strain-hardening behavior of twinning-induced plasticity steels: theory, simulations, experiments [J]. Acta Materialia, 2013, 61(2): 494–510. doi: 10.1016/j.actamat.2012.09.064 [88] WONG S L, MADIVALA M, PRAHL U, et al. A crystal plasticity model for twinning- and transformation-induced plasticity [J]. Acta Materialia, 2016, 118: 140–151. doi: 10.1016/j.actamat.2016.07.032 [89] PROUST G, TOMÉ C N, KASCHNER G C. Modeling texture, twinning and hardening evolution during deformation of hexagonal materials [J]. Acta Materialia, 2007, 55(6): 2137–2148. doi: 10.1016/j.actamat.2006.11.017 [90] BEYERLEIN I J, TOMÉ C N. A dislocation-based constitutive law for pure Zr including temperature effects [J]. International Journal of Plasticity, 2008, 24(5): 867–895. doi: 10.1016/j.ijplas.2007.07.017 [91] WANG H, WU P D, WANG J, et al. A crystal plasticity model for hexagonal close packed (HCP) crystals including twinning and de-twinning mechanisms [J]. International Journal of Plasticity, 2013, 49: 36–52. doi: 10.1016/j.ijplas.2013.02.016 [92] WU P D, GUO X Q, QIAO H, et al. A constitutive model of twin nucleation, propagation and growth in magnesium crystals [J]. Materials Science and Engineering: A, 2015, 625: 140–145. doi: 10.1016/j.msea.2014.11.096 [93] XIE Q J, ZHU Z W, KANG G Z, et al. Crystal plasticity-based impact dynamic constitutive model of magnesium alloy [J]. International Journal of Mechanical Sciences, 2016, 119: 107–113. [94] CHENG J H, GHOSH S. A crystal plasticity FE model for deformation with twin nucleation in magnesium alloys [J]. International Journal of Plasticity, 2015, 67(1): 148–170. doi: 10.1016/j.ijmecsci.2016.10.012 [95] CHENG J H, GHOSH S. Crystal plasticity finite element modeling of discrete twin evolution in polycrystalline magnesium [J]. Journal of the Mechanics and Physics of Solids, 2017, 99: 512–538. doi: 10.1016/j.jmps.2016.12.008 [96] WINEY J M, GUPTA Y M. Shock wave compression of hexagonal-close-packed metal single crystals: time-dependent, anisotropic elastic-plastic response of beryllium [J]. Journal of Applied Physics, 2014, 116(3): 033505. doi: 10.1063/1.4889886 [97] RENGANATHAN P, WINEY J M, GUPTA Y M. Shock compression and release of a-axis magnesium single crystals: anisotropy and time dependent inelastic response [J]. Journal of Applied Physics, 2017, 121(3): 035901. doi: 10.1063/1.4974365 [98] FENG B, BRONKHORST C A, ADDESSIO F L, et al. Coupled elasticity, plastic slip, and twinning in single crystal titanium loaded by split-Hopkinson pressure bar [J]. Journal of the Mechanics and Physics of Solids, 2018, 119: 274–297. doi: 10.1016/j.jmps.2018.06.018 [99] FENG B, BRONKHORST C A, ADDESSIO F L, et al. Coupled nonlinear elasticity, plastic slip, twinning, and phase transformation in single crystal titanium for plate impact loading [J]. Journal of the Mechanics and Physics of Solids, 2019, 127: 358–385. doi: 10.1016/j.jmps.2019.03.019 [100] KONDO R, TADANO Y, SHIZAWA K. A phase-field model of twinning and detwinning coupled with dislocation-based crystal plasticity for HCP metals [J]. Computational Materials Science, 2014, 95: 672–683. doi: 10.1016/j.commatsci.2014.08.034 [101] LIU C, SHANTHRAJ P, DIEHL M, et al. An integrated crystal plasticity-phase field model for spatially resolved twin nucleation, propagation, and growth in hexagonal materials [J]. International Journal of Plasticity, 2018, 106: 203–227. [102] LIU G S, MO H X, WANG J, et al. Coupled crystal plasticity finite element-phase field model with kinetics-controlled twinning mechanism for hexagonal metals [J]. Acta Materialia, 2021, 202: 399–416. doi: 10.1016/j.actamat.2020.11.002 -

下载:

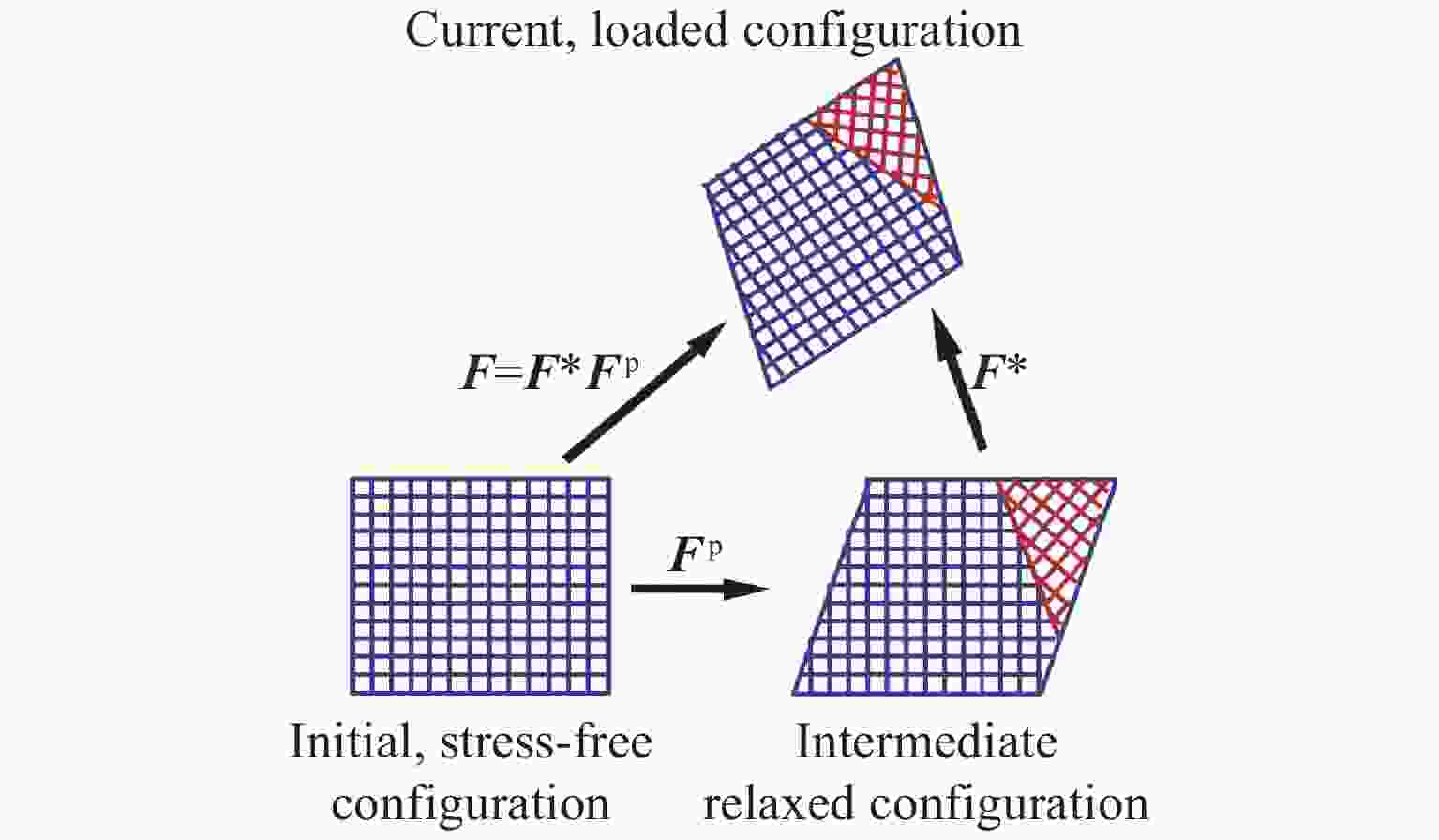

下载: