Impact Characteristics of Drone Aircraft in Airbag Cushion Landing

-

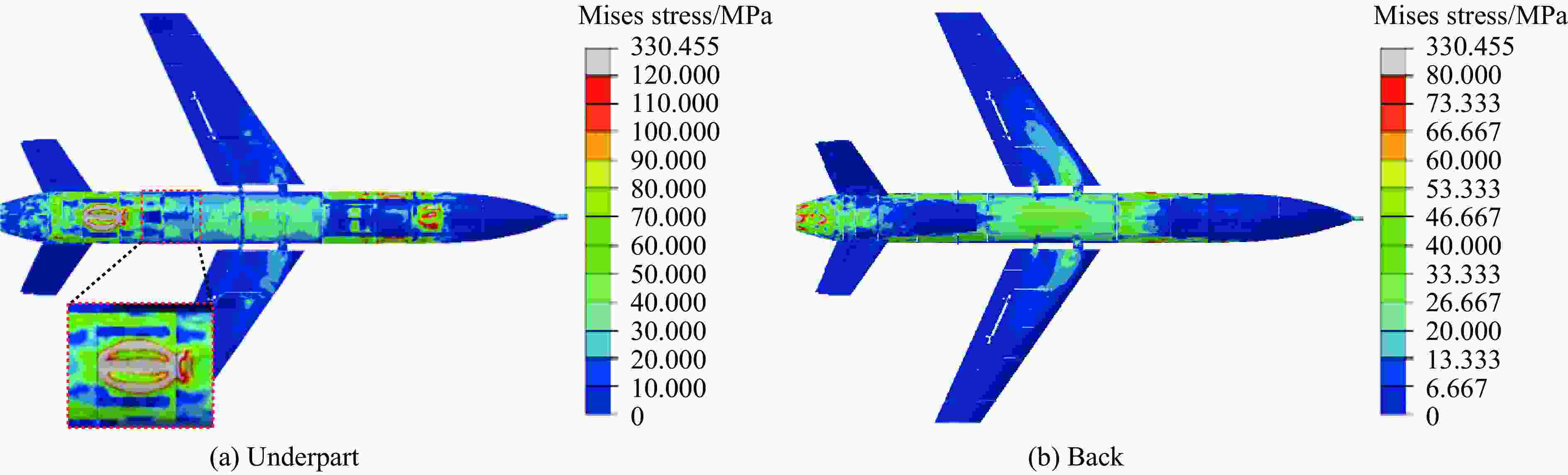

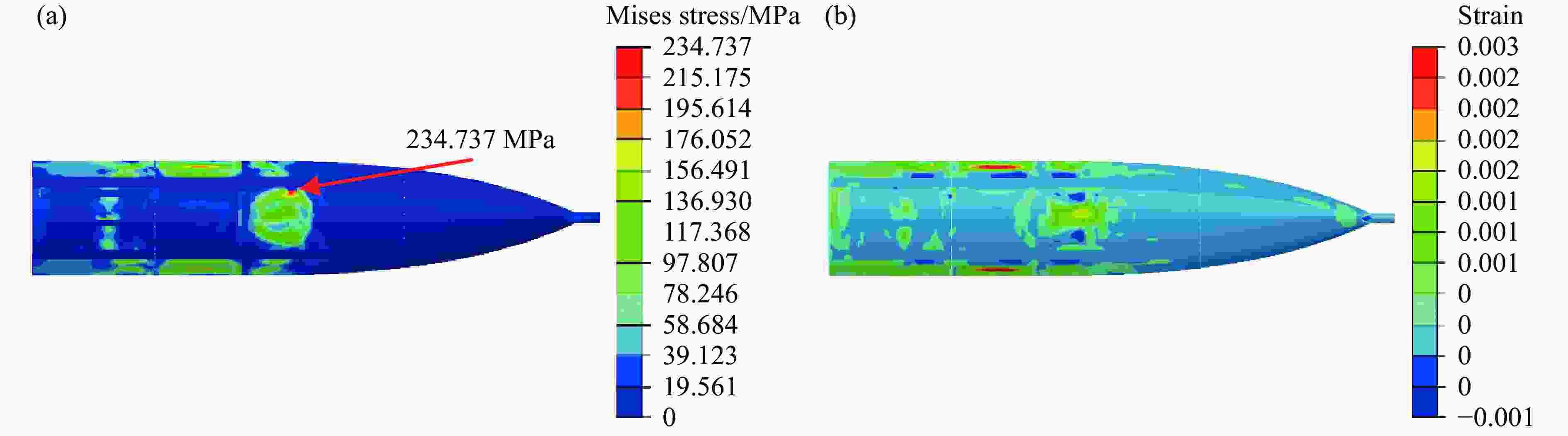

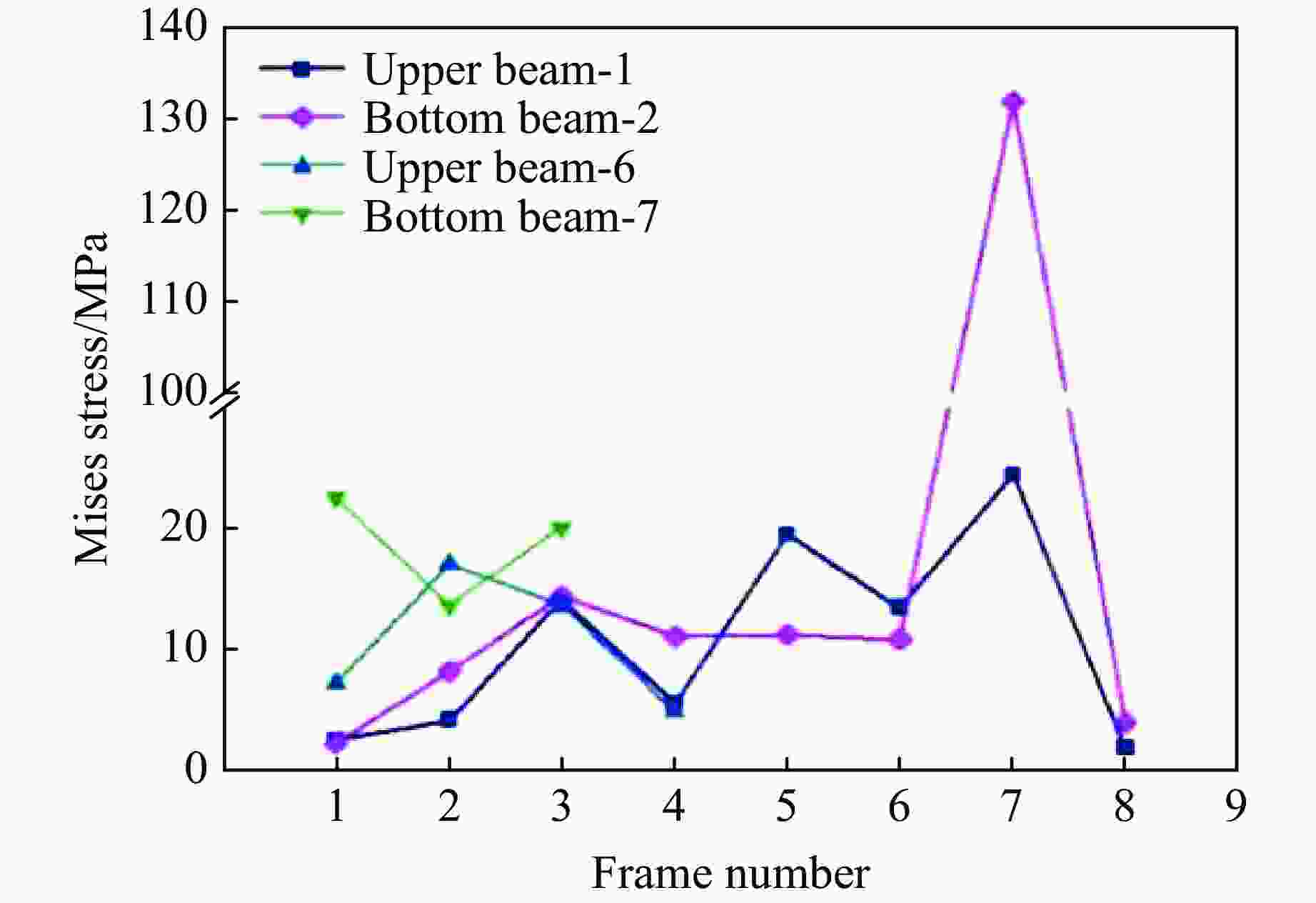

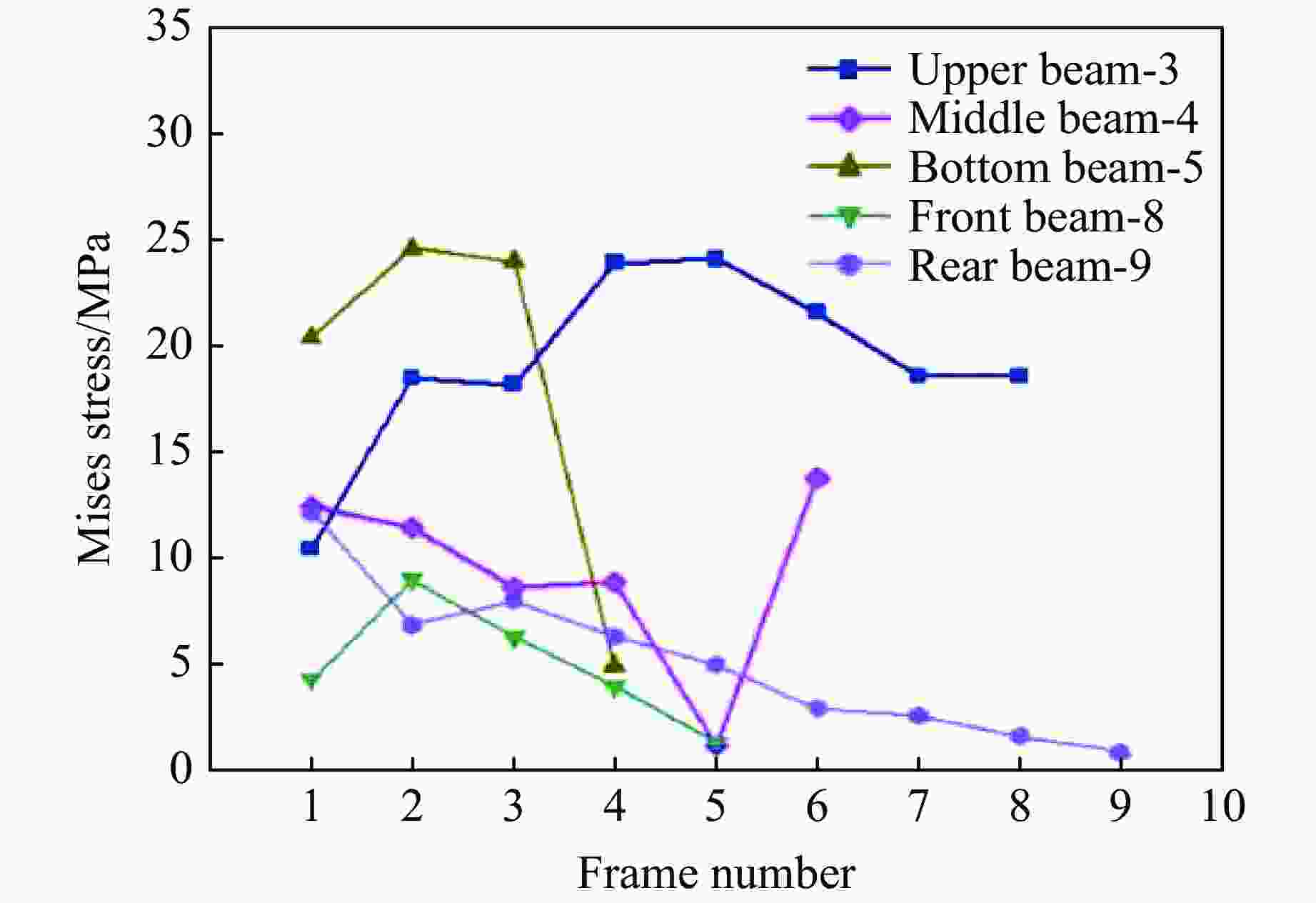

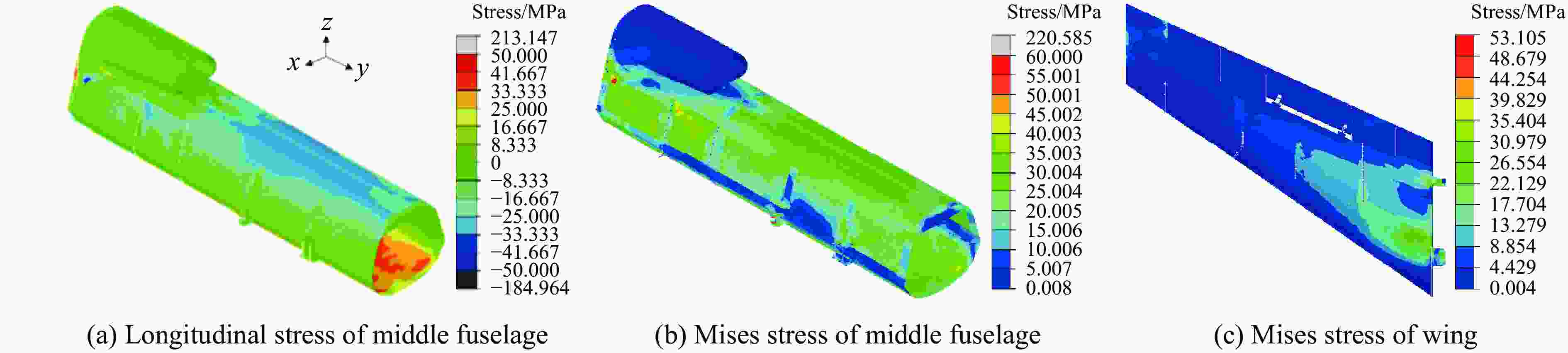

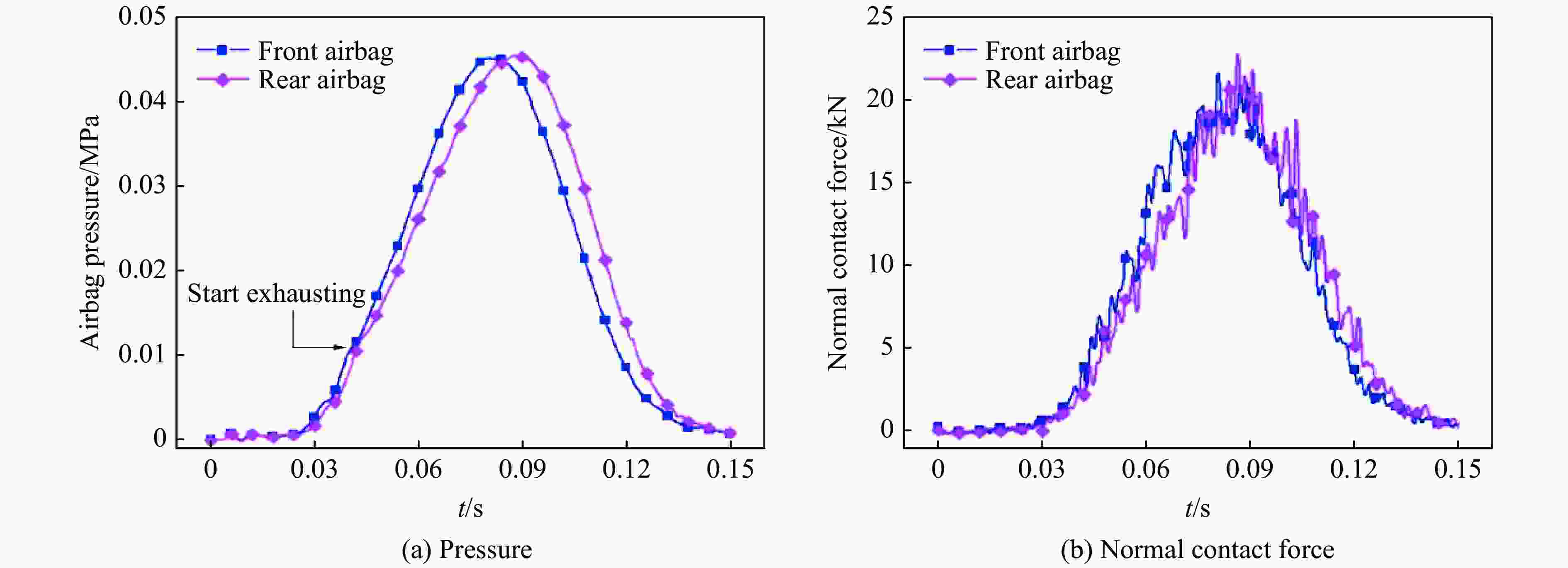

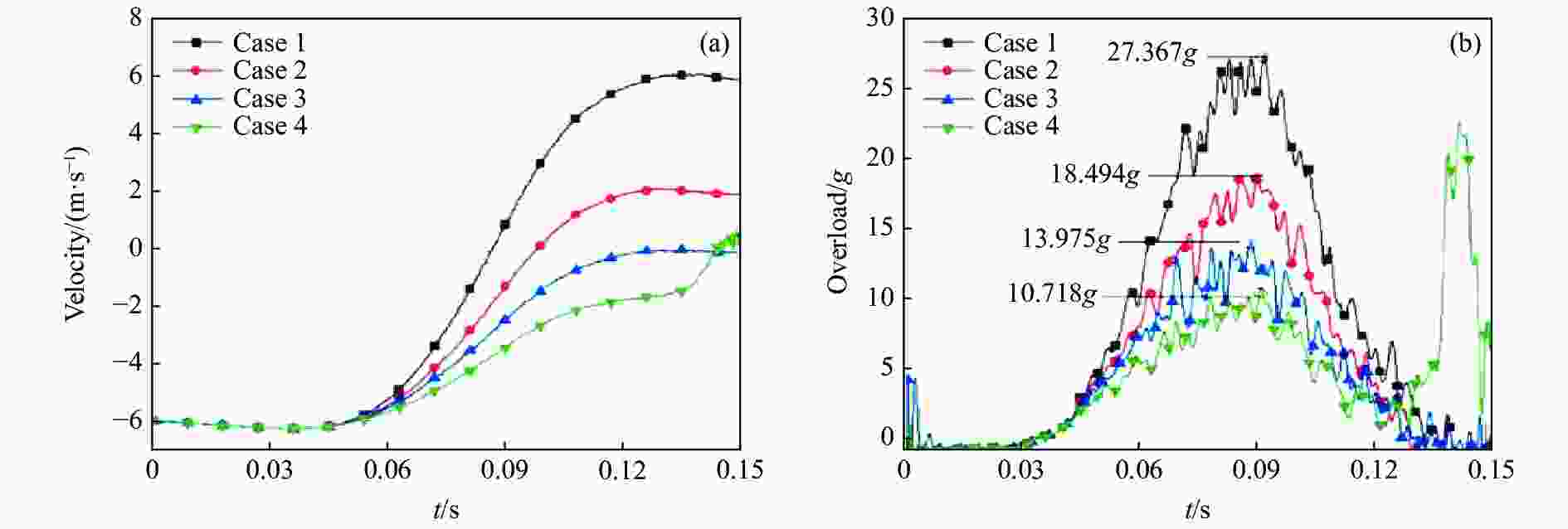

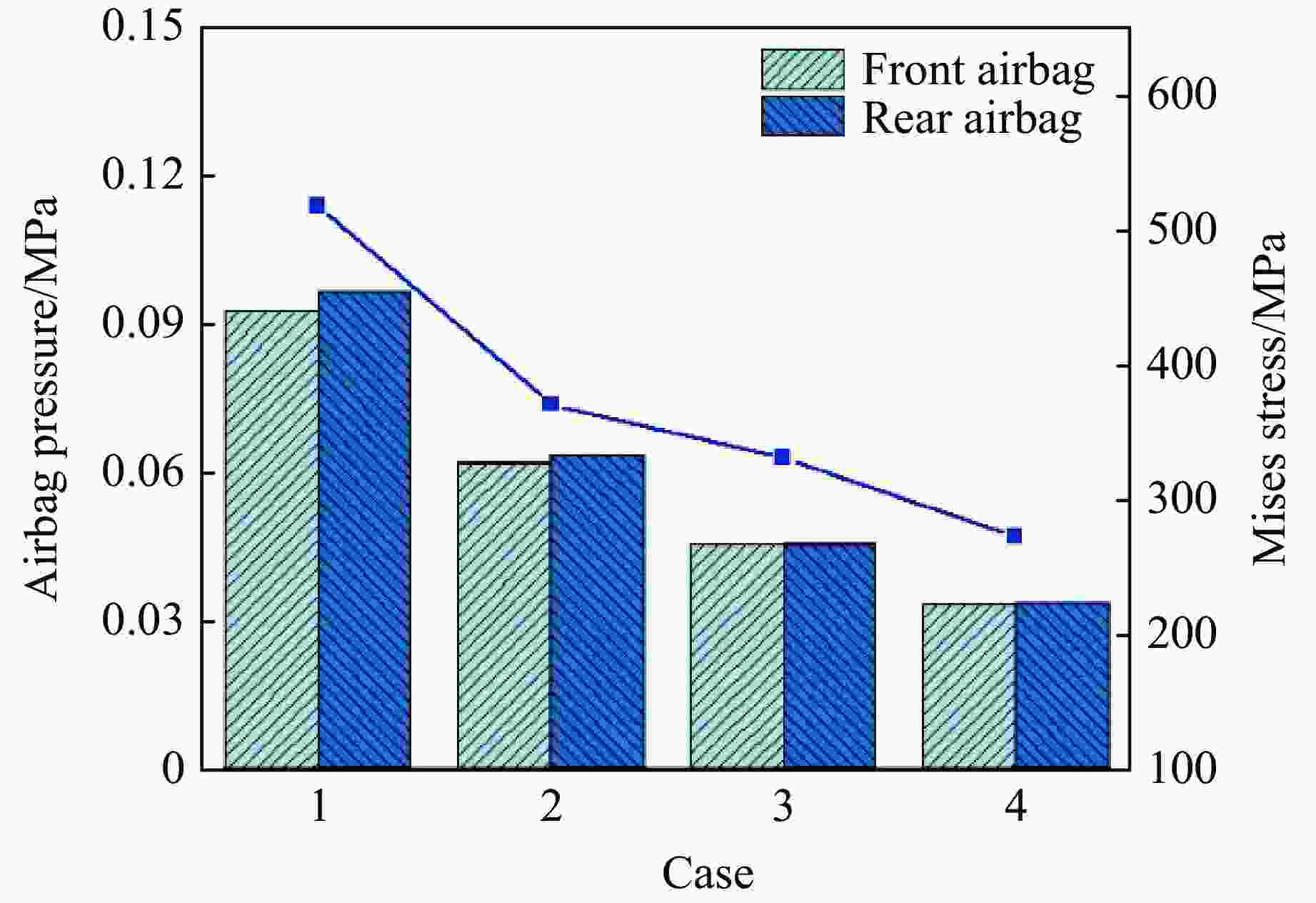

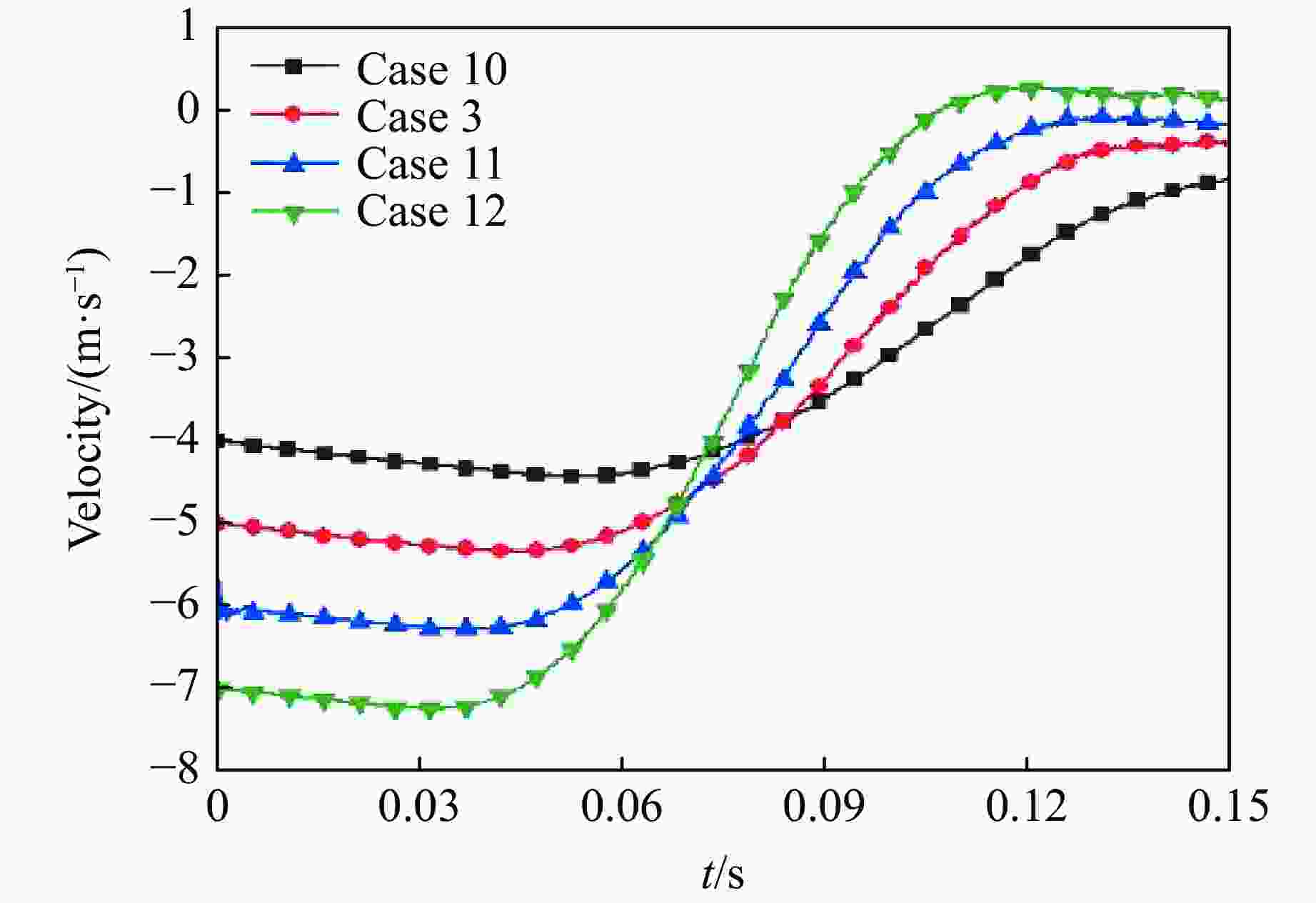

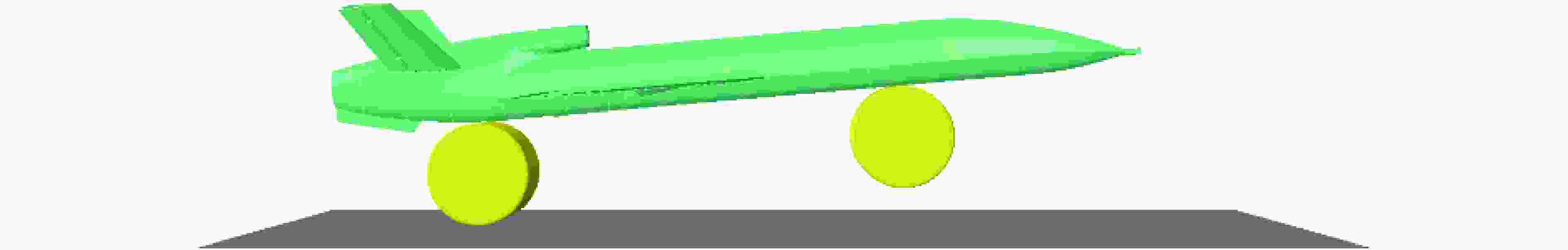

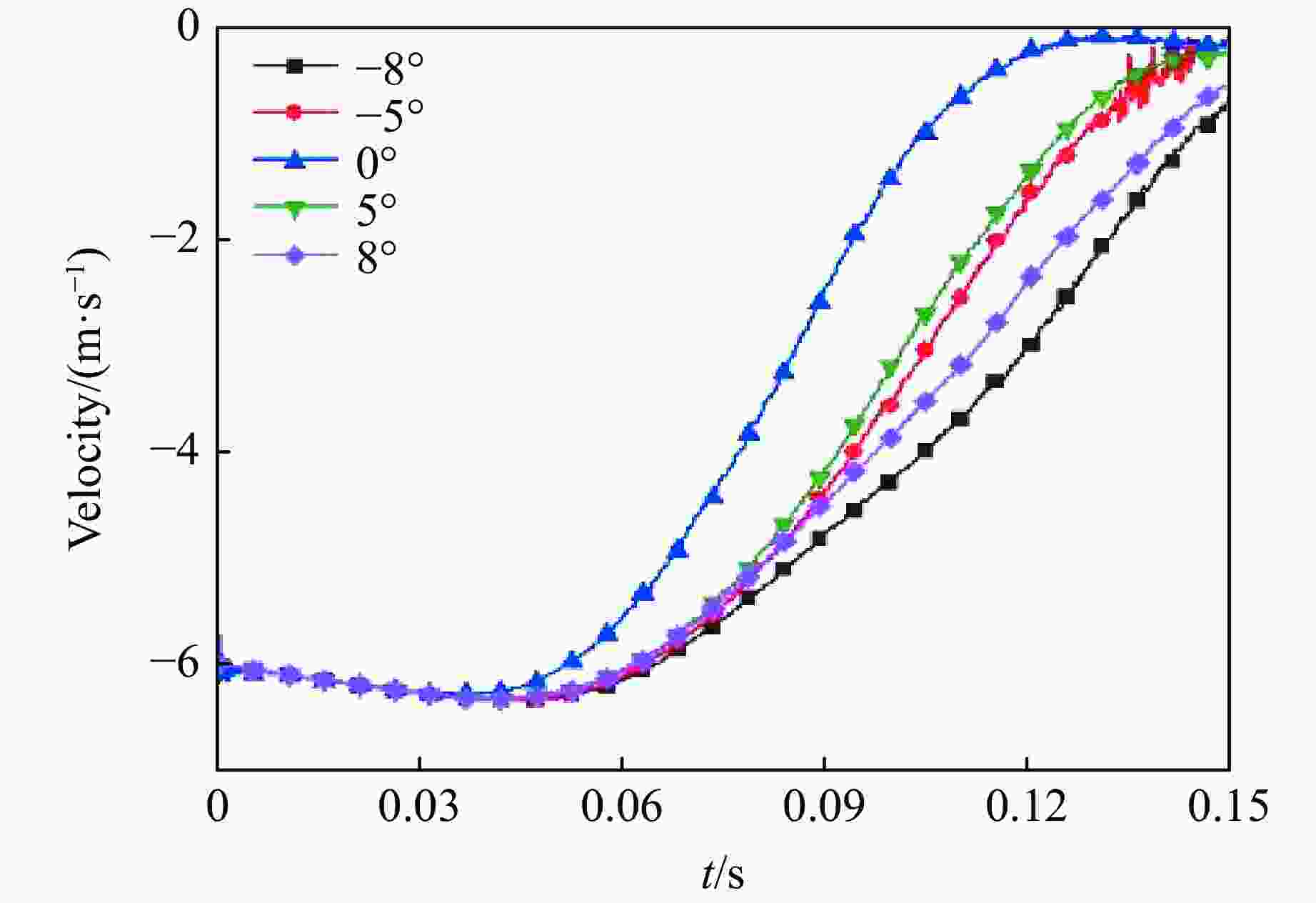

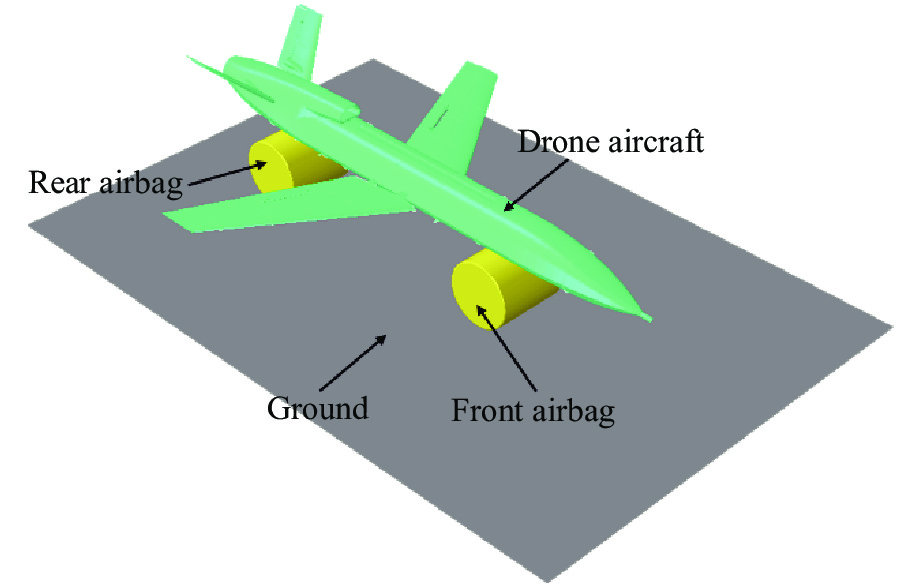

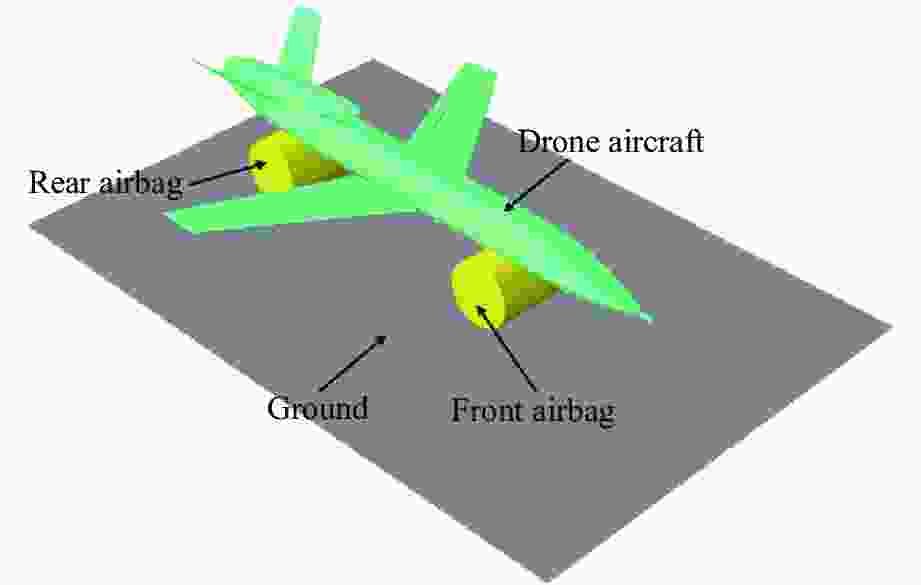

摘要: 针对缓冲着陆过程中靶机气囊的瞬态动力学响应问题,采用显式动力计算方法和均压气囊模型分析靶机气囊缓冲着陆阶段机身、机翼在冲击作用下的动力学响应,得到靶机回收过程中的姿态与强度特性和气囊变化参数。探讨了气囊缓冲参数(排气口面积、气囊初始内压及排气阈值)和靶机状态等参数对靶机着陆过程中机身的影响。结果表明:标准工况下,经过气囊缓冲后的靶机姿态、强度符合安全着陆要求。通过分析着陆过程中的相关参数发现,气囊排气口面积对缓冲效果影响较大,气囊排气压力阈值和初始内压影响较小,同一气囊对靶机不同着陆初始速度的适应性高,带有俯仰角的靶机后着陆后机身部分区域的局部应力偏大。该方法可以广泛用于飞机气囊缓冲的动力学计算,结合气囊落震试验以获取相应的气囊参数和机身结构响应数据,为靶机设计提供依据。Abstract: Aiming at the transient dynamic response of drone aircraft cushion landing with airbag, the explicit dynamic calculation method and pressure equalizing airbag model are adopted to analyze the dynamic response of drone aircraft fuselage and wings under impact during cushion landing with airbag, and the attitude and strength characteristics and airbag parameters in the recovery process of drone aircraft are obtained. The effects of airbag cushion parameters (orifice area, initial internal pressure and exhaust threshold) and drone aircraft state on the fuselage of drone aircraft during landing are discussed. The results show that: under the standard conditions, the aircraft’s attitude and strength meet the requirements of safe landing after buffering with airbag. Through the analysis of different landing parameters, it is found that the area of the airbag exhaust vent has a great impact on the cushioning effect, while the threshold of the airbag exhaust pressure and the initial internal pressure have little impact on it. The same airbag has high adaptability to different initial landing speeds of drone aircraft. The local stress of the later landing fuselage of the drone aircraft with pitch angle is too large. This method can be widely used in the dynamic calculation of aircraft airbag cushion. Combined with the airbag drop test, the corresponding airbag parameters and fuselage structure response data can be obtained, which provides a basis for the design of target aircraft.

-

Key words:

- drone aircraft /

- airbag /

- cushion landing /

- dynamic response /

- cushion parameter

-

表 1 靶机材料的相关参数

Table 1. Aircraft material parameters

Material Density/(g·cm−3) Elastic modulus/

GPaPoisson’s ratio Yield stress/

MPaAluminium alloy 2.800 66 0.330 325 Alloy structural steel 7.760 196 0.300 835 Glass fiber composite 2.030 23 0.074 Carbon fiber composite 1.560 58 0.074 表 2 不同缓冲工况的相关参数

Table 2. Relevant parameters of different cushion conditions

Case No. Orifice

area/mm2Initial internal

pressure/MPaDischarge pressure

threshold/kPaLanding

speed/(m·s−1)Pitch

angle/(°)1 0 0.101 10.1 6 0 2 1696.4 0.101 10.1 6 0 3 2827.4 0.101 10.1 6 0 4 3958.4 0.101 10.1 6 0 5 2827.4 0.106 10.1 6 0 6 2827.4 0.108 10.1 6 0 7 2827.4 0.110 10.1 6 0 8 2827.4 0.101 30.3 6 0 9 2827.4 0.101 50.5 6 0 10 2827.4 0.101 10.1 4 0 11 2827.4 0.101 10.1 5 0 12 2827.4 0.101 10.1 7 0 13 2827.4 0.101 10.1 6 5 14 2827.4 0.101 10.1 6 −5 15 2827.4 0.101 10.1 6 8 16 2827.4 0.101 10.1 6 −8 -

[1] 温金鹏, 李斌, 杨智春. 缓冲气囊冲击减缓研究进展 [J]. 宇航学报, 2010, 31(11): 2438–2447. doi: 10.3873/j.issn.1000-1328.2010.11.002WEN J P, LI B, YANG Z C. Progress of study on impact attenuation capability of airbag cushion system [J]. Journal of Astronautics, 2010, 31(11): 2438–2447. doi: 10.3873/j.issn.1000-1328.2010.11.002 [2] 戈嗣诚, 施允涛. 无人机回收气囊缓冲特性研究 [J]. 南京航空航天大学学报, 1999, 31(4): 458–463. doi: 10.3969/j.issn.1005-2615.1999.04.016GE S C, SHI Y T. Study on cushioning characteristics of air bag for RPV recovery [J]. Journal of Nanjing University of Aeronautics & Astronautics, 1999, 31(4): 458–463. doi: 10.3969/j.issn.1005-2615.1999.04.016 [3] 邵志建, 裴锦华. 某无人机横向圆柱排气式气囊着陆装置缓冲过程研究 [J]. 航天返回与遥感, 2016, 37(2): 26–33. doi: 10.3969/j.issn.1009-8518.2016.02.004SHAO Z J, PEI J H. Simulation of bi-cylindrical airbag cushioning system for pilotless aircraft [J]. Spacecraft Recovery & Remote Sensing, 2016, 37(2): 26–33. doi: 10.3969/j.issn.1009-8518.2016.02.004 [4] NEFSKE D J. A basic airbag model [C]//National Automobile Engineering Meeting.1972. [5] WANG J T, NEFSKE D J. A new CAL3D airbag inflation model [C]//SAE International Congress and Exposition, 1988. [6] 张红英, 杨璐瑜, 李姝磊. 空降空投中的气囊缓冲包装技术 [J]. 包装工程, 2016, 37(17): 20–24. doi: 10.19554/j.cnki.1001-3563.2016.17.006ZHANG H Y, YANG L Y, LI S L. Airbag cushion packaging technology in airborne airdrop [J]. Packaging Engineering, 2016, 37(17): 20–24. doi: 10.19554/j.cnki.1001-3563.2016.17.006 [7] 周强, 谭百贺. 可控排气式气囊着陆缓冲特性研究 [J]. 应用力学学报, 2019, 36(3): 687–690. doi: 10.11776/cjam.36.03.D039ZHOU Q, TAN B H. Study on landing buffer characters of a controllable vent airbag [J]. Chinese Journal of Applied Mechanics, 2019, 36(3): 687–690. doi: 10.11776/cjam.36.03.D039 [8] MARKLUND P O, NILSSON L. Simulation of airbag inflation processes using a coupled fluid structure approach [J]. Computational Mechanics, 2002, 29(4/5): 289–297. doi: 10.1007/S00466-002-0341-Z [9] 周默涵, 狄长春, 杨玉良, 等. 圆柱筒式空投气囊缓冲模拟 [J]. 包装工程, 2017, 38(17): 128–132. doi: 10.19554/j.cnki.1001-3563.2017.17.027ZHOU M H, DI C C, YANG Y L, et al. Simulation of cushion characteristic of cylindrical airdrop airbag [J]. Packaging Engineering, 2017, 38(17): 128–132. doi: 10.19554/j.cnki.1001-3563.2017.17.027 [10] SIMULIA D C S. Abaqus analysis user’s manual [EB/OL]. 2019. https://classes.engineering.wustl.edu/2009/spring/mase5513/abaqus/docs/v6.6/books/usb/default.htm?startat=pt05ch18s02abm24.html. [11] 冯晓伟, 卢永刚, 李永泽. 飞机目标在爆炸冲击波作用下的毁伤效应评估方法 [J]. 高压物理学报, 2019, 33(4): 045101. doi: 10.11858/gywlxb.20180687FENG X W, LU Y G, LI Y Z. Damage assessment method of aircraft targets under blast wave [J]. Chinese Journal of High Pressure Physics, 2019, 33(4): 045101. doi: 10.11858/gywlxb.20180687 [12] 周旋, 周仕明, 李道奎. 着陆缓冲气囊的无反弹设计方法研究 [J]. 载人航天, 2020, 26(2): 190–199. doi: 10.3969/j.issn.1674-5825.2020.02.009ZHOU X, ZHOU S M, LI D K. Research on design methods of landing impact attenuating airbag without rebound [J]. Manned Spaceflight, 2020, 26(2): 190–199. doi: 10.3969/j.issn.1674-5825.2020.02.009 -

下载:

下载: