Design and Energy Absorption Characteristic Analysis of a New Bio-Bamboo Thin-Walled Circular Tube

-

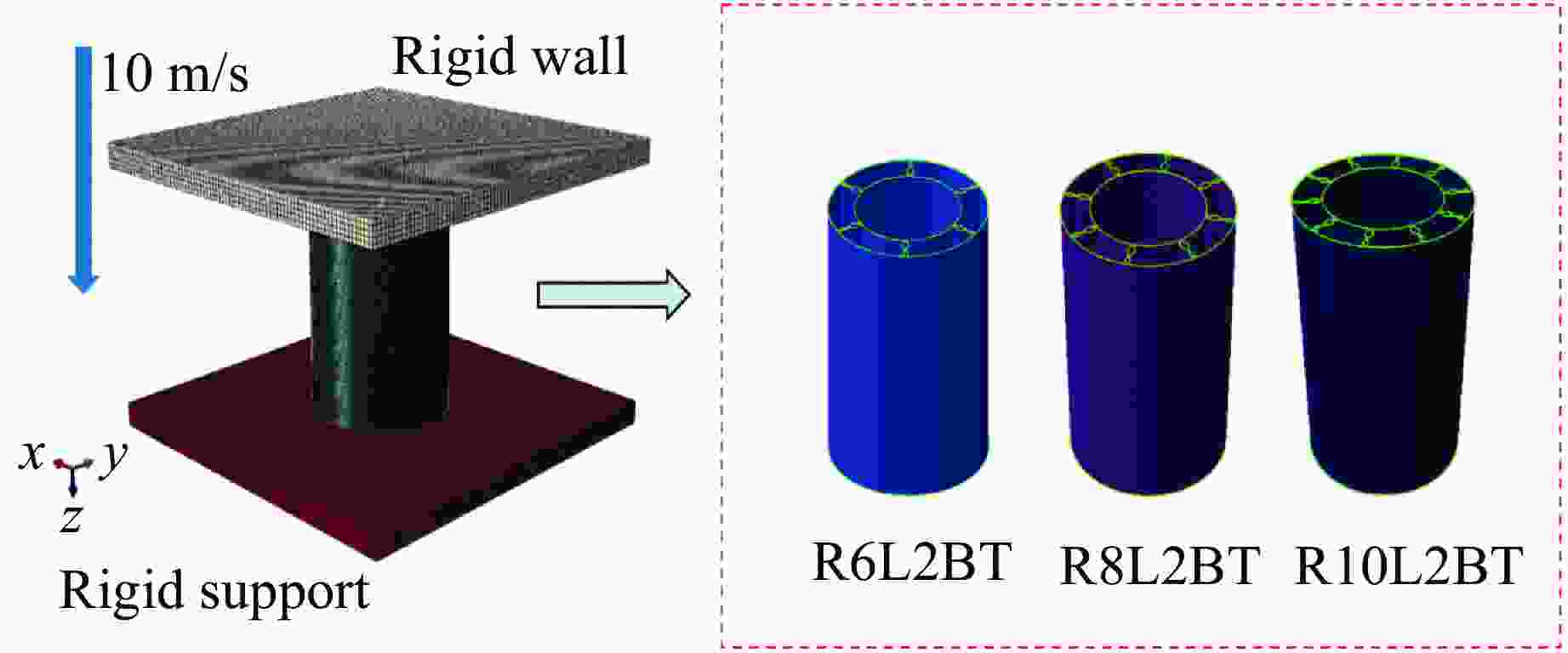

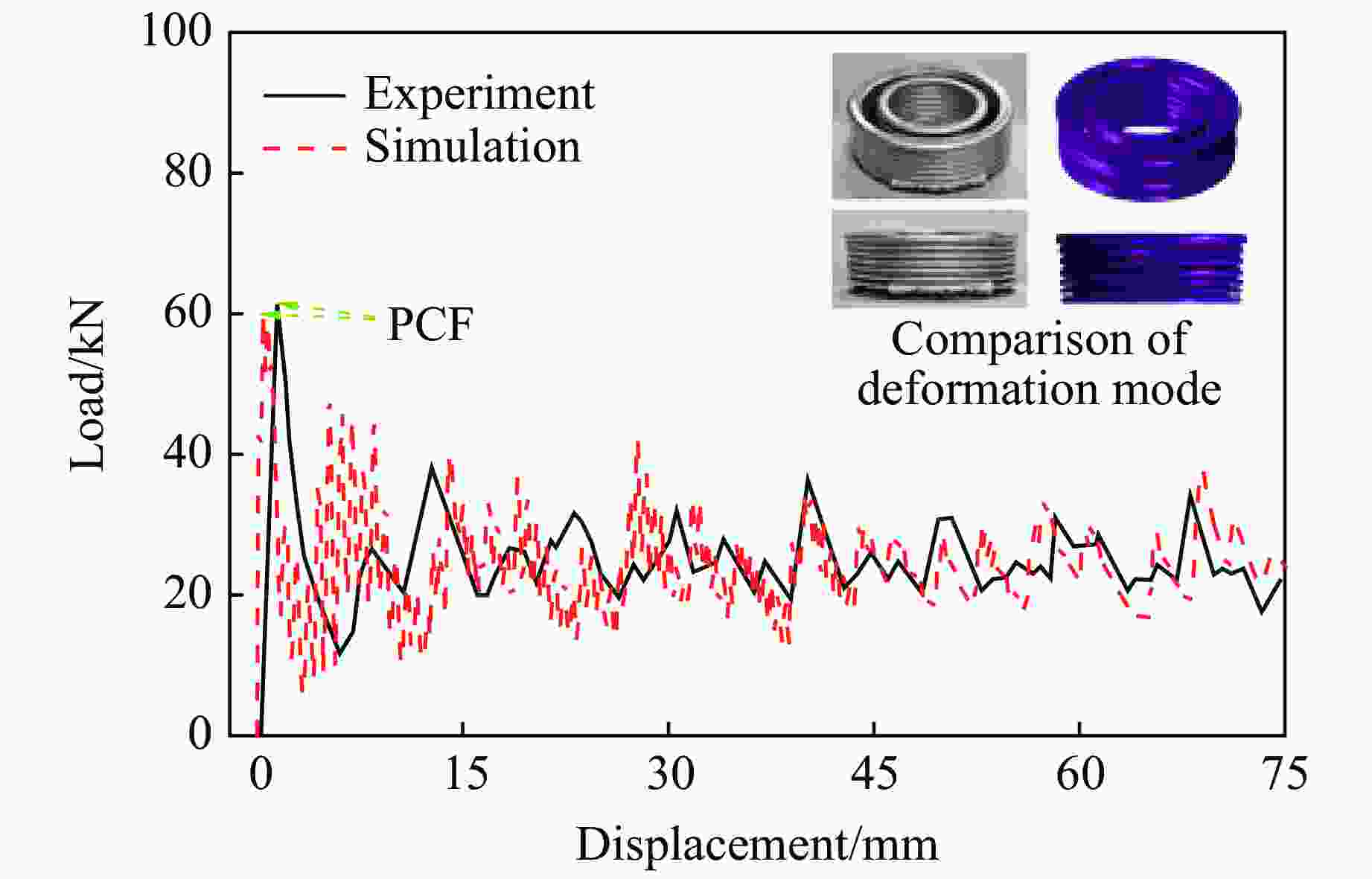

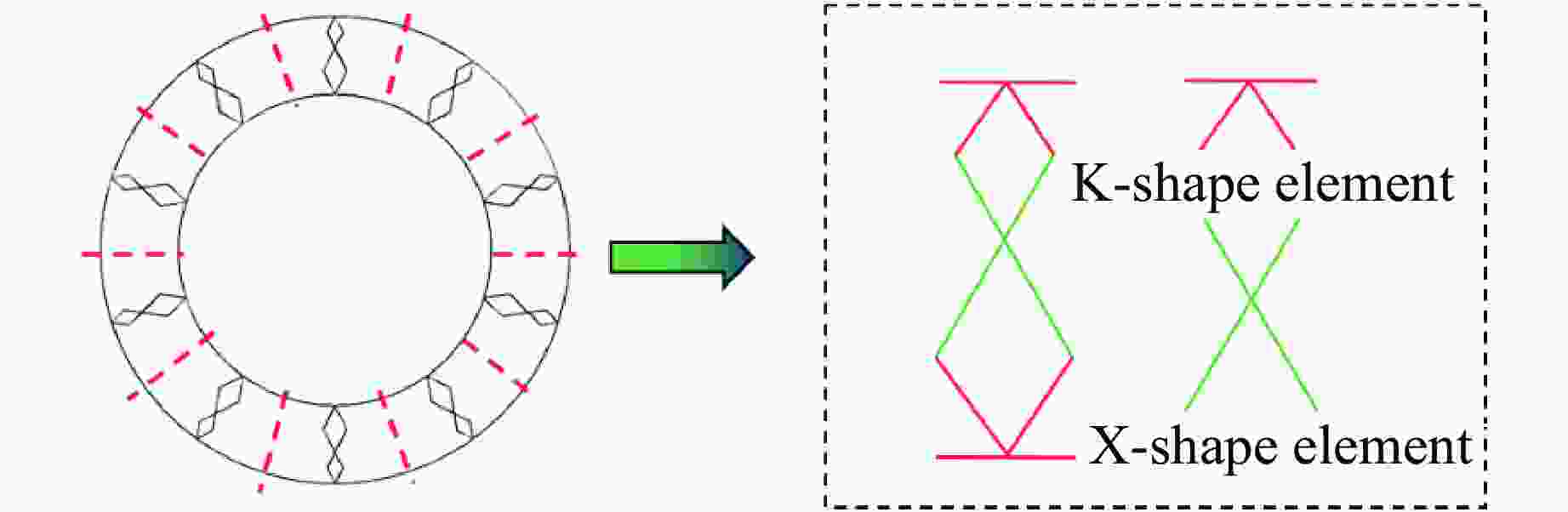

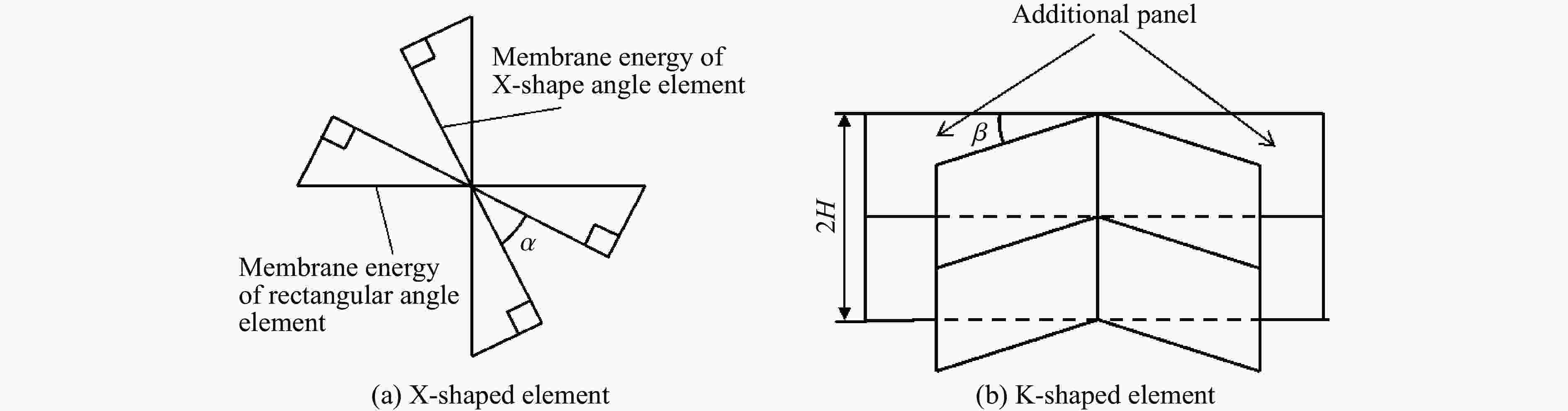

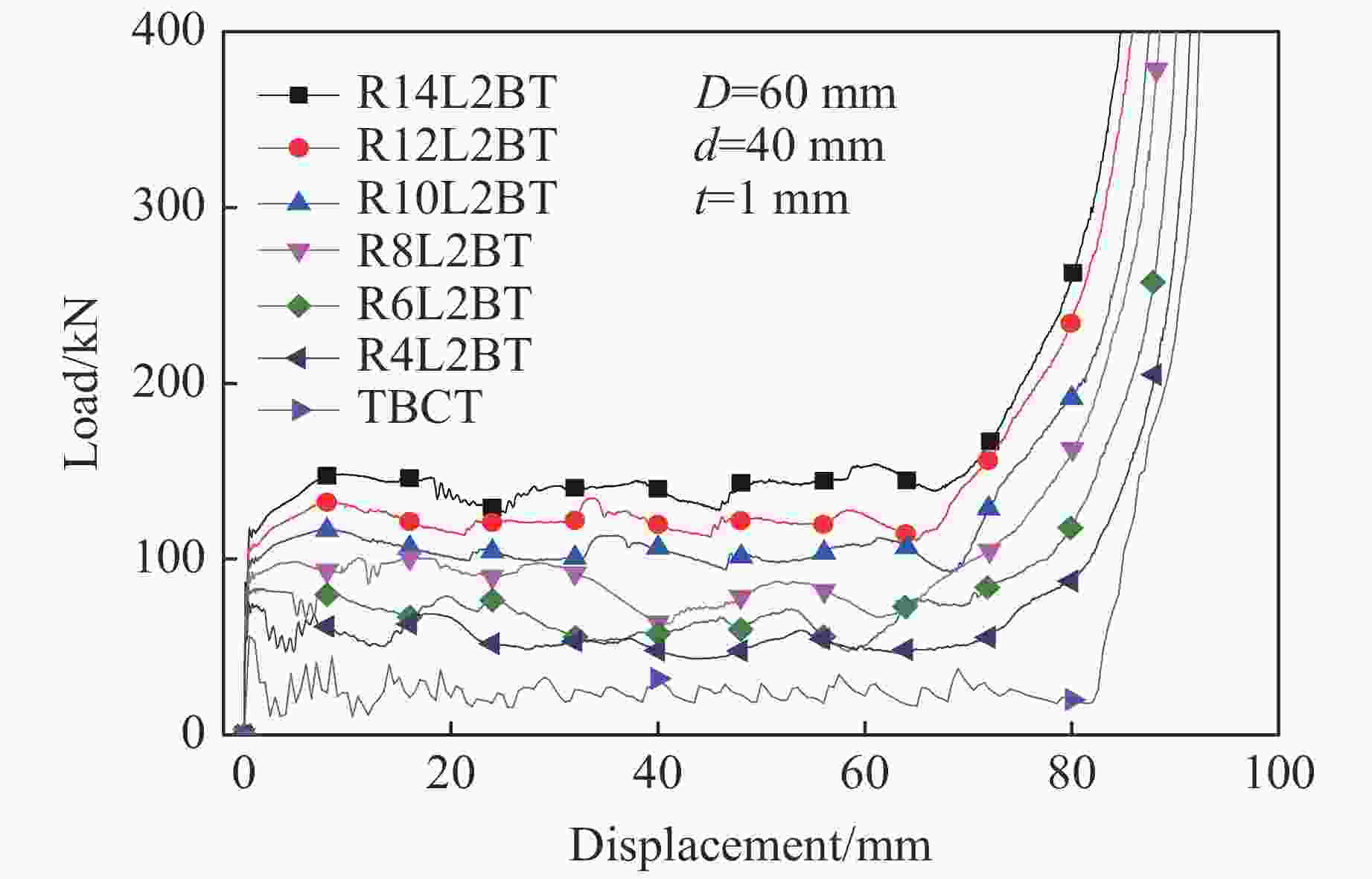

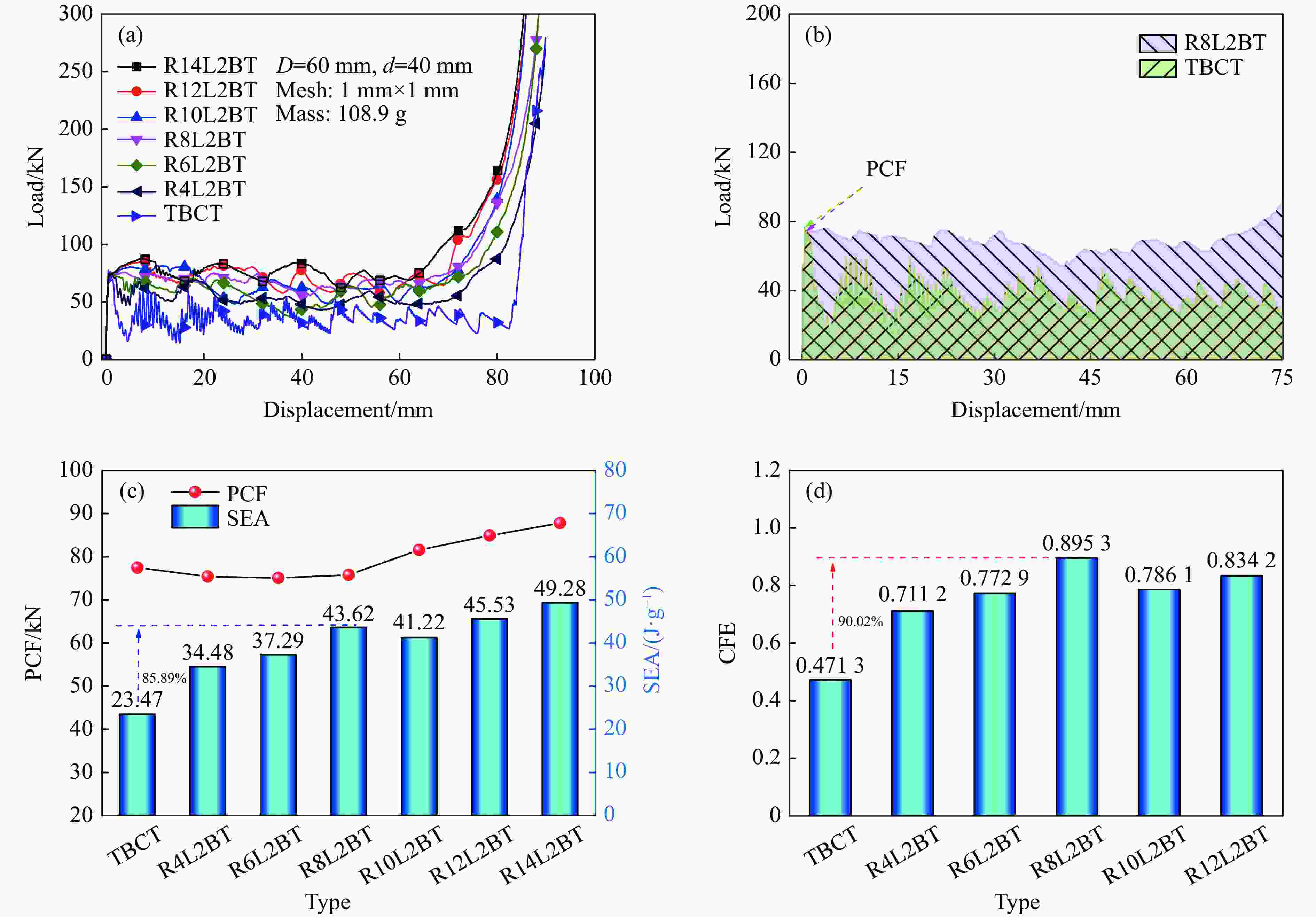

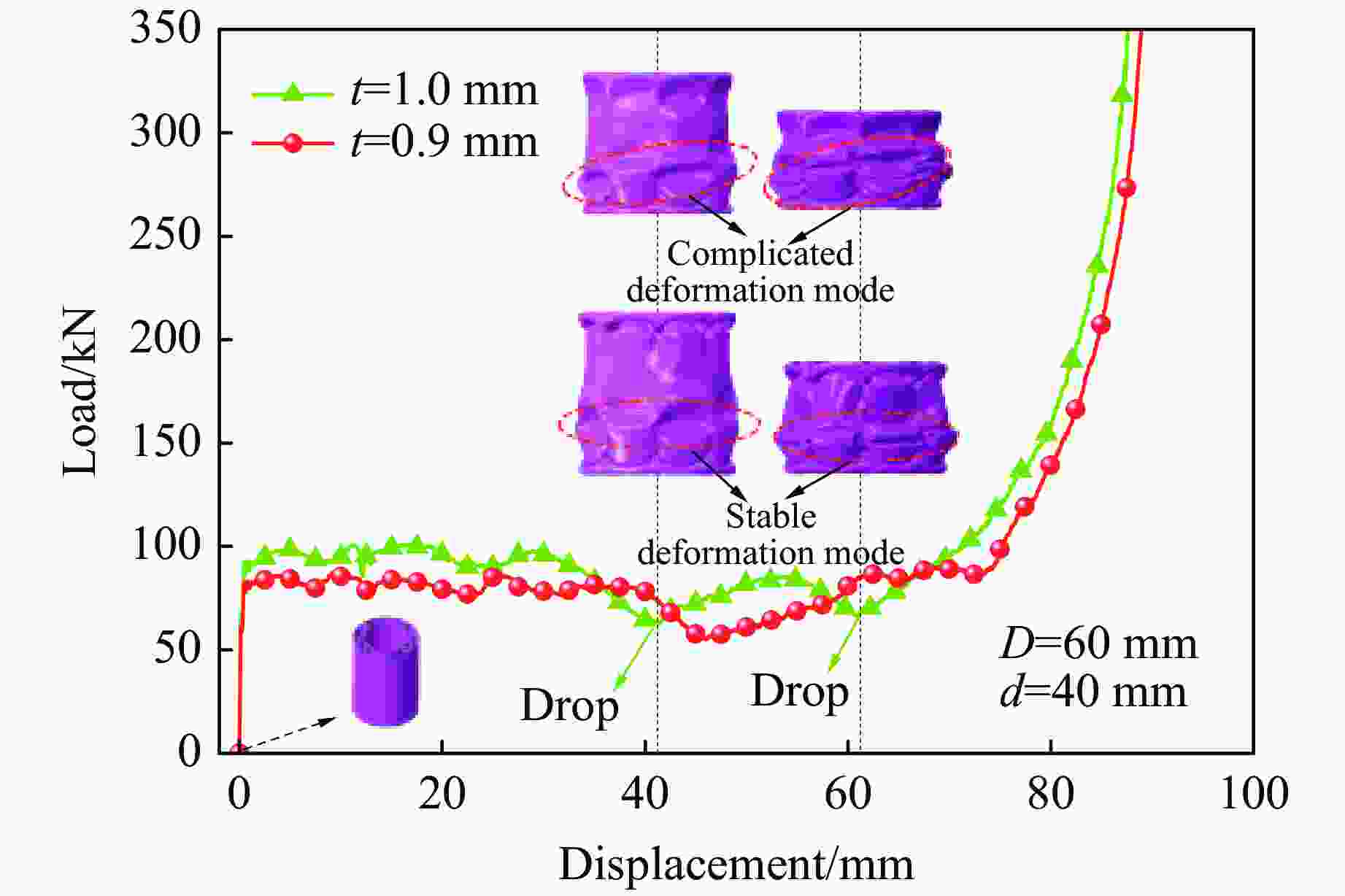

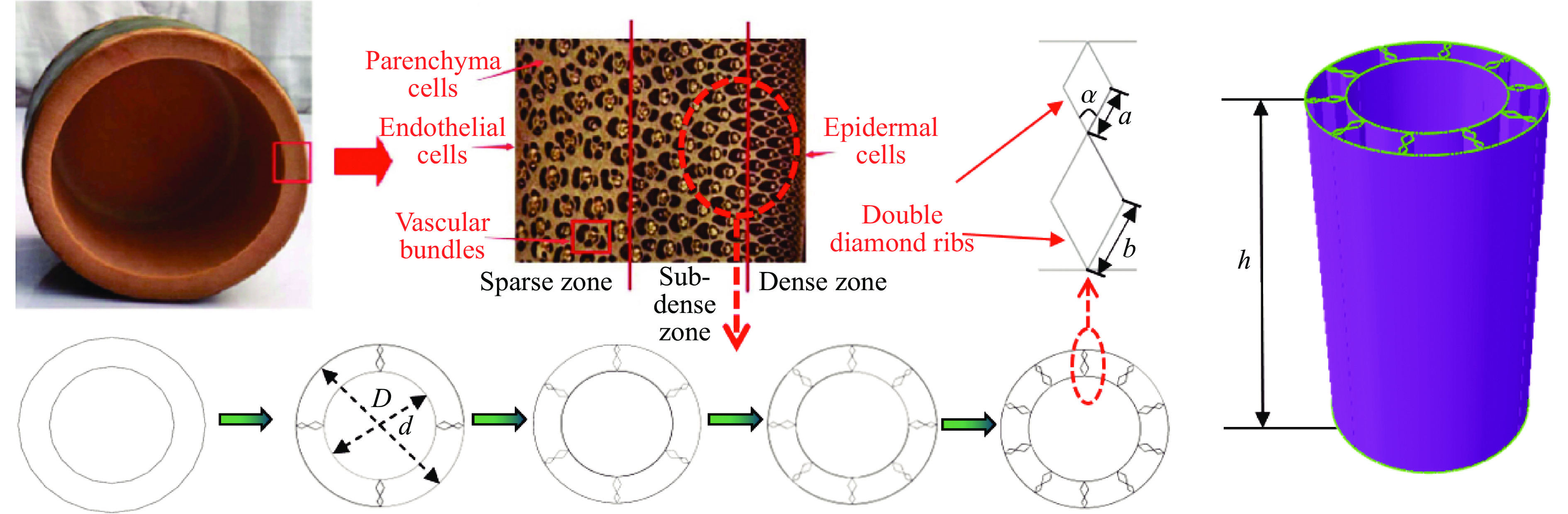

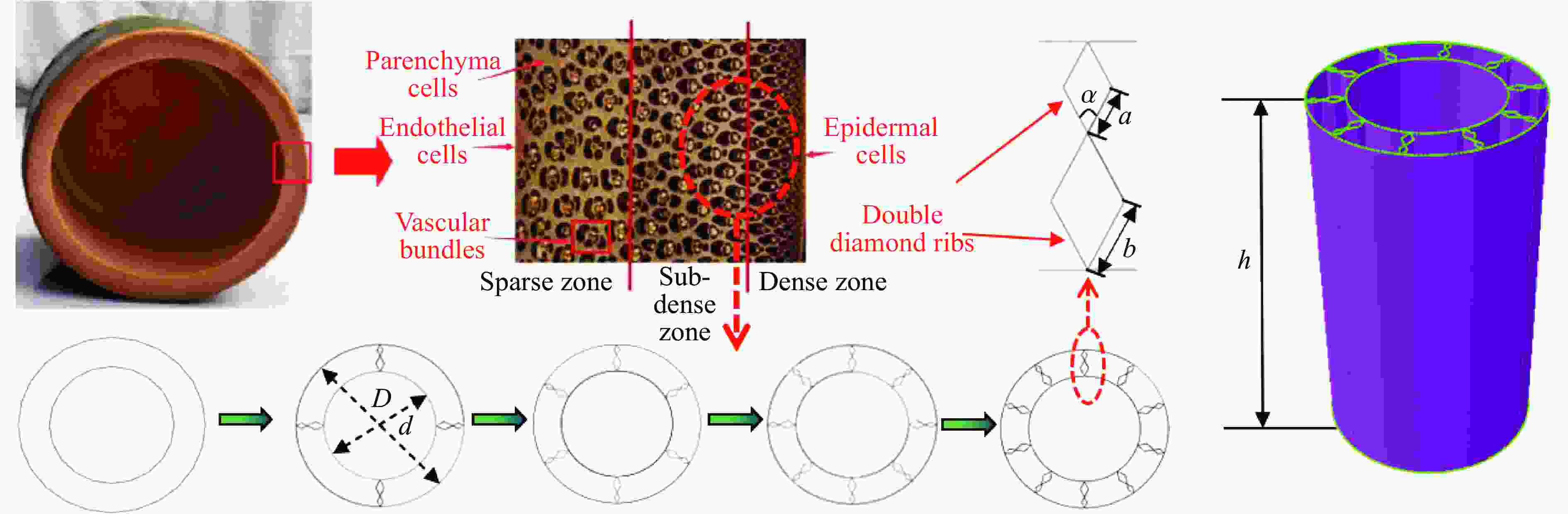

摘要: 受自然界毛竹微观结构的启发,在传统双圆管结构的基础上,在内、外圆管之间引入双菱形肋骨,设计了一种新型仿竹薄壁圆管。基于超折叠单元理论,建立了轴向压缩时仿竹薄壁圆管的理论分析模型。利用ABAQUS 有限元软件对新型仿竹薄壁圆管进行轴向压缩的数值模拟,分析了双菱形肋骨数、内管直径、壁厚等因素对新型仿竹薄壁管耐撞性和变形模式的影响,并与传统双圆管结构进行了对比。结果表明:理论预测与数值模拟结果吻合,平均压缩力和比吸能的误差均在10%以内。与传统双圆管相比,新型仿竹薄壁圆管的比吸能提高了83.61%,压缩力效率提高了198.65%。肋骨数对结构耐撞性能有显著影响,随着双菱形肋骨数目的增加,结构的比吸能逐渐增加,初始峰值力也随之提高;肋骨数较少时,结构出现局部屈曲变形,影响其吸能能力。内管直径越小,初始峰值力越高;内管直径越大,比吸能越小。Abstract: Inspired by the microstructure of natural bamboo, a new bio-bamboo thin-walled tube was designed by introducing double-rhombic ribs between inner and outer tubes on the basis of the traditional double-circular tube structure. Based on the theory of simplified super folding element, theoretical models of bio-bamboo circular tubes under axial compression were established. Finite element software ABAQUS was used to simulate the axial compression of these models. For crashworthiness and deformation mode of bio-bamboo thin-walled tube, the effects of those number of double-rhombic ribs, diameter of inner tube, wall thickness were analyzed, and it was compared with the traditional structure. The results show that the theoretical prediction is consistent with numerical simulation, and the errors of average compression force and specific energy absorption are less than 10%. Compared with traditional double-circular tube, the specific energy absorption of the bio-bamboo thin-walled tube is increased by 83.61% and the compression force efficiency is increased by 198.65%. The number of ribs has a significant effect on the crashworthiness of the structure. With the number increase of double-rhombic ribs, both specific structural energy absorption and peak crushing force increases. When the number of ribs is small, the structure appears local buckling deformation, which affects the energy absorption crashworthiness. The smaller the diameter of inner tube, the higher the initial peak force, and the larger the diameter of inner tube, the smaller the energy absorption.

-

Key words:

- bio-bamboo /

- double-rhombic ribs /

- thin-walled circular tube /

- specific energy absorption

-

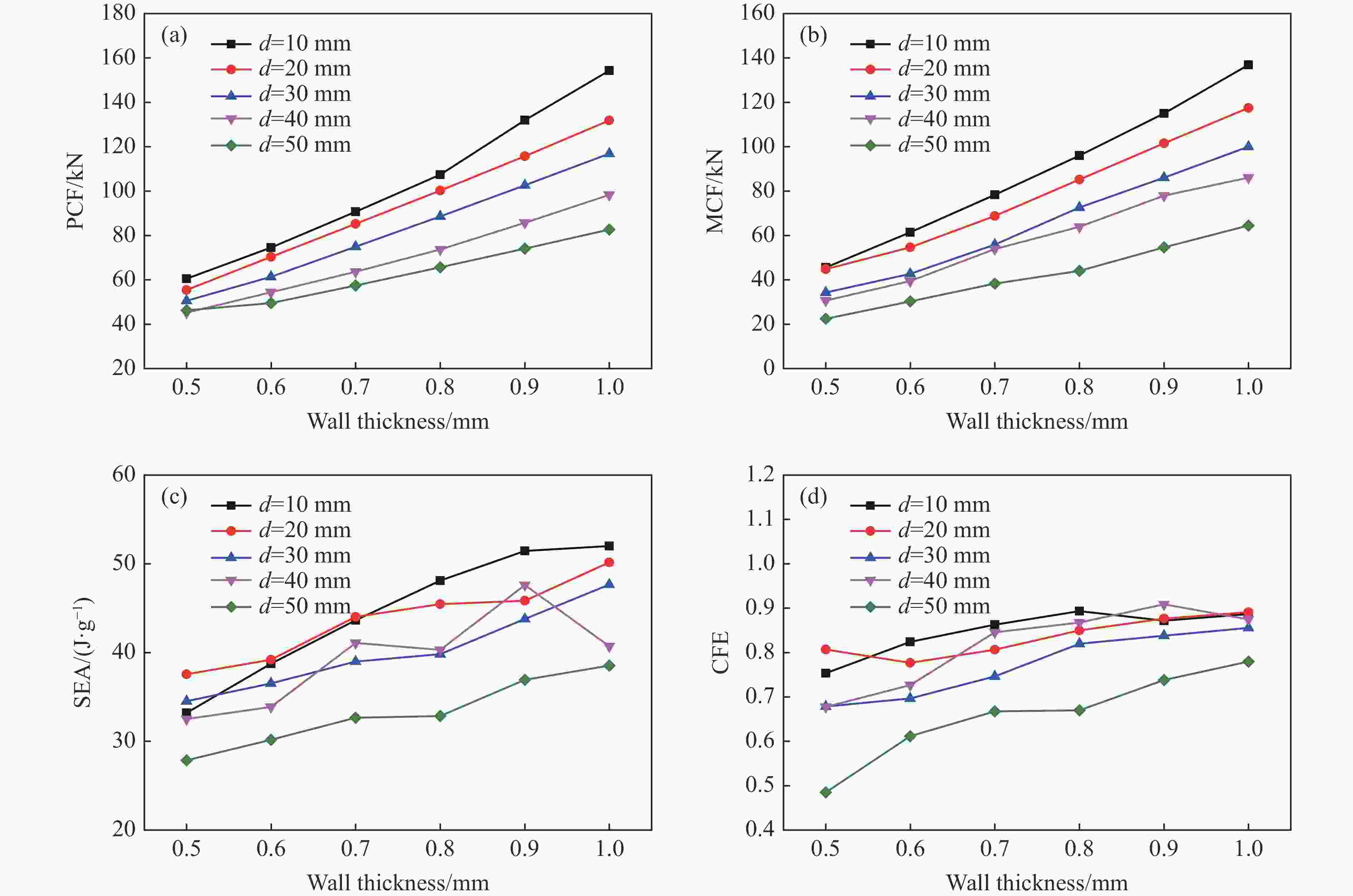

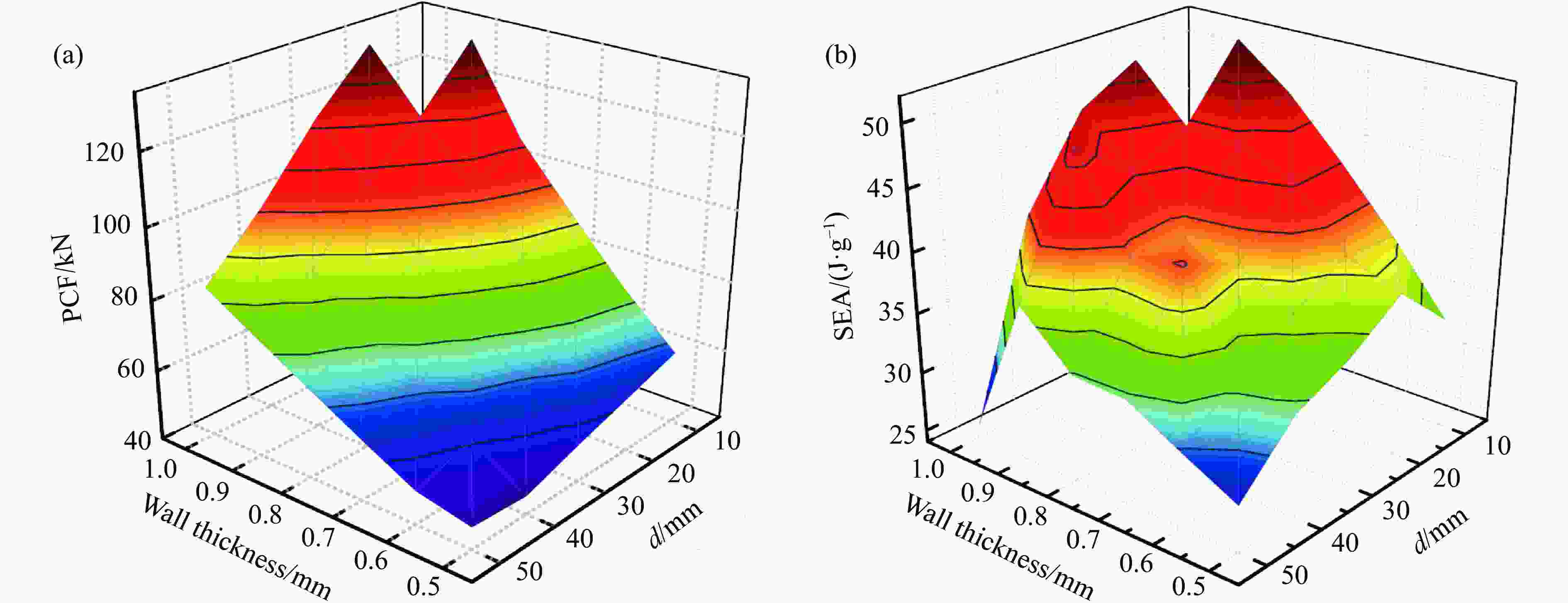

图 10 不同内管直径和壁厚的R8L2BT的耐撞性比较: (a)初始峰值力,(b)平均压缩力,(c)比吸能,(d)压缩力效率

Figure 10. Crashworthiness comparison of R8L2BT with different inner circle diameters and wall thicknesses: (a) peak crushing force (PCF), (b) mean crushing force (MCF), (c) specific energy absorption (SEA), (d) crushing force efficiency (CFE)

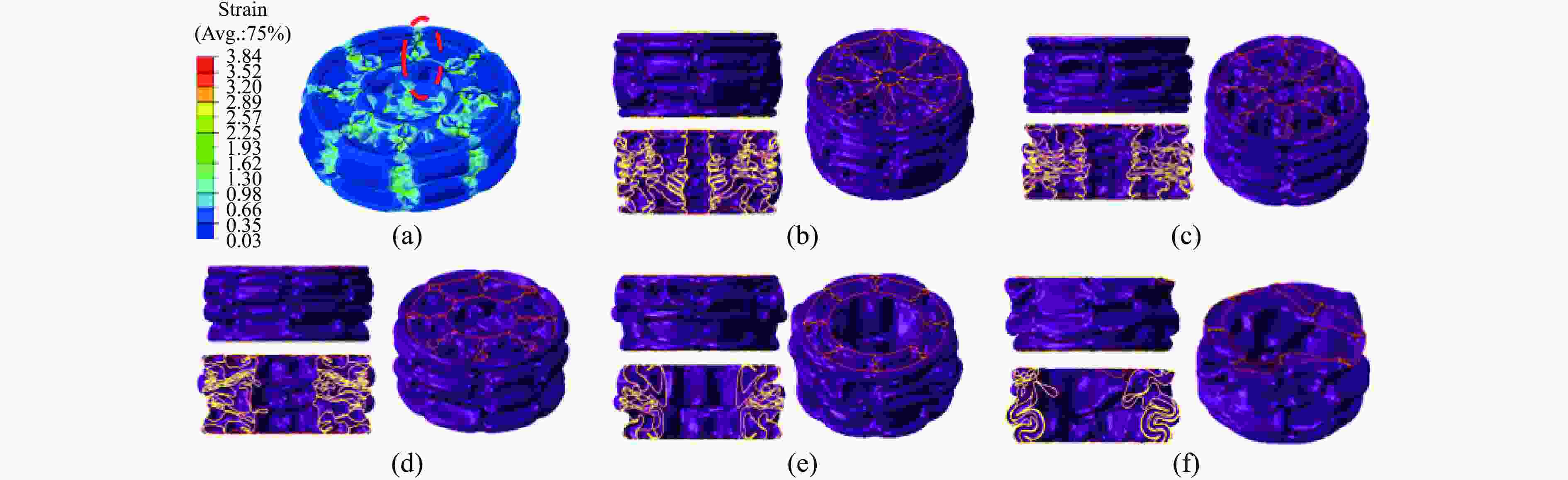

图 11 不同内管直径的R8L2BT的变形模式(t = 0.8 mm):(a)R8L2BT等效塑性应变d = 30 mm,(b) d = 10 mm,(c) d = 20 mm,(d) d = 30 mm,(e) d = 40 mm,(f) d = 50 mm

Figure 11. R8L2BT deformation modes with different inner tube diameters(t = 0.8 mm): (a) equivalent plastic strain nephogram of R8L2BT (d=30 mm), (b) d = 10 mm, (c) d = 20 mm,(d) d = 30 mm, (e) d = 40 mm, (f) d = 50 mm

表 1 数值模拟与理论计算结果对比

Table 1. Comparison between numerical simulation and theoretical calculation results

Type MCF SEA Num./kN Theor./kN Error/% Num./(J·g−1) Theor./(J·g−1) Error/% R4L2BT 53.59 52.59 −1.86 35.14 34.47 −1.88 R6L2BT 66.96 66.49 −0.71 38.42 38.15 −0.69 R8L2BT 86.04 80.51 −6.34 40.69 38.07 −6.33 R10L2BT 104.52 95.54 −8.59 49.99 45.69 −8.59 R12L2BT 121.22 115.45 −4.75 51.54 49.08 −4.75 R14L2BT 134.51 124.51 −7.43 55.42 51.77 −6.57 表 2 R8L2BT与TBCT耐撞性比较

Table 2. Comparison of crashworthiness between R8L2BT and TBCT

Type Mass/g EA/J SEA/(J·g−1) PCF/kN MCF/kN CFE/% t/mm R8L2BT 119.8 5703.52 47.62 85.76 77.94 90.88 0.9 TBCT 119.8 3106.41 25.93 85.18 25.93 30.44 1.4 -

[1] SUN X J, ZHANG H, MENG W J, et al. Primary resonance analysis and vibration suppression for the harmonically excited nonlinear suspension system using a pair of symmetric viscoelastic buffers [J]. Nonlinear Dynamics, 2018, 94: 1243–1265. doi: 10.1007/s11071-018-4421-9 [2] XIE S C, WANG N, YANG W L, et al. Energy absorption performance of thin-walled metal plate due to upheaval deformation based on experiments and numerical simulation [J]. Thin-Walled Structures, 2018, 131: 258–273. doi: 10.1016/j.tws.2018.07.006 [3] XU X, ZHANG Y, CHENG X, et al. Crushing behaviors of hierarchical sandwich-walled columns [J]. International Journal of Mechanical Sciences, 2019, 161/162: 105021. doi: 10.1016/j.ijmecsci.2019.105021 [4] VINAYAGAR K, KUMAR A S. Crashworthiness analysis of double section bi-tubular thin-walled structures [J]. Thin Walled Structures, 2017, 112: 184–193. doi: 10.1016/j.tws.2016.12.008 [5] 吴伟, 张辉, 曹美文, 等. 仿生BCC结构的准静态压缩数值模拟及吸能性 [J]. 高压物理学报, 2020, 34(6): 062402. doi: 10.11858/gywlxb.20200578WU W, ZHANG H, CAO M W, et al. Numerical simulation of quasi-static compression and snergy absorption of bionic BCC structure [J]. Chinese Journal of High Pressure Physics, 2020, 34(6): 062402. doi: 10.11858/gywlxb.20200578 [6] ESTRADA Q, SZWEDOWICZ D, RODRIGUEZ-MENDEZ A, et al. Effect of radial clearance and holes as crush initiators on the crashworthiness performance of bi-tubular profiles [J]. Thin Walled Structures, 2019, 140: 43–59. doi: 10.1016/j.tws.2019.02.039 [7] FAN Z, LU G, LIU K. Quasi-static axial compression of thin-walled tubes with different cross-sectional shapes [J]. Engineering Structures, 2013, 55(4): 80–89. [8] 姚如洋, 赵振宇, 尹冠生, 等. 薄壁开孔圆管在轴向荷载作用下的理论研究 [J]. 振动与冲击, 2020, 39(2): 141–147.YAO R Y, ZHAO Z Y, YIN G S, et al. Theoretical study on thin-walled perforated circular tube under axial load [J]. Journal of Vibration and Shock, 2020, 39(2): 141–147. [9] SONG J, XU S, XU L, et al. Experimental study on the crashworthiness of bio-inspired aluminum foam-filled tubes under axial compression loading [J]. Thin-Walled Structures, 2020, 155: 106937. doi: 10.1016/j.tws.2020.106937 [10] 杨欣, 范晓文, 许述财, 等. 仿虾螯结构薄壁管设计及耐撞性分析 [J]. 爆炸与冲击, 2020, 40(4): 59–69.YANG X, FAN X W, XU S C, et al. Design and crashworthiness analysis of thin-walled tubes with simulated shrimps [J]. Explosion and Shock Waves, 2020, 40(4): 59–69. [11] 闫栋, 王根伟, 宋辉, 等. 类向日葵夹芯圆柱壳径向冲击数值模拟 [J]. 高压物理学报, 2020, 34(5): 054201. doi: 10.11858/gywlxb.20190858YAN D, WANG G W, SONG H, et al. Numerical simulation of radial impact on sunflower-like sandwich cylindrical shell [J]. Chinese Journal of High Pressure Physics, 2020, 34(5): 054201. doi: 10.11858/gywlxb.20190858 [12] FU J, LIU Q, LIU F K, et al. Design of bionic-bamboo thin-walled structures for energy absorption [J]. Thin-Walled Structures, 2019, 135: 400–413. doi: 10.1016/j.tws.2018.10.003 [13] CHEN B C, ZOU M, LIU G M, et al. Experimental study on energy absorption of bionic tubes inspired by bamboo structures under axial crushing [J]. International Journal of Impact Engineering, 2018, 115(5): 48–57. [14] CHEN W, WIERZBICKI T. Relative merits of single-cell, multi-cell and foam-filled thin-walled structures in energy absorption [J]. Thin Walled Structures, 2001, 39(4): 287–306. doi: 10.1016/S0263-8231(01)00006-4 [15] WIERZBICKI T, ABRAMOWICZ W. On the crushing mechanics of thin-walled structures [J]. Journal of Applied Mechanics, 1983, 50(4a): 727–734. doi: 10.1115/1.3167137 [16] TRAN T N, HOU S J, HAN X, et al. Theoretical prediction and crashworthiness optimization of multi-cell triangular tubes [J]. Thin-Walled Structures, 2014, 82: 183–195. [17] TRAN T N, HOU S J, HAN X, et al. Crushing analysis and numerical optimization of angle element structures under axial impact loading [J]. Composite Structures, 2015, 119: 422–435. doi: 10.1016/j.compstruct.2014.09.019 -

下载:

下载: