Fracture Characteristics of Layered Phyllite

-

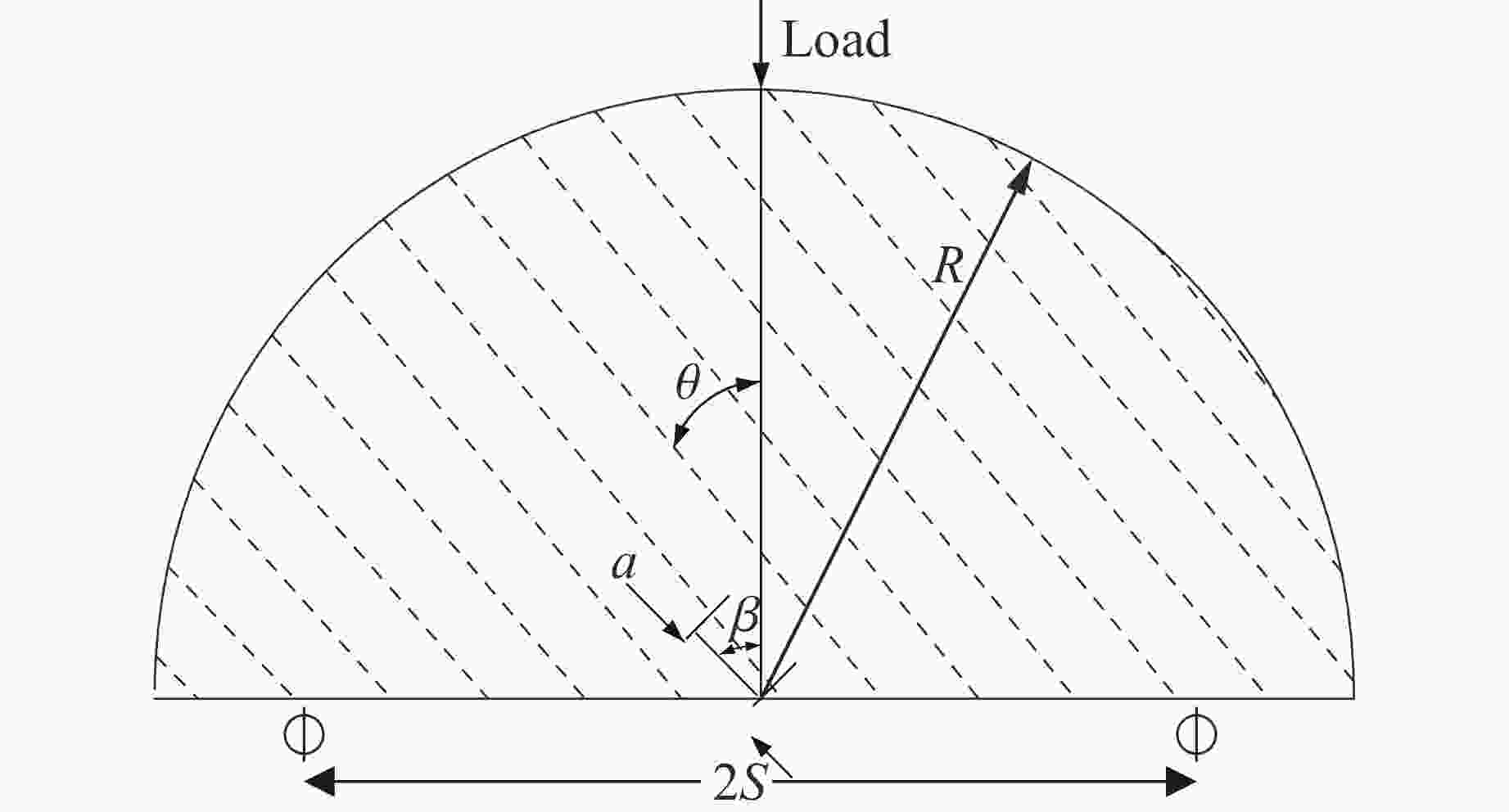

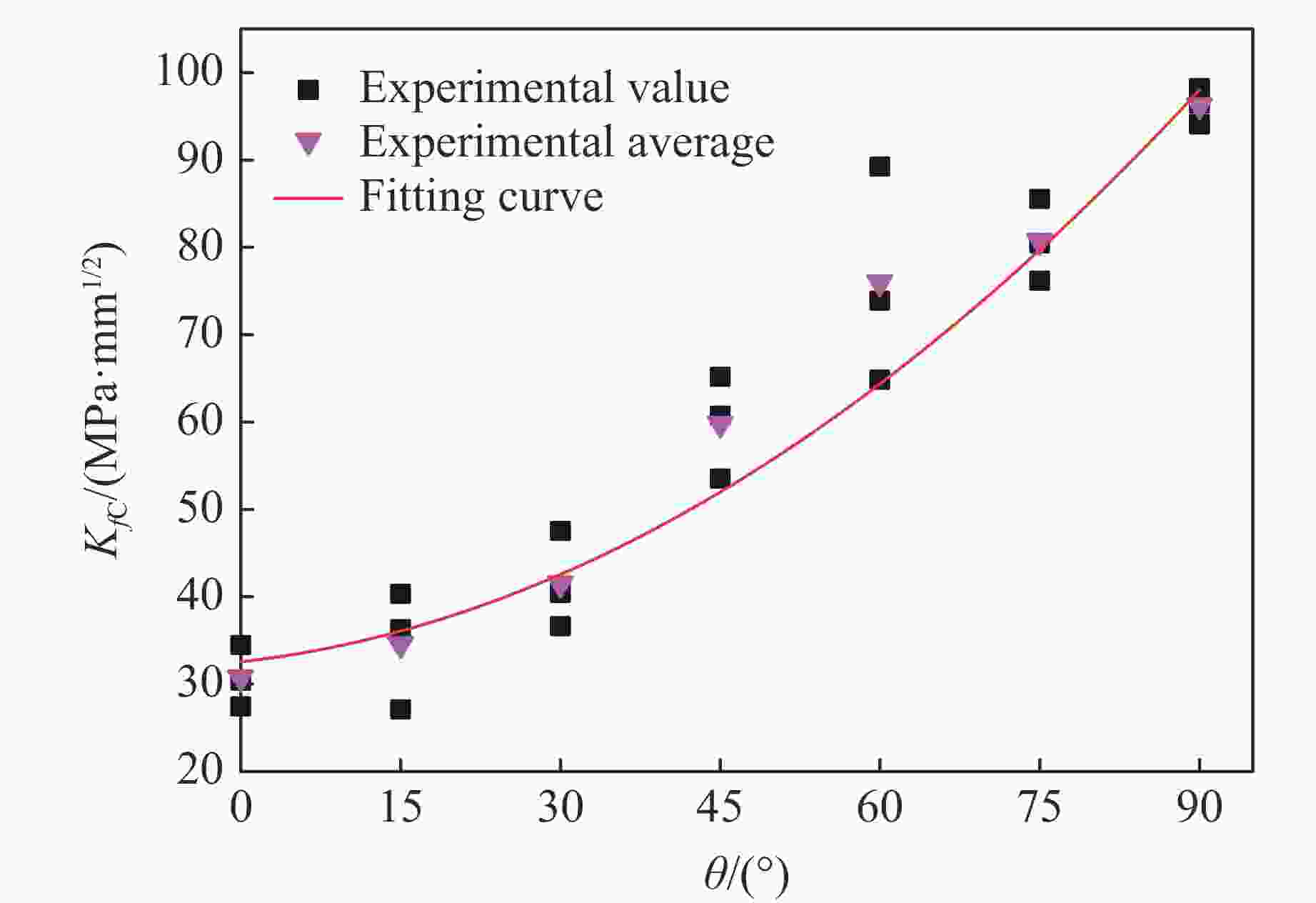

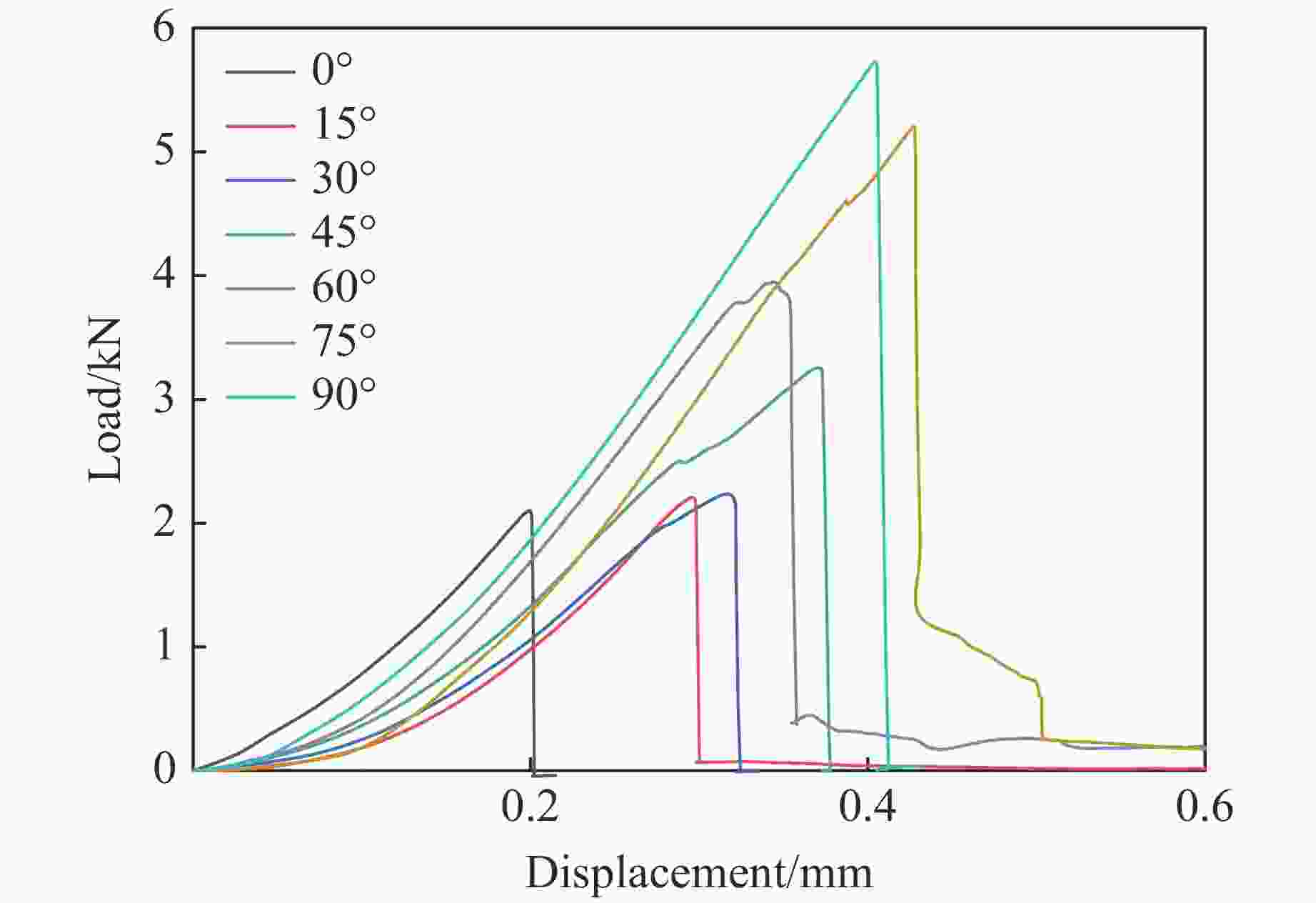

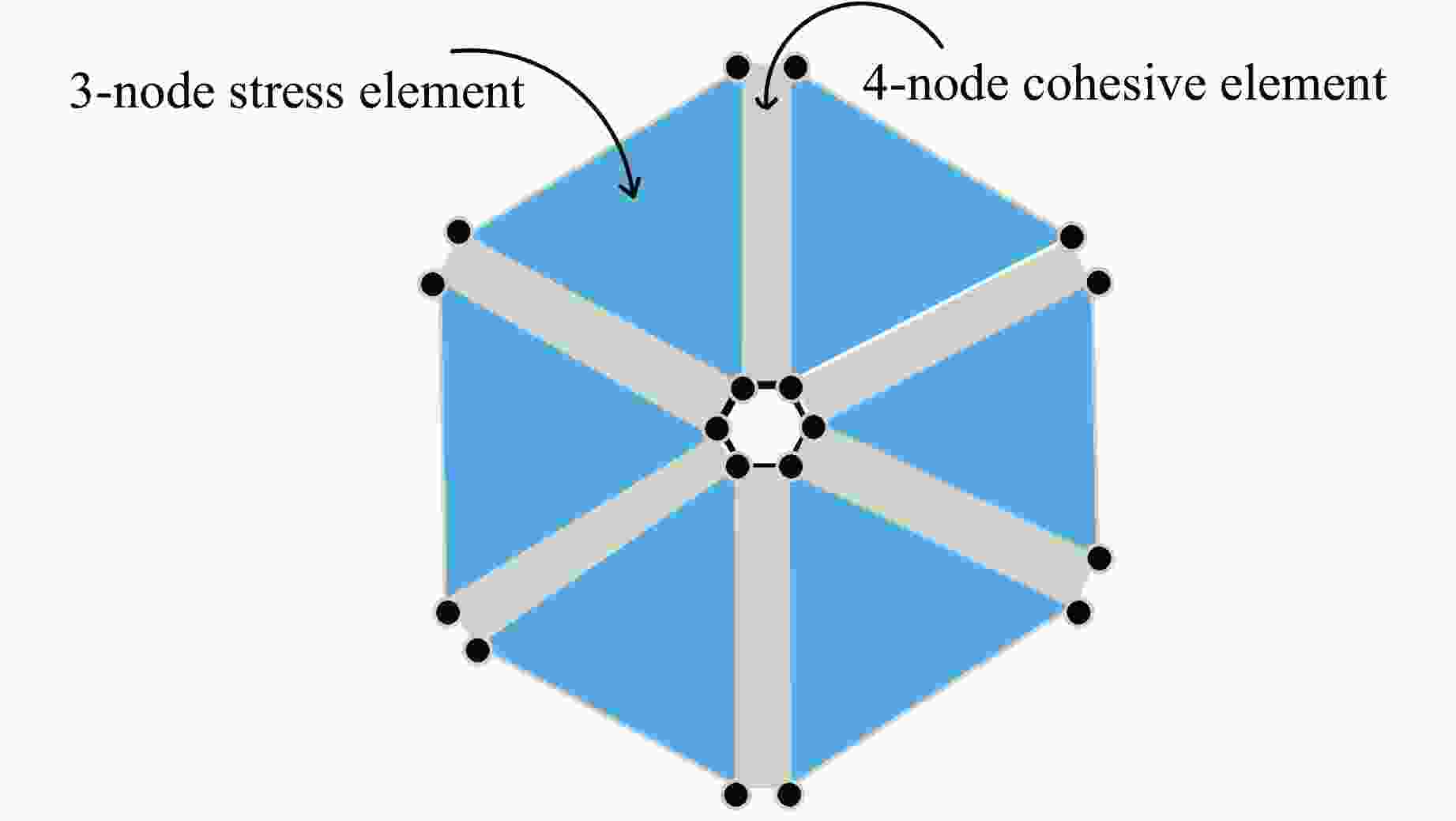

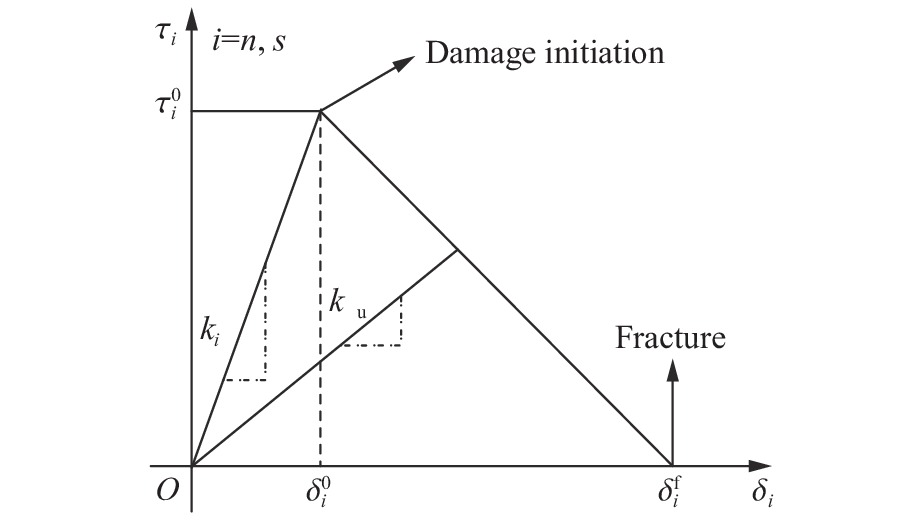

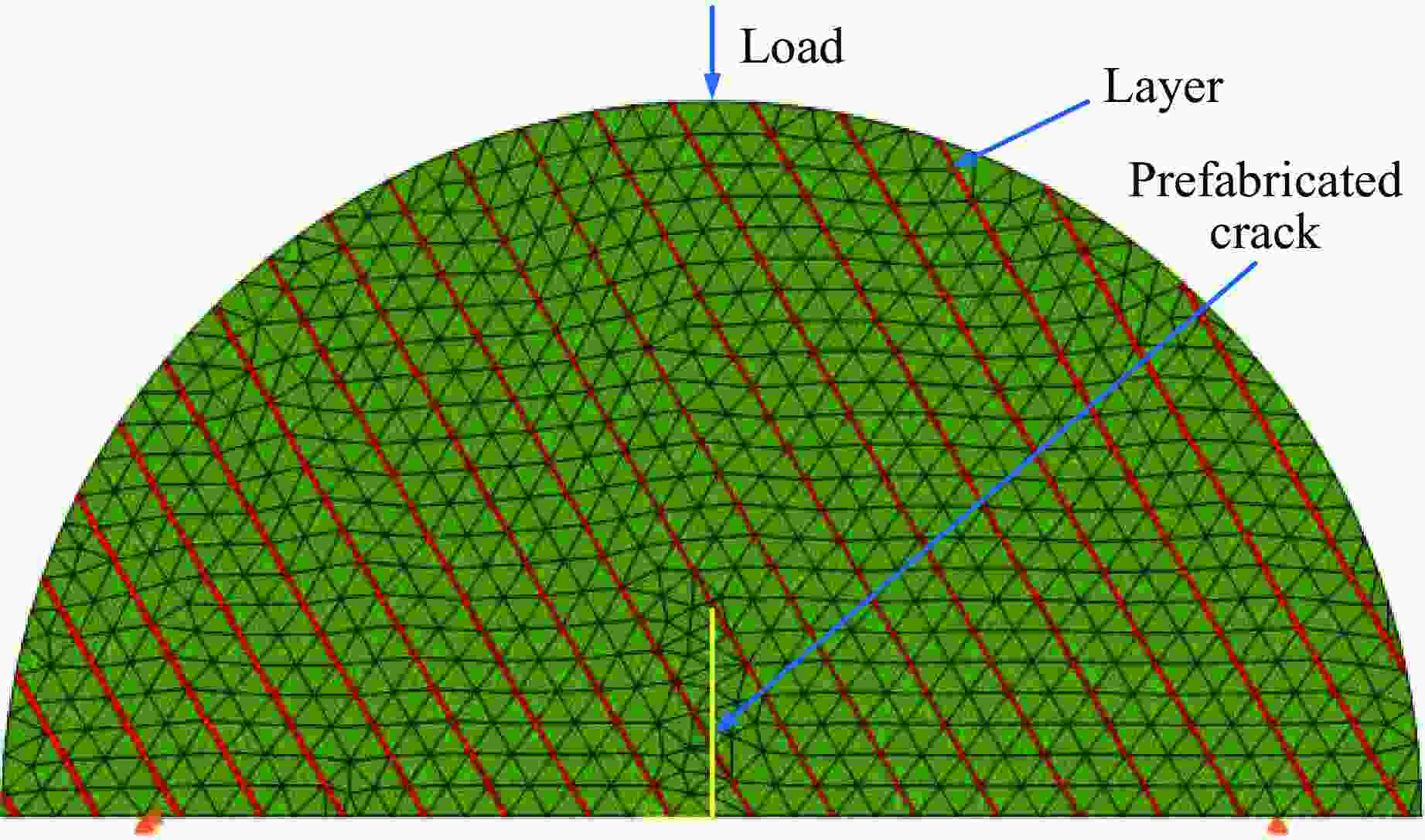

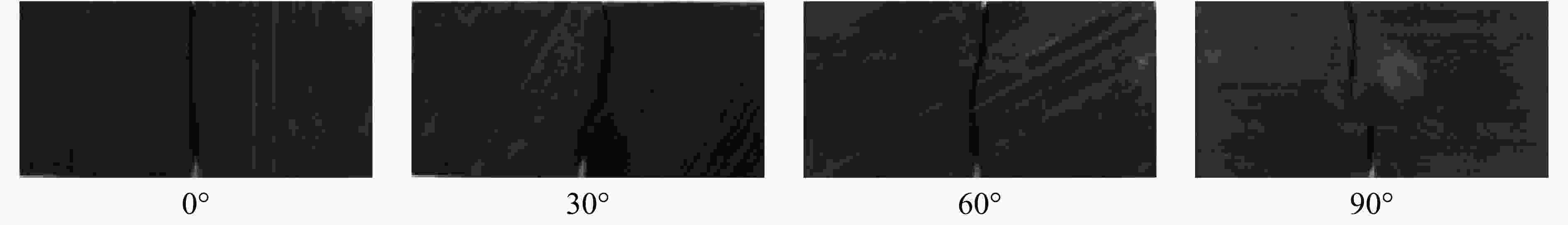

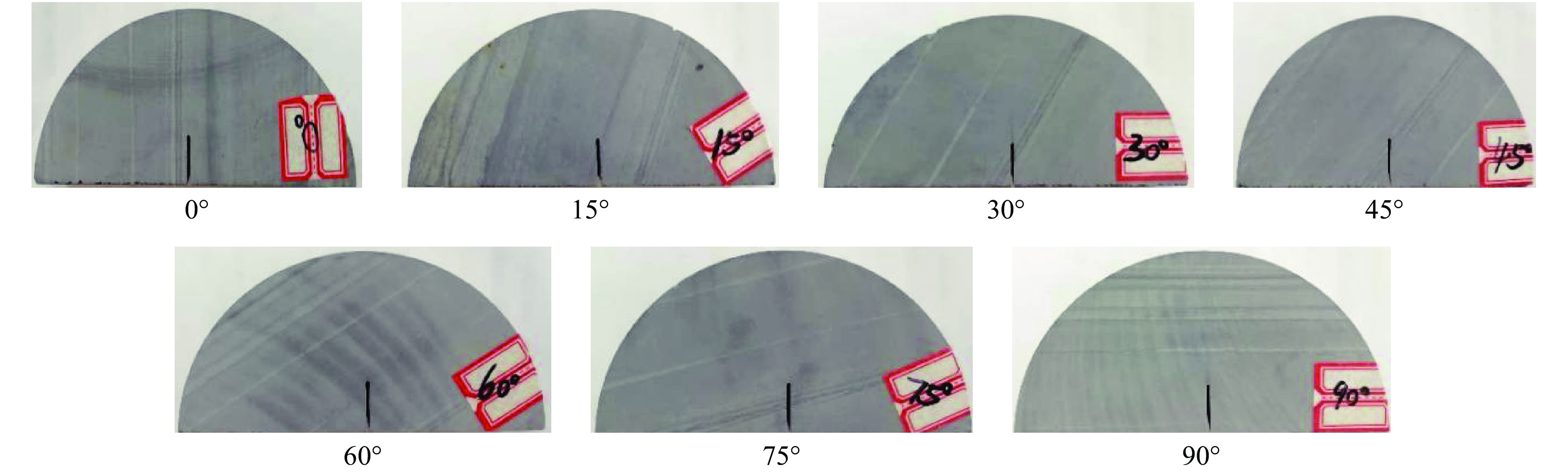

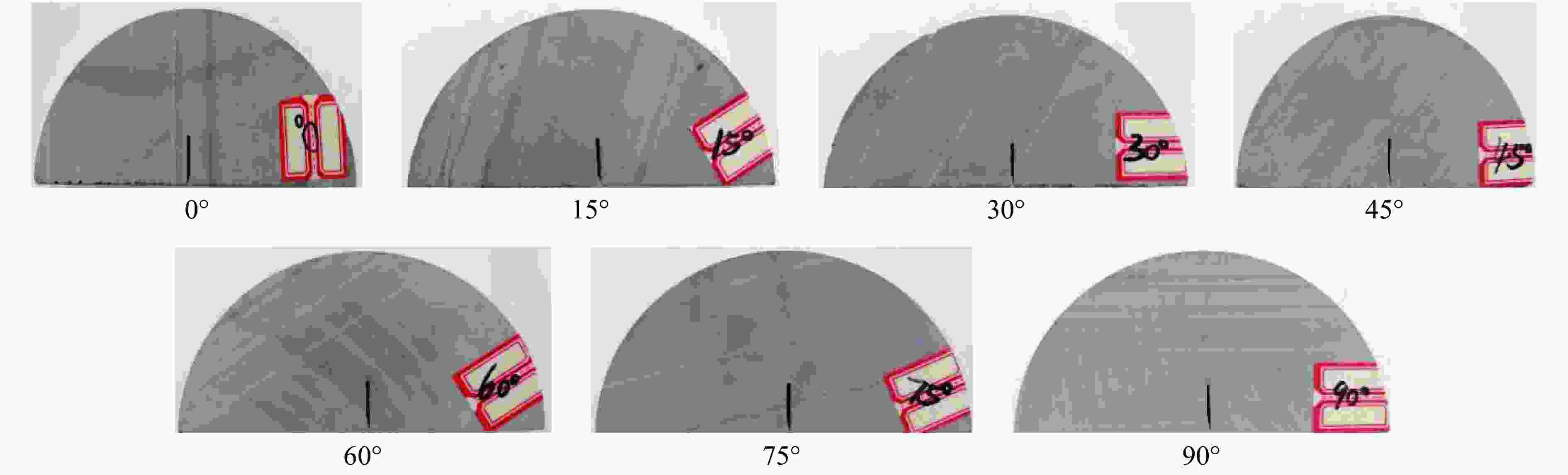

摘要: 采用中心直切槽半圆盘层状岩样测试了层状千枚岩的断裂性能,并基于黏结单元建立了层状岩石的有限元数值计算模型,系统研究了层理倾角、层理强度、层理间距及切缝倾角等参数对层状千枚岩断裂特性的影响。结果表明:当层理倾角在0°~90°范围内时,Ⅰ型断裂韧度逐渐增大,峰值载荷和峰值位移也呈增大趋势;层理倾角为零时,发生张拉破坏。层理倾角在15°~45°时,剪切破坏占主导;层理倾角在60°~90°时,张拉破坏占主导。层理倾角为零时,破坏模式受层理强度影响较小;层理倾角分别为15°和30°时,随着层理强度增大,试样由剪切破坏向拉-剪耦合破坏演化;层理倾角在45°~90°时,试样均呈现拉-剪耦合破坏,且随着层理强度增大,试样有向拉伸破坏为主演化的趋势。层理间距较小时,裂纹呈沿层–穿层阶梯状扩展趋势明显;切缝倾角较大时,裂纹穿层扩展趋势明显。Abstract: Based on the half-disk layered rock sample with central straight cutting groove, tests on fracture performances of layered phyllite were conducted, and the finite element numerical model of layered rock was developed. The influences of bedding dip angle, bedding strength, bedding thickness, span and different cutting angle on the fracture performances of layered phyllite was systematically studied. The results show that with the change of bedding dip angle from 0° to 90°, model Ⅰ fracture toughness value increases gradually, and the peak load and peak displacement also show increasing trend. When the bedding dip angle is 0°, the tensile failure occurs. When the bedding dip angle is 15°−45°, the shear failure is dominant, and when the bedding dip angle is 60°−90°, the tensile failure is dominant. When the bedding dip angle is 0°, the failure mode is less affected by the bedding strength. For cases with angle of 15° and 30°, with the increase of bedding strength, the specimen changes from shear failure to tensile-shear coupling failure. As the angle ranges from 45° to 90°, the specimens show tensile-shear coupling failure. With the increase of bedding strength, the specimens seem to fail by tension. When the bedding distance is small, the crack shows an obvious ladder-like growth along the bedding plane.

-

表 1 中心直切槽半圆盘无量纲应力强度因子结果比较[27]

Table 1. Comparison of dimensionless stress intensity factor for a half disk with a central straight slotted[27]

a/R S/R YⅠ Error/% This paper Ref.[27] 0.1 0.5 2.752 2.724 1.03 0.3 0.5 2.493 2.538 −1.77 0.8 0.5 12.850 12.665 1.46 表 2 模型中的单元力学细观参数

Table 2. Microscopic parameters of element mechanics in the model

Element type Location Elastic modulus/GPa Poisson’s ratio Density/(kg·mm−3) Entity element Rock material 37.76 0.23 2.623 × 103 Element type Location Tensile strength/MPa Shear strength/MPa Normal stiffness/(MPa·mm−1) Tangential stiffness/(MPa·mm−1) Failure displacement/mm Cohensive element Bedding 3.3 9 9442 3838 0.05 Stroma 6.6 19 37768 15353 0.10 表 3 不同层理倾角试样的试验与数值模拟结果对比

Table 3. Comparison between experimental and numerical simulationresults of specimens with different bedding dip angles

Bedding dip angle/(°) Load-displacement curves Test failure result Simulated failure result 0

15

30

45

60

75

90

表 4 各层理倾角试样在不同层理强度下的数值模拟破坏结果

Table 4. Numerical failures of each bedding dip angles' specimen under different bedding strength

Bedding dip angle/(°) Simulated result 0.5 0.8 1.1 1.5 0

15

30

45

60

75

90

表 5 各层理倾角试样在不同层理间距下的数值模拟破坏结果

Table 5. Numerical simulation failure results of each bedding dip angles' specimen under different bedding distance

Bedding dip angle/(°) Simulated result d=3 mm d=5 mm d=8 mm d=12 mm 0

15

30

45

60

75

90

表 6 各层理倾角试样在不同切缝倾角下的数值模拟破坏结果

Table 6. Numerical failures of each bedding dip angles' specimen under different cutting seam dip angles

Bedding dip angle/(°) Simulated result β=0° β=30° β=45° β=60° 0

15

30

45

60

75

90

-

[1] 姜永东, 鲜学福, 郭臣业. 层状岩质边坡失稳的燕尾突变模型 [J]. 重庆大学学报, 2008, 31(5): 553–557. doi: 10.11835/j.issn.1000-582X.2008.05.018JIANG Y D, XIAN X F, GUO C Y. A swallowtail catastrophe model on destabilization of stratified rock slope [J]. Journal of Chongqing University, 2008, 31(5): 553–557. doi: 10.11835/j.issn.1000-582X.2008.05.018 [2] 谢和平, 高峰, 鞠杨, 等. 页岩储层压裂改造的非常规理论与技术构想 [J]. 工程科学与技术, 2012, 44(6): 1–6. doi: 10.15961/j.jsuese.2012.06.006XIE H P, GAO F, JU Y, et al. Unconventional theories and strategies for fracturing treatments of shale gas strata [J]. Advanced Engineering Sciences, 2012, 44(6): 1–6. doi: 10.15961/j.jsuese.2012.06.006 [3] CEN C S, PAN E N, AMADEI B. Determination of deformability and tensile strength of anisotropic rock using Brazilian tests [J]. International Journal of Rock Mechanics and Mining Sciences, 1998, 35(1): 43–61. doi: 10.1016/S0148-9062(97)00329-X [4] 刘运思, 傅鹤林, 饶军应, 等. 不同层理方位影响下板岩各向异性巴西圆盘劈裂试验研究 [J]. 岩石力学与工程学报, 2012, 31(4): 785–791. doi: 10.3969/j.issn.1000-6915.2012.04.018LIU Y S, FU H L, RAO J Y, et al. Research on brazilian disc splitting tests for anisotropy of slate under influence of different bedding orientations [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(4): 785–791. doi: 10.3969/j.issn.1000-6915.2012.04.018 [5] 李德建, 祁浩, 李春晓, 等. 含层理面煤试样的巴西圆盘劈裂实验及数值模拟研究 [J]. 矿业科学学报, 2020, 5(2): 150–159. doi: 10.19606/j.cnki.jmst.2020.02.003LI D J, QI H, LI C X, et al. Brazilian disc splitting tests and numerical simulations on coal samples containing bedding planes [J]. Journal of Mining Science and Technology, 2020, 5(2): 150–159. doi: 10.19606/j.cnki.jmst.2020.02.003 [6] 殷志强, 谢广祥, 胡祖祥, 等. 不同瓦斯压力下煤岩三点弯曲断裂特性研究 [J]. 煤炭学报, 2016, 41(2): 424–431. doi: 10.13225/j.cnki.jccs.2015.0598YIN Z Q, XIE G X, HU Z X, et al. Investigation on fracture mechanism of coal rock on three-point bending tests under different gas pressures [J]. Journal of China Coal Society, 2016, 41(2): 424–431. doi: 10.13225/j.cnki.jccs.2015.0598 [7] 张宁博, 单仁亮, 赵善坤, 等. 不同煤岩介质弯载作用下的断裂特征 [J]. 煤炭学报, 2020, 45(Suppl 2): 671–681.ZHANG N B, SHAN R L, ZHAO S K, et al. Investigation on cracking features of different patterns of rock under bending load [J]. Journal of China Coal Society, 2020, 45(Suppl 2): 671–681. [8] 魏炯, 朱万成, 李如飞, 等. 岩石抗拉强度和断裂韧度的三点弯曲试验研究 [J]. 水利与建筑工程学报, 2016, 14(3): 128–132, 142. doi: 10.3969/j.issn.1672-1144.2016.03.024WEI J, ZHU W C, LI R F, et al. Experiment of the tensile strength and fracture toughness of rock using notched three point bending test [J]. Journal of Water Resources and Architectural Engineering, 2016, 14(3): 128–132, 142. doi: 10.3969/j.issn.1672-1144.2016.03.024 [9] 李柯萱, 李铁. 不同加载速率下砂岩弯曲破坏的细观机理 [J]. 爆炸与冲击, 2019, 39(4): 043101. doi: 10.11883/bzycj-2018-0178LI K X, LI T. Micro-mechanism of bending failure of sandstone under different loadingrates [J]. Explosion and Shock Waves, 2019, 39(4): 043101. doi: 10.11883/bzycj-2018-0178 [10] 姚哨峰, 张振南, 葛修润, 等. 大理岩断裂能与细观结构几何特征相关性 [J]. 岩土力学, 2016, 37(8): 2341–2346. doi: 10.16285/j.rsm.2016.08.028YAO S F, ZHANG Z N, GE X R, et al. Correlation between fracture energy and geome-trical characteristic of mesostructure of marble [J]. Rock and Soil Mechanics, 2016, 37(8): 2341–2346. doi: 10.16285/j.rsm.2016.08.028 [11] 左建平, 周宏伟, 刘瑜杰. 不同温度下砂岩三点弯曲破坏的特征参量研究 [J]. 岩石力学与工程学报, 2010, 29(4): 705–712.ZUO J P, ZHOU H W, LIU Y J. Research on characteristic parameters of sandstone three-point bending failure under different temperatures [J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(4): 705–712. [12] 邓朝福, 刘建锋, 陈亮, 等. 不同粒径花岗岩断裂力学行为及声发射特征研究 [J]. 岩土力学, 2016, 37(8): 2313–2320. doi: 10.16285/j.rsm.2016.08.025DENG C F, LIU J F, CHEN L, et al. Fracture mechanical behaviors and acoustic emission characteristics of Beishan granites with different particle sizes [J]. Rock and Soil Mechanics, 2016, 37(8): 2313–2320. doi: 10.16285/j.rsm.2016.08.025 [13] 徐晓云, 张明明. T应力对半圆盘岩石试件裂纹断裂及扩展机理研究 [J]. 煤炭科学技术, 2018, 46(3): 80–84. doi: 10.13199/j.cnki.cst.2018.03.013XU X Y, ZHANG M M. Study on T stress affected to crack fracturing and extension mechanism of half disc rock specimen [J]. Coal Science and Technology, 2018, 46(3): 80–84. doi: 10.13199/j.cnki.cst.2018.03.013 [14] 张盛, 王龙飞, 常旭, 等. 中心直裂纹半圆盘试样的石灰岩断裂韧度尺寸效应试验研究 [J]. 岩土力学, 2019, 40(5): 1740–1749, 1760. doi: 10.16285/j.rsm.2017.2555ZHANG S, WANG L F, CHANG X, et al. Experimental study of size effect of fracture toughness of limestone using the notched semi-circular bend samples [J]. Rock and Soil Mechanics, 2019, 40(5): 1740–1749, 1760. doi: 10.16285/j.rsm.2017.2555 [15] 赵平劳. 层状结构岩石抗剪强度各向异性试验研究 [J]. 兰州大学学报(自然科学版), 1990, 26(4): 135–139. doi: 10.13885/j.is-sn.0455-2059.1990.04.024ZHAO P L. The experimental study of anisotropy of shear strength of bedded rock [J]. Journal of Lanzhou University (Natural Sciences), 1990, 26(4): 135–139. doi: 10.13885/j.is-sn.0455-2059.1990.04.024 [16] 裴建良, 苏立, 刘建锋, 等. 层状大理岩间接拉伸试验及断口形貌和断裂机理分析 [J]. 四川大学学报(工程科学版), 2014, 46(4): 39–45. doi: 10.15961/j.jsuese.2014.04.002PEI J L, SU L, LIU J F, et al. Indirect tensile test of layered marble and analysis of fracture morphology and mechanism [J]. Journal of Sichuan University (Engineering Science Edition), 2014, 46(4): 39–45. doi: 10.15961/j.jsuese.2014.04.002 [17] 裴建良, 刘建锋, 徐进. 层状大理岩卸荷力学特性试验研究 [J]. 岩石力学与工程学报, 2009, 28(12): 2496–2502. doi: 10.3321/j.issn:1000-6915.2009.12.016PEI J L, LIU J F, XU J. Experimental study of mechanical properties of layered marble under unloading condition [J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(12): 2496–2502. doi: 10.3321/j.issn:1000-6915.2009.12.016 [18] NASSERI M H B, RAO K S, RAMAMURTHY T. Anisotropic strength and deformational behavior of Himalayan schists [J]. International Journal of Rock Mechanics and Mining Sciences, 2003, 40(1): 3–23. doi: 10.1016/S1365-1609(02)00103-X [19] CHO J W, KIM H, JEON S, et al. Deformation and strength anisotropy of Asan gneiss, Boryeong shale, and Yeoncheon schist [J]. International Journal of Rock Mechanics and Mining Sciences, 2012, 50: 158–169. doi: 10.1016/j.ijrmms.2011.12.004 [20] 吕有厂. 层理性页岩断裂韧性的加载速率效应试验研究 [J]. 岩石力学与工程学报, 2018, 37(6): 1359–1370. doi: 10.13722/j.cnki.jrme.2017.1421LÜ Y C. Effect of bedding plane direction on fracture toughness of shale under different loading rates [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(6): 1359–1370. doi: 10.13722/j.cnki.jrme.2017.1421 [21] 赵子江, 刘大安, 崔振东, 等. 半圆盘三点弯曲法测定页岩断裂韧度(KIC)的实验研究 [J]. 岩土力学, 2018, 39(Suppl 1): 258–266. doi: 10.16285/j.rsm.2018.0571ZHAO Z J, LIU D A, CUI Z D, et al. Experimental study of determining fracture toughness KIC of shale by semi-disk three-point bending [J]. Rock and Soil Mechanics, 2018, 39(Suppl 1): 258–266. doi: 10.16285/j.rsm.2018.0571 [22] 衡帅, 刘晓, 李贤忠, 等. 张拉作用下页岩裂缝扩展演化机制研究 [J]. 岩石力学与工程学报, 2019, 38(10): 2031–2044. doi: 10.13722/j.cnki.jrme.2019.0270HENG S, LIU X, LI X Z, et al. Study on the fracture propagation mechanisms of shale under tension [J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(10): 2031–2044. doi: 10.13722/j.cnki.jrme.2019.0270 [23] 赵小平, 左建平, 裴建良. 锦屏层状大理岩断裂机制的细观试验研究 [J]. 岩石力学与工程学报, 2012, 31(3): 534–542. doi: 10.3969/j.issn.1000-6915.2012.03.011ZHAO X P, ZUO J P, PEI J L. Meso-experimental study of fracture mechanism of bedded marble in Jinping [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(3): 534–542. doi: 10.3969/j.issn.1000-6915.2012.03.011 [24] 黎立云, 宁海龙, 刘志宝, 等. 层状岩体断裂破坏特殊现象及机制分析 [J]. 岩石力学与工程学报, 2006, 25(Suppl 2): 3933–3938. doi: 10.3321/j.issn:1000-6915.2006.z2.093LI L Y, NING H L, LIU Z B, et al. Special phenomena of fracture and mechanism analysis of layered rock mass [J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(Suppl 2): 3933–3938. doi: 10.3321/j.issn:1000-6915.2006.z2.093 [25] 潘睿, 张广清. 层状岩石断裂能各向异性对水力裂缝扩展路径影响研究 [J]. 岩石力学与工程学报, 2018, 37(10): 2309–2318. doi: 10.13722/j.cnki.jrme.2018.0461PAN R, ZHANG G Q. The influence of fracturing energy anisotropy on hydraulic fracturing path in layered rocks [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(10): 2309–2318. doi: 10.13722/j.cnki.jrme.2018.0461 [26] KURUPPU M D, OBARA Y, AYATOLLAHI M R, et al. ISRM-suggested method for determining the mode I static fracture toughness using semi-circular bend specimen [J]. Rock Mechanics and Rock Engineering, 2014, 47(1): 267–274. doi: 10.1007/s00603-013-0422-7 [27] TUTLUOGLU L, KELES C. Mode I fracture toughness determination with straight notched disk bending method [J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(8): 1248–1261. doi: 10.1016/j.ijrmms.2011.09.019 [28] CHANG X, GUO T F, ZHANG S. Cracking behaviours of layered specimen with an interface crack in Brazilian tests [J]. Engineering Fracture Mechanics, 2020, 228: 106904. doi: 10.1016/j.engfracmech.2020.106904 [29] DOU F K, WANG J G, ZHANG X X, et al. Effect of joint parameters on fracturing behavior of shale in notched three-point-bending test based on discrete element model [J]. Engineering Fracture Mechanics, 2019, 205: 40–56. doi: 10.1016/j.engfracmech.2018.11.017 -

下载:

下载: