Numerical Simulation and Analysis of Fuze Explosive Trains under Shock Waves

-

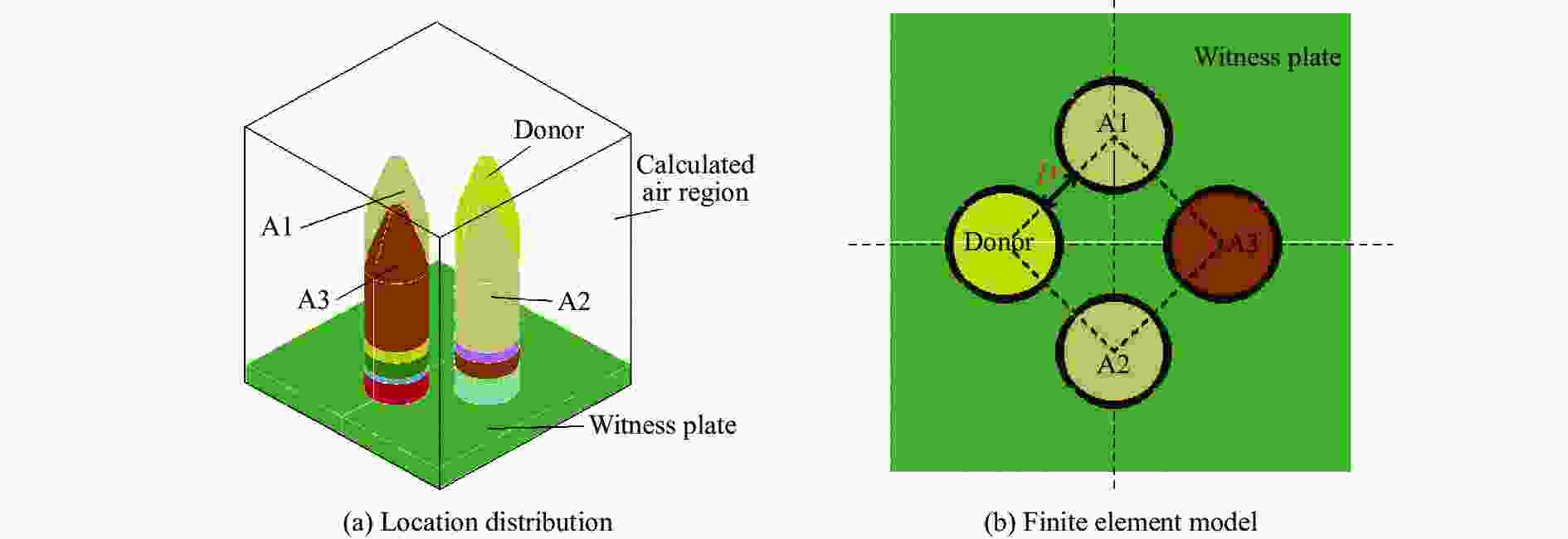

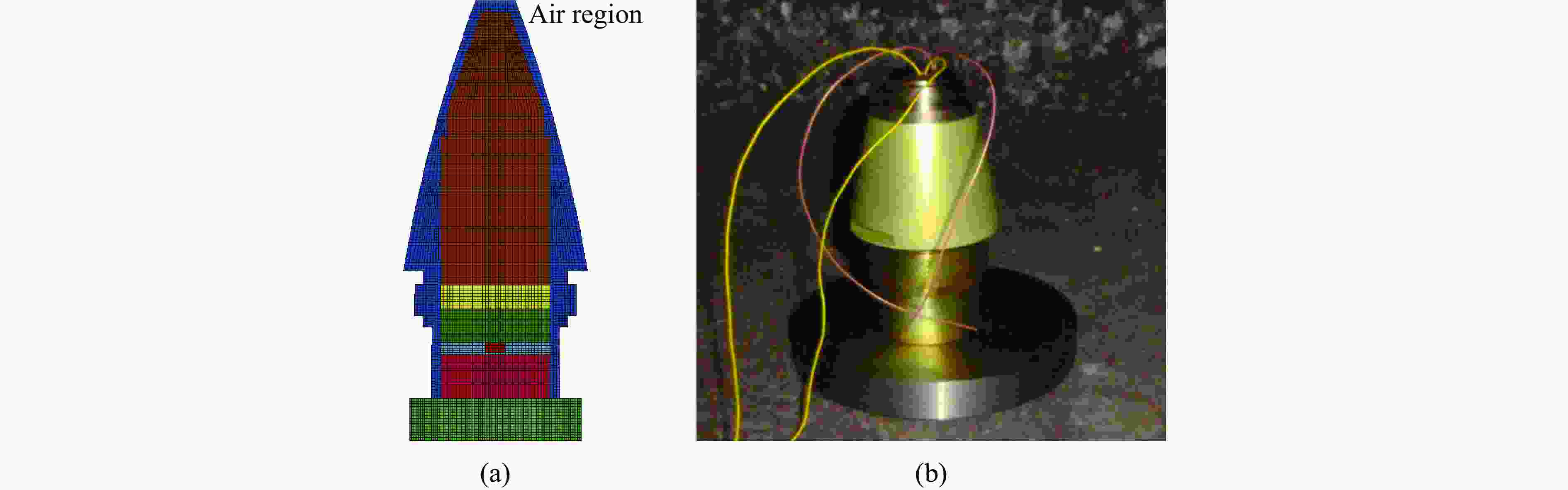

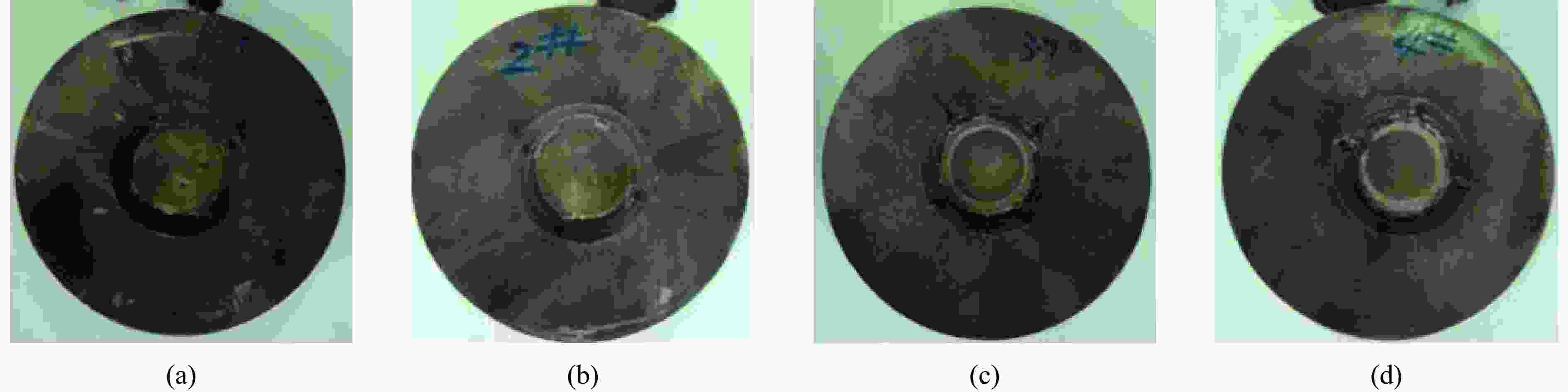

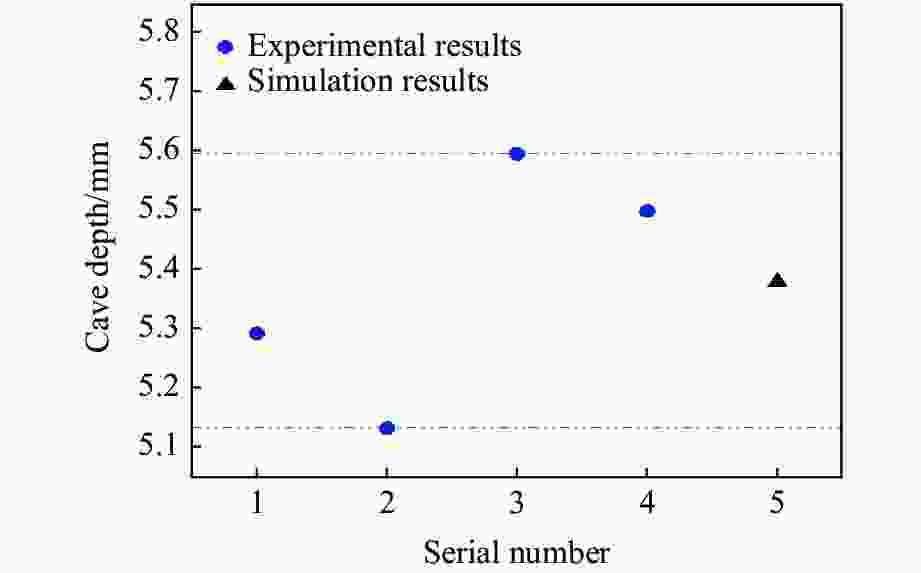

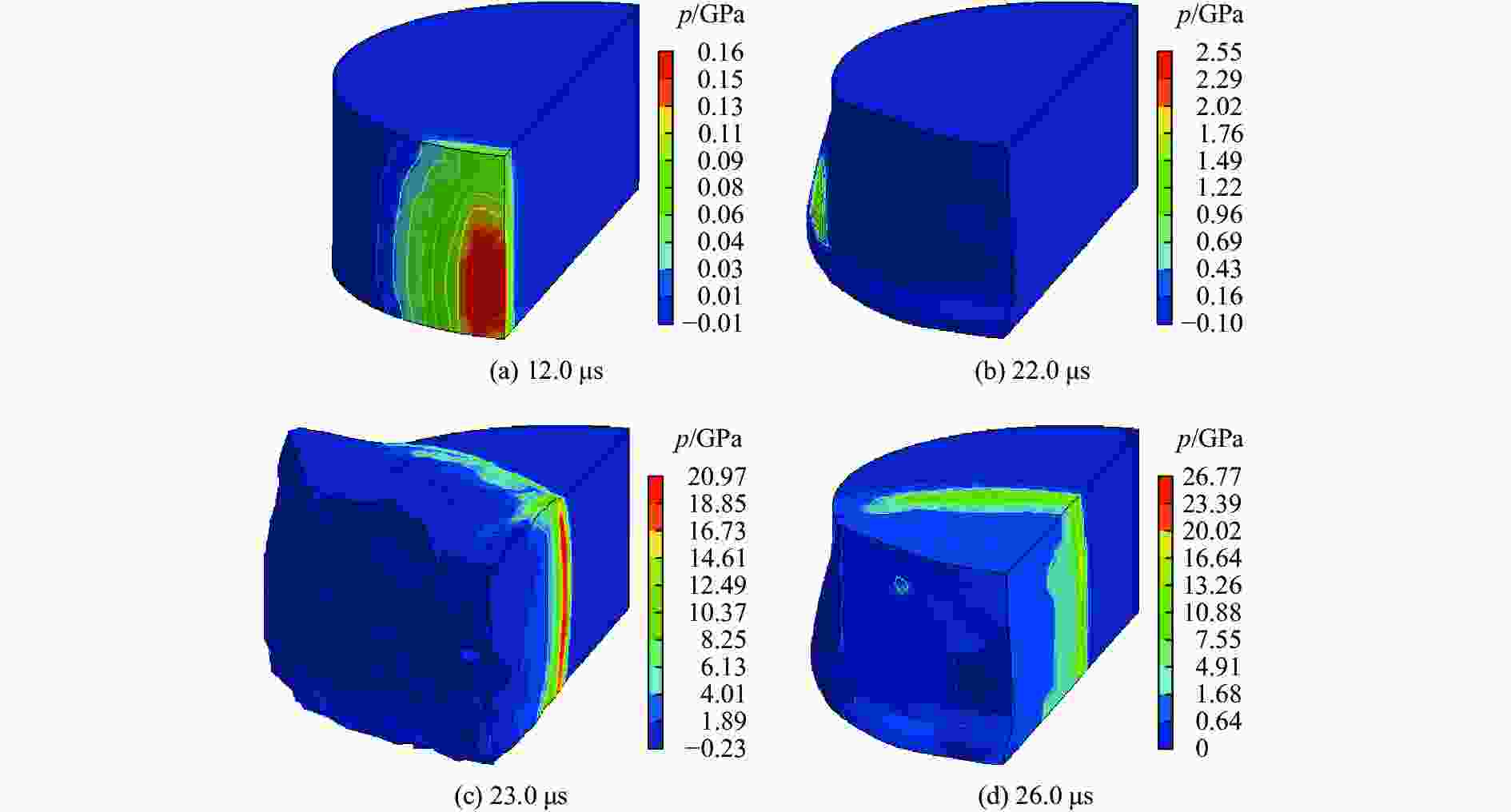

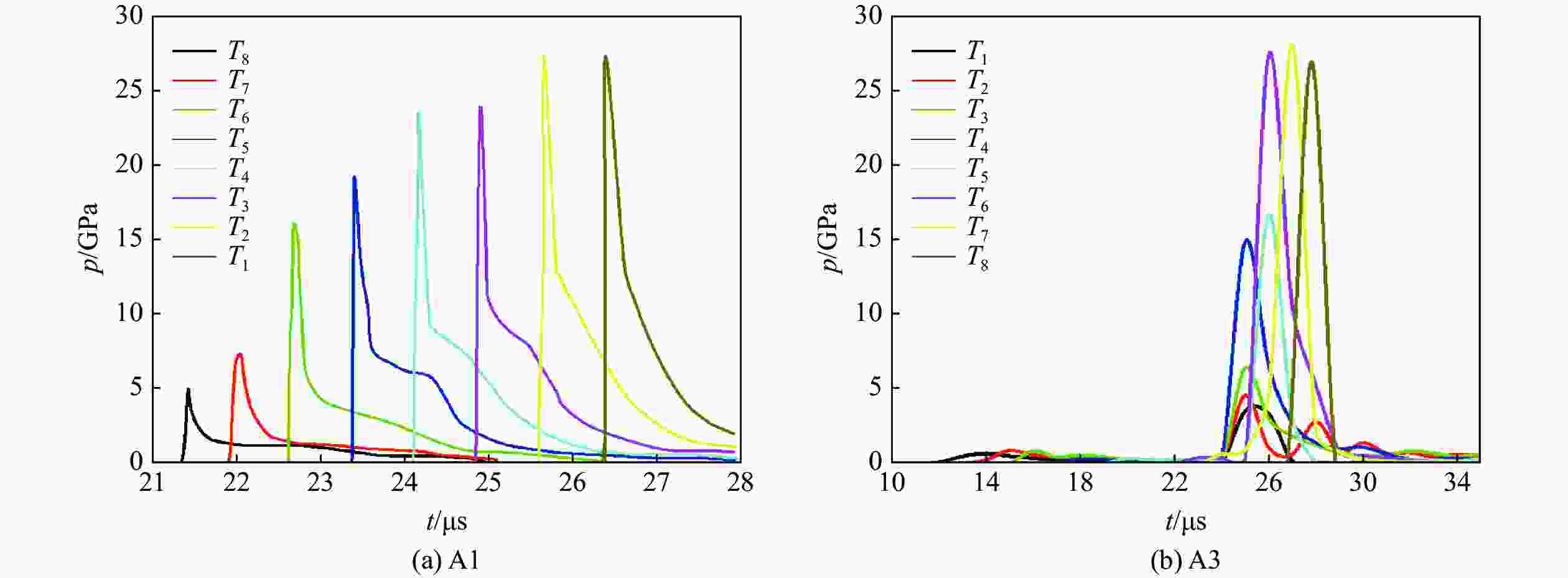

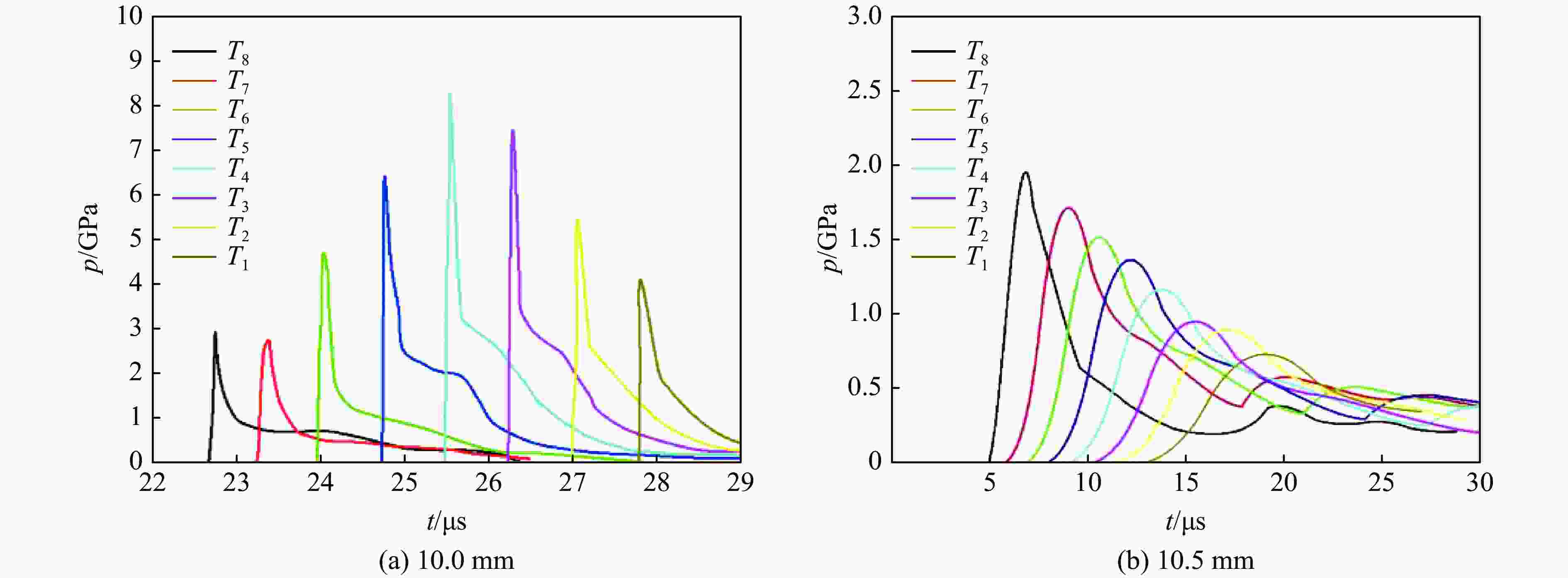

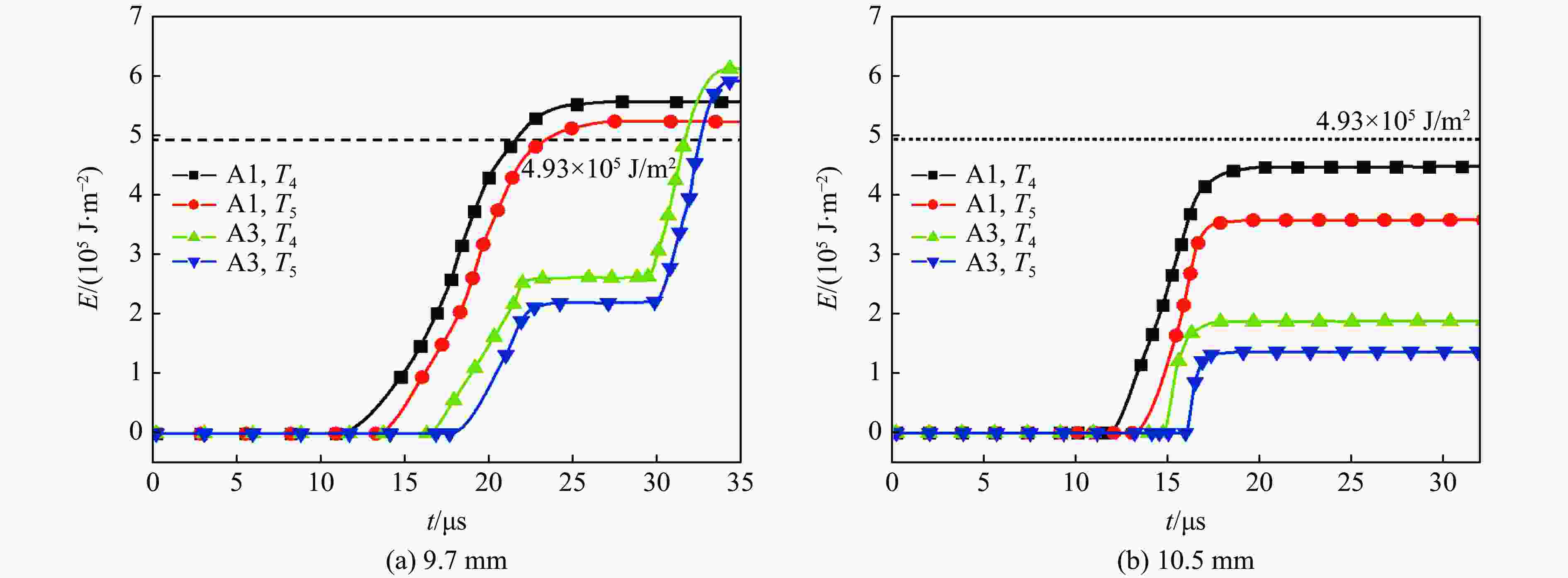

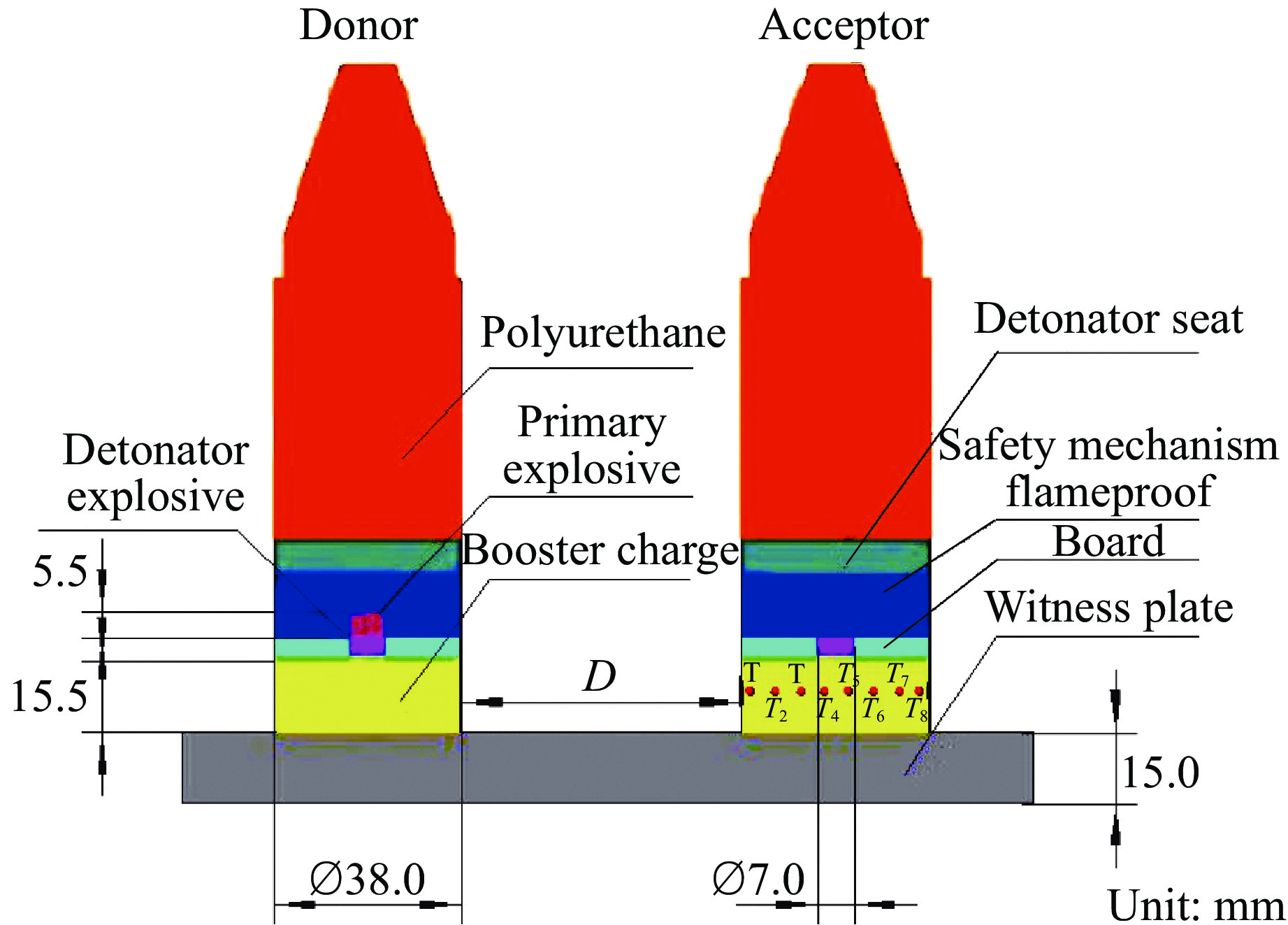

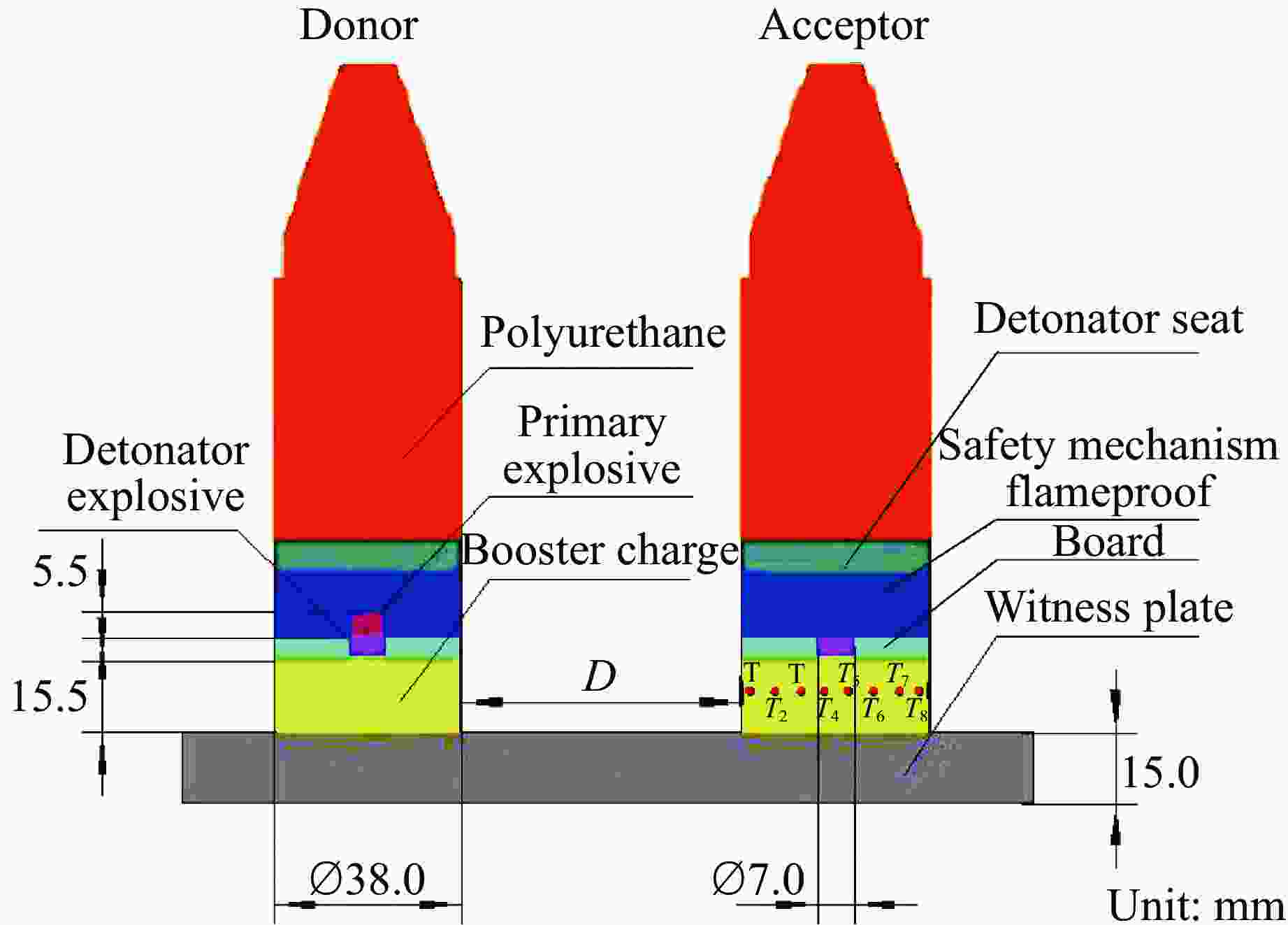

摘要: 为研究不敏感弹药或不敏感引信在战备和后勤贮存过程中的殉爆现象,利用装填JH-14C传爆药的某引信传爆序列,开展了冲击波作用下的殉爆数值模拟研究,获得了引信传爆序列爆轰波成长历程、传播规律以及临界殉爆距离,建立了冲击波能量判据,并给出了殉爆条件。结果表明:冲击波由传爆药左上向右下传播,在最右下端面处起爆,引信传爆序列的临界殉爆距离为9.7 mm;当作用冲击波能量大于临界起爆能量时,引信传爆序列发生殉爆。Abstract: In order to resolve the problem of martyred detonation of insensitive munitions or fuzes during combat readiness and logistical storage, numerical simulation of detonation sequence of the fuze under shock wave was carried out by using nonlinear finite element method. The growth course, propagation law and critical detonation distance of the fuze explosive train were obtained. And the criterion of shock wave energy was established and the condition of sympathetic detonation was given. The results showed that the detonation wave propagates from the top left to the bottom right and explodes at the bottom right, and the critical sympathetic detonation distance of the fuze explosive train is 9.7 mm. When the shock wave energy was greater than the critical detonation energy, the sympathetic detonation occurs in the fuze explosive train.

-

Key words:

- fuze explosive train /

- sympathetic detonation /

- detonation wave /

- shock wave energy

-

表 1 Comp B炸药的High Explosive Burn本构模型参数和JWL状态方程参数[9–10]

Table 1. High Explosive Burn constitutive model parameters and JWL equation parameters for Comp B[9–10]

$\;\rho $/(g·cm−3) S1 $\gamma $0 A0/GPa B0/GPa R1 R2 $\omega $ p0/GPa 1.717 0.798 0.33 524.23 767 4.2 1.1 0.34 8.5 JWL equation parameters for unreacted explosive and reaction product State A0/GPa B0/GPa R1 R2 $\omega $ G/GPa $\sigma_{\rm{y}}$/MPa $\;\rho $/(g·cm−3) p0/GPa D/(km·s−1) p/GPa Unreacted

explosive7 781.0 −5.31 11.3 1.13 0.8938 3.5 200 1.65 Reaction

product592.7 10.51 4.4 1.20 0.330 0 11.56 8.19 27.67 Rate of reaction a b c d e g x y z 0.02 0.667 0.667 0.350 0.667 0.667 7.0 2.0 3.0 Figmax FG1max FG2min I/μs−1 G1/(MPa·μs−1) G2/(MPa·μs−1) 0.022 1 0 4 × 106 1.4 × 107 7 × 108 表 3 紫铜、2024铝与4340钢的Johnson-Cook本构模型参数[12–13]

Table 3. Johnson-Cook constitutive model parameters for copper, 2024 aluminum and 4340 steel[12–13]

Material $\;\rho $/(g·cm−3) G/GPa A/MPa B/MPa n c m Tm/K Tr/K Cp/(J·kg−1·K−1) Copper 8.960 46.0 90 292 0.31 0.025 1.09 1356 300 383 2024 aluminum 2.785 28.6 265 426 0.34 0.015 1.00 445 300 875 4340 steel 7.830 77.0 792 510 0.26 0.014 1.03 1793 300 477 表 4 紫铜、2024铝、4340钢的Grüneisen状态方程参数[12–13]

Table 4. Grüneisen equation of state parameters of copper, 2024 aluminum and 4340 steel[12–13]

Material C/(km·s−1) S1 $\gamma $0 Copper 3.940 1.489 1.99 2024 aluminum 5.328 1.338 2.00 4340 steel 4.569 1.490 2.17 表 5 不同距离下殉爆数值模拟结果

Table 5. Numerical simulation results at different distances

Distance/mm Numerical simulation results A1 A2 A3 8.5 Detonation Detonation Detonation 9.0 Detonation Detonation Detonation 9.7 Detonation Detonation Detonation 10.0 Partial reaction Partial reaction No detonation 10.3 No detonation No detonation No detonation 10.5 No detonation No detonation No detonation -

[1] WANG F J, CHEN H M, MA C, et al. Construction of backscattering echo caused by cloud in laser fuze [J]. Optik, 2018, 171: 153–160. doi: 10.1016/j.ijleo.2018.06.028 [2] SHARP A, ANDRADE J, RUFFINI N. Design for reliability for the high reliability fuze [J]. Reliability Engineering & System Safety, 2018, 181: 54–61. [3] 韩炎晖, 娄文忠, 冯跃, 等. 慢速烤燃环境下引信热响应特性测试与仿真 [J]. 兵工学报, 2019, 40(5): 946–953.HAN Y H, LUO W Z, YUE F, et al. Measurement and simulation of thermal response characteristics of fuze in slow cook-off test [J]. Acta Armamentarii, 2019, 40(5): 946–953. [4] KIM B, PARK J, LEE K C, et al. A reactive flow model for heavily aluminized cyclotrimethylene-trinitramine [J]. Journal of Applied Physics, 2014, 116(2): 023512. doi: 10.1063/1.4887811 [5] KIM B, KIM M, SUN T, et al. Simulating sympathetic detonation using the hydrodynamic models and constitutive equations [J]. Journal of Mechanical Science and Technology, 2016, 30(12): 5491–5502. doi: 10.1007/s12206-016-1117-2 [6] MOSTAFA H E, MEKKY W F, EL-DAKHAKHNI W W. Sympathetic detonation wave attenuation using polyurethane foam [J]. Journal of Materials in Civil Engineering, 2014, 26(8): 04014046. doi: 10.1061/(ASCE)MT.1943-5533.0000934 [7] 陈朗, 王晨, 鲁建英, 等. 炸药殉爆实验和数值模拟 [J]. 北京理工大学学报, 2009, 29(6): 497–500, 524.CHEN L, WANG C, LU J Y, et al. Experiment & simulation of sympathetic detonation tests [J]. Transactions of Beijing Institute of Technology, 2009, 29(6): 497–500, 524. [8] CHEN L, WANG C, FENG C G, et al. Study on random initiation phenomenon for sympathetic detonation of explosive [J]. Defence Technology, 2013, 9(4): 224–228. doi: 10.1016/j.dt.2013.12.002 [9] 刘鹏飞. 破片特性对冲击起爆B炸药比动能阈值的影响[D]. 太原: 中北大学, 2017.LIU P F. Influence of fragment characteristics on the threshold specific kinetic energy of impacting on covered Comp B [D]. Taiyuan: North University of China, 2017. [10] SCHWER L E. Impact and detonation of COMP-B: an example using the LS-DYNA EOS: ignition and growth of reaction in high explosives [C]//12th International LS-DYNA User Conference. Detroit, USA: 2012. [11] 李硕, 袁俊明, 刘玉存, 等. 聚黑-14C 的传爆装置冲击起爆实验及数值模拟 [J]. 火炸药学报, 2016, 39(6): 63–68, 79.LI S, YUAN J M, LIU Y C, et al. Experiment and numerical simulation of shock initiation of JH-14C detonation device [J]. Chinese Journal of Explosive & Propellants, 2016, 39(6): 63–68, 79. [12] BUYUK M, KURTARAN H, MARZOUGUI D, et al. Automated design of threats and shields under hypervelocity impacts by using successive optimization methodology [J]. International Journal of Impact Engineering, 2008, 35(12): 1449–1458. doi: 10.1016/j.ijimpeng.2008.07.057 [13] 时党勇, 李裕春, 张胜民. 基于ANSYS/LS-DYNA 8.1进行显式动力分析 [M]. 北京: 清华大学出版社, 2005.SHI D Y, LI Y C, ZHANG S M. Explicit dynamics based on ANSYS/LS-DYNA8.1 force analysis [M]. Beijing: Tsinghua University Press, 2009. [14] 袁俊明, 李硕, 刘玉存, 等. 聚奥-9C装药的传爆管殉爆 [J]. 爆炸与冲击, 2018, 38(3): 632–638.YUAN J M, LI S, LIU Y C, et al. Sympathetic detonation of booster pipe with JO-9C charge [J]. Explosion and Shock Waves, 2018, 38(3): 632–638. [15] FOAN G C M, GOLEY G D. Shock initiation in gap test configurations [C]//7th Symposium on Detonation. Annapolis, USA: Naval Surface Weapons Center, 1981. [16] 王泽溥, 郑志良. 爆炸及其防护[M]. 北京: 兵器工业出版社, 2008.WANG Z P, ZHENG Z L. Explosion and protection [M]. Beijing: Ordnance Industry Press, 2008. -

下载:

下载: