Three-Dimensional Numerical Simulation of Explosive in Drop Hammer Impact Test and Sample Thickness Effect

-

摘要: 为了研究落锤实验中炸药的概率点火行为以及试样厚度对点火的影响,对脆性炸药PBX-2的落锤实验开展了三维数值模拟。采用有限元与离散元相结合的方法,并考虑了炸药材料的非均匀性,获得了炸药在不同落高下的点火概率分布,落高计算结果与文献报道的实验结果相符。此外,研究了落锤实验中试样厚度对炸药温升过程及点火阈值的影响,拟合得到了压力峰值和点火阈值随试样厚度变化的估算公式,可以为实验设计提供参考。

-

关键词:

- 落锤实验 /

- 厚度效应 /

- 有限元-离散元结合方法 /

- 三维数值模拟

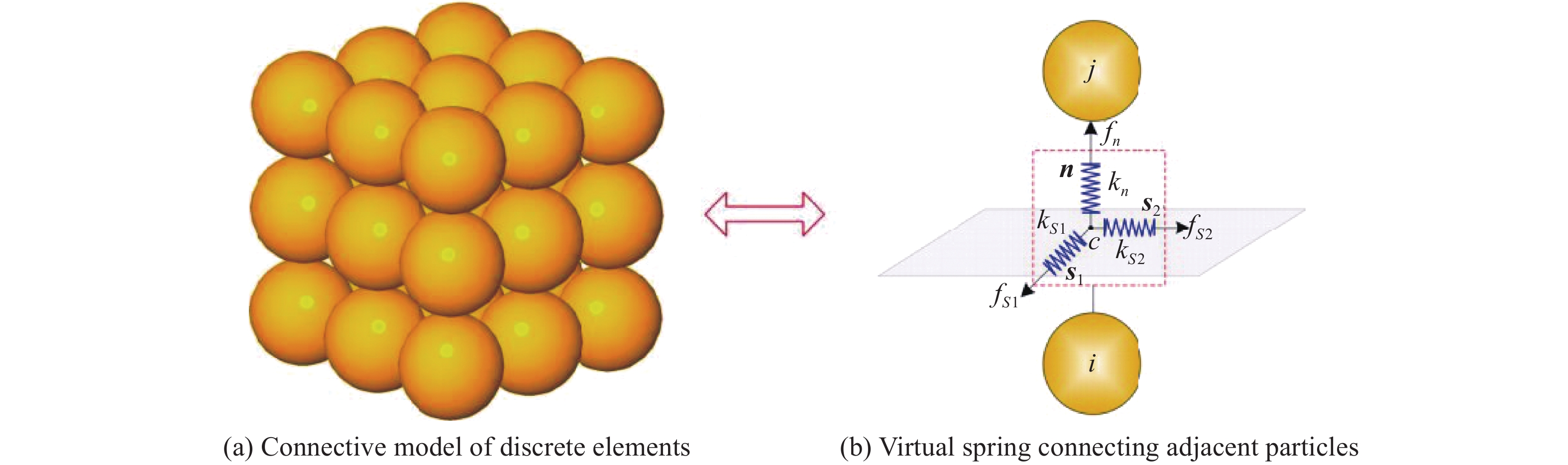

Abstract: In order to study the probability ignition behavior of explosive and the influence of sample thickness on ignition in drop weight test, a three-dimensional numerical simulation of brittle explosive PBX-2 is carried out. The three-dimensional numerical simulation method combining the finite element method and the discrete element method is adopted, and the non-uniformity of explosive material is considered. The ignition probability distribution of explosive under different falling height is obtained. The calculation result of falling height is consistent with the experimental result reported in literature. The influence of sample thickness on the temperature rise process and ignition threshold height of explosive in drop weight test is studied. The estimation formula of pressure peak value and ignition threshold with sample thickness is obtained by fitting, which can provide reference for experimental design. -

$\;\rho $/(kg·m−3) Q/(J·kg−1) Z/s−1 E0/(J·mol−1) R/(J·mol−1·K−1) 1 850 2.092 × 106 4.78 × 1013 1.439 × 105 8.314 5 Material $\;\rho $/(kg·m−3) E/GPa $\nu$ c/(J·kg−1·K−1) $\kappa$/(W·m−1·K−1) PBX-2 1 850 5 0.26 1 020 0.302 Q235 7 850 206 0.30 502 16.270 表 3 不同落高下的点火情况

Table 3. Ignition situation of PBX-2 underdifferent drop height

Drop height/m Times of ignition Ignition probability/% 5.5 7 28 6.0 9 36 6.5 13 52 7.0 18 72 7.5 25 100 -

[1] SMALLWOOD J M, FIELD J E. Hot-spot ignition mechanisms for explosives and propellants [J]. Philosophical Transactions of the Royal Society A: Mathematical Physical and Engineering Sciences, 1992, 339(1654): 269–283. [2] BALZER J E, PROUD W G, WALLEY S M, et al. High-speed photographic study of the drop-weight impact response of RDX/DOS mixtures [J]. Combustion and Flame, 2003, 135(4): 547–555. doi: 10.1016/j.combustflame.2003.08.009 [3] 吴艳青, 黄风雷, 艾德友. HMX颗粒炸药低速撞击点火实验研究 [J]. 爆炸与冲击, 2011, 31(6): 592–599.WU Y Q, HUANG F L, AI D Y. Experimental study on low-velocity impact ignition for HMX granular explosives [J]. Explosion and Shock Waves, 2011, 31(6): 592–599. [4] WALLEY S M, FIELD J E, BIERS R A, et al. The use of glass anvils in drop-weight studies of energetic materials [J]. Propellants, Explosives, Pyrotechnics, 2015, 40(3): 351–365. doi: 10.1002/prep.201500043 [5] 代晓淦, 向永, 申春迎, 等. 大药片落锤撞击感度研究 [J]. 爆炸与冲击, 2006, 26(4): 381–384. doi: 10.3321/j.issn:1001-1455.2006.04.017DAI X G, XIANG Y, SHEN C Y, et al. Study of drop hammer impact sensitivity for big-bill explosives [J]. Explosion and Shock Waves, 2006, 26(4): 381–384. doi: 10.3321/j.issn:1001-1455.2006.04.017 [6] 刘志跃, 代晓淦, 黄毅民. 炸药落锤试验点火机理的数值分析 [J]. 计算力学学报, 2009, 26(4): 595–599, 612. doi: 10.7511/jslx20094027LIU Z Y, DAI X G, HUANG Y M. Numerical analysis on the ignition mechanism of explosive in drop-weight test [J]. Chinese Journal of Computational Mechanics, 2009, 26(4): 595–599, 612. doi: 10.7511/jslx20094027 [7] 赵娟, 徐洪涛, 冯晓军. 装药条件对B炸药落锤撞击响应的影响研究 [J]. 爆破器材, 2014, 43(6): 6–10. doi: 10.3969/j.issn.1001-8352.2014.06.002ZHAO J, XU H T, FENG X J. Effects of charge conditions on the drop hammer impact response of composition B [J]. Explosive Materials, 2014, 43(6): 6–10. doi: 10.3969/j.issn.1001-8352.2014.06.002 [8] 陈鹏, 屈可朋, 陈荣, 等. 落锤加载下反应材料的反应性能 [J]. 火炸药学报, 2019, 42(2): 197–201, 206.CHEN P, QU K P, CHEN R, et al. Reactive properties of reactive material under the load of drop-weight [J]. Chinese Journal of Explosives & Propellants, 2019, 42(2): 197–201, 206. [9] 袁俊明, 刘玉存, 曹文军. B炸药落锤撞击点火的数值模拟 [J]. 含能材料, 2013, 21(1): 30–34. doi: 10.3969/j.issn.1006-9941.2013.01.007YUAN J M, LIU Y C, CAO W J. Numerical simulation of drop weight impact ignition on composite explosive [J]. Chinese Journal of Energetic Materials, 2013, 21(1): 30–34. doi: 10.3969/j.issn.1006-9941.2013.01.007 [10] 王勖成, 邵敏. 有限单元法基本原理和数值方法 [M]. 2版. 北京: 清华大学出版社, 1997.WANG X C, SHAO M. Basic principle and numerical method of the finite element method [M]. 2nd ed. Beijing: Tsinghua University Press, 1997. [11] 王文强. 离散元方法及其在材料和结构力学响应分析中的应用 [D]. 合肥: 中国科学技术大学, 2000.WANG W Q. Application of the discrete element method in response analysis of materials and structural mechanics [D]. Hefei: University of Science and Technology of China, 2000. [12] 黄彬彬, 傅华, 喻寅, 等. 基于有限元-离散元结合方法的Steven实验三维数值模拟 [J]. 含能材料, 2020, 28(10): 995–1002. doi: 10.11943/CJEM2020115HUANG B B, FU H, YU Y, et al. Three-dimensional numerical simulation of Steven test by the combined finite-discrete element method [J]. Chinese Journal of Energetic Materials, 2020, 28(10): 995–1002. doi: 10.11943/CJEM2020115 [13] ESPINOSA H D, ZAVATTIERI P D. A grain level model for the study of failure initiation and evolution in polycrystalline brittle materials. Part I: theory and numerical implementation [J]. Mechanics of Materials, 2003, 35(3/4/5/6): 333–364. [14] TVERGAARD V, HUTCHINSON J W. The influence of plasticity on mixed mode interface toughness [J]. Journal of the Mechanics and Physics of Solids, 1993, 41(6): 1119–1135. doi: 10.1016/0022-5096(93)90057-M [15] 孙宝平, 段卓平, 万经伦, 等. 基于Visco-SCRAM模型的侵彻装药点火研究 [J]. 爆炸与冲击, 2015, 35(5): 689–695. doi: 10.11883/1001-1455(2015)05-0689-07SUN B P, DUAN Z P, WAN J L, et al. Investigation on ignition of an explosive charge in a projectile during penetration based on Visco-SCRAM model [J]. Explosion and Shock Waves, 2015, 35(5): 689–695. doi: 10.11883/1001-1455(2015)05-0689-07 [16] 刘睿, 韩勇, 代晓淦, 等. 初始裂纹对高聚物粘结炸药低速撞击点火影响数值模拟研究 [J]. 含能材料, 2019, 27(10): 812–818. doi: 10.11943/CJEM2019152LIU R, HAN Y, DAI X G, et al. Numerical simulation on the influence of the initial crack on polymer bonded explosive ignition under low velocity impact [J]. Chinese Journal of Energetic Materials, 2019, 27(10): 812–818. doi: 10.11943/CJEM2019152 [17] 傅华, 刘仓理, 王文强, 等. 细观尺度下塑料粘结炸药热点生成的初步模拟 [J]. 爆炸与冲击, 2008, 28(6): 515–520. doi: 10.3321/j.issn:1001-1455.2008.06.006FU H, LIU C L, WANG W Q, et al. Preliminary simulation of hot spot formation for plastic bonded explosives at mesoscale [J]. Explosion and Shock Waves, 2008, 28(6): 515–520. doi: 10.3321/j.issn:1001-1455.2008.06.006 [18] FRANK-KAMENETSKII A A. On the mathematical theory of thermal explosions [J]. Acta Physicochim Urs, 1942, 16: 357–361. [19] 董海山, 周芬芬. 高能炸药及相关物性能 [M]. 北京: 科学出版社, 1989.DONG H S, ZHOU F F. High explosives and related property [M]. Beijing: Science Press, 1989. [20] 代晓淦, 吕子剑, 申春迎, 等. 两种尺寸JOB-9003炸药慢速烤燃试验及数值模拟研究[C]//第八届全国爆炸力学学术会议. 井冈山, 2007: 29–32.DAI X G, LÜ Z J, SHEN C Y, et al. Slow roasting test and numerical simulation of JOB-9003 explosive with two kinds of size [C]//The 8th National Conference on Explosive Mechanics. Jinggangshan, 2007: 29–32. [21] 肖玮, 李亮亮, 苏健军, 等. TNT在热和撞击加载作用下的点火性能 [J]. 火炸药学报, 2013, 36(2): 38–41. doi: 10.3969/j.issn.1007-7812.2013.02.009XIAO W, LI L L, SU J J, et al. Ignition performances of TNT under temperature and impact loading actions [J]. Chinese Journal of Explosives & Propellants, 2013, 36(2): 38–41. doi: 10.3969/j.issn.1007-7812.2013.02.009 -

下载:

下载: