| [1] |

刘姗姗, 刘亚军, 张英杰, 等. 碳纤维-泡沫铝夹芯板低速冲击响应 [J]. 高压物理学报, 2020, 34(3): 034202.LIU S S, LIU Y J, ZHANG Y J, et al. Low-velocity impact response of carbon fiber-aluminum foam sandwich plate [J]. Chinese Journal of High Pressure Physics, 2020, 34(3): 034202.

|

| [2] |

王永欢, 徐鹏, 范志强, 等. 球形孔开孔泡沫铝的力学特性及准静态压缩变形机制 [J]. 高压物理学报, 2019, 33(1): 014201.WANG Y H, XU P, FAN Z Q, et al. Mechanical characteristics and quasi-static compression deformation mechanism of open-cell aluminum foam with spherical cells [J]. Chinese Journal of High Pressure Physics, 2019, 33(1): 014201.

|

| [3] |

张国栋, 李翔宇, 梁民族, 等. 内部爆炸载荷下泡沫铝夹心柱壳动态响应仿真研究 [J]. 高压物理学报, 2018, 32(2): 024101.ZHANG G D, LI X Y, LIANG M Z, et al. Dynamic response of sandwich cylinders cored with aluminum foam under internal blast loading [J]. Chinese Journal of High Pressure Physics, 2018, 32(2): 024101.

|

| [4] |

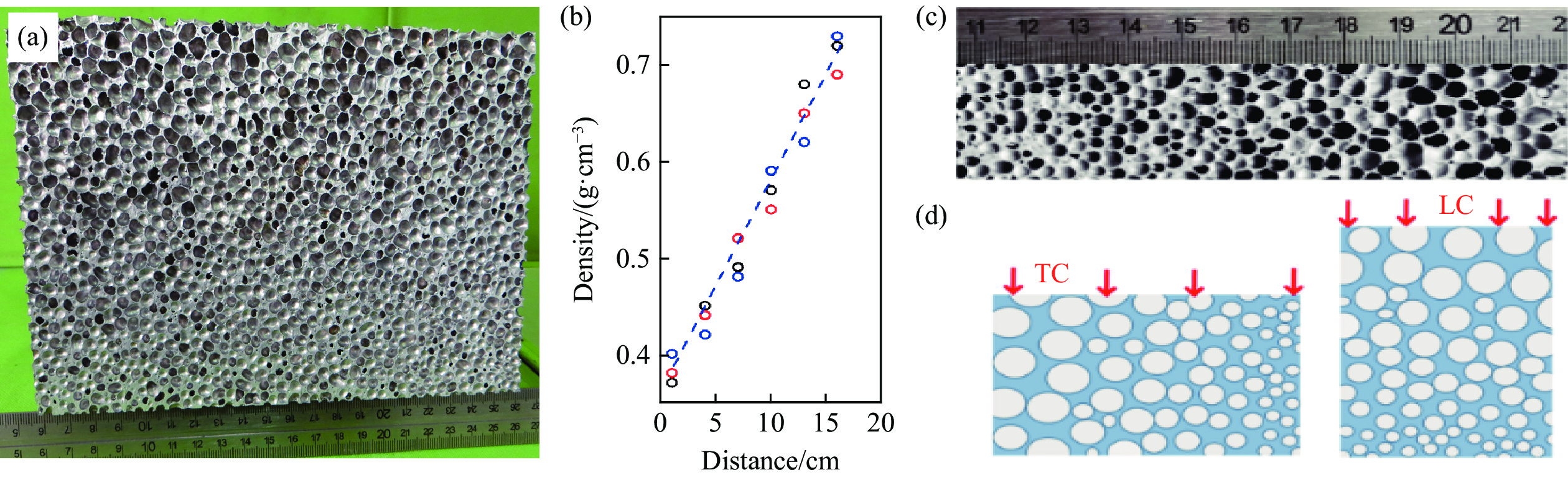

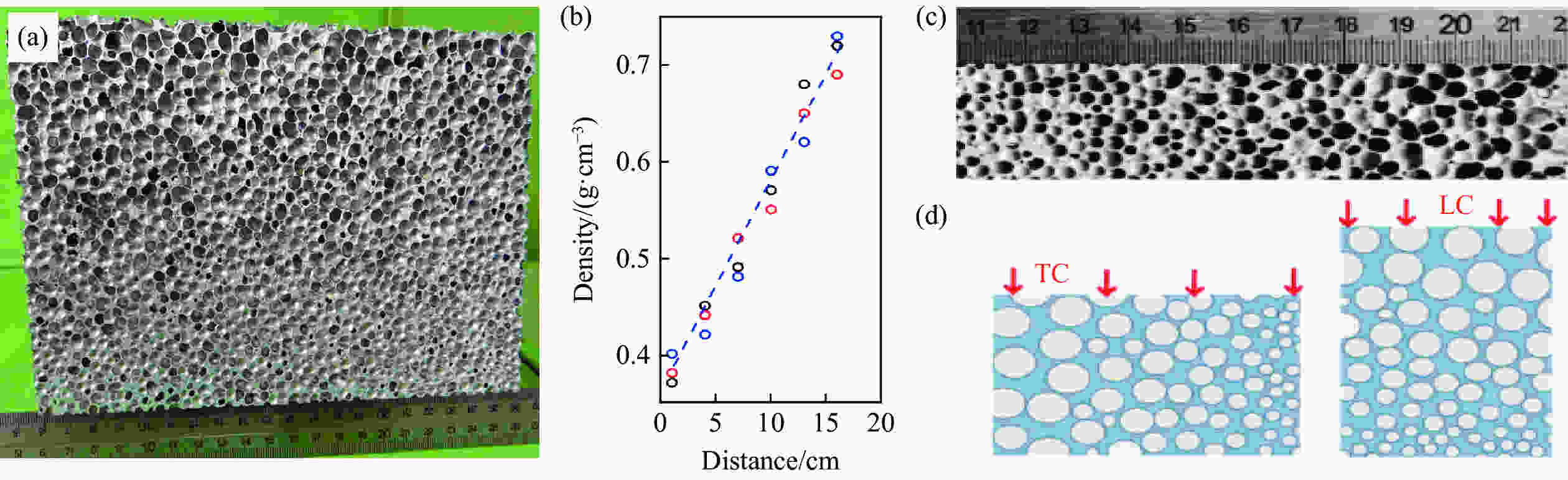

HE S, ZHANG Y, DAI G, et al. Preparation of density-graded aluminum foam [J]. Materials Science and Engineering: A, 2014, 618: 496–499. doi: 10.1016/j.msea.2014.08.087

|

| [5] |

杨旭东, 成莹, 郑远兴, 等. 梯度泡沫铝的制备及力学性能研究进展 [J]. 热加工工艺, 2019, 48(12): 16–20.YANG X D, CHENG Y, ZHENG Y X, et al. Research development of preparation and mechanical properties of graded aluminum foam [J]. Hot Working Technology, 2019, 48(12): 16–20.

|

| [6] |

HANGAI Y, MORITA T, UTSUNOMIYA T. Functionally graded aluminum foam consisting of dissimilar aluminum alloys fabricated by sintering and dissolution process [J]. Materials Science and Engineering A, 2017, 696: 544–551. doi: 10.1016/j.msea.2017.04.070

|

| [7] |

XIA Y, WU C, LIU Z X, et al. Protective effect of graded density aluminum foam on RC slab under blast loading—an experimental study [J]. Construction and Building Materials, 2018, 111: 209–222.

|

| [8] |

曹娇. 功能密度梯度泡沫铝及其填充结构的吸能性能研究[D]. 长沙: 湖南大学, 2015.CAO J. Study on crashworthiness of functionally graded density aluminum foam-filled tapered thin-walled structures [D]. Changsha: Hunan University, 2015.

|

| [9] |

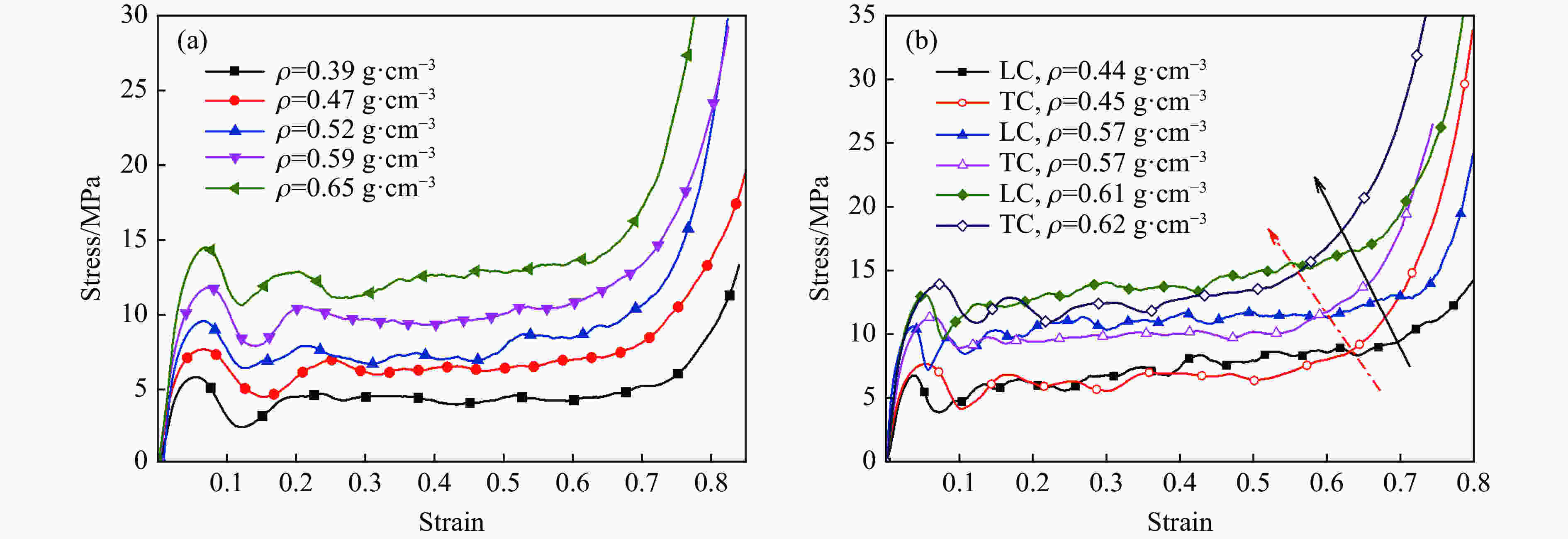

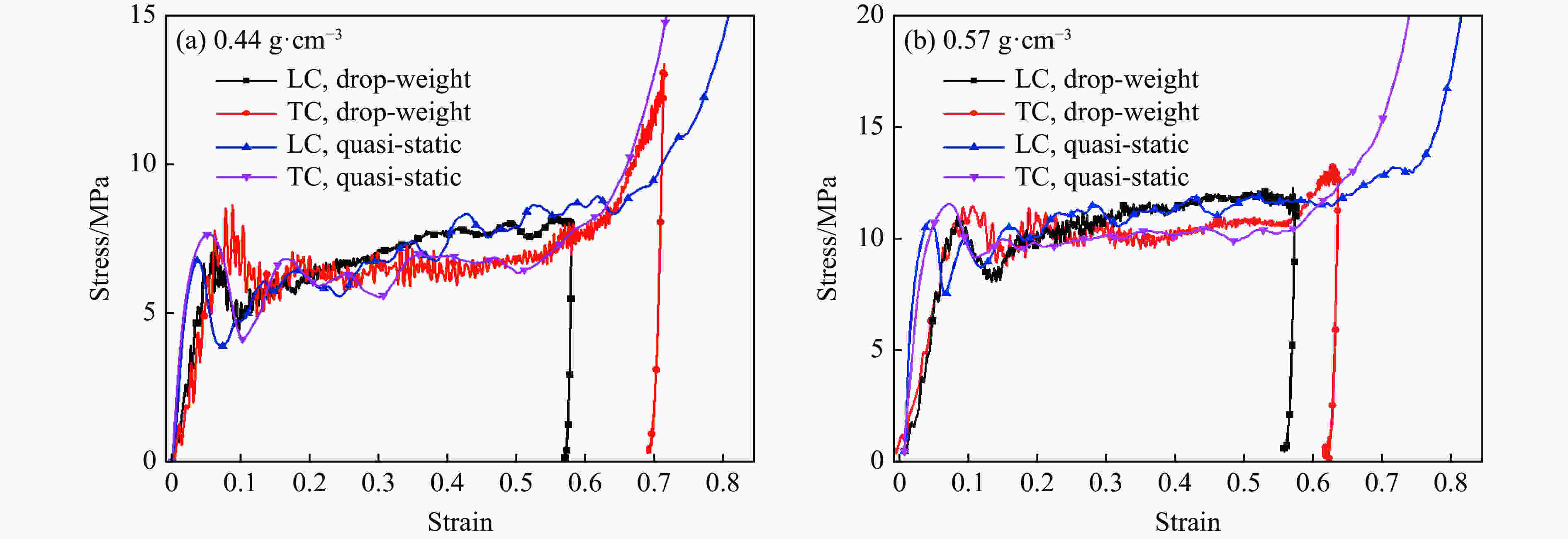

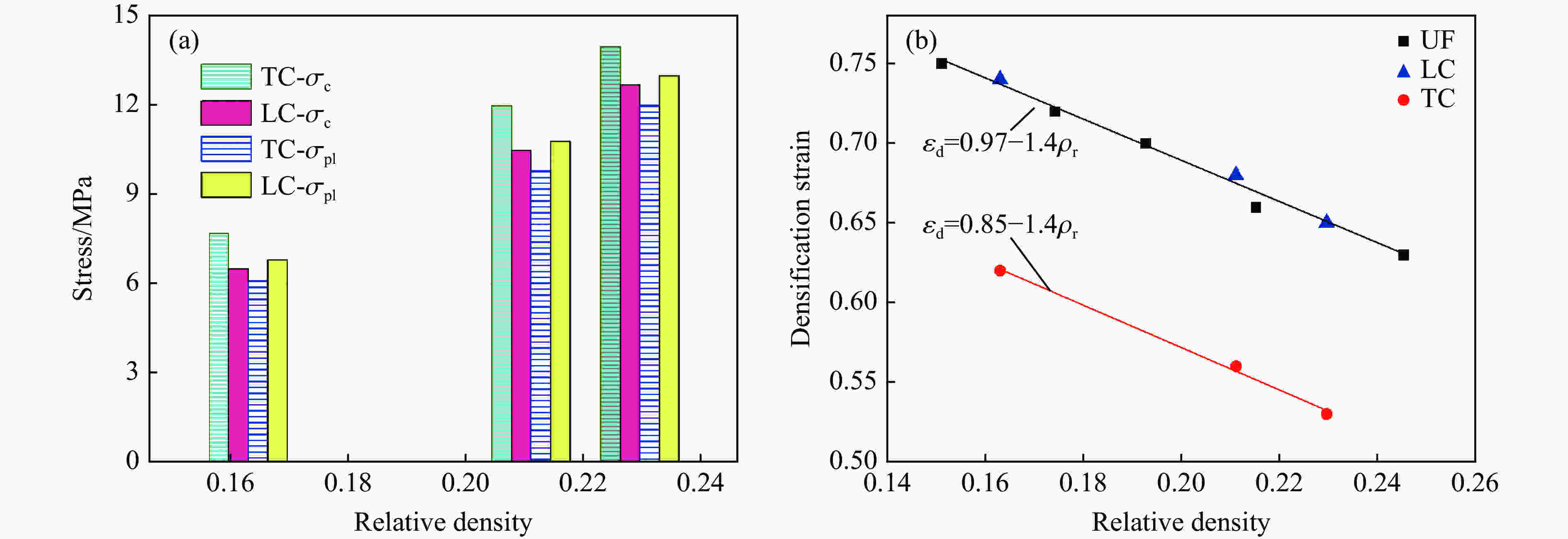

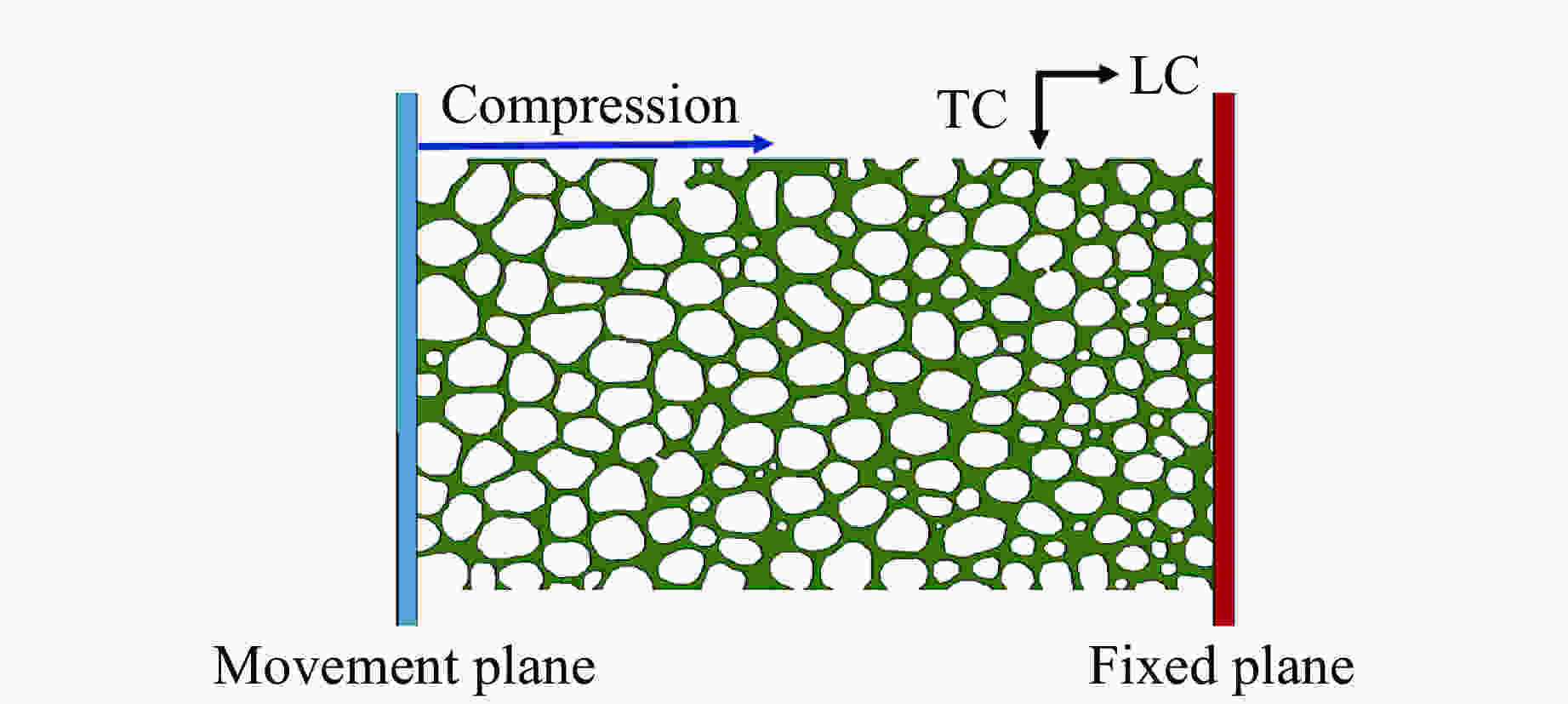

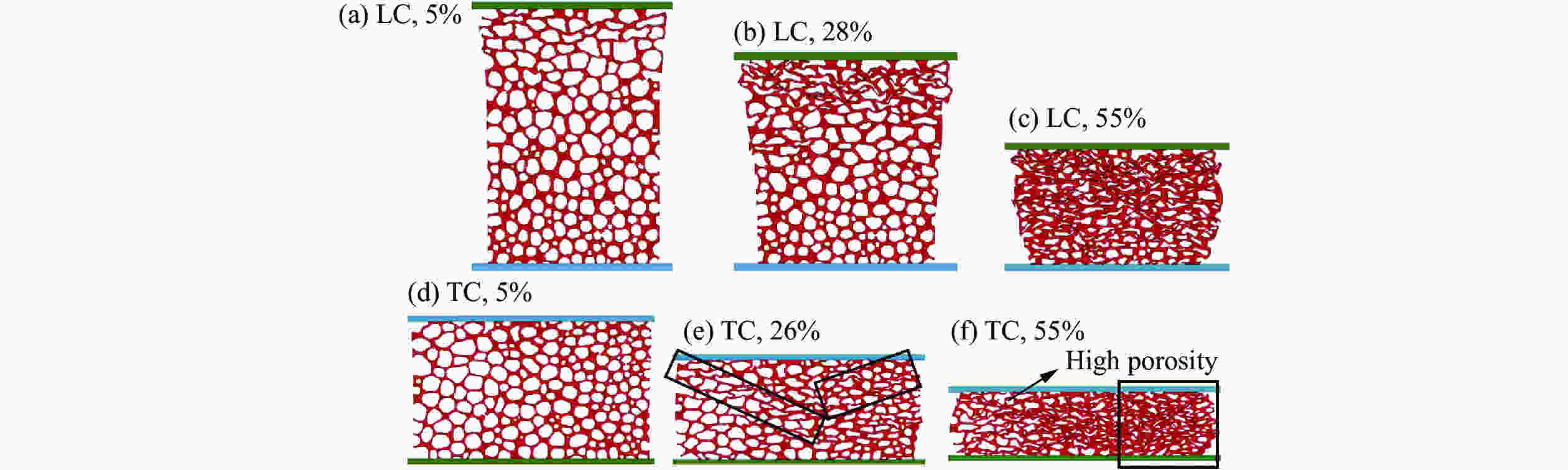

ZHANG B, HU S, FAN Z. Anisotropic compressive behavior of functionally density graded aluminum foam prepared by controlled melt foaming process [J]. Materials, 2018, 11: 2470–2480. doi: 10.3390/ma11122470

|

| [10] |

AMSTERDAM E, HOSSON J T M D, ONCK P R. On the plastic collapse stress of open-cell aluminum foam [J]. Scripta Materialia, 2008, 59(6): 653–656. doi: 10.1016/j.scriptamat.2008.05.025

|

| [11] |

GIBSON L J, ASHBY M F. Cellular solids : structure and properties [M]. Cambridge, UK: Cambridge University Press, 1997.

|

| [12] |

MU Y, YAO G. Anisotropic compressive behavior of closed-cell Al–Si alloy foams [J]. Materials Science and Engineering: A, 2010, 527: 1117–1119. doi: 10.1016/j.msea.2009.09.045

|

| [13] |

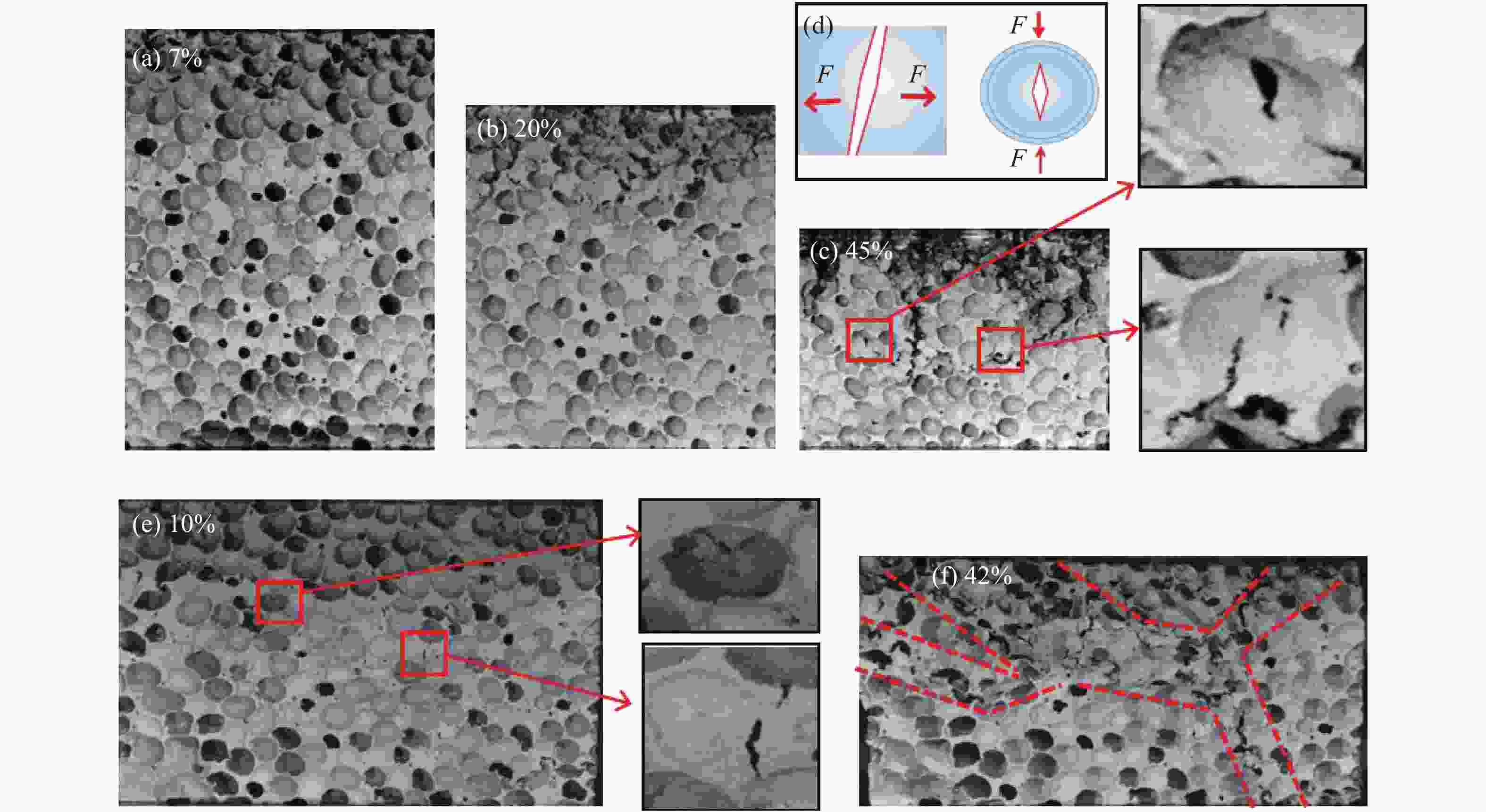

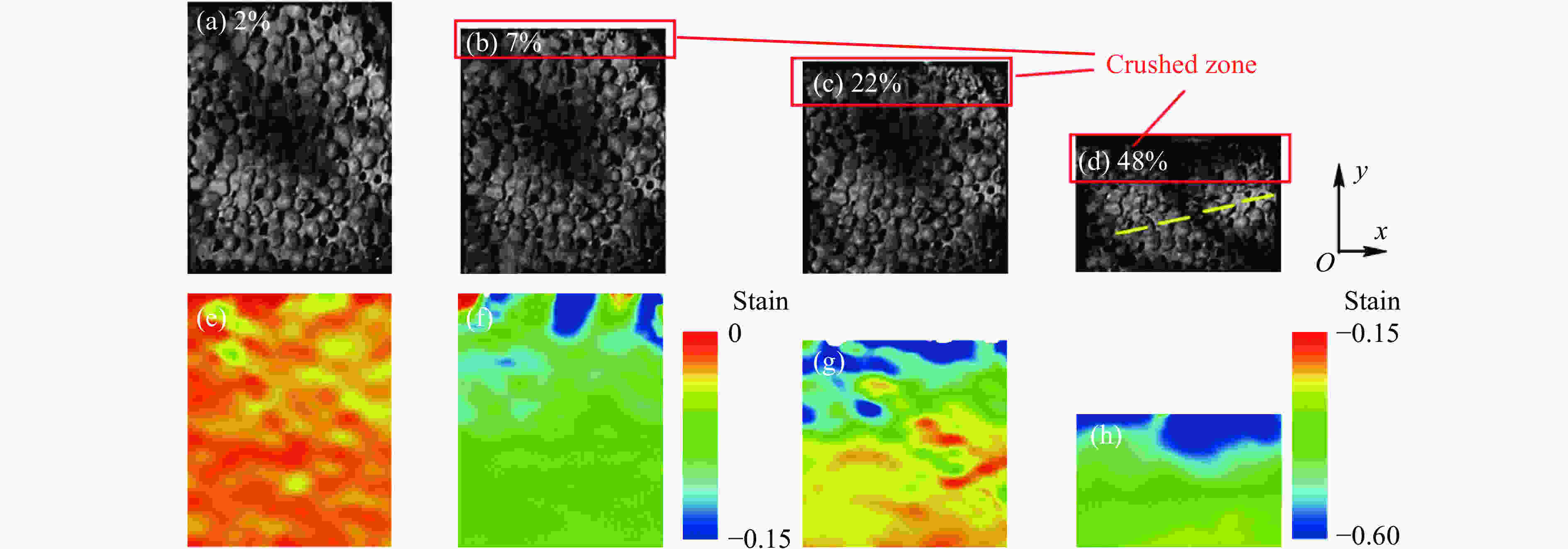

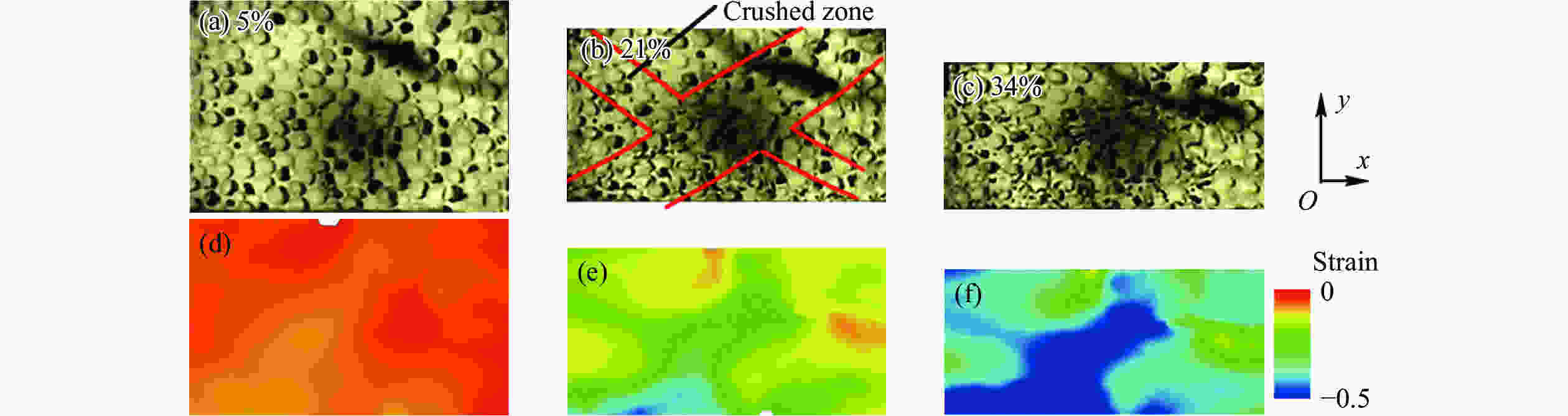

FAN Z, ZHANG B, GAO Y, et al. Deformation mechanisms of spherical cell porous aluminum under quasi-static compression [J]. Scripta Materialia, 2018, 142: 32–35. doi: 10.1016/j.scriptamat.2017.08.019

|

| [14] |

AMSTERDAM E, HOSSON J T M, et al. Failure mechanisms of closed-cell aluminum foam under monotonic and cyclic loading [J]. Acta Materialia, 2006, 54: 4465–4472. doi: 10.1016/j.actamat.2006.05.033

|

下载:

下载: