Low-Velocity Impact Response of Carbon Fiber-Aluminum Foam Sandwich Plate

-

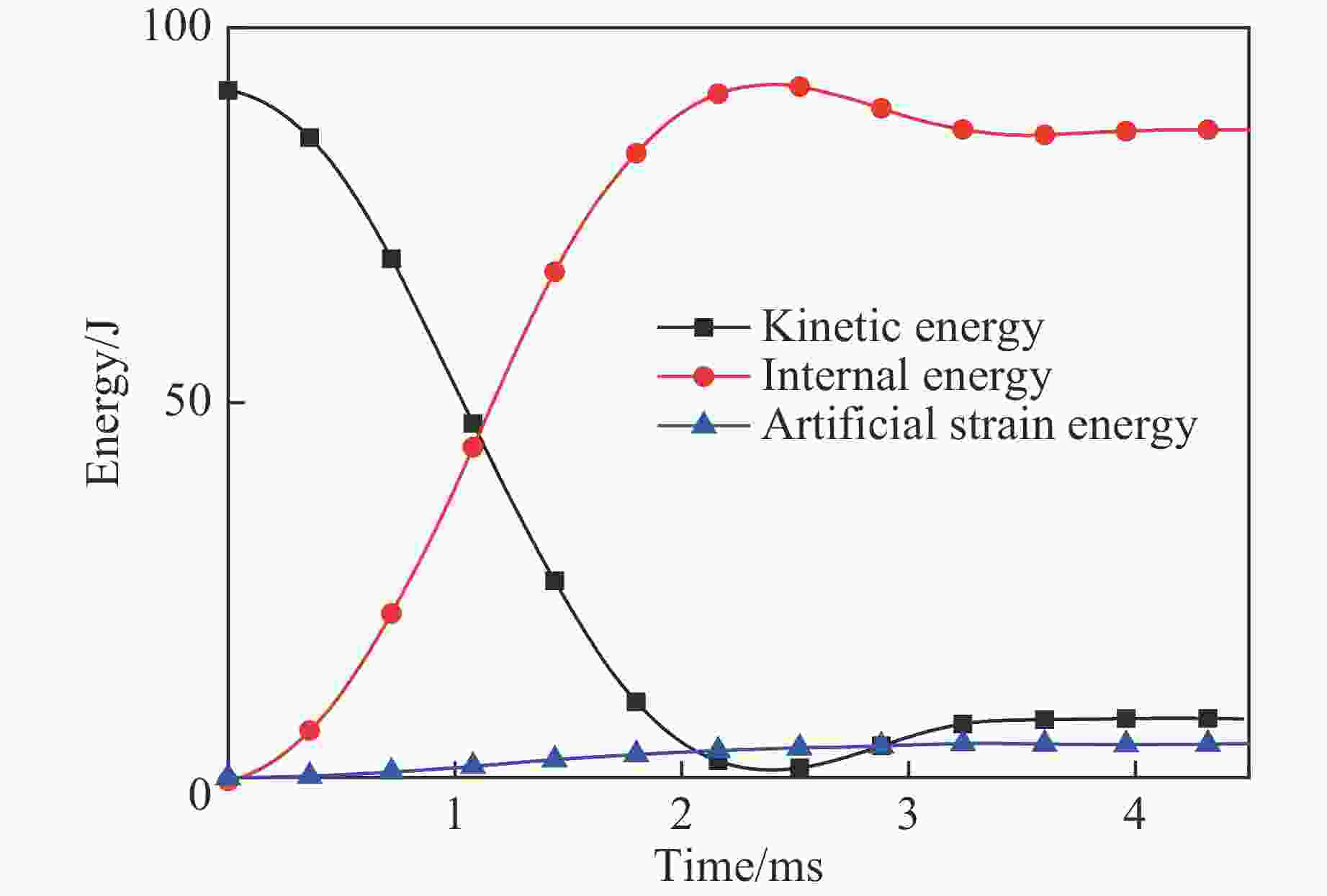

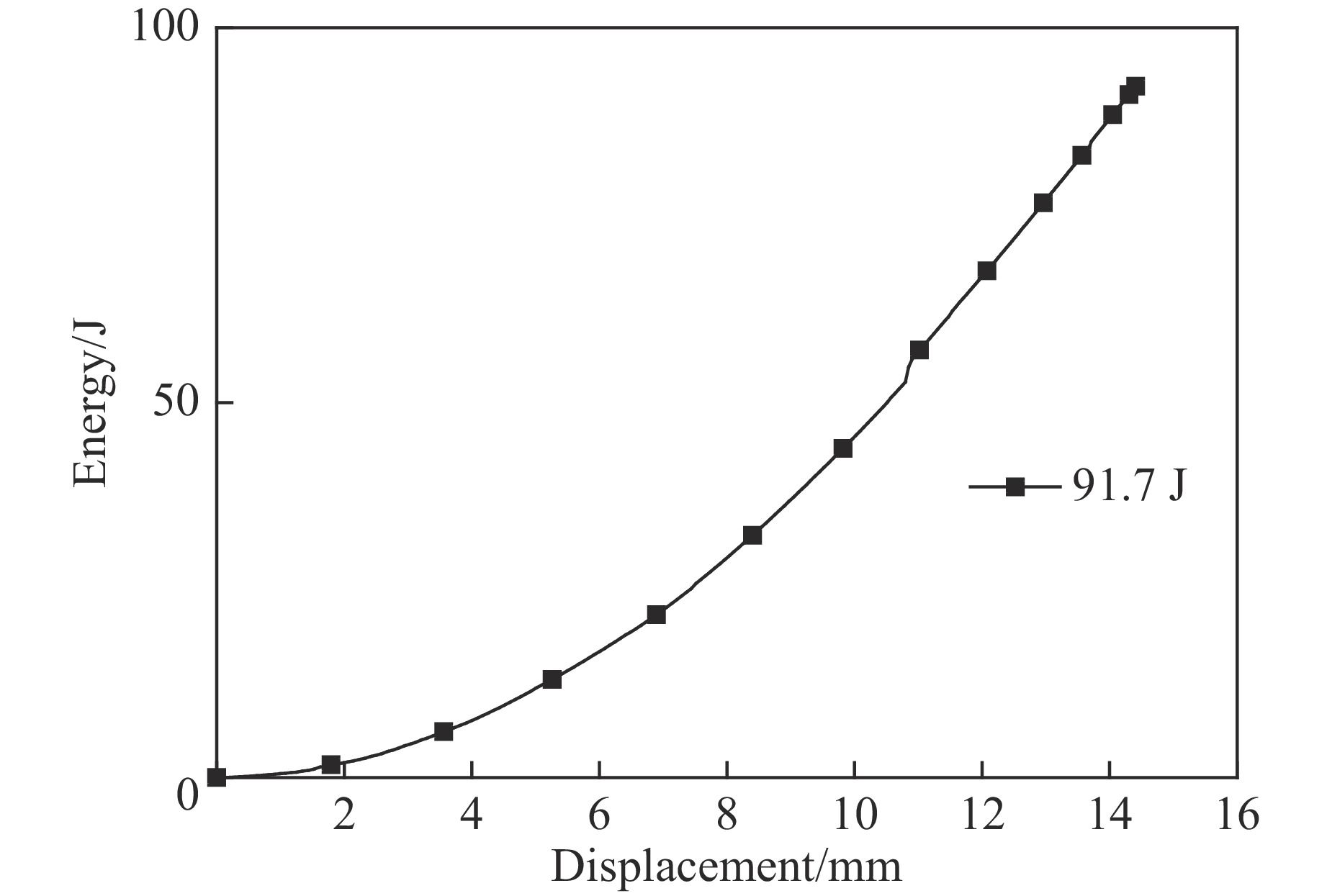

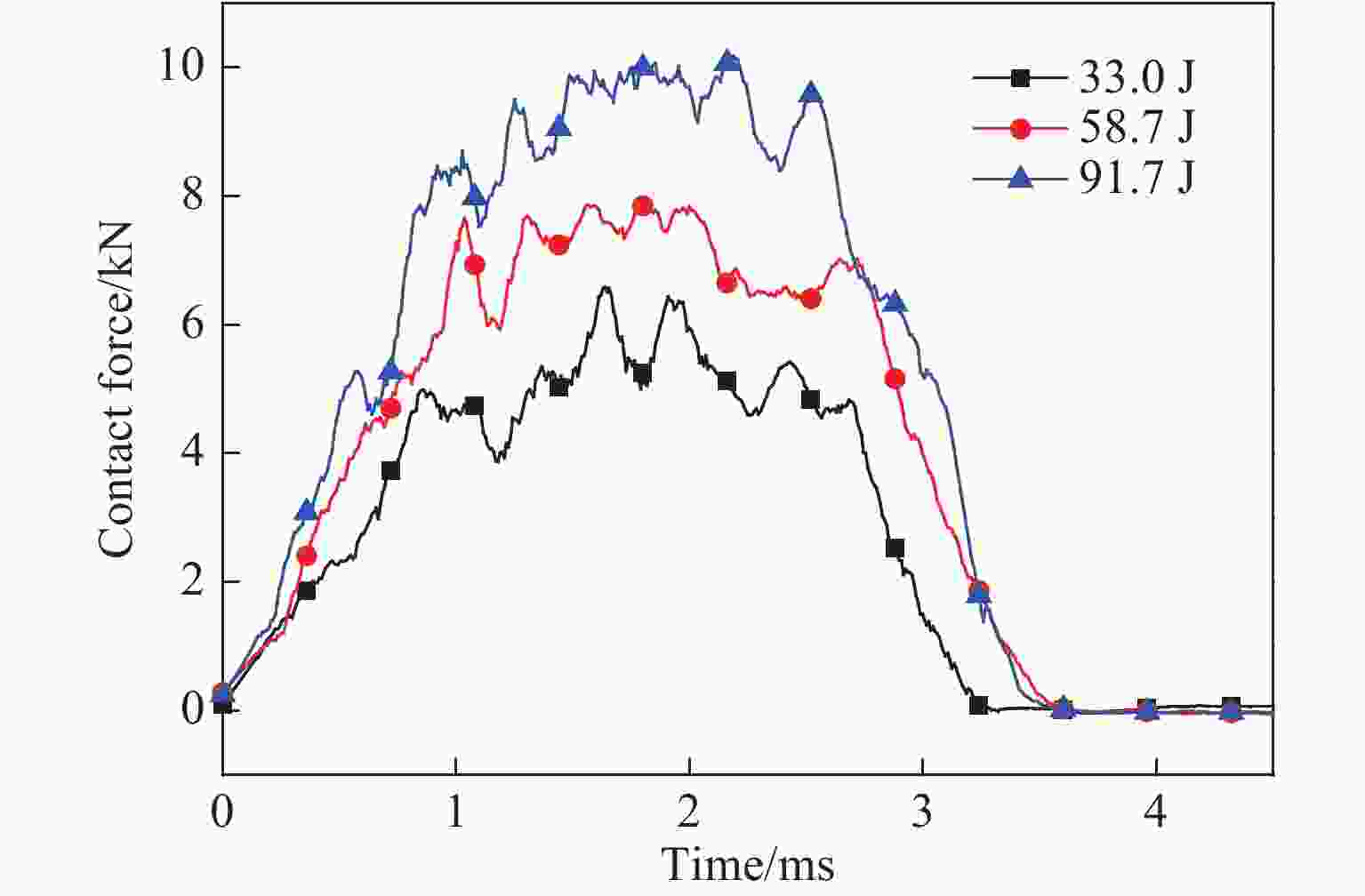

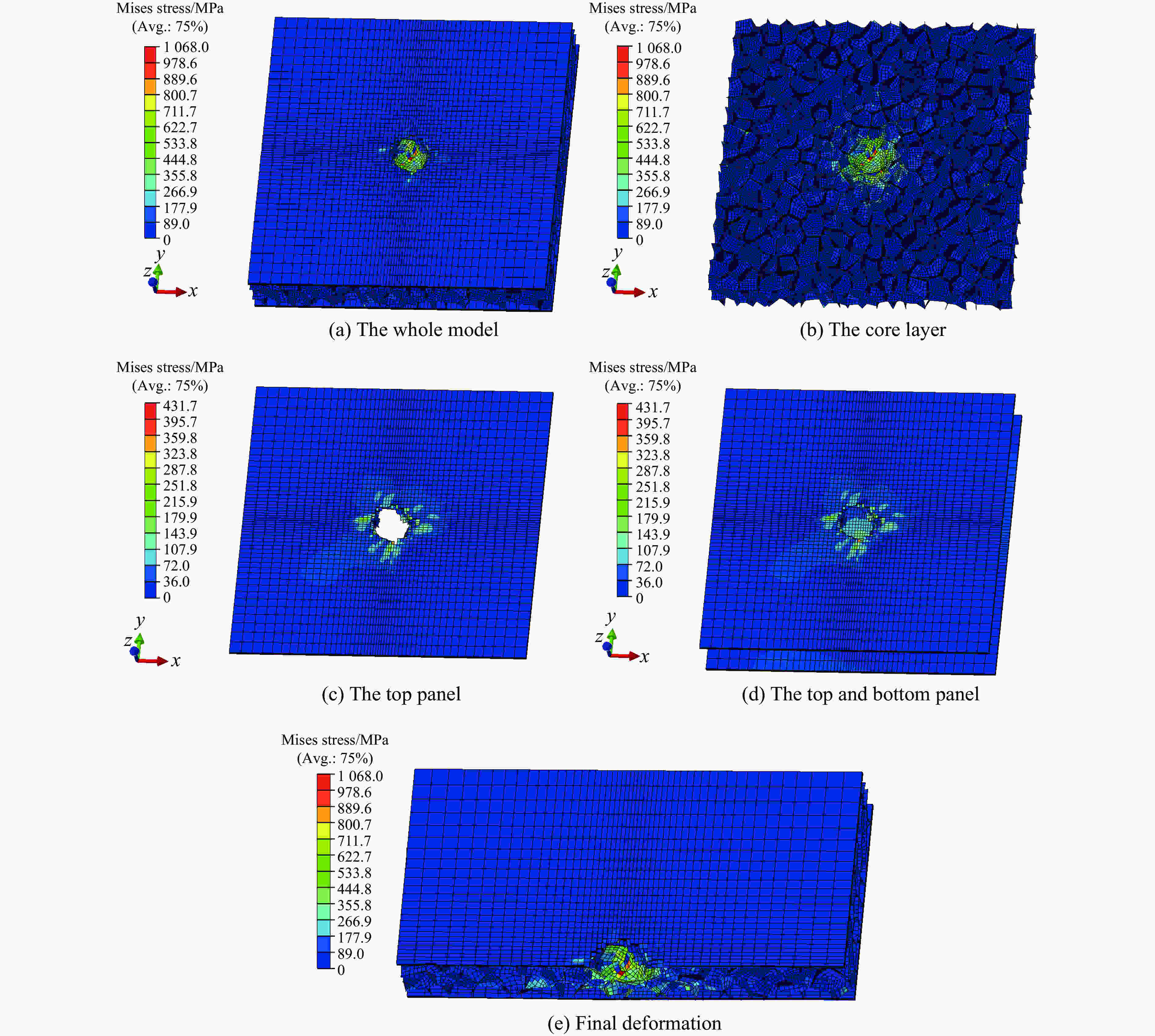

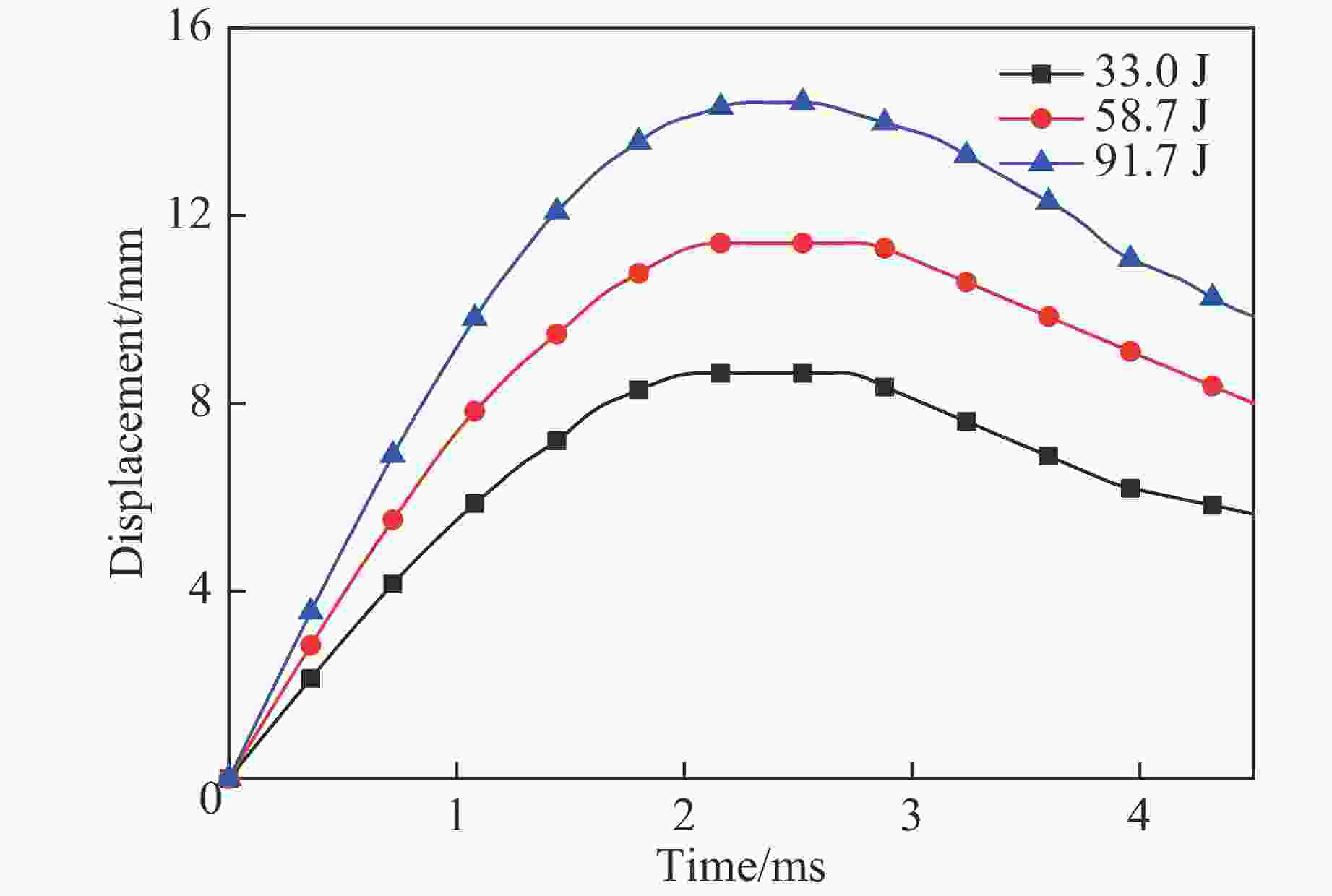

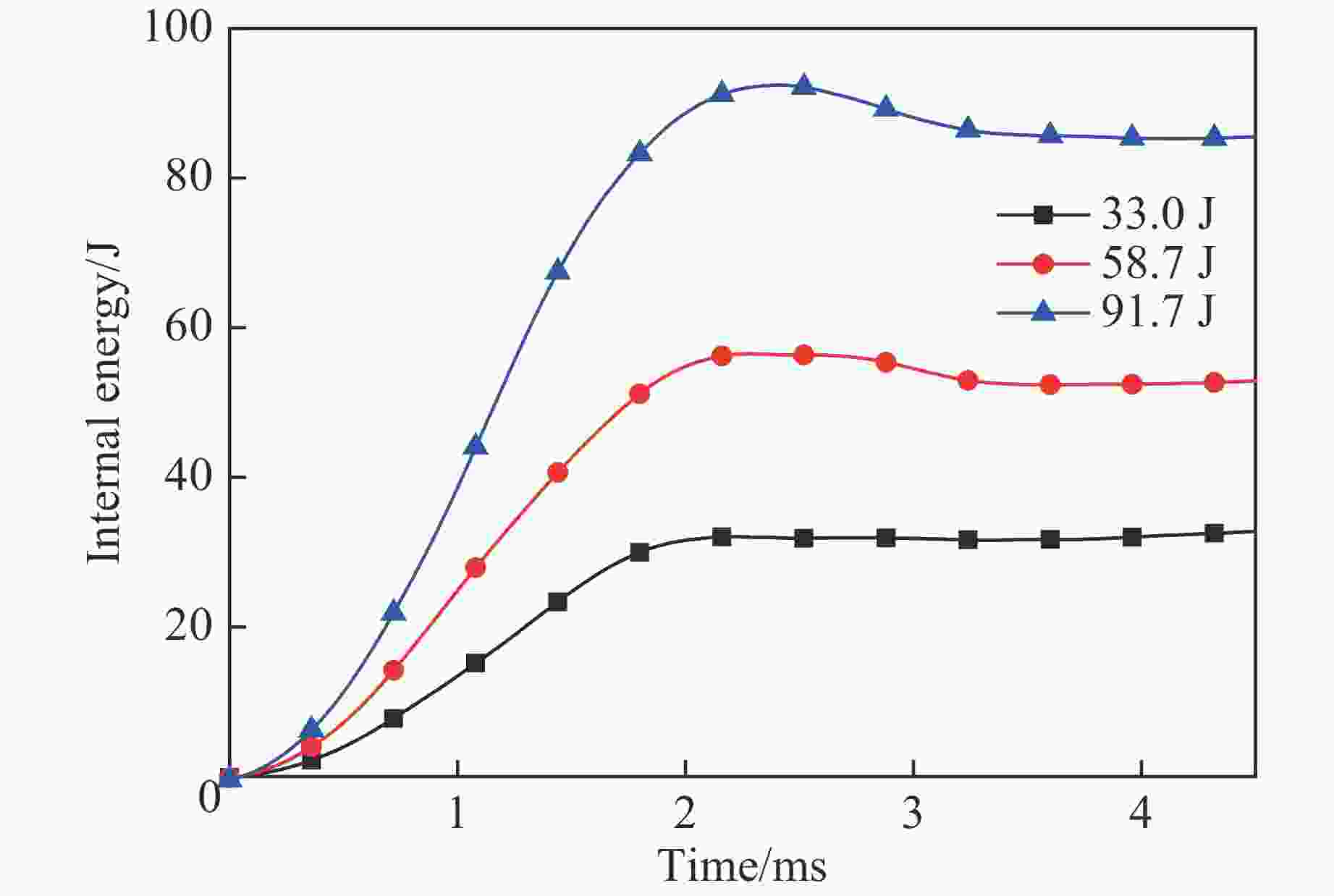

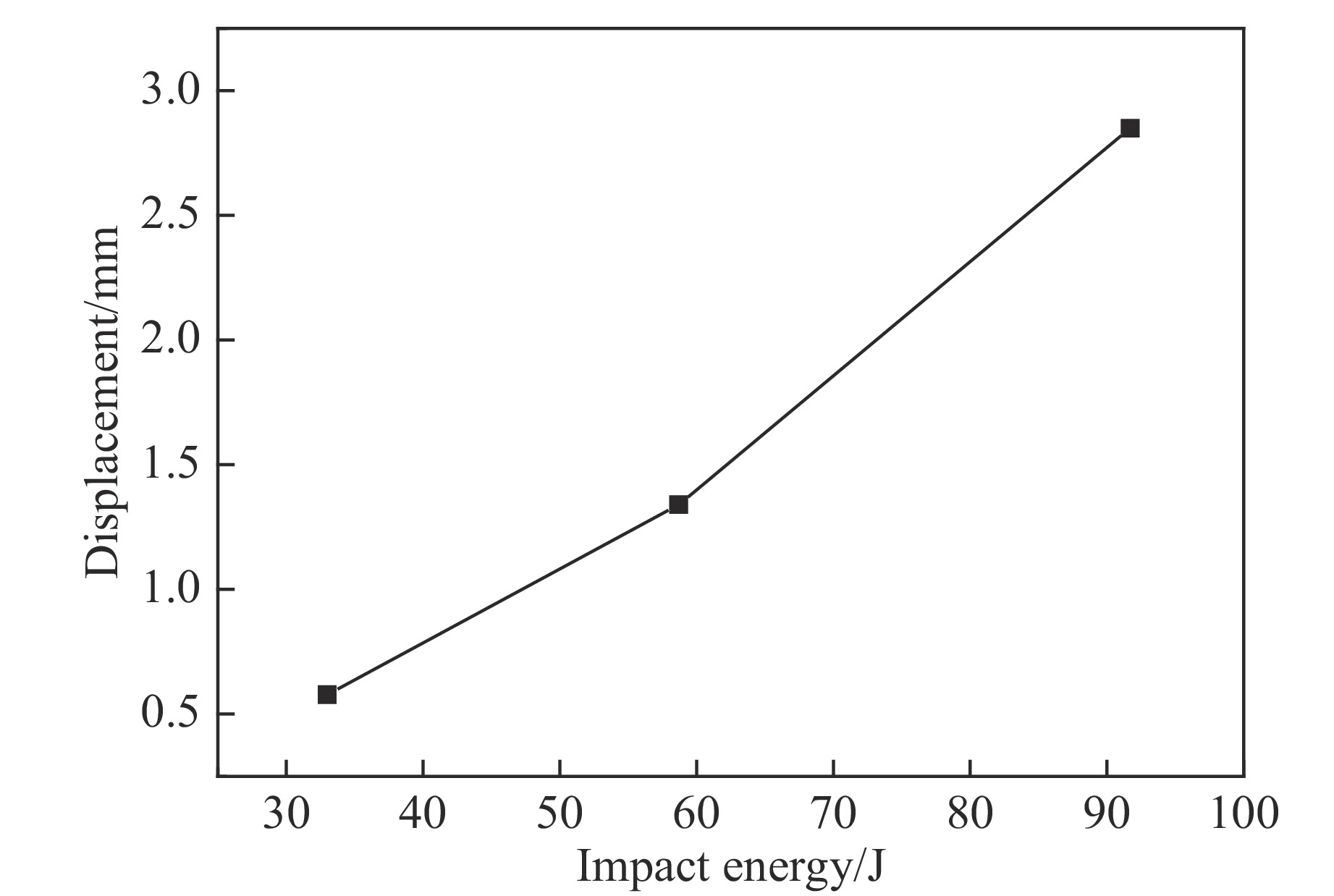

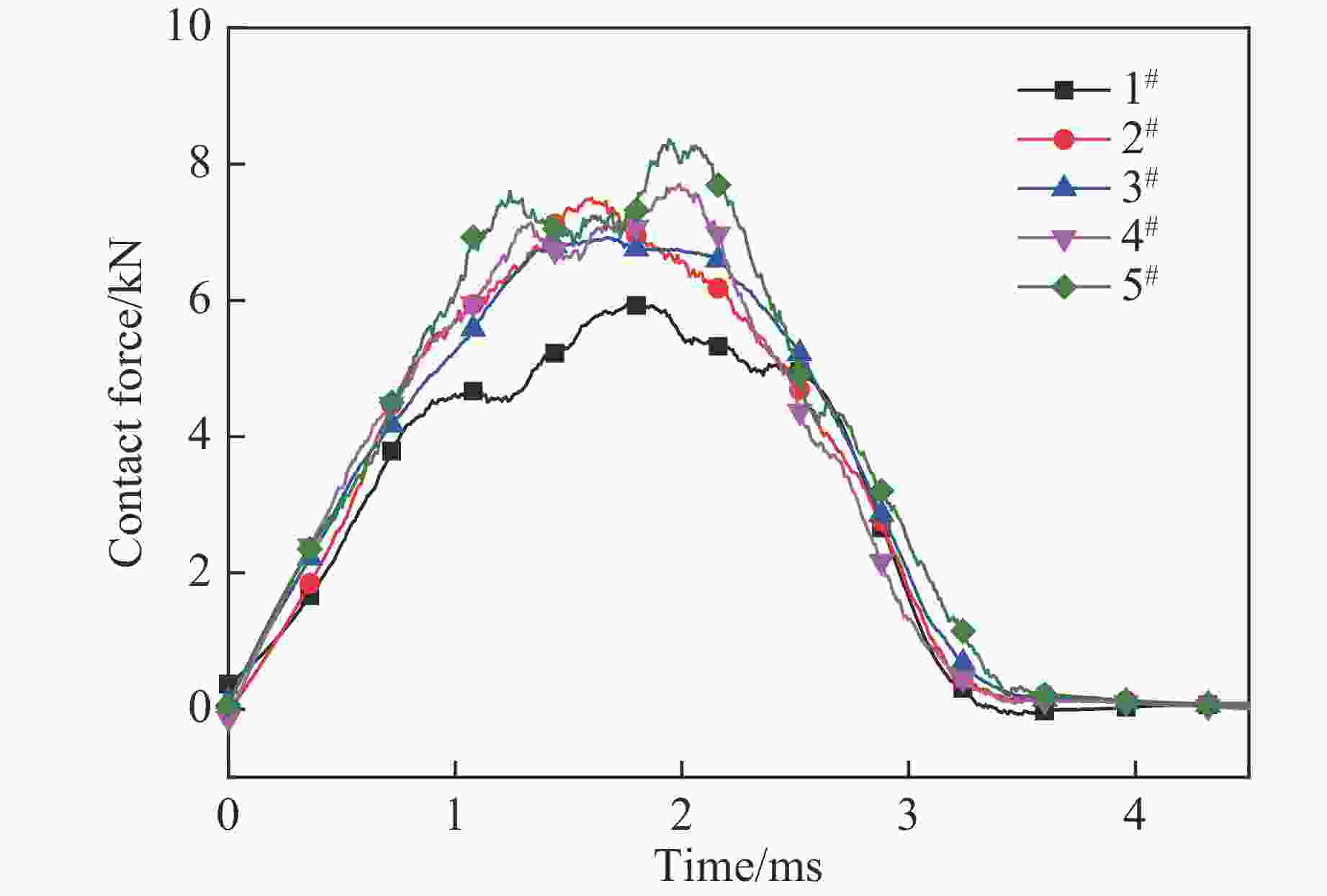

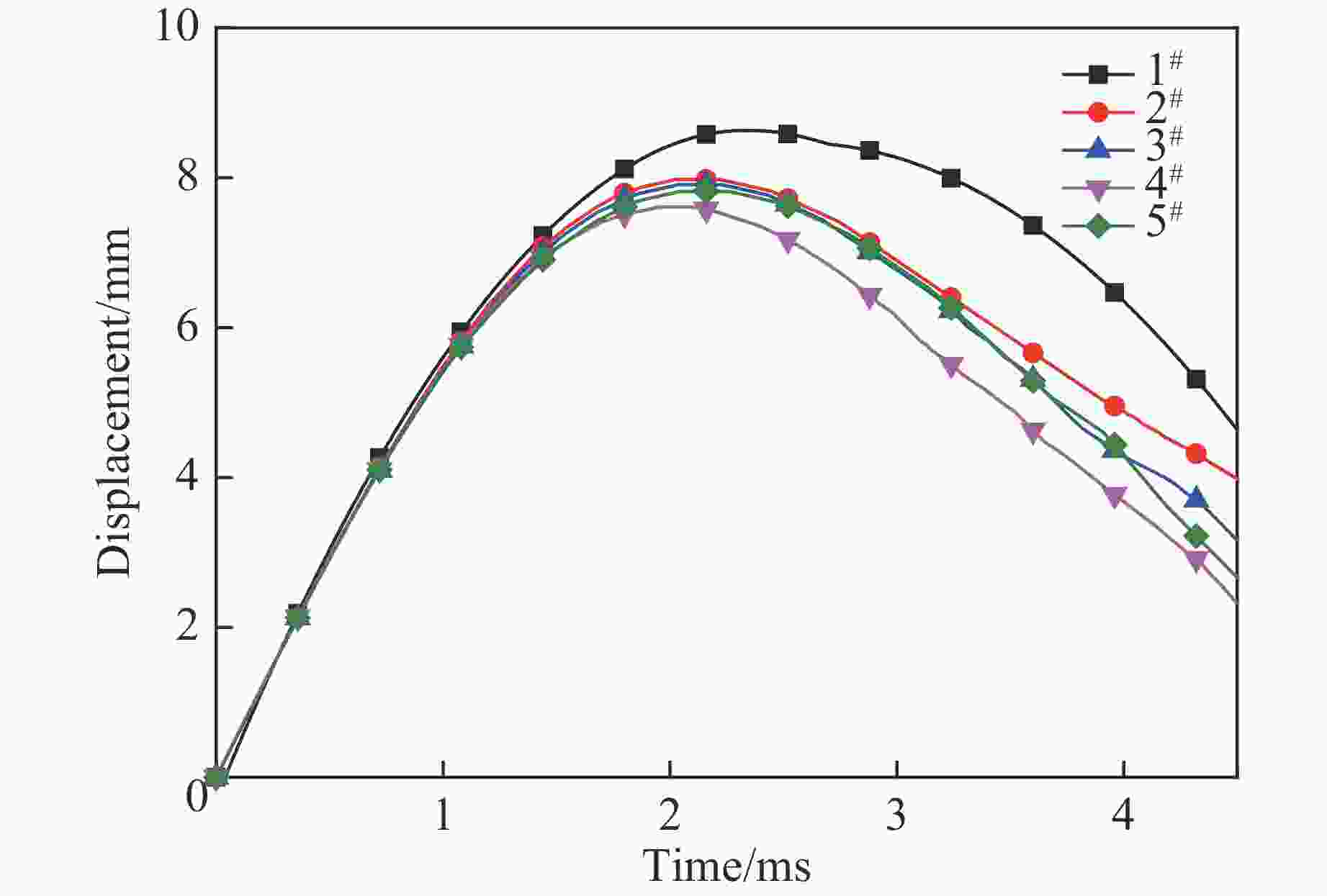

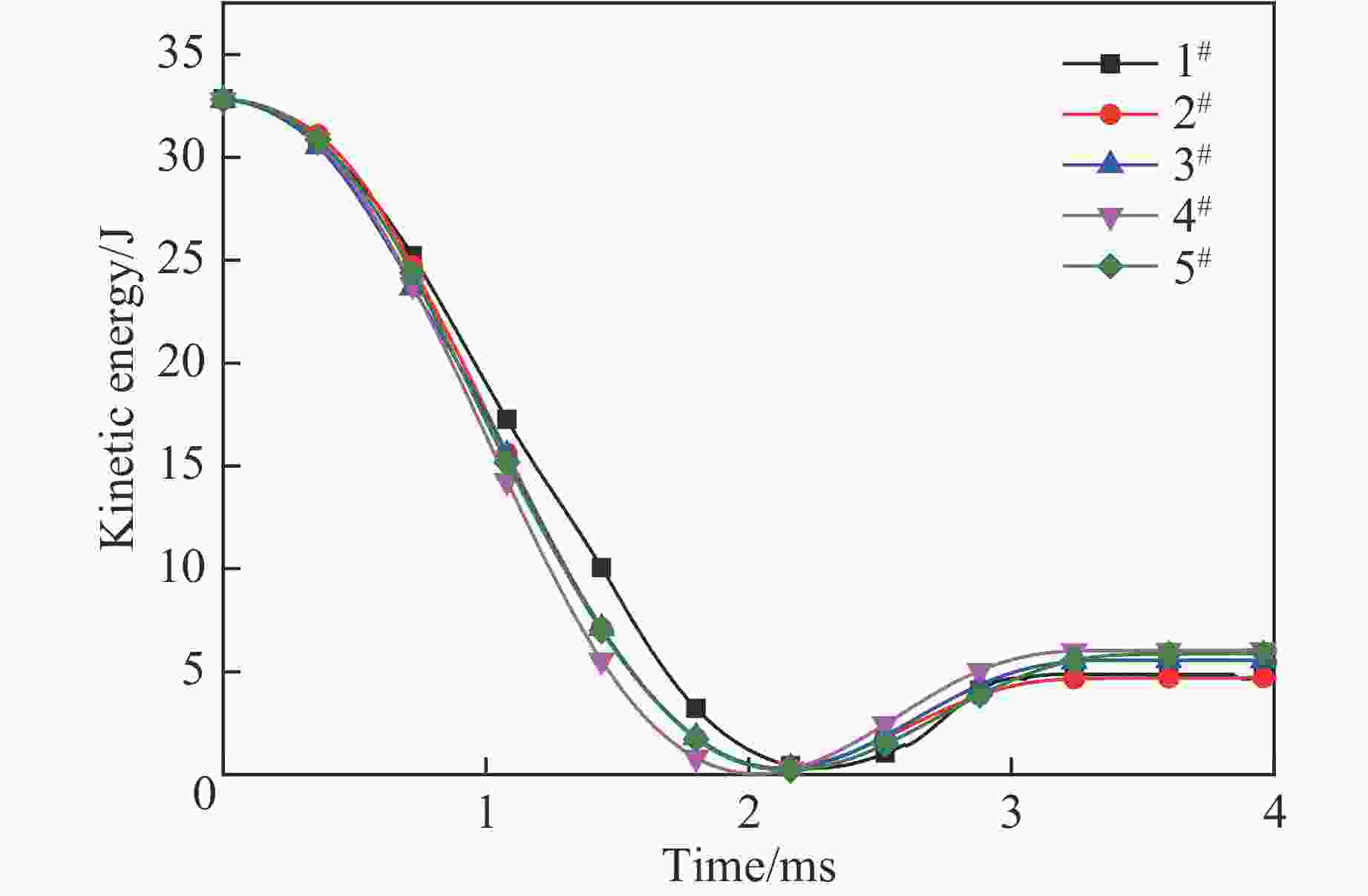

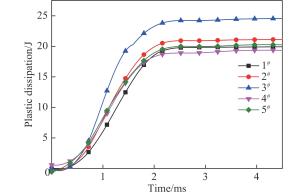

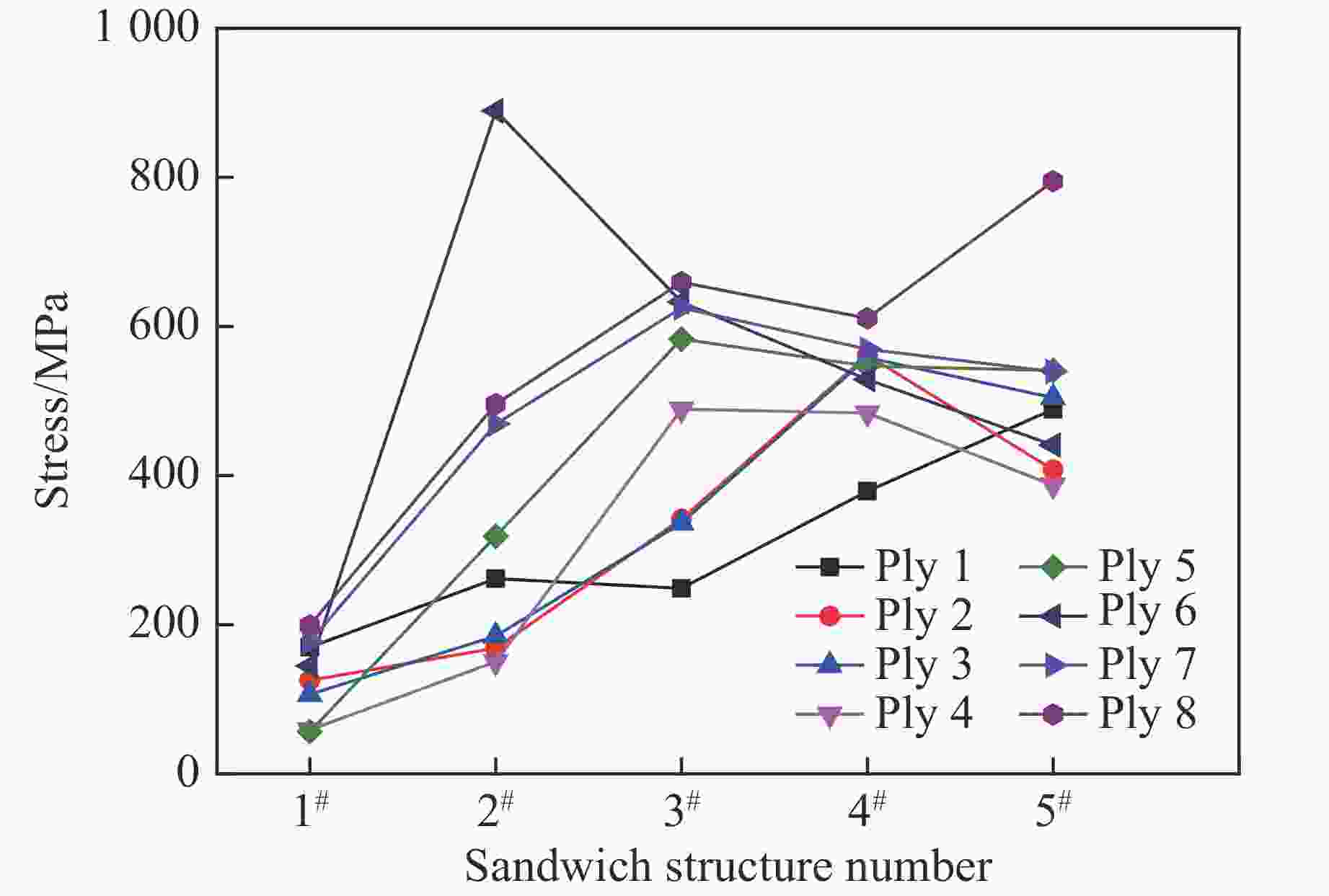

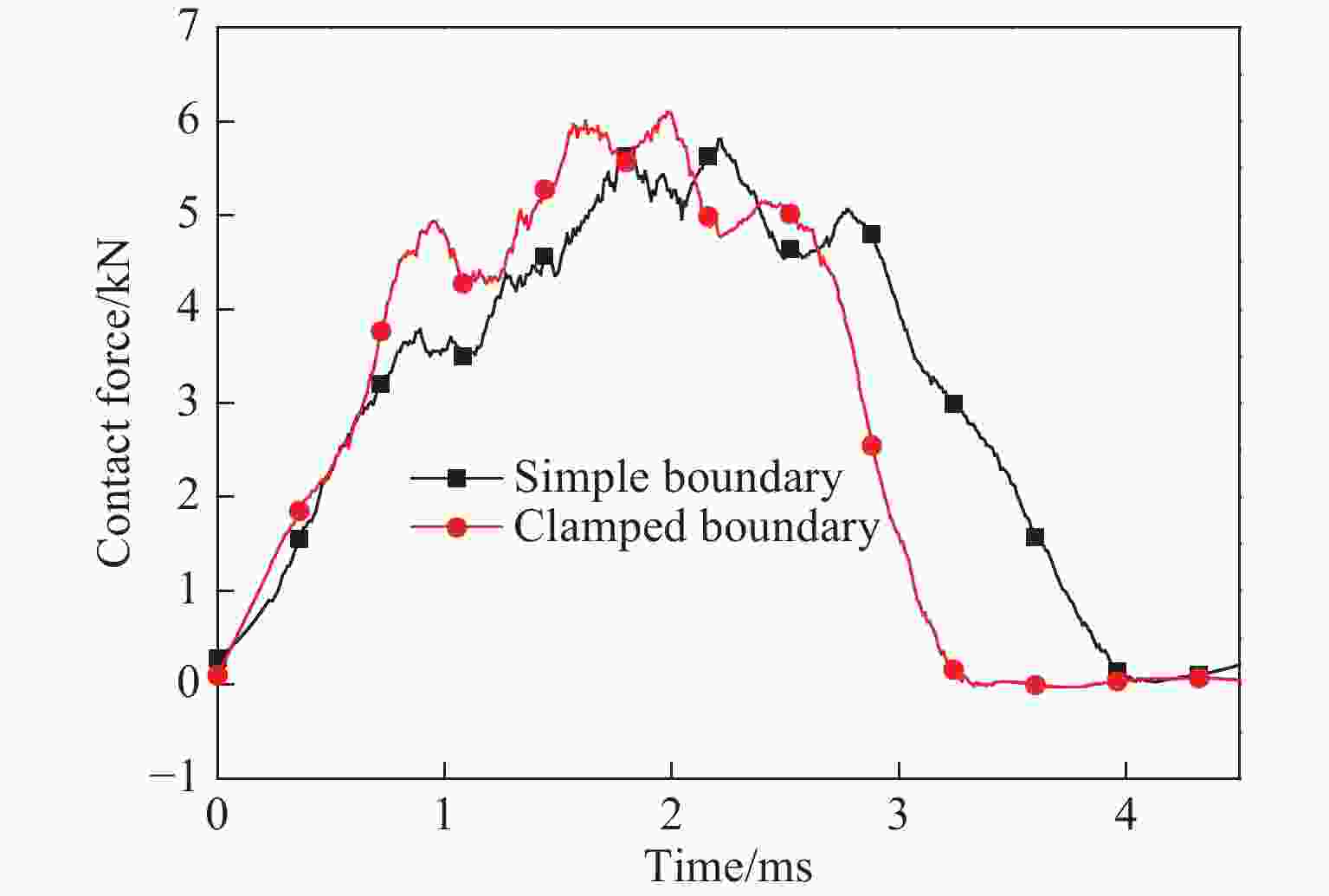

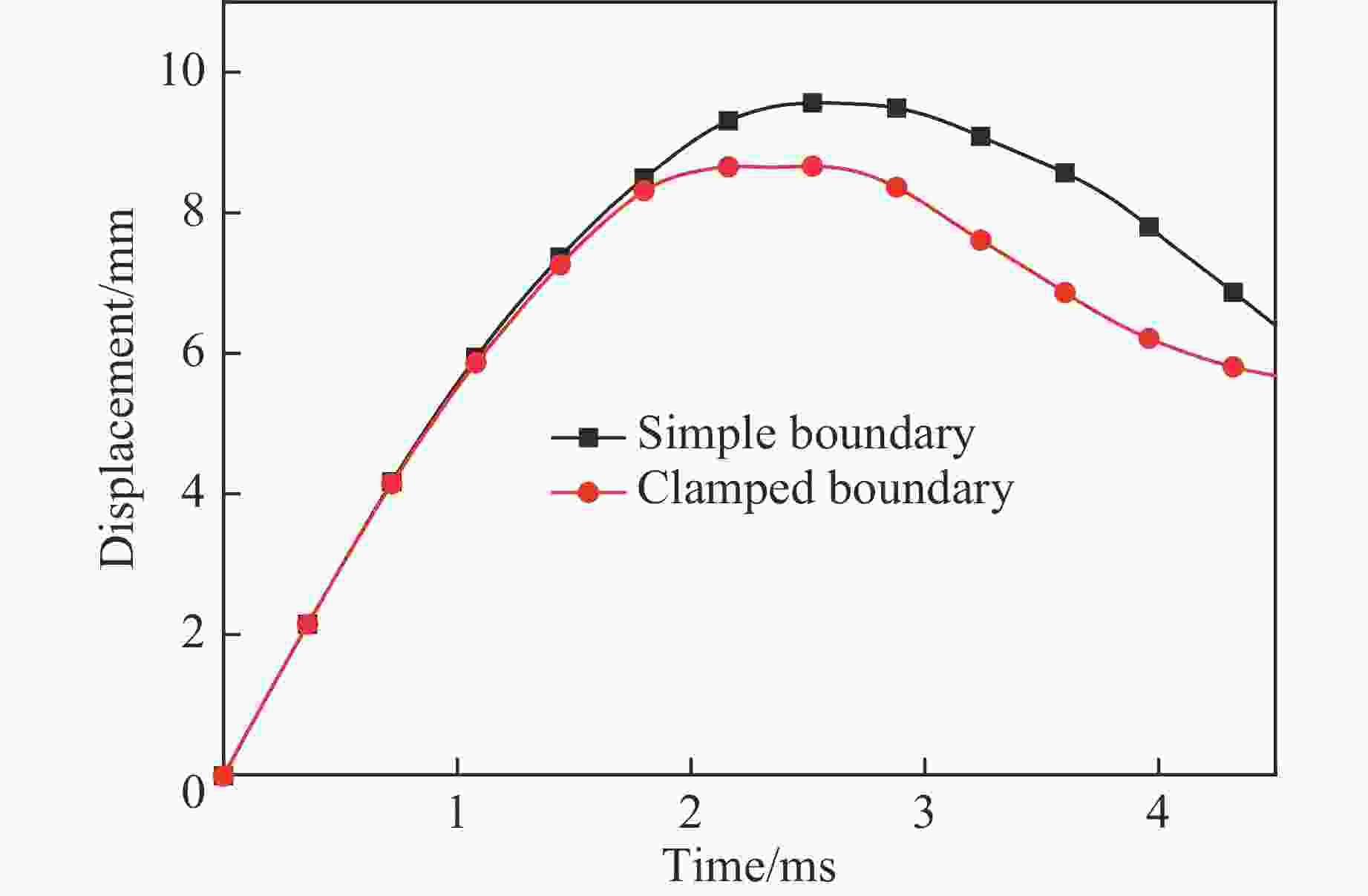

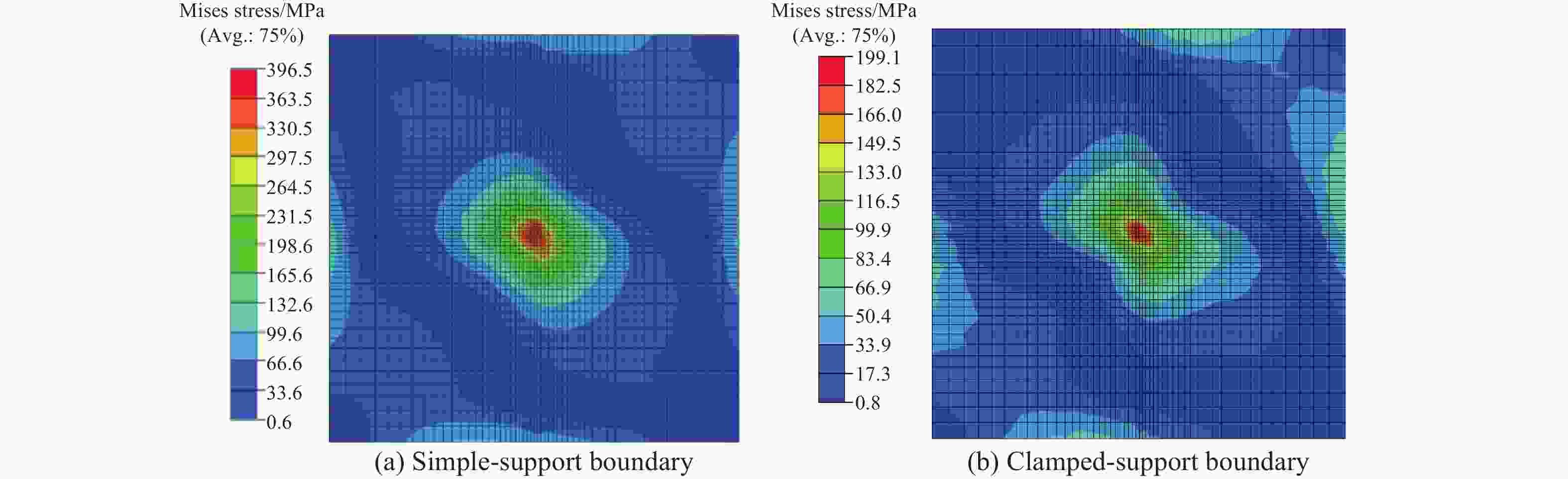

摘要: 为研究夹芯结构的低速冲击响应,以碳纤维(T700)/环氧树脂复合材料层合板为上下面板,以闭孔泡沫铝为芯层,模拟夹芯板落锤冲击时的损伤演化过程。复合材料层合板采用三维实体单元建模,基于有限元软件ABAQUS中的用户子程序VUMAT,引入三维Hashin失效准则模拟复合材料的损伤破坏;采用二次应力准则,Cohesive单元模拟黏结层的层间失效;闭孔泡沫铝芯层采用3D Voronoi细观模型建模。分析复合材料夹芯结构在落锤冲击下的损伤起始、损伤扩展和最终破坏模式,通过锤头的接触力、位移、夹芯板的内能、后面板的最大位移研究夹层结构的能量吸收情况及抗冲击特性,得出了在质量保持不变的情况下,5种芯层相对密度和厚度的耦合关系中的最优设计是芯层相对密度15.0%,厚度为10 mm,为满足实际工程中的需求提供了设计依据。Abstract: In order to study the low velocity impact response of the core-layer structure, this paper simulates the damage process of sandwich structure, that carbon fiber (T700)/epoxy composite laminates are used as the top and bottom panel, the foam aluminum is used as core layer, under impact loading of drop hammer. The composite laminates were modeled with three-dimensional solid elements, and the failure criteria of three-dimensional Hashin were introduced to simulate the damage of composite materials by the user subroutine VUMAT in the finite element software ABAQUS. The bonding layer failure between the layers was simulated with criterion of the secondary stress and cohesive unit. The aluminum foam core layer was modeled by a 3D Voronoi mesoscopic model. By analyzing the damage initiation, damage propagation and final failure modes of composite sandwich structures under low speed impact, the progressive failure mechanism of composite materials was clarified. The contact force and displacement through the hammer head, internal energy of sandwich panel, rear panel to study the stress distribution and maximum displacement energy absorption and impact resistance of sandwich structure. The optimal design of the coupling relation between the relative density and thickness of five different core layers under the condition of a certain quality control have been obtained, which provides designed guidance for satisfying the requirements of practical engineering.

-

E1/GPa E2/GPa ν G12/GPa G13/GPa G23/GPa 180 10 0.28 2.6 3.9 3.9 Xt/MPa Xc/MPa Yt/MPa Yc/MPa S12/MPa ρ/(g·cm–3) 2 500 1 250 60 186 85 1.95 Knn/(GPa·mm–1) Kss(= Ktt)/(GPa·mm–1) N/MPa S(= T)/MPa G1/(J·m–2) G2(= G3)/(J·m–2) 120 43 30 80 520 970 表 3 Al6061-T6材料参数

Table 3. Material parameters of Al6061-T6

ρ/(g·cm–3) E/GPa ν A/MPa B/MPa N m 2.7 70 0.28 265 426 0.34 1 表 4 不同能量下后面板的撕裂程度

Table 4. Tear degree of rear panel under different energy

Impact energy/J Tear layers 33.0 0 58.7 3 91.7 5 表 5 5种不同的夹芯结构

Table 5. Five different sandwich structures

Structure type Plane size of specimen/

(mm × mm)Stacking sequence Upper (lower) panel thickness /mm Core relative density/% The thickness of the core layer/mm Diameter of impactor/mm Impact energy/J 1# 100 × 100 [45°/0°/−45°/90°]s 1 10.0 15.0 12.5 33.0 2# 12.5 12.0 3# 15.0 10.0 4# 17.5 8.6 5# 20.0 7.5 表 6 5种不同结构后面板的撕裂程度

Table 6. Tear degree of rear panel for five sandwich structures

Structure No. Tear layers 1# 0 2# 3 3# 5 4# 7 5# 8 -

[1] 王巍, 安子军, 彭春彦, 等. 泡沫铝填充钢/铝复合管轴向抗冲击吸能特性 [J]. 哈尔滨工程大学学报, 2017, 38(7): 1093–1099.WANG W, AN Z J, PENG C Y, et al. Simulative research on the energy absorption characteristics of aluminum foam-filled steel/Al clad tube under axial impact loading [J]. Journal of Harbin Engineering University, 2017, 38(7): 1093–1099. [2] 骆伟, 谢伟, 刘敬喜. 芯层几何构形对复合材料波纹夹层结构冲击特性的影响 [J]. 江苏科技大学学报(自然科学版), 2018, 32(1): 21–26.LUO W, XIE W, LIU J X. Research on dynamic characteristics of a sandwich structures with various core shapes under impact loads [J]. Journal of Jiangsu University of Science and Technology (Natural Science Edition), 2018, 32(1): 21–26. [3] TITA V, CARVALHO J D, VANDEPITTE D. Failure analysis of low velocity impact on thin composite laminates: experimental and numerical approaches [J]. Composite Structures, 2008, 83(4): 413–428. doi: 10.1016/j.compstruct.2007.06.003 [4] 韩守红, 吕振华. 铝泡沫夹层结构抗爆炸性能仿真分析及优化 [J]. 兵工学报, 2010, 31(11): 1468–1474.HAN S H, LÜ Z H. Numerical simulation of blast-resistant performance of aluminum foam sandwich structures and optimization [J]. Acta Armamentarii, 2010, 31(11): 1468–1474. [5] 李志斌, 卢芳云. 泡沫铝夹芯板压入和侵彻性能的实验研究 [J]. 振动与冲击, 2015(4): 1–5.LI Z B, LU F Y. Tests for indentation and perforation of sandwich panels with aluminium foam core [J]. Journal of Vibration and Shock, 2015(4): 1–5. [6] 赵金华, 曹海琳, 晏义伍, 等. 泡沫铝夹层结构复合材料低速冲击性能 [J]. 材料工程, 2018, 46(1): 92–98. doi: 10.11868/j.issn.1001-4381.2015.001295ZHAO J H, CAO H L, YAN Y W, et al. Low velocity impact properties of aluminum foam sandwich structural composite [J]. Journal of Materials Engineering, 2018, 46(1): 92–98. doi: 10.11868/j.issn.1001-4381.2015.001295 [7] 荣誉. 梯度泡沫金属力学性能的Lagrangian分析 [D]. 太原: 太原理工大学, 2018. [8] HASHIN Z. Failure criteria for unidirectional fiber composites [J]. Journal of Applied Mechanics, 1980, 47: 329–334. doi: 10.1115/1.3153664 [9] 谭开忍, 肖熙. 含有腐蚀缺陷海底管道极限载荷分析 [J]. 海洋工程, 2006, 24(3): 63–67. doi: 10.3969/j.issn.1005-9865.2006.03.010TAN K R, XIAO X. Analysis on limit load of corroded submarine pipelines [J]. The Ocean Engineering, 2006, 24(3): 63–67. doi: 10.3969/j.issn.1005-9865.2006.03.010 [10] 沈鋆. 极限载荷分析法在压力容器分析设计中的应用 [J]. 石油化工设备, 2011, 40(4): 35–38. doi: 10.3969/j.issn.1000-7466.2011.04.010SHEN J. Limit load analysis application in pressure vessel analytical design [J]. Petro-Chemical Equipment, 2011, 40(4): 35–38. doi: 10.3969/j.issn.1000-7466.2011.04.010 [11] 肖先林, 王长金, 赵桂平. 碳纤维复合材料-泡沫铝夹芯板的冲击响应 [J]. 振动与冲击, 2018, 37(15): 110–117.XIAO X L, WANG C J, ZHAO G P. Dynamic responses of carbon fiber composite sandwich panels with aluminum foam core subjected to impact loading [J]. Journal of Vibration and Shock, 2018, 37(15): 110–117. [12] JOHNSON G R, COOK W H. Fracture characteristics of three metals subjected to various strains, strains rates, temperatures and pressures [J]. Engineering Fracture Mechanics, 1985, 21(1): 31–48. doi: 10.1016/0013-7944(85)90052-9 [13] 熊明洋, 向忠, 胡旭东, 等. 基于ABAQUS的CCF300碳纤维层合板低速冲击破坏数值模拟 [J]. 轻工机械, 2017, 35(4): 27–32. doi: 10.3969/j.issn.1005-2895.2017.04.006XIONG M Y, XIANG Z, HU X D, et al. Numerical simulation of low velocity impact failure of CCF300 carbon fiber laminate based on ABAQUS [J]. Light Industry Machinery, 2017, 35(4): 27–32. doi: 10.3969/j.issn.1005-2895.2017.04.006 [14] 陈县辉. 基于内聚力单元的层合板低速冲击响应模拟研究 [D]. 太原: 中北大学, 2014. [15] STUBSS C. Compilation strategies: alternate approaches to achieve low power consumption [J]. Electronic Component News, 2008, 52(4): 11–113. [16] FOO C C, SEAH L K, CHAI G B. Low-velocity impact failure of aluminium honeycomb sandwich panels [J]. Composite Structures, 2008, 85(1): 20–28. doi: 10.1016/j.compstruct.2007.10.016 [17] SAHU S, MONDAL D P, CHO J U, et al. Low-velocity impact characteristics of closed cell AA2014-SiCp composite foam [J]. Composites Part B: Engineering, 2019, 160: 394–401. doi: 10.1016/j.compositesb.2018.12.054 -

下载:

下载: