Impact Resistance of Symmetrical and Asymmetric Tempered Laminated Glass

-

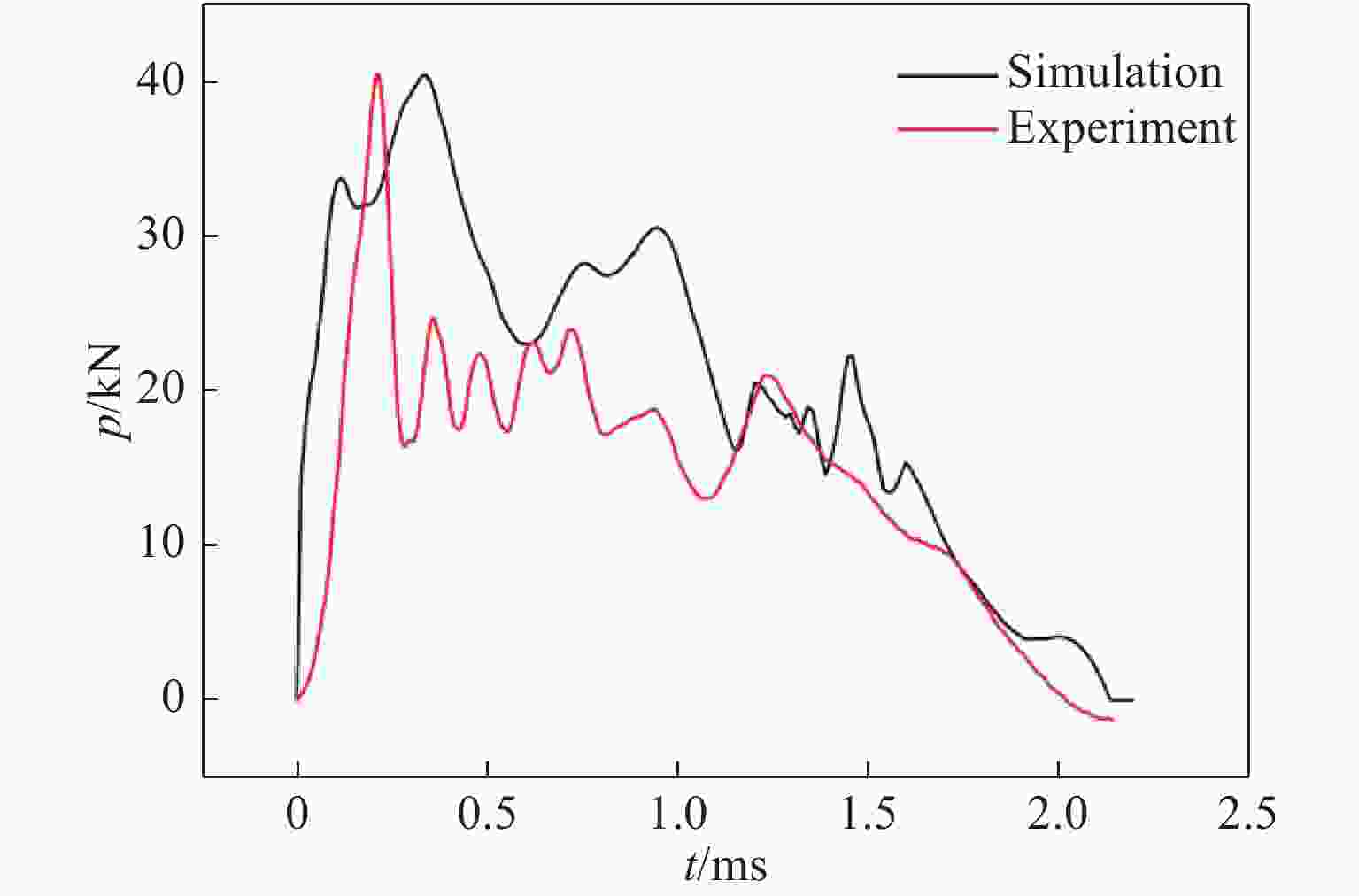

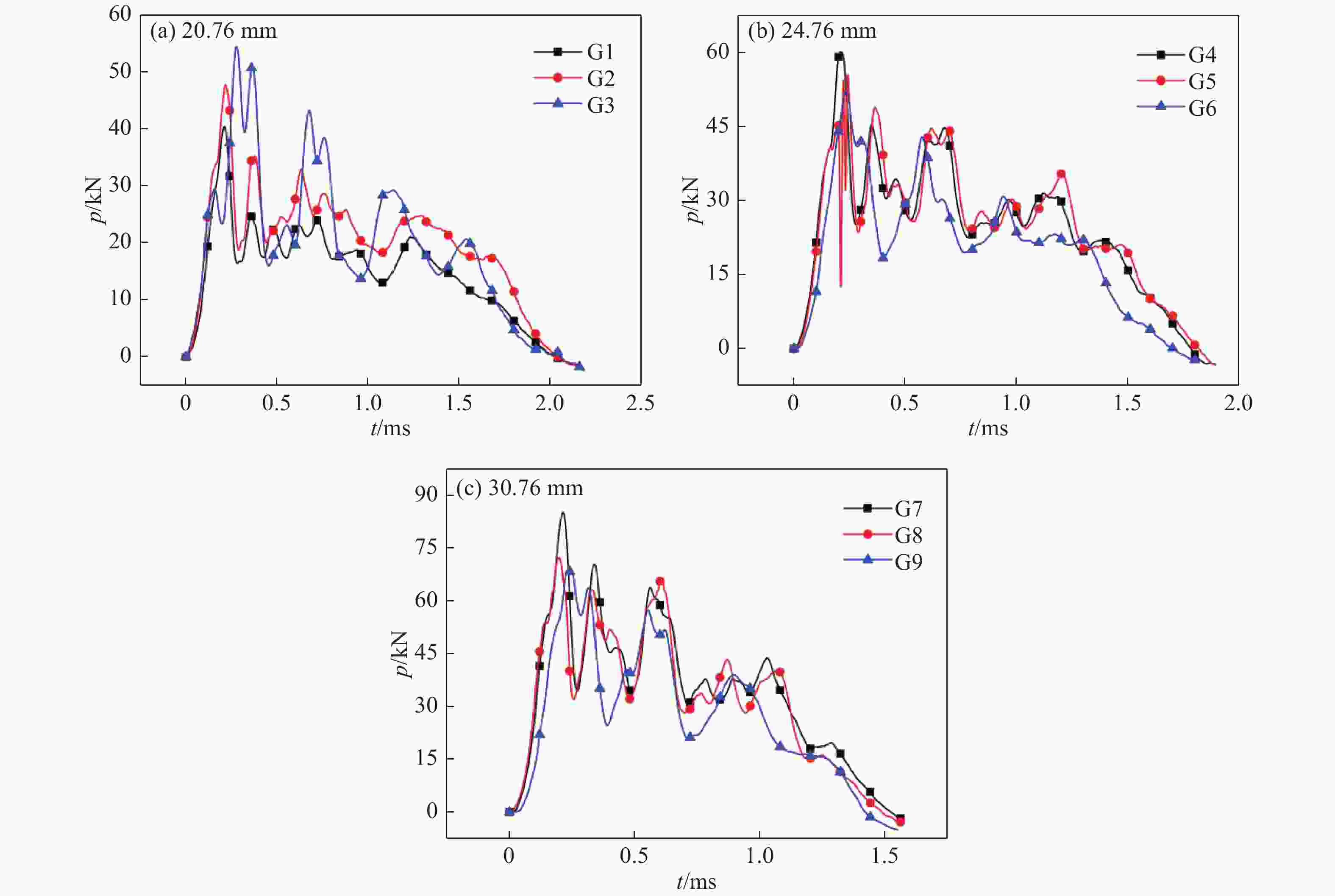

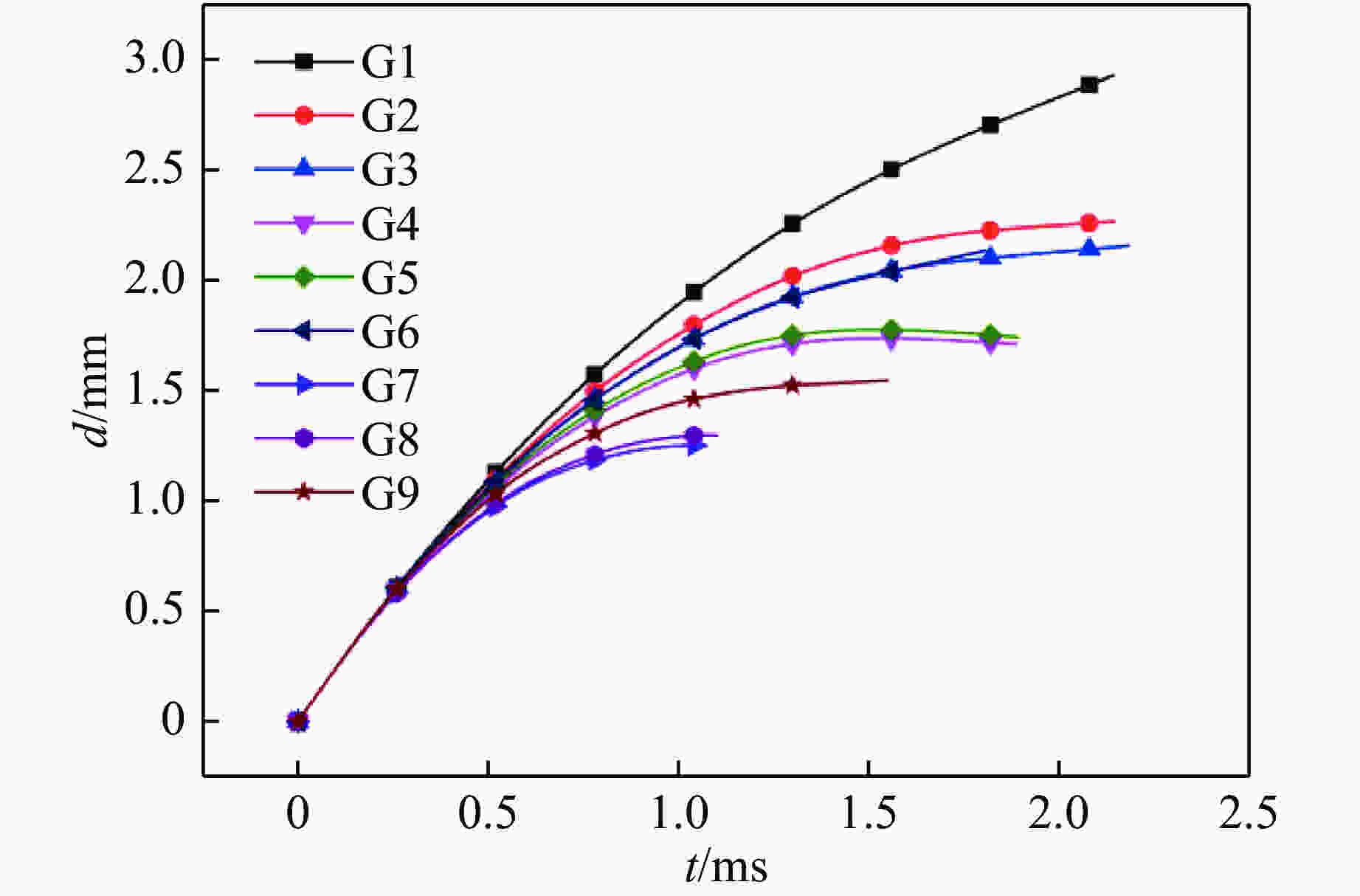

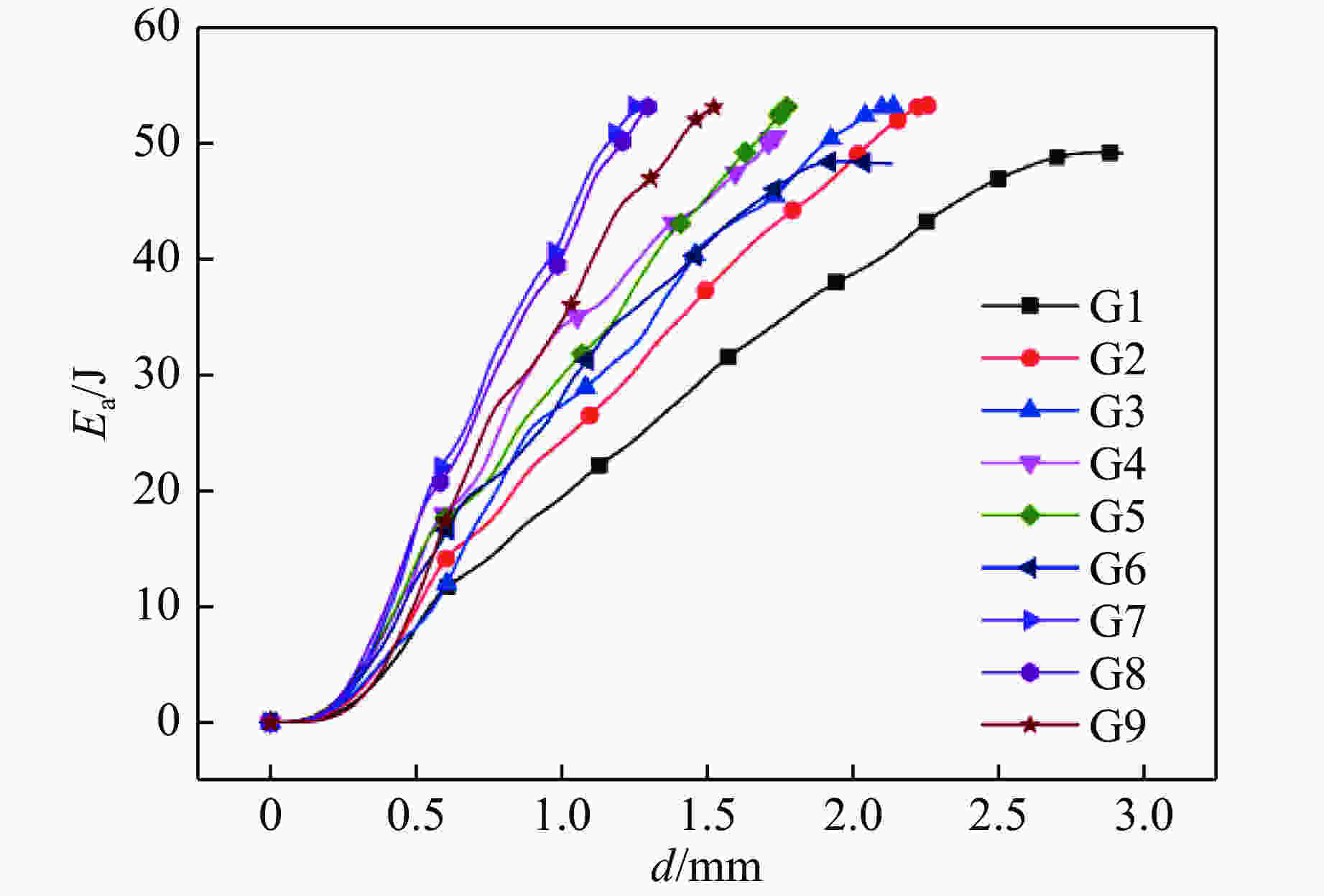

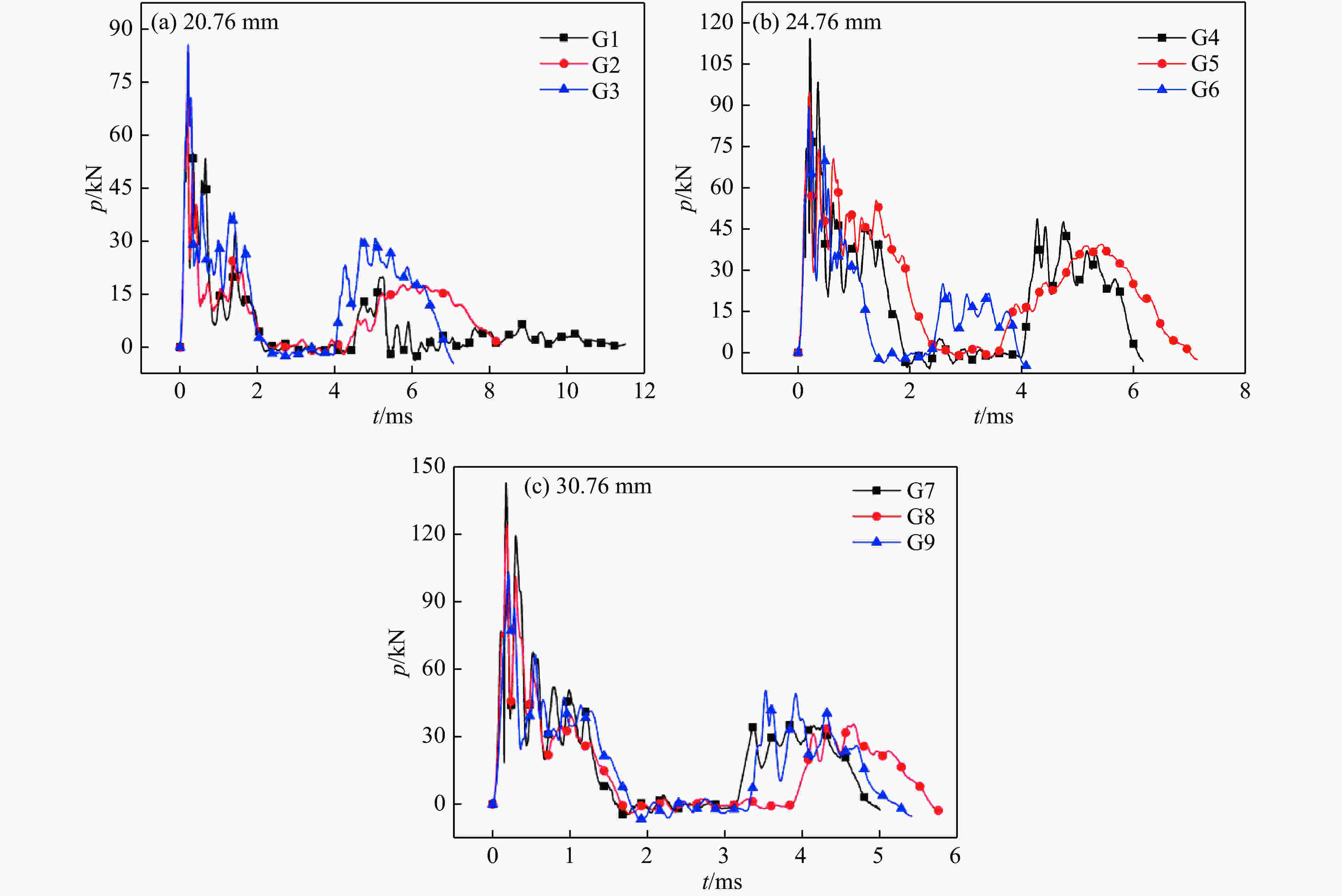

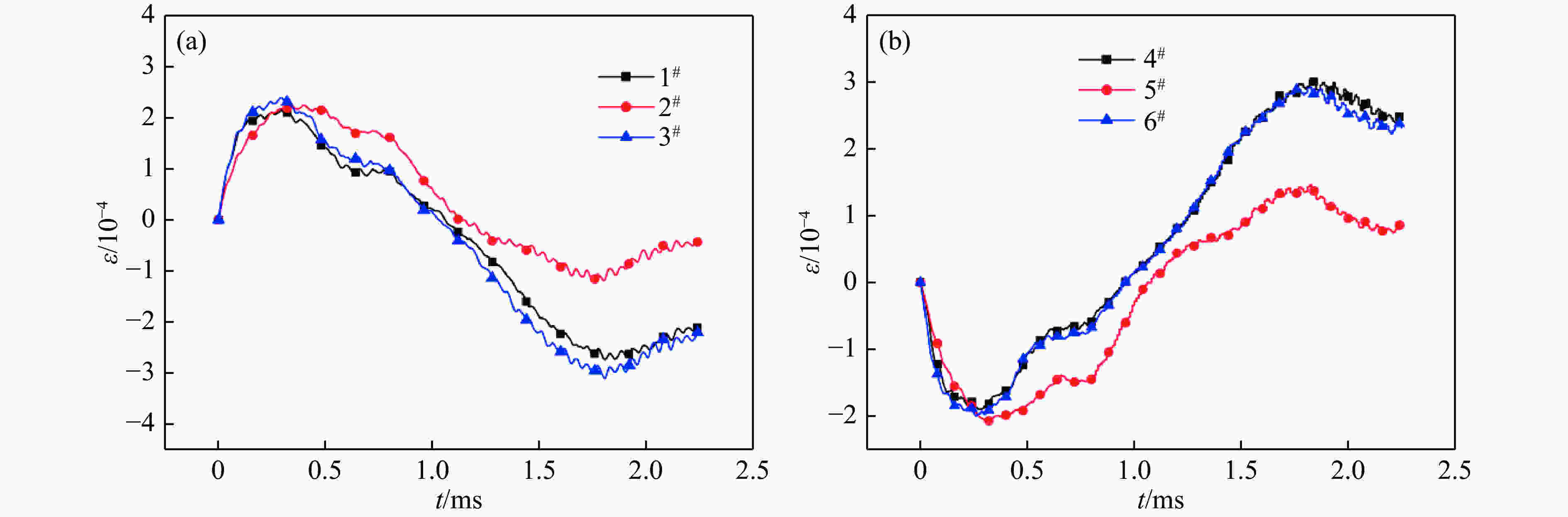

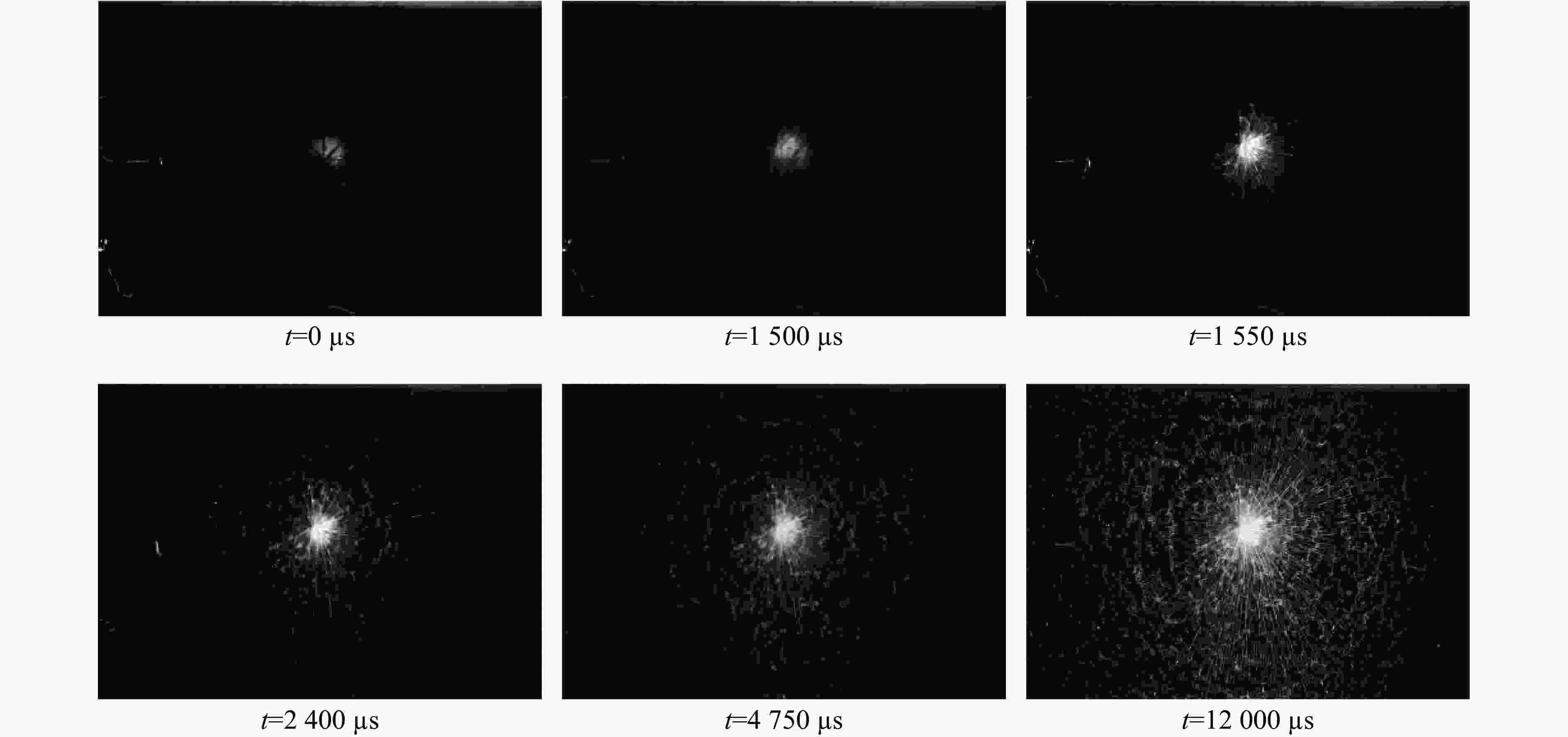

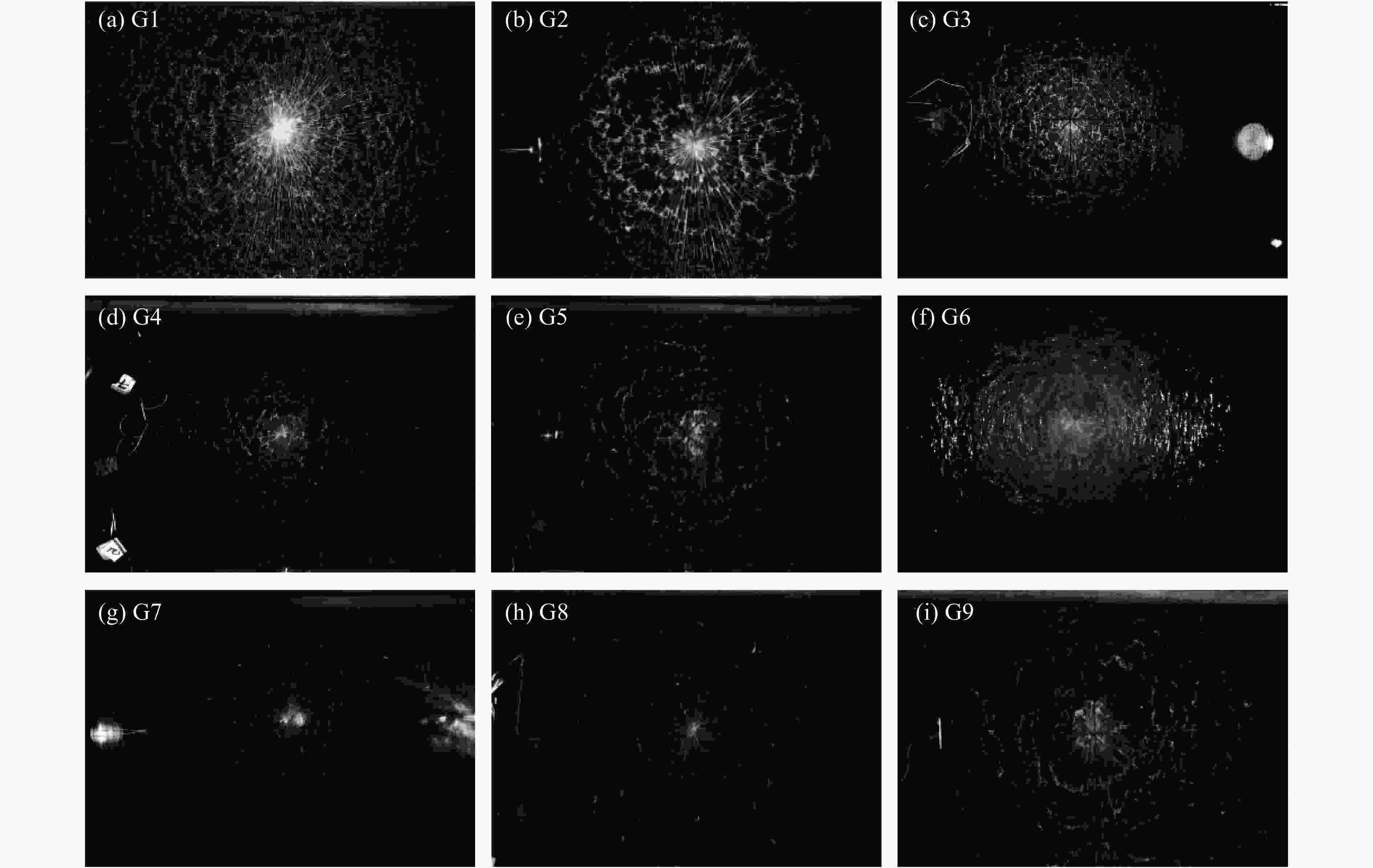

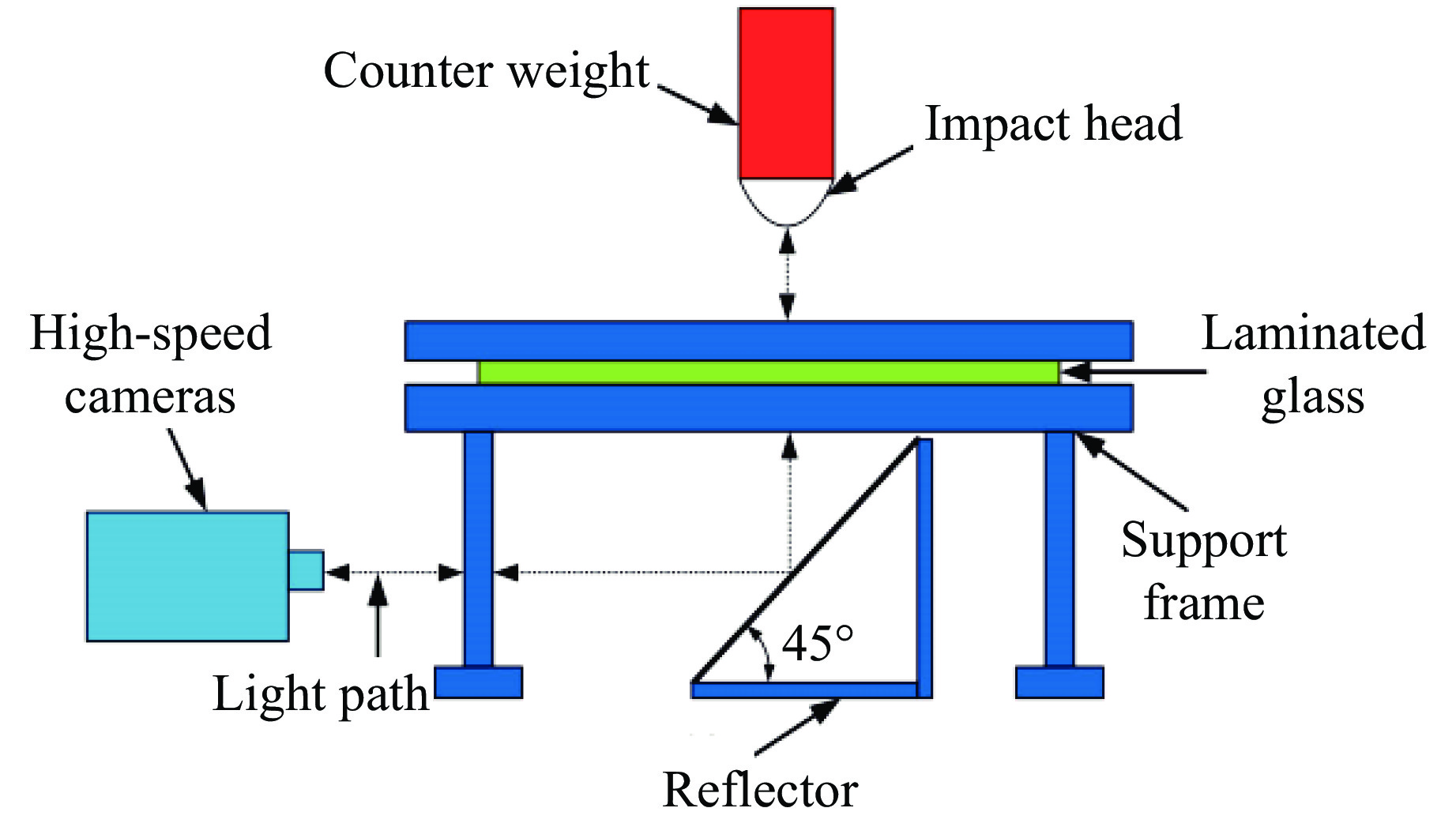

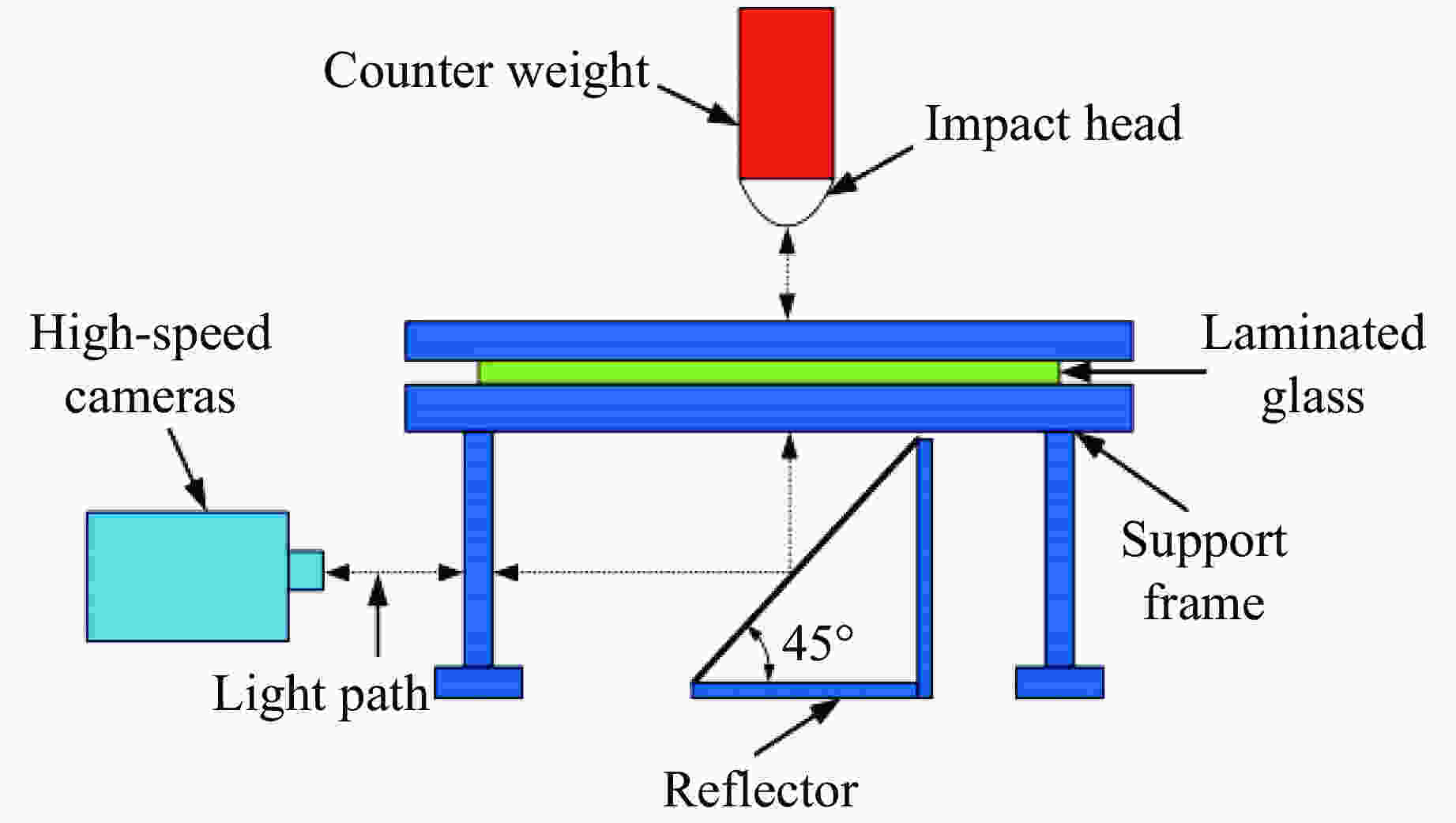

摘要: 钢化夹层玻璃的透光性好、安全性能高,广泛应用于汽车、高层建筑等领域。为了研究不同玻璃厚度分布钢化夹层玻璃的抗冲击性能,进行了9种PVB钢化夹层玻璃的落锤冲击实验,分析未破裂状态和破裂状态下钢化夹层玻璃的冲击力、应变和位移随时间的变化规律。同时,利用高速摄像机记录裂纹的产生和扩展情况,分析破裂状态下夹层玻璃的裂纹分布形态。结果表明:钢化夹层玻璃的抗冲击性能与玻璃层数、厚度分布密切相关。双层钢化夹层玻璃中,外层玻璃越厚,内层玻璃越薄,抗冲击性能越好;三层钢化夹层玻璃中,外层玻璃越薄,内层玻璃越厚,抗冲击性能越好。Abstract: Due to good light transmittance and great safety performance, tempered laminated glass has been widely used in automobiles, high-rise buildings and other fields. To explore the effect of glass thickness distribution on the impact resistance of tempered laminated glass, the drop hammer impact tests were performed on nine kinds of PVB tempered laminated glass, and the changes of impact force, strain and displacement of the tempered laminated glass with time were obtained under unfracture state and fracture state. Meanwhile, high-speed cameras were used to record the generation and expansion of cracks, and the crack distributions of the laminated glass were analyzed under the fracture state. The results show that the impact resistance is closely related to the number of layers and the thickness distribution of tempered laminated glass. For double-layer tempered laminated glass, when the outer glass is thicker and the inner glass is thinner, the impact resistance is better. For the three-layer tempered laminated glass, when the outer glass is thinner and the inner glass is thicker, the impact resistance is better.

-

Key words:

- PVB laminated glass /

- drop hammer impact test /

- crack distribution /

- impact resistance

-

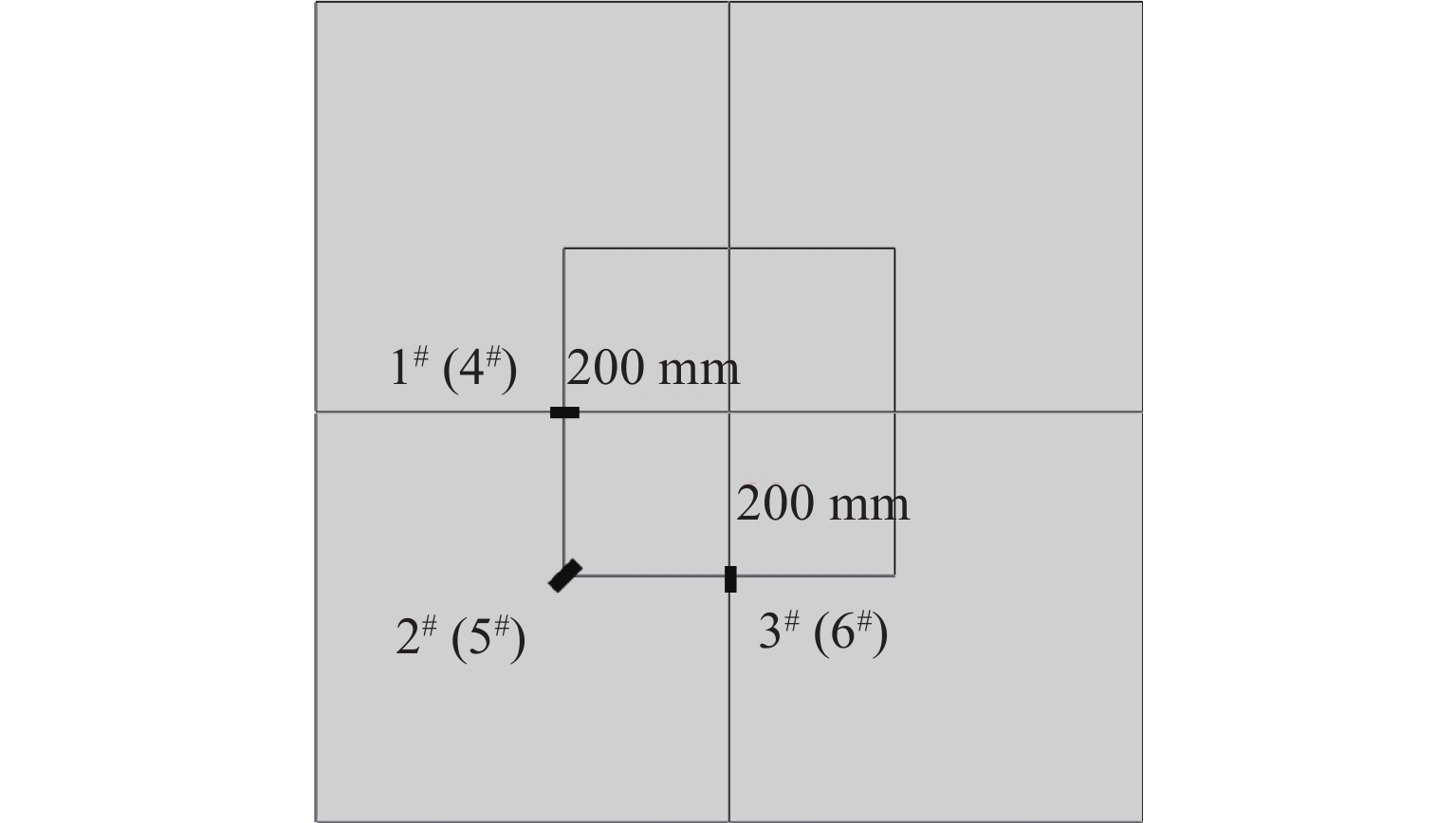

表 1 实验试样

Table 1. Experimental specimens

No. Total thickness/mm Structure Thickness/mm Quantity of glass layer/piece G1 20.76 8/0.76/12 G2 G/PVB/G 10/0.76/10 2 G3 12/0.76/8 G4 24.76 6/0.38/8/0.38/10 G5 G/PVB/G/PVB/G 8/0.38/8/0.38/8 3 G6 10/0.38/8/0.38/6 G7 30.76 8/0.38/10/0.38/12 G8 G/PVB/G/PVB/G 10/0.38/10/0.38/10 3 G9 12/0.38/10/0.38/8 表 2 落锤冲击实验的实验结果

Table 2. Experimental results from drop hammer impact test

No. Drop height/mm Impact energy/J Peak impact force/kN Fracture mode G1 650 114.802 63.51 Inner and outer glass fracture G2 700 123.632 73.62 Inner glass fracture G3 800 141.294 85.54 Inner glass fracture G4 900 158.960 114.25 Inner glass fracture G5 850 150.125 95.03 Inner glass fracture G6 850 150.125 89.12 Inner and outer glass fracture G7 850 150.125 142.93 Inner glass fracture G8 650 114.802 124.36 Inner glass fracture G9 600 105.970 103.24 Inner glass fracture 表 3 外层玻璃的最大拉应变和内层玻璃的最大压应变

Table 3. Maximum tensile strains of the outer glass and maximum compressive strain of the inner glass

No. Test point Strain/10−4 Glassy layer No. Test point Strain/10−4 Glassy layer 1 2.14 4 −1.90 G1 2 2.24 G1 5 −2.09 3 2.38 6 −2.00 1 2.17 4 −2.08 G2 2 1.91 Outer glass G2 5 −1.94 Inner glass 3 1.85 6 −2.03 1 2.13 4 −1.90 G3 2 2.24 G3 5 −2.10 3 2.39 6 −2.00 -

[1] 李胜杰. 爆炸载荷下夹层玻璃的动态响应及裂纹扩展的研究 [D]. 太原: 太原理工大学, 2015.LI S J. Study on the dynamic response and cracks propagation of laminated glass subjected to blast load [D]. Taiyuan: Taiyuan University of Technology, 2015. [2] 张晓颖, 李胜杰, 李志强. 爆炸载荷作用下夹层玻璃动态响应的数值模拟 [J]. 兵工学报, 2018, 39(7): 1379–1388. doi: 10.3969/j.issn.1000-1093.2018.07.016ZHANG X Y, LI S J, LI Z Q. Numerical simulation of dynamic response of laminated glass subjected to blast load [J]. Acta Armamentarii, 2018, 39(7): 1379–1388. doi: 10.3969/j.issn.1000-1093.2018.07.016 [3] LE J, SONG L X, PENG X F, et al. Fracture mechanics analysis of thermally tempered glass plate: fracture induced by an embedded crack [J]. International Journal of Fracture, 2005, 132(4): 299–309. doi: 10.1007/s10704-005-1889-3 [4] 庞世红. 夹层玻璃等效厚度研究 [D]. 北京: 中国建筑材料科学研究总院, 2009.PANG S H. Effective thickness research of laminated glass [D]. Beijing: China Building Materials Academy, 2009. [5] 李胜杰, 李志强, 王志华, 等. 爆炸载荷作用下夹层玻璃裂纹扩展的研究 [J]. 兵工学报, 2014, 35(Suppl 2): 72–77.LI S J, LI Z Q, WANG Z H, et al. Study of crack propagation in laminated glass under blast loads [J]. Acta Armamentarii, 2014, 35(Suppl 2): 72–77. [6] BEHR R A, KREMER P A, DHARANI L R, et al. Dynamic strains in architectural laminated glass subjected to low velocity impacts from small projectiles [J]. Journal of Materials Science, 1999, 34(23): 5749–5756. doi: 10.1023/A:1004702100357 [7] SAXE T J, BEHR R A, MINOR J E, et al. Effects of missile size and glass type on impact resistance of “Sacrificial Ply” laminated glass [J]. Journal of Architectural Engineering, 2002, 8(1): 24–39. doi: 10.1061/(ASCE)1076-0431(2002)8:1(24) [8] 张宗恒, 张红, 姚小虎, 等. 低速冲击下PVB夹层玻璃的破坏模式试验研究 [J]. 兵工学报, 2017, 38(Suppl 1): 113–119.ZHANG Z H, ZHANG H, YAO X H, et al. Experimental study of failure modes of PVB laminated glass under low-velocity impact [J]. Acta Armamentarii, 2017, 38(Suppl 1): 113–119. [9] 陈晶晶, 许骏, 刘博涵, 等. PVB夹层玻璃裂纹扩展的参数化实验研究 [J]. 汽车工程, 2015, 37(2): 235–240.CHEN J J, XU J, LIU B H, et al. Parametric experimental study on the crack propagation of PVB laminated glass [J]. Automotive Engineering, 2015, 37(2): 235–240. [10] CHEN J J, XU J, YAO X F, et al. Different driving mechanisms of in-plane cracking on two brittle layers of laminated glass [J]. International Journal of Impact Engineering, 2014, 69: 80–85. doi: 10.1016/j.ijimpeng.2014.02.014 [11] 许骏, 刘博涵, 葛东云, 等. 低速冲击下的聚乙烯醇缩丁醛夹层风挡玻璃动态响应研究 [J]. 兵工学报, 2010, 31(Suppl 1): 136–139.XU J, LIU B H, GE D Y, et al. Research on dynamic response of PVB laminated windshield subjected to low velocity impact [J]. Acta Armamentarii, 2010, 31(Suppl 1): 136–139. [12] 臧孟炎, 宋子林, 杨忠高. 行人保护分析用风挡玻璃的有限元模型 [J]. 华南理工大学学报(自然科学版), 2014, 42(4): 143–148. doi: 10.3969/j.issn.1000-565X.2014.04.022ZANG M Y, SONG Z L, YANG Z G. Finite element model of windscreenfor pedestrian protection [J]. Journal of South China University of Technology (Natural Science Edition), 2014, 42(4): 143–148. doi: 10.3969/j.issn.1000-565X.2014.04.022 [13] 林德佳, 臧孟炎. 基于内聚力模型的夹层玻璃冲击破坏仿真分析 [J]. 机械工程学报, 2017, 53(22): 176–181. doi: 10.3901/JME.2017.22.176LIN D J, ZANG M Y. Research on impact fracture behavior of the laminated glass based on cohesive zone model [J]. Journal of Mechanical Engineering, 2017, 53(22): 176–181. doi: 10.3901/JME.2017.22.176 [14] 王欣, 李科峰, 凡思军, 等. Tm3+掺杂Bi2O3-SiO2-PbO玻璃的~2 μm发光光谱性质 [J]. 无机材料学报, 2013, 28(2): 165–170. doi: 10.3724/SP.J.1077.2013.12219WANG X, LI K F, FAN S J, et al. Spectral properties of ~2 μm emission of Tm3+ doped Bi2O3-SiO2-PbO glass [J]. Journal of Inorganic Materials, 2013, 28(2): 165–170. doi: 10.3724/SP.J.1077.2013.12219 [15] ZHAO X L, LIANG X J, LUO H Y, et al. Third-order nonlinear optical properties of silver quantum dots doped in sodium borosilicate glass [J]. Journal of Inorganic Materials, 2013, 28(9): 1003–1008. doi: 10.3724/SP.J.1077.2013.12771 [16] XU X Q, XU J, CHEN J J, et al. Investigation of dynamic multi-cracking behavior in PVB laminated glass plates [J]. International Journal of Impact Engineering, 2017, 100: 62–74. doi: 10.1016/j.ijimpeng.2016.10.013 [17] 包亦望, 刘正权. 钢化玻璃自爆机理与自爆准则及其影响因素 [J]. 无机材料学报, 2016, 31(4): 401–406. doi: 10.15541/jim20150444BAO Y W, LIU Z Q. Mechanism and criterion of spontaneous breakage of tempered glass [J]. Journal of Inorganic Materials, 2016, 31(4): 401–406. doi: 10.15541/jim20150444 [18] LIU B H, XU T N, XU X Q, et al. Energy absorption mechanism of polyvinyl butyral laminated windshield subjected to head impact: experiment and numerical simulations [J]. International Journal of Impact Engineering, 2016, 90: 26–36. doi: 10.1016/j.ijimpeng.2015.11.010 [19] ZHANG X H, HAO H, MA G W. Laboratory test and numerical simulation of laminated glass window vulnerability to debris impact [J]. International Journal of Impact Engineering, 2013, 55: 49–62. doi: 10.1016/j.ijimpeng.2013.01.002 [20] ALTER C, KOLLING S, SCHNEIDER J. An enhanced non-local failure criterion for laminated glass under low velocity impact [J]. International Journal of Impact Engineering, 2017, 109: 342–353. doi: 10.1016/j.ijimpeng.2017.07.014 [21] CHEN S H, ZANG M Y, WANG D, et al. Finite element modelling of impact damage in polyvinyl butyral laminated glass [J]. Composite Structures, 2016, 138: 1–11. doi: 10.1016/j.compstruct.2015.11.042 -

下载:

下载: