| [1] |

赵春红, 秦现生.高压水射流切割技术及其应用[J].机床与液压, 2006(2):1-3. doi: 10.3969/j.issn.1001-3881.2006.02.001ZHAO C H, QIN X S.High pressure water jet cutting technology and its application [J].Machine Tool and Hydraulics, 2006(2):1-3. doi: 10.3969/j.issn.1001-3881.2006.02.001

|

| [2] |

张振, 章巧芳.高压喷嘴的射流仿真研究[J].机电工程, 2013, 30(2):185-187. http://d.old.wanfangdata.com.cn/Periodical/jdgc201302015ZHANG Z, ZHANG Q F.Study on jet simulation of high pressure nozzle[J].Journal of Mechanical and Electrical Engineering, 2013, 30(2):185-187. http://d.old.wanfangdata.com.cn/Periodical/jdgc201302015

|

| [3] |

BYRAN E L.High energy jet as a new concept for wood machining[J].Forest Prod J, 1963, 13(8):305-312.

|

| [4] |

SHANMUGAM D K, CHEN F L, SIORES E, et al.Comparative study of jetting machining technologies over laser machining technology for cutting composite materials [J].Compos Struct, 2002, 57(1):289-296. doi: 10.1016-S0263-8223(02)00096-X/

|

| [5] |

ARLEO F, ANNONI M, BASHA A, et al.Analysis of the effects of droplets collisions on the stability of a pure water jet by means of 3D numerical simulations[C]//10th AITEM Conference.Naples, Italy, 2011.

|

| [6] |

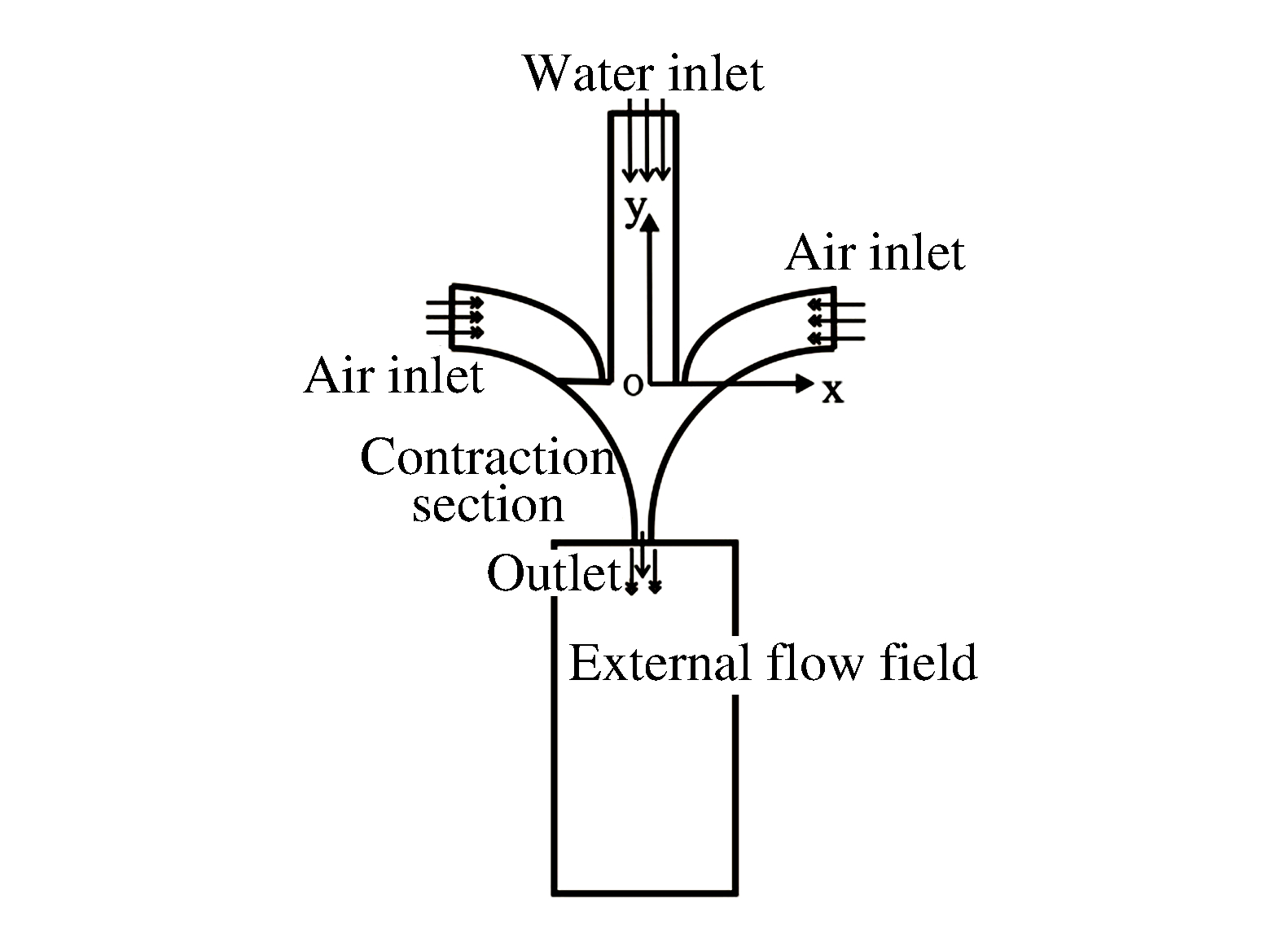

ANNONI M, ARLEO F, MALMASSARI C.CFD aided design and experimental validation of an innovative air assisted pure water jet cutting system [J].J Mater Proc Tech, 2014, 214(8):1647-1657. doi: 10.1016/j.jmatprotec.2014.01.020

|

| [7] |

BASHA A, ANNONI M, MONNO M, et al.Investigation of the hydrodynamic characteristics of AWJ cutting head [J].Int J Mach Mach Mater, 2013, 14(1):105-122. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f15e0bb5da7b23915425f5123fa3440f

|

| [8] |

ZOHOURKARI I, ZOHOOR M, ANNONI M.Investigation of the effects of machining parameters on material removal rate in abrasive waterjet turning [J].Adv Mechan Eng, 2014, 35(1):110-121. http://cn.bing.com/academic/profile?id=0b1a54b34e914ab8db1d5ac2a635ca77&encoded=0&v=paper_preview&mkt=zh-cn

|

| [9] |

OH T M, CHO G C.Characterization of effective parameters in abrasive waterjet rock cutting [J].Rock Mechan Rock Eng, 2014, 47(2):745-756. doi: 10.1007/s00603-013-0434-3

|

| [10] |

胡贵华, 俞涛, 刘小健.前混合磨料水射流喷嘴内液固两相流的数值模拟[J].机电一体化, 2005, 11(6):20-23. doi: 10.3969/j.issn.1007-080X.2005.06.004HU G H, YU T, LIU X J.The numerical simulation of two phase flow about the liquid and solid in nozzle of DIA jet[J].Mechatroni, 2005, 11(6):20-23. doi: 10.3969/j.issn.1007-080X.2005.06.004

|

| [11] |

熊佳, 雷玉勇, 杨志峰, 等.基于FLUENT的磨料水射流喷嘴内流场的可视化研究[J].润滑与密封, 2008, 33(6):51-55. doi: 10.3969/j.issn.0254-0150.2008.06.014XIONG J, LEI Y Y, YANG Z F, et al.Visual research of flow field in the nozzle of abrasive water jet based on FLUENT[J].Lubrication Engineering, 2008, 33(6):51-55. doi: 10.3969/j.issn.0254-0150.2008.06.014

|

| [12] |

候荣国.磨料水射流切割性能和喷嘴内外流场的仿真研究[D].济南: 山东大学, 2006.HOU R G.Study on the cutting performance of abrasive water jet and simulation of the velocity inside and outside the nozzle [D].Jinan: Shandong University, 2006.

|

| [13] |

杨敏官, 王育立, 康灿, 等.微型超高压宝石喷嘴内部的空化与磨损[J].高压物理学报, 2010, 24(4):286-292. http://www.gywlxb.cn/CN/abstract/abstract768.shtmlYANG M G, WANG Y L, KANG C, et al.Cavitation and wear in the micro jewel nozzle of ultra-high pressure water jet [J].Chinese Journal of High Pressure Physics, 2010, 24(4):286-292. http://www.gywlxb.cn/CN/abstract/abstract768.shtml

|

| [14] |

刘伟, 李火坤, 刘成梅, 等.基于FLUENT的动态高压微射流内部孔道流场的数值模拟[J].高压物理学报, 2012, 26(1):113-120. http://www.gywlxb.cn/CN/abstract/abstract1433.shtmlLIU W, LI H K, LIU C M, et al.Numerical simulation of microchannel of dynamic high-pressure microfluidization based on FLUENT[J].Chinese Journal of High Pressure Physics, 2012, 26(1):113-120. http://www.gywlxb.cn/CN/abstract/abstract1433.shtml

|

下载:

下载: