Strain Rate Effect and Energy Absorption Characteristics of Russian Pine

-

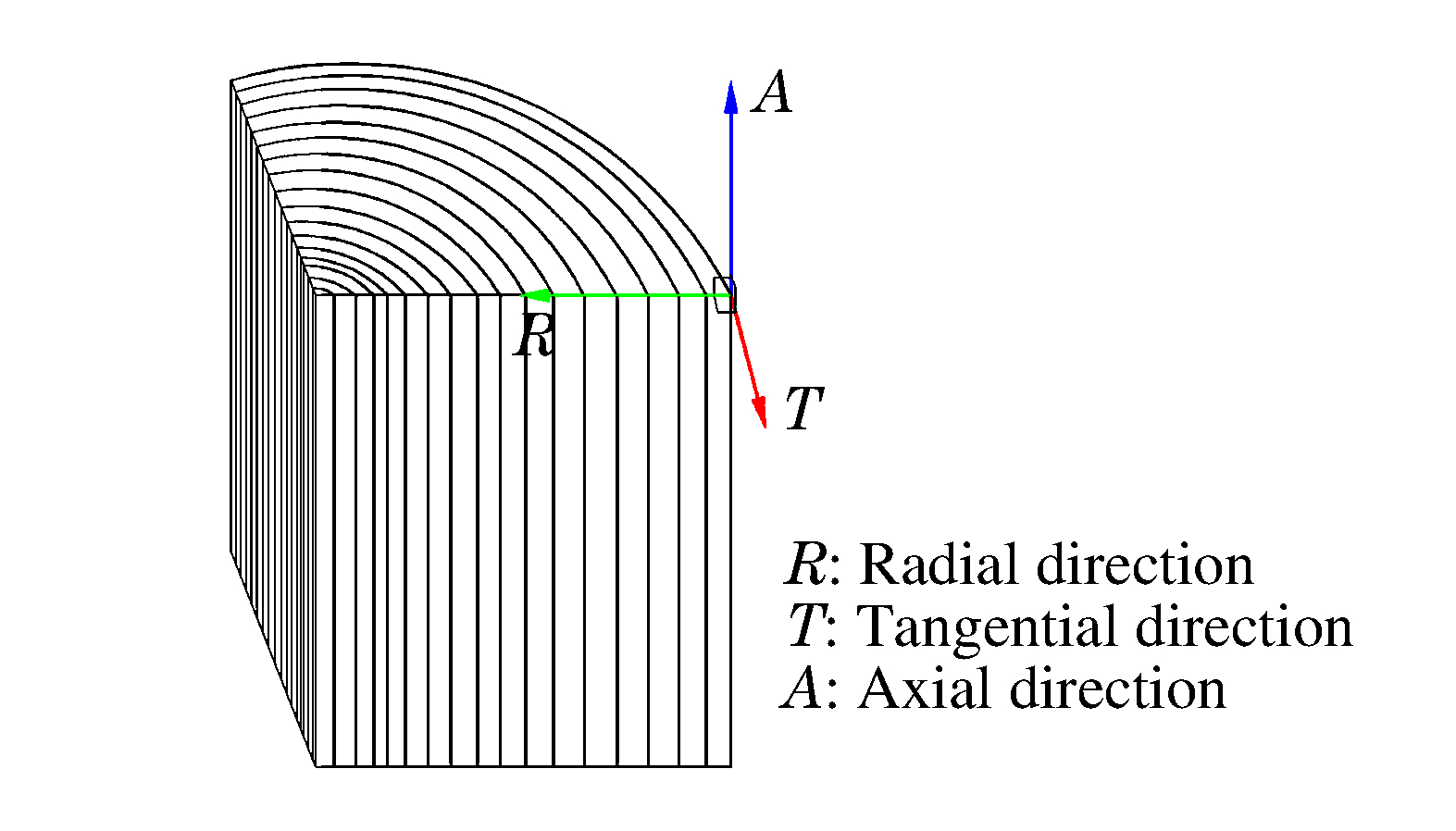

摘要: 针对广泛应用于包装运输和侵彻试验等工程领域的俄罗斯红松,实验研究了其在准静态载荷下的应力-应变关系和破坏模式。结果表明:俄罗斯红松在弦向和径向的变形均经历弹性变形、塑性变形和密实化3个阶段,而轴向在达到屈服极限后经历较小的塑性变形,然后发生破坏失效;弦向和径向破坏以沿纤维方向解离为主,而轴向破坏以扭结破碎为主。采用分离式霍普金森压杆装置,在500~5 000 s-1的应变率范围内对俄罗斯红松进行了高应变率动态压缩实验。结果表明:与弦向和径向相比,轴向初始屈服应力对应变率更敏感;随着应变率的升高,径向平台应力比弦向增加得更快;弦向和径向的吸能能力随应变率的增加逐渐提高,而轴向则逐渐下降;动态载荷下的破坏模式与准静态载荷下的破坏模式具有较高的相似性。Abstract: The Russian pine is widely used in packaging, transportation and penetration test.In this paper, we studied the stress-strain relationship and the failure mode of the Russian pine under quasi-static loading.The results show that the deformations of the pine in the radial and tangential directions undergo three phases:elastic deformation, plastic deformation and densification, and in the axial direction the pine undergoes small plastic deformations and damages when the yield limit is reached.The failure mode of the tangential and radial directions is mainly dissociated along the fiber direction, and the axial failure mode is dominated by the kink crack.Furthermore, we carried out high strain-rate dynamic compression tests of the Russian pine at the strain rates ranging from 500 s-1 to 5 000 s-1 using the split Hopkinson pressure bar system.The results show that the initial yield stress in the axial direction is more sensitive than that in the tangential and radial directions.The radial platform stress increases more rapidly with the strain rate than the tangential platform stress.The energy absorption capacity along the tangential and radial directions increases gradually as the strain rate increases, while it decreases gradually along the axial direction.The failure mode under dynamic loading is highly similar to that under the quasi-static loading.

-

Key words:

- Russian pine /

- high strain rate /

- initial yield stress /

- plateau stress /

- energy absorption

-

表 1 轴向SHPB实验数据

Table 1. SHPB experimental data along axial direction

No. l0/(mm) d0/(mm) pa/(MPa) v/(m/s) ${{{\dot{\varepsilon }}}_{\text{ave}}}$/(s-1) LS-1-1 5.14 11.00 0.17 5.9 557 L-1-1 5.16 10.90 0.17 5.6 575 L-1-2 5.12 11.00 0.17 7.1 804 L-1-3 5.20 11.02 0.17 9.8 1404 L-2-1 5.18 11.00 0.17 12.6 1918 L-2-2 5.14 10.90 0.17 15.2 2670 L-2-3 5.10 10.92 0.17 17.3 3091 L-3-1 5.12 11.02 0.22 20.8 3750 L-3-2 5.30 10.98 0.26 22.7 4025 L-3-3 5.24 11.04 0.32 25.1 4635 -

[1] DA SILVA A, KYRIAKIDES S.Compressive response and failure of balsa wood[J].Int J Solids Struct, 2007, 44(25):8685-8717. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=35bd84d27b92e5a1ea746cfda24aa785 [2] GALICKI J, CZECH M.Tensile strength of softwood in LR orthotropy plane[J].Mech Mater, 2005, 37(6):677-686. doi: 10.1016/j.mechmat.2004.07.001 [3] OUDJENE M, KHELIFA M.Elasto-plastic constitutive law for wood behaviour under compressive loadings[J].Constr Build Mater, 2009, 23(11):3359-3366. doi: 10.1016/j.conbuildmat.2009.06.034 [4] BENABOU L.Kink band formation in wood species under compressive loading[J].Exp Mech, 2007, 48(5):647-656. doi: 10.1007/s11340-007-9098-9 [5] ZHONG W Z, HUANG X C, HAO Z M, et al.Investigation on failure mode of spruce under different loading conditions[J].Appl Mech Mater, 2011, 80:556-560. http://www.scientific.net/AMM.80-81.556 [6] AL-SALLOUM Y, ALMUSALLAM T, IBRAHIM S M, et al.Rate dependent behavior and modeling of concrete based on SHPB experiments[J].Cem Concr Compos, 2015, 55:34-44. doi: 10.1016/j.cemconcomp.2014.07.011 [7] 王少恒, 杨震琦, 管公顺, 等.空心球/铝合金复合材料动态压缩性能与损伤破碎特性[J].高压物理学报, 2013, 27(3):439-446. http://www.gywlxb.cn/CN/abstract/abstract1588.shtmlWANG S H, YANG Z Q, GUAN G S, et al.Dynamic compression and damage pattern of hollow microsphere/aluminum alloy composites[J].Chinese Journal of High Pressure Physics, 2013, 27(3):439-446. http://www.gywlxb.cn/CN/abstract/abstract1588.shtml [8] 窦金龙, 汪旭光, 刘云川.杨木的动态力学性能[J].爆炸与冲击, 2008, 28(4):367-371. doi: 10.3321/j.issn:1001-1455.2008.04.014DOU J L, WANG X G, LIU Y C.Dynamic mechanical behaviors of poplar wood[J].Explosion and Shock Waves, 2008, 28(4):367-371. doi: 10.3321/j.issn:1001-1455.2008.04.014 [9] 许威, 花军, 张绍群, 等.基于SHPB试验的桦木压缩动力学特性[J].林业科学, 2015, 51(5):95-101. http://d.old.wanfangdata.com.cn/Periodical/lykx201505011XU W, HUA J, ZHANG S Q, et al.Research on dynamic compression characteristics of birch wood based on SHPB test [J].Scientia Silvae Sinicae, 2015, 51(5):96-101. http://d.old.wanfangdata.com.cn/Periodical/lykx201505011 [10] 钟卫洲, 宋顺成, 黄西成, 等.三种加载方向下云杉静动态力学性能研究[J].力学学报, 2011, 43(6):1141-1150. http://d.old.wanfangdata.com.cn/Conference/7500448ZHONG W Z, SONG S C, HUANG X C, et al.Research on static and dynamic mechanical properties of spruce wood by three loading directions[J]. Chinese Journal of Theoretical & Applied Mechanics, 2011, 43(6):1141-1150. http://d.old.wanfangdata.com.cn/Conference/7500448 [11] WIDEHAMMAR S.Stress-strain relationships for spruce wood:influence of strain rate, moisture content and loading direction[J].Exp Mech, 2004, 44(1):44-48. doi: 10.1007/BF02427975 [12] VURAL M, RAVICHANDRAN G.Dynamic response and energy dissipation characteristics of balsa wood:experiment and analysis[J].Int J Solids Struct, 2003, 40(9):2147-2170. doi: 10.1016/S0020-7683(03)00057-X [13] PUCHI-CABRERA E S.Simple constitutive description of Al-5·5Mg alloy deformed at elevated temperatures and strain rates[J].Mater Sci Technol, 2006, 22(6):699-705. doi: 10.1179/174328406X86137 [14] TABARSA T, YINGHEI C.Stress-strain response of wood under radial compression.Part Ⅰ.test method and influences of cellular properties[J].Wood Fiber Sci, 2000, 32(2):144-152. http://www.cabdirect.org/abstracts/20000610039.html [15] TAN P J, REID S R, HARRIGAN J J, et al.Dynamic compressive strength properties of aluminium foams.Part Ⅰ-experimental data and observations[J].J Mech Phys Solids, 2005, 53(10):2174-2205. doi: 10.1016/j.jmps.2005.05.007 [16] WOUTS J, HAUGOU G, OUDJENE M, et al.Strain rate effects on the compressive response of wood and energy absorption capabilities.Part A:experimental investigations[J].Compos Struct, 2016, 149:315-328. doi: 10.1016/j.compstruct.2016.03.058 -

下载:

下载: