Instability of Aluminum Honeycomb Sandwich Panelunder Blast Loading

-

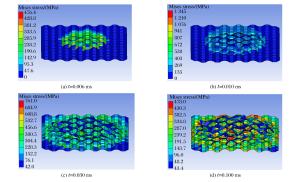

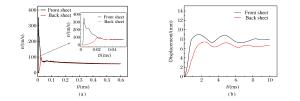

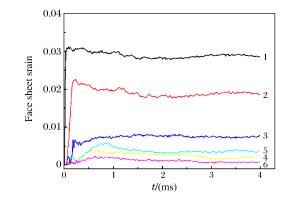

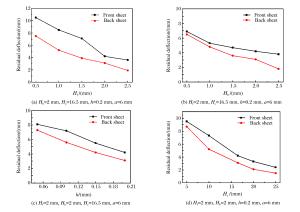

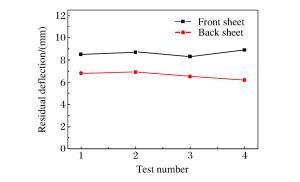

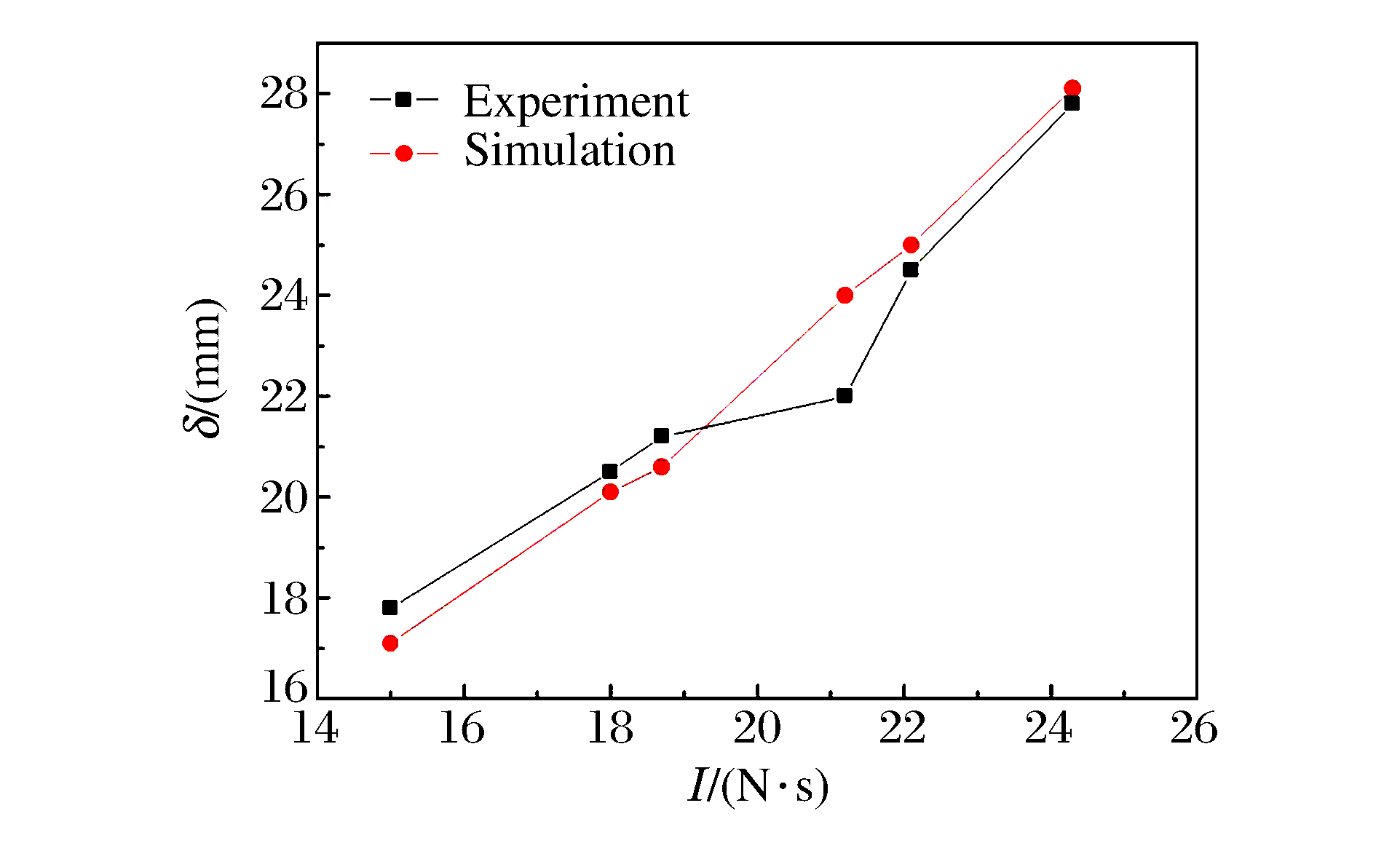

摘要: 基于非线性动力学软件AUTODYN,对铝蜂窝夹芯板在爆炸冲击载荷作用下的失稳过程进行三维数值模拟。通过建立不同参数规格的铝蜂窝夹芯板的实体模型,研究其前、后面板在TNT爆炸冲击作用下的动态响应及塑性阶段的失稳变形。计算结果表明:随着铝蜂窝板前、后面板厚度,夹芯层铝箔高度和厚度的增加,铝蜂窝板在爆炸冲击载荷下的最终残余变形量均明显减小,抵抗变形的能力增强;对于夹芯层胞元形状不同但相对密度相同的铝蜂窝板,因冲击载荷下单轴压缩“惯性效应”差异较小,其面板在爆炸载荷作用下的最终残余变形量差异不大。Abstract: In the present work, based on the nonlinear dynamics software AUTODYN, we performed a three-dimensional simulation of the instability process of the aluminum honeycomb sandwich panels under blast loading.By establishing the solid model of aluminum honeycomb sandwich panels with different parameters, we studied the dynamic response of the front and back sheets under the TNT impact and the instability deformation in the plastic stage.The results achieved from our calculation show that with the increase of the thickness of the aluminum honeycomb panel, the height and thickness of the aluminum foil, the final residual deformation of the aluminum honeycomb panel under blast loading is obviously reduced and its deformation-resistance ability is enhanced.For the aluminum honeycomb panels with different cell shapes but the same relative density, the distinction of the panels' final residual deformation under blast loading is not significant because there is little difference in "inertia effect" under the uniaxial compression condition.

-

Key words:

- mechanics of explosion /

- safety protection /

- instability /

- AUTODYN /

- aluminum honeycomb sandwich panel

-

表 1 铝蜂窝板材料参数

Table 1. Material parameters of aluminum honeycomb panel

Material Elastic modulus/(GPa) Shear modulus/(GPa) Poisson ratio Yield strength/(MPa) Failure strain Al-2024 72.4 28 0.3 75 0.1 表 2 TNT炸药的材料参数

Table 2. Material parameters of TNT explosive

ρTNT/(g/cm3) A/(GPa) B/(GPa) R1 R2 ω vC-J/(km/s) EC-J/(GJ/m3) pC-J/(GPa) 1.63 373.77 3.75 4.15 0.90 0.35 6.93 6 21 表 3 空气参数

Table 3. Material parameters of air

ρg/(kg/m3) eg/(kJ/g) γ 1.225 206.8 1.4 表 4 Al-5083H116本构方程参数

Table 4. Constitutive equation parameters of Al-5083H116

ρAl/(g/cm3) νAl Am/(MPa) Bm/(MPa) n Cm Tm/(K) εf 2.7 0.3 290 596 0.551 0.001 893 0.1 表 5 铝蜂窝板材料参数

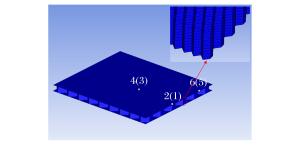

Table 5. Material parameters of aluminum honeycomb panel

Material Hf/(mm) Hb/(mm) Hc/(mm) h/(mm) a/(mm) ρ Al5083 2 2 16.5 0.05 6 0.022 表 6 不同胞元铝蜂窝板参数

Table 6. Parameters of aluminum honeycomb panel with different cell shapes

Test No. Cell shapes Hc/(mm) h/(mm) a/(mm) ρ 1 Hexagon 16.5 0.20 6 0.089 2 Diamond 16.5 0.27 6 0.090 3 Rectangle 16.5 0.27 6 0.090 4 Triangle 16.5 0.15 6 0.087 -

[1] PAIK J K, THAYAMBALLI A K, KIM G S.The strength characteristics of aluminum honeycomb sandwich panels[J].Thin Wall Struct, 1999, 35(3):205-231. doi: 10.1016/S0263-8231(99)00026-9 [2] JEN Y M, CHANG L Y.Evaluating bending fatigue strength of aluminum honeycomb sandwich beams using local parameters[J].Int J Fatigue, 2008, 30(6):1103-1114. doi: 10.1016/j.ijfatigue.2007.08.006 [3] HOU B, ZHAO H, PATTOFATTO S, et al.Inertia effects on the progressive crushing of aluminium honeycombs under impact loading[J].Int J Solids Struct, 2012, 49(19):2754-2762. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=0ad6d8c1425c43df8bb9c0d242736265 [4] ZHAO H, GARY G.Crushing behaviour of aluminium honeycombs under impact loading[J].Int J Impact Eng, 1998, 21(10):827-836. doi: 10.1016/S0734-743X(98)00034-7 [5] JEN Y M, CHANG L Y.Effect of thickness of face sheet on the bending fatigue strength of aluminum honeycomb sandwich beams[J].Eng Fail Anal, 2009, 16(4):1282-1293. doi: 10.1016/j.engfailanal.2008.08.004 [6] LI X, WANG Z, ZHU F, et al.Response of aluminium corrugated sandwich panels under air blast loadings:experiment and numerical simulation[J].Int J Impact Eng, 2014, 65:79-88. doi: 10.1016/j.ijimpeng.2013.11.002 [7] 张旭红, 王志华, 赵隆茂.爆炸载荷作用下铝蜂窝夹芯板的动力响应[J].爆炸与冲击, 2009, 29(4):356-360. doi: 10.3321/j.issn:1001-1455.2009.04.004ZHANG X H, WANG Z H, ZHAO L M.Dynamic responses of sandwich plates with aluminum honeycomb cores subjected to blast loading[J].Explosion and Shock Waves, 2009, 29(4):356-360. doi: 10.3321/j.issn:1001-1455.2009.04.004 [8] 谭思博, 侯兵, 李玉龙, 等.基体材料对铝蜂窝动态强化特性的影响[J].爆炸与冲击, 2015, 35(1):16-21. http://d.old.wanfangdata.com.cn/Periodical/bzycj201501003TAN S B, HOU B, LI Y L, et al.Effect of base materials on the dynamic enhancement of aluminium honeycombs[J].Explosion and Shock Waves, 2015, 35(1):16-21. http://d.old.wanfangdata.com.cn/Periodical/bzycj201501003 [9] HEIMBS S, MIDDENDORF P, MAIER M.Honeycomb sandwich material modeling for dynamic simulations of aircraft interior components[C]//Proceedings of the 9th International LS-DYNA Users Conference.Dearborn, Michigan, 2006. [10] 胡玉琴.铝蜂窝夹层板等效模型研究及数值分析[D].南京: 南京航空航天大学, 2008.HU Y Q.Equivalent models research and numerical analysis of aluminum honeycomb sandwich plates[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2008. [11] 贾宪振, 胡毅亭, 董明荣, 等.深水环境中水下爆炸冲击波作用下圆柱壳动态响应的数值模拟研究[J].振动与冲击, 2008, 27(5):160-165. doi: 10.3969/j.issn.1000-3835.2008.05.041JIA X Z, HU Y T, DONG M R, et al.Dynamic response of cylindrical shell subjected to underwater explisive shock waves in deep water[J].Journal of Vibration and Shock, 2008, 27(5):160-165. doi: 10.3969/j.issn.1000-3835.2008.05.041 [12] 夏博文, 魏亚杰, 饶国宁, 等.含铝炸药爆炸作用下的水中圆柱壳动态响应数值研究[J].爆破器材, 2014, 43(6):1-5. doi: 10.3969/j.issn.1001-8352.2014.06.001XIA B W, WEI Y J, RAO G N, et al.Dynamic response of underwater cylindrical shells subjected to blast loads of aluminized explosives[J].Explosive Materials, 2014, 43(6):1-5. doi: 10.3969/j.issn.1001-8352.2014.06.001 [13] 于川, 李良忠.含铝炸药爆轰产物JWL状态方程研究[J].爆炸与冲击, 1999, 19(3):274-279. http://d.old.wanfangdata.com.cn/Periodical/bzycj199903014YU C, LI L Z.Studies on JWL equation of state of detonation product for aluminized explosive[J].Explosion and Shock Waves, 1999, 19(3):274-279. http://d.old.wanfangdata.com.cn/Periodical/bzycj199903014 [14] 李冀祺, 马素贞.爆炸力学[M].北京:科学出版社, 1992. [15] 汪维.钢筋混凝土构件在爆炸载荷作用下的毁伤效应及评估方法研究[D].长沙: 国防科学技术大学, 2012.WANG W.Study on damage effects and assessments method of reinforced concrete structural members under blast loading[D].Changsha: National University of Defense Technology, 2012. [16] FLECK N A, DESHPANDE V S.The resistance of clamped sandwich beams to shock loading[J].J Appl Mech, 2004, 71(3):386-401. doi: 10.1115/1.1629109 [17] 余同希, 邱信明.冲击动力学[M].北京:清华大学出版社, 2011. [18] 高玉华.铝合金LC4和LY24CZ在高应变率拉伸和压缩下的本构关系[J].材料科学与工艺, 1994, 2(2):24-29. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199400849627GAO Y H.Dynamic and tensile properties of Al alloys LC4 and LY12CZ at high strain rate[J].Material Sicence and Technology, 1994, 2(2):24-29. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199400849627 [19] 孙瑞雪, 徐磊, 赵文博.不同应变速率下5083铝合金的拉伸性能及端口形貌[J].轻金属, 2012(8):59-61. doi: 10.3969/j.issn.1002-1752.2012.08.016SUN R X, XU L, ZHAO W B.The tensile properties and fracture morphologies of 5083 aluminum alloy under different strain rates[J].Light Metals, 2012(8):59-61. doi: 10.3969/j.issn.1002-1752.2012.08.016 -

下载:

下载: