Coatings of WC/Co Prepared by a Shaped Charge Explosion

-

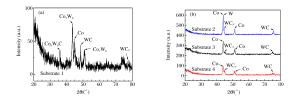

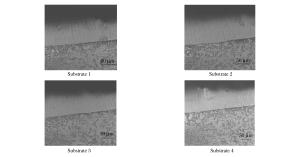

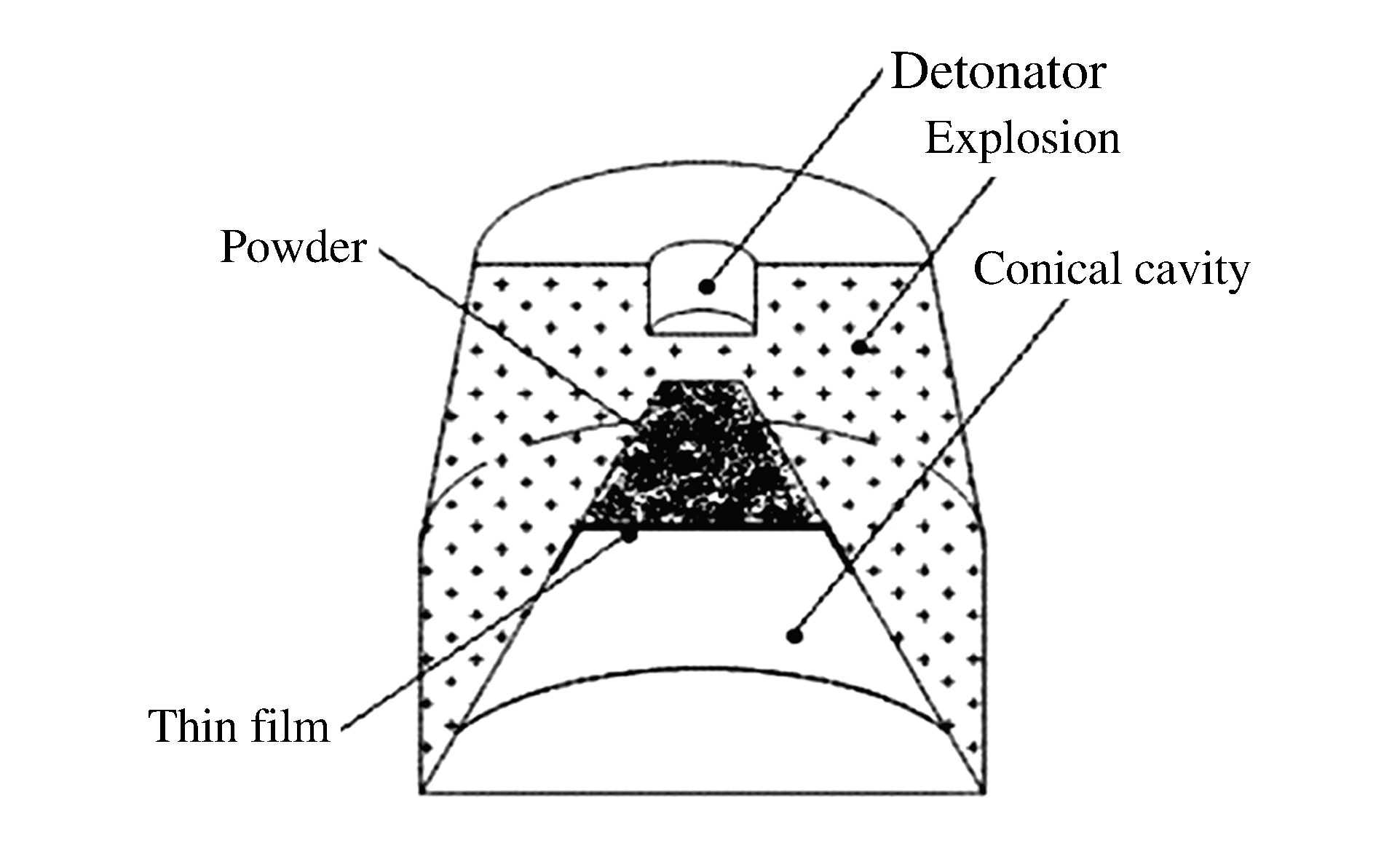

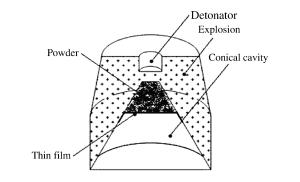

摘要: 利用聚能装药爆炸喷涂技术在基板表面制备了WC/Co(Co的质量分数为10%)涂层,简述了聚能装药爆炸喷涂的技术工艺。利用X射线衍射仪、金相显微镜对经聚能装药爆炸喷涂得到的涂层进行表征、分析。实验结果显示,使用WC/CoC2O4·2H2O(21.7%,CoC2O4·2H2O质量分数)机械混合粉末制备的涂层比使用WC/Co(10%)机械混合粉末制备的涂层均匀致密,并且涂层氧化脱碳程度明显降低。随着WC/CoC2O4·2H2O(21.7%)机械混合粉末中气体分散剂含量的增加,经聚能装药爆炸喷涂技术制备的涂层孔隙率逐渐降低,涂层均匀,致密性逐渐增强。Abstract: The technology of preparing coatings using a shaped-charge explosion was briefly introduced and employed to produce coatings of WC/Co (10%, mass fraction of Co) on the surface of the charge's substrates.The properties of the coatings were analyzed and characterized by means of X-ray diffraction analysis and optical microscopy.The results indicate that the uniform and compact coatings prepared from the mechanically mixed powder of WC/CoC2O4·2H2O (21.7%, mass fraction of CoC2O4·2H2O) by a shaped-charge explosion are better than those prepared from the mechanically mixed powder of WC/Co (10%), and the degree of oxidation and decarburization of the coatings was also lower than that of the later.With the increase of the gas dispersant in the mechanically mixed powder of WC/CoC2O4·2H2O, the porosity of the coatings was gradually decreased whereas its uniformity and compactness were gradually strengthened.

-

Key words:

- shaped-charge explosion /

- WC/Co coating /

- gas dispersing agent

-

表 1 实验方案

Table 1. Experimental scheme

Experiment No. Powder mass ratio Mass fraction of gasdispersing agent Density of powder/(g/cm3) Substrate 1 90: 10 (WC: Co) 2.43 1 2 78.3: 21.7 (WC: CoC2O4·2H2O) 2.41 2 3 78.3: 21.7 (WC: CoC2O4·2H2O) 20%(RDX) 2.38 3 4 78.3: 21.7 (WC: CoC2O4·2H2O) 40%(RDX) 2.40 4 表 2 厚度测量结果

Table 2. Thickness measurement result

Experiment No. a/(mm) b/(mm) c/(mm) d/(mm) 2 0.18 0.17 0.16 0.12 3 0.14 0.14 0.12 0.12 4 0.11 0.12 0.12 0.11 -

[1] 蒋伟, 赵金平, 龚敏.热喷涂技术及其发展[J].中国涂料, 2006, 21(11):51-52. doi: 10.3969/j.issn.1006-2556.2006.11.019JIANG W, ZHAO J P, GONG M.Thermal spray technology and its development[J].China Coatings, 2006, 21(11):51-52. doi: 10.3969/j.issn.1006-2556.2006.11.019 [2] 华绍春, 王汉功, 汪刘应, 等.热喷涂技术的研究进展[J].金属热处理, 2008, 33(5):82-87. http://d.old.wanfangdata.com.cn/Periodical/jsrcl200805023HUA S C, WANG H G, WANG L Y, et al.Development on thermal spray technology[J].Heat Treatment of Metals, 2008, 33(5):82-87. http://d.old.wanfangdata.com.cn/Periodical/jsrcl200805023 [3] 吴朝军, 吴晓峰, 杨杰.热喷涂技术在我国航天领域的应用[J].金属加工(热加工), 2009(18):23-27. http://d.old.wanfangdata.com.cn/Periodical/jxgr-rjg200918009WU C J, WU X F, YANG J.Thermal spray technology in the field of aerospace[J].MW Metal Forming, 2009(18):23-27. http://d.old.wanfangdata.com.cn/Periodical/jxgr-rjg200918009 [4] 何洪泉, 王峰, 张兰.热喷涂系列综述之一:等离子喷涂[J].山东陶瓷, 2005, 28(3):14-17. doi: 10.3969/j.issn.1005-0639.2005.03.004HE H Q, WANG F, ZHANG L.A review of thermal spraying:plasma spraying[J].Shandong Ceramics, 2005, 28(3):14-17. doi: 10.3969/j.issn.1005-0639.2005.03.004 [5] FAGOAGA I, VIVIENTE J L, GAVIN P, et al.Multilayer coatings by continuous detonation system spray technique[J].Thin Solid Films, 1998, 317(1):259-265. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ef0325bdda588a4b18e5672755275412 [6] YINGLONG W.Friction and wear performances of detonation-gun-and plasma-sprayed ceramic and cermet hard coatings under dry friction[J].Wear, 1993, 161(1/2):69-78. http://www.sciencedirect.com/science/article/pii/004316489390454T [7] 许磊, 张春华, 张松, 等.爆炸喷涂研究的现状及趋势[J].金属热处理, 2004, 29(2):21-25. doi: 10.3969/j.issn.0254-6051.2004.02.007XU L, ZHANG C H, ZHANG S, et al.Status and trends of explosion spraying[J].Heat Treatment of Metals, 2004, 29(2):21-25. doi: 10.3969/j.issn.0254-6051.2004.02.007 [8] GROMILOV S A, KINELOVSKⅡ S A, POPOV Y N, et al.On the possibility of physicochemical transformation of substances upon shaped-charge application of coats[J].Combust Explos Shock Waves, 1997, 33(6):734-736. doi: 10.1007/BF02671807 [9] GROMILOV S A, KINELOVSKⅡ S A, KIREENKO I B.Surface of a titanium target after interaction with shaped-charge jet particles[J].Combust Explos Shock Waves, 2003, 39(5):601-605. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bf1ba85df714dd57fc28aa5f83447b1f [10] KINELOVSKⅡ S A, GROMILOV S A.Specific features of the formation of crystalline phases of the W-C-N system in a cumulative process[J].Combust Explos Shock Waves, 2001, 37(2):243-246. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cf515b1623541b1fb6c1247b9778cbcf [11] GROMILOV S A, KINELOVSKⅡ S A.Formation of phases upon collision of a shaped-charge flow of particles with a titanium target[J].Combust Explos Shock Waves, 2002, 38(1):114-118. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=4a8cd053c986c091c4f07a66b50f8586 [12] KINELOVSKⅡ S A, ALEKSEEV A V, GROMILOV S A, et al.Formation of a specific layer on the surface of a metallic target interacting with a shaped-charge jet of boron-containing liners[J].Combust Explos Shock Waves, 2006, 42(2):231-236. doi: 10.1007/s10573-006-0044-4 [13] GROMILOV S A, ALEKSEEV A V, KINELOVSKⅡ S A, et al.Layers produced by entrapment of a shaped-charge jet in a titanium target[J].Combust Explos Shock Waves, 2003, 39(6):727-732. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=5954f7b94edae4025bcf30f53f43b172 [14] 李如江, 刘晓红, 高永宏, 等.聚能装药爆炸喷涂制备硬质耐磨涂层的新工艺: 102251210A [P].2011-11-23.LI R J, LIU X H, GAO Y H, et al.The new technology of manufacture of hard and wear resistant coating with shaped charge explosive: 102251210A [P].2011-11-23. [15] 李如江, 周鹏, 刘晓红, 等.在大直径管内壁制备耐磨防锈涂层的装置及方法: 103966595A [P].2014-08-06.LI R J, ZHOU P, LIU X H, et al.The apparatus and method of manufacture of wear and anti-rust coating in large diameter pipe wall: 103966595A [P].2014-08-06. -

下载:

下载: