Effect of Aluminum Particle Size on Thermal Decomposition Characteristics of Emulsion Matrix

-

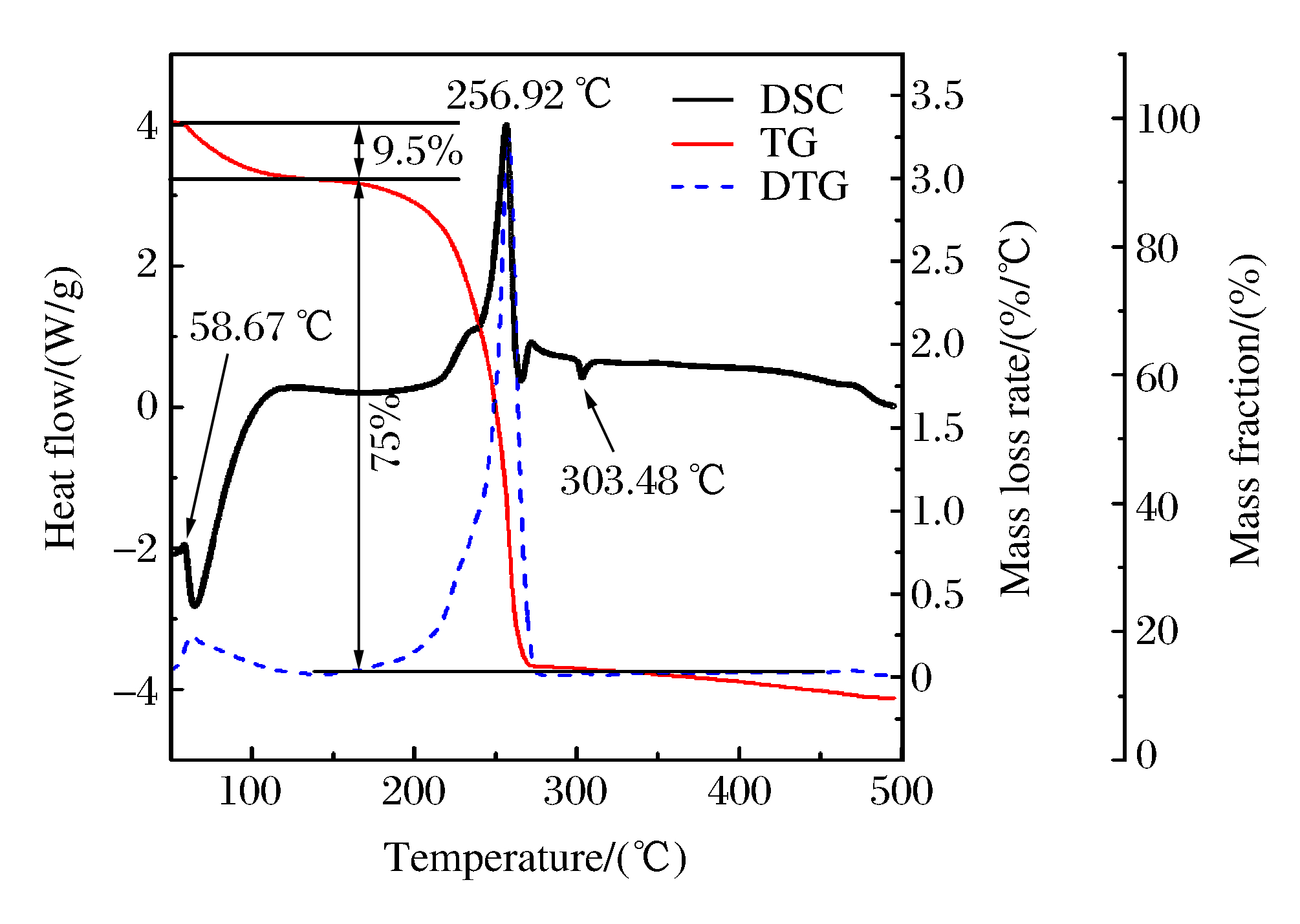

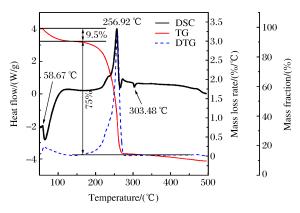

摘要: 为了研究铝粉粒度对乳化炸药基质热稳定性的影响,运用DSC-TG联用差示扫描量热仪,考察了添加不同粒度铝粉的乳化炸药基质在不同升温速率下的热分解特性,以获得热分解动力学参数。结果表明,铝粉的加入降低了乳化炸药基质的热分解温度,分解反应活化能减小,即基质热安定性降低,且随着铝粉粒度的减小,该趋势更加明显。与不添加铝粉的乳化炸药相比,在实验范围内不同粒度的铝粉对乳化炸药基质的热分解机理未产生影响,均为受随机成核和随后生长控制的反应级数n=1的Mample单行法则。研究成果可为含铝乳化炸药热安定性的相关研究提供理论参考。Abstract: Adding aluminum powder into emulsion explosive can increase its explosion heat and work capability, but also raise its heat sensitivity.In order to study the effect of the aluminum particle size on the thermal stability of the emulsion matrix, the thermal decomposition characteristics of the emulsion matrix containing aluminum powders of different particle sizes were examined using differential scanning calorimetry (DSC) and thermal gravimetric (TG) methods at various heating rates, and the kinetic parameters of thermal decomposition were obtained.The results show that the addition of aluminum powder reduces the peak temperature, the activation energy and thermal stability.Moreover, this trend becomes more obvious with the decrease of the aluminum particle size.Compared with the case of the emulsion explosive without the powder addition, the aluminum powders with different particle sizes have no effect on the thermal decomposition mechanism functions of the emulsion matrix in the scope of experiments and they are controlled by nucleation and growth mechanism and the mechanism function could be described with Mample principle with a reaction order of n=1.The results can provide theoretical guidance for corresponding thermal stability research of aluminized emulsion explosive.

-

Key words:

- emulsion matrix /

- aluminum powder /

- particle size /

- thermal decomposition /

- activation energy

-

表 1 乳化炸药基质配方

Table 1. Main ingredients of emulsion matrix

Component Chemical name Chemical formula Mole mass/(g/mol) Mass fraction/(%) Oxidants Ammonium nitrate NH4NO3 80.0 69.5 Sodium nitrate NaNO3 85.0 12.2 Solvent Water H2O 18.0 10.0 Combustibles Paraffin wax C18H38 254.5 2.1 Compound wax C22-28H46-58 ≈392.0 3.6 Emulsifier SP-80 C24H44O6 428.0 2.6 表 2 样品配比

Table 2. Sample ratio

Sample Mass fraction/(%) Aluminum particle size/(μm) Emulsion matrix Al powder 1# 95 5 111.9 2# 95 5 177.2 3# 95 5 314.2 4# 100 0 0 表 3 不同升温速率和反应深度下4种样品的反应温度

Table 3. Reaction temperatures of 4 samples at various heating rates and reaction depths

α β/(℃/min) T/(K) 1# 2# 3# 4# 0.4 5 518.164 518.562 520.541 519.980 10 531.357 530.665 530.206 530.017 20 543.586 543.259 543.833 544.527 30 551.194 550.979 551.878 550.375 0.5 5 523.290 523.969 525.617 525.905 10 536.491 536.444 535.600 536.136 20 548.892 548.242 548.351 550.605 30 555.652 555.602 556.747 555.839 表 4 由Flynn-Wall-Ozawa法求得的4种样品的动力学参数

Table 4. Kinetic parameters of 4 samples calculated with Flynn-Wall-Ozawa method

Sample α=0.4 α=0.5 E/(kJ/mol) r Q/(kJ/mol) E/(kJ/mol) r Q/(kJ/mol) 1# 123.00 0.998 48 0.018 89 127.22 0.996 69 0.027 89 2# 124.95 0.999 98 0.002 14 130.50 0.998 63 0.017 94 3# 128.11 0.993 31 0.039 62 132.17 0.995 59 0.032 25 4# 129.02 0.991 67 0.044 27 133.66 0.989 95 0.048 58 -

[1] 汪旭光.乳化炸药[M].第2版.北京:冶金工业出版社, 2008:3-11.WANG X G.Emulsion explosives[M].2nd ed.Beijing:Metallurgical Industry Press, 2008:3-11. [2] OTHMER K.Encyclopedia of chemical technology[M].New York:Wiley Inter Science, 1979:629-631. [3] 宋敬埔, 吴红梅.我国乳化炸药的研究近况及发展建议[J].爆破器材, 2003, 32(4):5-10. doi: 10.3969/j.issn.1001-8352.2003.04.002SONG J P, WU H M.The recent research and development advice on the emulsion explosives in our country[J].Explosive Materials, 2003, 32(4):5-10. doi: 10.3969/j.issn.1001-8352.2003.04.002 [4] BJARNHOLT G.Effects of aluminium and lithium fluoride admixtures on metal acceleration ability of Comp B[C]//Proceedings of the 6th International Symposium on Detonation.San Diego, 1976: 510-520. [5] JOHNSON J N, TANG P K, FOREST C A.Shock-wave initiation of heterogeneous reactive solids[J].J Appl Phys, 1985, 57(9):4323-4334. doi: 10.1063/1.334591 [6] GUIRGUIS R H, MILLER P J.Time-dependent equations of state for aluminized underwater explosives[C]//Proceedings of the 10th International Symposium on Detonation.Boston, 1993: 675-682. [7] TAO W C, TARVER C M, KURY J W, et al.Understanding composite explosive energetics: 4.reactive flow modeling of aluminum reaction kinetics in PETN and TNT using normalized product equation of state[C]//Proceedings of the 10th International Symposium on Detonation.Boston, 1993: 351-356. [8] MURAVYEV N, FROLOV Y, PIVKINA A, et al.Influence of particle size and mixing technology on combustion of HMX/Al compositions[J].Propell Explos Pyrot, 2010, 35(3):226-232. doi: 10.1002/prep.v35:3 [9] RITTER H, BRAUN S.High explosives containing ultrafine aluminum ALEX[J].Propell Explos Pyrot, 2001, 26(6):311-314. doi: 10.1002/1521-4087(200112)26:6<311::AID-PREP311>3.0.CO;2-S [10] 冯晓军, 王晓峰, 李媛媛, 等.铝粉粒度和爆炸环境对含铝炸药爆炸能量的影响[J].火炸药学报, 2013, 36(6):24-27. doi: 10.3969/j.issn.1007-7812.2013.06.004FENG X J, WANG X F, LI Y Y, et al.Effect of aluminum particle size and explosion atmosphere on the energy of explosion of aluminized explosive[J].Chinese Journal of Explosives&ropellants, 2013, 36(6):24-27. doi: 10.3969/j.issn.1007-7812.2013.06.004 [11] 王彩玲, 陈松, 赵省向, 等.AI粉对RDX机械感度的影响[J].火工品, 2010(1):32-34. doi: 10.3969/j.issn.1003-1480.2010.01.009WANG C L, CHEN S, ZHAO S X, et al.Influence of Al powder on mechanical sensitivity of RDX[J].Initiators&Pyrotechnics, 2010(1):32-34. doi: 10.3969/j.issn.1003-1480.2010.01.009 [12] 金朋刚, 郭炜, 王建灵, 等.不同粒度铝粉在HMX基炸药中的能量释放特性[J].含能材料, 2015, 23(10):989-993. doi: 10.11943/j.issn.1006-9941.2015.10.013JIN P G, GUO W, WANG J L, et al.Energy releasing characteristics of aluminum powder in HMX-based explosives[J].Chinese Journal of Energetic Materials, 2015, 23(10):989-993. doi: 10.11943/j.issn.1006-9941.2015.10.013 [13] 汪旭光, 聂森林, 云主惠, 等.浆状炸药的理论与实践[M].北京:冶金工业出版社, 1985:26.WANG X G, NIE S L, YUN Z H, et al.Theory and practice of slurry explosive[M].Beijing:Metallurgical Industry Press, 1985:26. [14] 蔡正千.热分析[M].北京:高等教育出版社, 1993:235-236.CAI Z Q.Thermoanalysis[M].Beijing:Higher Education Press, 1993:235-236. [15] WESLEY W W.Thermal analysis[M].3rd ed.New York:John Wiley and Sons Inc, 1986:127-131. -

下载:

下载: