Numerical Study of Inertial Effects of Concrete-Like Materials in Split Hopkinson Pressure Bar Tests

doi: 10.11858/gywlxb.2017.02.003

-

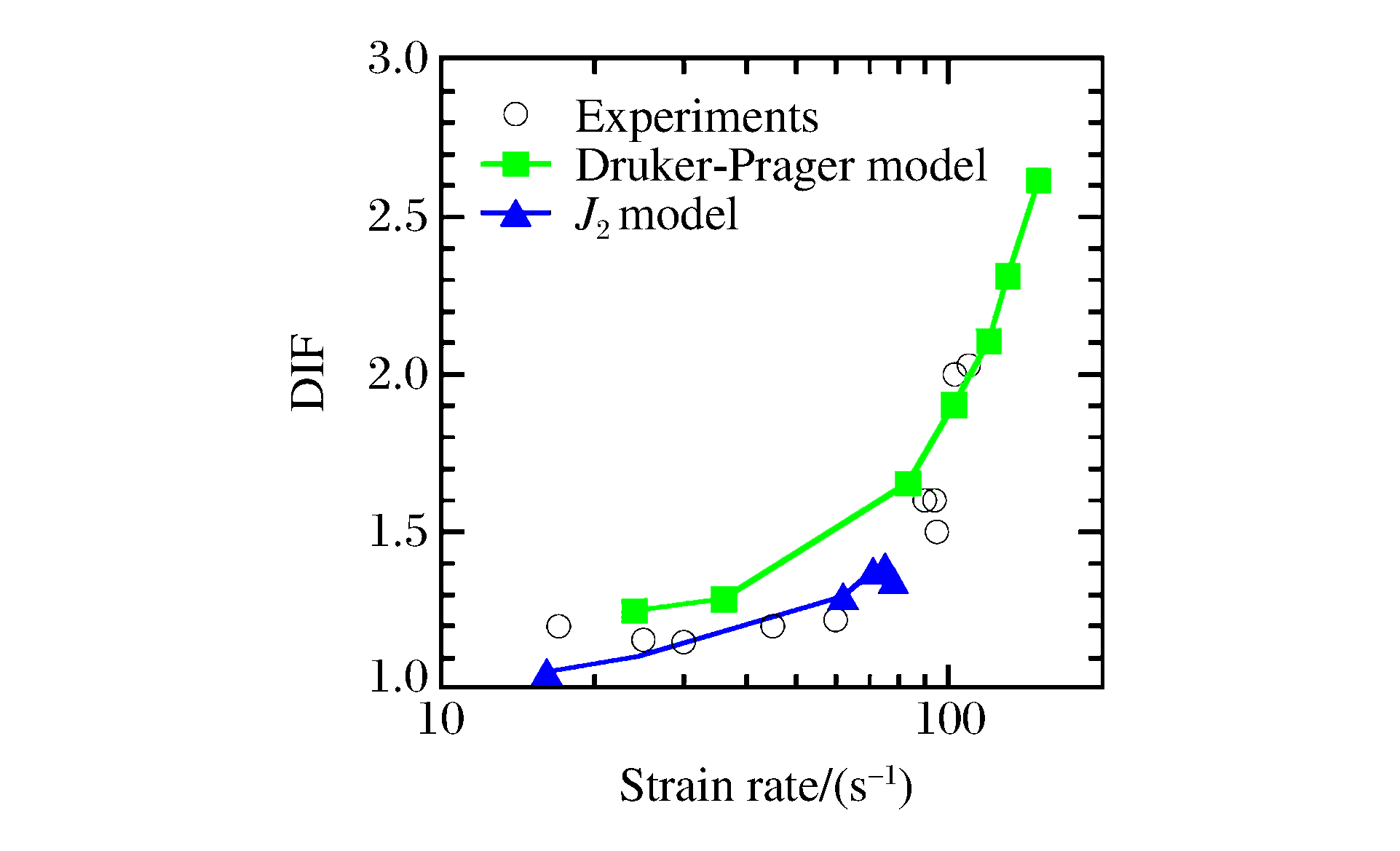

摘要: 分离式霍普金森压杆(SHPB)被广泛应用于测试混凝土类材料在高应变率(10~103 s-1)下的动态增强效应。为更好地理解这类问题,进行了数值模拟研究,采用J2本构模型研究SHPB试验中的纵向惯性效应,线性Drucker-Prager模型研究SHPB试验中的径向惯性效应。研究结果表明:纵向惯性效应不影响动态增强因子;径向惯性效应对动态增强因子有影响,但不是混凝土类材料在高应变率下动态增强因子提高的最主要原因。Abstract: The split Hopkinson pressure bar (SHPB) technique has been widely used to measure the dynamic strength enhancement of concrete-like materials at high strain rates ranging from 10 to 103 s-1.In this research, computational simulation models were employed to obtain a better understanding of this technique.The constitutive models of J2 and the linear Drucker-Prager were employed to study the axial and lateral inertial effects on SHPB test.The results show that the axial inertia does not affect the DIF (dynamic increase factor) and the lateral inertia confinement is not the most important factor that causes an apparent increase of the DIF for concrete and concrete-like materials at high strain rates.

-

Figure 1. DIF versus strain rate[3]

-

[1] TAI Y S.Uniaxial compression tests at various loading rates for reactive powder concrete[J].Theor Appl Fract Mech, 2009, 52(1):14-21. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=33877d53996f2426b29c0d0edc3d82ab [2] LI Q M, MENG H.About the dynamic strength enhancement of concrete-like materials in a split Hopkinson pressure bar test[J].Int J Solids Struct, 2003, 40(2):343-360. doi: 10.1016/S0020-7683(02)00526-7 [3] KIM D J, SIRIJAROONCHAI K, EL-TAWIL S, et al.Numerical simulation of the split Hopkinson pressure bar test technique for concrete under compression[J].Int J Impact Eng, 2010, 37(2):141-149. doi: 10.1016/j.ijimpeng.2009.06.012 [4] BISCHOFF P H, PERRY S H.Compressive behavior of concrete at high strain-rates[J].Mater Struct, 1991, 24(6):425-450. doi: 10.1007/BF02472016 [5] GORHAM D A.Specimen inertia in high strain-rate compression[J].J Phys D, 1989, 22(12):1888-1893. doi: 10.1088/0022-3727/22/12/014 [6] DAVIES E D H, HUNTER S C.The dynamic compression testing of solids by the method of the split hopkinson pressure bar[J].J Mech Phys Solids, 1963, 11(3):155-179. doi: 10.1016/0022-5096(63)90050-4 [7] BERTHOLF L D, KARNES C H.2-Dimensional analysis of split Hopkinson pressure bar system[J].J Mech Phys Solids, 1975, 23(1):1-19. doi: 10.1016/0022-5096(75)90008-3 [8] GROTE D L, PARK S W, ZHOU M.Dynamic behavior of concrete at high strain rates and pressures:Ⅰ.experimental characterization[J].Int J Impact Eng, 2001, 25(9):869-886. doi: 10.1016/S0734-743X(01)00020-3 [9] COTSOVOS D M, PAVLOVIC M N.Numerical investigation of RC structural walls subjected to cyclic loading[J].Comput Concrete, 2005, 2(3):215-238. doi: 10.12989/cac.2005.2.3.215 [10] MOHR D, GARY G, LUNDBERG B.Evaluation of stress-strain curve estimates in dynamic experiments[J].Int J Impact Eng, 2010, 37(2):161-169. doi: 10.1016/j.ijimpeng.2009.09.007 [11] LU J F, ZHUANG Z, SHIMAMURA K, et al.Application of numerical simulation to SHPB test to investigate the dynamic compressive behavior of material with failure[C]//Progress in Experimental and Computational Mechanics in Engineering.Switzerland, 2003: 433-438. [12] LU J F, ZHUANG Z, SHIMAMURA K.Development of a material constitutive for high-rate using a combined experiment/computation method[C]//Advances in Fracture and Failure Prevention.Switzerland, 2004: 269-276. [13] LI Q M, MENG H.Correlation between the accuracy of a SHPB test and the stress uniformity based on numerical experiments[J].Int J Impact Eng, 2003, 28(5):537-555. doi: 10.1016/S0734-743X(02)00073-8 [14] KOLSKY H.An investigation of the mechanical studies in plastic wave propagation[J].J Mech Phys Solids, 1949, 10(10):195-223. [15] ZHU J, HU S S, WANG L L.An analysis of stress uniformity for concrete-like specimens during SHPB tests[J].Int J Impact Eng, 2009, 36(1):61-72. doi: 10.1016/j.ijimpeng.2008.04.007 [16] 尚兵, 胡时胜, 姜锡权.金属材料SHPB实验数据处理的三波校核法[J].爆炸与冲击, 2009, 30(4):429-432. doi: 10.3321/j.issn:1001-1455.2009.04.017SHANG B, HU S S, JIANG X Q.A three-wave coupling method for data treatment in SHPB experiments with metal samples[J].Explosion and Shock Waves, 2009, 30(4):429-432. doi: 10.3321/j.issn:1001-1455.2009.04.017 -

下载:

下载: