Numerical Simulation of Influence of Projectiles' Boundary Effect on Ballistic Resistance Property of 2A12 Aluminum Alloy Targets

-

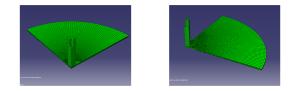

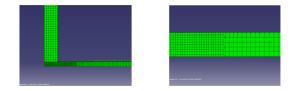

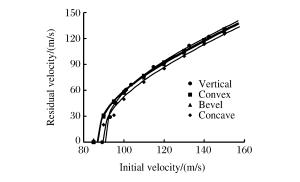

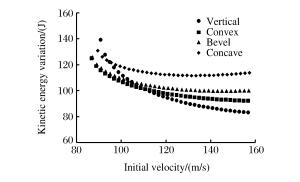

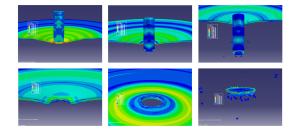

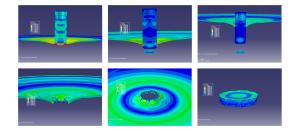

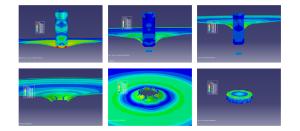

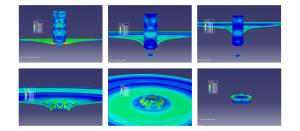

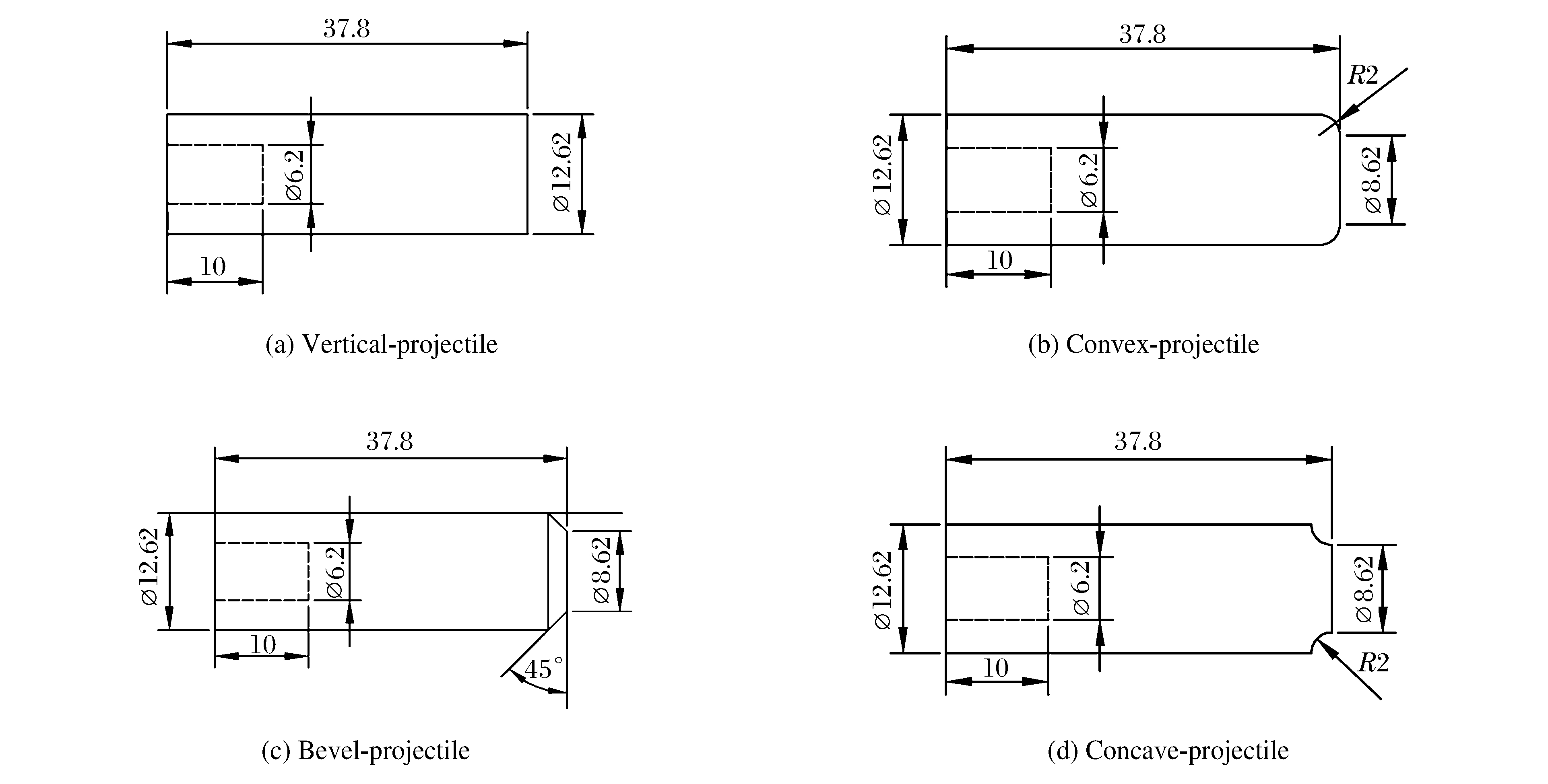

摘要: 利用有限元软件ABAQUS建立仿真模型,研究不同边界条件的弹体撞击2 mm厚的2A12铝合金靶体,得出初始结构目标剩余速度和弹道极限速度。根据仿真结果,分析弹体边界效应对靶板失效模式以及抗侵彻性能的影响。研究结果表明,弹体的边界效应对于靶体的剩余速度影响很小,当弹体初速较高时几乎可以忽略不计,而对于靶体的失效模式影响则较大,内凹过渡弹体撞击靶体所产生的整体变形和裂纹扩展程度最高,其次分别为斜切过渡、外凸过渡和垂直过渡。此外,弹体的初始速度也会影响到靶体的结构变形,影响程度与弹体的边界效应有关。Abstract: The finite element software, ABAQUS, has been used to establish the simulation models in order to study the performance of 2A12 aluminum alloy targets (with a thickness of 2 mm) impacted by projectiles (with different boundary conditions), and the data of the targets' residual velocities and ballistic limit velocities have been obtained. Based on the simulation results, the influence of the boundary effect on the projectile target failure models and ballistic resistance property are analyzed. The results achieved on the basis of the numerical study show that the influence of the projectiles' boundary effect on the targets' residual velocities is very much limited, becoming almost negligible when the projectile's velocity is high. However, this effect on the targets' failure models is significantly great:the targets' whole deformation and crack extension are increasingly more and more obvious when impacted by vertical-projectiles, convex-projectiles, bevel-projectiles, and concave-projectiles. In addition, the initial velocity of the projectiles can also influence the structural deformations, the degree of which is related to the projectiles' boundary effect.

-

Key words:

- numerical simulation /

- boundary effect /

- impact /

- single target

-

E/(GPa) Tr/(K) Tm/(K) m ${{\dot \varepsilon }_0}$/(s-1) c2/(MPa) 71.7 293 863 1.426 1.11×10-3 288.0 c1 ω A/(MPa) σu/(MPa) εu C 0.071 3 0.0 400.0 635.0 0.125 5 0.001 D1 D2 D3 D4 D5 D6 0.116 0.211 -2.172 0.012 -0.012 56 13.04 E/(GPa) ν ρ/(kg/m3) σ0/(MPa) Et/(MPa) 204 0.33 7 850 1 900 15 000 表 3 数值模拟结果

Table 3. Data of numerical simulations

Vertical Convex Bevel Concave vi/(m/s) vr/(m/s) vi/(m/s) vr/(m/s) vi/(m/s) vr/(m/s) vi/(m/s) vr/(m/s) 89.31 0 85 0 85 2.31 85 0 93.13 29.26 90 30.89 90 29.72 90 19.98 96.00 45.29 95 47.35 95 46.33 95 31.29 100.50 59.44 100 57.34 100 57.04 100 49.72 101.05 60.67 110 76.76 110 74.74 110 69.44 103.53 66.61 120 92.38 120 89.71 120 85.16 114.78 86.89 130 105.49 130 103.43 130 99.52 132.42 111.69 140 118.38 140 116.61 140 113.39 142.22 122.02 150 130.68 150 128.56 150 125.17 表 4 弹体对靶体的弹道极限及模型参数

Table 4. Ballistic limits and model constants of targets against projectiles

Projectile mode a vbl/(m/s) p Vertical 0.98 90.8 2.75 Convex 0.98 86.8 2.46 Bevel 0.97 87.1 2.45 Concave 0.96 89.5 2.40 -

[1] BϑRVIK T, LANGSETH M, HOPPERSTAD O S, et al.Ballistic penetration of steel plates[J].Int J Impact Eng, 1999, 22(9/10):855-886. http://d.old.wanfangdata.com.cn/OAPaper/oai_doaj-articles_36278031d934370d0099c597aff9631b [2] BϑRVIK T, HOPPERSTAD O S, BERSTAD T, et al.A computational model of viscoplasticity and ductile damage for impact and penetration[J].Euro J Mech A/Solids, 2001, 20(5):685-712. doi: 10.1016/S0997-7538(01)01157-3 [3] RUSINEK A, RODRÍGUEZ-MARTÍNEZ J A, ARIAS A, et al.Influence of conical projectile diameter on perpendicular impact of thin steel plate[J].Eng Fract Mech, 2008, 75(10):2946-2967. doi: 10.1016/j.engfracmech.2008.01.011 [4] GUPTA N K, IQBAL M A, SEKHON G S.Experimental and numerical studies on the behavior of thin aluminum plates subjected to impact by blunt-and hemispherical-nosed projectiles[J].Int J Impact Eng, 2006, 32(12):1921-1944. doi: 10.1016/j.ijimpeng.2005.06.007 [5] 张伟, 魏刚, 肖新科.7A04高强铝合金抗杆弹正撞击性能实验研究[J].高压物理学报, 2011, 25(5):401-406. http://www.gywlxb.cn/CN/abstract/abstract1392.shtmlZHANG W, WEI G, XIAO X K.Experimental study on ballistic resistance property of 7A04 aluminum against rod projectiles impact[J].Chinese Journal of High Pressure Physics, 2011, 25(5):401-406. http://www.gywlxb.cn/CN/abstract/abstract1392.shtml [6] 邓云飞, 张伟, 曹宗胜.间隙对A3钢薄板抗卵形头弹侵彻性能影响的实验研究[J].振动与冲击, 2013, 32(12):95-99. doi: 10.3969/j.issn.1000-3835.2013.12.018DENG Y F, ZHANG W, CAO Z S.Effect of gap on behavior of a double-layered A3 steel shield against penetration of ogival rigid projectiles[J].Journal of Vibration and Shock, 2013, 32(12):95-99. doi: 10.3969/j.issn.1000-3835.2013.12.018 [7] XIAO X K, ZHANG W, WEI G, et al.Effect of projectile hardness on deformation and fracture behavior in the Taylor impact test [J].Mater Design, 2010, 31(10):4913-4920. doi: 10.1016/j.matdes.2010.05.027 [8] 张伟, 肖新科, 魏刚.7A04铝合金的本构关系和失效模型[J].爆炸与冲击, 2011, 31(1):81-87. http://d.old.wanfangdata.com.cn/Periodical/bzycj201101014ZHANG W, XIAO X K, WEI G.Constitutive relation and fracture model of 7A04 aluminum alloy [J].Explosion and Shock Waves, 2011, 31(1):81-87. http://d.old.wanfangdata.com.cn/Periodical/bzycj201101014 [9] 张伟, 魏刚, 肖新科.2A12铝合金本构关系和失效模型[J].兵工学报, 2013, 34(3):276-282. http://d.old.wanfangdata.com.cn/Periodical/bgxb201303004ZHANG W, WEI G, XIAO X K.Constitutive relation and fracture criterion of 2A12 aluminum alloy [J].Acta Armamentarii, 2013, 34(3):276-282. http://d.old.wanfangdata.com.cn/Periodical/bgxb201303004 [10] LING Y.Uniaxial true stress-strain after necking[J].AMP Journal of Technology, 1996(5):37-48. http://d.old.wanfangdata.com.cn/NSTLQK/NSTL_QKJJ0221015086/ [11] 魏刚.铝合金板抗杆弹撞击性能研究[D].哈尔滨: 哈尔滨工业大学, 2010: 16-19. http://cdmd.cnki.com.cn/Article/CDMD-10213-1011261371.htmWEI G.Invesgation of deformation and fracture behavior associated mechanisms of the metal kinetic energy projectiles[D].Harbin: Harbin Institute of Technology, 2010: 16-19. http://cdmd.cnki.com.cn/Article/CDMD-10213-1011261371.htm [12] BϑRVIK T, HOPPERSTAD O S, BERSTAD T, et al.A computational model of viscoplasticity and ductile damage for impact and penetration[J].Euro J Mech A/Solids, 2001, 20(5):685-712. doi: 10.1016/S0997-7538(01)01157-3 [13] 孟凡柱.铝合金板抗刚性弹体撞击性能研究[D].天津: 中国民航大学, 2014: 42-44.MENG F Z.Invisitigationon the ballistic resistence property of aluminum alloy targets [D].Tianjin: Civil Aviation University of China, 2014: 42-44. [14] RECHT R F, IPSON T W.Ballistic perforation dynamics [J].J Appl Mech, 1963, 30(3):384-391. doi: 10.1115/1.3636566 -

下载:

下载: