Thermoelectric Properties of P-Type PbTe Prepared by High Pressure

-

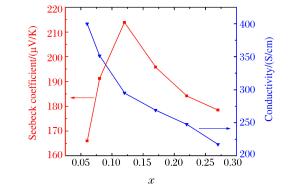

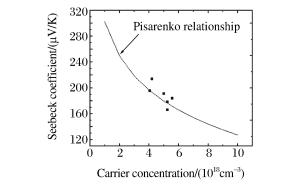

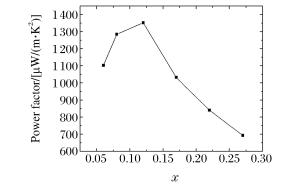

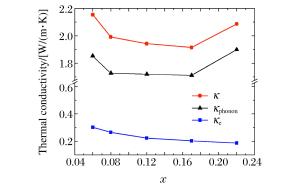

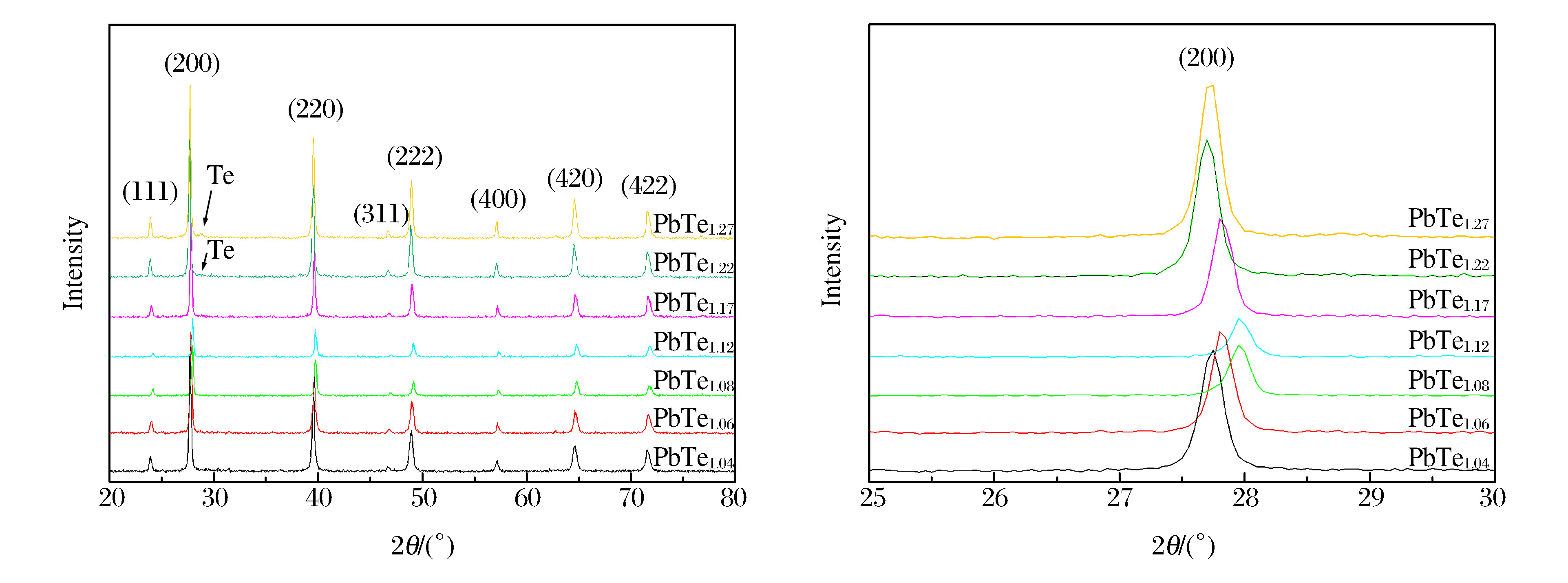

摘要: PbTe是目前唯一商业化应用的温差发电用中温区热电材料。大量研究表明,高压方法能够合成热电材料并有效调制其电声输运性能。目前针对PbTe的高压研究均为n型材料,而热电材料的应用还需要热膨胀系数相近的p型材料。因此,利用高压合成技术快速制备了Te过量的PbTe热电材料,并对其室温下的热电输运性质进行了测试和分析。结果表明,当Te过量6%时,PbTe为空穴导电,属于p型半导体;通过改变Te的含量,能够优化PbTe的电声输运性能,提高其功率因子且降低热导率。高压合成p型PbTe1.12的最大热电优值达到0.21,比相同方法制备的标准化学计量比的PbTe提高了50%。研究结果表明,高压方法结合化学计量比调整能够制备出高热电性能的p型PbTe热电材料。Abstract: PbTe is the only thermoelectric material that has been commercially used for power generation in the medium temperature. It has been found that the n-type PbTe with high performance can be synthesized by high pressure method, but so far there has been no report on similarly prepared p-type PbTe, which is also needed for the application of thermoelectric materials. In this study, we successfully synthesized PbTe with an excess of Te using the high pressure method, and studied their thermoelectric properties at room temperature. It turns out that the main carriers of PbTe with 6% excess Te are holes, indicating that they are p-type semiconductors. By changing the content of Te, we optimized the electrical transport properties of PbTe and decreased their thermal conductivities. The maximum figure-of-merit, 0.21, was obtained for p-type PbTe1.12, which is about 50% higher than that of PbTe with standard stoichiometric ratio synthesized by the same method. All the results show that the high pressure method, combined with the adjustment of the stoichiometric ratio, can prepare p-type PbTe thermoelectric materials that possess high thermoelectric performance.

-

Key words:

- high pressure /

- thermoelectric materials /

- PbTe /

- transport properties

-

表 1 高压合成PbTe1+x的霍尔系数、载流子浓度(n)、载流子迁移率(u)和载流子有效质量(m*)

Table 1. Hall coefficient, carrier concentration (n), Hall mobility (u) and carrier effective mass (m*)of PbTe1+x prepared by high pressure method

x Hall coefficient/

(cm3/C)n/

(1018cm-3)u/

[cm2/(V·s)]m*/

(me)0.04 -0.24 26.36 63.41 — 0.06 1.19 5.25 476.16 0.250 0.08 1.25 5.00 439.37 0.278 0.12 1.49 4.20 439.36 0.277 0.17 1.54 4.05 415.41 0.248 0.22 1.12 5.57 277.99 0.288 0.27 1.19 5.25 258.78 0.268 表 2 高压合成PbTe1+x的热电优值

Table 2. Figure-of-merit of PbTe1+x prepared by high pressure method

x ZT 0.06 0.16 0.08 0.20 0.12 0.21 0.17 0.17 0.22 0.12 -

[1] GOLDSMID H J.Introduction to thermoelectricity[M].Germany:Springer, 2009. [2] LALONDE A D, PEI Y, WANG H, et al.Lead telluride alloy thermoelectrics[J].Mater Today, 2011, 14(11):526-532. doi: 10.1016/S1369-7021(11)70278-4 [3] RAVICH Y I, EFIMOVA B A, SMIRNOV I A.Semiconducting lead chalcogenides[M].New York:Plenum Press, 1970. [4] FAN H, SU T, LI H, et al.High temperature thermoelectric properties of PbTe prepared by high pressure method[J].Mater Sci-Poland, 2015, 33(1):152-156. doi: 10.1515/msp-2015-0004 [5] ZHU P, IMAI Y, ISODA Y, et al.Electrical transport and thermoelectric properties of PbTe prepared by HPHT[J].Mater Trans, 2004, 45(11):3102-3105. doi: 10.2320/matertrans.45.3102 [6] OVSYANNIKOV S V, SHCHENNIKOV V V.High-pressure thermopower of PbTe-based compounds[J].Phys Status Solidi B, 2004, 241(14):3231-3234. doi: 10.1002/(ISSN)1521-3951 [7] 宿太超, 朱品文, 马红安, 等.高温高压掺杂N型PbTe的热电性能[J].高压物理学报, 2007, 21(1):55-58. doi: 10.3969/j.issn.1000-5773.2007.01.009SU T C, ZHU P W, MA H A, et al.Thermoelectric properties of N-type PbTe prepared by HPHT[J].Chinese Journal of High Pressure Physics, 2007, 21(1):55-58. doi: 10.3969/j.issn.1000-5773.2007.01.009 [8] SU T, ZHU P, MA H, et al.Electrical transport and high thermoelectric properties of PbTe doped with Bi2Te3 prepared by HPHT[J].Solid State Commun, 2006, 138(12):580-584. doi: 10.1016/j.ssc.2006.04.018 [9] SU T, JIA X, MA H, et al.Thermoelectric properties of nonstoichiometric PbTe prepared by HPHT[J].J Alloy Compd, 2009, 468(1):410-413. doi: 10.1016-j.jallcom.2008.01.012/ [10] 陈波, 孙振亚, 黎明发, 等.高压烧结对n型PbTe基材料热电性能的影响[J].高压物理学报, 2012, 26(2):121-126. http://www.gywlxb.cn/CN/Y2012/V26/I2/121CHEN B, SU Z Y, LI M F, et al.Effect of high pressure sintering on the thermoelectric properties of n-type PbTe[J].Chinese Journal of High Pressure Physics, 2012, 26(2):121-126. http://www.gywlxb.cn/CN/Y2012/V26/I2/121 [11] BREBRICK R F, ALLGAIER R S.Composition limits of stability of PbTe[J].J Chem Phys, 1960, 32(6):1826-1831. doi: 10.1063/1.1731029 [12] 陈波. 高压烧结制备PbSe基热电材料的微结构与热电性能研究[D]. 武汉: 武汉理工大学, 2012. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y2099114CHEN B. Thermoelectric properties and microstructure of PbSe based thermoelectric materials fabricated with high pressure sintering[D]. Wuhan: Wuhan University of Technology, 2012. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y2099114 [13] RAVICH Y, EFIMOVA B, SMIRNOV I.Semiconducting lead chalcogenides[M].New York:Plenum Press, 1970. [14] ORIHASHI M, NODA Y, KAIBE H T, et al.Evaluation of thermoelectric properties of impurity-doped PbTe[J].Mater Trans, 1998, 39(6):672-678. doi: 10.2320/matertrans1989.39.672 [15] LI Z, XIAO C, FAN S J, et al.Dual vacancies:an effective strategy realizing synergistic optimization of thermoelectric property in BiCuSeO[J].J Am Chem Soc, 2015, 137(20):6587-6593. doi: 10.1021/jacs.5b01863 -

下载:

下载: