Experimental Diagnostic of Ejecta on Sn Sample in Shock Melting

-

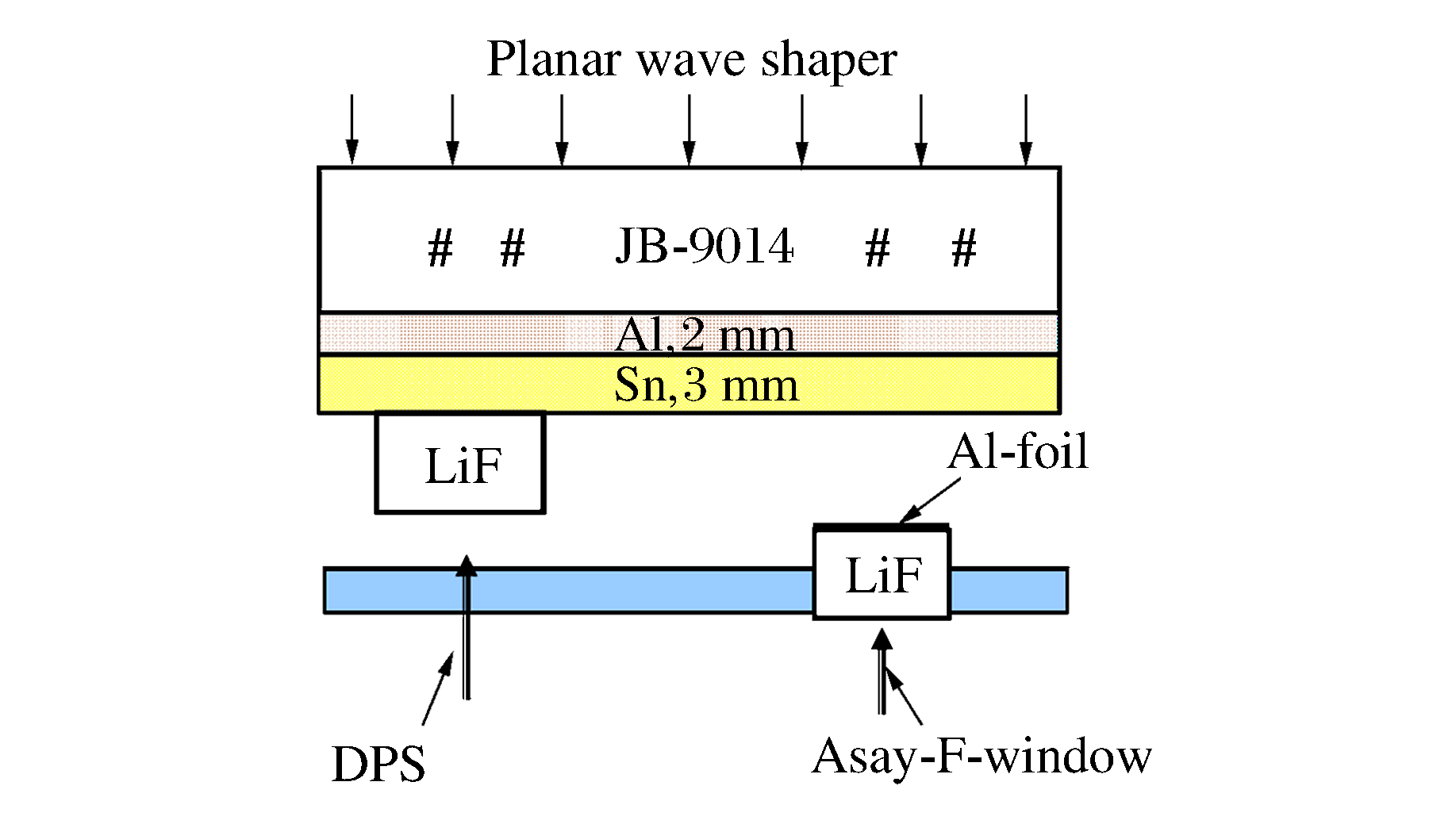

摘要: 强冲击熔化状态下,金属样品表面微喷射大幅增加,难以诊断。针对该问题,利用Asay-F窗技术,通过实验诊断,得到了熔化状态下不同表面加工状态锡样品表面微喷射物质的质量、密度、速度和空间分布等信息,分析了表面加工状态对表面喷射物质量及特征的影响。结果发现,对于熔化状态的金属样品,表面粗糙度仍是决定微喷射物质量大小、速度及空间分布的重要因素,且相关特征均呈现随表面粗糙度增大而增大的趋势。研究结果为认识熔化状态下材料的微喷特性及构建物理模型提供了重要数据。Abstract: It is a big challenge for measuring the rapidly-increasing ejecta from the melted metal sample under intense shock loading.In this work, we experimentally investigated the ejecta mass, density and velocity distributions on a melted Sn target by adopting the Asay-F-window technique, and focused on the influence of the surface machined states on the ejecta properties.Our results show that the surface perturbation plays a dominate role in the amount, velocity and spatial distribution of the ejected particles, and these quantities tend to increase with the increasing of the surface roughness when the Sn is melted on shock or release.Our research is expected to contribute a lot to better understanding the ejecta behavior and constructing the physical ejecta source model for melted metal upon shock or release.

-

Key words:

- Sn /

- ejecta /

- melting /

- surface preparation

-

表 1 t=4.0μs时刻微喷物质特征量:空间宽度、累计质量、密度范围和速度范围

Table 1. Ejecta quantities of interest at t=4.0μs:layer thickness, areal mass, volume density interval and velocity interval

Ra/(μm) Layer thickness/(mm) Areal mass/(g/m2) Volume density interval/(kg/m3) Velocity interval (ue/ufs) 0.2 0 0 0 1 0.8 3.0 260 0-1100 1.00-1.28 1.6 3.5 300 0-1200 1.00-1.35 3.2 4.6 380 0-1600 1.00-1.46 -

[1] ASAY J R, MIX L P, PERRY F C.Ejection of material from shocked surface[J].Appl Phys Lett, 1976, 29(5):284-287. doi: 10.1063/1.89066 [2] ASAY J R.Thick-plate technique for measuring ejecta from shocked surface[J].J Appl Phys, 1978, 49(12):6173-6175. doi: 10.1063/1.324545 [3] ASAY J R, BERTHOLF L D.A model for estimating the effects of surface roughness on mass ejection from shocked materials: SAND-78-1256[R].USA: Sandia National Laboratory, 1978. [4] ASAY J R.Materials ejection from shock-loaded free surfaces of aluminum and lead: SAND-76-0542[R].USA: Sandia National Laboratory, 1976. https://www.researchgate.net/publication/236493993_Material_ejection_from_shock-loaded_free_surfaces_of_aluminum_and_lead [5] ZELLNER M B, MCNEIL W V, HAMMERBERG J E, et al.Probing the underlying physics of ejecta production from shocked Sn samples[J].J Appl Phys, 2008, 103(12):123502. doi: 10.1063/1.2939253 [6] ZELLNER M B, MCNEIL W V, GRAY G T Ⅲ, et al.Surface preparation methods to enhance dynamic surface property measurements of shocked metal surfaces[J].J Appl Phys, 2008, 103(8):083521. doi: 10.1063/1.2906107 [7] ZELLNER M B, GROVER M, HAMMERBERG J E, et al.Effects of shock-breakout pressure on ejection of micron-scale material from shocked tin surfaces[J].J Appl Phys, 2007, 102(1):013522. doi: 10.1063/1.2752130 [8] VOGAN W S, ANDERSON W W, GROVER M, et al.Piezoelectric characterization of ejecta from shocked tin surfaces[J].J Appl Phys, 2005, 98(11):113508. doi: 10.1063/1.2132521 [9] BUTTLER W T, ZELLNER M B, OLSON R T, et al.Dynamic comparisons of piezoelectric ejecta diagnostics[J].J Appl Phys, 2007, 101(6):063547. doi: 10.1063/1.2712177 [10] BUTTLER W T, HIXSON R S, KING N S P, et al.Method to separate and determine the amount of ejecta produced in a second-shock material-fragmentation event[J].Appl Phys Lett, 2007, 90(15):151921. doi: 10.1063/1.2722676 [11] SORENSON D S, MINICH R W, ROMERO J L, et al.Ejecta particle size distributions for shock loaded Sn and Al metals[J].J Appl Phys, 2002, 92(10):5830-5836. doi: 10.1063/1.1515125 [12] 陈军, 经福谦, 张景琳, 等.冲击作用下金属表面微喷射的分子动力学模拟[J].物理学报, 2002, 51(10):2386-2392. http://d.old.wanfangdata.com.cn/Periodical/wlxb200210041CHEN J, JING F Q, ZHANG J L, et al.Molecular dynamics simulation of micro particle ejection from a shock-impacted metal surface[J].Acta Physica Sinica, 2002, 51(10):2386-2392. http://d.old.wanfangdata.com.cn/Periodical/wlxb200210041 [13] 王裴, 邵建立, 秦承森.加载波前沿宽度对铝表面微射流的影响[J].物理学报, 2009, 58(2):1064-1070. doi: 10.3321/j.issn:1000-3290.2009.02.061WANG P, SHAO J L, QIN C S.Effect of loading-wave-front width on micro-jet from aluminum surface[J].Acta Physica Sinica, 2009, 58(2):1064-1070. doi: 10.3321/j.issn:1000-3290.2009.02.061 [14] 王裴, 秦承森, 张树道, 等.SPH方法对金属表面微射流的数值模拟[J].高压物理学报, 2004, 18(2):149-156. doi: 10.3969/j.issn.1000-5773.2004.02.010WANG P, QIN C S, ZHANG S D, et al.Simulated microjet from free surface of aluminum using smoothed particle hydrodynamics[J].Chinese Journal of High Pressure Physics, 2004, 18(2):149-156. doi: 10.3969/j.issn.1000-5773.2004.02.010 [15] 叶雁, 汪伟, 李作友, 等.用高速摄影和脉冲同轴全息照相联合诊断微射流[J].高压物理学报, 2009, 23(6):471-475. doi: 10.3969/j.issn.1000-5773.2009.06.012YE Y, WANG W, LI Z Y, et al.High-speed photography and pulsed in-line holography diagnostics of microjet[J].Chinese Journal of High Pressure Physics, 2009, 23(6):471-475. doi: 10.3969/j.issn.1000-5773.2009.06.012 [16] 马云, 汪小松, 李欣竹, 等.ASAY膜法测量微物质喷射总质量不确定度的初步实验研究[J].高压物理学报, 2006, 20(2):207-210. doi: 10.3969/j.issn.1000-5773.2006.02.016MA Y, WANG X S, LI X Z, et al.Study of the uncertainty of the ejected mass measured by ASAY foil method[J].Chinese Journal of High Pressure Physics, 2006, 20(2):207-210. doi: 10.3969/j.issn.1000-5773.2006.02.016 [17] ZELLNER M B, BUTTLER W T.Exploring Richtmyer-Meshkov instability phenomena and ejecta cloud physics[J].Appl Phys Lett, 2008, 93(11):114102. doi: 10.1063/1.2982421 [18] 陈永涛, 任国武, 汤铁钢, 等.用于微层裂现象诊断的Asay-F窗技术[J].高压物理学报, 2013, 27(6):897-900. http://www.gywlxb.cn/CN/abstract/abstract1654.shtmlCHEN Y T, REN G W, TANG T G, et al.Asay-F-window applied to diagnostic of micro-spall phenomena[J].Chinese Journal of High Pressure Physics, 2013, 27(6):897-900. http://www.gywlxb.cn/CN/abstract/abstract1654.shtml [19] HOLTKAMP D B, CLARK D A, CRAIN M D, et al.Development of a non-radiographic spall and damage diagnostic[C]//FURNISH M D, GUPTA Y M, FORBES J W.Shock Compression of Condensed Matter-2003.New York: American Institute of Physics, 2003: 473-476. https://www.researchgate.net/publication/234927613_Development_of_a_Non-Radiographic_Spall_and_Damage_Diagnostic -

下载:

下载: