Evolution of the Mechanical Behavior of Pyrophyllite Gasket between Flat Anvils under Different Loading Pressures

-

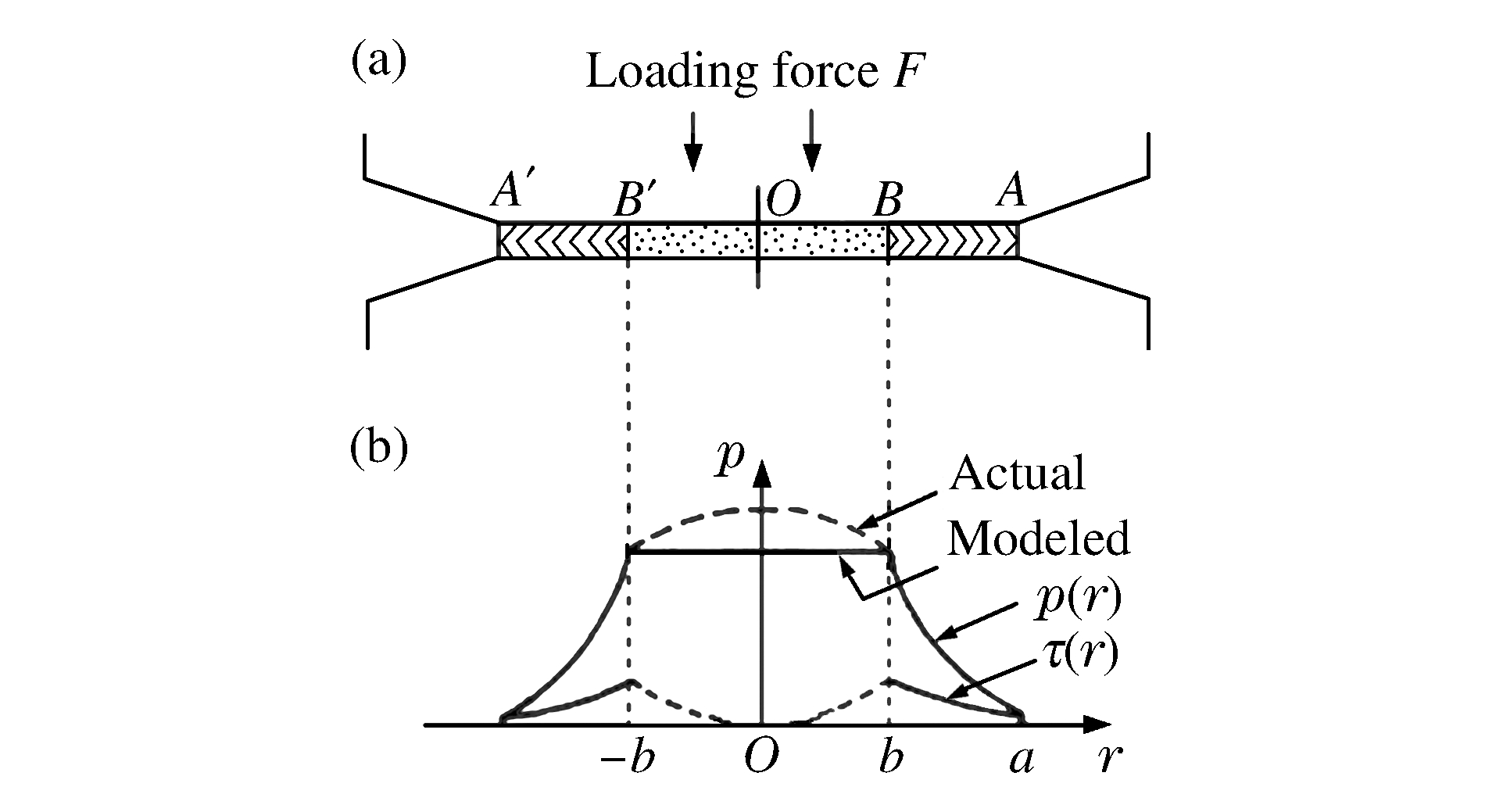

摘要: 以Wakatsuki提出的恒定加载压力下封垫的压缩模型为基础,采用直径20 mm的硬质合金平面对顶压砧,测量了不同外部加载压力下叶蜡石封垫的临界厚度、弹性区半径以及回弹率等数据;结合对中心压力的标定,以及对回收封垫的图像处理分析和相关计算,给出了封垫内弹性区和塑性区的压力分布随外加压力变化的规律,并估算了准静水压区范围。实验表明:平面对顶压砧间封垫塑性区内的剪切强度随压力提高而增加,中心的压力随外加压力的提高而增加,其增加的比率具有逐渐上升的特点。Abstract: On the basis of the compressible gasket model presented by Wakatsuki, we investigated the squeezing behavior of a pyrophyllite gasket using a Bridgman type high pressure apparatus with an anvil top diameter of 20 mm.A series of data including the critical thickness, the elastic region diameter, the compression spring-back rate etc., were measured under different loading forces.Combining with the pressure calibration at the center of the gasket, the image-analysis of recovered discs and related calculations, we described the evolution of the mechanical state and pressure distribution in the elastic and plastic regions of gasket along with the increase of the loading force, and then estimated the region of quasi-hydrostatic pressure in the gasket.The experimental results show that the increase rate of the center pressure with the loading force shows an upward trendency, which is a feature of the Bridgman anvils.

-

Key words:

- Bridgman anvil /

- pyrophyllite gasket /

- shearing strength /

- distribution of pressure

-

表 1 叶蜡石封垫的实验条件与结果

Table 1. Experimental conditions and results of pyrophyllite gaskets

Sample

No.Color p/(GPa) hc/(mm) h/(mm)

(hi>hc)hr/(mm)

(hi>hc)$\frac{\overline{h_{\mathrm{r}}}-\bar{h}}{\overline{h_{\mathrm{r}}}} /(\%)$ $\frac{h_{\mathrm{c}}}{2 a}$ A Red 1.44 1.67 1.33 1.59 16.35 0.08 B Red 1.44 1.92 1.36 1.82 25.27 0.10 C White 1.44 1.72 1.08 1.68 35.71 0.09 D White 0.72 1.90 1.24 1.79 30.73 0.10 E White 0.36 2.09 1.68 2.00 16.00 0.11 Note:p is the average pressure on the whole disc,and 2a is the diameter of the gasket, a=10 mm. 表 2 不同外加压力下叶蜡石圆片的测量和计算结果(初始厚度为1.2 mm)

Table 2. Measured and calculated results of pyrophyllite gaskets under different loading forces (hi=1.2 mm)

Sample p/(GPa) rn/(mm) $\overline{p_{\mathrm{e}}} /(\mathrm{GPa})$ n Δrn/(mm) $\frac{p_{n-1}+p_{n}}{2} /(\mathrm{GPa})$ Δpn/Δrn pc/(GPa) B1 0.36 10.0 0.36 0 0.85 B2 0.54 10.0 0.54 0 1.28 B3 0.71 10.0 0.71 0 1.70 B4 0.89 7.31 0.95 1 2.69 0.83 0.09 2.13 B5 1.07 7.05 1.25 2 1.48 1.04 0.27 2.55 B6 1.25 6.83 1.55 3 1.06 1.32 0.44 2.98 B7 1.44 6.23 1.96 4 0.94 1.68 0.46 3.45 Note: $\frac{p_{n-1}+p_{n}}{2}$ is the median pressure in the inner ring of the plastic area, and pc is the center pressure of calibrated experiment. -

[1] Bridgeman P W. Collected Experimental Papers(Seven Volumes)[M]. Cambridge, MA: Harvard University Press, 1964. [2] Wentorf R H Jr. Modern Very High Pressure Techniques[M]. London: Butterworths Press, 1962: 1-50, 163-180. [3] Hall H T. Ultra-high pressure apparatus[J]. Rev Sci Instrum, 1960, 31: 125-131. doi: 10.1063/1.1716907 [4] Wakatsuki M, Ichinose K, Aoki T. Notes on compressible gasket and Bridgman-anvil type high pressure apparatus[J]. Jpn J Appl Phys, 1972, 11: 578-590. doi: 10.1143/JJAP.11.578 [5] Hemley R J, Mao H K, Shen G Y, et al. X-ray imaging of stress and strain of diamond, iron, and tungsten at megabar pressures[J]. Science, 1997, 276: 1242-1245. doi: 10.1126/science.276.5316.1242 [6] Erements M I. High Pressure Experimental Methods[M]. New York: Oxford University Press, 1996: 18-48. [7] William A B. Diamnod anvil cell, 50th birthday[J]. High Pressure Research, 2009, 29: 163-186. doi: 10.1080/08957950802597239 [8] Macavei J, Schulz H. Beryllium gaskets suitable for pressures up to 10 GPa[J]. Rev Sci Instrum, 1990, 61: 2236-2238. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=5063710 [9] Zou G, Ma Y Z, Mao H K, et al. Application of diamond gasket on the XRD study at high pressure and high temperature[C]//Manghnani M H, Nellis W J, Nicol M F. Proceedings of AIRAPT 17. Honolulu, HI: Universities Press(India)Limited, 2000, 2: 1107-1108. [10] Lin J F, Shu J F, Mao H K, et al. Amorphous boron gasket in diamond anvil cell research[J]. Rev Sci Instrum, 2003, 74: 4732. doi: 10.1063/1.1621065 [11] He D W, Zhao Y S, Sheng T D, et al. Bulk metallic glass gasket for high pressure in situ X-ray diffraction[J]. Rev Sci Instrum, 2003, 74: 3012-3016. doi: 10.1063/1.1575926 [12] Zou G T, Ma Y Z, Mao H K, et al. A diamond gasket for the laser-heated diamond anvil cell[J]. Rev Sci Instrum, 2001, 72: 1298-1301. doi: 10.1063/1.1343864 [13] Vaisnys R J, Montgomery P W. Materials for ultrahigh pressure sealing in Bridgman anvil devices[J]. Rev Sci Instrum, 1964, 35: 985-989. doi: 10.1063/1.1718969 [14] Forsgren K F, Drickamer H G. Design variables for a high pressure cell with supported taper pistons[J]. Rev Sci Instrum, 1965, 36: 1709-1712. doi: 10.1063/1.1719446 [15] Bandyopadhyay A K, Chatterjee S, Gopal E S R, et al. Optimization of gasket thickness in a Bridgman anvil system[J]. Rev Sci Instrum, 1981, 52: 1232-1235. doi: 10.1063/1.1136746 [16] Chan K S, Huang T L, Grzybowski T A, et al. Pressure concentrations due to plastic deformation of thin films or gaskets between anvils[J]. J Appl Phys, 1982, 53: 6607-6612. doi: 10.1063/1.330091 [17] Dunstan D J. Theory of the gasket in diamond anvil high pressure cells[J]. Rev Sci Instrum, 1989, 60: 3789-3795. doi: 10.1063/1.1140442 [18] Kashigin E N. Gasket for sealing high pressure equipment[J]. Chem Petrol Eng, 1993, 29: 122-124. doi: 10.1007/BF01149361 [19] Polotnyak S B, Idesman A V. Numerical modeling of the mechanical state of deformable gaskets in diamond anvil cell[J]. J Mater Process Tech, 1996, 60: 685-690. doi: 10.1016/0924-0136(96)02405-3 [20] 聂崇礼, 陈琦.超高压装置中的封垫问题[J].高压物理学报, 1988, 2: 113-118. http://www.cnki.com.cn/Article/CJFDTotal-GYWL198802002.htmNie C L, Chen Q. Gasket problem in the ultra-high pressure apparatus[J]. Chinese Journal of High Pressure Physics, 1988, 2: 113-118. (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-GYWL198802002.htm [21] 陈丽英, 刘秀茹, 吴学华, 等.用Bridgman压砧研究我国几种叶蜡石的剪切强度[J].珠宝科技, 2004, 16: 6-10. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zbkj200404002Chen L Y, Liu X R, Wu X H, et al. Investigation of shear strength several Chines pyrophyllites by using Bridgman anvils[J]. Jewellery Science and Technology, 2004, 16: 6-10. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zbkj200404002 [22] 周开勇, 俞新陆.超高压封垫材料力学的测试技术[J].高压物理学报, 1990, 4(1): 7-16. http://www.cnki.com.cn/Article/CJFDTotal-GYWL199001001.htmZhou K Y, Yu X L. A mechanical test technique for super high pressure gasket material[J]. Chinese Journal of High Pressure Physics, 1990, 4(1): 7-16. (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-GYWL199001001.htm [23] Bean V E, Akimoto S, Bell P M, et al. Another step toward an international practical pressure scale: 2nd AIRATP IPPS task group report[J]. Physica, 1988, 139: 52-54. http://www.sciencedirect.com/science/article/pii/0378436386905218 [24] 陈丽英.快速大幅度增压法测量NaCl的Grüneisen参数[D].成都: 西南交通大学, 2005.Chen L Y. Measuring Grüneisen parameter of NaCl by double-quick and larger range compression[D]. Chengdu: Southwest Jiaotong University, 2005. (in Chinese) [25] 吕世杰, 罗建太, 苏磊, 等.滑块式六含八超高压实验装置及其压力温度标定[J].物理学报, 2009, 58: 6852-6857. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wlxb200910031Lü S J, Luo J T, Su L, et al. A slide-type multi-anvil ultrahigh pressure apparatus and calibrations of its pressure and temperature[J]. Acta Physica Sinica, 2009, 58: 6852-6857. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wlxb200910031 -

下载:

下载: