Effect of Material Particle Size on the Properties of Powder Liner

-

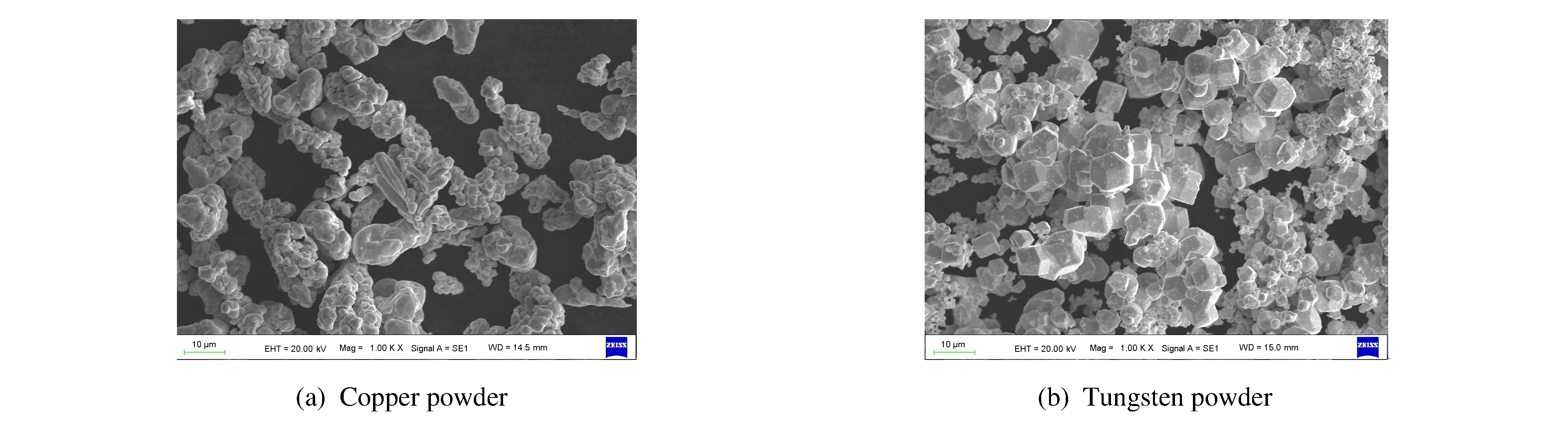

摘要: 为研究粉末材料的颗粒尺寸及其分布对粉末药型罩特性的影响,以W、Cu粉末为药型罩的主体材料,添加少量Bi粉以增加其流动性,在配比一定的条件下,通过改变各组分的颗粒尺寸,制备了3种药型罩。利用扫描电子显微镜,观察了W、Cu粉末的颗粒形貌,发现W粉的颗粒形状为规则的结晶体,而Cu粉颗粒的形状不规则。对3种药型罩进行了微观结构观察、密度测定、维氏硬度测定以及破甲威力实验。结果表明:在粉末材料特性和配比一定的条件下,减小颗粒尺寸可有效提高粉末药型罩的致密性、密度和破甲威力,但对维氏硬度的影响不明显。Abstract: In order to investigate the influence of particle size of powder material and its distribution on the properties of powder liner, W and Cu powders were chosen as the main material of shaped charge liner, and a bit of bismuth powder was added to increase the liquidity of the mixed powders.The particle properties of the W and Cu powders were studied by means of scanning electron microscopy.It showed that the W powder was regular, while the Cu powder was irregular.In the condition of material mixture ratio being certain, three sets of liners were developed through changing the particle size of each component, and their microstructure, density, Vickers hardness and penetration power were studied.The results show that reducing the particle size can effectively improve the compactness, density and penetration power of powder liner when the powder material properties and proportion are unchanged, but it has no significant effect on the Vickers hardness of powder liner.

-

Key words:

- powder material /

- particle size /

- liner /

- penetration power

-

表 1 常见粉末药型罩材料的基本特性

Table 1. Basic characteristics of common powder liner material

Material Tm/(℃) ρ/(g/cm3) Crystal structure Cu 1 083 8.9 Face-centered cubic W 3 400 19.3 Body-centered cubic Mo 2 600 10.2 Body-centered cubic Bi 270 9.8 Hexagonal system Sn 230 7.3 Body-centered cubic Ta 3 010 16.6 Body-centered cubic 表 2 3种粉末药型罩的颗粒度组成

Table 2. Particle size composition of three types of powder liners

Liner Particle size W Cu Bi 1# Small Small Moderate 2# Small Moderate Moderate 3# Moderate Moderate Large 表 3 药型罩密度

Table 3. Densities of the liners

Liner Density/(g/cm3) Average density/(g/cm3) No.1 No.2 No.3 1# 12.30 12.38 12.34 12.34 2# 12.25 12.20 12.18 12.21 3# 11.98 12.15 12.08 12.07 Spinning copper liner 8.91 8.90 8.89 8.90 表 4 药型罩的维氏硬度

Table 4. Vickers hardness of the liners

Liner Vickers hardness/(MPa) Average hardness/(MPa) No.1 No.2 No.3 1# 288.89 302.82 296.26 295.99 2# 308.75 297.86 287.19 297.93 3# 297.86 312.82 333.38 314.68 Spinning copper liner 288.26 292.07 284.93 288.42 表 5 实验结果

Table 5. Experimental results

Liner Serial No. Entry hole size Penetration depth/(mm) Average penetration

depth/(mm)1# 1 Ø20 mm 130 128.6 2 20 mm×22 mm 125 3 Ø22 mm 128 4 Ø20 mm 132 5 Ø19 mm 128 2# 1 Ø23 mm 128 118.4 2 Ø22 mm 121 3 23 mm×22 mm 115 4 Ø20 mm 118 5 Ø25 mm 110 3# 1 23 mm×21 mm 113 111.0 2 Ø22 mm 118 3 Ø25 mm 112 4 Ø23 mm 105 5 Ø23 mm 107 Spinning copper liner Ø20 mm 100.0 -

[1] Azharonok V V, Krat'ko L E, Goncharik S V, et al. Character of the fast jet efflux upon detonation of shaped charges[J]. J Eng Phys Thermophys, 2008, 81(3): 494-498. doi: 10.1007/s10891-008-0059-7 [2] 郁锐, 李福金, 薛鑫莹, 等.药型罩壁厚变化率对破甲威力影响的研究[J].弹箭与制导学报, 2010, 30(1): 134-136. http://www.cqvip.com/Main/Detail.aspx?id=33007927Yu R, Li F J, Xue X Y, et al. Study on the influence of rate of liner thickness change on the penetration[J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2010, 30(1): 134-136. (in Chinese) http://www.cqvip.com/Main/Detail.aspx?id=33007927 [3] Zygmunt B, Wilk Z. Formation of jets by shaped charges with metal powder liners[J]. Propell Explos Pyrot, 2008, 33(6): 482-487. doi: 10.1002/prep.200800015 [4] Jackowski A, Wodarczyk E. The influence of repressing liners made from sintered copper on jet formation[J]. J Mater Process Technol, 2006, 171(1): 21-26. http://www.sciencedirect.com/science/article/pii/S0924013605006552 [5] Zhang X, Wu C, Huang F. Penetration of shaped charge jets with tungsten-copper and copper liners at the same explosive-to-liner mass ratio into water[J]. Shock Waves, 2010, 20(3): 263-267. doi: 10.1007/s00193-010-0248-0 [6] 景青波, 景振禹, 石健.粉末药型罩金属粒度级配及热处理对聚能射流性能的影响[J].火炸药学报, 2008, 31(1): 42-44. http://www.cqvip.com/Main/Detail.aspx?id=27636324Jing Q B, Jing Z Y, Shi J. The influence of metal particles arrangement of powder shaped charge liner and its thermal treatment on performance of jet[J]. Chinese Journal of Explosives and Propellants, 2008, 31(1): 42-44. (in Chinese) http://www.cqvip.com/Main/Detail.aspx?id=27636324 [7] Olsson M, Bexell U. Friction characteristics and material transfer tendency in metal powder compaction[J]. Wear, 2011, 271(9/10): 1903-1908. http://www.sciencedirect.com/science/article/pii/S0043164811001372 [8] 甘卫平, 陈招科, 杨伏良.粉末粒度对高硅铝合金显微组织及性能的影响[J].中国有色金属学报, 2005, 15(5): 721-726. http://www.cnki.com.cn/Article/CJFDTotal-ZYXZ200505010.htmGan W P, Chen Z K, Yang F L. Effect of particle size on microstructure and properties of high-silicon aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 721-726. (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-ZYXZ200505010.htm [9] Piotter V, Zeep B, Norajitra P, et al. Development of a powder metallurgy process for tungsten components[J]. Fusion Eng Des, 2008, 83(10/11/12): 1517-1520. http://www.sciencedirect.com/science/article/pii/S0920379608001415 [10] Bier W, Dariel M P, Frage N, et al. Die compaction of copper powder designed for material parameter identification[J]. Int J Mech Sci, 2007, 49(6): 766-777. doi: 10.1016/j.ijmecsci.2006.09.026 -

下载:

下载: