Research on the Explosibility of Gaseous Epoxypropane-Aluminum Dust-Air Hybrid Mixtures

-

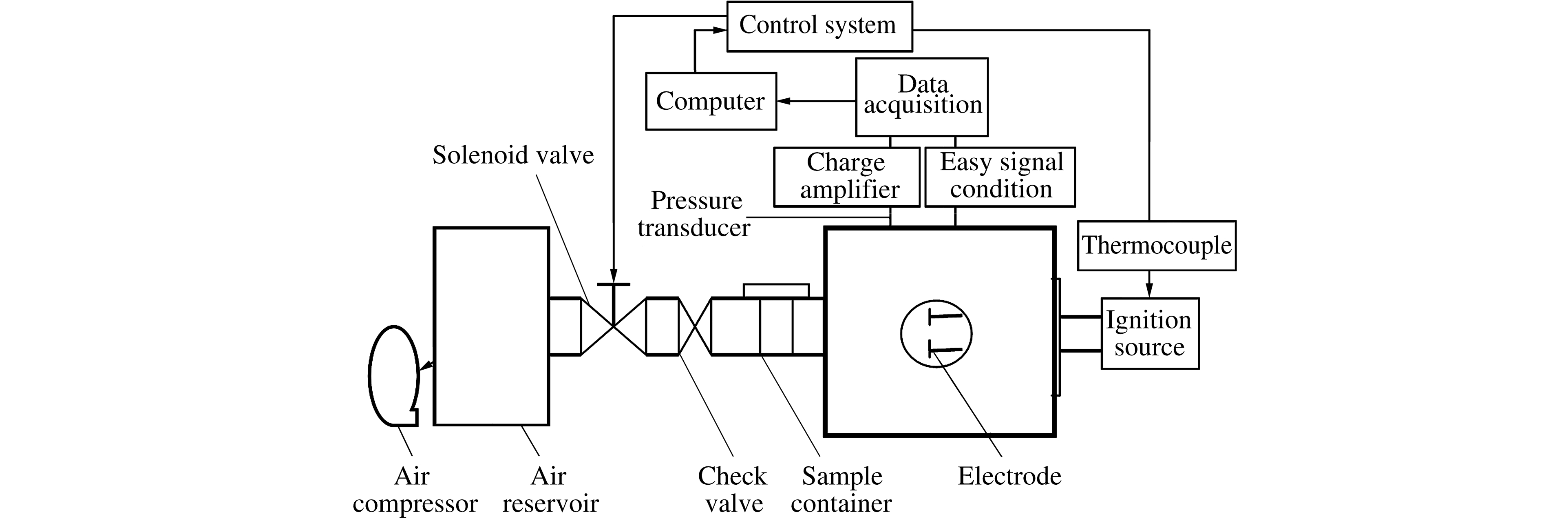

摘要: 为了评估环氧丙烷蒸气-铝粉-空气杂混合物的爆炸危险性,在5 L圆柱形爆炸装置中分别对铝粉、环氧丙烷蒸气及铝粉与环氧丙烷蒸气共存条件下的杂混合物进行了爆炸浓度下限的实验研究。结果表明:环氧丙烷蒸气可使杂混合物的爆炸下限浓度降低;杂混合物的最大爆炸压力上升速率由于环氧丙烷蒸气的存在而增强;当铝粉浓度较低时,环氧丙烷蒸气的加入使最大爆炸压力明显增加,之后随着铝粉浓度的增加,最大爆炸压力反而减小。Abstract: To evaluate the hazard of combined gaseous epoxypropane-aluminum dust explosions, a 5 L spherical exploding device was used to measure the lower limit of explosion densities of aluminum dust in aluminum dust-air mixtures and gaseous epoxypropane-aluminum dust-air hybrid mixtures, and gaseous epoxypropane in gaseous epoxypropane-air mixtures.The results show that the existence of gas epoxypropane can reduce the lower limit of explosion density of the hybrid mixtures, and enlarge the rate of pressure rise of the hybrid mixtures; at low aluminum dust concentration, the maximum overpressures rise due to the existence of gaseous epoxypropane, and then fall with increasing aluminum dust concentration.

-

表 1 不同点火延迟时间下不同浓度铝粉-空气混合物的爆炸参数

Table 1. Explosion parameters of aluminium dust-air mixtures at different ignition delay time

CAl/(g/m3) td/(ms) pmax/(MPa) (dp/dt)max/(MPa/s) 500 60 0.851 47.8 500 60 0.766 51.9 500 60 0.817 62.8 500 70 0.715 25.3 500 70 0.670 36.0 500 70 0.813 48.5 500 50 0.772 50.3 500 50 0.762 40.1 500 50 0.758 57.6 500 40 0.794 55.2 500 40 0.722 39.4 500 40 0.701 54.9 310 80 0.434 7.5 310 80 0.377 12.1 310 80 0.484 8.5 310 70 0.500 16.0 310 70 0.528 15.5 310 70 0.546 15.2 310 60 0.670 22.5 310 60 0.637 18.8 310 60 0.694 24.0 310 50 0.601 19.0 310 50 0.511 18.3 310 50 0.624 16.1 200 60 ─ ─ 200 60 ─ ─ 200 60 ─ ─ 200 60 0.413 6.6 200 60 ─ ─ 200 60 0.270 2.1 200 60 ─ ─ 200 60 ─ ─ 200 60 0.382 3.4 200 20 ─ ─ 200 20 ─ ─ 200 20 ─ ─ 200 20 ─ ─ 200 20 ─ ─ 200 20 0.607 17.7 200 20 ─ ─ 200 20 ─ ─ 200 20 0.546 11.0 200 20 ─ ─ 200 20 ─ ─ 200 20 ─ ─ 200 20 ─ ─ 200 20 0.570 18.6 200 30 ─ ─ 200 30 ─ ─ 200 30 ─ ─ 200 30 0.605 12.3 200 30 0.451 5.0 200 30 ─ ─ 200 30 ─ ─ 200 30 0.432 21.4 200 40 ─ ─ 200 40 ─ ─ 200 40 ─ ─ 200 40 0.444 6.8 200 40 ─ ─ 200 40 ─ ─ 200 40 ─ ─ 200 40 ─ ─ 200 40 ─ ─ 200 40 0.590 8.9 200 40 ─ ─ 200 40 ─ ─ 200 40 ─ ─ 200 40 0.486 5.9 150 20 ─ ─ 150 20 ─ ─ 150 30 ─ ─ 150 30 ─ ─ 150 60 ─ ─ 150 60 ─ ─ 150 40 ─ ─ 150 40 ─ ─ Note:“─” denotes that the mixture in the vessel was not initiated in the experiment. 表 2 环氧丙烷蒸气-空气混合物的爆炸参数

Table 2. Explosion parameters of gaseous epoxypropane-air mixtures

φPO/(%) pmax/(MPa) (dp/dt)max/(MPa/s) 2.8 0.320 13.20 2.8 0.227 3.51 2.8 0.234 3.93 2.8 0.290 9.13 2.1 0.240 4.08 2.1 0.221 4.93 2.1 0.258 4.62 1.4 ─ ─ 1.4 ─ ─ 1.4 ─ ─ 1.4 ─ ─ 1.4 ─ ─ 1.4 ─ ─ 1.4 ─ ─ Note:“─” denotes that the mixture in the vessel was not initiated in the experiment. 表 3 环氧丙烷的体积分数为1.4%时环氧丙烷蒸气-铝粉-空气杂混合物的爆炸参数

Table 3. Explosion parameters of gaseous epoxypropane-aluminum dust-air hybrid mixtures with a volume fraction of gaseous epoxypropane of 1.4%

CAl/(g/m3) td/(ms) pmax/(MPa) (dp/dt)max/(MPa/s) 500 60 0.685 72.3 500 60 0.694 85.9 500 60 0.707 68.8 310 60 0.645 40.7 310 60 0.716 50.4 310 60 0.674 37.2 200 20 0.748 131.0 200 20 0.749 102.6 200 20 0.721 74.2 100 20 0.484 14.2 100 20 0.485 11.4 100 20 0.528 37.0 80 20 0.345 11.4 80 20 0.417 8.5 80 20 0.445 12.3 60 20 0.203 4.3 60 20 0.403 11.1 60 20 0.435 16.2 50 20 ─ ─ 50 20 ─ ─ 50 20 ─ ─ 50 20 ─ ─ 50 20 0.218 4.2 30 20 ─ ─ 30 20 ─ ─ 30 20 ─ ─ 30 20 ─ ─ 30 20 ─ ─ 30 20 ─ ─ 30 20 0.035 2.3 25 20 ─ ─ 25 20 ─ ─ 25 20 ─ ─ 25 20 ─ ─ 25 20 ─ ─ 25 20 ─ ─ 25 20 ─ ─ Note:“─” denotes that the mixture in the vessel was not initiated in the experiment. -

[1] Britton L G. Avoiding Static Ignition Hazards in Chemical Operations[M]. New York, USA: Center for Chemical Process Safety/AIChE, 1999: 172. [2] Dufaud O, Perrin L, Traore M, et al. Explosions of vapour/dust hybrid mixtures: A particular class[J]. Powder Technol, 2009, 190(1/2): 269-273. http://www.sciencedirect.com/science/article/pii/S0032591008002301 [3] Cashdollar K L, Sapko M J, Weiss E S, et al. Laboratory and mine dust explosion research at the Bureau of Mines[C]//Cashdollar K L, Hertzberg M. Industrial Dust Explosions: Symposium on Industrial Dust Explosions. West Conshohocken, USA: ASTM International, 1987: 107-123. [4] Cashdollar K L. Coal dust explosibility[J]. J Loss Prev Process Ind, 1996, 9(1): 65-76. doi: 10.1016/0950-4230(95)00050-X [5] Chatrathi K. Dust and hybrid explosibility in a 1 m3 spherical chamber[J]. Process Saf Prog, 1994, 13(4): 183-189. doi: 10.1002/prs.680130403 [6] Pilão R, Ramalho E, Pinho C. Explosibility of cork dust in methane/air mixtures[J]. J Loss Prev Process Ind, 2006, 19(1): 17-23. doi: 10.1016/j.jlp.2005.05.001 [7] Denkevits A. Explosibility of hydrogen-graphite dust hybrid mixtures[J]. J Loss Prev Process Ind, 2007, 20: 698-707. doi: 10.1016/j.jlp.2007.04.033 [8] Foniok R. Hybrid dispersive mixtures and inertized mixtures of coal dust: Explosiveness and ignitability[J]. Staub Reinhalt Luft, 1985, 45(4): 151-154. http://www.researchgate.net/publication/283749099_EXPLOSIVENESS_AND_IGNITABILITY [9] Liu Y, Sun J, Chen D. Flame propagation in hybrid mixture of coal dust and methane[J]. J Loss Prev Process Ind, 2007, 20(4/5/6): 691-697. http://www.sciencedirect.com/science/article/pii/S0950423007000629 [10] 司荣军, 王春秋.瓦斯对煤尘爆炸特性影响的实验研究[J].中国安全科学学报, 2006, 16(12): 86-91. http://d.wanfangdata.com.cn/Periodical/zgaqkxxb200612016Si R J, Wang C Q. Experimental research on the influence of gas on the character of coal dust explosion[J]. China Safety Science Journal, 2006, 16(12): 86-91. (in Chinese) http://d.wanfangdata.com.cn/Periodical/zgaqkxxb200612016 [11] Garcia-Agreda A, Di Benedetto A, Russo P, et al. Dust/gas mixtures explosion regimes[J]. Powder Technol, 2011, 205(1/2/3): 81-86. http://www.sciencedirect.com/science/article/pii/S0032591010004705 [12] Nifuku M, Tsujita H, Fujino K, et al. Ignitability assessment of shredder dusts of refrigerator and the prevention of the dust explosion[J]. J Loss Prev Process Ind, 2006, 19(2/3): 181-186. http://www.sciencedirect.com/science/article/pii/S0950423005000471 [13] Dufaud O, Perrin L, Traoré M. Dust/vapour explosions: Hybrid behaviours?[J]. J Loss Prev Process Ind, 2008, 21(4): 481-484. doi: 10.1016/j.jlp.2007.11.005 [14] Zhang Q, Li W, Lin D C, et al. Influence of nitromethane concentration on ignition energy and explosion parameters in gaseous[J]. J Hazard Mater, 2011, 185(2/3): 756-762. http://www.ncbi.nlm.nih.gov/pubmed/20965653 [15] 谭汝媚, 张奇, 黄莹.环境湿度对环氧丙烷蒸气爆炸参数的影响[J].高压物理学报, 2013, 27(3): 325-330. http://www.cnki.com.cn/Article/CJFDTotal-GYWL201303002.htmTan R M, Zhang Q, Huang Y. Ambient humidity influence on explosion characteristics parameters of gaseous epoxypropane[J]. Chinese Journal of High Pressure Physics, 2013, 27(3): 325-330. (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-GYWL201303002.htm [16] Liu Q M, Li X D, Bai C H. Deflagration to detonation transition in aluminum dust-air mixture under weak ignition condition[J]. Combust Flame, 2009, 156(4): 914-921. doi: 10.1016/j.combustflame.2008.10.025 [17] 汪佩兰, 王海福, 李盛, 等.含能材料粉尘爆炸压力和压力上升速率的研究[J].兵工学报, 1995(3): 59-63. http://www.cqvip.com/Main/Detail.aspx?id=1697930Wang P L, Wang H F, Li S, et al. A study on the pressure and rate of pressure rise in energetic material dusts[J]. Acta Armamentarii, 1995(3): 59-63. (in Chinese) http://www.cqvip.com/Main/Detail.aspx?id=1697930 [18] Zhang Q, Tan R, Huang Y, et al. Effects of humidity on minimum ignition energy of gaseous epoxypropane/air mixtures[J]. J Loss Prev Process Ind, 2012, 25(6): 982-988. doi: 10.1016/j.jlp.2012.05.013 [19] Dufaud O, Traoré M, Perrin L, et al. Experimental investigation and modelling of aluminum dusts explosions in the 20 L sphere[J]. J Loss Prev Process Ind, 2010, 23(2): 226-236. doi: 10.1016/j.jlp.2009.07.019 -

下载:

下载: