Numerical Simulation of Double-Sided Explosive Welding

-

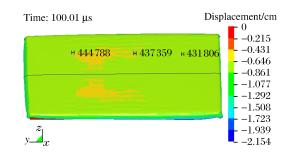

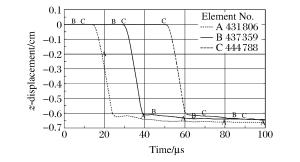

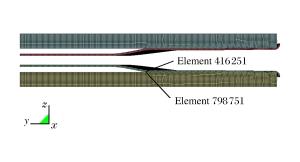

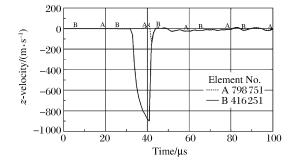

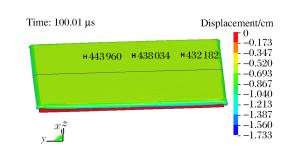

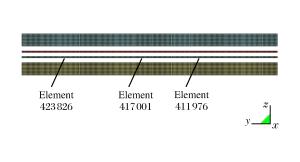

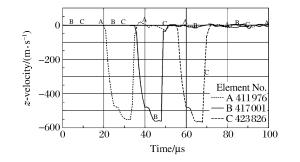

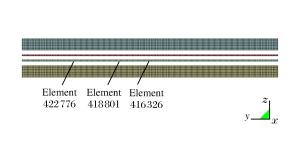

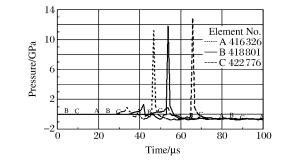

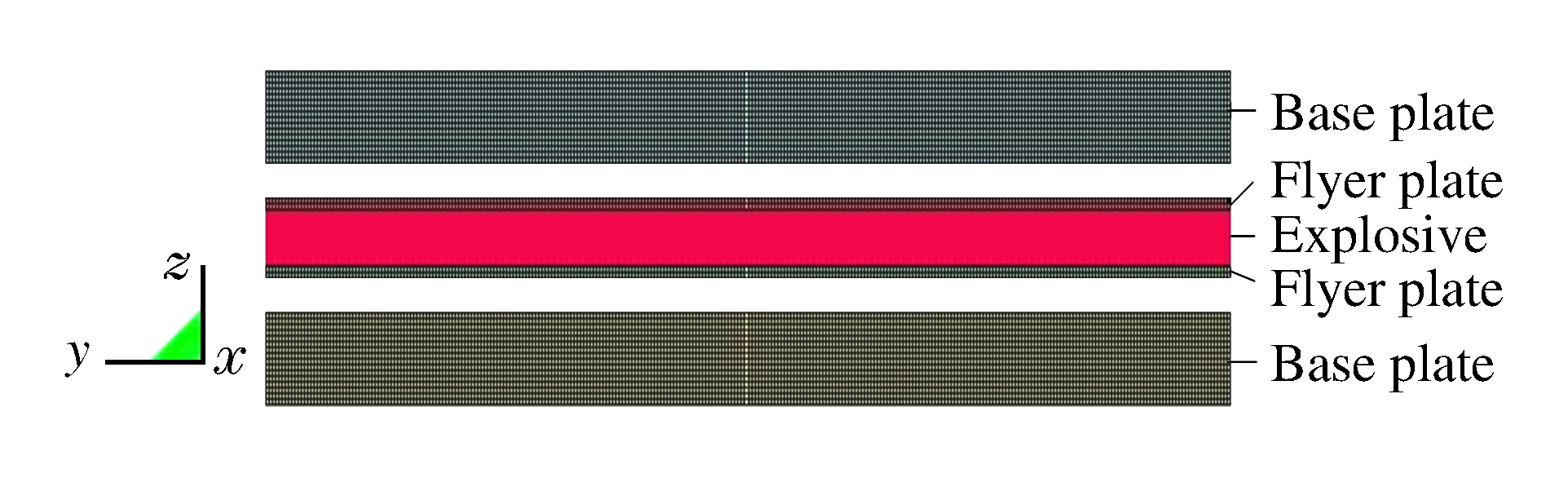

摘要: 双面爆炸焊接一次起爆可同时焊接两组复合板,而且使炸药临界厚度显著降低,提高了炸药的能量利用率,解决了爆炸焊接现存的高噪低效问题。借助ANSYS/LS-DYNA动力学分析软件,运用光滑粒子流体动力学方法(SPH)与有限元(FEM)耦合算法,对双面爆炸焊接进行了三维数值模拟,并将模拟结果与实验结果和理论计算结果进行了对比。结果表明,数值模拟结果与实验结果较吻合,且与Deribas的理论计算结果一致性较好,说明Deribas公式和SPH-FEM耦合方法对双面爆炸焊接具有较好的指导意义。Abstract: The high noise and low efficiency of explosive welding can be improved by the double-sided explosive welding which can clad two composite plates simultaneously and significantly reduce the critical thickness of stable detonation of explosives.In this study, we simulated the double-sided explosive welding using the explicit finite element program LS-DYNA combined with the SPH (Smoothed Particle Hydrodynamics) and FEM (Finite Element Method) coupling, and compared the simulation results with the experiment and the calculation results.The results showed that the simulation results were in good agreement with the experiment results as well as the theoretical calculation results of Deribas's.It shows that the Deribas's formula and SPH-FEM coupling method can provide theoretical guidance for the engineering application of double-sided explosive welding.

-

表 1 计算模型中材料的相关参数

Table 1. Related parameters of materials in calculation models

Calculationmodel Flyer plate Base plate Gap

δ/mmSize of explosive/(mm×mm×mm) Material Size/(mm×mm×mm) Material Size/(mm×mm×mm) Ⅰ 45 steel 300×150×2 Q235 300×150×16 6 300×150×10 Ⅱ 45 steel 300×150×2 Q235 300×150×16 6 300×150×5 ρ/(g·cm-3) D/(m·s-1) AJWL/GPa BJWL/GPa R1 R2 ω E0/(kJ·cm-3) 1.12 4 510 326.42 5.808 9 5.80 1.56 0.57 3.323 ρ/(g·cm-3) G/GPa A/GPa B/GPa C n m Tm/K Tr/K 7.83 77 0.792 0.51 0.014 0.26 1.03 1 793 294 表 4 10 mm药厚下碰撞速度理论计算结果与数值模拟结果的比较

Table 4. Comparison of collision velocity between theoretical calculation and numerical simulation with explosive thickness of 10 mm

Theoreticalformula Massfraction Collision velocity/(m·s-1) Error/% Theoretical calculation[18] Simulation Gurney 0.75 1 089 897 -21.0 Aziz 0.75 711 897 20.0 Deribas 0.75 853 897 4.9 表 5 5 mm药厚下碰撞速度理论计算结果与数值模拟结果的比较

Table 5. Comparison of collision velocity between theoretical calculation and numerical simulation with explosive thickness of 5 mm

Theoreticalformula Massfraction Collision velocity/(m·s-1) Error/% Theoretical calculation[18] Simulation Gurney 0.45 863 565 -52.7 Aziz 0.45 480 565 15.0 Deribas 0.45 576 565 -1.9 表 6 10 mm药厚下碰撞压力理论计算结果与数值模拟结果的比较

Table 6. Comparison of collision pressure betweentheoretical calculation and numerical simulationwith explosive thickness of 10 mm

Theoreticalformula Collision pressure/GPa Error/% Calculation Simulation Gurney 22.08 17.08 -29.3 Aziz 14.42 17.08 15.6 Deribas 17.30 17.08 -1.3 表 7 5 mm药厚下碰撞压力理论计算结果与数值模拟结果的比较

Table 7. Comparison of collision pressure betweentheoretical calculation and numerical simulationwith explosive thickness of 5 mm

Theoreticalformula Collision pressure/GPa Error/% Calculation Simulation Gurney 17.50 11.25 -55.6 Aziz 9.73 11.25 13.5 Deribas 11.68 11.25 -3.8 -

[1] JOHNSON G R, PETERSON E H, STRYK R A.Incorporation of an SPH option into the EPIC code for a wide range of high velocity impact computations[J].International Journal of Impact Engineering, 1993, 14(1/2/3/4):385-394. http://www.sciencedirect.com/science/article/pii/0734743X93900367 [2] JOHNSON G R, STRYK R A, BEISSEL S R, et al.An algorithm to automatically convert distorted finite elements into meshless particle during dynamics deformation[J].International Journal of Impact Engineering, 2002, 27(10):997-1013. doi: 10.1016/S0734-743X(02)00030-1 [3] ATTAWAY S W, HEINSTEIN M, SWEGLE J.Coupling of smoothed particle hydrodynamics with the finite element method[J].Nuclear Engineering and Design, 1994, 150(2/3):199-205. http://www.sciencedirect.com/science/article/pii/0029549394901368 [4] TANAKA K. Numerical studies on the explosive welding by smoothed particle hydrodynamis[C]. Materials Science Forum, 2007, 566: 61-64. http://meetings.aps.org/link/BAPS.2007.SHOCK.V2.7 [5] 李晓杰, 莫非, 闫鸿浩, 等.爆炸焊接界面波的数值模拟[J].爆炸与冲击, 2011, 31(6):653-657. http://www.oalib.com/paper/4137328LI X J, MO F, YAN H H, et al.Numerical simulation of interface waves in steel explosive welding[J].Explosion and Shock Waves, 2011, 31(6):653-657. http://www.oalib.com/paper/4137328 [6] 张登霞, 李国豪.低碳钢爆炸焊接界面波与板材无量纲强度关系的试验研究[J].爆炸与冲击, 1983, 3(2):23-29. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-SPDE201210003054.htmZHANG D X, LI G H.An experimental relation between interface wave form of explosion welding mild steel and material[J].Explosion and Shock Waves, 1983, 3(2):23-29. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-SPDE201210003054.htm [7] 张登霞, 李国豪, 周之洪, 等.材料强度在爆炸焊接界面波形成过程中的作用[J].力学学报, 1984, 16(1):73-80. http://www.irgrid.ac.cn/handle/1471x/4082ZHANG D X, LI G H, ZHOU Z H, et al.Effect of material strength on forming process of explosive welding interface wave[J].Chinese Journal of Theoretical and Applied Mechanics, 1984, 16(1):73-80. http://www.irgrid.ac.cn/handle/1471x/4082 [8] 刘江, 郑远远, 沈宗宝.基于SPH方法的爆炸焊接过程模拟[J].焊接技术, 2013, 42(12):17-20. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hanjiejs201312005LIU J, ZHENG Y Y, SHEN Z B.Simulation of explosive welding process by using of the SPH[J].Welding Technology, 2013, 42(12):17-20. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hanjiejs201312005 [9] 缪广红, 马宏昊, 沈兆武, 等.蜂窝结构炸药及其应用[J].含能材料, 2014, 22(5):693-697. http://www.cnki.com.cn/Article/CJFDTotal-HNCL201405025.htmMIAO G H, MA H H, SHEN Z W, et al.Explosives with structure of honeycomb and its application[J].Chinese Journal of Energetic Materials, 2014, 22(5):693-697. http://www.cnki.com.cn/Article/CJFDTotal-HNCL201405025.htm [10] 章冠人, 陈大年.凝聚炸药起爆动力学[M].北京:国防工业出版社, 1991. [11] 肖定军, 郭学彬, 蒲传金.单孔护壁爆破数值模拟[J].化工矿物与加工, 2008(7):22-24. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgkwyjg200807007XIAO D J, GUO X B, PU C J.Numerical simulation for single hole-unilateral blasting[J].Industrial Minerals & Processing, 2008(7):22-24. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgkwyjg200807007 [12] 李裕春, 时党勇, 赵远.ANSYS11.0/LS-DYNA基础理论与工程实践[M].北京:中国水利水电出版社, 2008. [13] 宋锦泉. 乳化炸药爆轰特性研究[D]. 北京: 北京科技大学, 2000.SONG J Q. Research on detonation characteristics of emulsion explosives[D]. Beijing: University of Science and Technology Beijing, 2000. [14] LIU G R, LIU M B. 光滑粒子流体动力学——一种无网格粒子法[M]. 韩旭, 译. 长沙: 湖南大学出版社, 2005. [15] 程国强, 李守新.金属材料在高应变率下的热粘塑性本构模型[J].弹道学报, 2004, 11(6):18-22. https://www.wenkuxiazai.com/doc/3935ac1dfad6195f312ba6c0.htmlCHENG G Q, LI S X.A thermo-viscoplastic constitutive model of metallic materials at high strain rates[J].Journal of Ballistics, 2004, 11(6):18-22. https://www.wenkuxiazai.com/doc/3935ac1dfad6195f312ba6c0.html [16] 时党勇, 李裕春, 张胜民.基于ANSYS/LS-DYNA8.1进行显示动力学分析[M].北京:清华大学出版社报, 2005. [17] 缪广红, 李亮, 江向阳, 等.爆炸复合界面波形变化的数值模拟研究[J].煤矿爆破, 2017(3):1-4. http://cdmd.cnki.com.cn/Article/CDMD-10141-2005070793.htmMIAO G H, LI L, JIANG X Y, et al.Numerical simulation on interface waves variation in explosive welding[J].Coal Mine Blasting, 2017(3):1-4. http://cdmd.cnki.com.cn/Article/CDMD-10141-2005070793.htm [18] 缪广红, 王章文, 周任俊, 等.双面爆炸复合理论计算与实验结果的对比研究[J].爆破, 2017, 34(2):117-120. https://www.doc88.com/p-4377429453267.htmlMIAO G H, WANG Z W, ZHOU R J, et al.Comparative study on theoretical calculation and experimental results of double-sided explosive cladding[J].Blasting, 2017, 34(2):117-120. https://www.doc88.com/p-4377429453267.html -

下载:

下载: