Prediction Model of Maximum Displacement for RC Slabsunder Blast Load Based on Machine Learning

-

摘要: 钢筋混凝土(reinforced concrete,RC)板作为工程结构的主要受力构件,在遭受意外爆炸或恐怖袭击时极易发生破坏,甚至引起结构的整体倒塌,因此,了解和预测混凝土板在爆炸作用下的动力响应,对增强工程结构的抗爆防护能力、减轻生命和财产经济损失具有非常重要的意义。收集整理了国内外文献中普通RC板爆炸试验和基于试验进行参数化分析的数值模拟数据,采用机器学习回归算法中的支持向量机和高斯过程回归两种算法等对近场爆炸作用下RC板的最大位移进行预测;运用改进的偏差-方差分解原理对模型的泛化性能进行分析,同时将机器学习模型与现有的预测方法进行对比;最后,采用置换特征重要性和Sobol全局敏感性分析方法,从局部和整体对模型特征进行解释,增加模型的可靠性。结果表明:支持向量机和高斯过程回归两种机器学习方法的泛化性能都较好,并且高斯过程回归算法的预测效果优于支持向量机算法。对比现有预测方法发现,机器学习方法更优,具有较高的预测精度和计算效率,且得出了不同输入参数对模型输出结果的影响,实现了对输出结果的可解释性,进一步验证了其可靠性。研究结果可为机器学习在爆炸领域的应用提供参考。

-

关键词:

- 机器学习 /

- 钢筋混凝土板 /

- 爆炸荷载 /

- Sobol全局敏感性分析 /

- 偏差-方差分解

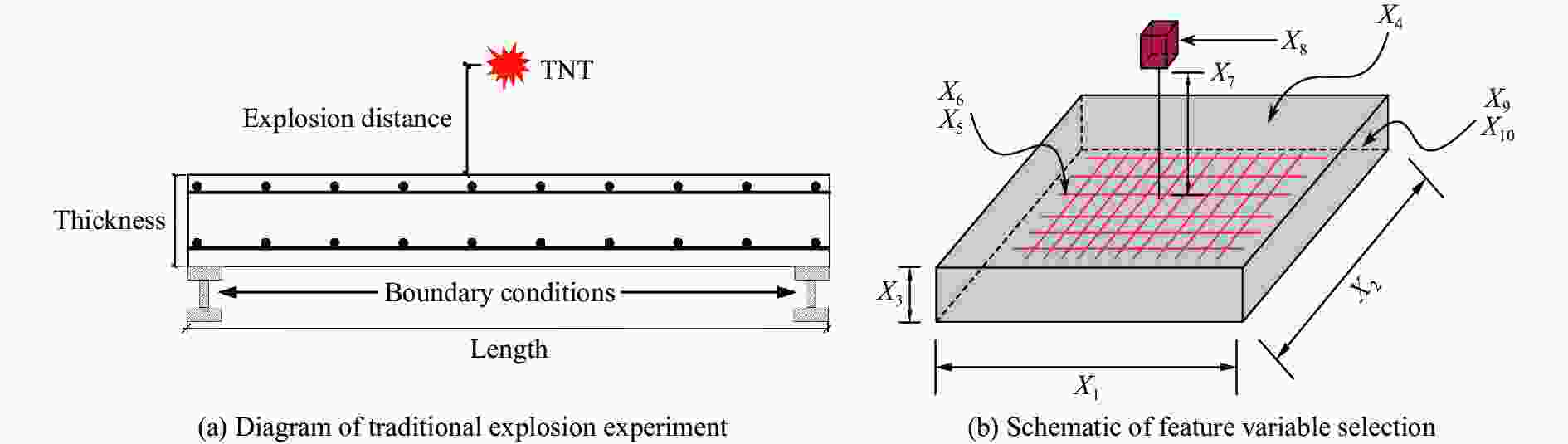

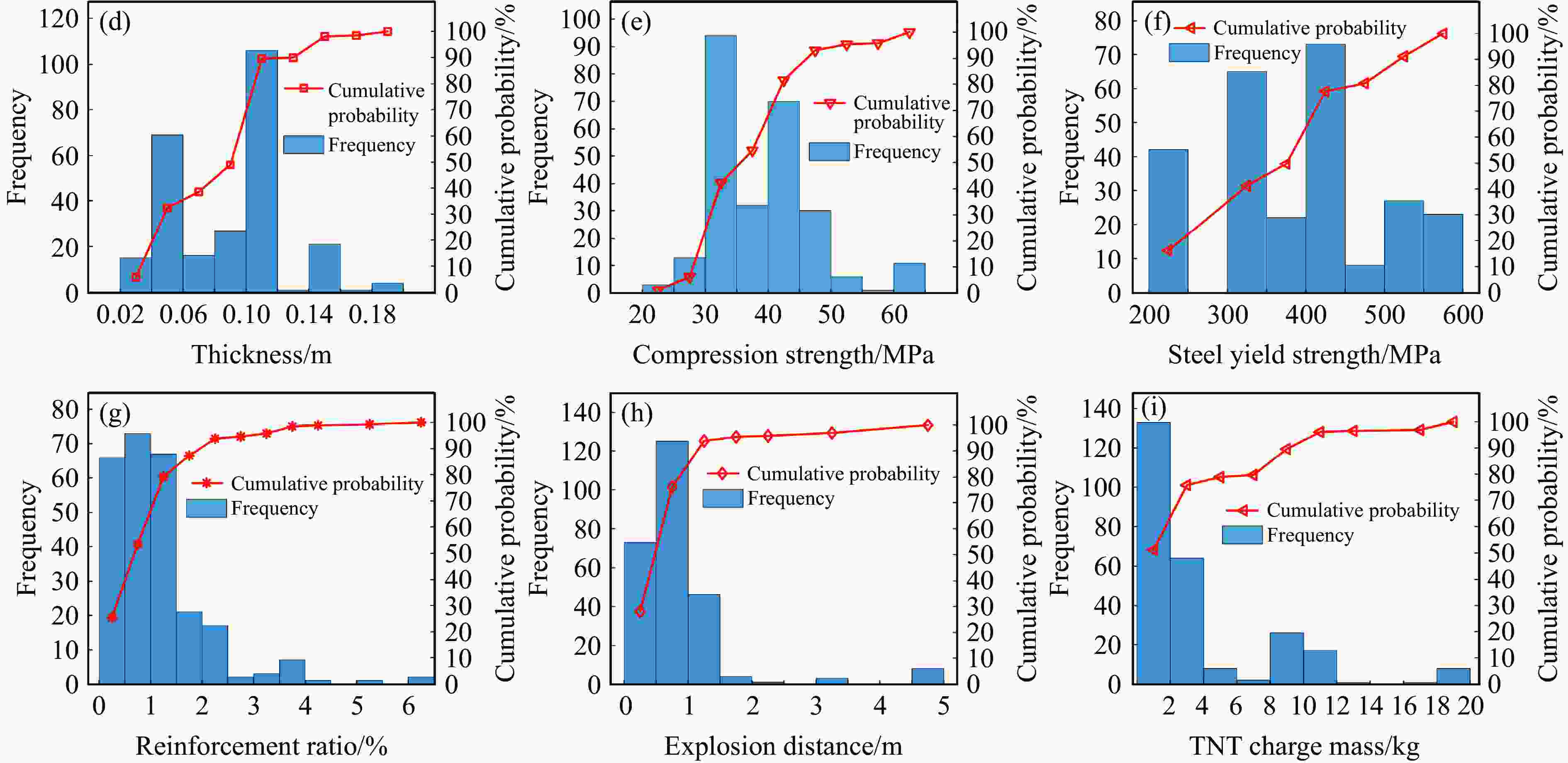

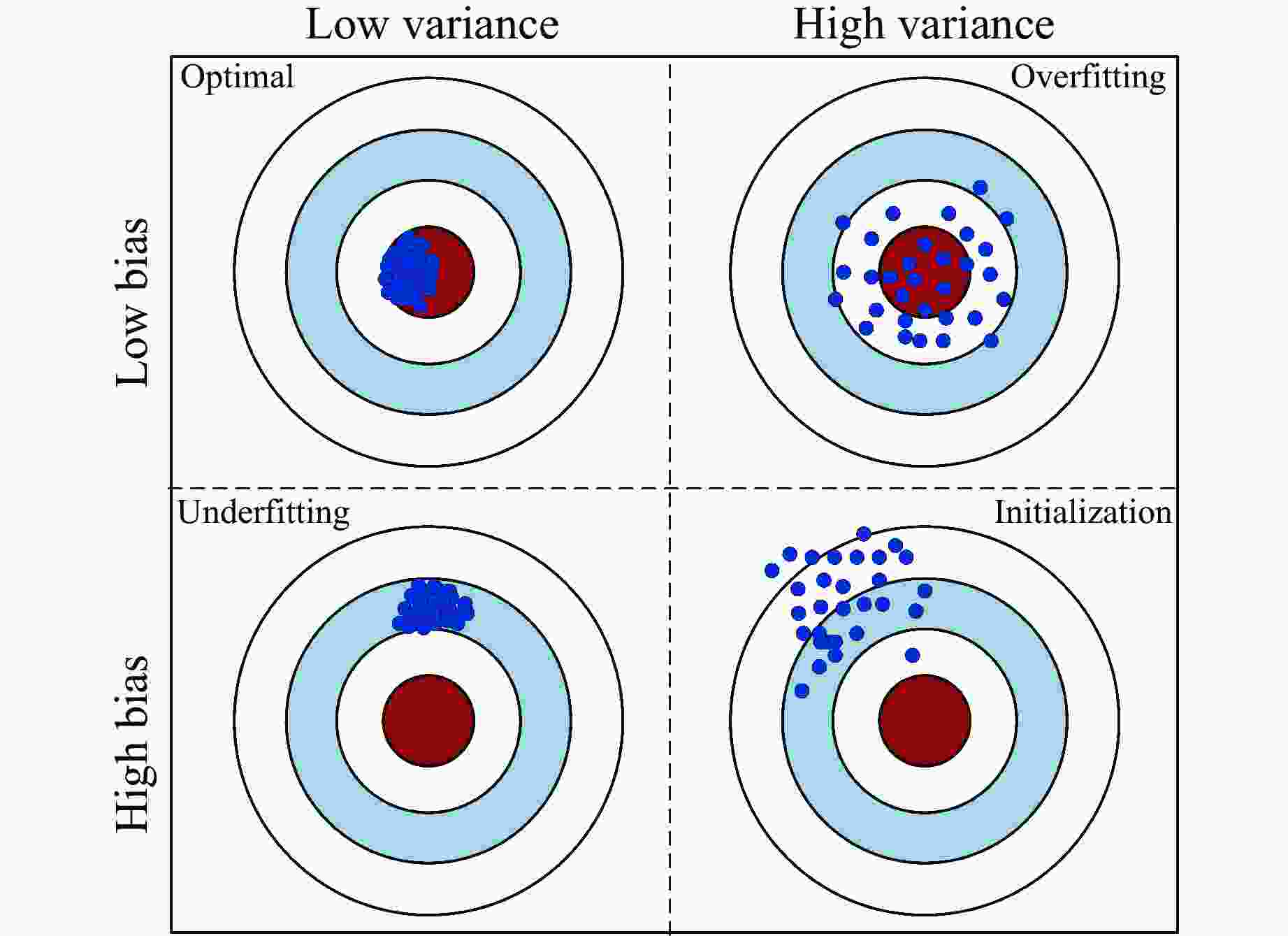

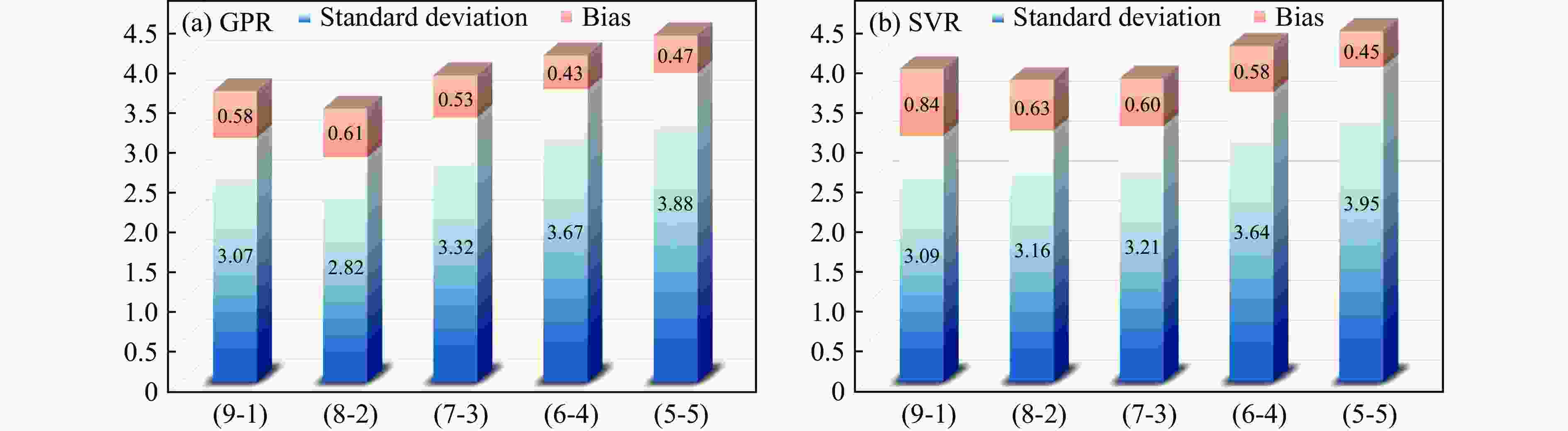

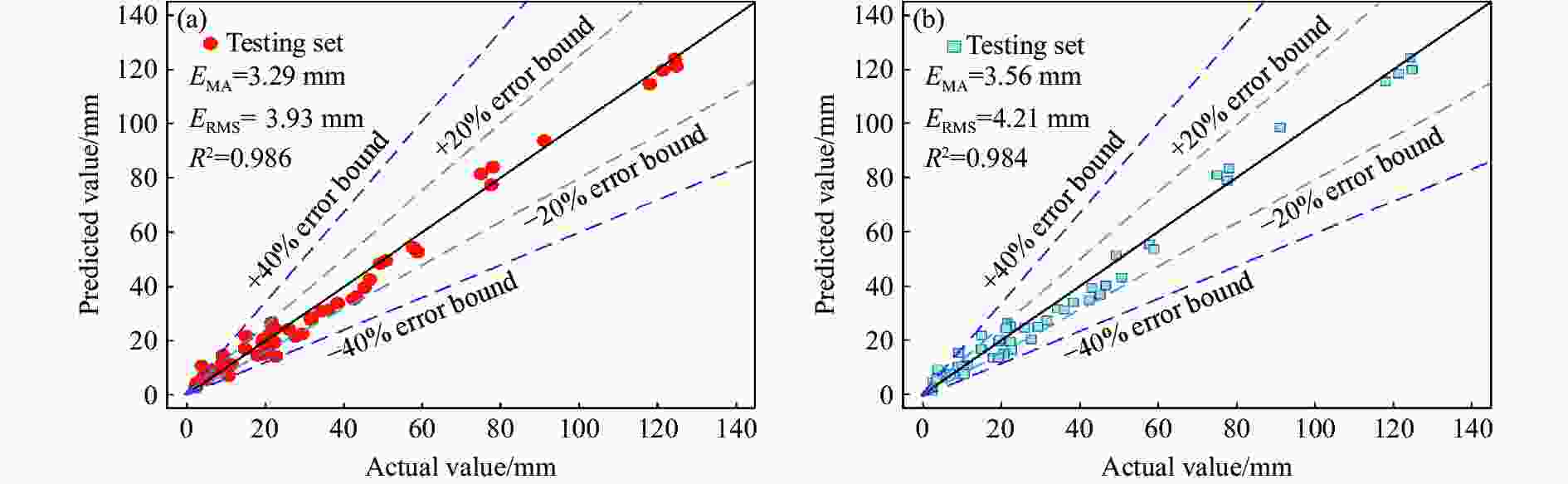

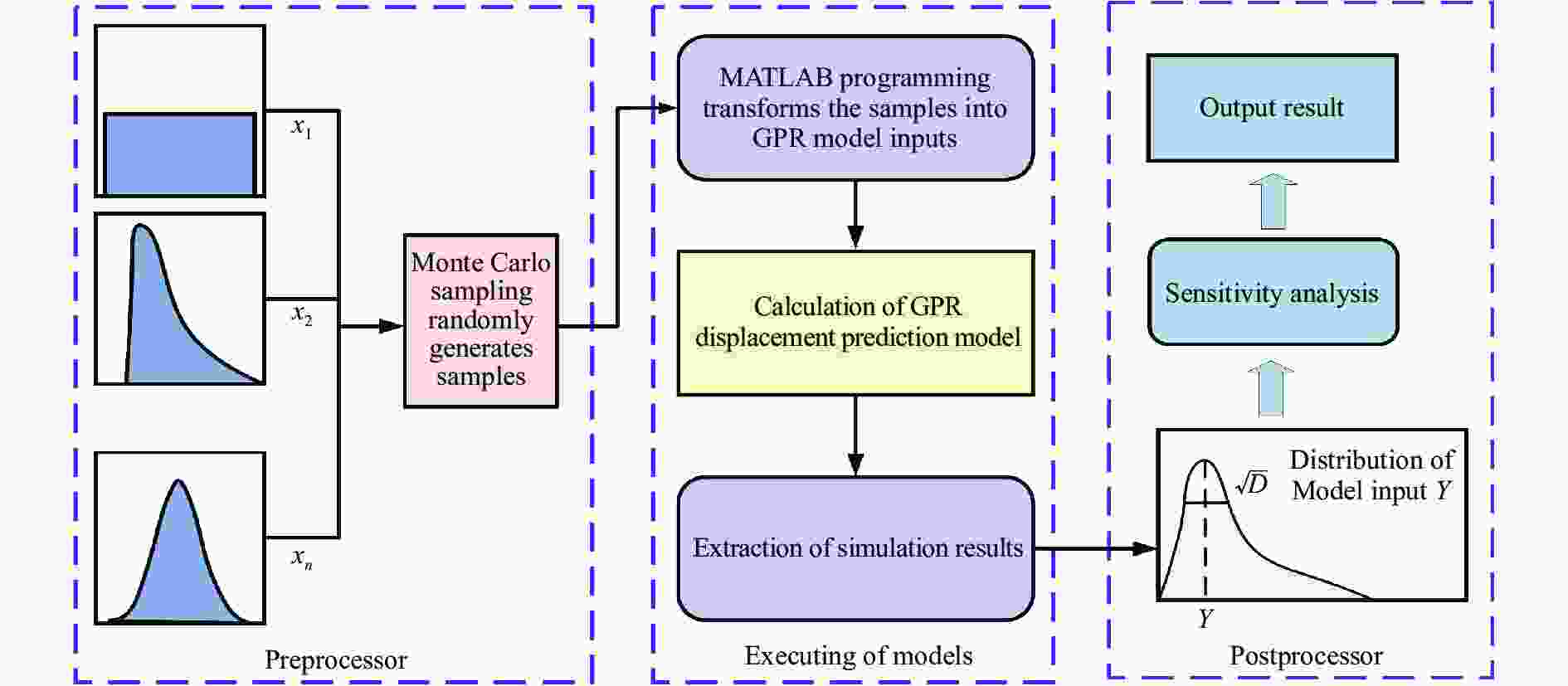

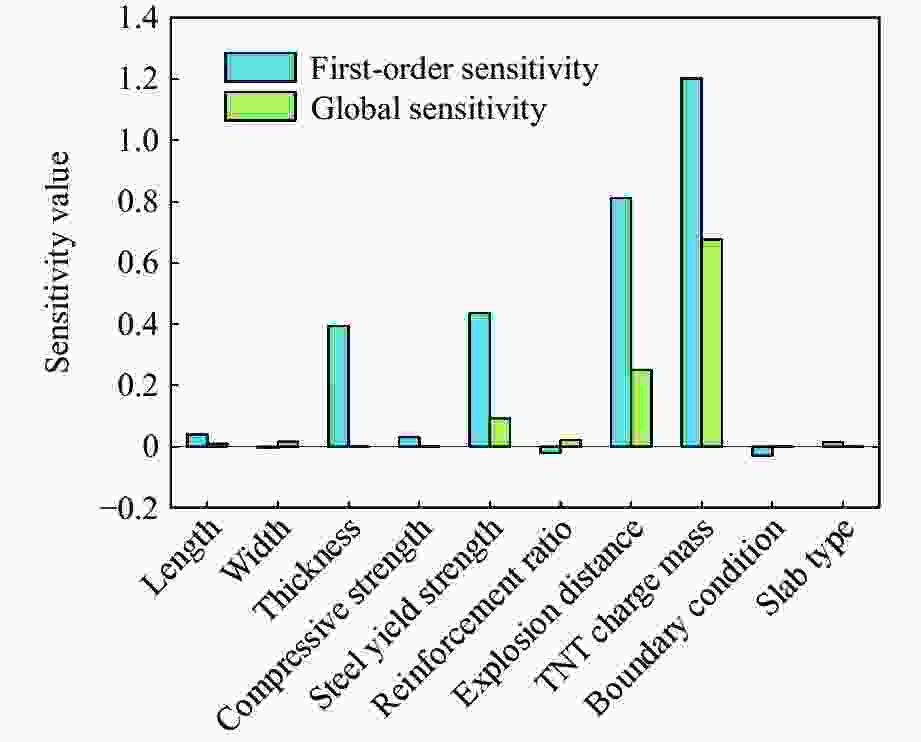

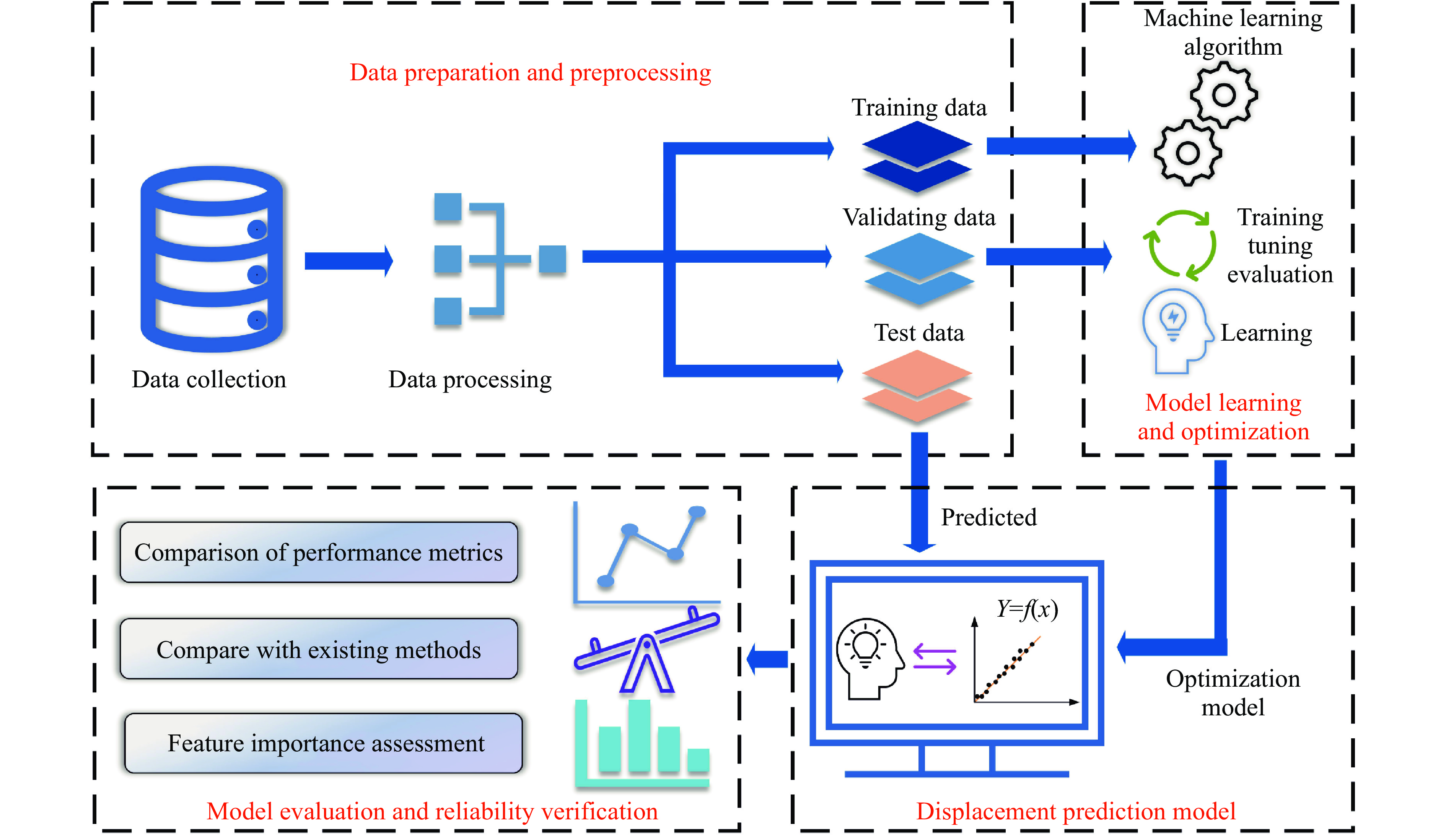

Abstract: As the main force components of engineering structures, reinforced concrete slab are prone to damage when it is subjected to terrorist attacks or accidental explosions, and even cause the overall collapse of the structure. Therefore, it is of great significance to understand and predict the dynamic response of concrete slab under the action of explosions to enhance the anti-explosion protection ability of engineering structure and reduce the economic loss of life and property. In this paper, the numerical simulation data of ordinary reinforced concrete slab explosion test and parametric analysis based on the test in the literature in China and abroad are collected. The support vector machine and Gaussian process regression algorithms in machine learning regression algorithm are used to predict the maximum displacement of reinforced concrete slab under near-field explosion. The generalization performance of the model is analyzed by using the improved deviation-variance decomposition principle. At the same time, the machine learning model is compared with the existing prediction methods. Finally, the replacement feature importance and Sobol global sensitivity analysis method are used to explain the model from the local and global to increase the reliability of the model. The above results show that the generalization performance of the two machine learning methods is better, but the prediction effect of the Gaussian process regression algorithm is better than that of the support vector machine algorithm. At the same time, compared with the existing prediction methods, it is found that the machine learning method is better, with higher prediction accuracy and computational efficiency. The influence of different input parameters on the output results of the model is obtained, which realizes the interpretability of the output results and further increases its reliability. -

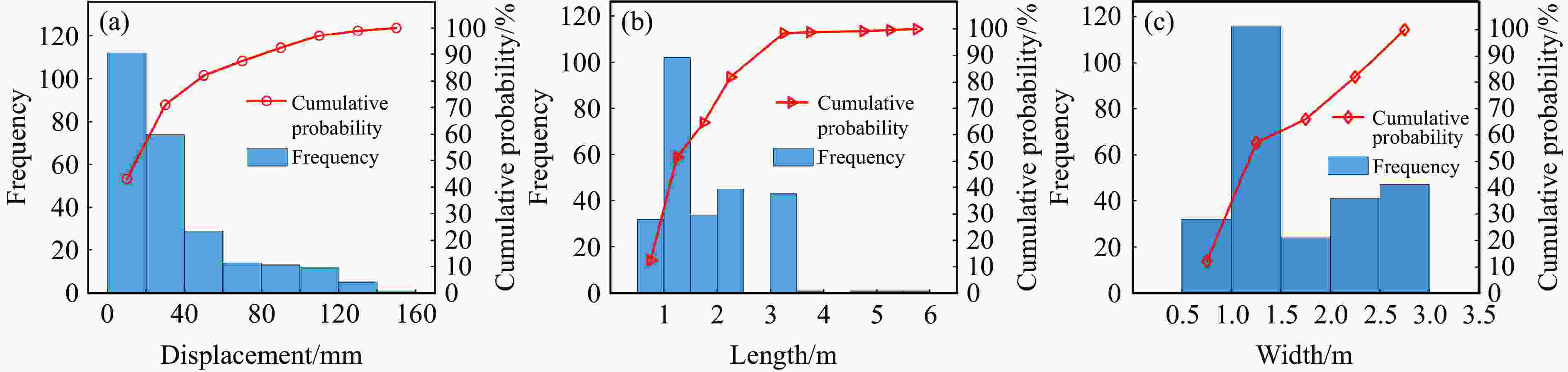

表 1 数据集数值型特征的统计描述

Table 1. Statistical description of numerical feature of data sets

Variance Feature/Output Mean/Count SD Max Min 1/4 Q 1/2 Q 3/4 Q X1 Length/m 1.66 0.84 6.00 0.75 1.00 1.38 2.00 X2 Width/m 1.56 0.78 3.00 0.75 1.00 1.20 2.00 X3 Thickness/m 0.09 0.04 0.20 0.03 0.05 0.10 0.10 X4 Compressive strength/MPa 37.50 8.39 63.00 20.00 30.00 39.50 40.45 X5 Steel yield strength/MPa 385.13 95.66 600.00 235.00 335.00 400.00 425.00 X6 Reinforcement ratio/% 1.14 0.93 6.12 0.20 0.49 0.84 1.34 X7 Explosion distance/m 0.80 0.84 5.00 0.10 0.40 0.60 0.89 X8 TNT charge mass/kg 3.27 4.38 20.00 0.01 0.36 1.58 3.42 X9 Boundary conditions (B1)58,(B2)79,(B3)5,(B4)45,(B5)29,(B6)14,(B7)13,(B8)2,(B9)20 X10 One-way/Two-way (One-way slab)98/(Two-way slab)162 Y Displacement/mm 34.55 31.59 142.00 1.16 12.23 22.45 43.54 表 2 ML方法与现有方法对比

Table 2. Comparison of ML model with existing methods

Case Existing method detail Maximum displecement/mm Error of existing

method/%Error of

ML/%Exp. Existing method ML 1 LS-DYNA-mesh, 5 mm[20] 25.7 25.10 25.27 2.33 1.67 2 LS-DYNA- mesh, 10 mm[20] 25.7 35.20 25.27 36.96 1.67 3 LS-DYNA- mesh, 20 mm[20] 25.7 35.60 25.27 38.52 1.67 4 SDOF[12] 1.8 2.02 2.66 12.22 47.74 5 SDOF[12] 10.5 10.51 10.59 0.10 0.90 6 SDOF[12] 13.9 15.09 12.99 8.56 6.57 7 SDOF[12] 38.9 37.69 37.80 3.11 2.83 8 Medium-structure interaction theory[15] 4.8 4.19 5.51 12.71 14.69 9 Medium-structure interaction theory[15] 8.4 7.37 7.09 12.26 15.60 10 Medium-structure interaction theory[15] 10.2 11.80 8.67 15.69 14.98 11 LS-DYNA-mesh, 5 mm[13] 9.0 8.40 8.15 6.67 9.49 12 LS-DYNA-mesh, 5 mm[13] 23.1 21.30 18.76 7.79 18.79 13 LS-DYNA-mesh, 5 mm[13] 5.1 5.70 9.78 11.76 91.72 14 LS-DYNA-mesh, 5 mm[13] 9.9 10.50 10.34 6.06 4.43 -

[1] LEI Y G, YANG B, JIANG X W, et al. Applications of machine learning to machine fault diagnosis: a review and roadmap [J]. Mechanical Systems and Signal Processing, 2020, 138: 106587. doi: 10.1016/j.ymssp.2019.106587 [2] SUN H, BURTON H V, HUANG H L. Machine learning applications for building structural design and performance assessment: state-of-the-art review [J]. Journal of Building Engineering, 2021, 33: 101816. doi: 10.1016/j.jobe.2020.101816 [3] REN Q, DING L C, DAI X D, et al. Prediction of compressive strength of concrete with manufactured sand by ensemble classification and regression tree method [J]. Journal of Materials in Civil Engineering, 2021, 33(7): 04021135. doi: 10.1061/(ASCE)MT.1943-5533.0003741 [4] LI Z, ZHANG J P, LIU T, et al. Using PSO-SVR algorithm to predict asphalt pavement performance [J]. Journal of Performance of Constructed Facilities, 2021, 35(6): 04021094. doi: 10.1061/(ASCE)CF.1943-5509.0001666 [5] YETILMEZSOY K, SIHAG P, KIYAN E, et al. A benchmark comparison and optimization of Gaussian process regression, support vector machines, and M5P tree model in approximation of the lateral confinement coefficient for CFRP-wrapped rectangular/square RC columns [J]. Engineering Structures, 2021, 246: 113106. doi: 10.1016/J.ENGSTRUCT.2021.113106 [6] 赵春风, 何凯城, 卢欣, 等. 双钢板混凝土组合板抗爆性能分析 [J]. 爆炸与冲击, 2021, 41(9): 095102. doi: 10.11883/bzycj-2020-0291ZHAO C F, HE K C, LU X, et al. Analysis on the blast resistance of steel concrete composite slab [J]. Explosion and Shock Waves, 2021, 41(9): 095102. doi: 10.11883/bzycj-2020-0291 [7] ZHAO C F, WANG Q, LU X, et al. Numerical study on dynamic behaviors of NRC slabs in containment dome subjected to close-in blast loading [J]. Thin-Walled Structures, 2019, 135: 269–284. doi: 10.1016/j.tws.2018.11.013 [8] WANG W, ZHAGN D, LU F Y, et al. Experimental study and numerical simulation of the damage mode of a square reinforced concrete slab under close-in explosion [J]. Engineering Failure Analysis, 2013, 27: 41–51. doi: 10.1016/j.engfailanal.2012.07.010 [9] THIAGARAJAN G, KADAMBI A V, ROBERT S, et al. Experimental and finite element analysis of doubly reinforced concrete slabs subjected to blast loads [J]. International Journal of Impact Engineering, 2015, 75: 162–173. doi: 10.1016/j.ijimpeng.2014.07.018 [10] MAAZOUN A, BELKASSEM B, REYMEN B, et al. Blast response of RC slabs with externally bonded reinforcement: experimental and analytical verification [J]. Composite Structures, 2018, 200: 246–257. doi: 10.1016/j.compstruct.2018.05.102 [11] FENG J, ZHOU Y Z, WANG P, et al. Experimental research on blast-resistance of one-way concrete slabs reinforced by BFRP bars under close-in explosion [J]. Engineering Structures, 2017, 150: 550–561. doi: 10.1016/j.engstruct.2017.07.074 [12] WU C, OEHLERS D J, REBENTROST M, et al. Blast testing of ultra-high performance fibre and FRP-retrofitted concrete slabs [J]. Engineering Structures, 2009, 31(9): 2060–2069. doi: 10.1016/j.engstruct.2009.03.020 [13] YAO S J, ZHANG D, CHEN X G, et al. Experimental and numerical study on the dynamic response of RC slabs under blast loading [J]. Engineering Failure Analysis, 2016, 66: 120–129. doi: 10.1016/j.engfailanal.2016.04.027 [14] 高琴. 高强钢筋混凝土板在爆炸载荷下的动态响应研究 [D]. 武汉: 武汉科技大学, 2019.GAO Q. Study on dynamic response of high strength reinforced concrete slab subjected to blast loads [D]. Wuhan: Wuhan University of Science and Technology, 2019. [15] 郭樟根, 曹双寅, 王安宝, 等. 化爆作用下FRP加固RC板的试验研究及动力响应分析 [J]. 工程力学, 2016, 33(3): 120–127. doi: 10.6052/j.issn.1000-4750.2014.07.0658GUO Z G, CAO S Y, WANG A B, et al. Dynamic response analysis and test study on FRP strengthened RC slabs subjected to blast loading [J]. Engineering Mechanics, 2016, 33(3): 120–127. doi: 10.6052/j.issn.1000-4750.2014.07.0658 [16] 孙文彬. 钢筋混凝土板的爆炸荷载试验研究 [J]. 辽宁工程技术大学学报(自然科学版), 2009, 28(2): 217–220. doi: 10.3969/j.issn.1008-0562.2009.02.016SUN W B. Experimental studies on reinforced concrete (RC) slabs subjected to blast loads [J]. Journal of Liaoning Technical University (Natural Science), 2009, 28(2): 217–220. doi: 10.3969/j.issn.1008-0562.2009.02.016 [17] 汪维. 钢筋混凝土构件在爆炸载荷作用下的毁伤效应及评估方法研究 [D]. 长沙: 国防科学技术大学, 2012.WANG W. Study on damage effects and assessments method of reinforced concrete structural members under blast loading [D]. Changsha: National University of Defense Technology, 2012. [18] 汪维, 刘光昆, 汪琴, 等. 四边固支方形钢筋混凝土板抗爆试验研究 [J]. 兵工学报, 2018, 39(Suppl 1): 108–113.WANG W, LIU G K, WANG Q, et al. Experimental research on four-sides fixed square slabs under blast loading [J]. Acta Armamentarii, 2018, 39(Suppl 1): 108–113. [19] 汪维, 张舵, 卢芳云, 等. 方形钢筋混凝土板的近场抗爆性能 [J]. 爆炸与冲击, 2012, 32(3): 251–258. doi: 10.11883/1001-1455(2012)03-0251-08WANG W, ZHANG D, LU F Y, et al. Anti-explosion performances of square reinforced concrete slabs under close-in explosions [J]. Explosion and Shock Waves, 2012, 32(3): 251–258. doi: 10.11883/1001-1455(2012)03-0251-08 [20] 王强. 爆炸作用下钢筋混凝土板与穹顶60°配筋安全壳动态响应研究 [D]. 合肥: 合肥工业大学, 2019.WANG Q. Study on dynamic response of reinforced concrete slab and containment dome with 60° configuration under blast load [D]. Hefei: Hefei University of Technology, 2019. [21] LIN X S, ZHANG Y X, HAZELL P J. Modelling the response of reinforced concrete panels under blast loading [J]. Materials & Design, 2014, 56: 620–628. doi: 10.1016/j.matdes.2013.11.069 [22] SYED Z I, RAMAN S N, NGO T, et al. The failure behaviour of reinforced concrete panels under far-field and near-field blast effects [J]. Structures, 2018, 14: 220–229. doi: 10.1016/j.istruc.2018.03.009 [23] 何福康. 钢筋混凝土板静力极限分析及非线性爆炸响应 [D]. 广州: 华南理工大学, 2018.HE F K. Static limit analysis and nonlinear explosion response of reinforced concrete slabs [D]. Guangzhou: South China University of Technology, 2018. [24] 贾昊凯. 爆炸荷载作用下钢筋混凝土柱和板动力响应及损伤评定的数值模拟 [D]. 太原: 太原理工大学, 2012.JIA H K. Numerical simulation of the dynamic response and damage assessment for RC columns and slabs subject to blast loads [D]. Taiyuan: Taiyuan University of Technology, 2012. [25] 贾敬尧. 近距爆炸荷载作用下钢筋混凝土板的动力响应及损伤评估 [D]. 西安: 西安建筑科技大学, 2019.JIA J Y. Dynamic response and damage assessment of reinforced concrete slabs under close-in blast loading [D]. Xi’an: Xi’an University of Architecture and Technology, 2019. [26] 李天华. 爆炸荷载下钢筋混凝土板的动态响应及损伤评估 [D]. 西安: 长安大学, 2012.LI T H. Dynamic response and damage assessment of reinforced concrete slabs subjected to blast loading [D]. Xi’an: Chang’an University, 2012. [27] 李天华, 赵均海, 魏雪英, 等. 爆炸荷载下钢筋混凝土板的动力响应及参数分析 [J]. 建筑结构, 2012, 42(Suppl 1): 786–790. doi: 10.19701/j.jzjg.2012.s1.194LI T H, ZHAO J H, WEI X Y, et al. Dynamic response and parametric analysis on reinforced concrete slabs under blast loadings [J]. Building Structure, 2012, 42(Suppl 1): 786–790. doi: 10.19701/j.jzjg.2012.s1.194 [28] 史祥生. 爆炸荷载作用下钢筋混凝土板的损伤破坏分析 [D]. 天津: 天津大学, 2008.SHI X S. Damage assessment of RC slabs subjected to blast load [D]. Tianjin: Tianjin University, 2008. [29] 赵春风, 王强, 王静峰, 等. 近场爆炸作用下核电厂安全壳穹顶钢筋混凝土板的抗爆性能 [J]. 高压物理学报, 2019, 33(2): 025101. doi: 10.11858/gywlxb.20180598ZHAO C F, WANG Q, WANG J F, et al. Blast resistance of containment dome reinforced concrete slab in NPP under close-in explosion [J]. Chinese Journal of High Pressure Physics, 2019, 33(2): 025101. doi: 10.11858/gywlxb.20180598 [30] VAPNIK V N. The nature of statistical learning theory [M]. New York: Springer, 1995. [31] JALAL M, ARABALI P, GRASLEY Z, et al. Behavior assessment, regression analysis and support vector machine (SVM) modeling of waste tire rubberized concrete [J]. Journal of Cleaner Production, 2020, 273(12): 122960. doi: 10.1016/j.jclepro.2020.122960 [32] CHANG C C, LIN C J. LIBSVM: a library for support vector machines [J]. ACM Transactions on Intelligent Systems and Technology, 2011, 2(3): 27. doi: 10.1145/1961189.1961199 [33] 李启明, 喻泽成, 余波, 等. 钢筋混凝土柱地震破坏模式判别的两阶段支持向量机方法 [J]. 工程力学, 2022, 39(2): 148–158. doi: 10.6052/j.issn.1000-4750.2020.12.0937LI Q M, YU Z C, YU B, et al. Two-stage support vector machine method for failure mode classification of reinforcedconcrete columns [J]. Engineering Mechanics, 2022, 39(2): 148–158. doi: 10.6052/j.issn.1000-4750.2020.12.0937 [34] LI A N, SHAN S G, GAO W. Coupled bias-variance tradeoff for cross-pose face recognition [J]. IEEE Transactions on Image Processing, 2012, 21(1): 305–315. doi: 10.1109/TIP.2011.2160957 [35] 冯德成, 吴刚. 混凝土结构基本性能的可解释机器学习建模方法 [J]. 建筑结构学报, 2022, 43(4): 228–238. doi: 10.14006/j.jzjgxb.2020.0491FENG D C, WU G. Interpretable machine learning-based modeling approach for fundamental properties of concrete structures [J]. Journal of Building Structures, 2022, 43(4): 228–238. doi: 10.14006/j.jzjgxb.2020.0491 [36] ALMUSTAFA M K, NEHDI M L. Machine learning model for predicting structural response of RC slabs exposed to blast loading [J]. Engineering Structures, 2020, 221: 111109. doi: 10.1016/j.engstruct.2020.111109 [37] 李美水, 杨晓华. 基于Sobol方法的SWMM模型参数全局敏感性分析 [J]. 中国给水排水, 2020, 36(17): 95–102. doi: 10.19853/j.zgjsps.1000-4602.2020.17.017LI M S, YANG X H. Global sensitivity analysis of SWMM parameters based on sobol method [J]. China Water & Wastewater, 2020, 36(17): 95–102. doi: 10.19853/j.zgjsps.1000-4602.2020.17.017 -

下载:

下载: