Coalescence Behavior of Voids during One-Dimensional Strain Spallation

-

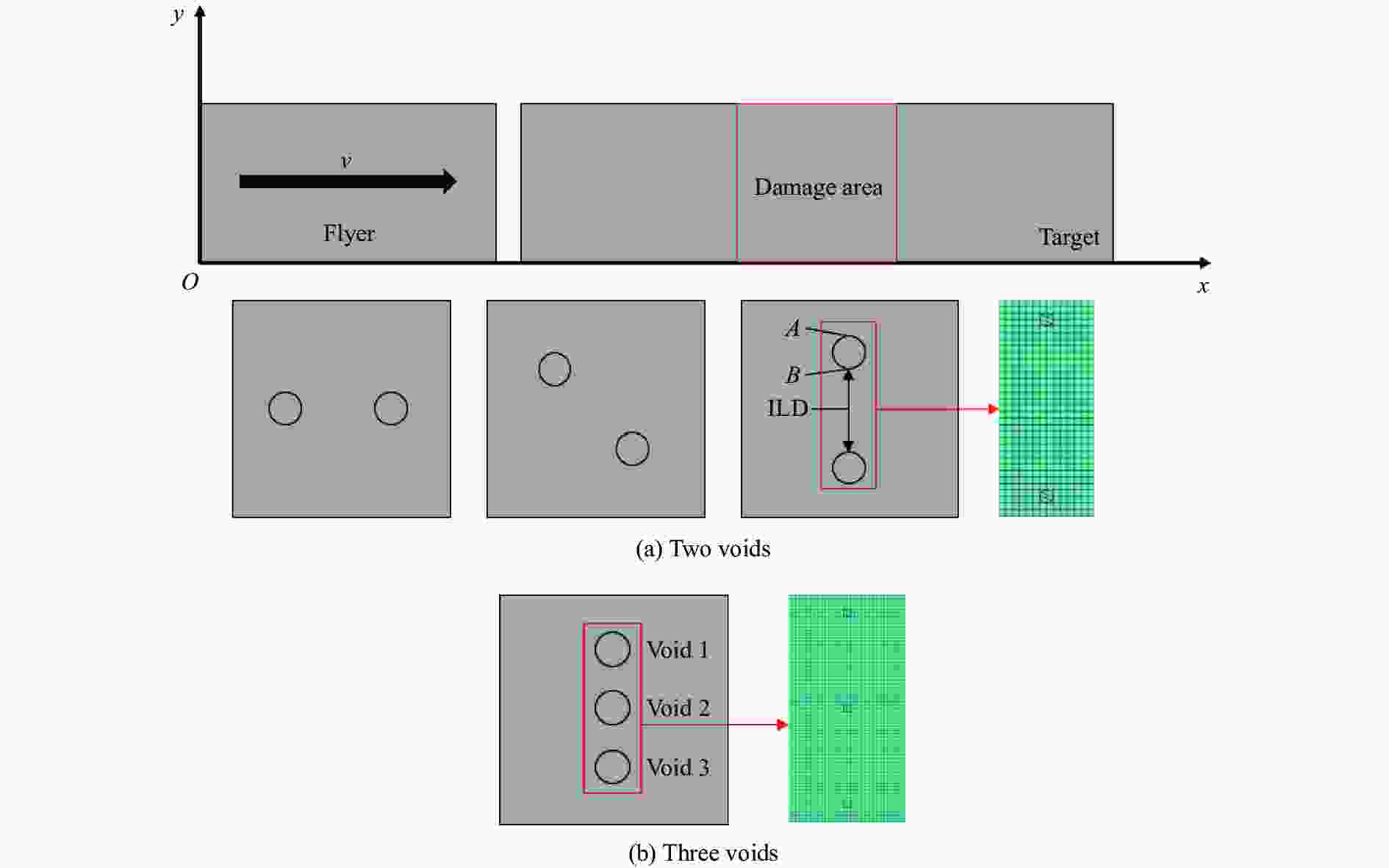

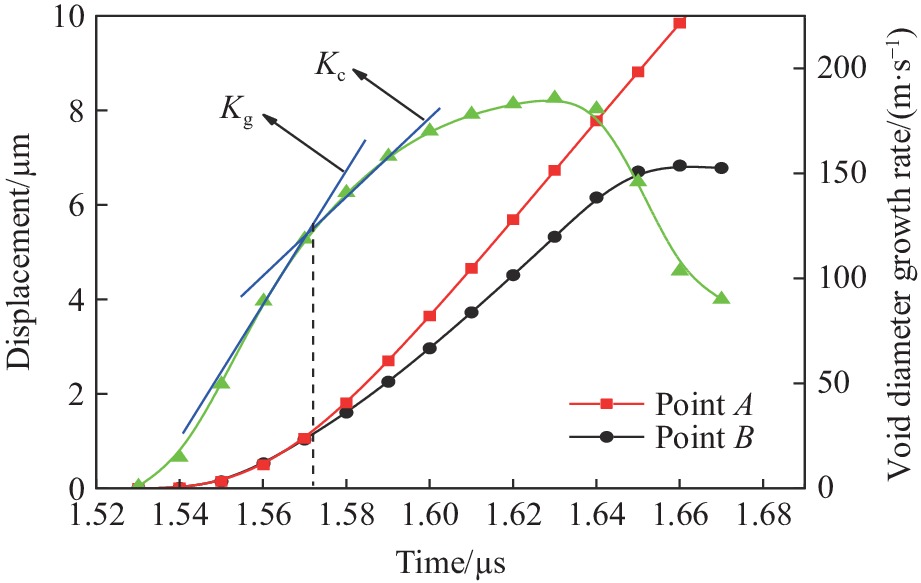

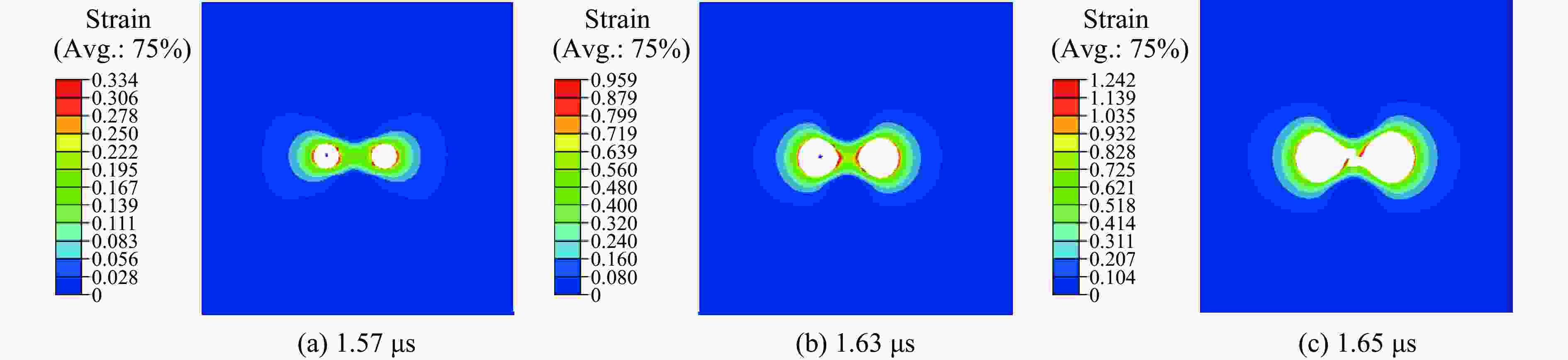

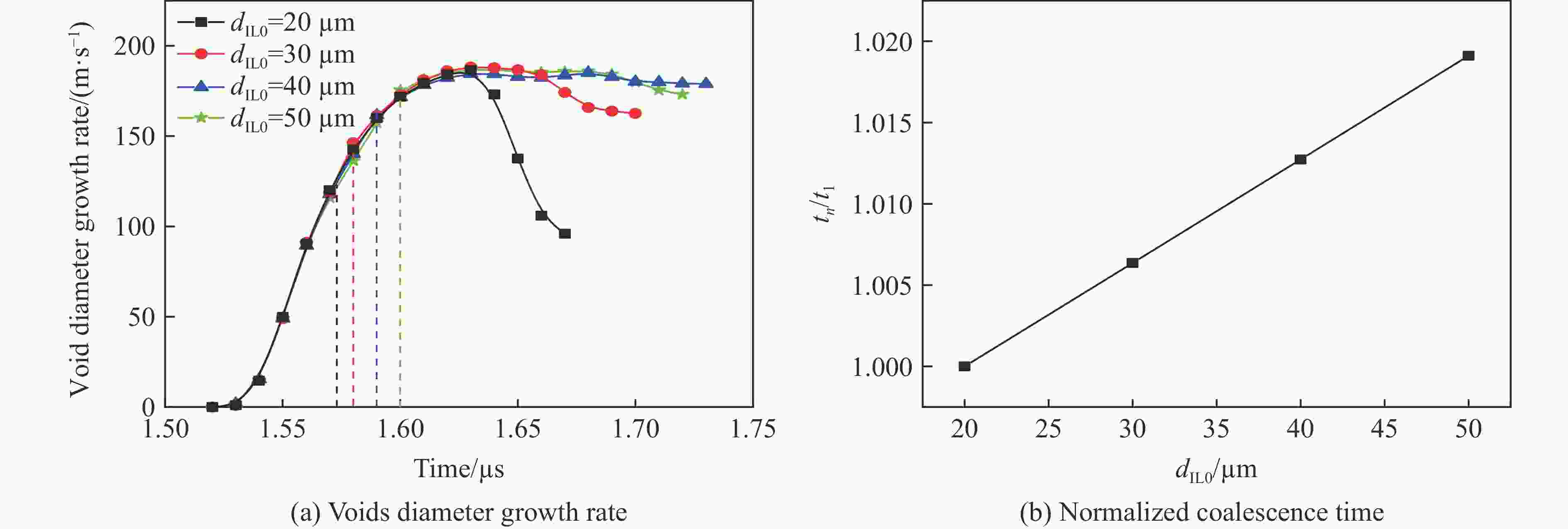

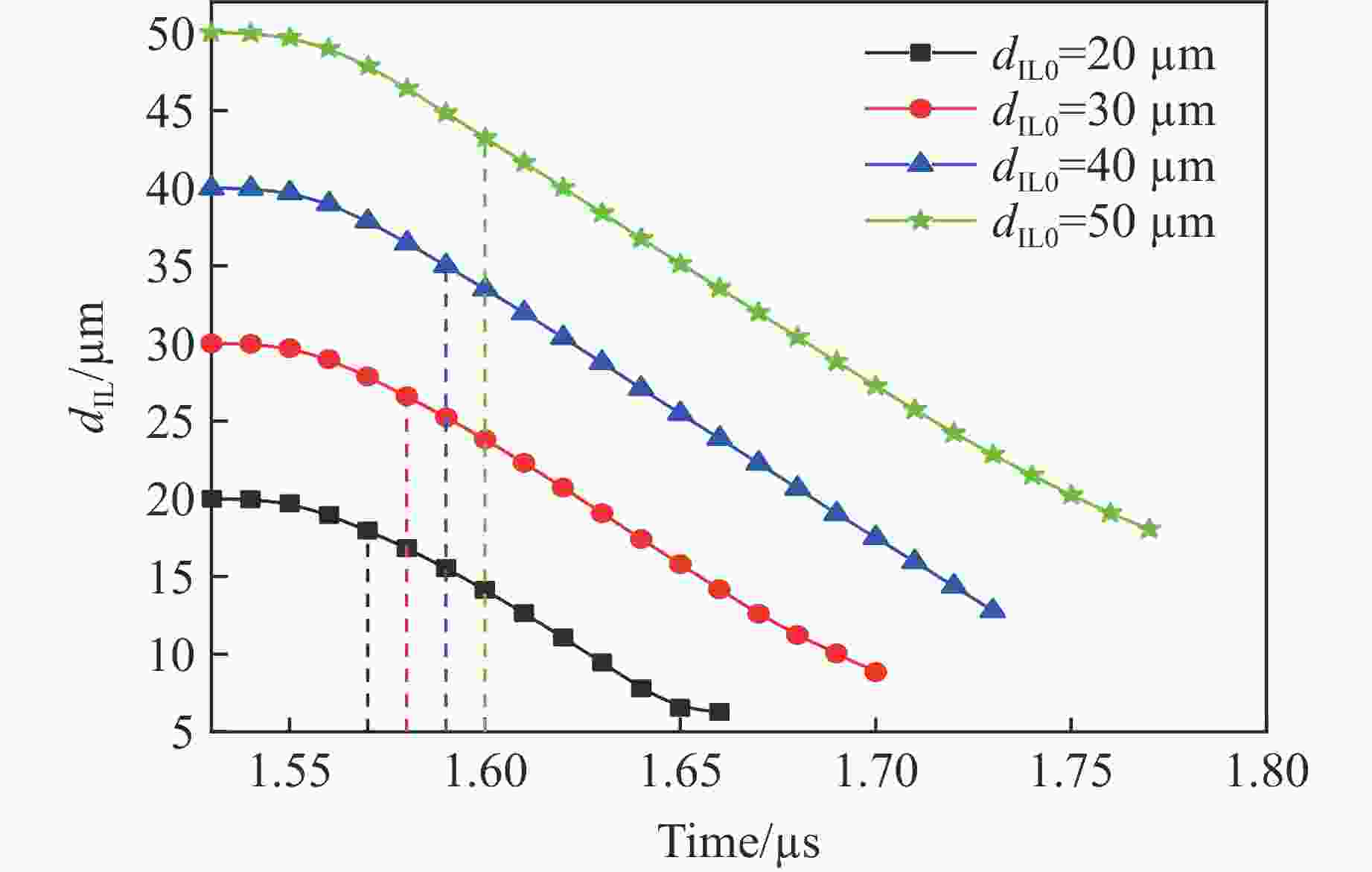

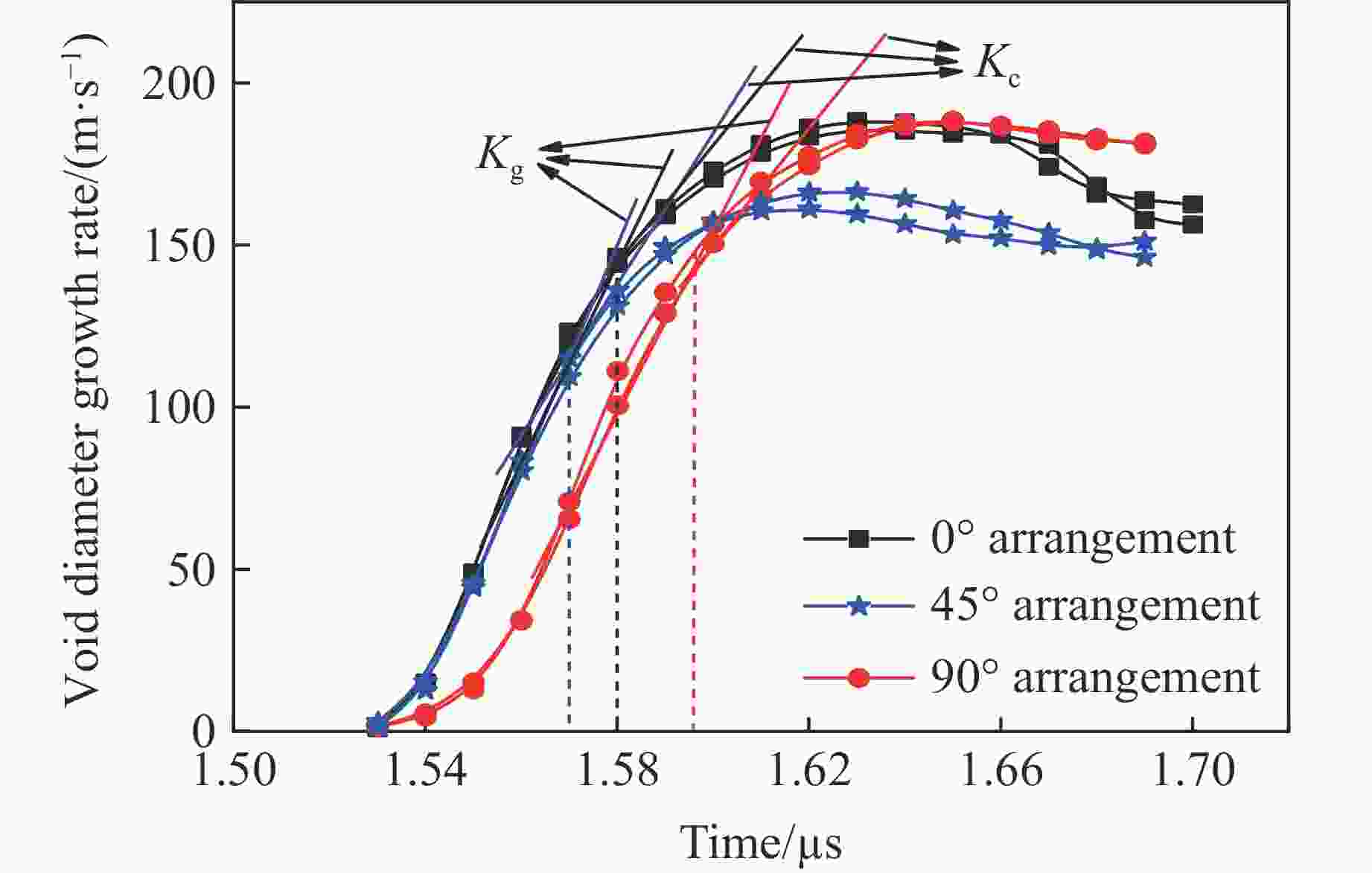

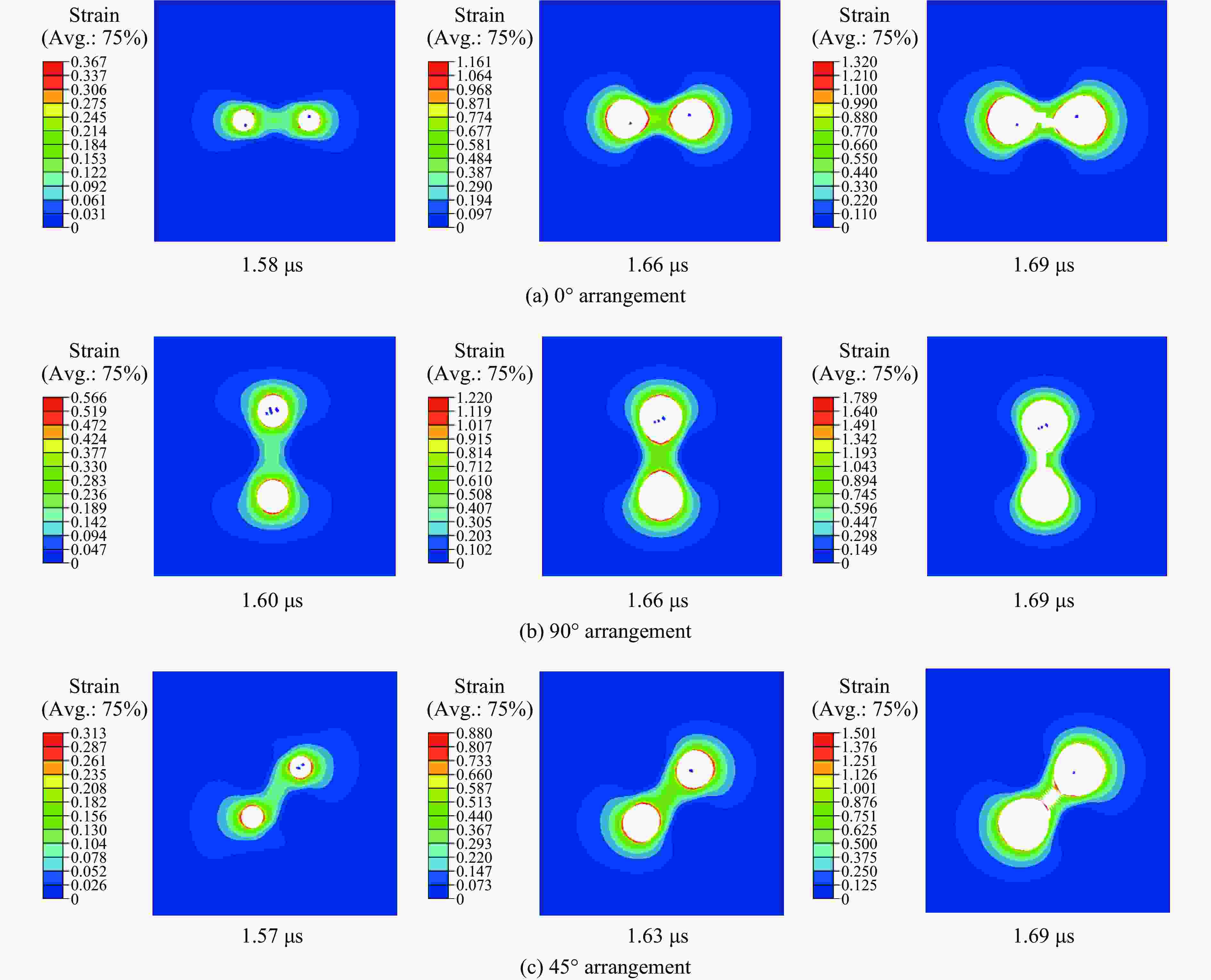

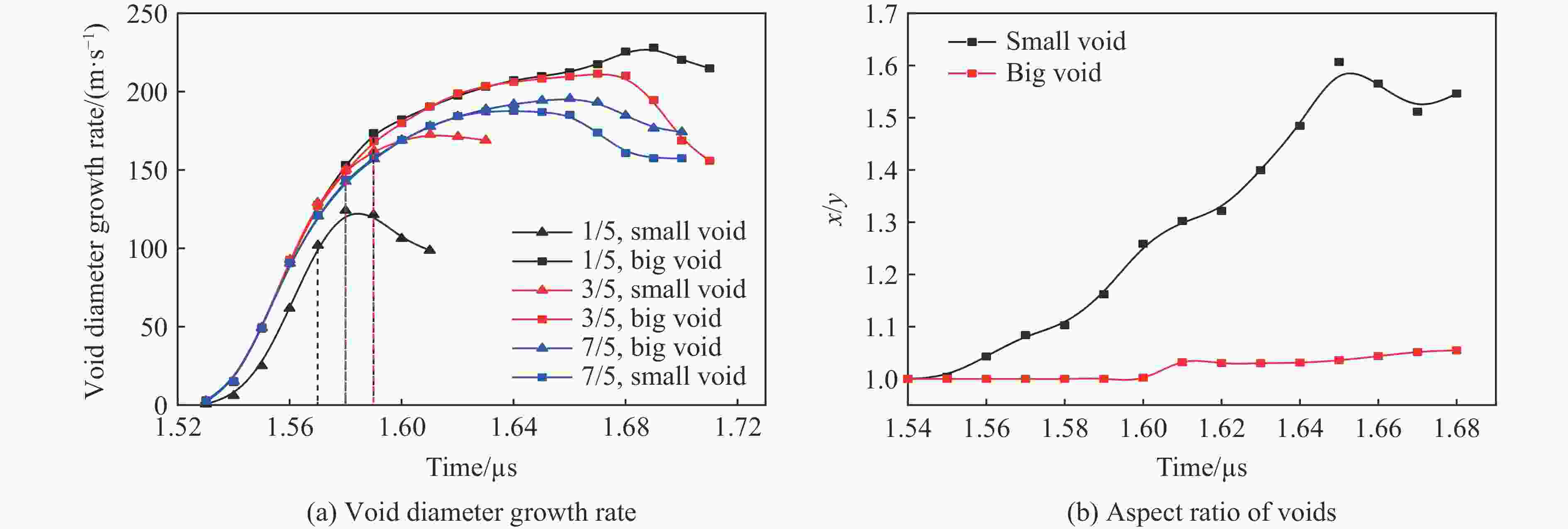

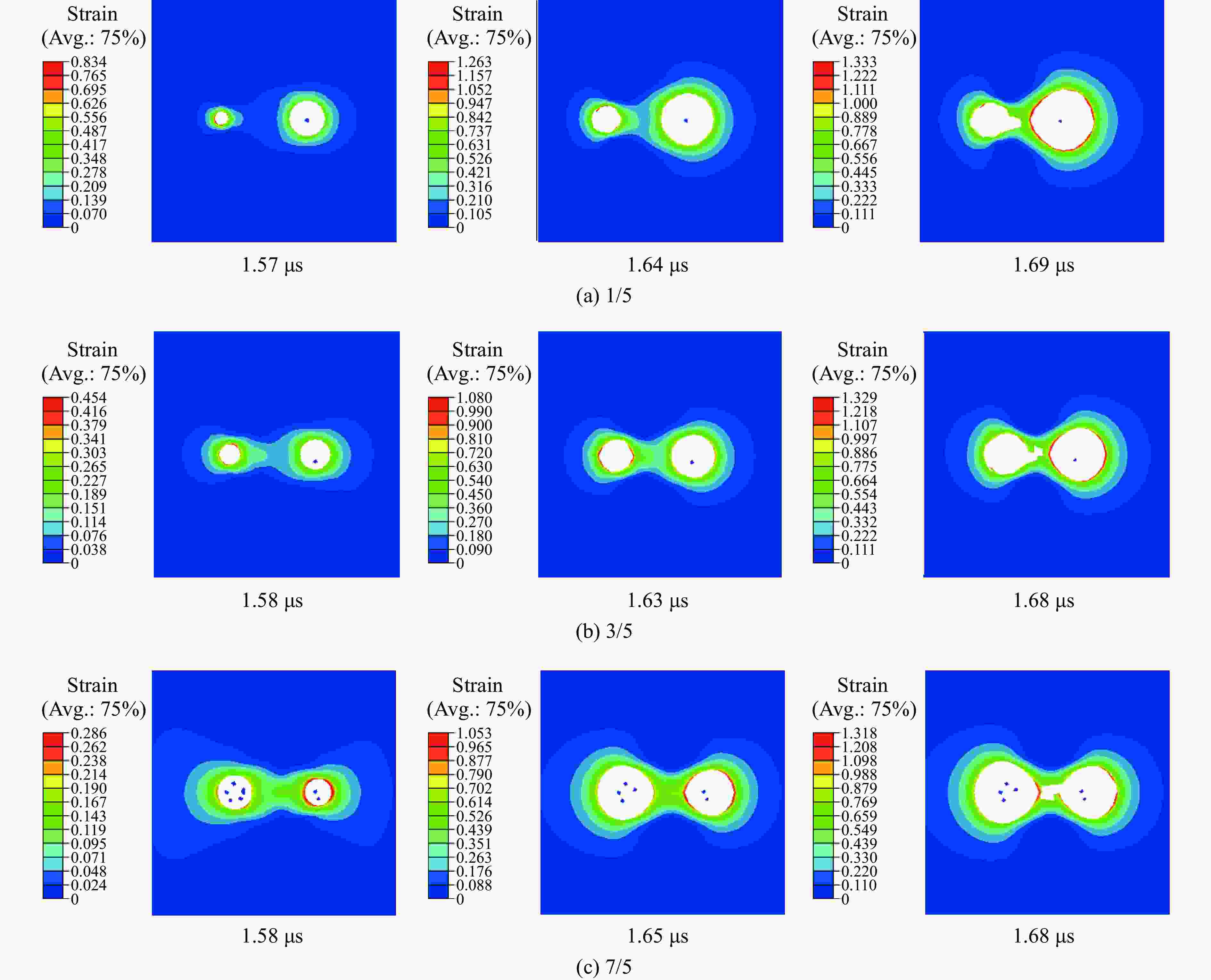

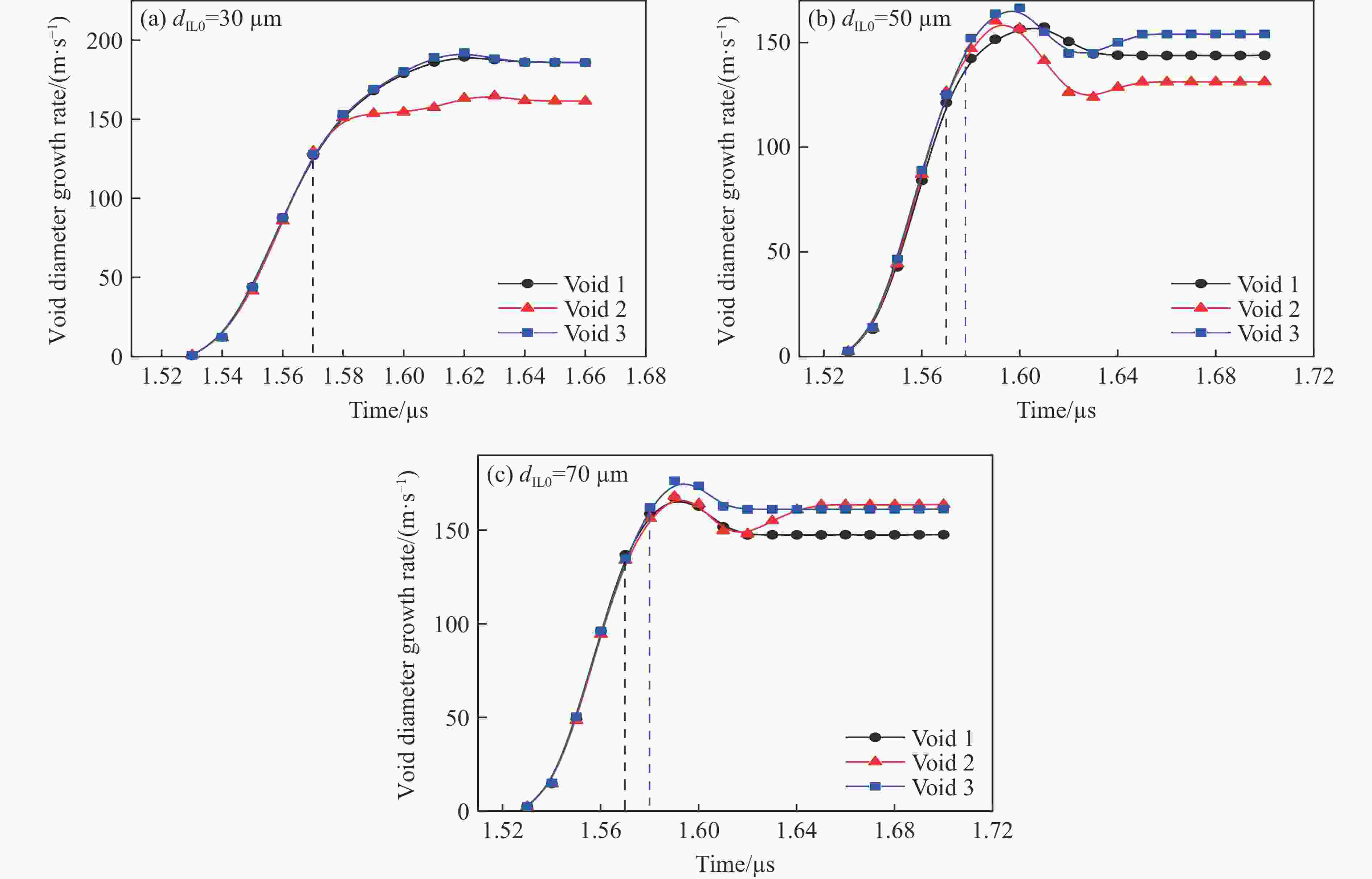

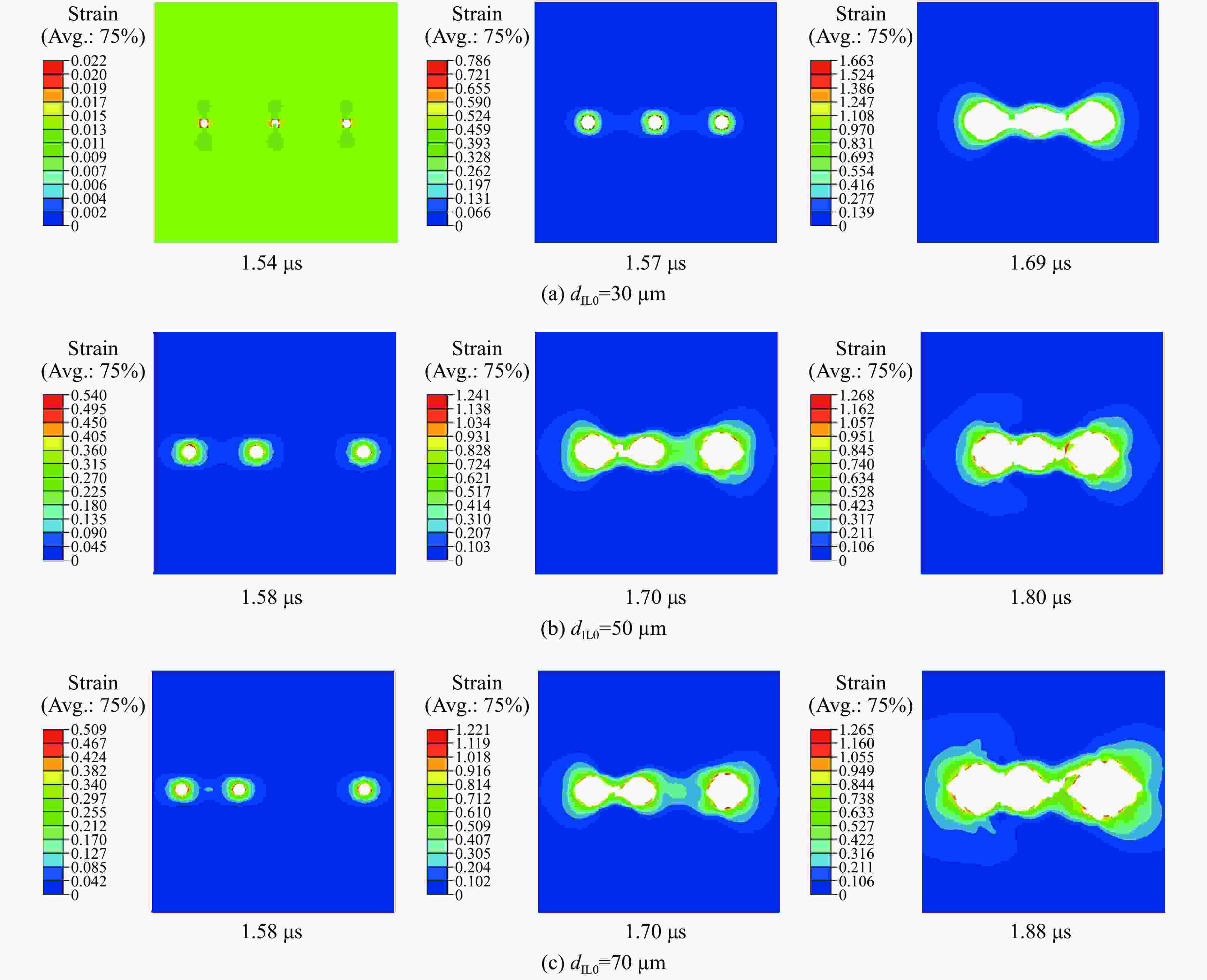

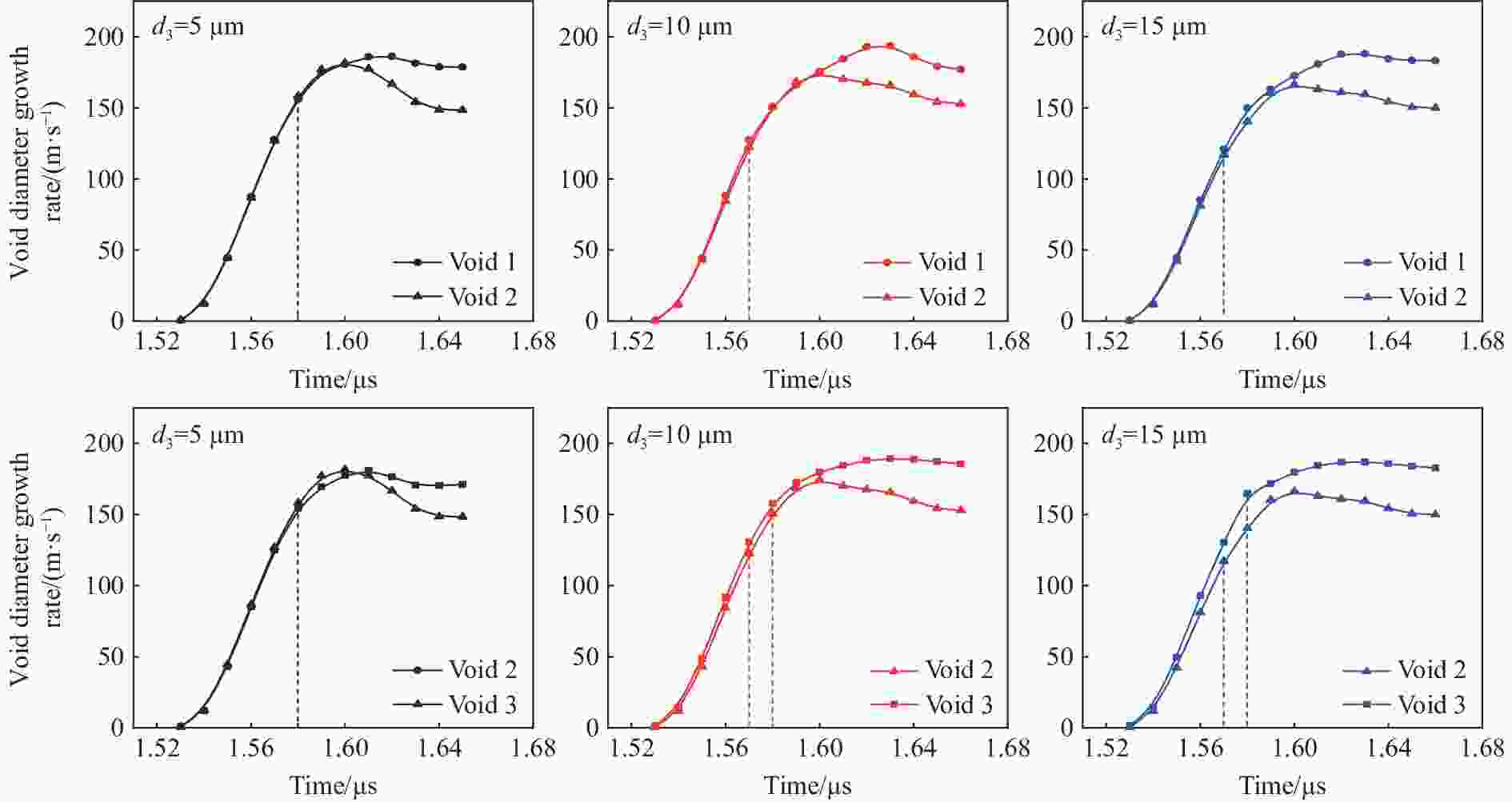

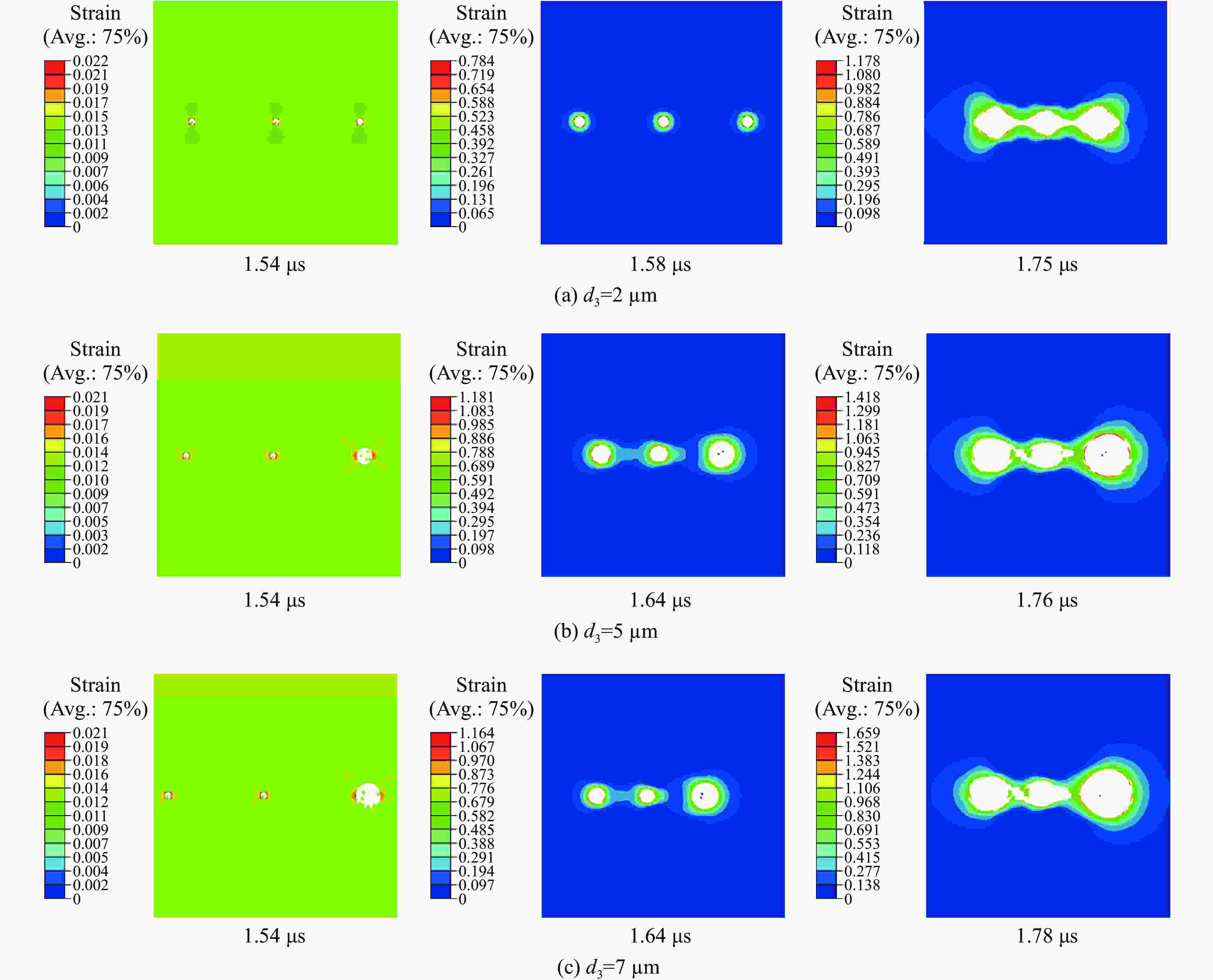

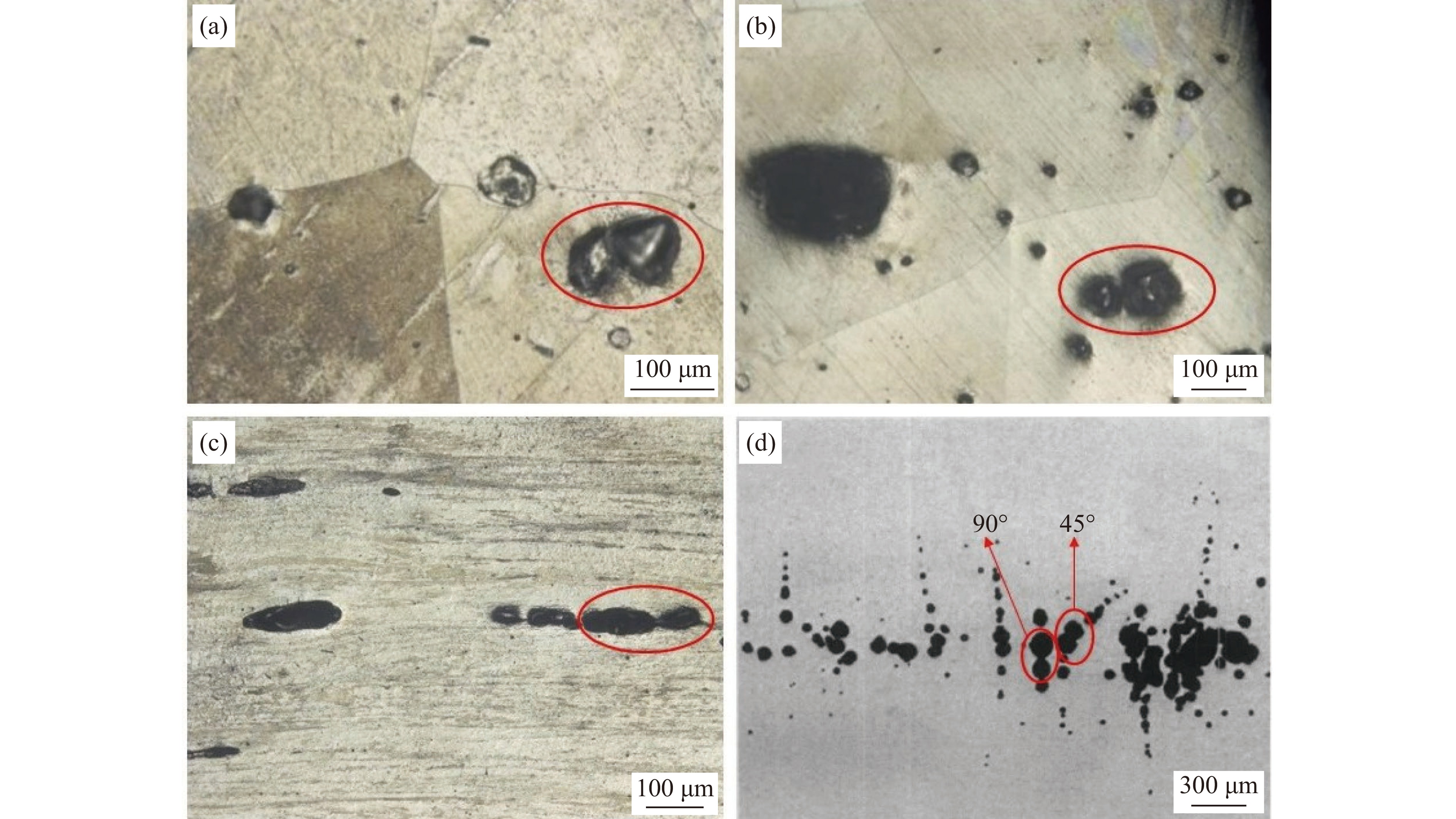

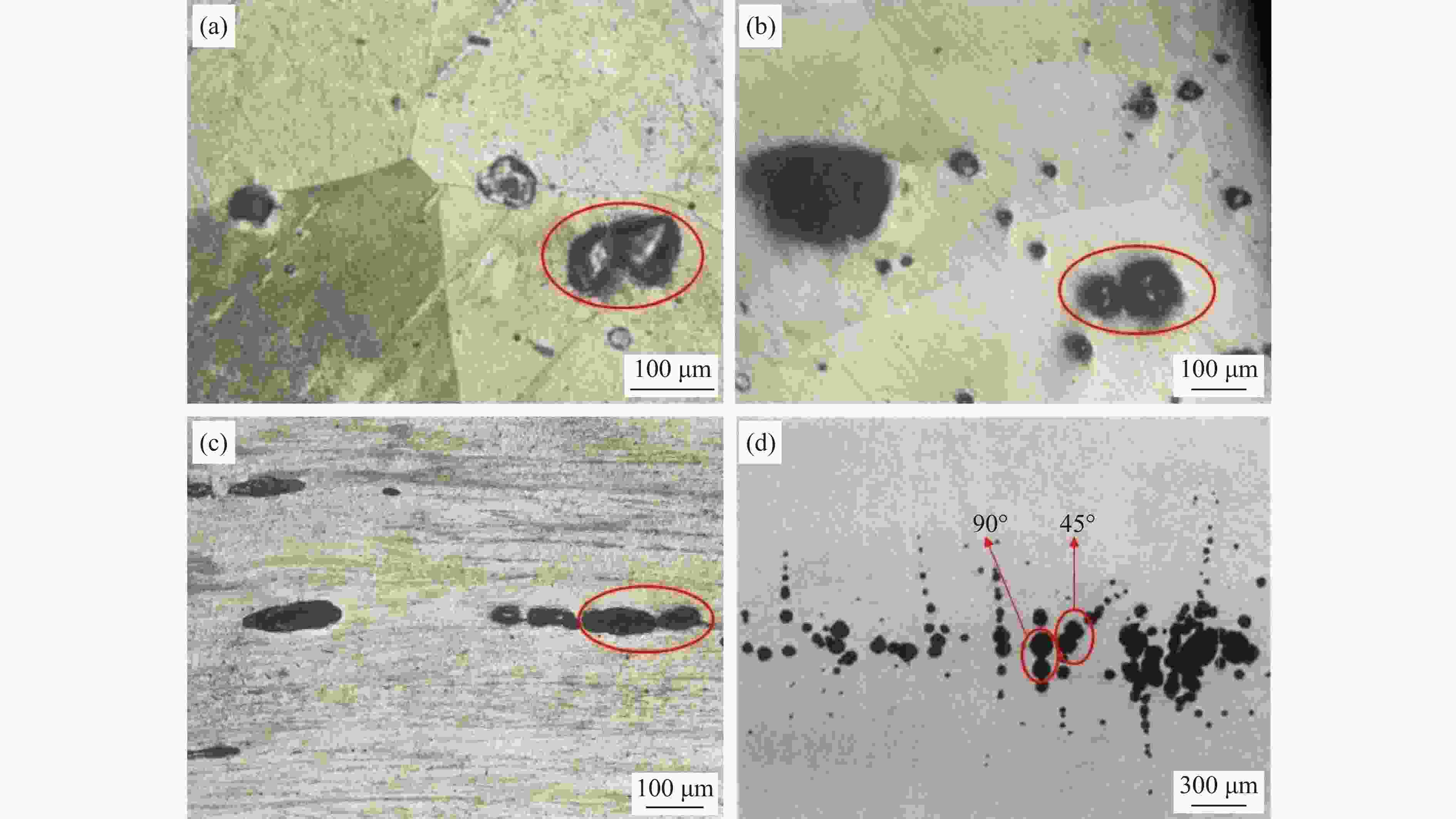

摘要: 延性金属的层裂行为包含孔洞成核、长大和聚集过程,其中孔洞聚集难以通过实验方法直接观测。采用有限元分析方法,研究了延性金属层裂过程中孔洞之间的聚集行为和竞争机制,讨论了孔洞间初始韧带距离、孔洞直径和孔洞位置分布对孔洞聚集的影响。通过实时统计孔洞长大过程中直径的变化,定量分析孔洞聚集的起始时刻。计算结果显示:当初始韧带距离由20 μm增加至50 μm时,相同孔径孔洞间聚集的起始时间不断延长,聚集时的直径增长加速度由1.717 Gm/s2降至0.602 Gm/s2;具有不同孔径比的孔洞之间发生聚集时,小孔优先向大孔靠拢;45°分布方式的孔洞在长大阶段的直径增长加速度最大,约为3.179 Gm/s2,且最早发生聚集。计算结果显示,在三孔聚集中,初始韧带距离和孔径相同的孔洞之间几乎同时发生聚集并贯通,且孔洞间聚集的起始时间随着初始韧带距离的增加而延长,大孔向附近小孔聚集的起始时刻较迟。计算结果揭示了层裂实验中难以观察到的孔洞长大和聚集的细观物理过程,对了解材料层裂的物理过程和本质具有重要的参考价值。Abstract: The spallation behavior of the ductile metals is a process involving nucleation, growth and coalescence of voids, and the coalescence of voids is difficult to directly observe experimentally. In this paper, the finite element analysis method was used to study the coalescence behavior and competition mechanism among the voids in the process of the ductile metal spallation. Influences of the initial ligament distance, the void diameter, and the void location distribution on the void coalescence were discussed. Through the real-time statistics of the change in diameter during the growth of the voids, the starting time of the coalescence of the voids was quantitatively analyzed. Results show that when the initial ligament distance increases from 20 μm to 50 μm, the initial time of coalescence among the same voids increases continuously, and the accelerations of the diameter increase decreases from about 1.717 Gm/s2 to 0.602 Gm/s2. When the coalescence occurs between voids with different aperture ratios, small voids preferentially aggregate to big voids. Voids with an angle of 45° have the largest diameter growth acceleration about 3.179 Gm/s2 in the growth stage, and the earliest coalescence occurs. For the coalescence among three voids, the calculation results show that the same voids with the same initial ligament distance aggregate and penetrate almost simultaneously, and the starting time of the coalescence between the voids increases with the increasing of the initial ligament distance. The aggregation of big voids to nearby small voids start later. Calculations in this paper reveal the mesoscopic physical process of void growth and coalescence, which is difficult to observe in spallation experiments, and have important reference value for the entire physical process and nature of the material spallation.

-

Key words:

- ductile metals /

- spallation /

- voids coalescence /

- numerical simulation

-

表 1 高纯铜的Johnson-Cook本构、损伤及状态方程参数[20-21]

Table 1. Johnson-Cook constitutive, damage and equation of state parameters of high-purity copper[20-21]

ρ/(kg·m-3) A/MPa B/MPa C m n ${\dot \varepsilon}_0$/s–1 Troom/K Tmelt/K 8910 90 292 0.025 1.09 0.31 1 300 1356 C0/(m·s-1) s Γ0 G/GPa d1 d2 d3 d4 d5 3910 1.51 2 46.6 0.54 4.89 3.03 0.014 1.12 -

[1] ANTOUN T, CURRAN D R, SEAMAN L, et al. Spall fracture [M]. Berlin: Springer, 2003. [2] MALLICK D D, PARKER J, WILKERSON J W, et al. Estimating void nucleation statistics in laser-driven spall [J]. Journal of Dynamic Behavior of Materials, 2020, 6(3): 268–277. doi: 10.1007/s40870-020-00248-6 [3] JONES D R, FENSIN S J, MARTINEZ D T, et al. Effect of peak stress and tensile strain-rate on spall in tantalum [J]. Journal of Applied Physics, 2018, 124(8): 085901. doi: 10.1063/1.5045045 [4] XIE P C, WANG Y G, SHI T Y, et al. Damage evolution and spall failure in copper under complex shockwave loading conditions [J]. Journal of Applied Physics, 2020, 128(5): 055111. doi: 10.1063/5.0009521 [5] 陈伟, 谢普初, 刘东升, 等. 晶粒尺寸对高纯铝板材层裂特性的影响 [J]. 爆炸与冲击, 2021, 41(4): 043102.CHEN W, XIE P C, LIU D S, et al. Effect of grain size on the spall behaviors of high-purity aluminum plates [J]. Explosion and Shock Waves, 2021, 41(4): 043102. [6] CURRAN D R, SEAMAN L, SHOCKEY D A. Dynamic failure of solids [J]. Physics Reports, 1987, 147(5/6): 253−388. [7] JOHNSON J N. Dynamic fracture and spallation in ductile solids [J]. Journal of Applied Physics, 1981, 52(4): 2812–2825. doi: 10.1063/1.329011 [8] 王永刚. 延性金属动态拉伸断裂及其临界损伤度研究 [D]. 绵阳: 中国工程物理研究院, 2006: 39−47.WANG Y G. Study on dynamic tensile fracture and critical damage degree of ductile metals [D]. Mianyang: China Academy of Engineering Physics, 2006: 39−47. [9] ZUREY A K, THISSELL W R, JOHNSON J N, et al. Micromechanics of spall and damage in tantalum [J]. Journal of Materials Processing Technology, 1996, 60(1): 261−267. [10] TU R C, WEI N, PEI Y M, et al. The effect of compression on the void coalescence under strong dynamic loading [J]. Advances in Materials Science and Engineering, 2022: 1–11. [11] YANG X, ZENG X, WANG J, et al. Atomic-scale modeling of the void nucleation, growth, and coalescence in Al at high strain rates [J]. Mechanics of Materials, 2019, 135(1): 98–113. [12] ZHAO L Y, LIU Y. Investigation on void growth and coalescence in single crystal copper under high-strain-rate tensile loading by atomistic simulation [J]. Mechanics of Materials, 2020, 151(1): 103615. [13] 王永刚, 徐东明. 高应变率下延性金属中微孔洞贯通行为的数值分析 [J]. 兵工学报, 2012, 33(9): 1095–1100.WANG Y G, XU D M. Simulation of void coalescence in ductile metals under high strain rate [J]. Acta Armamentarii, 2012, 33(9): 1095–1100. [14] HURE J. A coalescence criterion for porous single crystals [J]. Journal of the Mechanics and Physics of Solids, 2019, 124(1): 505–525. [15] HOLTE I, SRIVASTAVA A, MARTINEZ-PAEDA E, et al. Interaction of void spacing and material size effect on inter-void flow localization [J]. American Society of Mechanical Engineers Digital Collection, 2021, 88(2): 021010. [16] JIANG Z X, ZHONG Z, XIE P C, et al. Characteristics of the damage evolution and the free surface velocity profile with dynamic tensile spallation [J]. Journal of Applied Physics, 2022, 131(12): 125104. doi: 10.1063/5.0082361 [17] 陈伟. 晶粒尺寸对高纯铝动态力学行为与层裂特性的影响 [D]. 宁波: 宁波大学, 2020: 53−58.CHEN W. Effect of grain size on dynamic mechanical behavior and spallation characteristics of high-purity aluminum [D]. Ningbo: Ningbo University, 2020: 53−58. [18] 祁美兰. 高纯铝拉伸型动态破坏的临界行为研究 [D]. 武汉: 武汉理工大学, 2007: 44−46.QI M L. Critical behavior in dynamic tensile fracture of high purity aluminum [D]. Wuhan: Wuhan University of Technology, 2007: 44−46. [19] WILKERSON J W, RAMESH K T. Unraveling the anomalous grain size dependence of cavitation [J]. Physical Review Letters, 2016, 117(21): 215503. doi: 10.1103/PhysRevLett.117.215503 [20] 徐金中, 汤文辉. SPH方法在层裂损伤模拟中的应用 [J]. 强度与环境, 2009, 36(1): 1–7. doi: 10.3969/j.issn.1006-3919.2009.01.001XU J Z, TANG W H. Applications of SPH method to simulate spalling damage [J]. Structure & Environment Engineering, 2009, 36(1): 1–7. doi: 10.3969/j.issn.1006-3919.2009.01.001 [21] 汤铁钢, 刘仓理. 高应变率拉伸加载下无氧铜的本构模型 [J]. 爆炸与冲击, 2013, 33(6): 581–586. doi: 10.3969/j.issn.1001-1455.2013.06.004TANG T G, LIU C L. On the constitutive model for oxygen-free high-conductivity copper under high strain-rate tension [J]. Explosion and Shock Waves, 2013, 33(6): 581–586. doi: 10.3969/j.issn.1001-1455.2013.06.004 -

下载:

下载: