Effect of Constraints on the Penetration Resistance of Ceramic/Steel Composite Target Plate

-

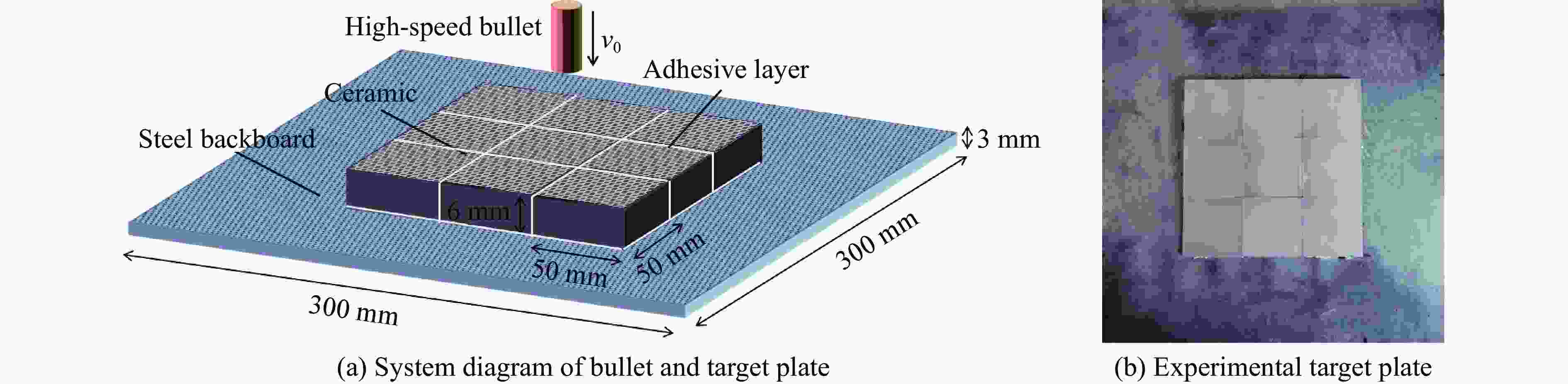

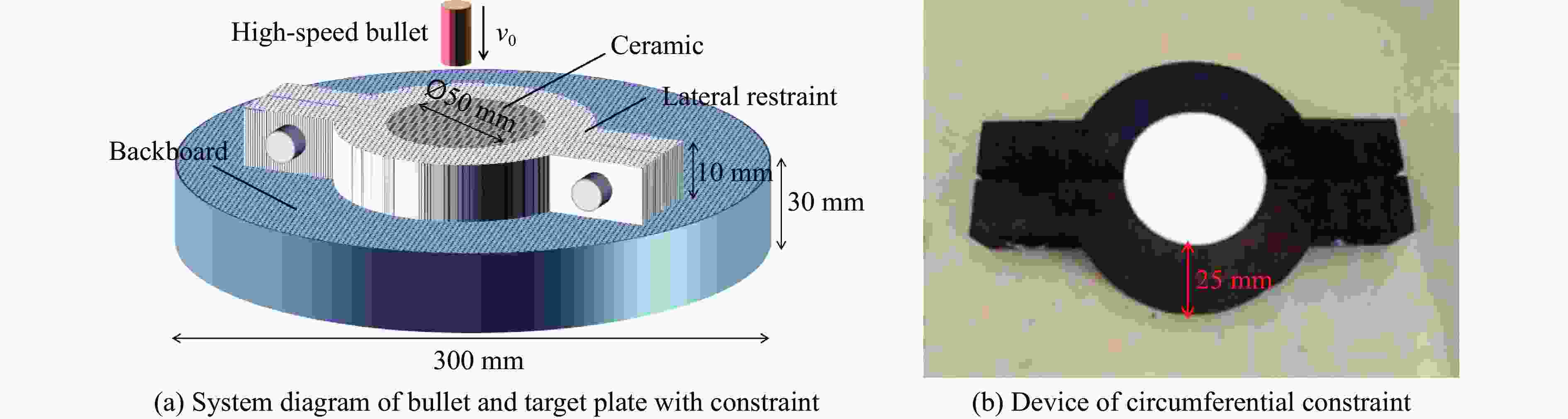

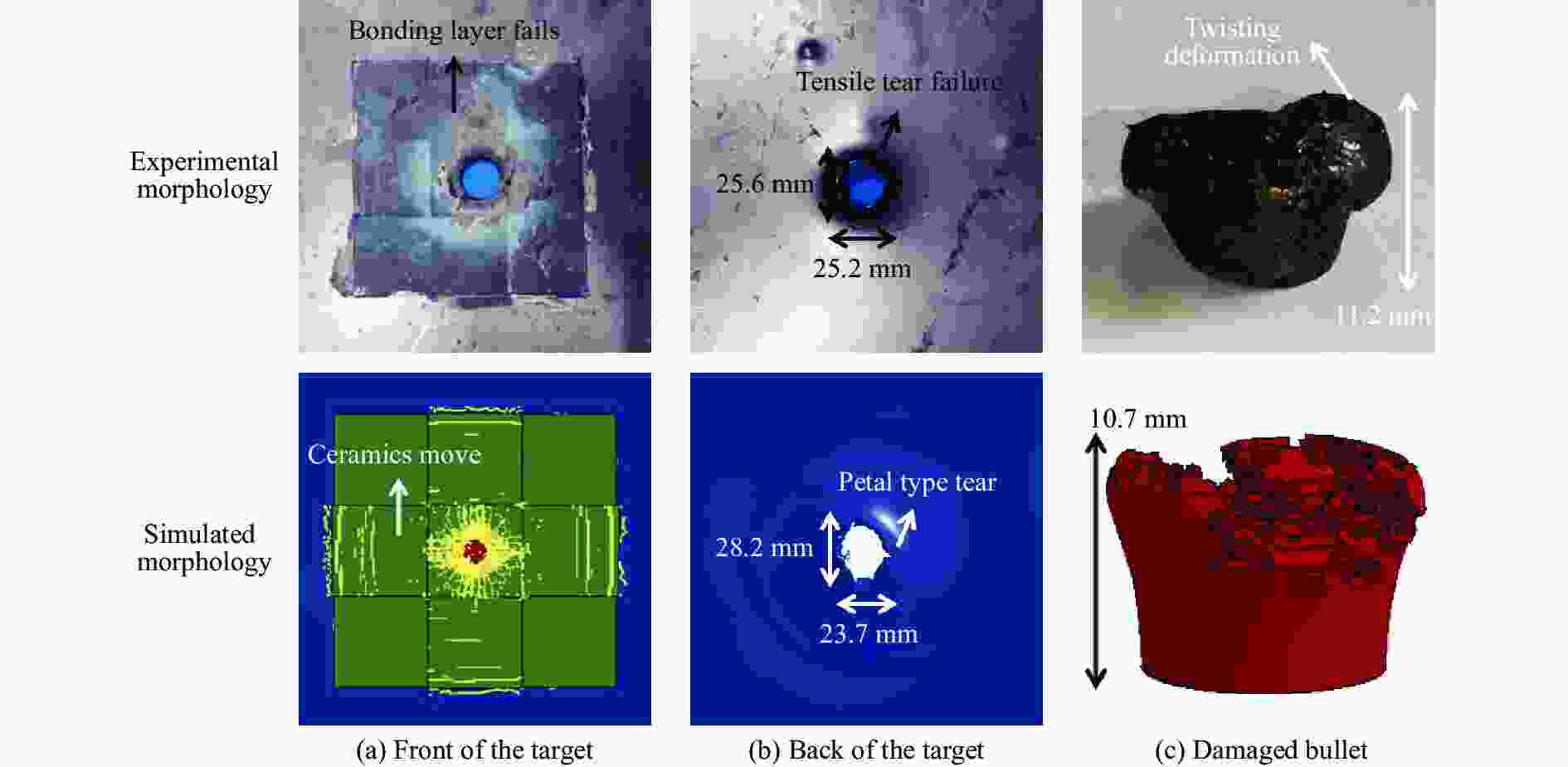

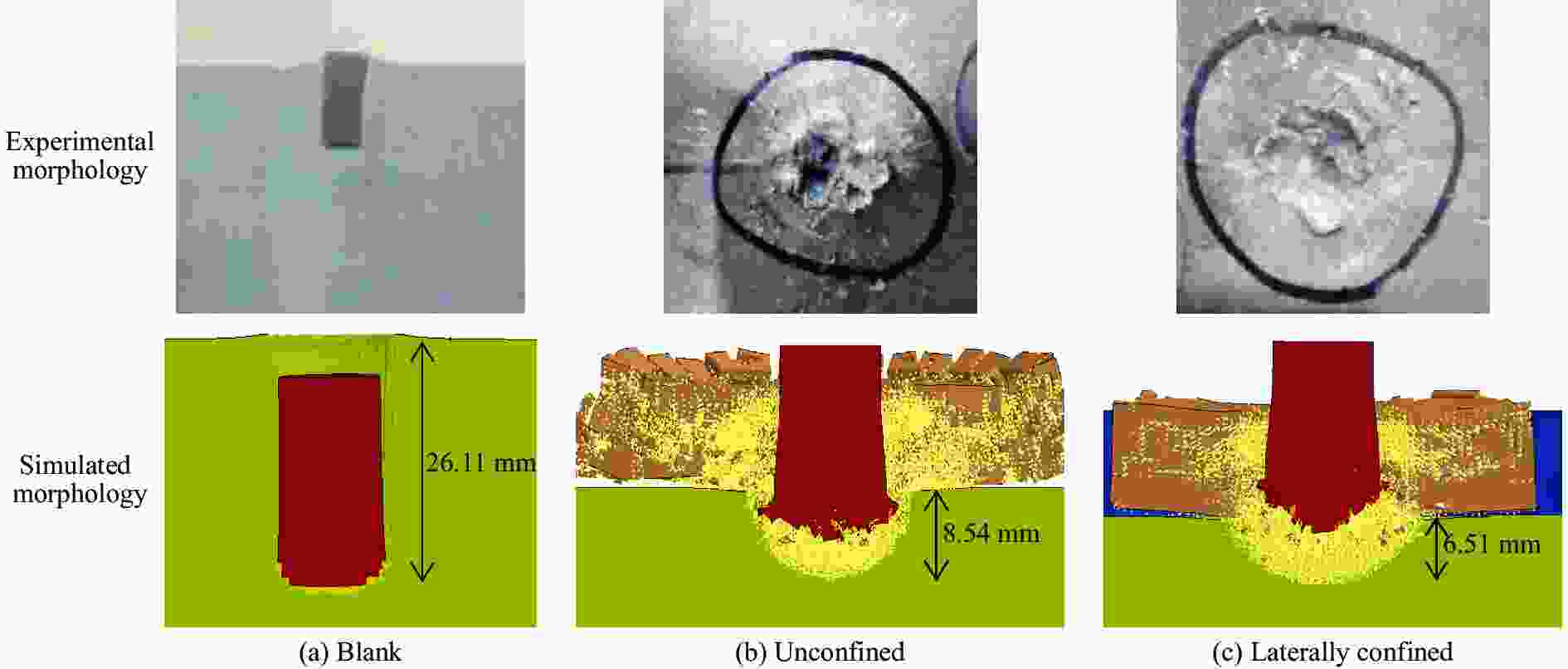

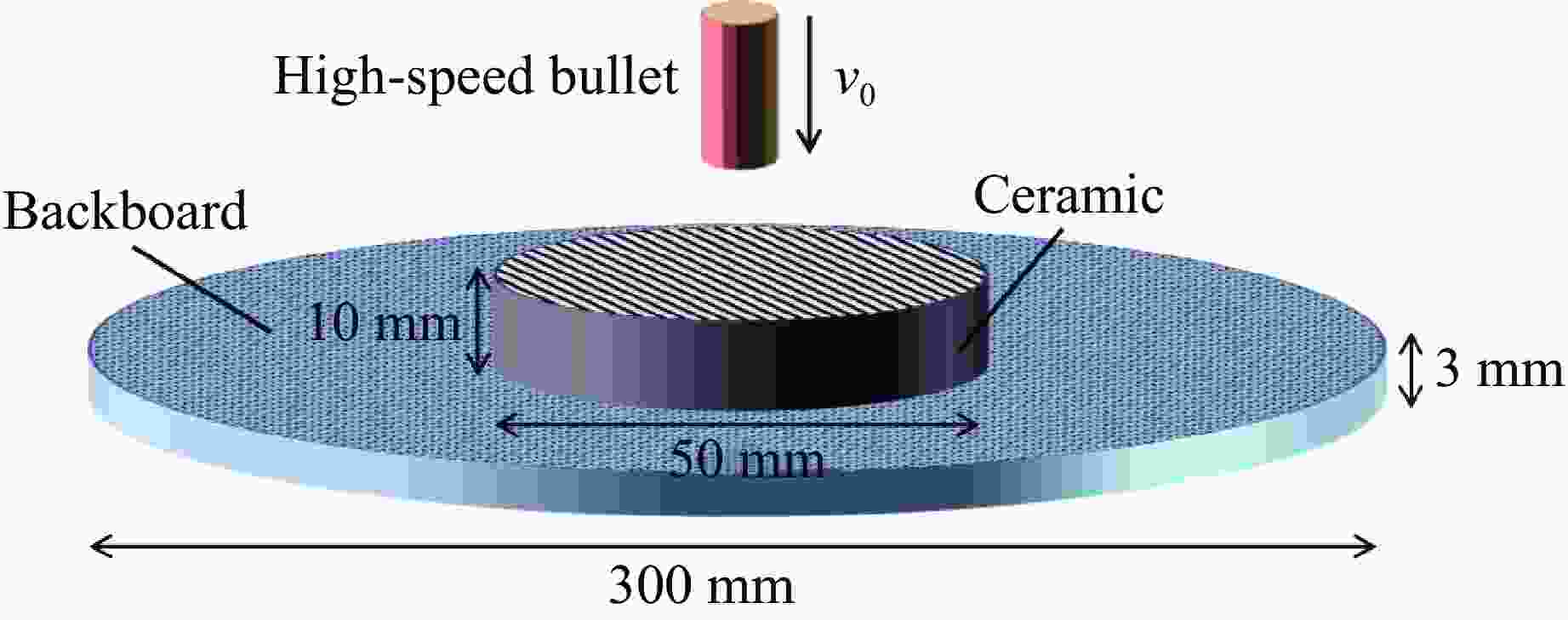

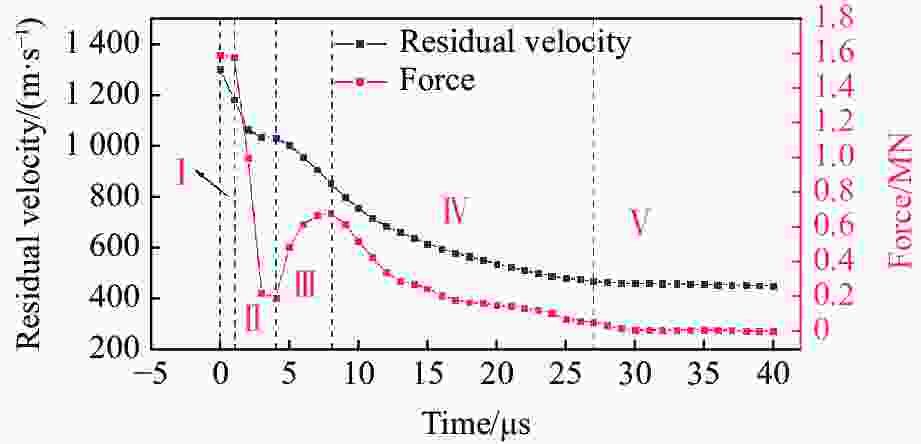

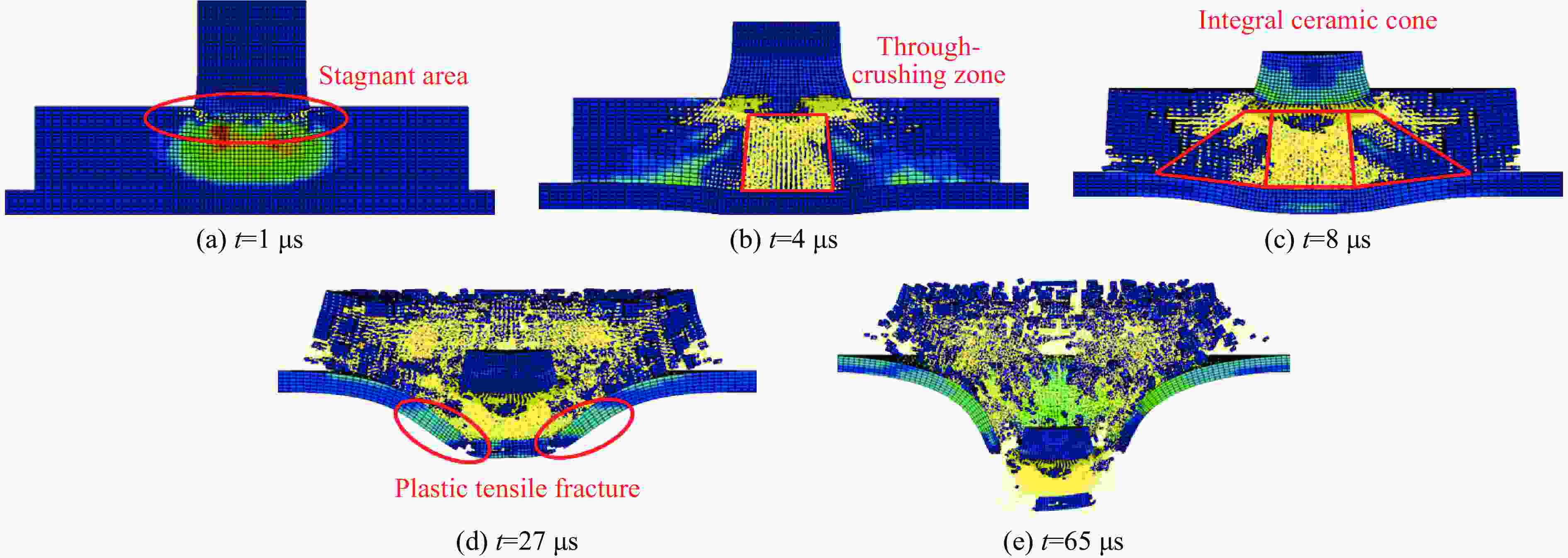

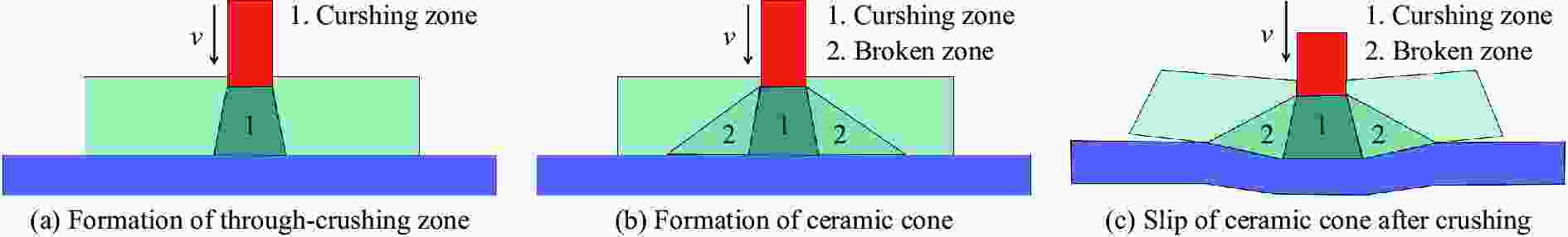

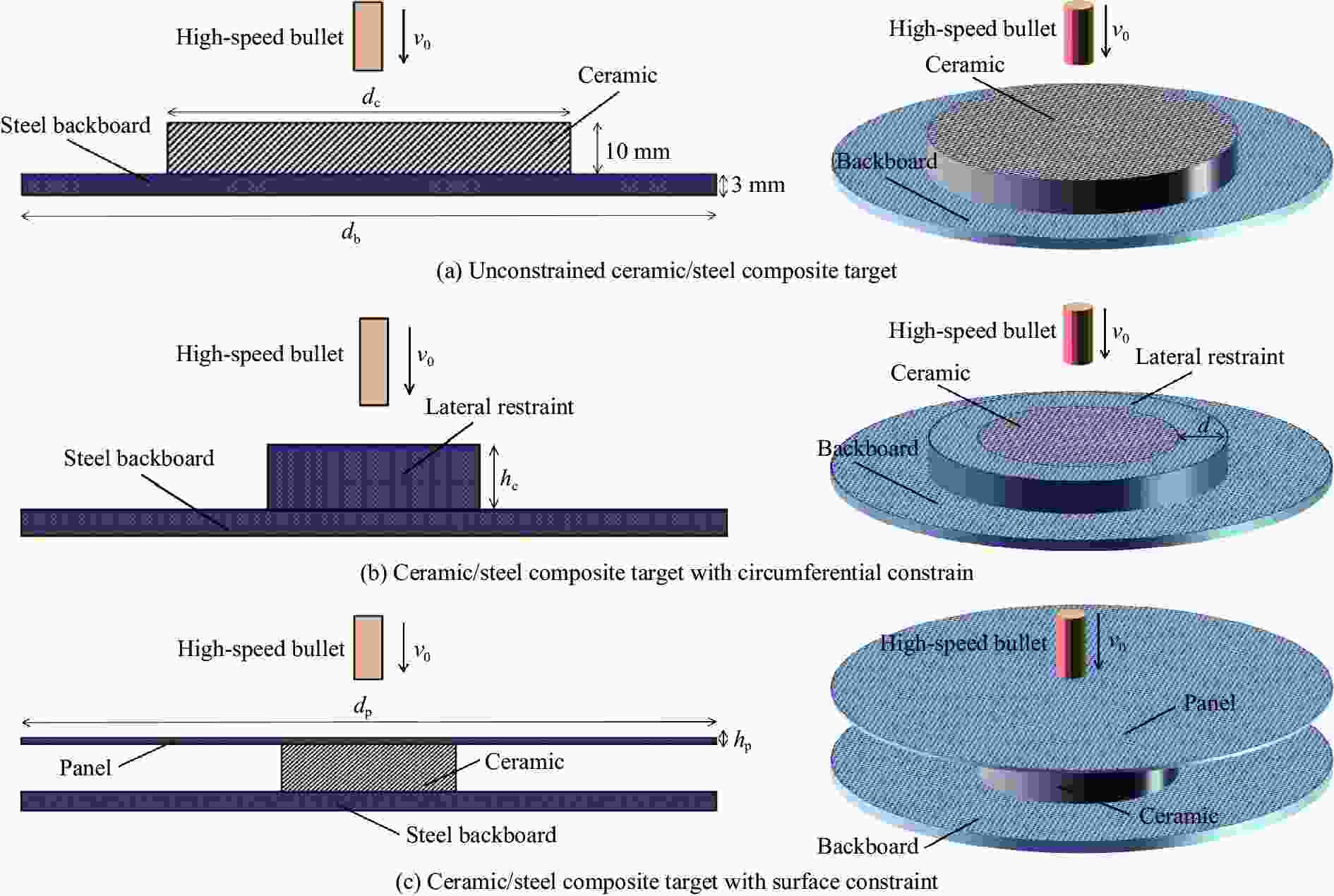

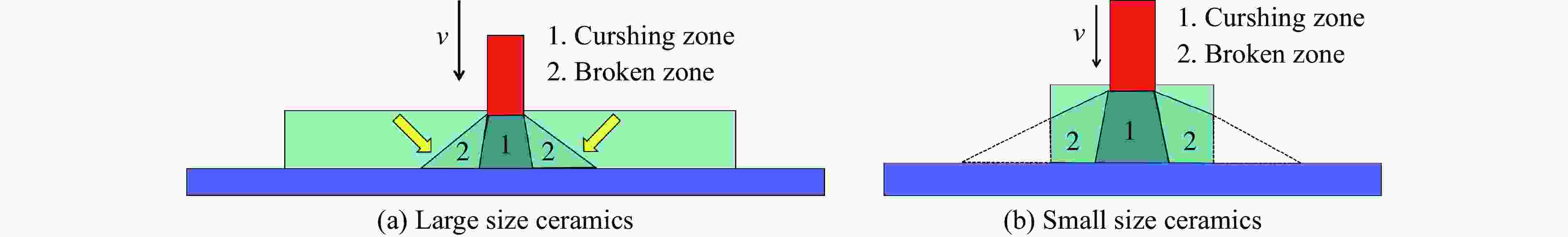

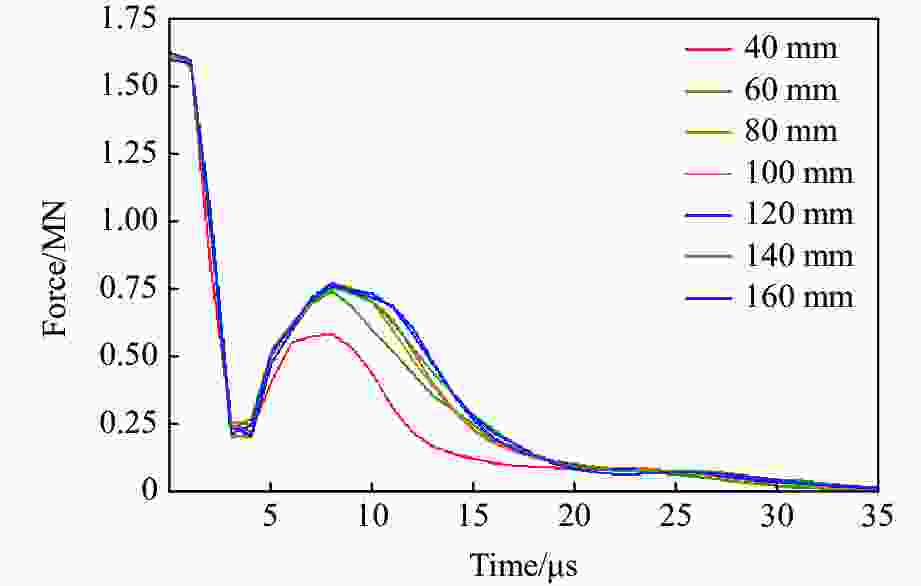

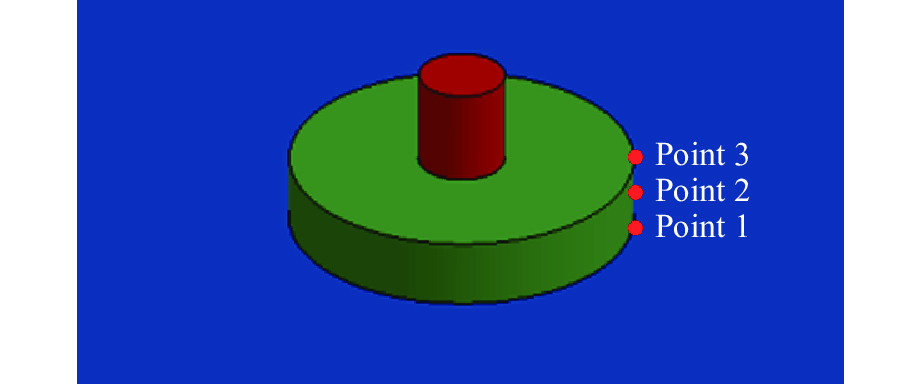

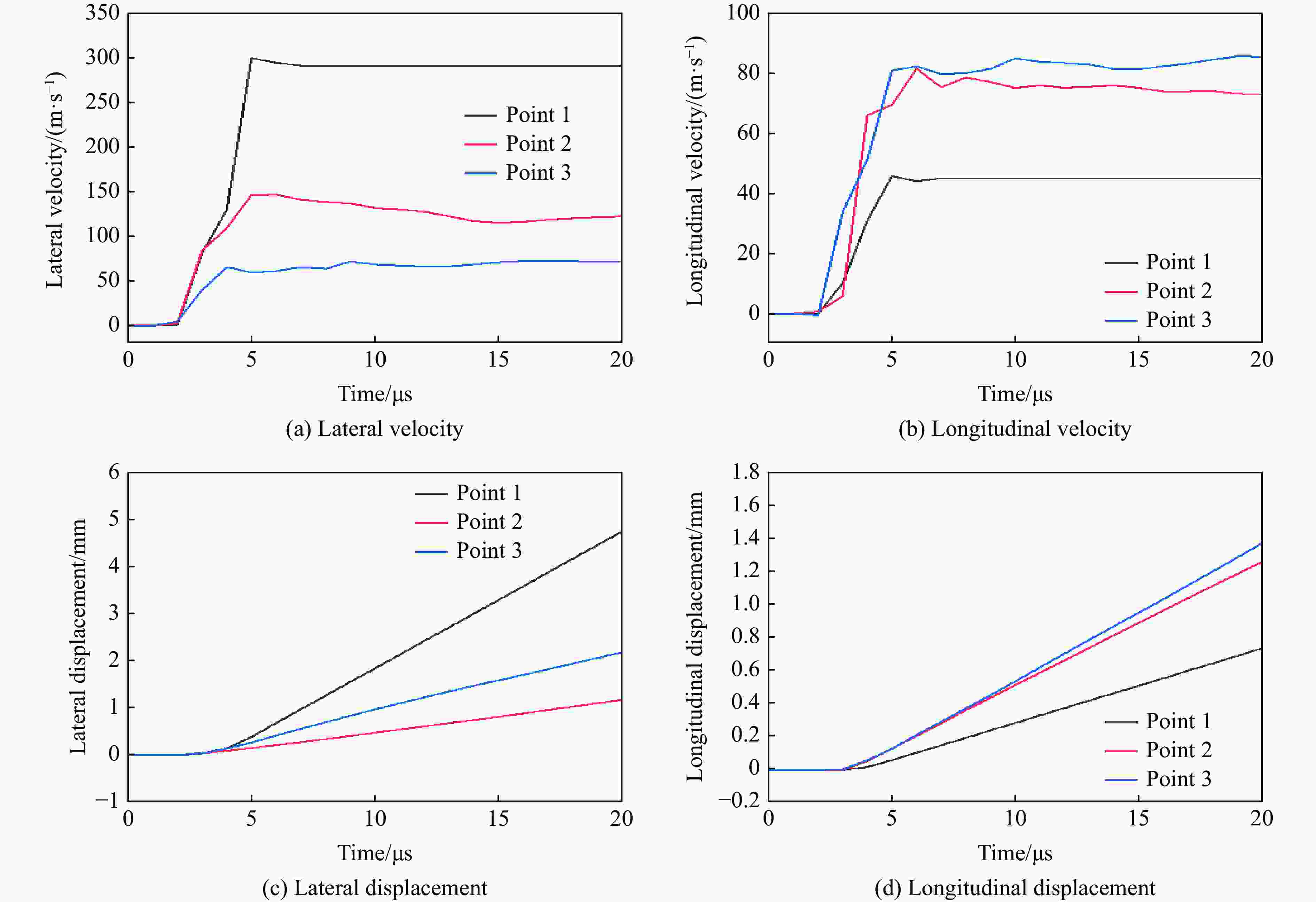

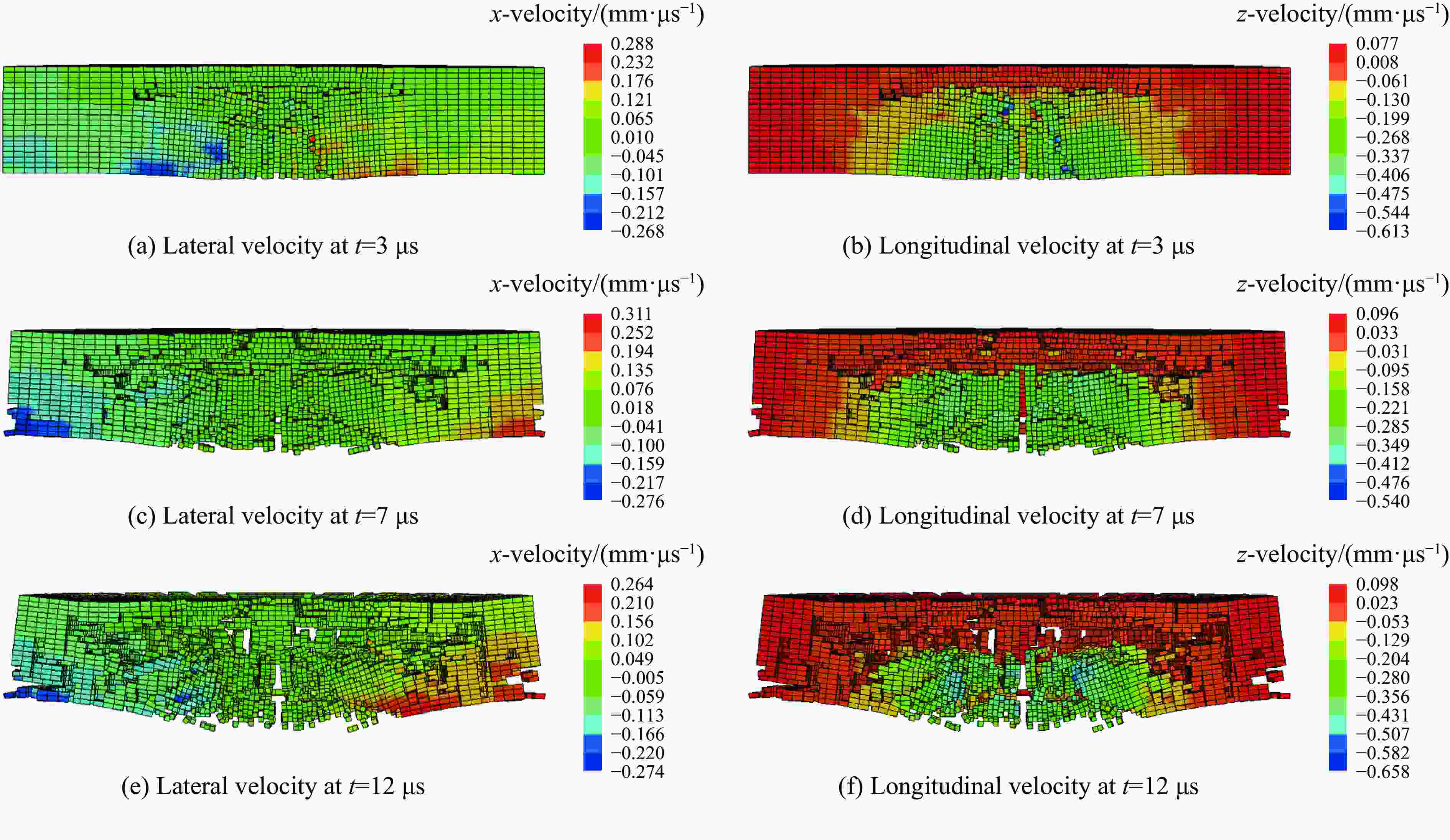

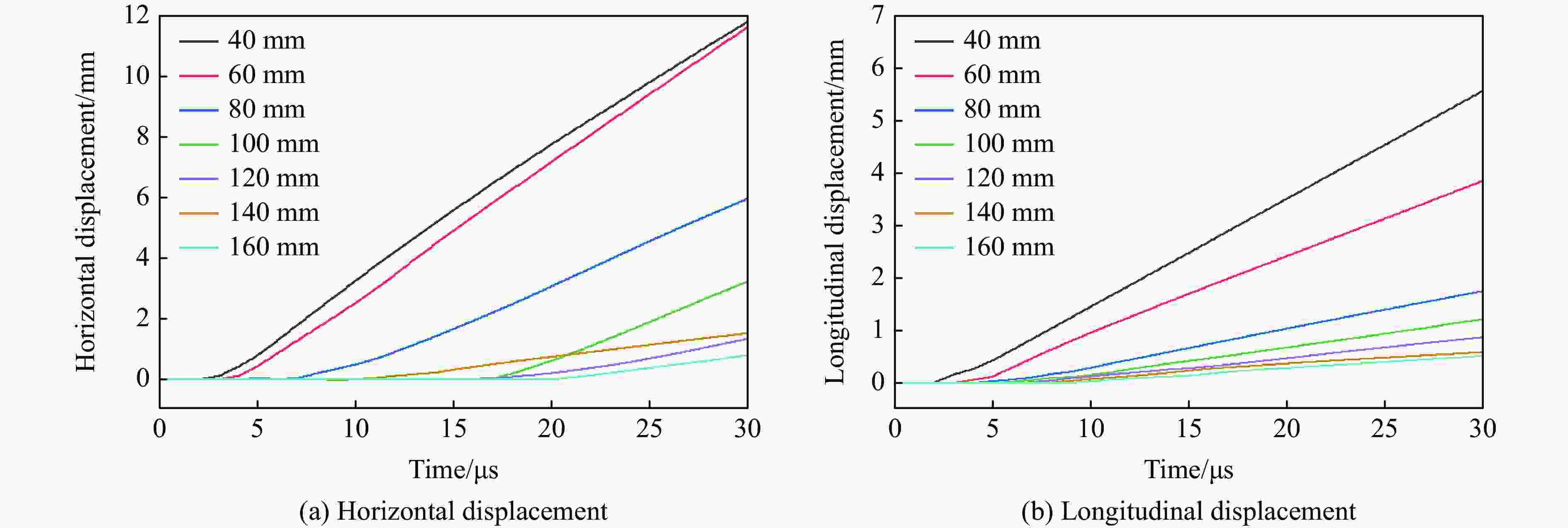

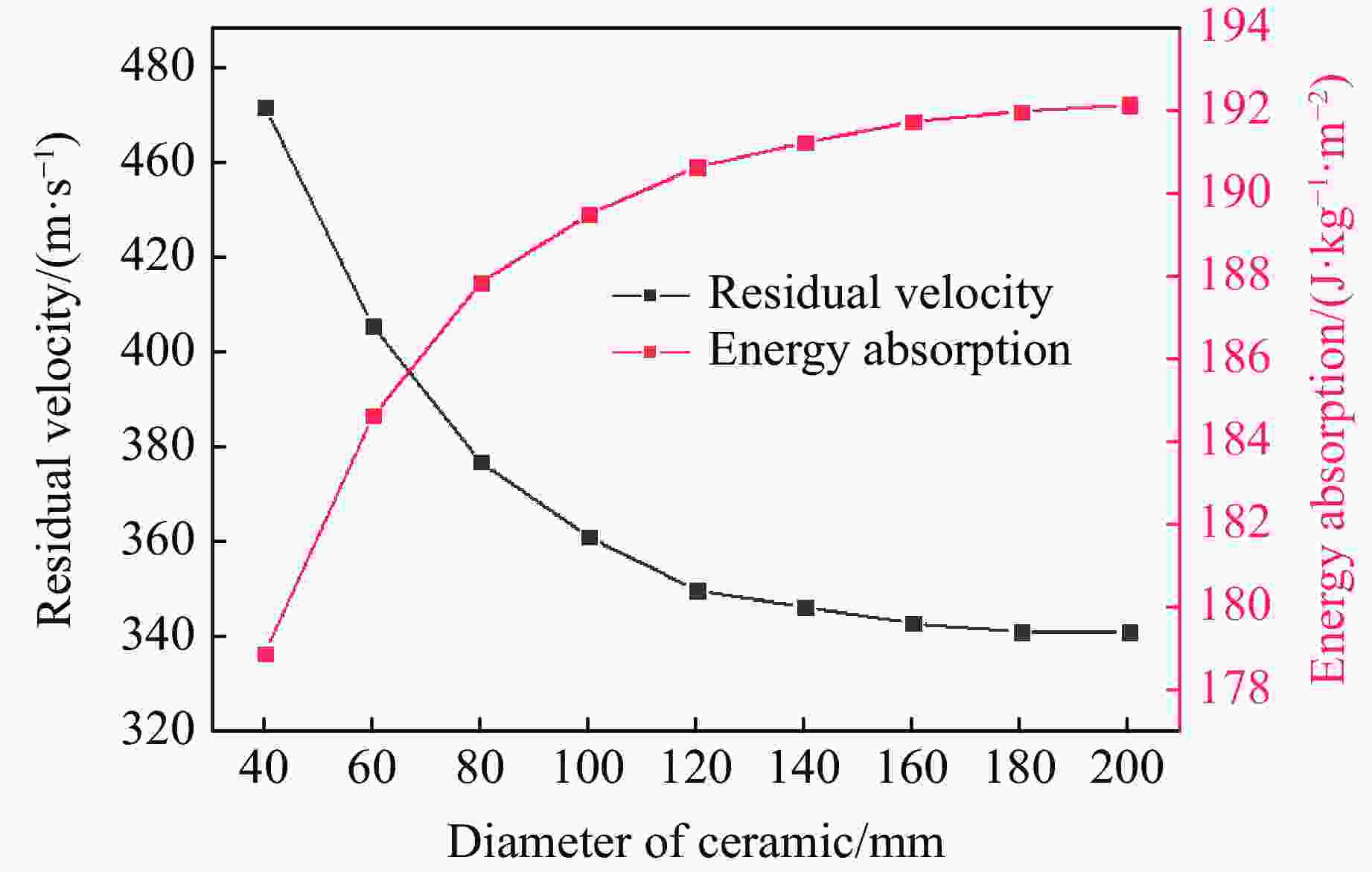

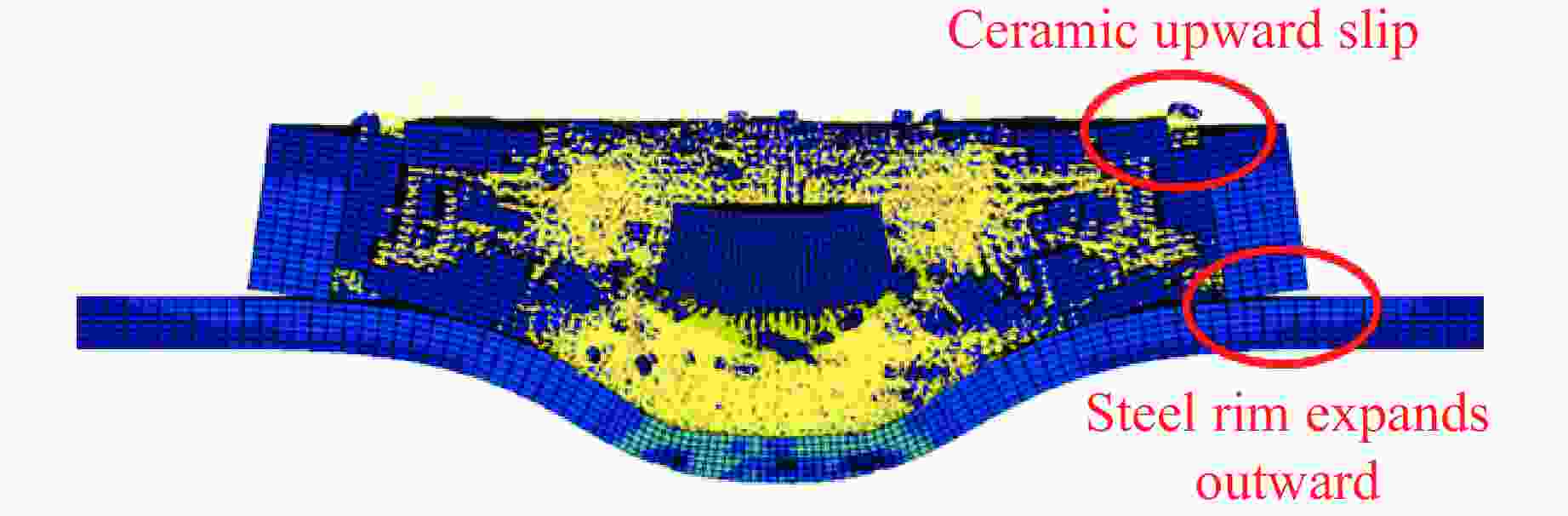

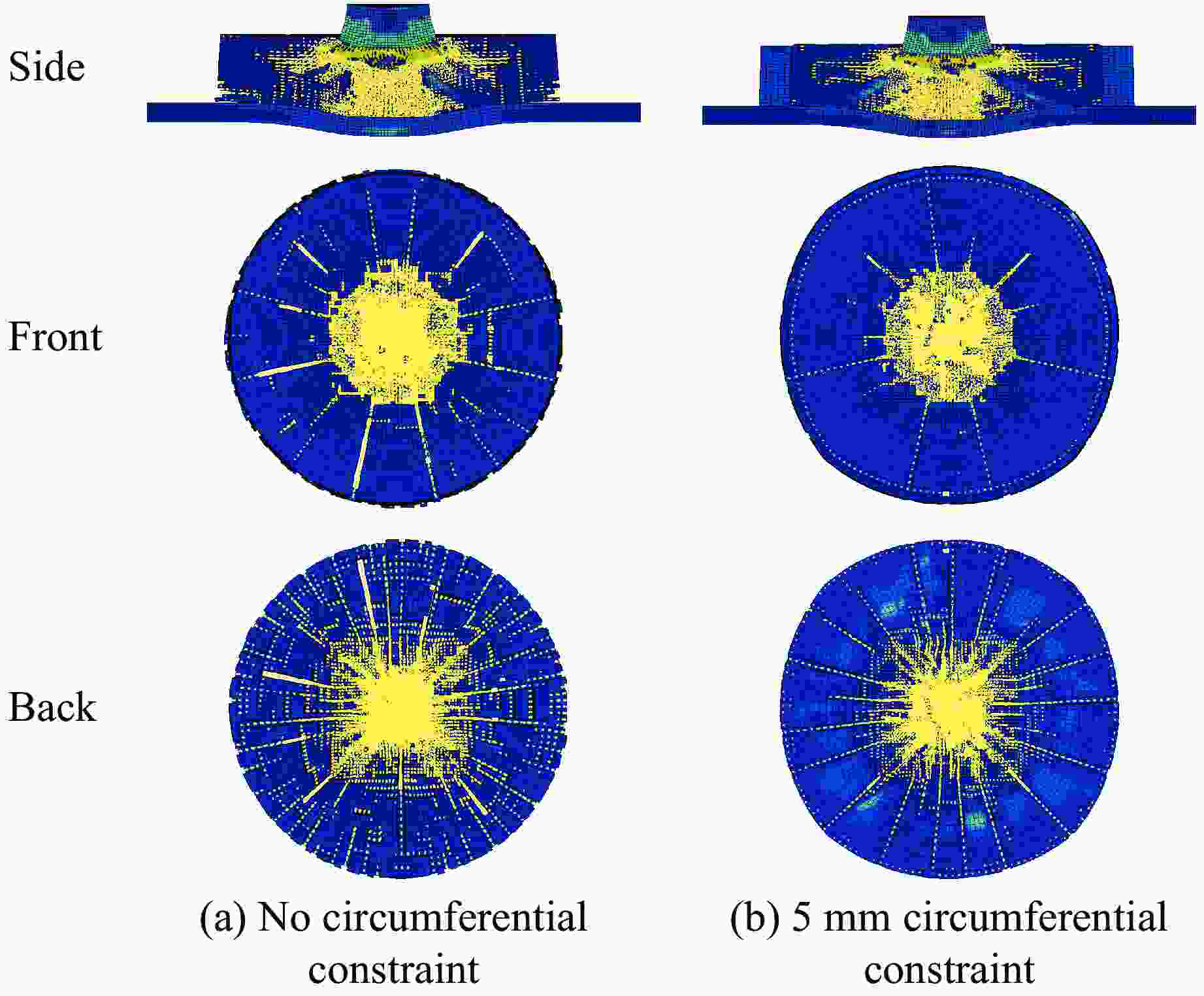

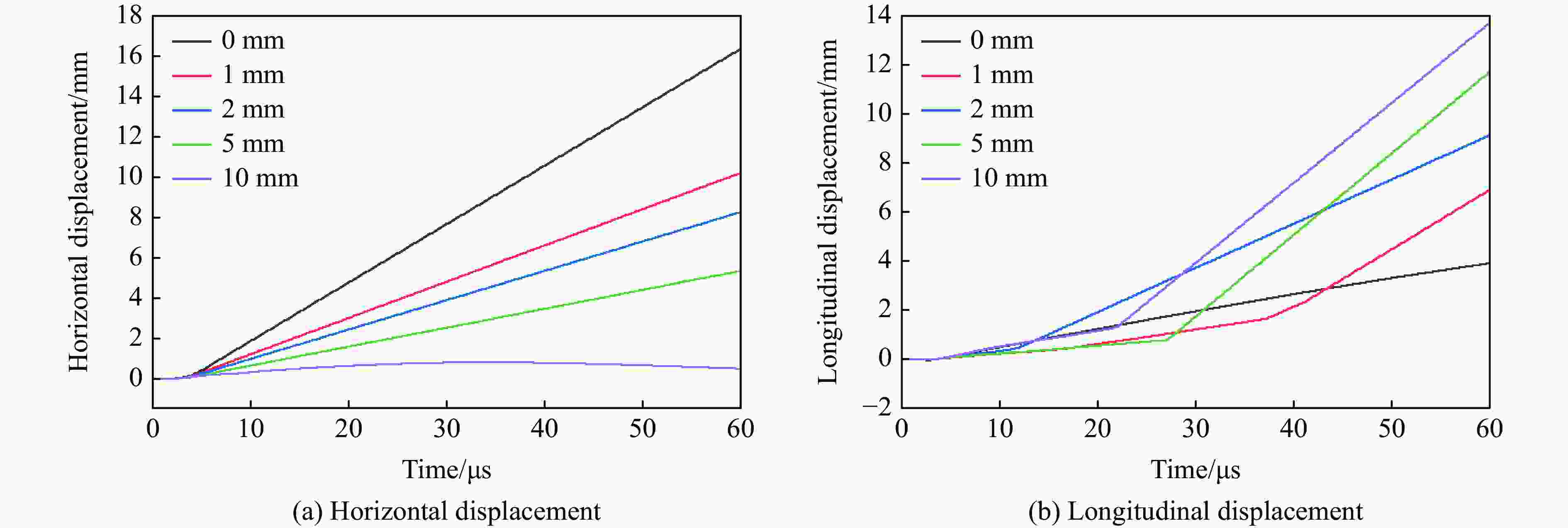

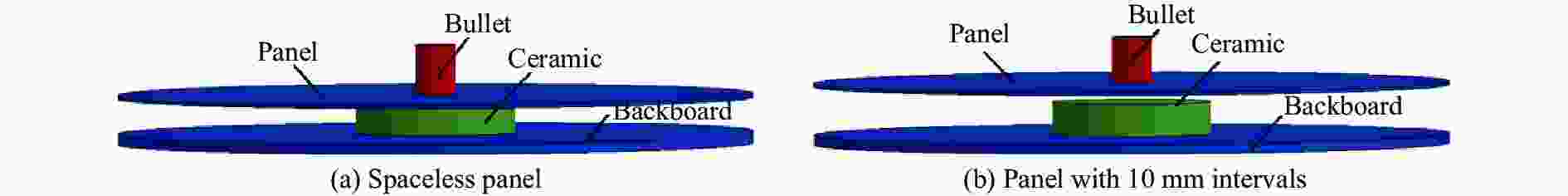

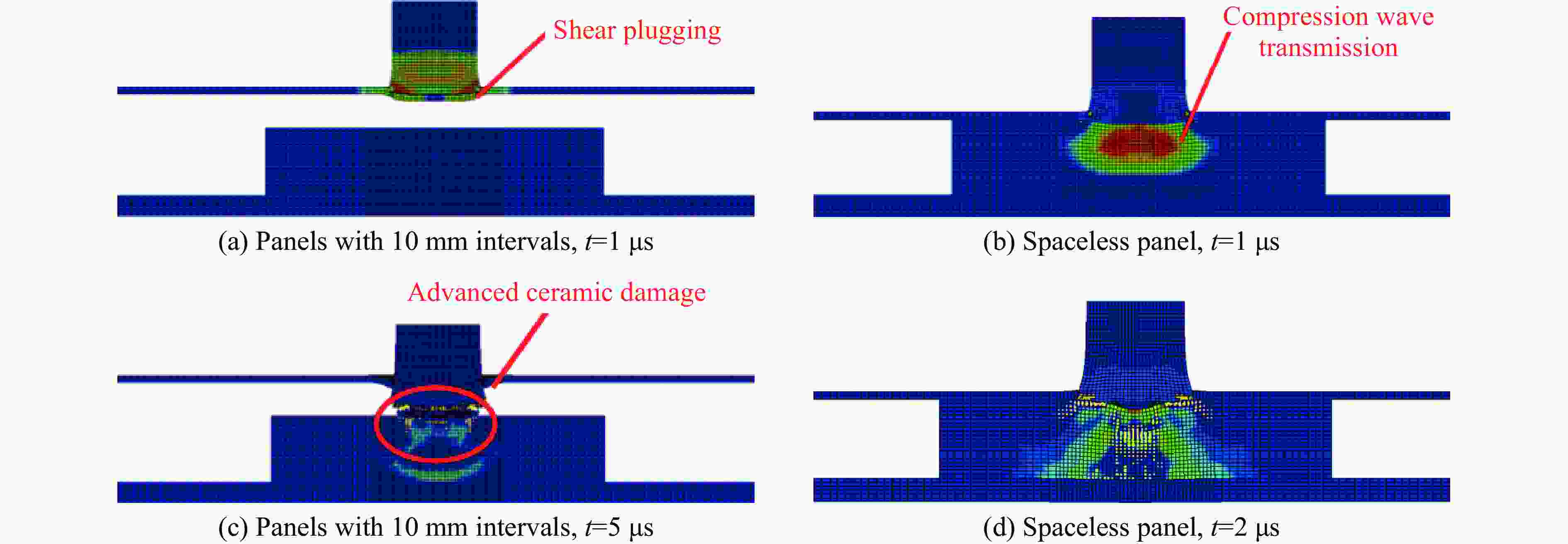

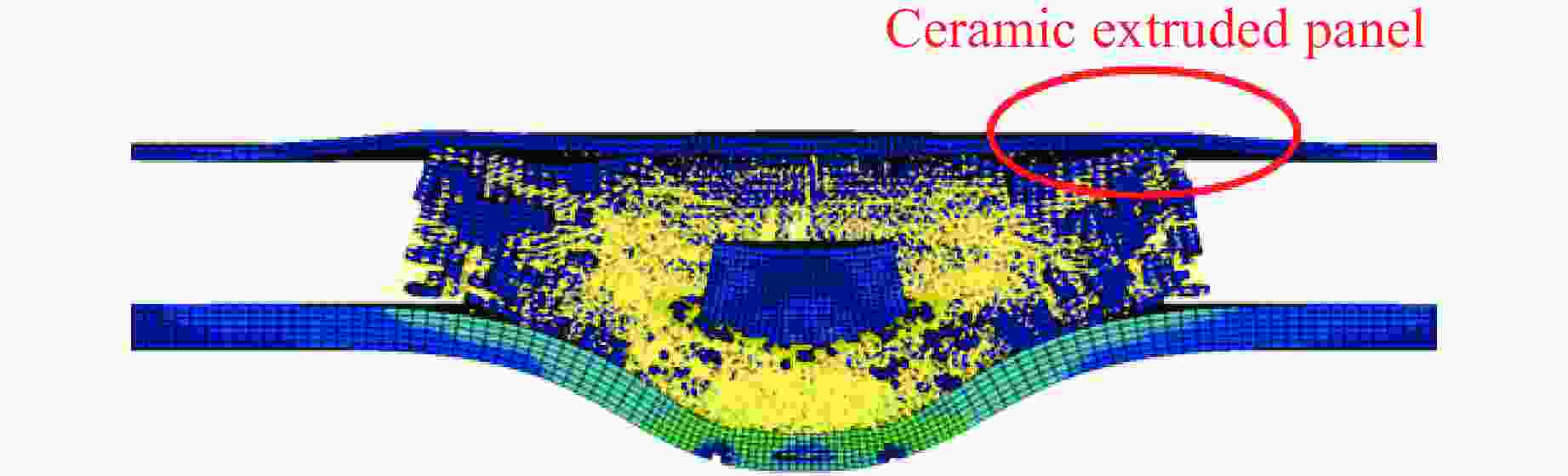

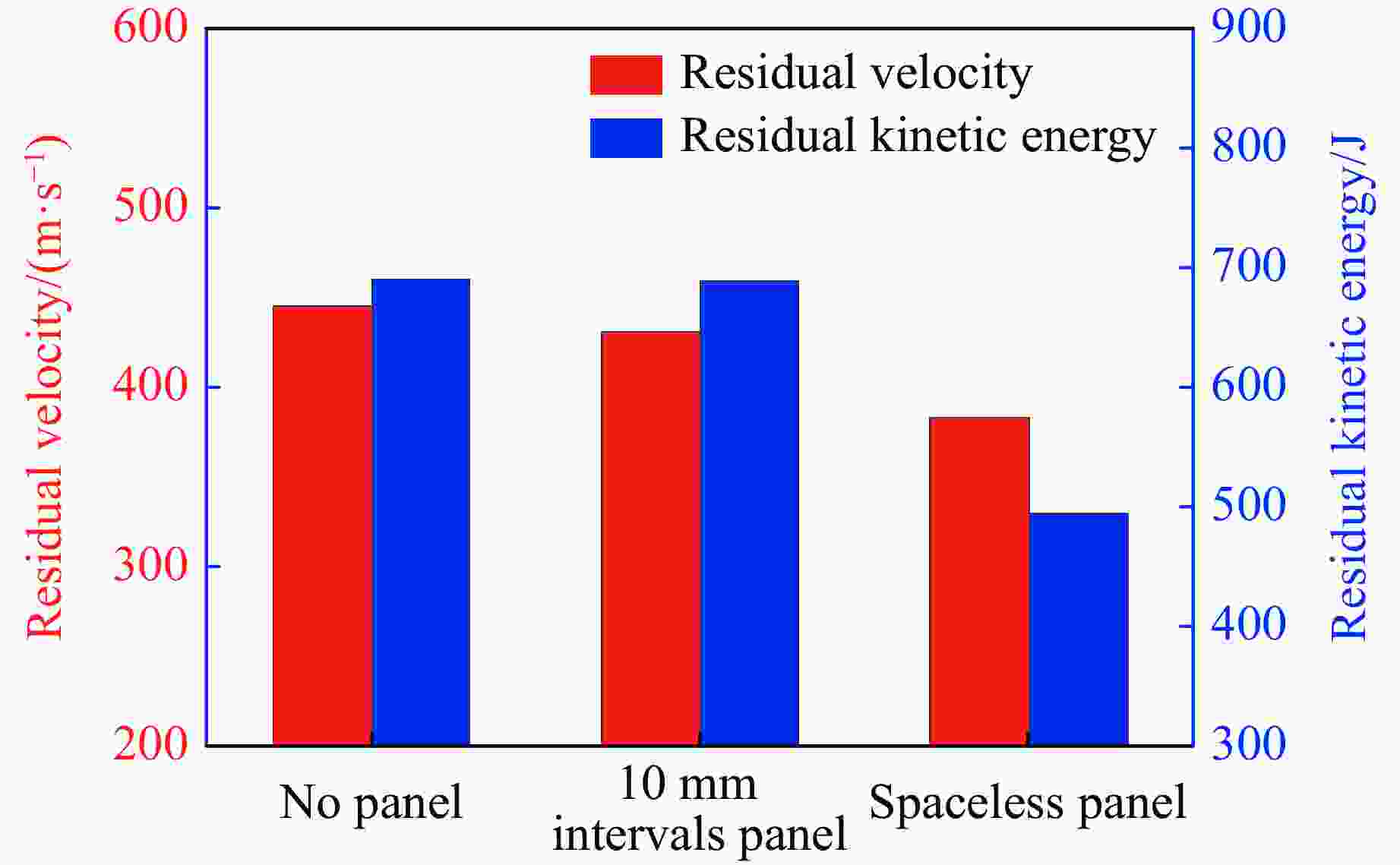

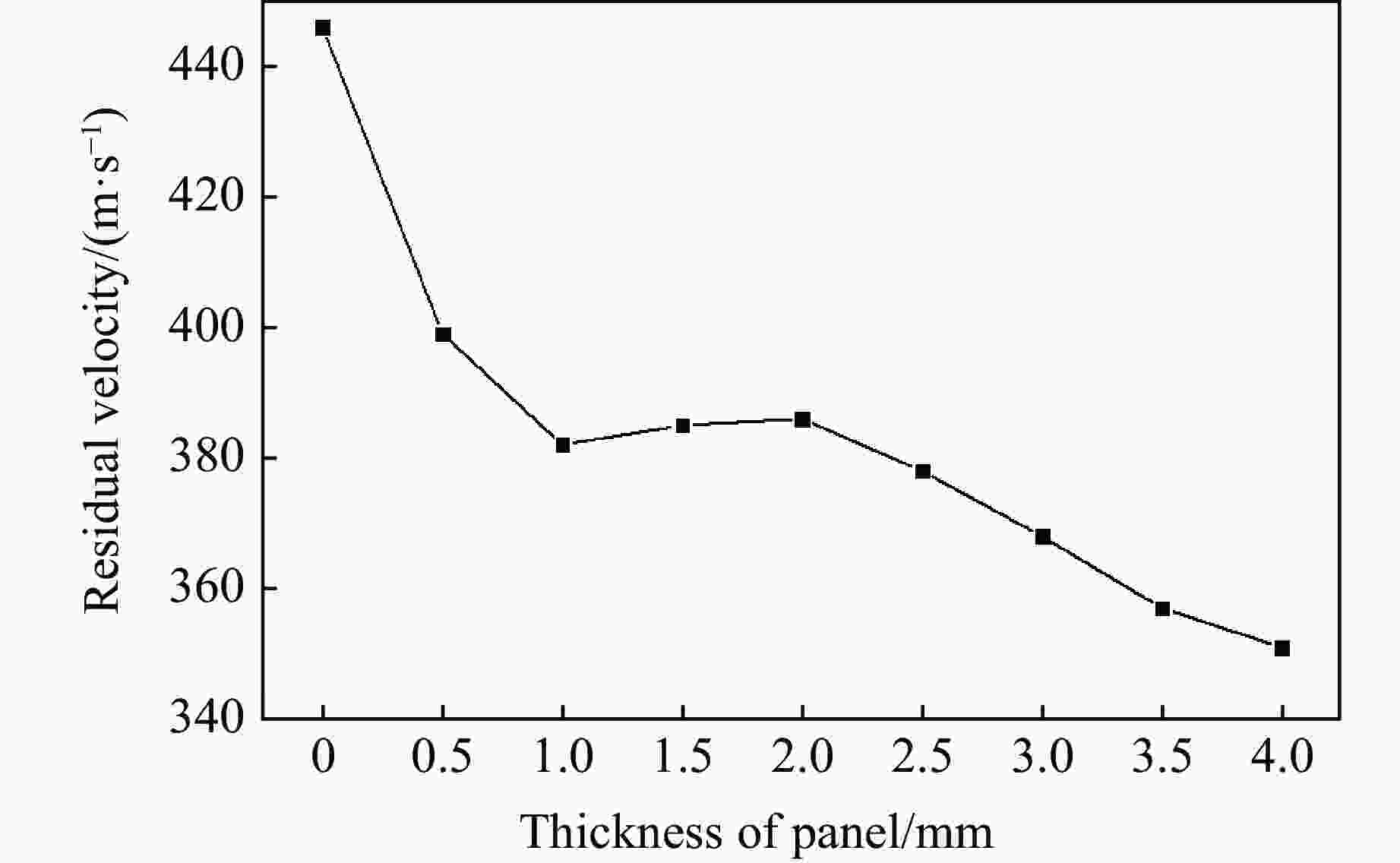

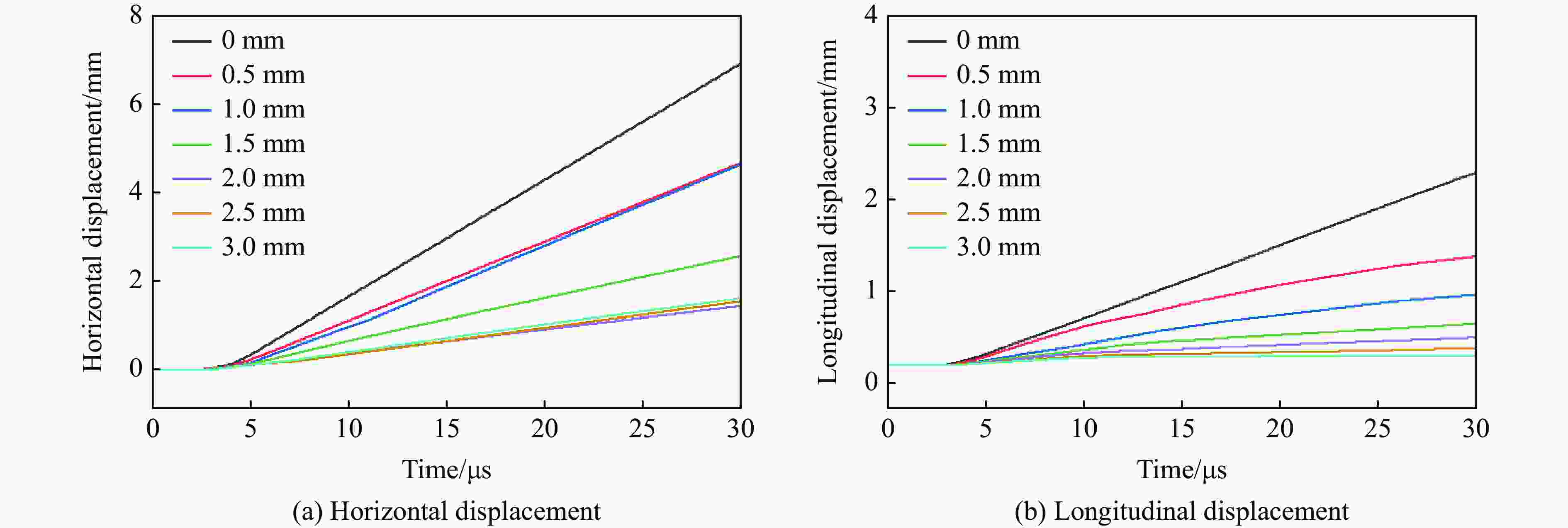

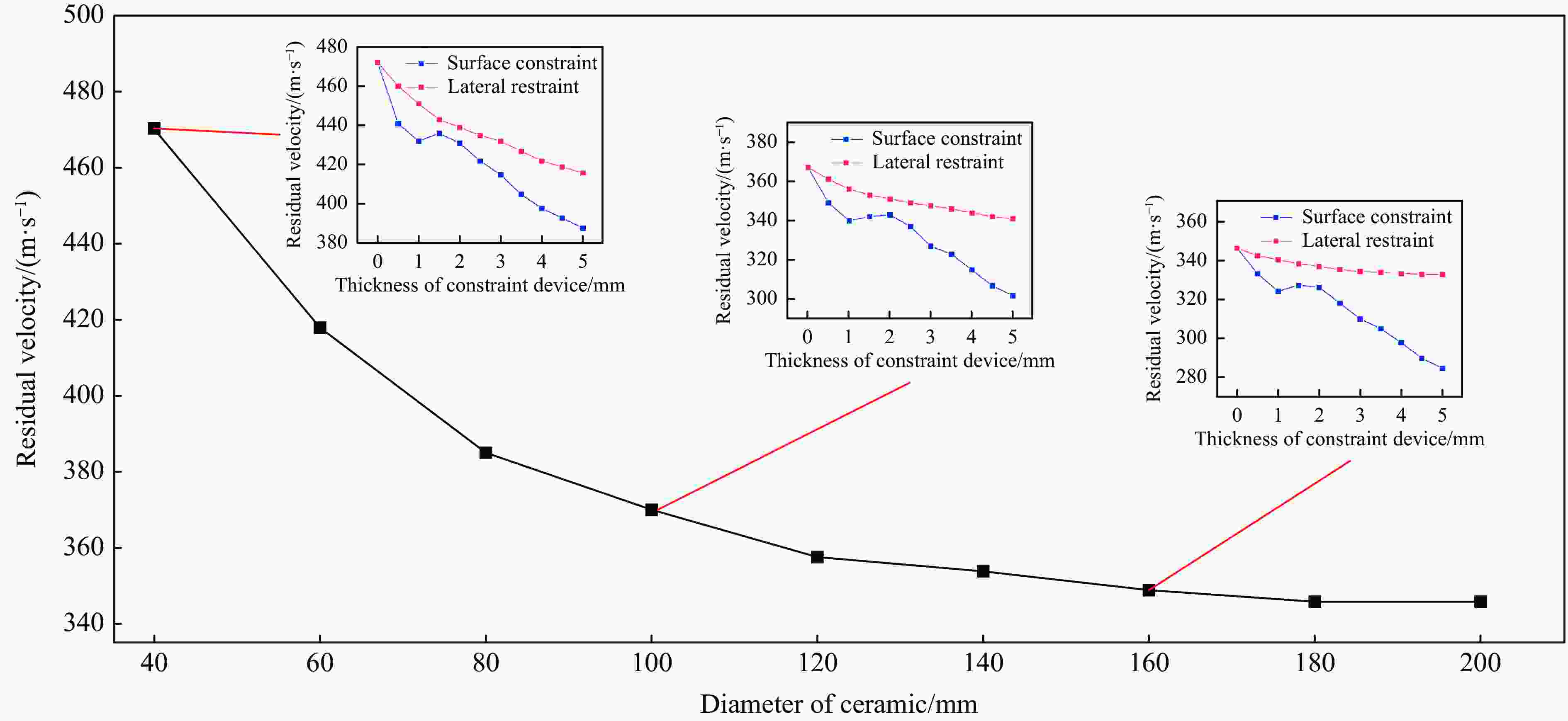

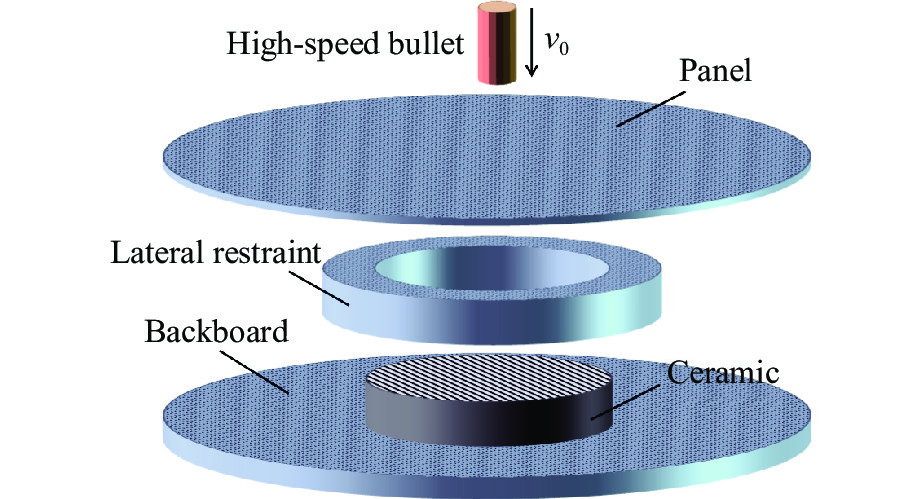

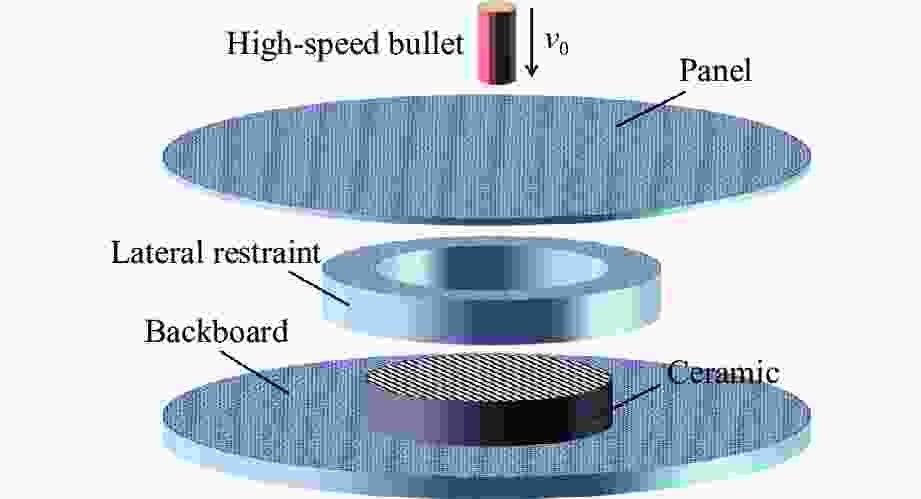

摘要: 为探究施加约束对陶瓷破碎位移规律和陶瓷复合装甲抗侵彻性能的影响,采用光滑粒子流体动力学-有限元法(SPH-FEM)对柱状弹侵彻陶瓷/钢复合靶板进行了数值模拟,根据陶瓷复合装甲的破坏响应特性和弹体运动、受力变化,对侵彻过程进行了阶段划分,并在此基础上分析了自约束、侧向约束、面板约束3种约束方式对陶瓷破碎位移的影响,并对靶板防护性能进行了改进。结果表明:通过施加约束限制陶瓷锥的位移是充分发挥陶瓷复合装甲防护能力的关键,施加3种约束方式均能够减小破碎陶瓷的横向位移或纵向位移,从而在一定范围内有效提升陶瓷复合靶板的抗侵彻能力。Abstract: In order to explore the effect of constraints on the displacement law of broken ceramics and the penetration resistance of ceramic composite armor, the SPH-FEM (smoothed particle hydrodynamics-finite element method) coupling method was used to simulate the penetration of cylindrical bullets into ceramic/steel composite target plates. According to the failure response characteristics of the ceramic composite armor, the movement of the bullet and the change of the force on the bullet, the penetration process was divided into stages. Based on this, the influence of self-restraint, circumferential restraint and panel restraint on the displacement law of broken ceramics was analyzed. The influence of different constraint forms on the improvement of target protection performance was also studied. In addition, the results show that limiting the displacement of ceramic cone by imposing constraints is the key to give full play to the protective ability of ceramic composite armor. The application of the three restraint forms can reduce the lateral or longitudinal displacement of the broken ceramics, thus the penetration resistance of the ceramic composite target can be improved in a certain range.

-

Key words:

- ceramic lightweight composite armor /

- breaking process /

- restraint /

- cylindrical bullet

-

Material ρ/(kg·m−3) E/GPa ν σ0/MPa Et/MPa C/s−1 P 45 steel 7850 210 0.3 335 525 40.4 5 Q235 steel 7800 210 0.3 235 250 40.4 5 表 2 T12A钢、6061铝合金和304钢的相关材料参数

Table 2. Mechanical parameters of T12A steel,6061 Al alloy and 304 steel

Material ρ/(kg·m−3) G/GPa cp/(J·kg−1·K−1) A/MPa B/MPa m n C1 T12A steel 7830 77.0 477 1300 510 0.94 0.26 0.014 6061 Al alloy 2700 27.6 885 290 125 1.00 0.34 0.100 304 steel 7900 77.0 423 340 730 1.03 0.35 0.014 Material ρ/(kg·m−3) G/GPa T/GPa A1 B1 C1 M N $S{_{\rm{F} }^{\rm{max} } }$/GPa SiC 3163 183 0.37 0.96 0.35 0 1.00 0.65 0.8 Al2O3 3700 90 0.20 0.93 0.31 0 0.60 0.60 1.3 Material σHEL/GPa pHEL/GPa THEL/GPa K1/GPa K2/GPa K3/GPa D1 D2 SiC 14.567 5.90 13.0 204.785 0 0 0.480 0.48 Al2O3 2.790 1.46 2.0 130.950 0 0 0.005 1.00 表 4 实验与数值模拟结果对比

Table 4. Comparison of numerical simulation and test results

No. v0/(m·s−1) vr K/σ Test/(m·s−1) SPH-FEM/(m·s−1) Error/% Test/(J·m2·kg−1) SPH-FEM/(J·m2·kg−1) Error/% 1 995.1 483.5 445 −8.0 119.8 125.5 4.7 2 986.3 468.6 417 −8.9 119.3 125.2 4.9 3 962.5 455.0 448 −1.5 113.9 115.0 8.7 No. v0/(m·s−1) Condition Structure form DOP Test/mm SPH-FEM/mm Error/% 4 758 Blank 70 mm Al alloy 26.92 26.11 −3.0 5 764 Unconfined 10 mm Al2O3 ceramics+30 mm Al alloy 8.37 8.54 1.6 6 756 Laterally confined 10 mm Al2O3 ceramics+30 mm Al alloy 6.83 6.51 −5.4 -

[1] 姚国文, 刘占芳, 詹先义. 极端冲击条件下脆性破坏的物理机制 [J]. 重庆大学学报(自然科学版), 2000, 23(4): 154–158. doi: 10.3969/j.issn.1000-582X.2000.04.037YAO G W, LIU Z F, ZHAN X Y. Physical mechanism of brittle material failure under critical shock conditions [J]. Journal of Chongqing University (Natural Science), 2000, 23(4): 154–158. doi: 10.3969/j.issn.1000-582X.2000.04.037 [2] 李超, 刘建超. 复合材料装甲技术的发展及应用 [J]. 化工新型材料, 2004, 32(6): 46–48, 53. doi: 10.3969/j.issn.1006-3536.2004.06.015LI C, LIU J C. Development and application of advanced composite armor technology [J]. New Chemical Materials, 2004, 32(6): 46–48, 53. doi: 10.3969/j.issn.1006-3536.2004.06.015 [3] WOODWARD R L. A simple one-dimensional approach to modelling ceramic composite armour defeat [J]. International Journal of Impact Engineering, 1990, 9(4): 455–474. doi: 10.1016/0734-743X(90)90035-T [4] HOGAN J D, FARBANIEC L, MALLICK D, et al. Fragmentation of an advanced ceramic under ballistic impact: mechanisms and microstructure [J]. International Journal of Impact Engineering, 2017, 102: 47–54. doi: 10.1016/j.ijimpeng.2016.12.008 [5] 余毅磊, 蒋招绣, 王晓东, 等. 轻型陶瓷/金属复合装甲抗垂直侵彻过程中陶瓷碎裂行为研究 [J]. 爆炸与冲击, 2021, 41(11): 113301. doi: 10.11883/bzycj-2021-0134YU Y L, JIANG Z X, WANG X D, et al. Research on ceramic fragmentation behavior of lightweight ceramic/metal composite armor during vertical penetration [J]. Explosion and Shock Waves, 2021, 41(11): 113301. doi: 10.11883/bzycj-2021-0134 [6] SHERMAN D, BEN-SHUSHAN T. Quasi-static impact damage in confined ceramic tiles [J]. International Journal of Impact Engineering, 1998, 21(4): 245−265. [7] FRANZEN R R, ORPHAL D L, ANDERSON C E. The influence of experimental design on depth-of-penetration (DOP) test results and derived ballistic efficiencies [J]. International Journal of Impact Engineering, 1997, 19(8): 727–737. doi: 10.1016/S0734-743X(97)00010-9 [8] WESTERLING L, LUNDBERG T. The influence of confinement on the protective capability of ceramic armour at two different velocities [C]//15th International Symposium on Ballistics. 1995: 283−290. [9] 李平. 陶瓷材料的动态力学响应及其抗长杆弹侵彻机理 [D]. 北京: 北京理工大学, 2002: 45−49.LI P. Dynamic mechanical response of ceramic materials and its resistance to long rod penetration [D]. Beijing: Beijing Institute of Technology, 2002: 45−49. [10] TIAN C, SUN Q T, AN X Y, et al. Influences of ceramic constraint on protection performances of ceramic-metal hybrid structures under impact loads [J]. International Journal of Mechanical Sciences, 2019, 159: 81–90. doi: 10.1016/j.ijmecsci.2019.05.042 [11] TIAN C, AN X Y, SUN Q T, et al. Experimental and numerical analyses of the penetration resistance of ceramic-metal hybrid structures [J]. Composite Structures, 2019, 211: 264–272. doi: 10.1016/j.compstruct.2018.12.021 [12] 胡德安, 韩旭, 肖毅华, 等. 光滑粒子法及其与有限元耦合算法的研究进展 [J]. 力学学报, 2013, 45(5): 639–652. doi: 10.6052/0459-1879-13-092HU D A, HAN X, XIAO Y H, et al. Research developments of smoothed particle hydrodynamics method and its coupling with finite element method [J]. Theoretical and Applied Mechanics, 2013, 45(5): 639–652. doi: 10.6052/0459-1879-13-092 [13] SWEGLE J W, HICKS D L, ATTAWAY S W. Smoothed particle hydrodynamics stability analysis [J]. Journal of Computational Physics, 1995, 116(1): 123–134. doi: 10.1006/jcph.1995.1010 [14] FERNÁNDEZ-MÉNDEZ S, BONET J, HUERTA A. Continuous blending of SPH with finite elements [J]. Computers & Structures, 2005, 83(17/18): 1448–1458. [15] 曹凌宇, 罗兴柏, 刘国庆, 等. 侧向约束陶瓷抗侵彻性能试验研究 [J]. 装甲兵工程学院学报, 2018, 32(5): 76–80. doi: 10.3969/j.issn.1672-1497.2018.05.014CAO L Y, LUO X B, LIU G Q, et al. Experimental study on the anti-penetration performance of lateral confinement ceramics [J]. Journal of Armored Corps Engineering College, 2018, 32(5): 76–80. doi: 10.3969/j.issn.1672-1497.2018.05.014 [16] 南宇翔, 蒋建伟, 王树有, 等. 子弹药落地冲击响应数值模拟及实验验证 [J]. 振动与冲击, 2013, 32(3): 182–187. doi: 10.3969/j.issn.1000-3835.2013.03.036NAN Y X, JIANG J W, WANG S Y, et al. Numerical simulation and test for impact response of submunitions drop [J]. Journal of Vibration and Shock, 2013, 32(3): 182–187. doi: 10.3969/j.issn.1000-3835.2013.03.036 [17] 陈长海, 朱锡, 侯海量, 等. 近距空爆载荷作用下双层防爆舱壁结构抗爆性能仿真分析 [J]. 海军工程大学学报, 2012, 24(3): 26–33. doi: 10.3969/j.issn.1009-3486.2012.03.006CHEN C H, ZHU X, HOU H L, et al. Numerical analysis of blast resistance of double-layer bulkhead structures subjected to close-range air blast [J]. Journal of Naval University of Engineering, 2012, 24(3): 26–33. doi: 10.3969/j.issn.1009-3486.2012.03.006 [18] HOLMQUIST T J, TEMPLETON D W, BISHNOI K D. Constitutive modeling of aluminum nitride for large strain, high-strain rate, and high-pressure applications [J]. International Journal of Impact Engineering, 2001, 25(3): 211–231. doi: 10.1016/S0734-743X(00)00046-4 [19] CRONIN D S, BUI K, KAUFMANN C, et al. Implementation and validation of the Johnson-Holmquist ceramic material model in LS-DYNA [C]//The 4th European LS-DYNA Users Conference. 2003, 1: 47−60. [20] 侯海量, 朱锡, 李伟. 轻型陶瓷/金属复合装甲抗弹机理研究 [J]. 兵工学报, 2013, 34(1): 105–114. doi: 10.3969/j.issn.1000-1093.2013.01.019HOU H L, ZHU X, LI W. Investigation on bullet proof mechanism of light ceramic/steel composite armor [J]. Acta Armamentarii, 2013, 34(1): 105–114. doi: 10.3969/j.issn.1000-1093.2013.01.019 [21] WILKINS M L. Use of boron compounds in lightweight armor [M]//MATKOVICH V I. Boron and refractory borides. Berlin: Springer, 1977: 633−648. -

下载:

下载: