Hybrid Bionic Design Based on the Internal Structures of Nacre and Strombus Gigas Shell

-

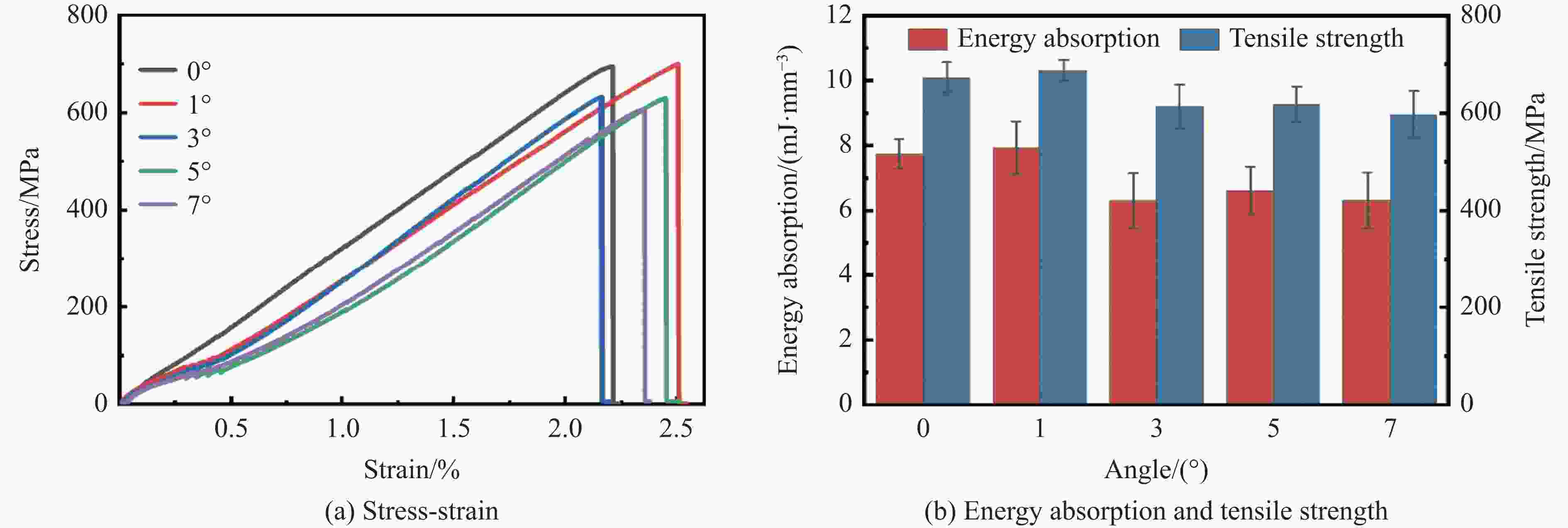

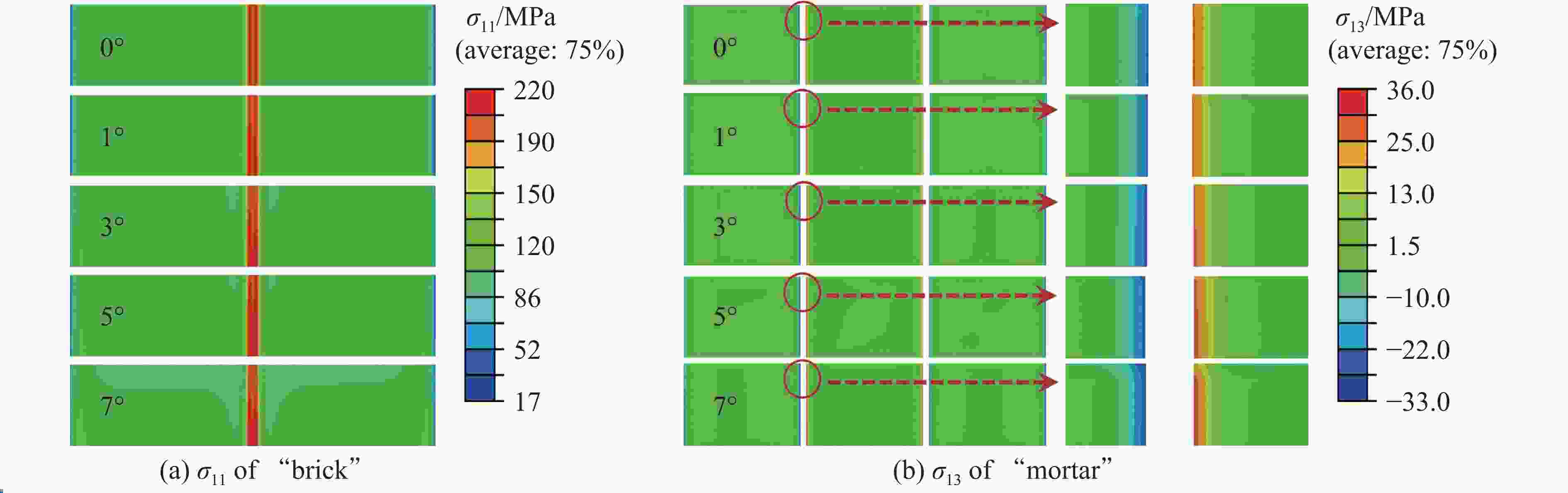

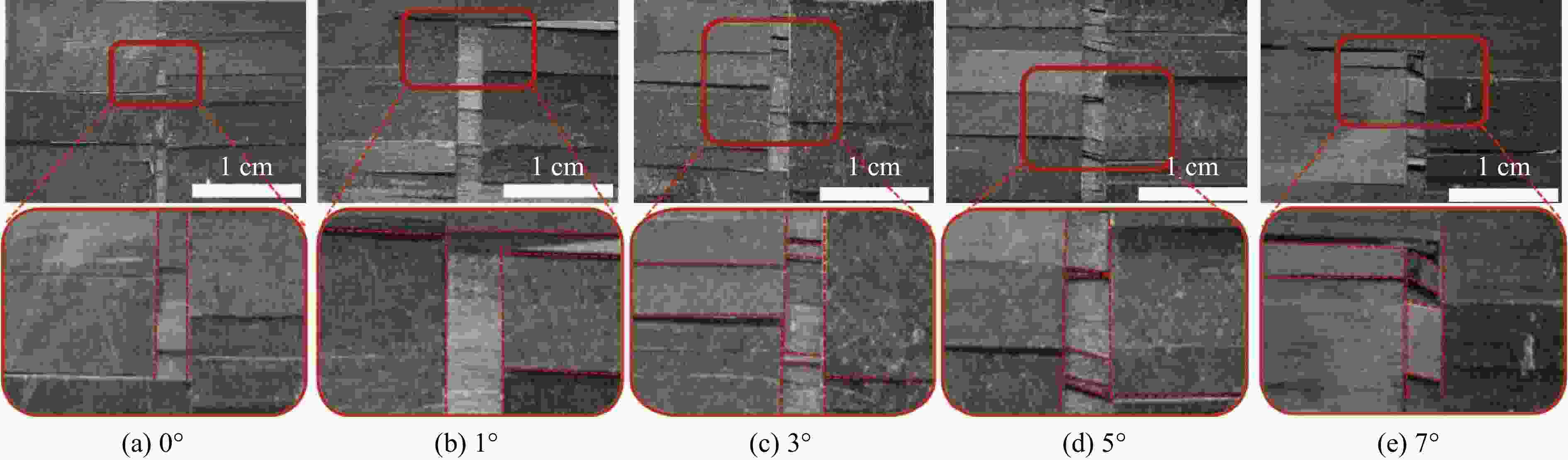

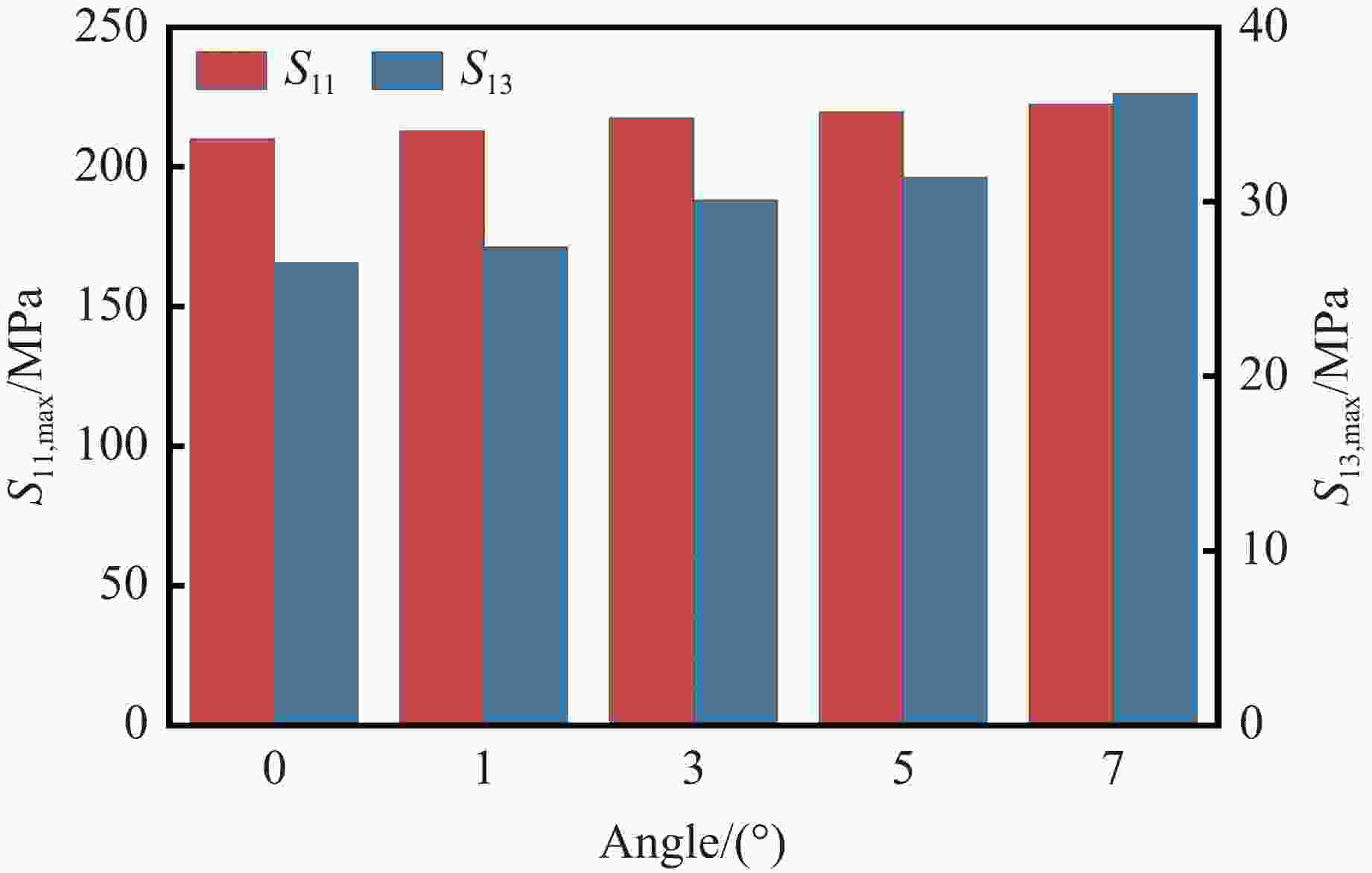

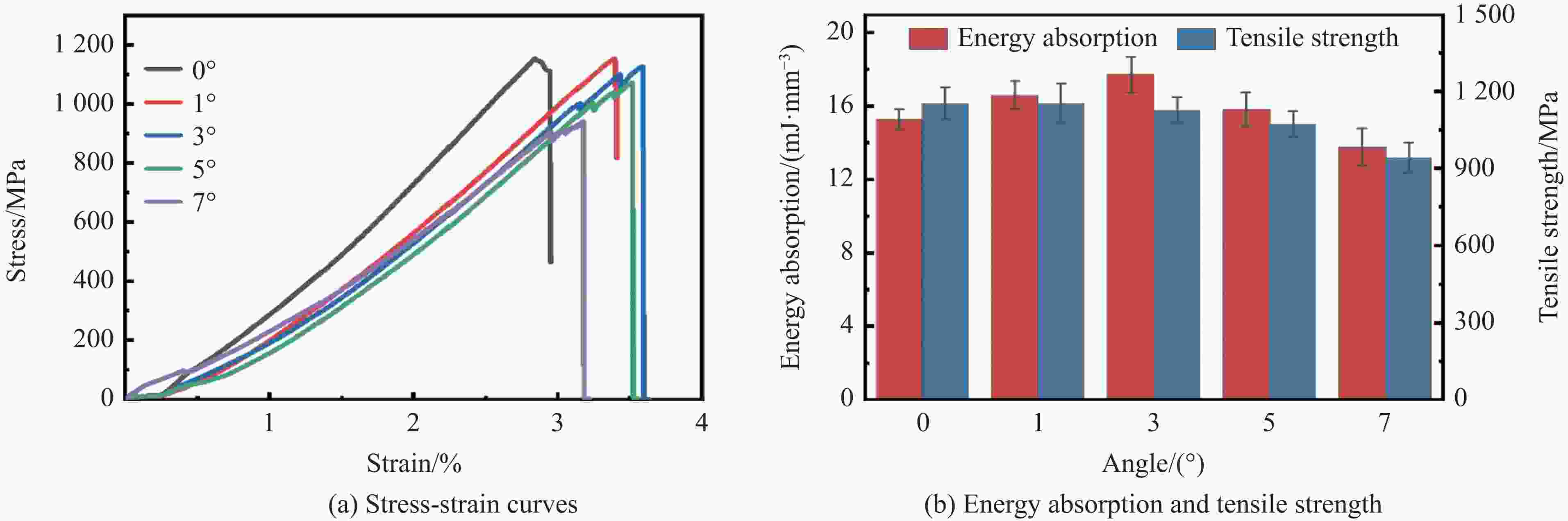

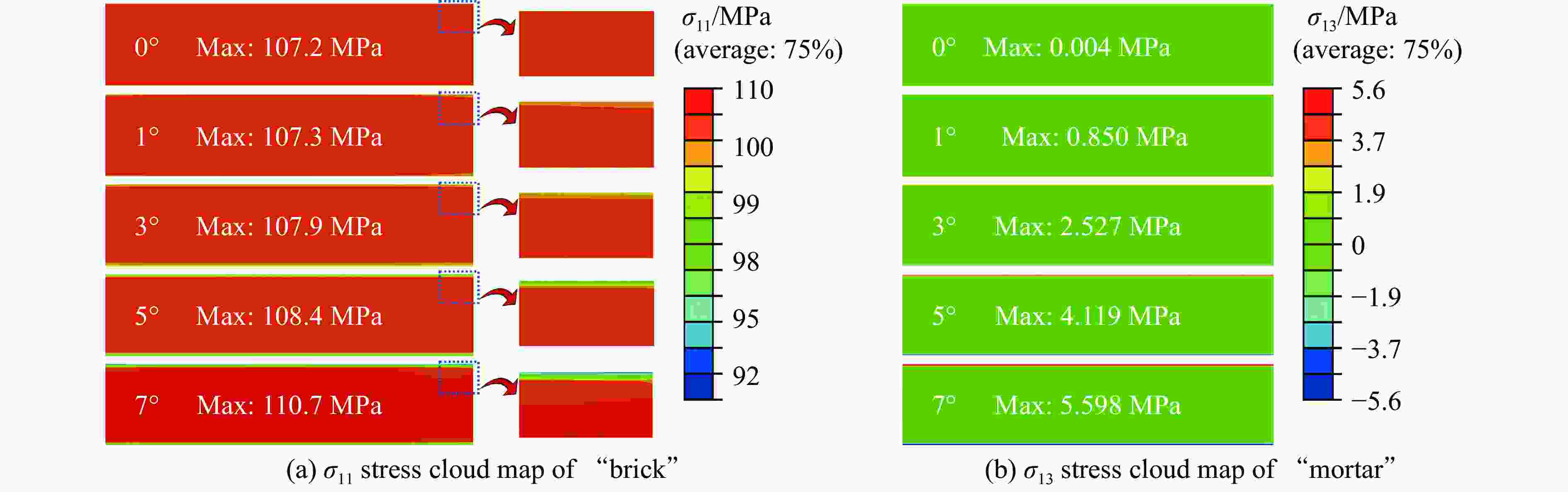

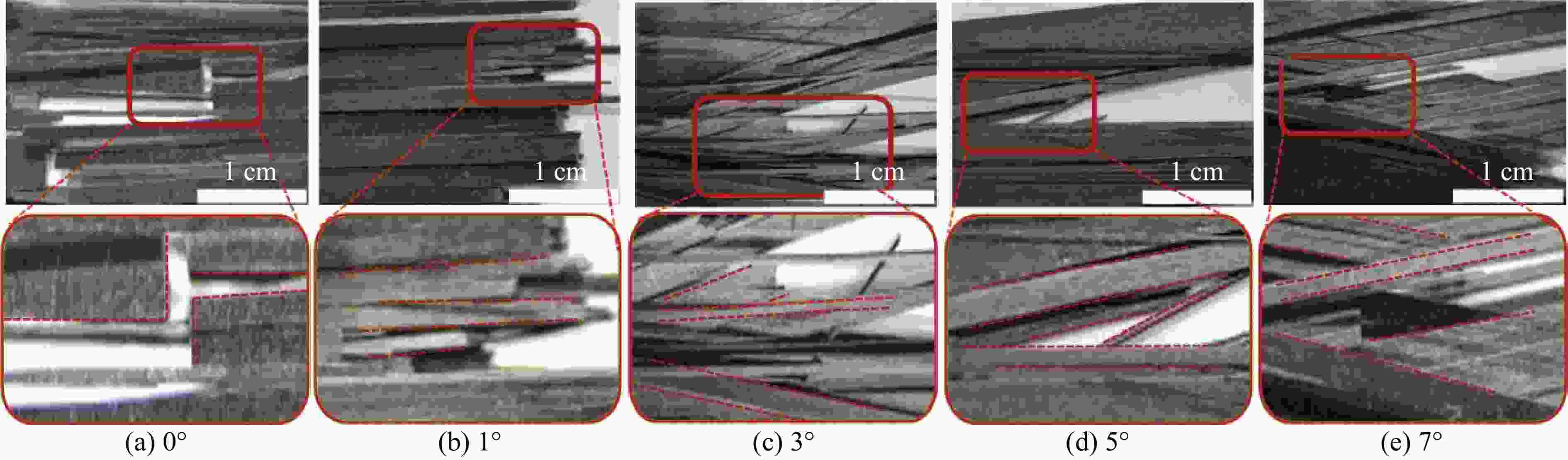

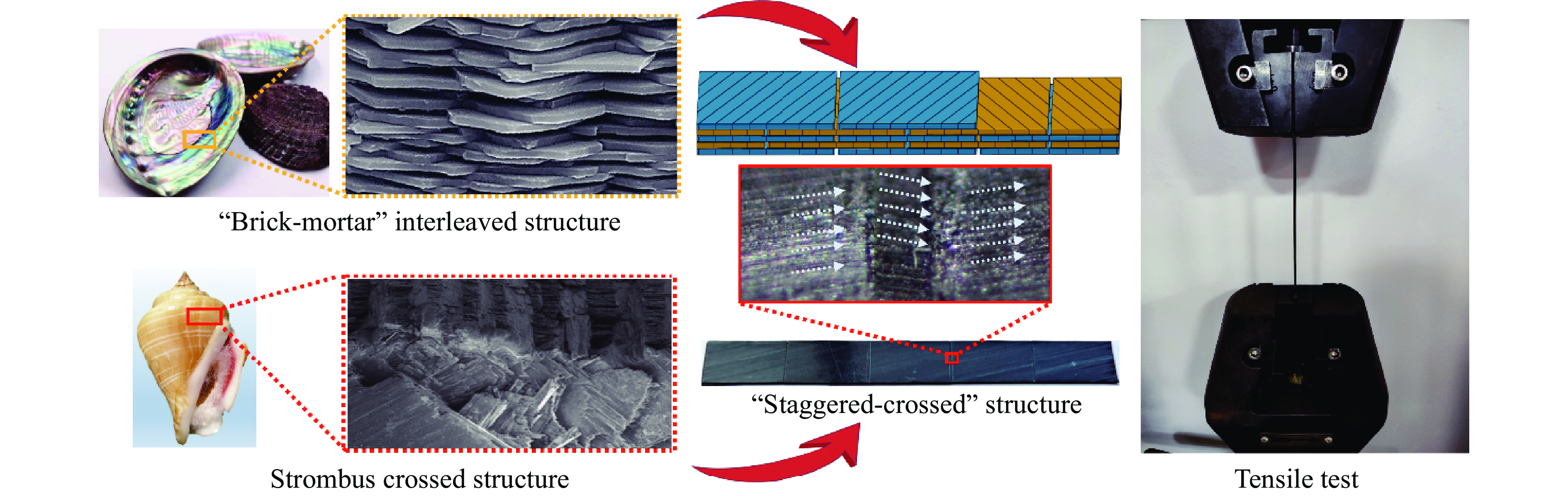

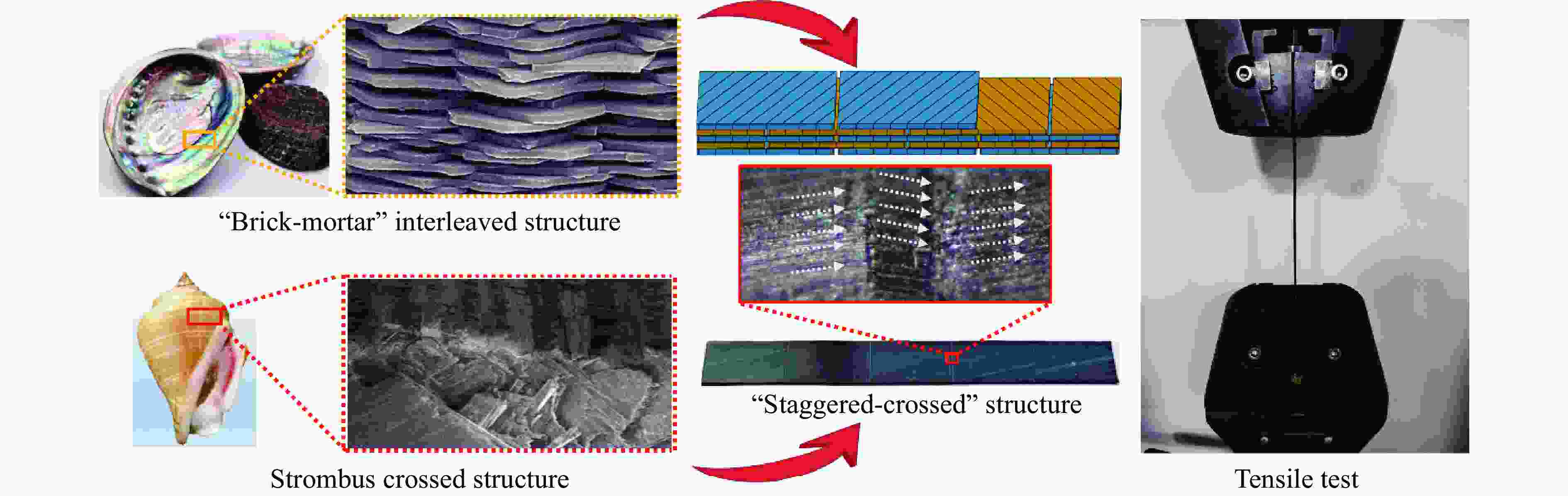

摘要: 融合多种生物材料内部结构的混合仿生结构设计是近年来兴起的一种材料强韧化设计新策略。采用碳纤维增强环氧树脂设计了一种由贝壳珍珠层“交错”结构和凤凰螺“交叉”结构融合而成的新型“交错-交叉”复合结构材料。实验和理论研究发现,珍珠层“交错”结构和凤凰螺“交叉”结构在内部载荷传递和应力分布调控方面存在显著差异,将两者进行简单混合将会导致局部应力集中,进而使材料性能劣化。通过优化该复合结构,提出了一种新型小角度连续纤维“交叉”叠层仿生结构,该结构能够优化材料内部的全场应力分布、抑制局部应力集中,形成延迟整体结构断裂失效的强韧化机制,有效解决材料性能的劣化问题。该研究结果有望为解决材料的强韧矛盾提供有益参考。Abstract: Hybrid biomimetic structure design, which integrates the internal structure of a variety of biomaterials, is a new strategy for strengthening and toughening materials in recent years. In this work, carbon fiber reinforced epoxy resin was used to design a new type of “staggered-crossed” composite structure material, which is composed of the “interleaved” structure of nacre shell and the “crossed” structure of strombus shell. Through experimental and theoretical research, it was found that there is a significant difference between the “interleaved” structure of nacre and the “crossed” structure of strombus in the internal load transfer and stress distribution regulation. A simple hybrid mix of the two will produce adverse factors such as local stress concentration and lead to material performance degradation. On this basis, a new type of small angle continuous fiber “crossed” layered biomimetic structure was proposed by further optimizing the composite structure. This structure can optimize the full field stress distribution inside the material, suppress local stress concentration, and form a toughening mechanism that delays the overall structural fracture failure, effectively solving the problem of material performance degradation. The research results are expected to provide a useful reference for solving the contradiction between strength and toughness of materials.

-

表 1 ABAQUS有限元模拟的相关力学参数

Table 1. ABAQUS finite element simulation related mechanical parameters

E1/GPa E2/GPa E3/GPa G12/GPa G13/GPa G23/GPa 41 3.4 3.4 3.6 3.6 2.5 μ12 μ13 μ23 E/GPa μ 0.03 0.03 0.23 3.5 0.25 -

[1] RITCHIE R O. The conflicts between strength and toughness [J]. Nature Materials, 2011, 10(11): 817–822. doi: 10.1038/nmat3115 [2] SHU C Q, YAO Z J, TAO X W, et al. Biomimetic micro-laminated structure endows cermet with excellent strength and toughness using CoCrCuFeNi as infiltration layers [J]. Ceramics International, 2023, 49(24): 39875–39885. doi: 10.1016/j.ceramint.2023.09.201 [3] SHIRVANIMOGHADDAM K, BAlAJI K V, YADAV R, et al. Balancing the toughness and strength in polypropylene composites [J]. Composites Part B:Engineering, 2021, 223(15): 1–33. [4] 张菡英, 刘明. 碳纤维复合材料的发展及应用 [J]. 工程塑料应用, 2015, 43(11): 132–135. doi: 10.3969/j.issn.1001-3539.2015.11.030ZHANG H Y, LIU M. Development and applications of carbon fiber reinforced polymer [J]. Engineering Plastics Applications, 2015, 43(11): 132–135. doi: 10.3969/j.issn.1001-3539.2015.11.030 [5] CANGIANO S, PLIZZARI G A. Fatigue behavior of fiber reinforced concrete: comparison between material and structural response [J]. Springer Netherlands, 2000, 122: 103652. [6] FRIEDRICH L F, COLPO A B, KOSTESKI L E, et al. A novel peridynamic approach for fracture analysis of quasi-brittle materials [J]. International Journal of Mechanical Sciences, 2022, 227: 107445. doi: 10.1016/j.ijmecsci.2022.107445 [7] VASILIEV V, LURIE S, SOLYAEV Y. New approach to failure of pre-cracked brittle materials based on regularized solutions of strain gradient elasticity [J]. Engineering Fracture Mechanics, 2021, 258: 108080. doi: 10.1016/j.engfracmech.2021.108080 [8] ESPINOSA H D, RIM J E, BARTHELAT F, et al. Merger of structure and material in nacre and bone-perspectives on de novo biomimetic materials [J]. Progress in Materials Science, 2009, 54(8): 1059–1100. doi: 10.1016/j.pmatsci.2009.05.001 [9] AVILA K E, KUECHEMANN S, ALHAFEZ I A, et al. Nanoscratching of metallic glasses: an atomistic study [J]. Tribology International, 2019, 139: 1–11. doi: 10.1016/j.triboint.2019.06.017 [10] ABDALLAH G, NGO T D, TRAN P. Three-dimensional Voronoi model of a nacre-mimetic composite structure under impulsive loading [J]. Composite Structures, 2016, 153: 278–296. doi: 10.1016/j.compstruct.2016.06.020 [11] WAN S J, Hu H, PENG J S, et al. Nacre-inspired integrated strong and tough reduced graphene oxide-poly (acrylic acid) nanocomposites [J]. Nanoscale, 2016, 8(10): 5649–5656. doi: 10.1039/C6NR00562D [12] DIMAS L S, BRATZEL G H, EYLON I, et al. Tough composites inspired by mineralized natural materials: computation, 3D printing, and testing [J]. Advanced Functional Materials, 2013, 23(36): 4629–4638. doi: 10.1002/adfm.201300215 [13] SCHILLINGER D , RUESS M . The finite cell method: a review in the context of higher-order structural analysis of CAD and image-based geometric models [J]. Archives of Computational Methods in Engineering, 2015, 22(3): 391−455. [14] WU K J, SONG Z Q, ZHANG S S, et al. Discontinuous fibrous bouligand architecture enabling formidable fracture resistance with crack orientation insensitivity [J]. Proceedings of the National Academy of Sciences of the United States of America, 2020, 117(27): 15465–15472. [15] SHARMA D, HIREMATH S S. Compressive and flexural properties of the novel lightweight tailored bio-inspired structures [J]. Thin-Walled Structures, 2022, 174: 109169. doi: 10.1016/j.tws.2022.109169 [16] JIA Z , YU Y, HOU S, et al. Si-biomimetic architected materials with improved dynamic performance [J]. Journal of the Mechanics and Physics of Solids, 2019, 125: 178−197. [17] DIPETTE S, URAL A, SANTHANAM S. Analysis of toughening mechanisms in the Strombus gigas shell [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2015, 48: 200–209. doi: 10.1016/j.jmbbm.2015.04.011 [18] 刘英志, 雷建银, 王志华. 冲击载荷下仿贝壳砖泥结构的动态响应 [J]. 高压物理学报, 2022, 36(1): 125–133.LIU Y Z, LEI J Y, WANG Z H. Dynamic response of narce-like brick and mortar structure under impact load [J]. Chinese Journal of High Pressure Physics, 2022, 36(1): 125–133. [19] NAVEEN J, JAWAID M, GOH K L, et al. Advancement in graphene-based materials and their nacre inspired composites for armour applications—a review [J]. Nanomaterials, 2021, 11(5): 1239. doi: 10.3390/nano11051239 [20] 张学骜, 王建方, 吴文健, 等. 贝壳珍珠层生物矿化及其对仿生材料的启示 [J]. 无机材料学报, 2006, 21(2): 257–266. doi: 10.3321/j.issn:1000-324X.2006.02.001ZHANG X A, WANG J F, WU W J, et al. Advances in biomineralization of nacreous layer and its inspiration for biomimetic materials [J]. Journal of Inorganic Materials, 2006, 21(2): 257–266. doi: 10.3321/j.issn:1000-324X.2006.02.001 [21] CHEN S M, GAO H L, SUN X H, et al. Superior biomimetic nacreous bulk nanocomposites by a multiscale soft-rigid dual-network interfacial design strategy [J]. Matter, 2019, 1(2): 412–427. doi: 10.1016/j.matt.2019.03.012 [22] 孙娜, 吴俊涛, 江雷. 贝壳珍珠层及其仿生材料的研究进展 [J]. 高等学校化学学报, 2011, 32(10): 2231–2239.SUN N, WU J T, JIANG L. Research progress of nacre and biomimetic synthesis of nacre-like materials [J]. Chemical Journal of Chinese Universities, 2011, 32(10): 2231–2239. [23] LIU S , LUAN Y , Zhou Z , et al. Hierarchical structure design of Strombus gigas shell inspired laminated artificial composites and the mechanical performance optimization strategy [J]. Mechanics of Advanced Materials and Structures, 2023, 30(12): 2495–2505. [24] ZHANG G L, PENG J B, LUAN Y B et al. Improved mechanical performance of Strombus gigas shell inspired artificial composites by regulating the laminated structure and interface bonding [J]. Mechanics of Advanced Materials and Structures, 2024, 31(22): 5692−5700. doi: 10.1080/15376494.2023.2218846 -

下载:

下载: