Particle Flow Simulation of Fracture Characteristics of Rock-Concrete Combination with Single Crack

-

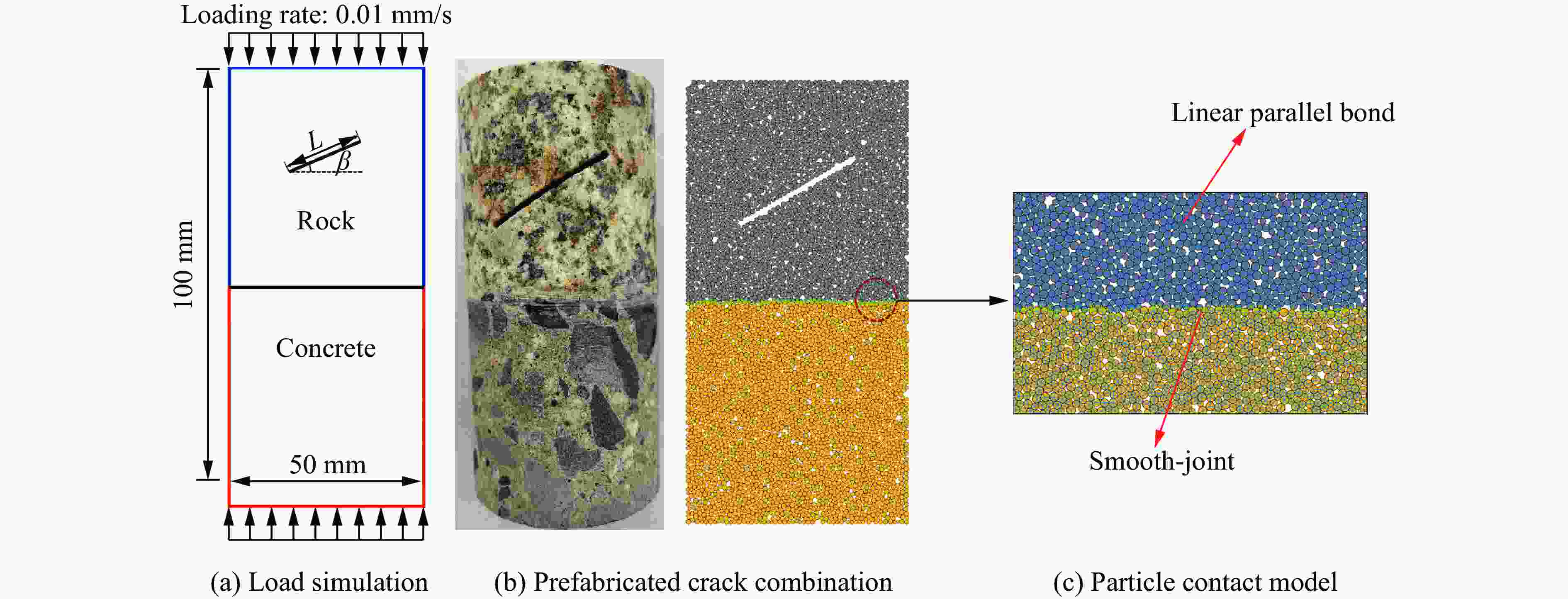

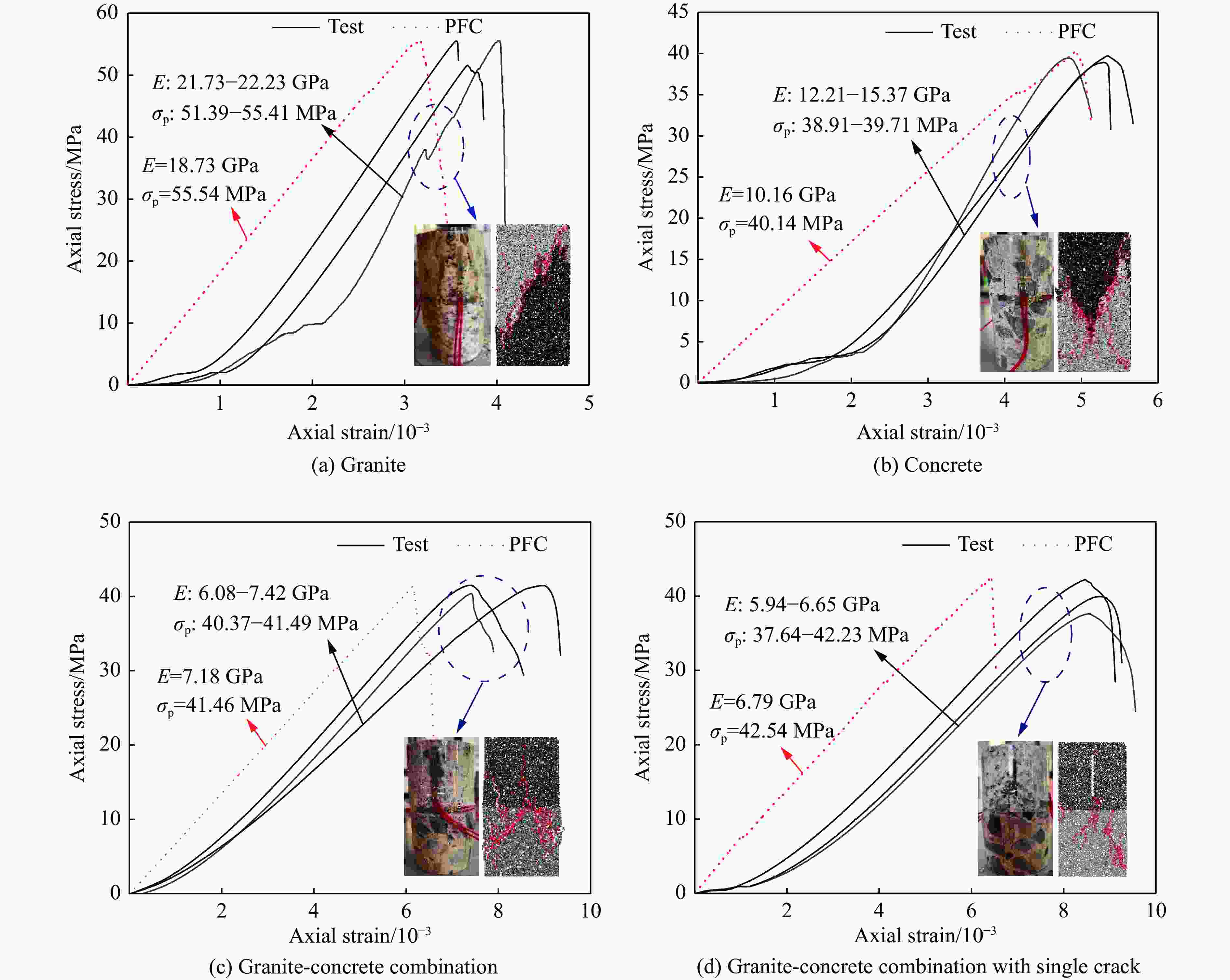

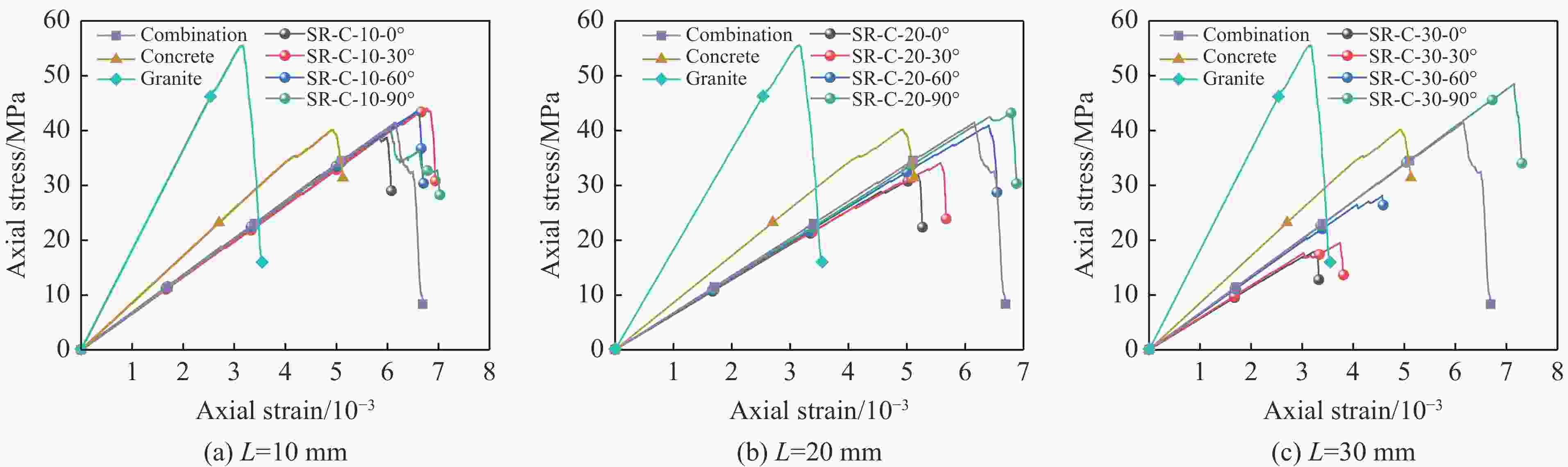

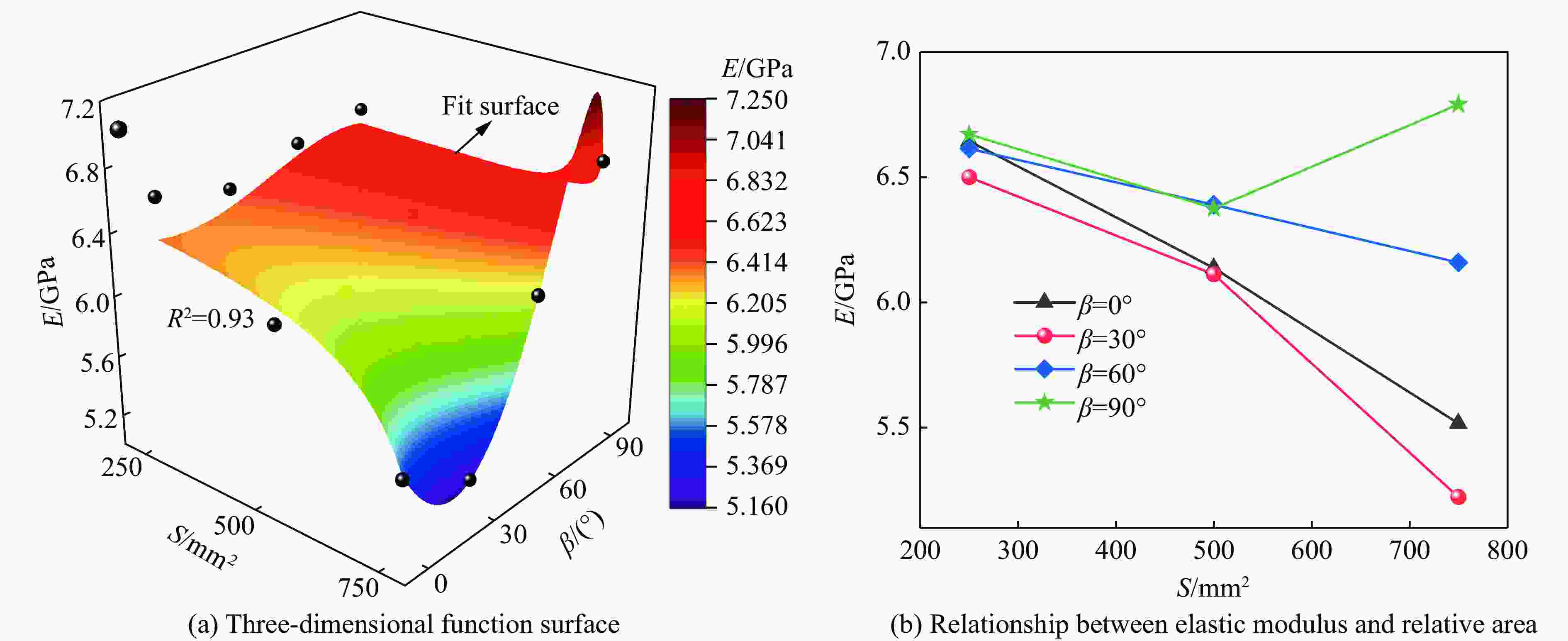

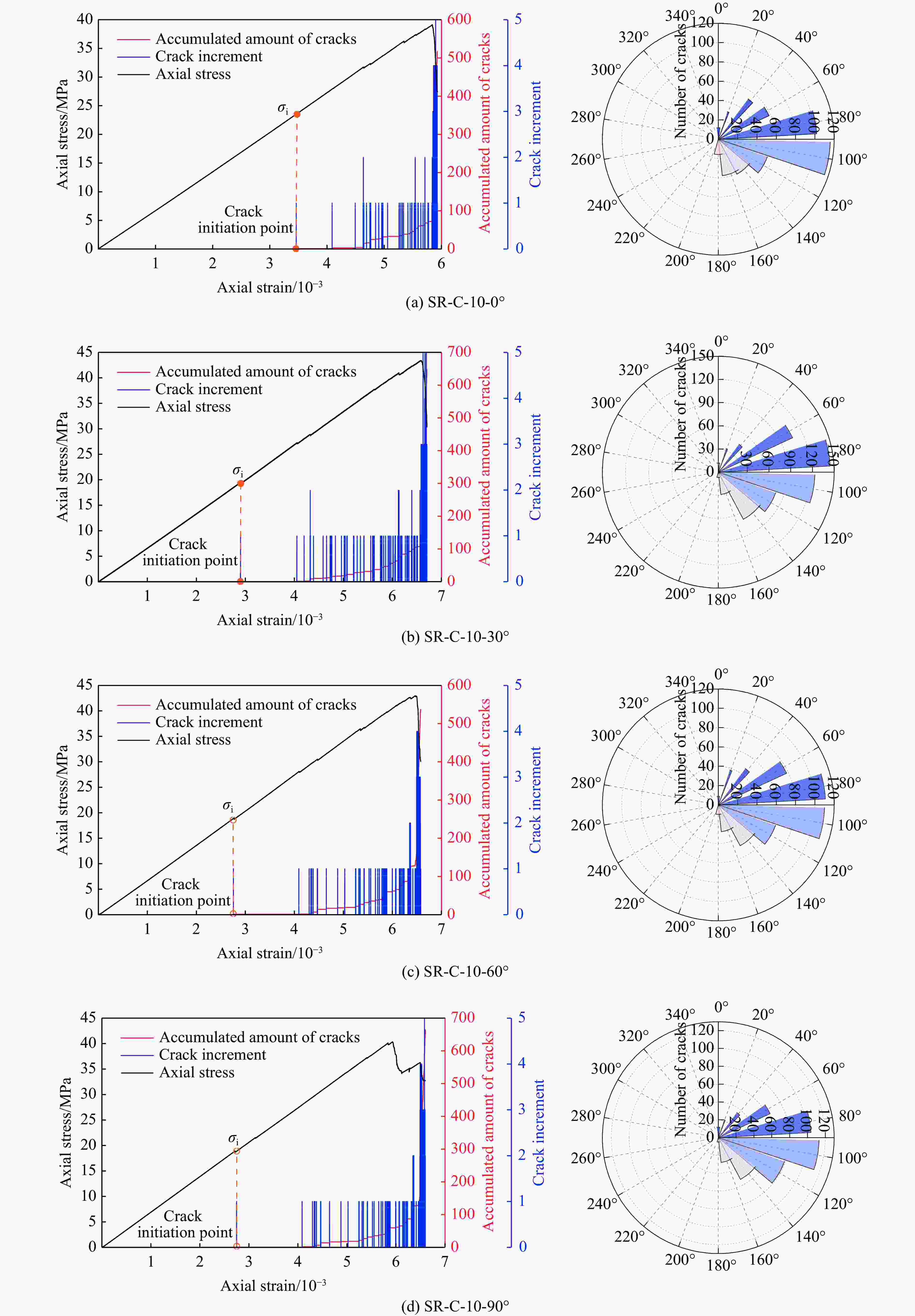

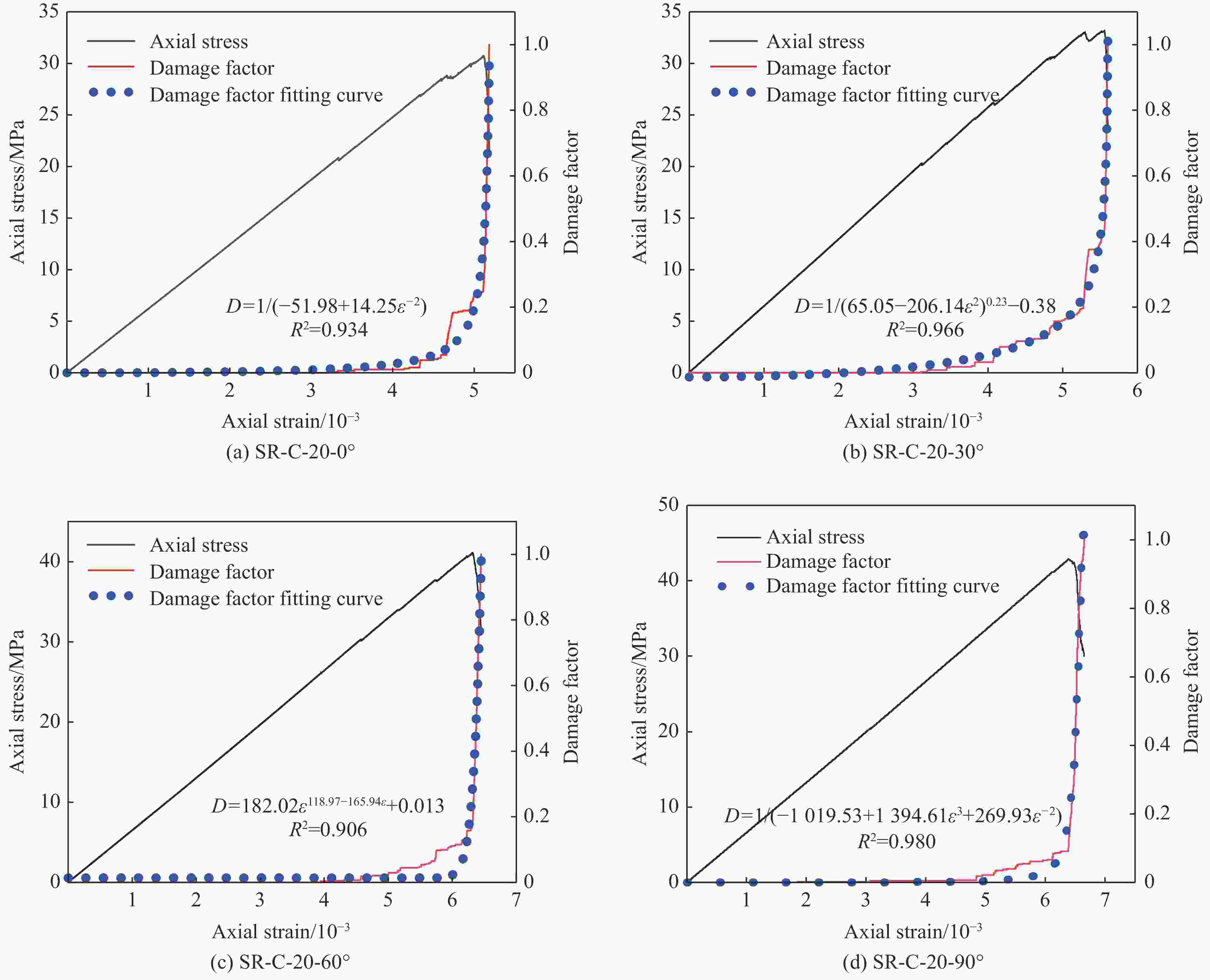

摘要: 为了研究不同长度及倾角的裂隙对岩石-混凝土组合体强度和破坏模式的影响,基于颗粒流模拟软件(PFC),通过对比预置裂隙试样的室内试验结果,选取最接近室内试验结果的一组数据标定细观参数,由此对含预置裂隙的岩石-混凝土组合体数值模型进行单轴压缩试验。结果表明:单裂隙岩石-混凝土组合体的承载能力和弹性模量随裂隙倾角的增大整体呈增大趋势,建立了不同裂隙长度和裂隙倾角的增量函数;裂隙长度对岩石-混凝土组合体力学特性的影响显著;岩石界面的应力状态和混凝土界面附近的约束效应决定裂纹能否扩展通过界面,根据裂纹的分布情况,分析发现裂纹萌生与扩展的根本原因是应力场的变化和转移,破坏过程中岩石-混凝土组合体的破坏模式由拉伸破坏逐渐转变成宏观剪切破坏,揭示了单裂隙岩石-混凝土组合体单轴压缩的损伤演化规律。Abstract: To study the influence of cracks with varying lengths and inclination angles on the strength and failure modes of rock-concrete combination, a numerical model of rock-concrete combination with pre-existing cracks was developed using the particle flow code (PFC). The model underwent calibration by comparing its results with indoor test data from prefabricated fractured specimens to select a set of microstructural parameters that closely align with the indoor test results. Subsequently, uniaxial compression tests were conducted on numerical models of rock-concrete composites containing pre-existing fractures. The results indicate that the bearing capacity and elastic modulus of fractured rock-concrete composites increase with the increase of fracture inclination angle. Moreover, functions were established to calculate the peak strength increment for fractures with varying lengths and inclination angles. The fracture length significantly influences the mechanical properties of composite models. The stress state at the rock interface and the confinement effect near the concrete interface determine whether cracks can extend through the interface. By analyzing the distribution of cracks, it was found that the fundamental reasons for crack initiation and propagation are the changes and transfers of the stress field. During the failure process, the failure mode gradually transitions from tension-dominated to macroscopic shear failure. The results reveal the damage evolution of uniaxial compression of single fissure rock-concrete combination material.

-

Key words:

- single crack /

- rock-concrete combination /

- uniaxial compression test /

- crack evolution /

- particle flow

-

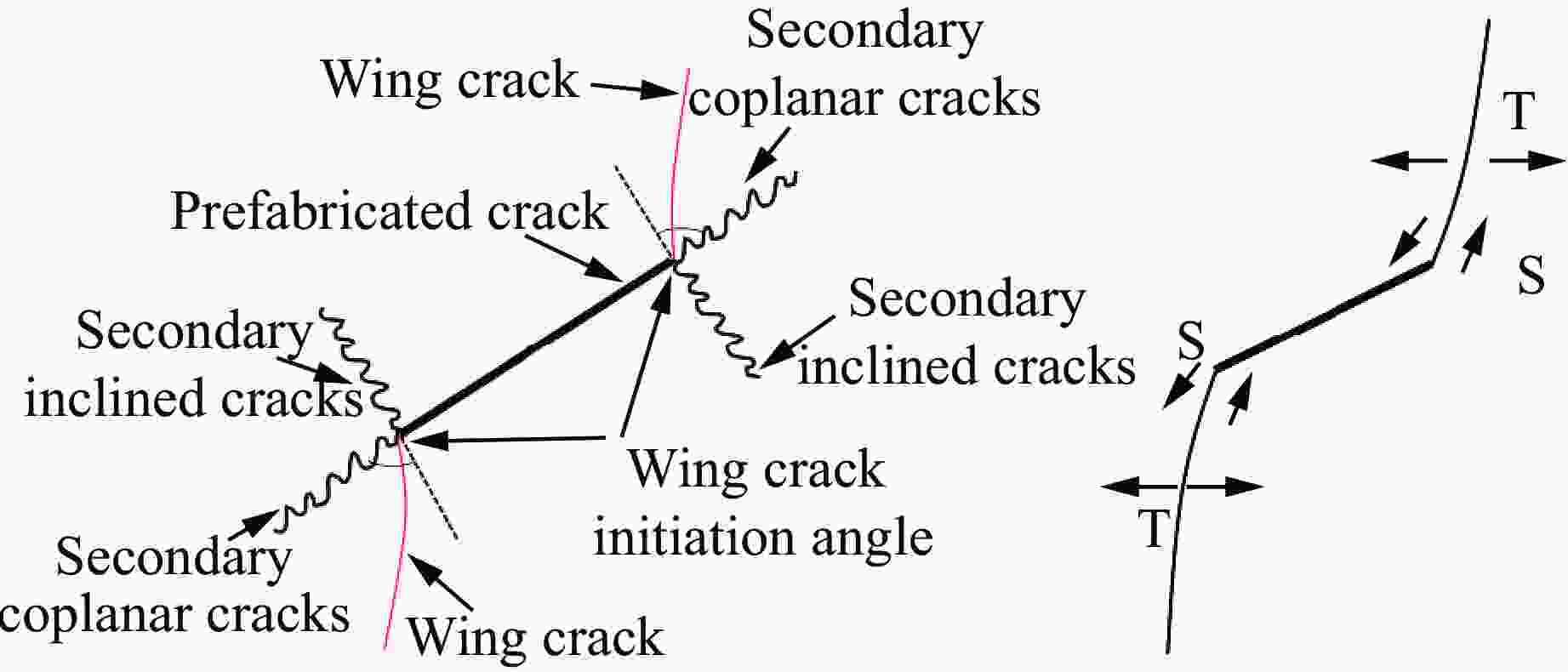

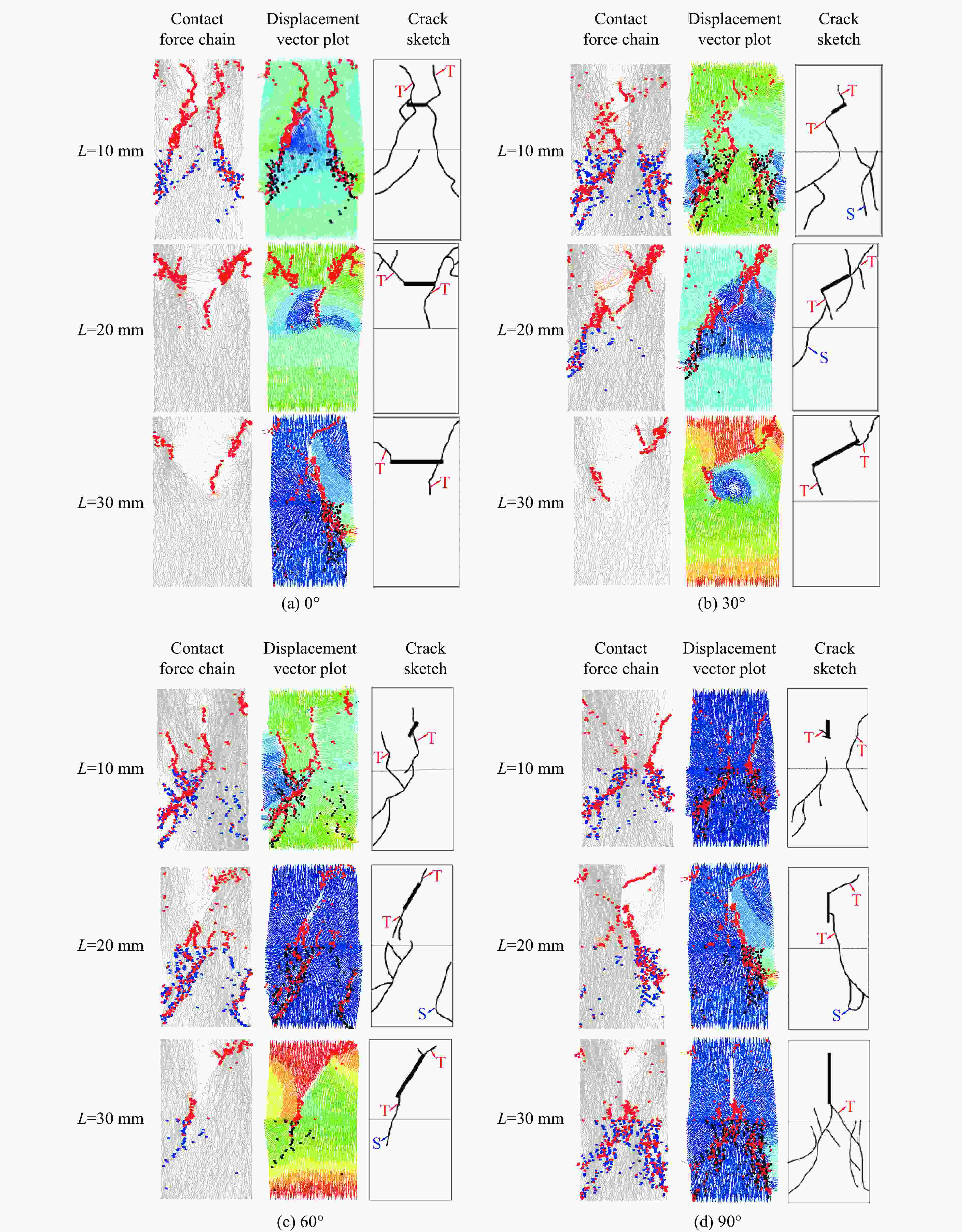

图 7 接触力链分布及颗粒位移(蓝色和黑色代表剪切裂纹,红色代表拉伸裂纹,灰色线代表压缩力链,橙色线代表拉伸力链)

Figure 7. Contact force chain distribution and particle displacement (Blue and black represent shear cracks, while red represents tensile cracks. The gray line represents the compression force chain, and the orange line represents the tensile force chain.)

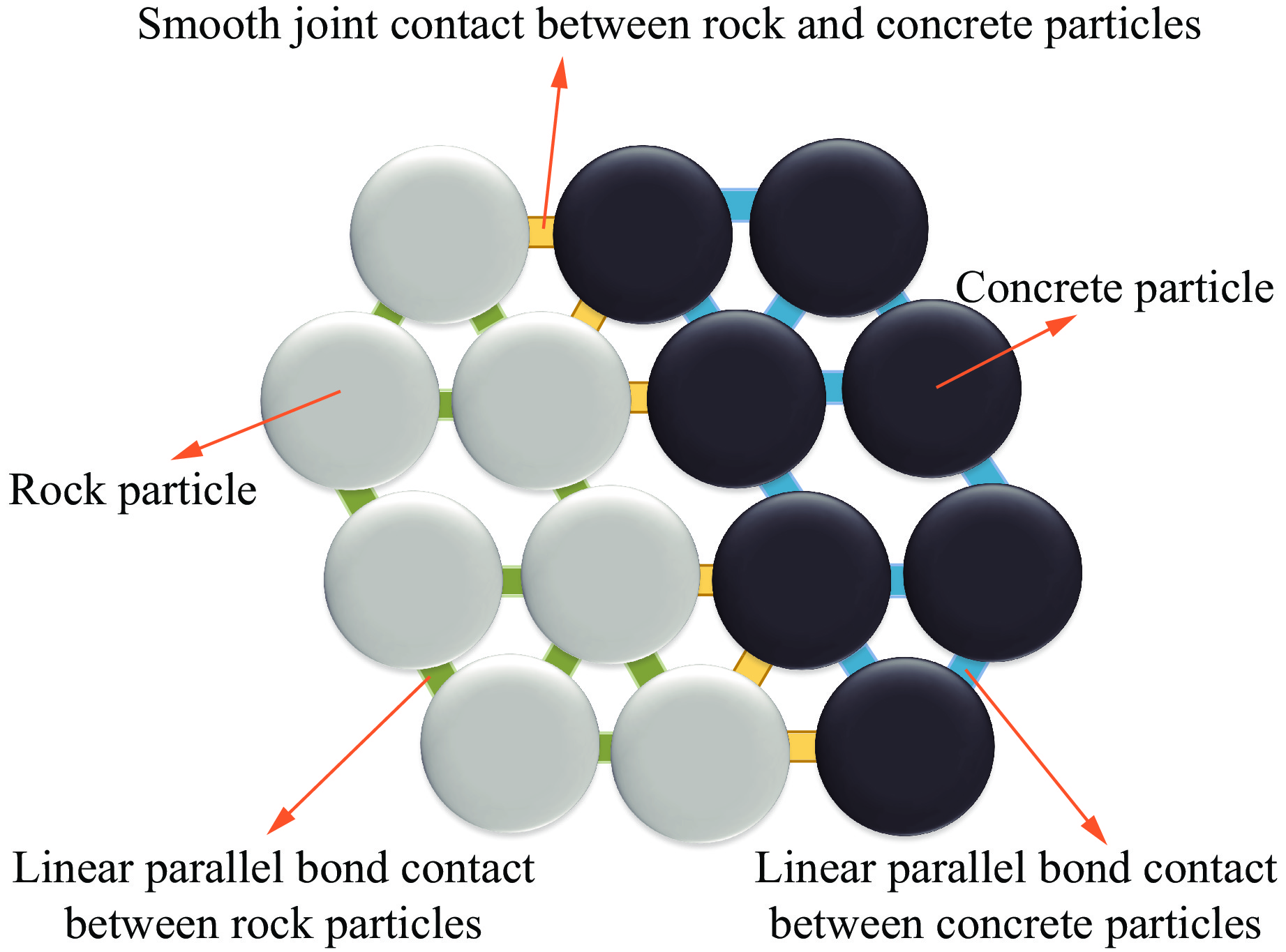

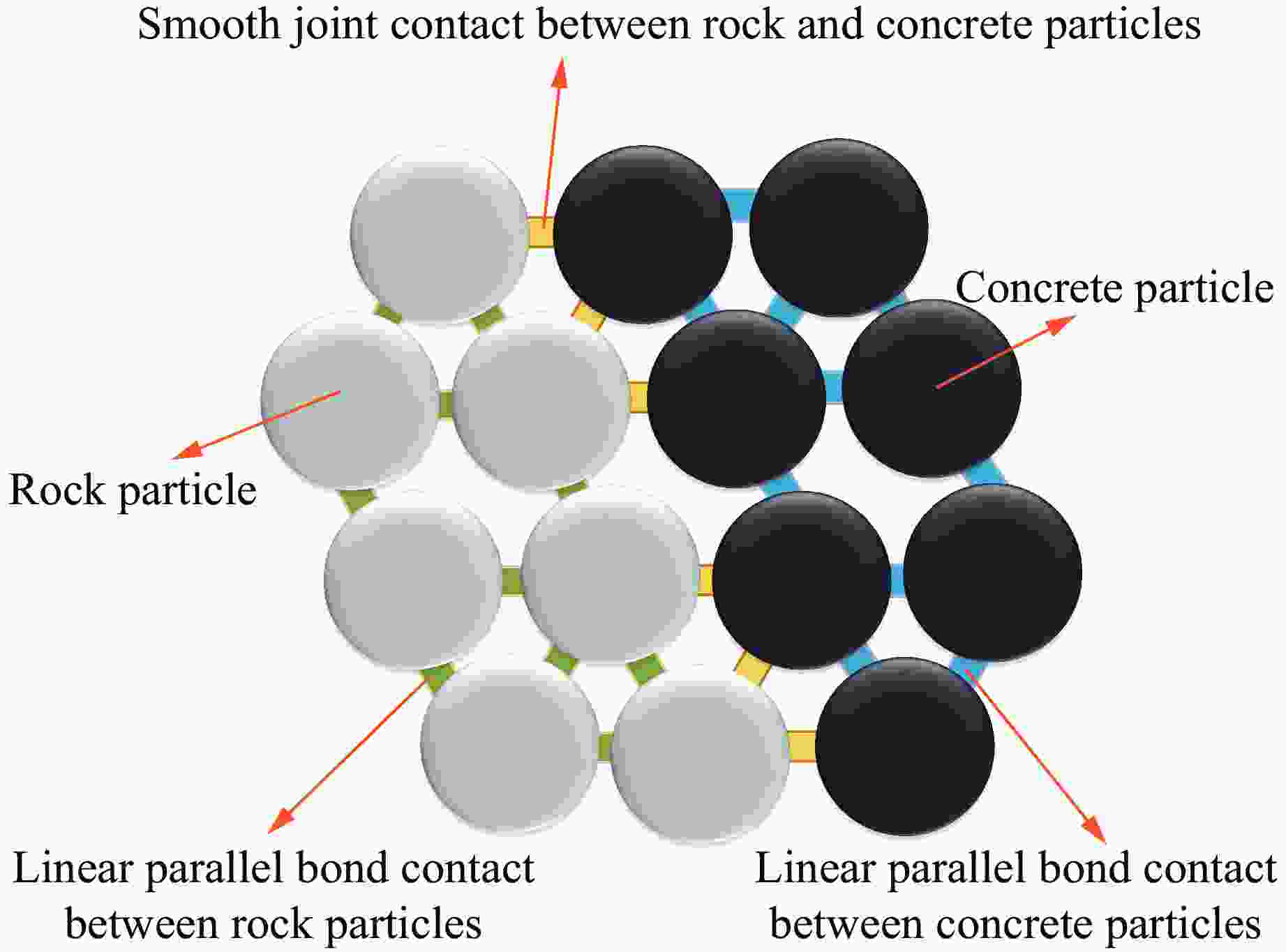

表 1 PFC模拟中的细观参数

Table 1. Mesostructure parameters in PFC simulation

Material Particle density/

(kg·m−3)Particle friction

coefficientEffective

modulus/GPaStiffness

ratioTensile strength/

MPaBonding

strength/MPaGranite 2790 0.3 17.5 2.53 50 150 Concrete 2360 0.2 8.0 1.33 51 50 Material Normal stiffness/

(MN·m−1)Shear stiffness/

(MN·m−1)Frictional

coefficientCohesion/

GPaJoint friction

angle/(°)Friction

angle/(°)Granite 90 450 0.6 20 0.5 30 Concrete 90 450 0.6 20 0.5 70 表 2 数值模拟方案

Table 2. Numerical simulation scheme

L/mm Rock-concrete combination model β=0° β=30° β=60° β=90° 10

20

30

表 3 岩石-混凝土组合体单轴压缩的数值计算结果

Table 3. Numerical results of rock-concrete combination under uniaxial compression

Sample L/mm β/(°) σp/MPa εp E/GPa σi/MPa σi/σp SR-C 41.48 0.61 7.180 25.47 0.614 SR-C-10-0° 10 0 38.90 0.59 6.644 23.51 0.604 SR-C-10-30° 10 30 44.01 0.68 6.500 19.52 0.444 SR-C-10-60° 10 60 43.41 0.66 6.614 18.87 0.435 SR-C-10-90° 10 90 40.37 0.61 6.671 18.87 0.467 SR-C-20-0° 20 0 31.85 0.52 6.137 20.32 0.638 SR-C-20-30° 20 30 34.06 0.56 6.112 20.24 0.594 SR-C-20-60° 20 60 40.90 0.64 6.390 26.10 0.638 SR-C-20-90° 20 90 43.23 0.68 6.376 12.25 0.283 SR-C-30-0° 30 0 18.18 0.33 5.516 12.65 0.696 SR-C-30-30° 30 30 19.53 0.37 5.222 14.30 0.732 SR-C-30-60° 30 60 28.13 0.46 6.159 19.84 0.705 SR-C-30-90° 30 90 42.54 0.71 6.791 19.75 0.464 -

[1] 武世岩, 黄彦华. 含弧形裂隙花岗岩裂纹扩展特征PFC模拟 [J]. 中南大学学报(自然科学版), 2023, 54(1): 169–182. doi: 10.11817/j.issn.1672-7207.2023.01.016WU S Y, HUANG Y H. PFC simulation on crack coalescence behavior of granite specimens containing an arc fissure [J]. Journal of Central South University (Science and Technology), 2023, 54(1): 169–182. doi: 10.11817/j.issn.1672-7207.2023.01.016 [2] CHEN Y A, XU J, PENG S J, et al. Experimental study on the acoustic emission and fracture propagation characteristics of sandstone with variable angle joints [J]. Engineering Geology, 2021, 292: 106247. doi: 10.1016/j.enggeo.2021.106247 [3] 张旭龙, 张盛, 安定超, 等. 平行双裂缝圆盘试样裂纹扩展过程的尺寸效应试验研究 [J]. 岩石力学与工程学报, 2023, 42(1): 115–128. doi: 10.13722/j.cnki.jrme.2021.1113ZHANG X L, ZHANG S, AN D C, et al. Experimental study on the size effect of crack propagation process of disk samples containing parallel double pre-existing flaws [J]. Chinese Journal of Rock Mechanics and Engineering, 2023, 42(1): 115–128. doi: 10.13722/j.cnki.jrme.2021.1113 [4] SHAO L Y, MAO J, ZHAO L H, et al. A three-dimensional deformable spheropolyhedral-based discrete element method for simulation of the whole fracture process [J]. Engineering Fracture Mechanics, 2022, 263: 108290. doi: 10.1016/j.engfracmech.2022.108290 [5] WANG Y, HAN J Q, SONG Z Y, et al. Macro-meso failure behavior of pre-flawed hollow-cylinder granite under multi-level cyclic loads: insights from acoustic emission and post-test CT scanning [J]. Engineering Fracture Mechanics, 2021, 258: 108074. doi: 10.1016/j.engfracmech.2021.108074 [6] LUO Y, GONG H L, XU K, et al. Progressive failure characteristics and energy accumulation of granite with a pre-fabricated fracture during conventional triaxial loading [J]. Theoretical and Applied Fracture Mechanics, 2022, 118: 103219. doi: 10.1016/j.tafmec.2021.103219 [7] 邵珠山, 李晓照. 基于细观力学的脆性岩石长期蠕变失效研究 [J]. 岩石力学与工程学报, 2016, 35(Suppl 1): 2644–2652. doi: 10.13722/j.cnki.jrme.2014.1496SHAO Z S, LI X Z. Research on long-term creep failure of brittle rock based on micromechanics [J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(Suppl 1): 2644–2652. doi: 10.13722/j.cnki.jrme.2014.1496 [8] WONG L N Y, EINSTEIN H H. Systematic evaluation of cracking behavior in specimens containing single flaws under uniaxial compression [J]. International Journal of Rock Mechanics and Mining Sciences, 2009, 46(2): 239–249. doi: 10.1016/j.ijrmms.2008.03.006 [9] YUAN H, XIAO T L, SHE H C, et al. Crack propagation law of rock with single fissure based on PFC2D [J]. Frontiers in Earth Science, 2023, 10: 977054. doi: 10.3389/feart.2022.977054 [10] ZHAO Y Q, LI Q S, ZHANG K, et al. Effect of fissure angle on energy evolution and failure characteristics of fractured rock under uniaxial cyclic loading [J]. Scientific Reports, 2023, 13(1): 2678. doi: 10.1038/s41598-022-26091-4 [11] 田文岭, 杨圣奇, 殷鹏飞. 张开与充填四裂隙脆性砂岩强度和贯通模式研究 [J]. 应用基础与工程科学学报, 2018, 26(5): 1005–1015. doi: 10.16058/j.issn.1005-0930.2018.05.008TIAN W L, YANG S Q, YIN P F. Strength and crack coalescence behavior of sandstone containing four filled or unfilled pre-existing fissures [J]. Journal of Basic Science and Engineering, 2018, 26(5): 1005–1015. doi: 10.16058/j.issn.1005-0930.2018.05.008 [12] 王卫华, 王小金, 姜海涛, 等. 单轴压缩作用下含不同倾角裂隙的类岩石试样力学特性 [J]. 科技导报, 2014, 32(28/29): 48–53. doi: 10.3981/j.issn.1000-7857.2014.h2.005WANG W H, WANG X J, JIANG H T, et al. Experimental research on mechanical properties of rocklike specimens containing single cracks of different inclination angles under uniaxial compression [J]. Science & Technology Review, 2014, 32(28/29): 48–53. doi: 10.3981/j.issn.1000-7857.2014.h2.005 [13] 孙朝阳. 不同裂隙角度对岩体强度影响研究 [J]. 煤炭技术, 2015, 34(6): 113–115. doi: 10.13301/j.cnki.ct.2015.06.042SUN Z Y. Research on influences of crack angle in rock on its peak strength [J]. Coal Technology, 2015, 34(6): 113–115. doi: 10.13301/j.cnki.ct.2015.06.042 [14] 徐贞社, 卞壮, 刘毅, 等. 组合裂隙及其倾角对岩石力学特性及破坏特征的影响 [J]. 矿业研究与开发, 2022, 42(11): 140–145. doi: 10.13827/j.cnki.kyyk.2022.11.026XU Z S, BIAN Z, LIU Y, et al. The influence of combined fissures and its dip angles on the mechanical properties and failure characteristics of rock [J]. Mining Research and Development, 2022, 42(11): 140–145. doi: 10.13827/j.cnki.kyyk.2022.11.026 [15] 吴钰, 任旭华, 张继勋, 等. 含裂隙岩石单轴压缩数值试验研究 [J]. 三峡大学学报(自然科学版), 2021, 43(2): 35–41. doi: 10.13393/j.cnki.issn.1672-948x.2021.02.007WU Y, REN X H, ZHANG J X, et al. Numerical and experimental study on rock containing pre-existing cracks under uniaxial compression [J]. Journal of China Three Gorges University (Natural Sciences), 2021, 43(2): 35–41. doi: 10.13393/j.cnki.issn.1672-948x.2021.02.007 [16] ZHOU X P, FU L, JU W, et al. An experimental study of the mechanical and fracturing behavior in PMMA specimen containing multiple 3D embedded flaws under uniaxial compression [J]. Theoretical and Applied Fracture Mechanics, 2019, 101: 207–216. doi: 10.1016/j.tafmec.2019.03.002 [17] 王磊, 商瑞豪, 刘怀谦, 等. 含多裂隙煤体裂纹细观演化规律与相互作用机制 [J]. 中国矿业大学学报, 2023, 52(2): 300–313. doi: 10.13247/j.cnki.jcumt.20220639WANG L, SHANG R H, LIU H Q, et al. Microcrack evolution law and interaction mechanism of coal with multiple cracks [J]. Journal of China University of Mining & Technology, 2023, 52(2): 300–313. doi: 10.13247/j.cnki.jcumt.20220639 [18] YANG K X, HU Q, ZHAO H, et al. Numerical study on the shear behavior of concrete-rock joints with similar triangular asperities [J]. Computers and Geotechnics, 2023, 159: 105468. doi: 10.1016/j.compgeo.2023.105468 [19] ZHAO J, FENG X T, ZHANG X W, et al. Brittle-ductile transition and failure mechanism of Jinping marble under true triaxial compression [J]. Engineering Geology, 2018, 232: 160–170. doi: 10.1016/j.enggeo.2017.11.008 [20] 赵宝云, 刘保县, 徐柯, 等. 单轴压缩作用下岩石混凝土一体两介质体破裂过程数值模拟 [J]. 西华大学学报(自然科学版), 2007, 26(6): 80–82. doi: 10.3969/j.issn.1673-159X.2007.06.027ZHAO B Y, LIU B X, XU K, et al. Numerical simulation of the failure process of rock and concrete bi-material specimen in uniaxial compression [J]. Journal of Xihua University (Natural Science), 2007, 26(6): 80–82. doi: 10.3969/j.issn.1673-159X.2007.06.027 [21] ZHAO B Y, LIU Y, HUANG T Z, et al. Experimental study on strength and deformation characteristics of rock-concrete composite specimens under compressive condition [J]. Geotechnical and Geological Engineering, 2019, 37(4): 2693–2706. doi: 10.1007/s10706-018-00787-9 [22] MOUZANNAR H, BOST M, LEROUX M, et al. Experimental study of the shear strength of bonded concrete-rock interfaces: surface morphology and scale effect [J]. Rock Mechanics and Rock Engineering, 2017, 50(10): 2601–2625. doi: 10.1007/s00603-017-1259-2 [23] 贺耀文. 金川二矿区深部工程地质及开采稳定性技术研究 [D]. 兰州: 兰州大学, 2021: 36−37.HE Y W. Study on deep engineering geology and mining stability technology of Jinchuan second mining area [D]. Lanzhou: Lanzhou University, 2021: 36−37. [24] 陶伟, 孙明露, 曹亮, 等. 川藏公路波林段某边坡稳定性以及滑动深度的分析 [J]. 四川建材, 2022, 48(2): 249–251. doi: 10.3969/j.issn.1672-4011.2022.02.126TAO W, SUN M L, CAO L, et al. Analysis of stability and sliding depth of a slope in the Bolin section of the Sichuan Tibet highway [J]. Sichuan Building Materials, 2022, 48(2): 249–251. doi: 10.3969/j.issn.1672-4011.2022.02.126 [25] 王明明, 刘俊伟, 汪大洋, 等. 断层岩岩体承载力和变形特性研究 [J]. 科学技术与工程, 2020, 20(23): 9546–9550. doi: 10.3969/j.issn.1671-1815.2020.23.042WANG M M, LIU J W, WANG D Y, et al. Study on bearing capacity and deformation characteristics of fault rock mass [J]. Science Technology and Engineering, 2020, 20(23): 9546–9550. doi: 10.3969/j.issn.1671-1815.2020.23.042 [26] 朱金焕. 基于细观模型的节理参数对岩石力学性能的影响 [J]. 水利科学与寒区工程, 2023, 6(3): 50–52. doi: 10.3969/j.issn.2096-5419.2023.03.013ZHU J H. Influence of joint parameters based on meso-model on mechanical properties of rock [J]. Hydro Science and Cold Zone Engineering, 2023, 6(3): 50–52. doi: 10.3969/j.issn.2096-5419.2023.03.013 [27] ZHANG Z H, GAO W L, LI K P, et al. Numerical simulation of rock mass blasting using particle flow code and particle expansion loading algorithm [J]. Simulation Modelling Practice and Theory, 2020, 104: 102119. doi: 10.1016/j.simpat.2020.102119 [28] 张振平, 盛谦, 付晓东, 等. 基于颗粒离散元的土石混合体直剪试验模拟研究 [J]. 应用基础与工程科学学报, 2021, 29(1): 135–146. doi: 10.16058/j.issn.1005-0930.2021.01.012ZHANG Z P, SHENG Q, FU X D, et al. Research on numerical direct shear test of soil-rock mixture based on particle flow code simulation [J]. Journal of Basic Science and Engineering, 2021, 29(1): 135–146. doi: 10.16058/j.issn.1005-0930.2021.01.012 [29] 张顺金. 裂隙岩体在单轴加载过程中变形、破裂规律的PFC2D数值模拟研究 [J]. 中国建材科技, 2022, 31(6): 69–73. doi: 10.12164/j.issn.1003-8965.2022.06.017ZHANG S J. PFC2D numerical simulation of fractured rock mass deformation and rupture law under uniaxial loading [J]. China Building Materials Science & Technology, 2022, 31(6): 69–73. doi: 10.12164/j.issn.1003-8965.2022.06.017 [30] 常玉鹏, 于洋, 杨凌云, 等. 基于PFC3D软件的原级配砂砾石料三轴试验研究 [J]. 人民黄河, 2023, 45(Suppl 1): 90–91.CHANG Y P, YU Y, YANG L Y, et al. Triaxial test of original graded sand gravel based on PFC3D [J]. Yellow River, 2023, 45(Suppl 1): 90–91. [31] 李琦. 单轴压缩过程中岩石-混凝土一体两介质体声发射特性研究 [D]. 邯郸: 河北工程大学, 2018: 21−22.LI Q. Research on acoustic emission characteristics of rock and concrete monolithic body in uniaxial compression [D]. Handan: Hebei University of Engineering, 2018: 21−22. [32] SHANG Y H, XU L R, LI Y W. Unloading response characteristics of cross fault caverns: effect of fault angles [J]. Geotechnical and Geological Engineering, 2022, 40(3): 1061–1073. doi: 10.1007/s10706-021-01942-5 [33] 汪杰, 付建新, 宋卫东, 等. 岩石-充填体组合模型力学特性及微裂纹演化特征颗粒流模拟 [J]. 中国矿业大学学报, 2020, 49(3): 453–462. doi: 10.13247/j.cnki.jcumt.001150WANG J, FU J X, SONG W D, et al. Particle flow simulation of mechanical properties and microcrack evolution characteristics of rock-backfill combined model [J]. Journal of China University of Mining & Technology, 2020, 49(3): 453–462. doi: 10.13247/j.cnki.jcumt.001150 [34] 孙旭曙. 节理岩体卸荷各向异性力学特性试验研究及工程应用 [D]. 武汉: 武汉大学, 2013: 32−33.SUN X S. Experimental research and its engineering application of anisotropic mechanics characteristic in jointed rock mass under unloading condition [D]. Wuhan: Wuhan University, 2013: 32−33. [35] 谭攀, 饶秋华, 李卓, 等. 考虑断裂韧度的PFC3D细观参数标定新方法 [J]. 中南大学学报(自然科学版), 2021, 52(8): 2849–2866. doi: 10.11817/j.issn.1672-7207.2021.08.030TAN P, RAO Q H, LI Z, et al. A new method for quantitative determination of PFC3D microscopic parameters considering fracture toughness [J]. Journal of Central South University (Science and Technology), 2021, 52(8): 2849–2866. doi: 10.11817/j.issn.1672-7207.2021.08.030 [36] XIA B W, LI Y, HU H R, et al. Effect of crack angle on mechanical behaviors and damage evolution characteristics of sandstone under uniaxial compression [J]. Rock Mechanics and Rock Engineering, 2022, 55(11): 6567–6582. doi: 10.1007/s00603-022-03016-1 [37] ZHOU X P, LONG Y D, Ye W. Experimental investigations on the cracking and mechanical responses of PMMA samples with two 3D embedded elliptic flaws under uniaxial compression [J]. Geohazard Mechanics, 2023, 1(1): 77–85. doi: 10.1016/j.ghm.2022.11.004 [38] CHANG X, WANG S R, LI Z, et al. Cracking behavior of concrete/rock bi-material specimens containing a parallel flaw pair under compression [J]. Construction and Building Materials, 2022, 360: 129440. doi: 10.1016/j.conbuildmat.2022.129440 [39] MA S Z, LIU K W, GUO T F, et al. Experimental and numerical investigation on the mechanical characteristics and failure mechanism of cracked coal & rock-like combined sample under uniaxial compression [J]. Theoretical and Applied Fracture Mechanics, 2022(122): 103583. doi: 10.1016/j.tafmec.2022.103583 -

下载:

下载: