Dynamic Responses of Aluminum Foam Sandwich Shells under Repeated Impact Loadings

-

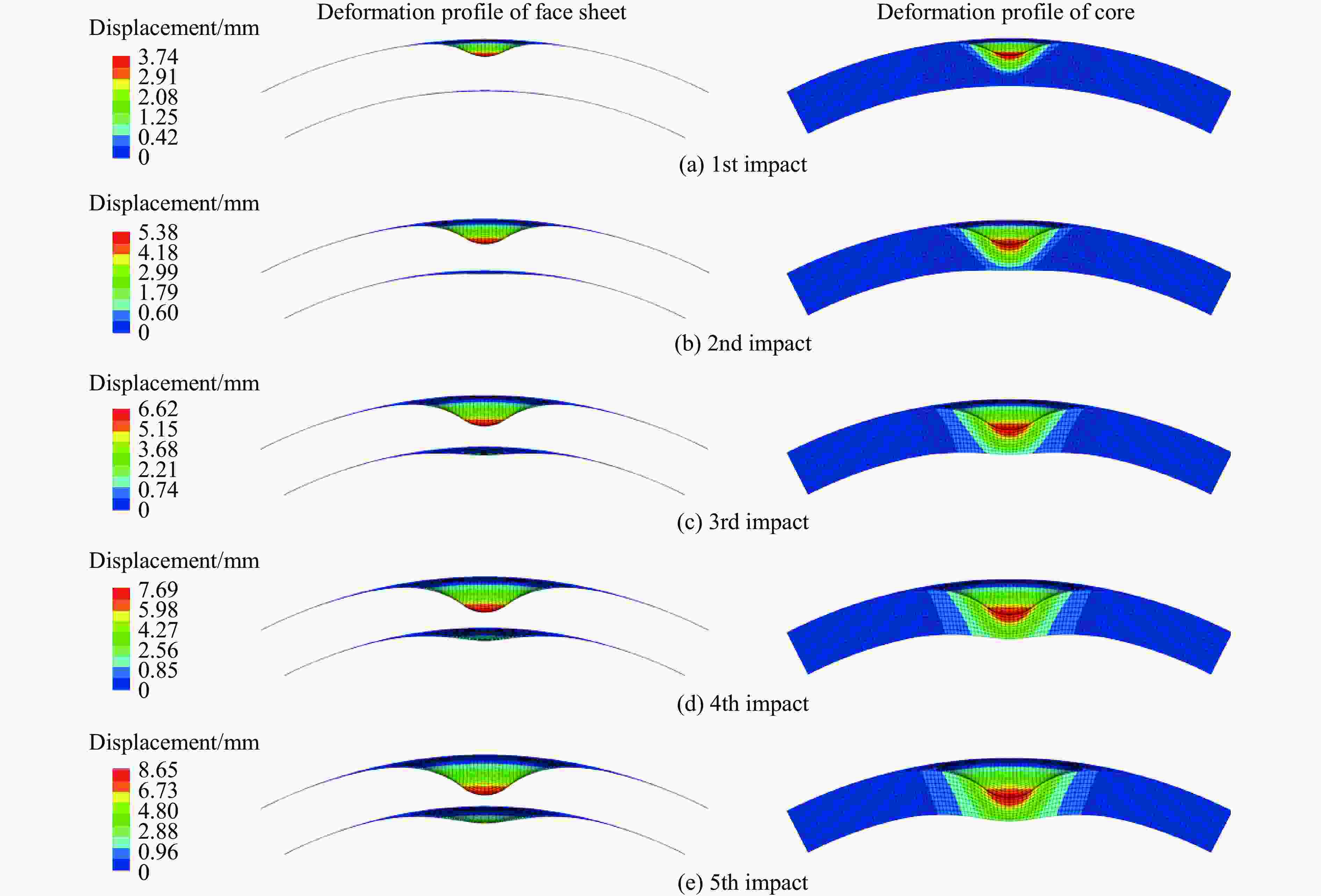

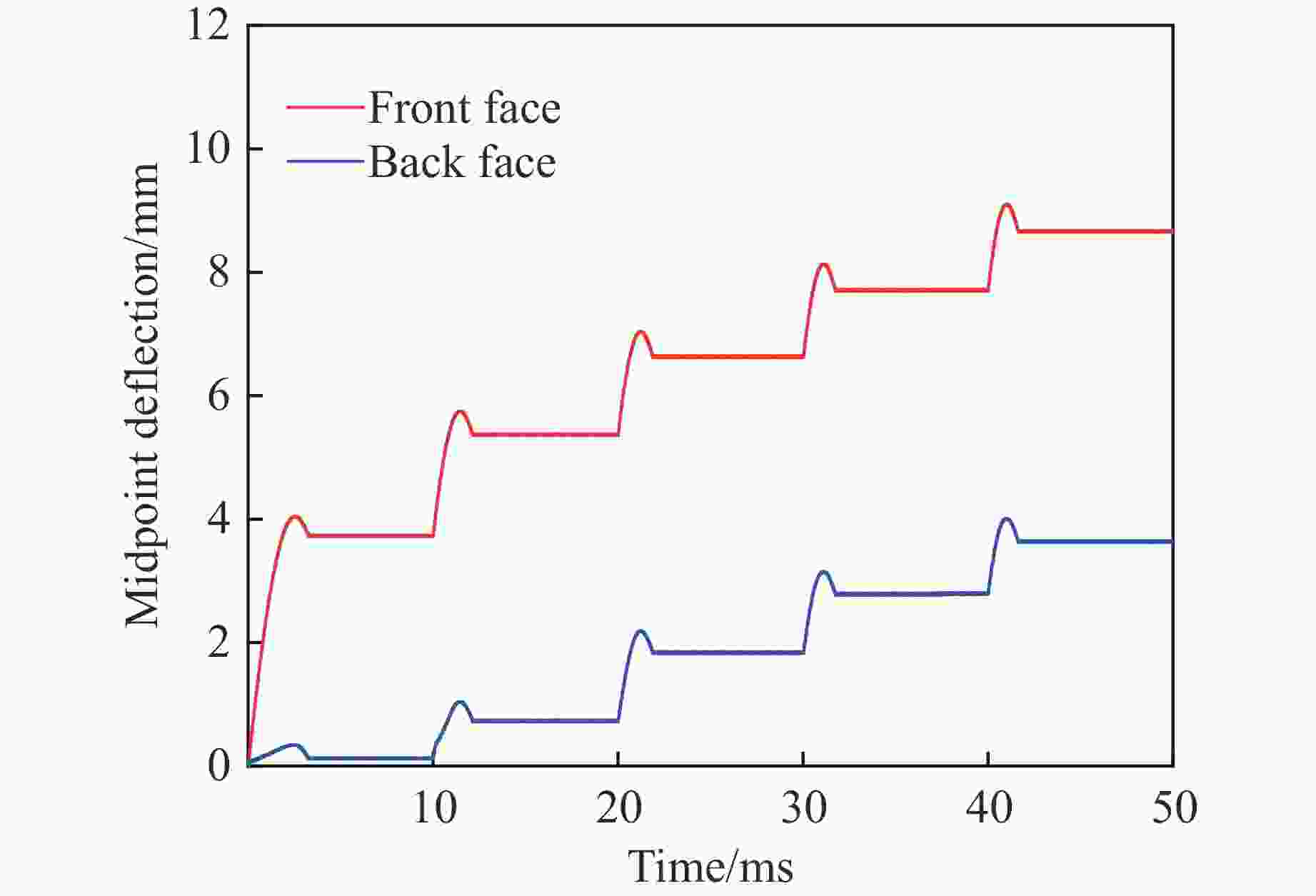

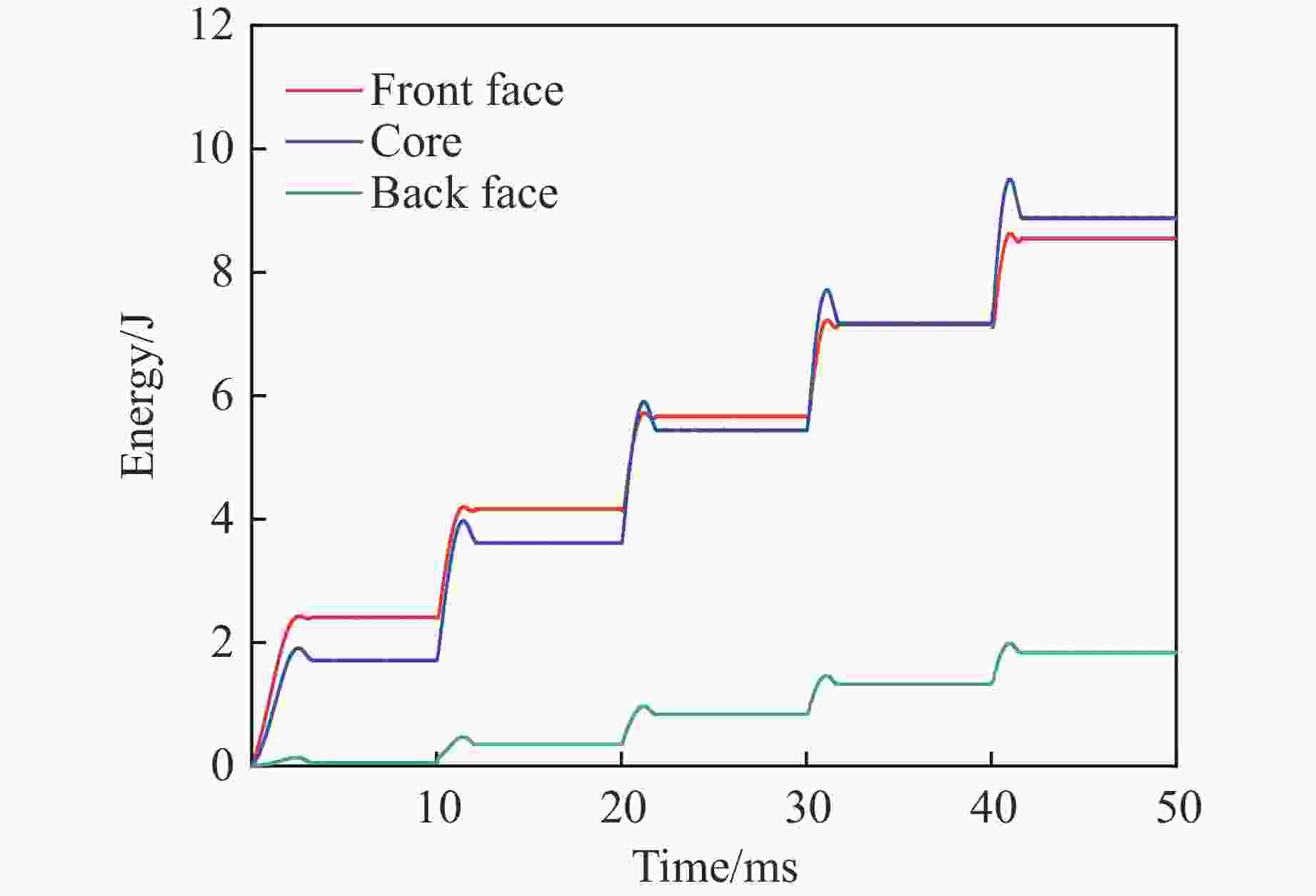

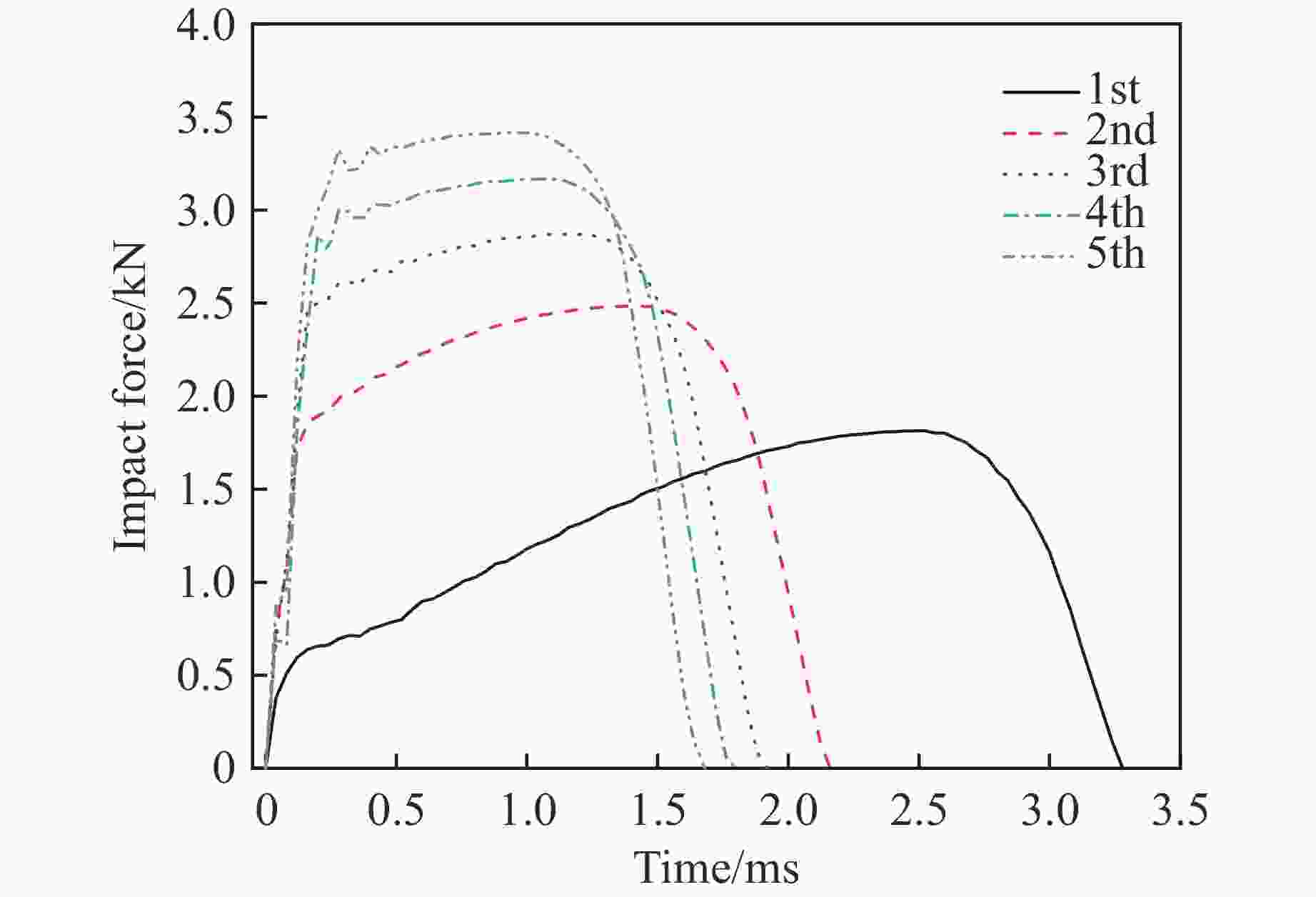

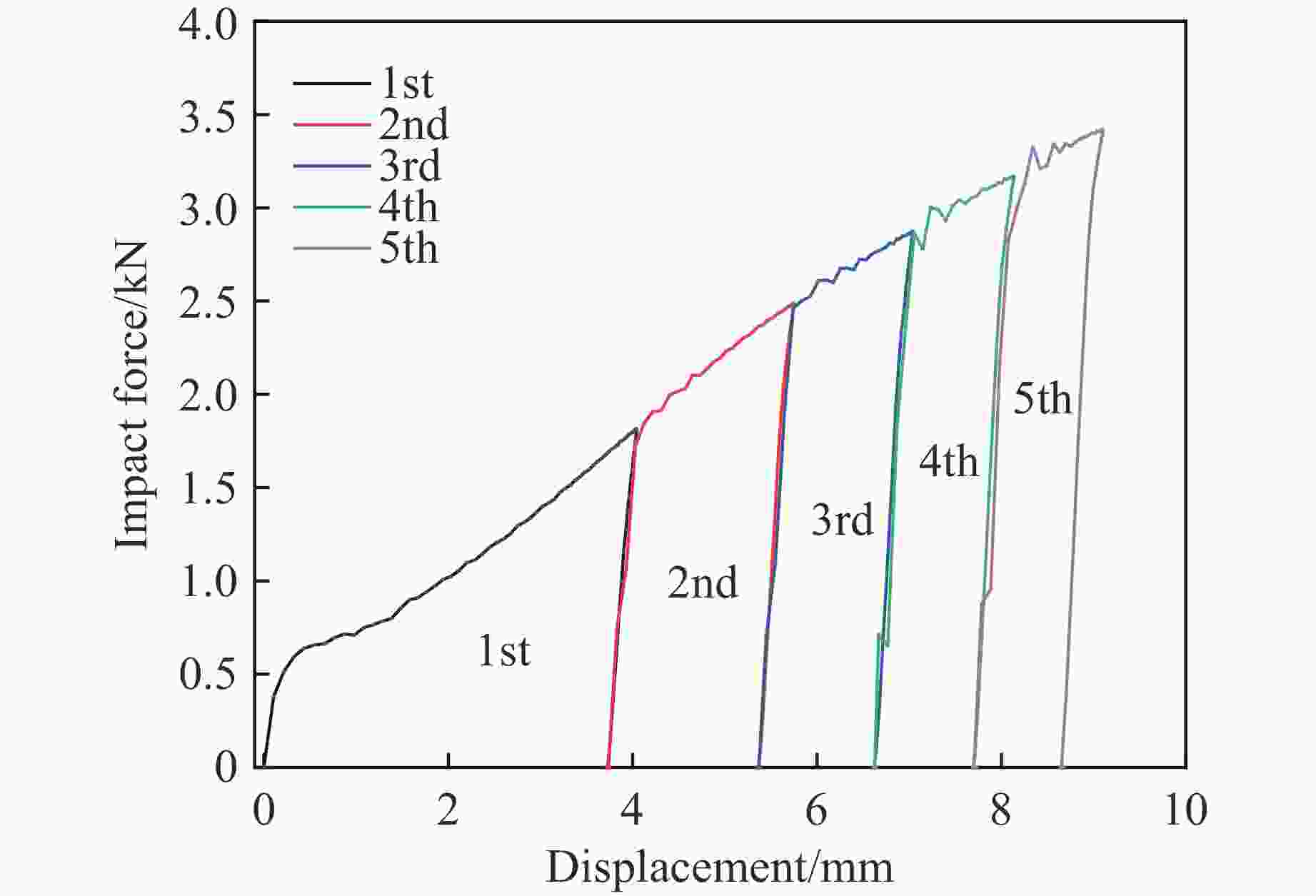

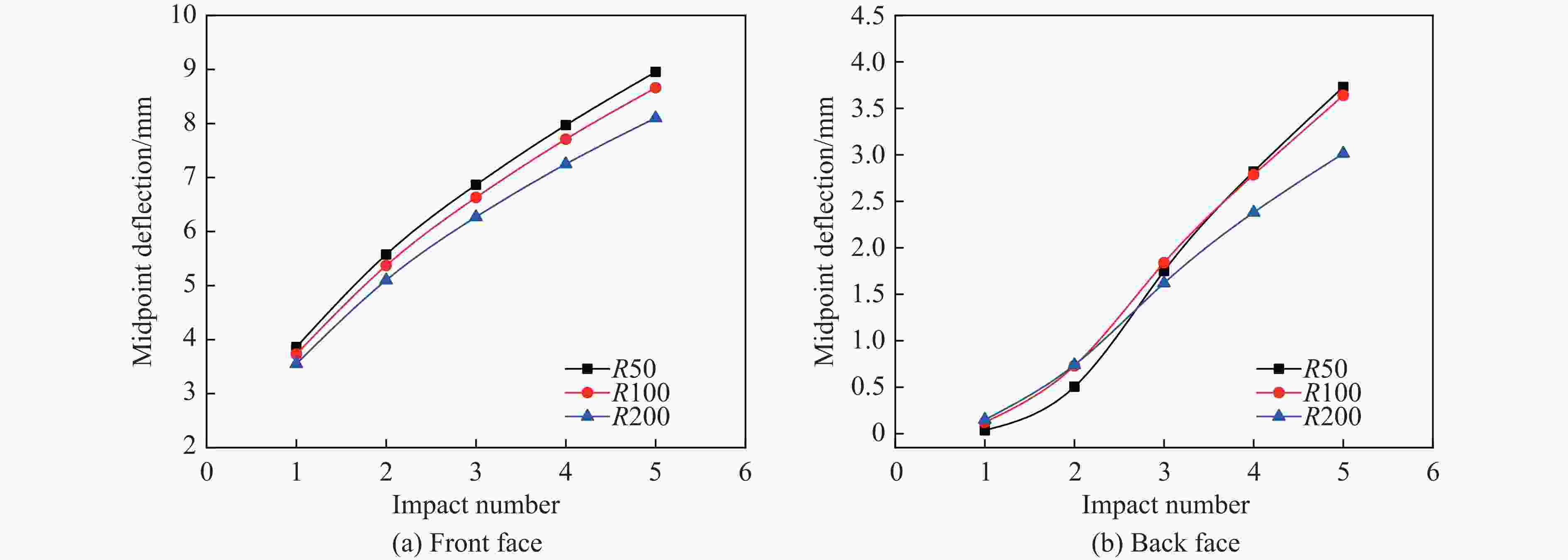

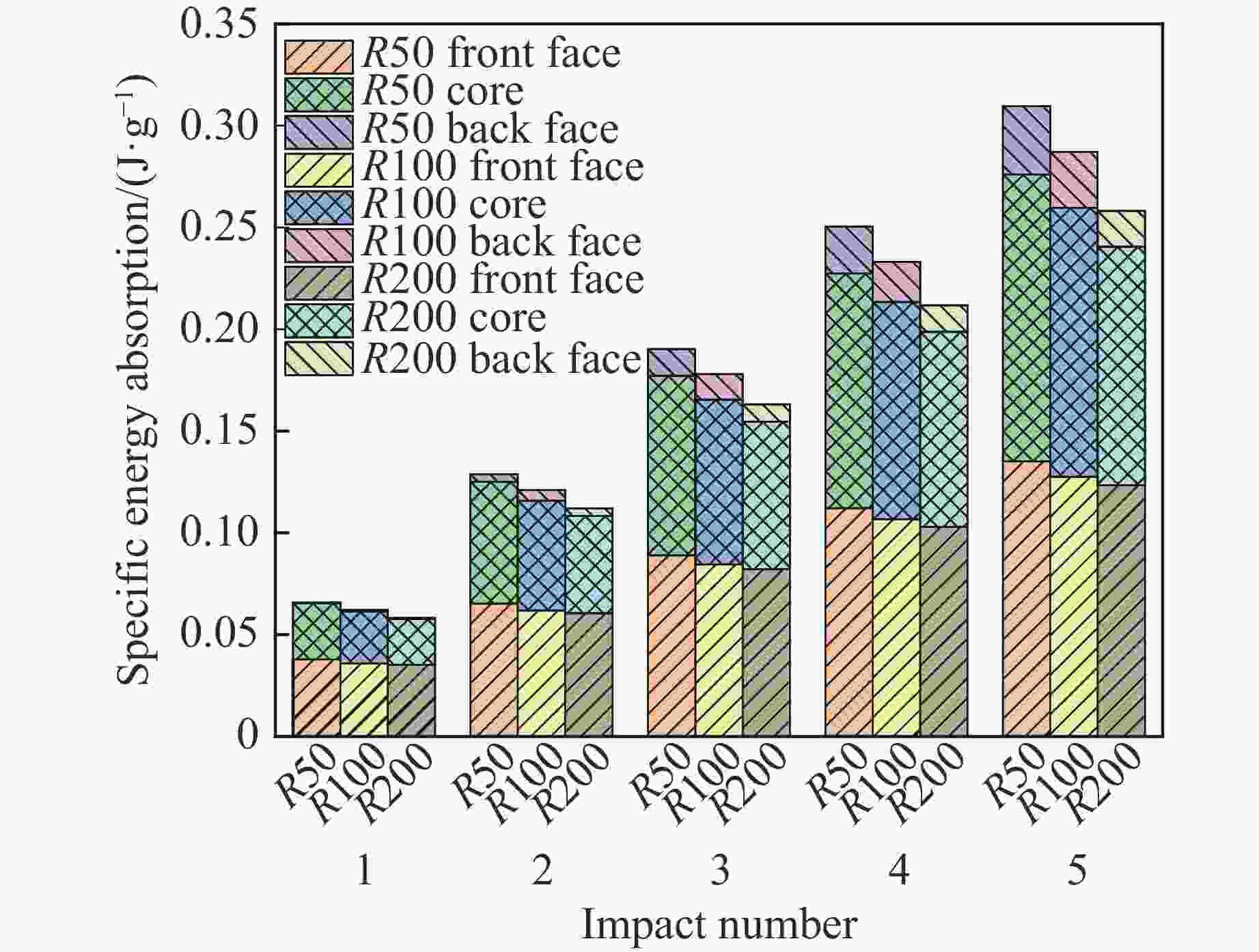

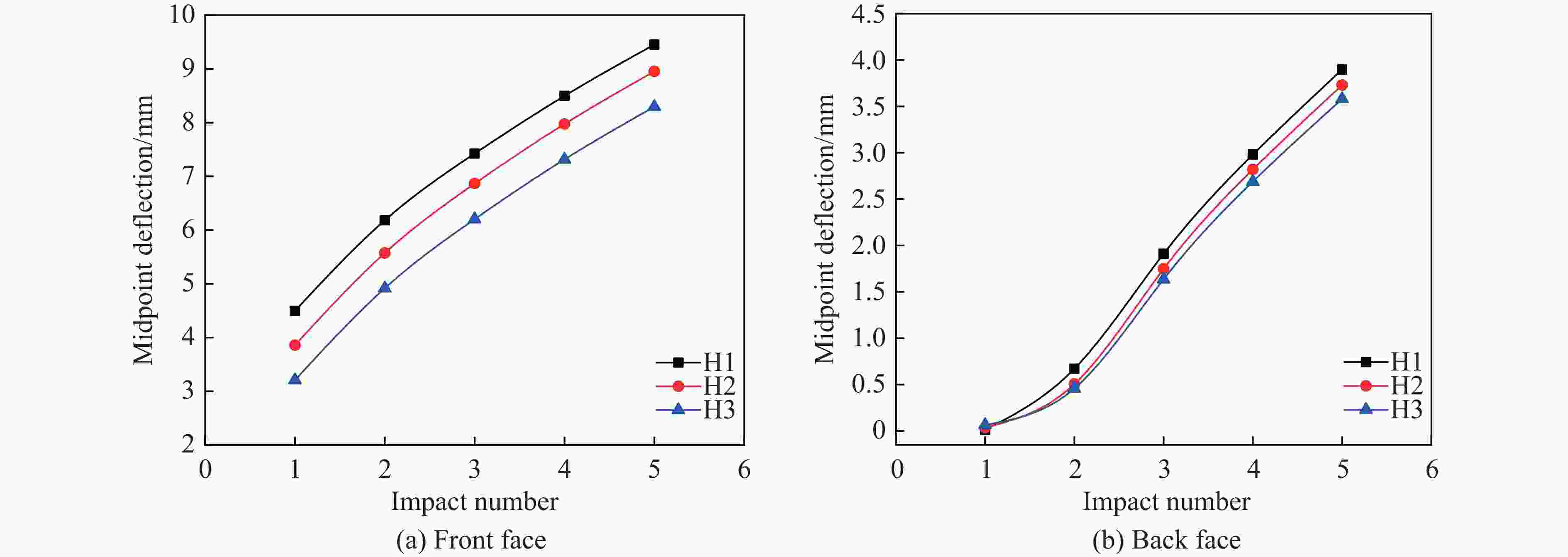

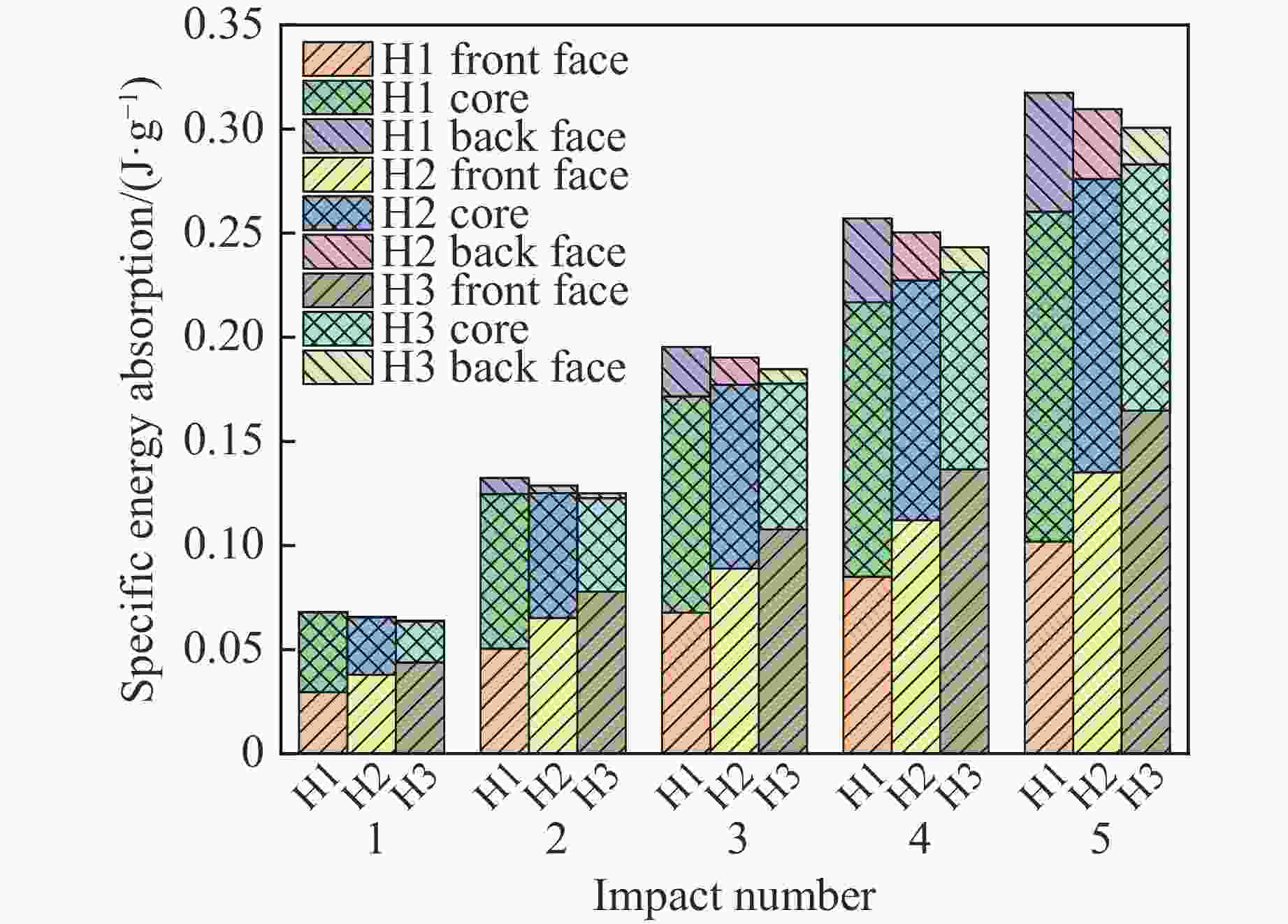

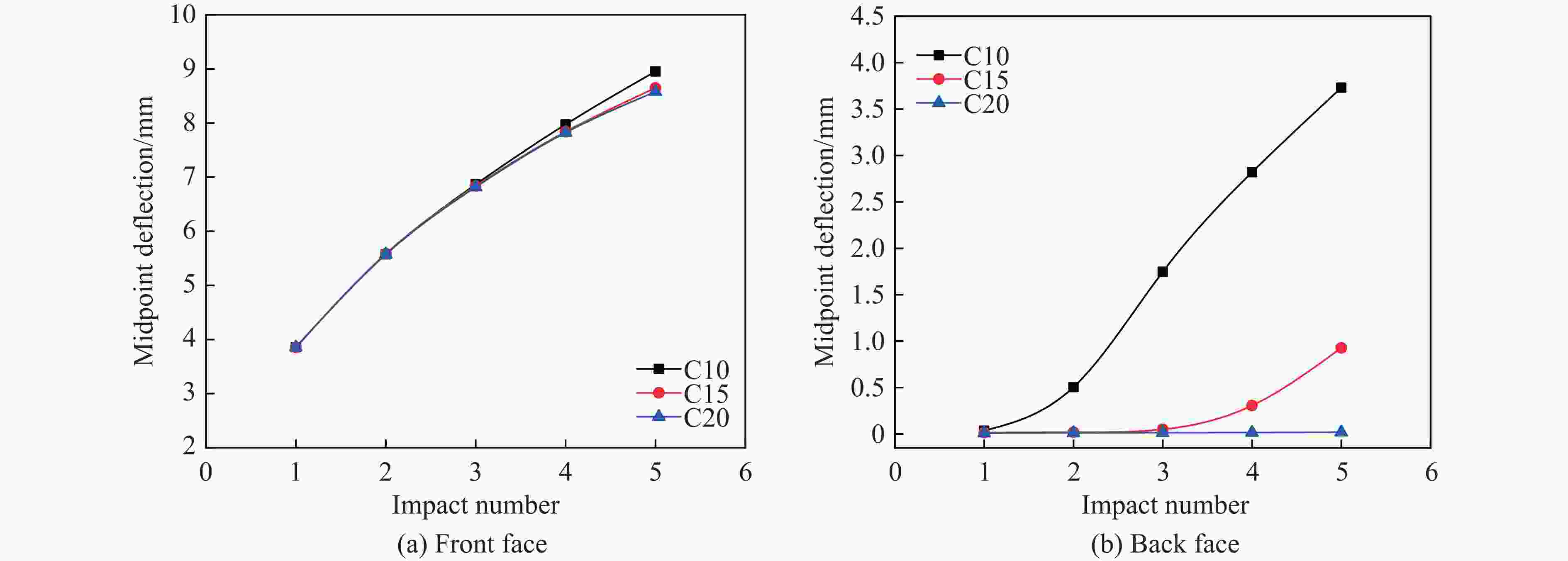

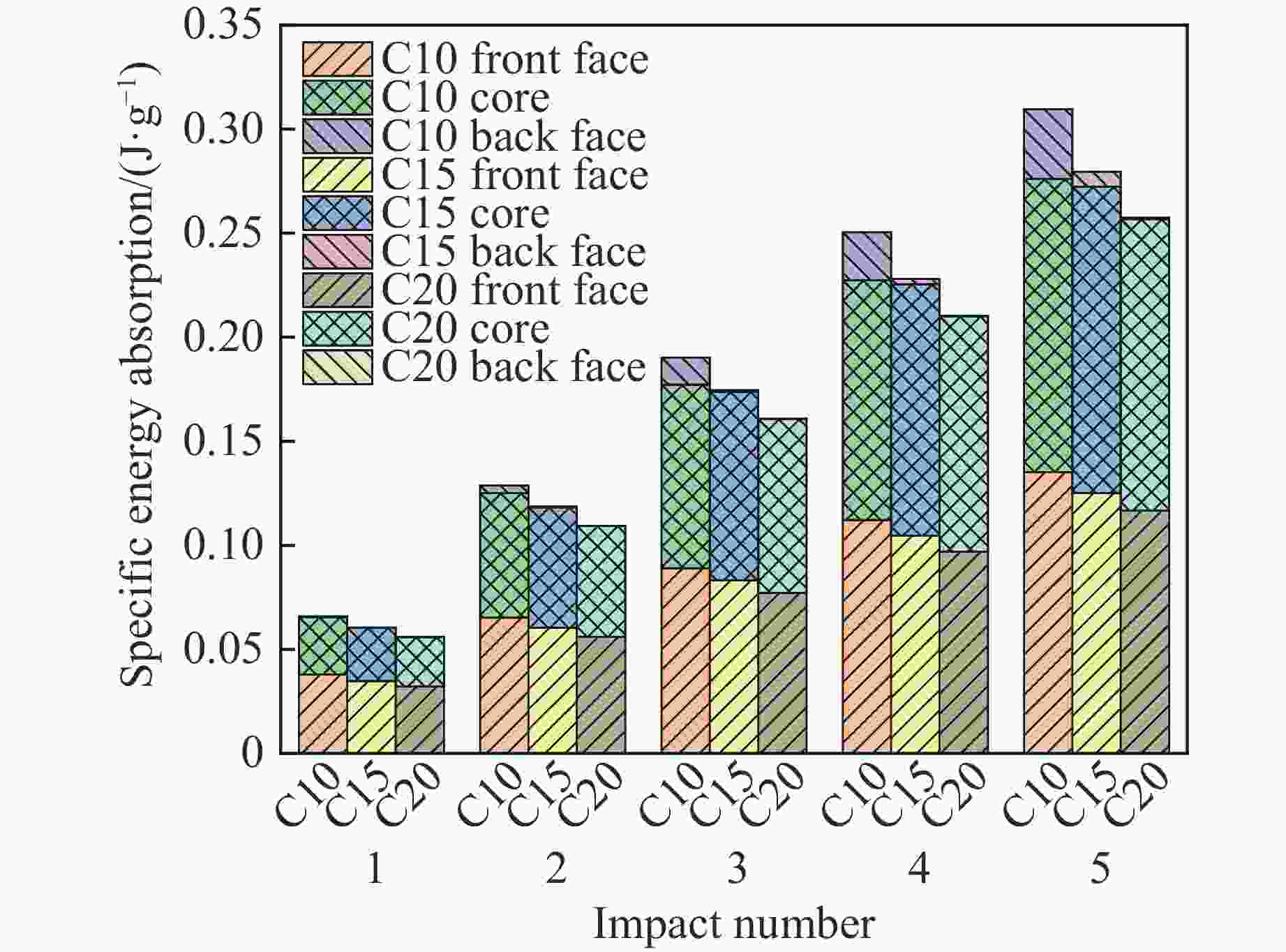

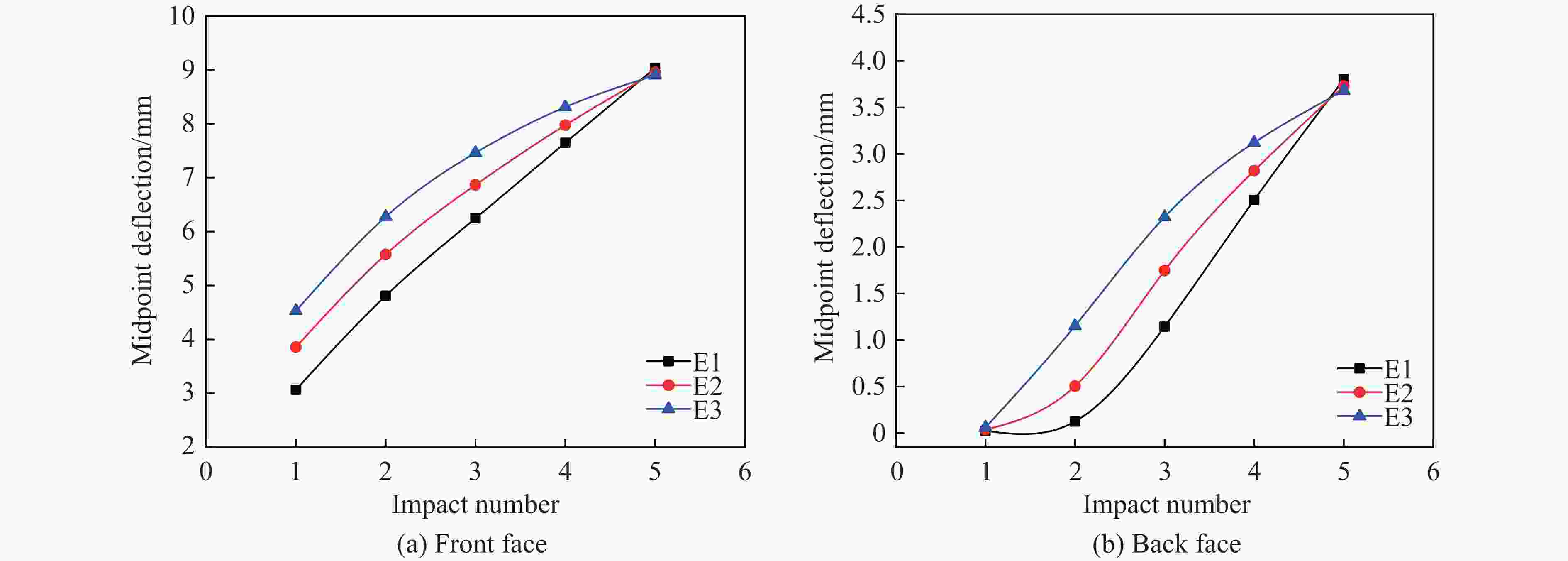

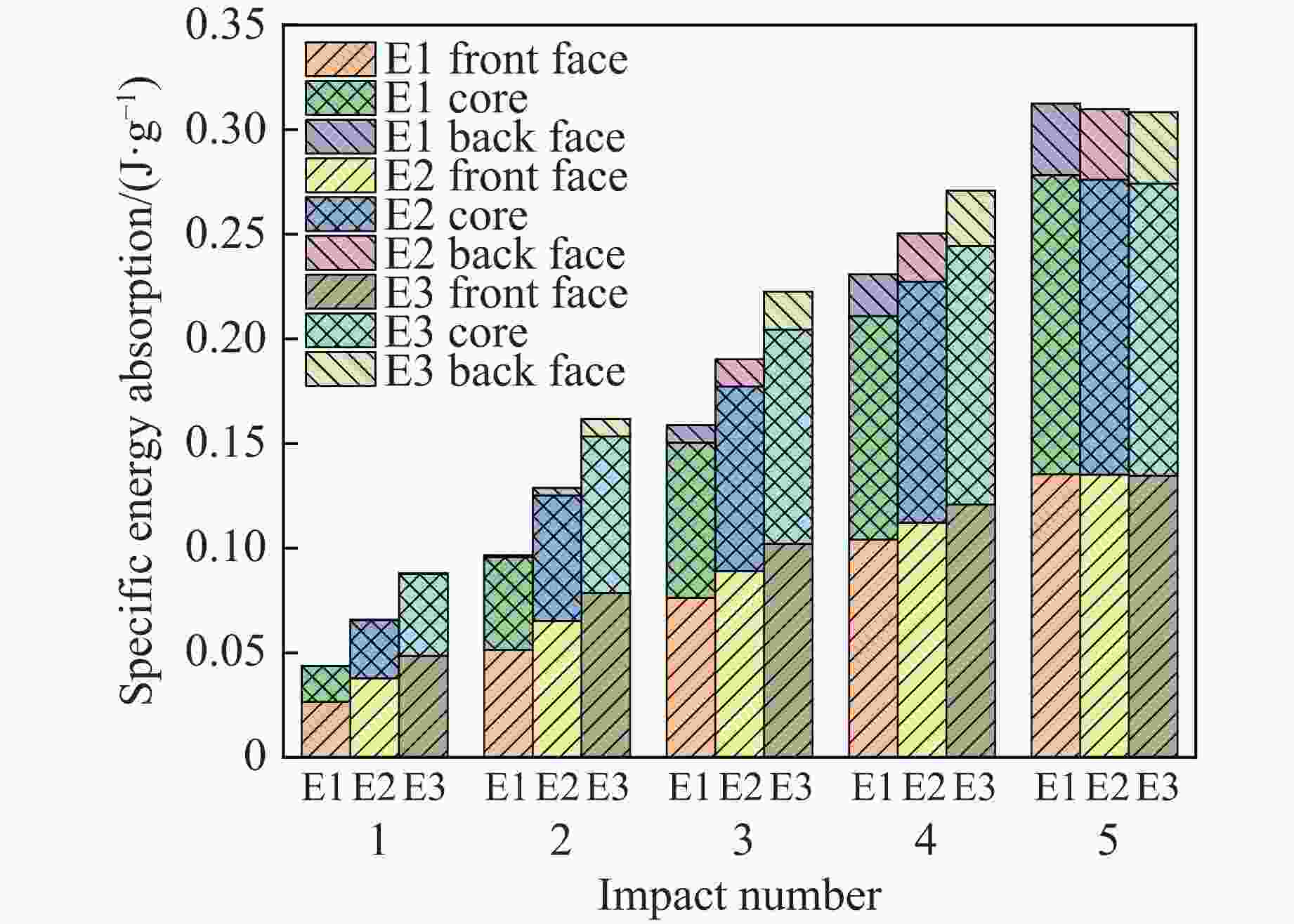

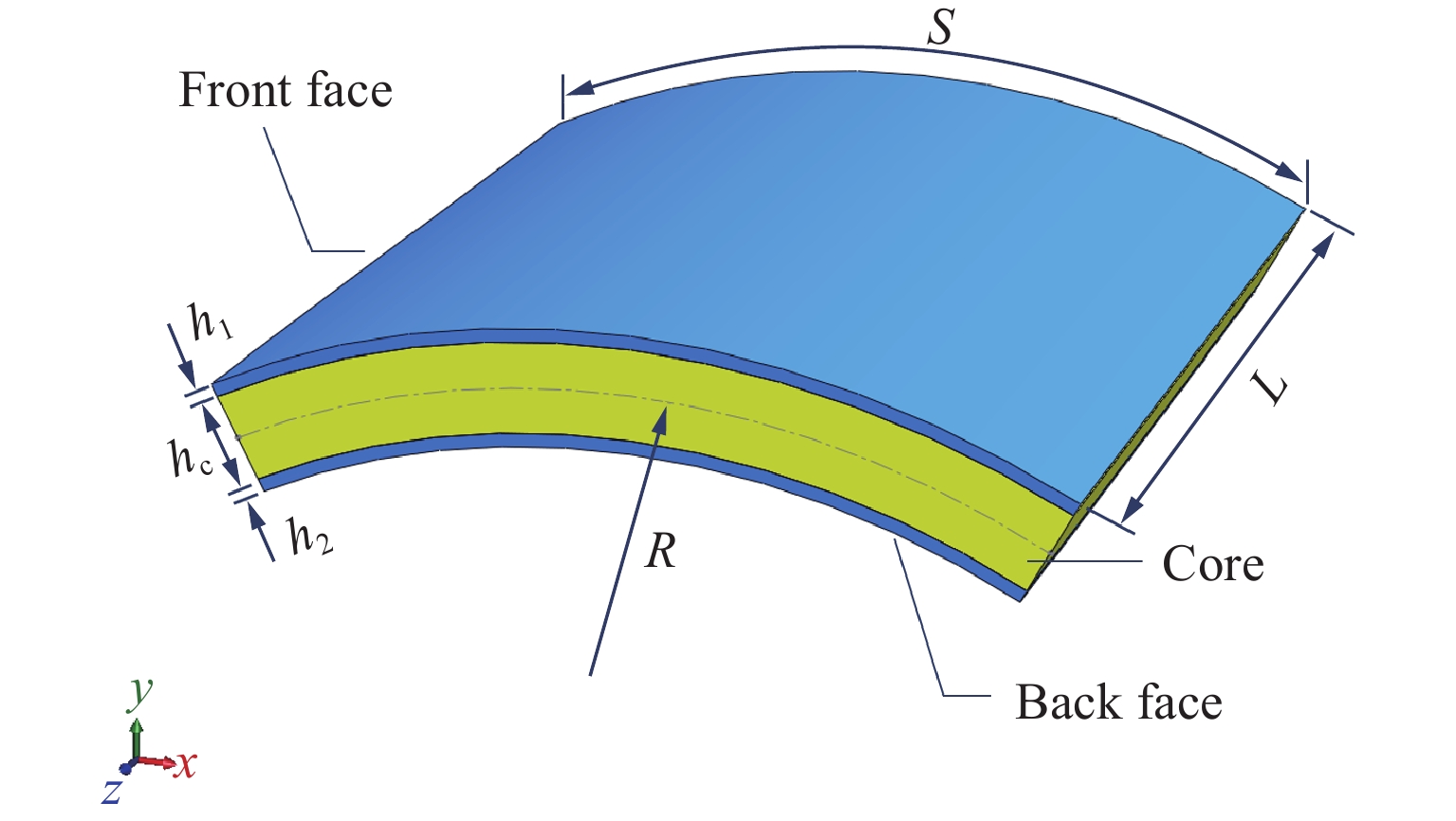

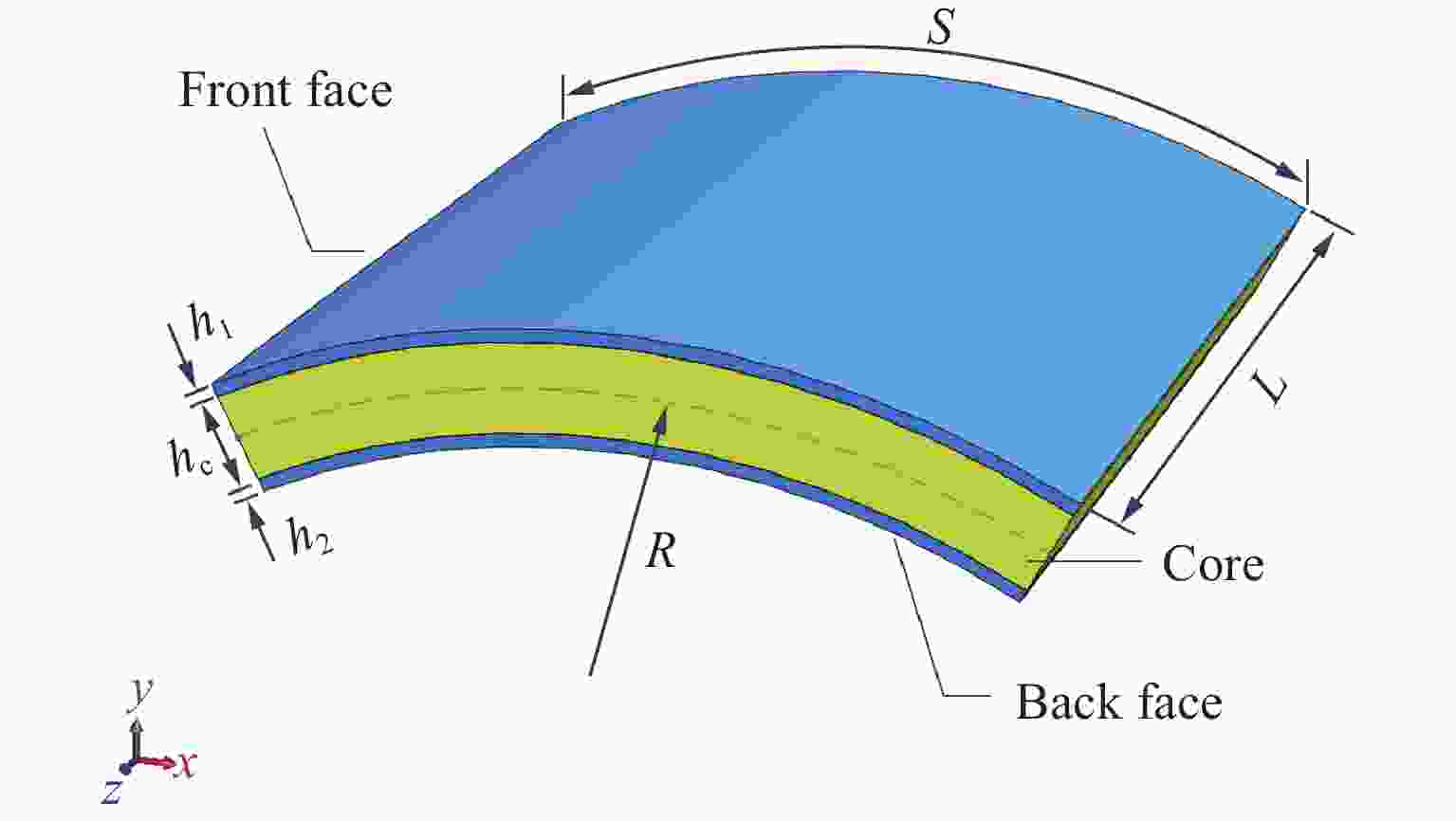

摘要: 通过数值模拟研究了泡沫铝夹芯壳在重复冲击载荷作用下的变形和能量耗散机理,分析了曲率半径、前后面板厚度分配、芯层厚度和冲击能量梯度对结构抗重复冲击性能和能量吸收能力的影响规律。结果表明:在重复冲击载荷作用下,泡沫铝夹芯壳结构的变形不断累积,前面板局部弯曲变形,芯层局部压缩,后面板整体弯曲变形。随着冲击次数的增加,冲击力峰值逐渐增大,冲击持续时间缩短,结构能量吸收能力降低,整体抗弯刚度增大。每次冲击能量相同时,泡沫铝夹芯壳结构曲率越大,能量吸收能力越强,同时前、后面板5次重复冲击后的中点挠度大于曲率较小的夹芯壳结构。5次重复冲击载荷作用下,前面板厚度较大且后面板厚度较小时,结构的比吸能较低,但后面板中点挠度较小。泡沫铝芯层厚度越大,结构的后面板挠度越小,但总比吸能降低。3种不同梯度的冲击能量作用下,递增能量工况下结构的吸能最多,前、后面板的挠度较大,递减能量工况下结构的吸能最少,前、后面板的挠度较小。Abstract: The deformation and energy dissipation mechanism of the aluminum foam sandwich shell under repeated impact loads were investigated by numerical simulation. The effects of radius of curvature, thicknesses distribution of the front/back face sheets, core thickness and impact energy gradient on the repeated impact resistance and energy absorption capacity of the structure were analyzed. It is shown that the deformation of the aluminum foam sandwich shell structure accumulates under repeated impact loads, with local bending deformation of the front face sheet, local compression of the foam core, and global bending deformation of the back face sheet. As impact times increases, the peak impact force and integrated bending stiffness increase, and the impact duration and energy absorption capacity decrease. When each impact energy is the same, for aluminum foam sandwich shell structure, the larger the curvature, the higher the energy absorption capacity, while the midpoint deflections of the front and back face sheets after five repeated impacts are larger than that of the shell structure with smaller curvature. Under five repeated impact loads, when the thickness of the front face is large and the back face is small, the specific energy absorption of the structure is lower, but the midpoint deflection of the back face is smaller. The larger the thickness of the aluminum foam core, the smaller the deflection of the back face of the structure, but the total specific energy absorption is reduced. Under the impact energy with three different gradients, the energy absorption of the structure is the highest when the impact energy is increased successively, and the deflections of the front and back faces are larger, while the energy absorption of the structure is the lowest, and the deflection of the front and back faces is smaller when the impact energy is decreased successively.

-

Key words:

- aluminum foam sandwich shell /

- repeated impact /

- dynamic response /

- energy absorption

-

表 1 面板的材料参数

Table 1. Material parameters of face sheet

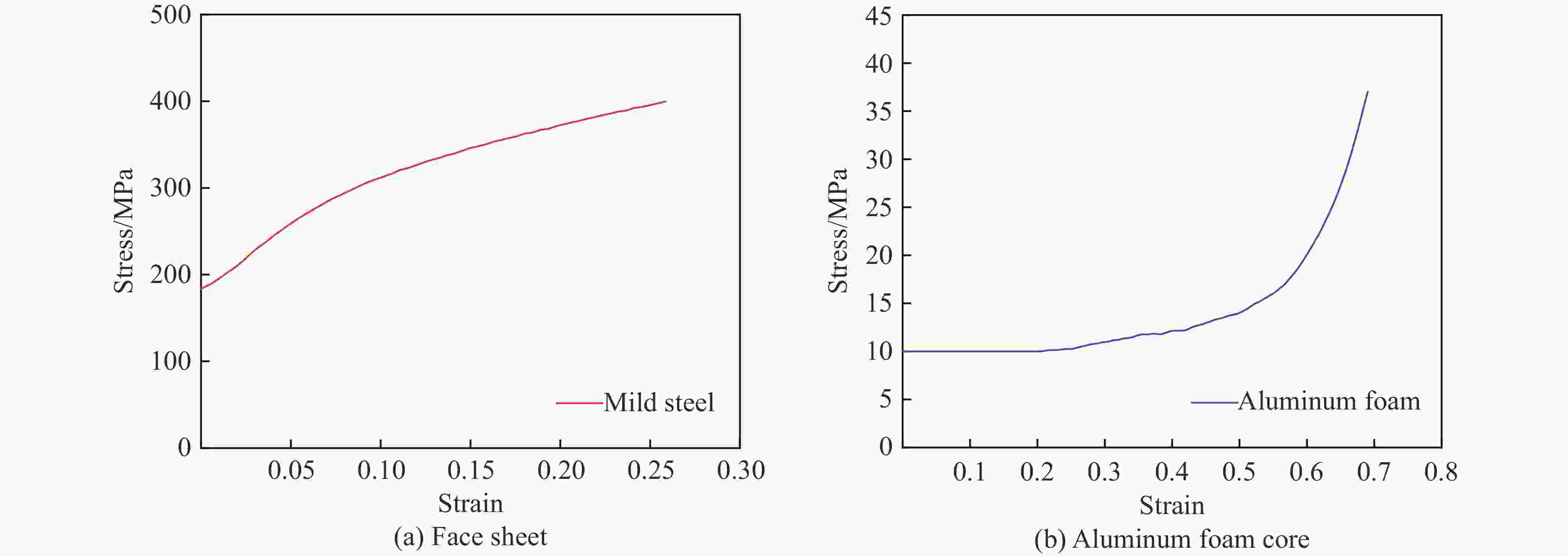

Material Density/(kg·m−3) Young modulus/GPa Yield stress/MPa Poisson’s ratio Mild steel 7800 210 182 0.3 表 2 泡沫铝芯层的材料参数

Table 2. Material parameters of aluminum foam core

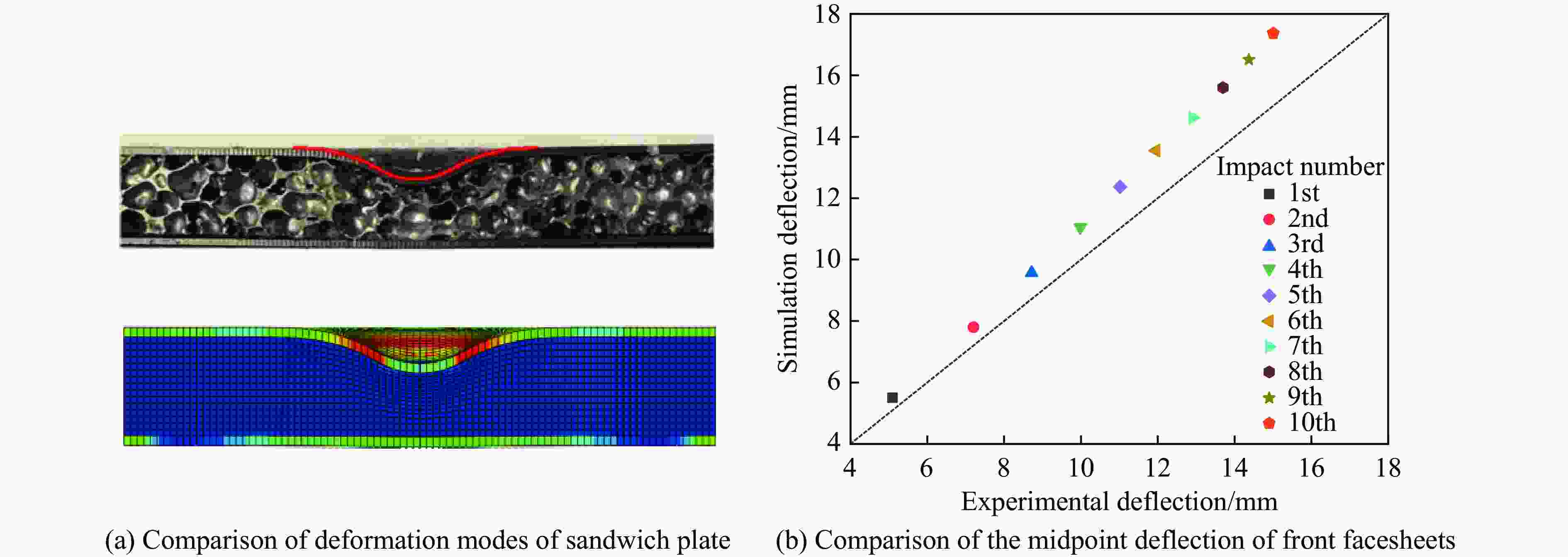

Material Relative density/

%Young’s modulus/

GPaPlateau stress/

MPaElastic Poisson’s

ratioPlastic Poisson’s

ratioPlastic stress

ratioAluminum foam 18.5 0.8 10 0.2 0 1.73 表 3 夹芯壳模型的几何参数

Table 3. Geometric parameters of sandwich shell model

Specimen R/mm α/(°) L/mm S/mm m/g R50 50 104 100 102.5 258.6 R100 100 54 100 100.4 268.5 R200 200 28 100 100.9 278.4 表 4 不同前、后面板厚度夹芯壳的几何参数

Table 4. Geometric parameters of different thickness of front and back face of sandwich shell

Specimen h1/mm h2/mm C/mm m/g H1 1.0 2.0 10 250.8 H2 1.5 1.5 10 258.6 H3 2.0 1.0 10 266.4 表 5 不同芯层厚度夹芯壳的几何参数

Table 5. Geometric parameters of sandwich shells with different core thicknesses

Specimen h1/mm h2/mm hc/mm m/g C10 1.5 1.5 10 258.6 C15 1.5 1.5 15 281.2 C20 1.5 1.5 20 304.0 表 6 5次冲击的能量配置工况

Table 6. Energy arrangement of five impacts

Case Impact energy/J 1st 2nd 3rd 4th 5th E1 12 15 18 21 24 E2 18 18 18 18 18 E3 24 21 18 15 12 -

[1] SINGH P, SHEIKH J, BEHERA B K. Metal-faced sandwich composite panels: a review [J]. Thin-Walled Structures, 2024, 195: 111376. doi: 10.1016/j.tws.2023.111376 [2] PALOMBA G, EPASTO G, CRUPI V. Lightweight sandwich structures for marine applications: a review [J]. Mechanics of Advanced Materials and Structures, 2022, 29(26): 4839–4864. doi: 10.1080/15376494.2021.1941448 [3] XIANG C P, QIN Q H, WANG M S, et al. Low-velocity impact response of sandwich beams with a metal foam core: experimental and theoretical investigations [J]. International Journal of Impact Engineering, 2019, 130: 172–183. doi: 10.1016/j.ijimpeng.2019.04.014 [4] JING L, SU X Y, CHEN D, et al. Experimental and numerical study of sandwich beams with layered-gradient foam cores under low-velocity impact [J]. Thin-Walled Structures, 2019, 135: 227–244. doi: 10.1016/j.tws.2018.11.011 [5] ZHANG W, QIN Q H, LI J F, et al. Deformation and failure of hybrid composite sandwich beams with a metal foam core under quasi-static load and low-velocity impact [J]. Composite Structures, 2020, 242: 112175. doi: 10.1016/j.compstruct.2020.112175 [6] ZHAO Y, YANG Z H, YU T L, et al. Mechanical properties and energy absorption capabilities of aluminium foam sandwich structure subjected to low-velocity impact [J]. Construction and Building Materials, 2021, 273: 121996. doi: 10.1016/j.conbuildmat.2020.121996 [7] 敬霖. 强动载荷作用下泡沫金属夹芯壳结构的动力学行为及其失效机理研究 [D]. 太原: 太原理工大学, 2012: 162–166.JING L. The dynamic mechanical behavior and failure mechanism of sandwich shells with metallic foam cores under intensive loading [D]. Taiyuan: Taiyuan University of Technology, 2012: 162–166. [8] JING L, WANG Z H, ZHAO M L. Response of metallic cylindrical sandwich shells subjected to projectile impact: experimental investigations [J]. Composite Structures, 2014, 107: 36–47. doi: 10.1016/j.compstruct.2013.07.011 [9] ZHOU X F, JING L. Low-velocity impact response of sandwich panels with layered-gradient metal foam cores [J]. International Journal of Impact Engineering, 2024, 184: 104808. doi: 10.1016/j.ijimpeng.2023.104808 [10] 朱凌, 蔡伟, 史诗韵, 等. 反复碰撞载荷下船体结构弹塑性动态响应研究进展 [J]. 船舶力学, 2021, 25(2): 256–262. doi: 10.3969/j.issn.1007-7294.2021.02.014ZHU L, CAI W, SHI S Y, et al. Review on elastic-plastic dynamic responses of ship structures under repeated impact loadings [J]. Journal of Ship Mechanics, 2021, 25(2): 256–262. doi: 10.3969/j.issn.1007-7294.2021.02.014 [11] XIAO W, LI Y G, HU Y, et al. Analytical study on the dynamic mechanical behaviours of foam-core sandwich plate under repeated impacts [J]. Thin-Walled Structures, 2024, 196: 111480. doi: 10.1016/j.tws.2023.111480 [12] 朱凌, 郭开岭, 余同希, 等. 泡沫金属夹芯梁在重复冲击下的动态响应 [J]. 爆炸与冲击, 2021, 41(7): 073101. doi: 10.11883/bzycj-2020-0198ZHU L, GUO K L, YU T X, et al. Dynamic responses of metal foam sandwich beams to repeated impacts [J]. Explosion and Shock Waves, 2021, 41(7): 073101. doi: 10.11883/bzycj-2020-0198 [13] GUO K L, MU M Y, ZHOU S, et al. Dynamic responses of metal foam sandwich beam under repeated impacts considering impact location and face thickness distribution [J]. Composites Part C: Open Access, 2023, 11: 100372. doi: 10.1016/j.jcomc.2023.100372 [14] GUO K L, ZHU L, LI Y G, et al. Experimental investigation on the dynamic behaviour of aluminum foam sandwich plate under repeated impacts [J]. Composite Structures, 2018, 200: 298–305. doi: 10.1016/j.compstruct.2018.05.148 [15] GUO K L, ZHU L, LI Y G, et al. Numerical study on mechanical behavior of foam core sandwich plates under repeated impact loadings [J]. Composite Structures, 2019, 224: 111030. doi: 10.1016/j.compstruct.2019.111030 [16] 郭开岭. 重复冲击载荷下船用泡沫金属夹芯结构动态力学行为研究 [D]. 武汉: 武汉理工大学, 2019: 137–164.GUO K L. Dynamic behavior of metal foam sandwich structures for ship under repeated impact loadings [D]. Wuhan: Wuhan University of Technology, 2019: 137–164. [17] LIU K, KANG S B, GAO S. Experimental and analytical study on impact response of stainless steel-aluminium foam-alloy steel sandwich panels [J]. International Journal of Impact Engineering, 2023, 179: 104661. doi: 10.1016/j.ijimpeng.2023.104661 [18] KUMAR P, STARGEL D S, SHUKLA A. Effect of plate curvature on blast response of carbon composite panels [J]. Composite Structures, 2013, 99: 19–30. doi: 10.1016/j.compstruct.2012.11.036 [19] LI X, HAO X, LI S Q, et al. Dynamic behavior of single curved fiber-metal hybrid lamina composite shells under blast loading-experimental observations [J]. Composites Science and Technology, 2023, 234: 109930. doi: 10.1016/j.compscitech.2023.109930 [20] DESHPANDE V S, FLECK N A. Isotropic constitutive models for metallic foams [J]. Journal of the Mechanics and Physics of Solids, 2000, 48(6/7): 1253–1283. doi: 10.1016/S0022-5096(99)00082-4 [21] ABRAMOWICZ W, JONES N. Dynamic axial crushing of square tubes [J]. International Journal of Impact Engineering, 1984, 2(2): 179–208. doi: 10.1016/0734-743X(84)90005-8 -

下载:

下载: