Mechanical Properties and Energy Evolution Characteristics of Concrete under Different Strain Rates and Content of MWCNTs

-

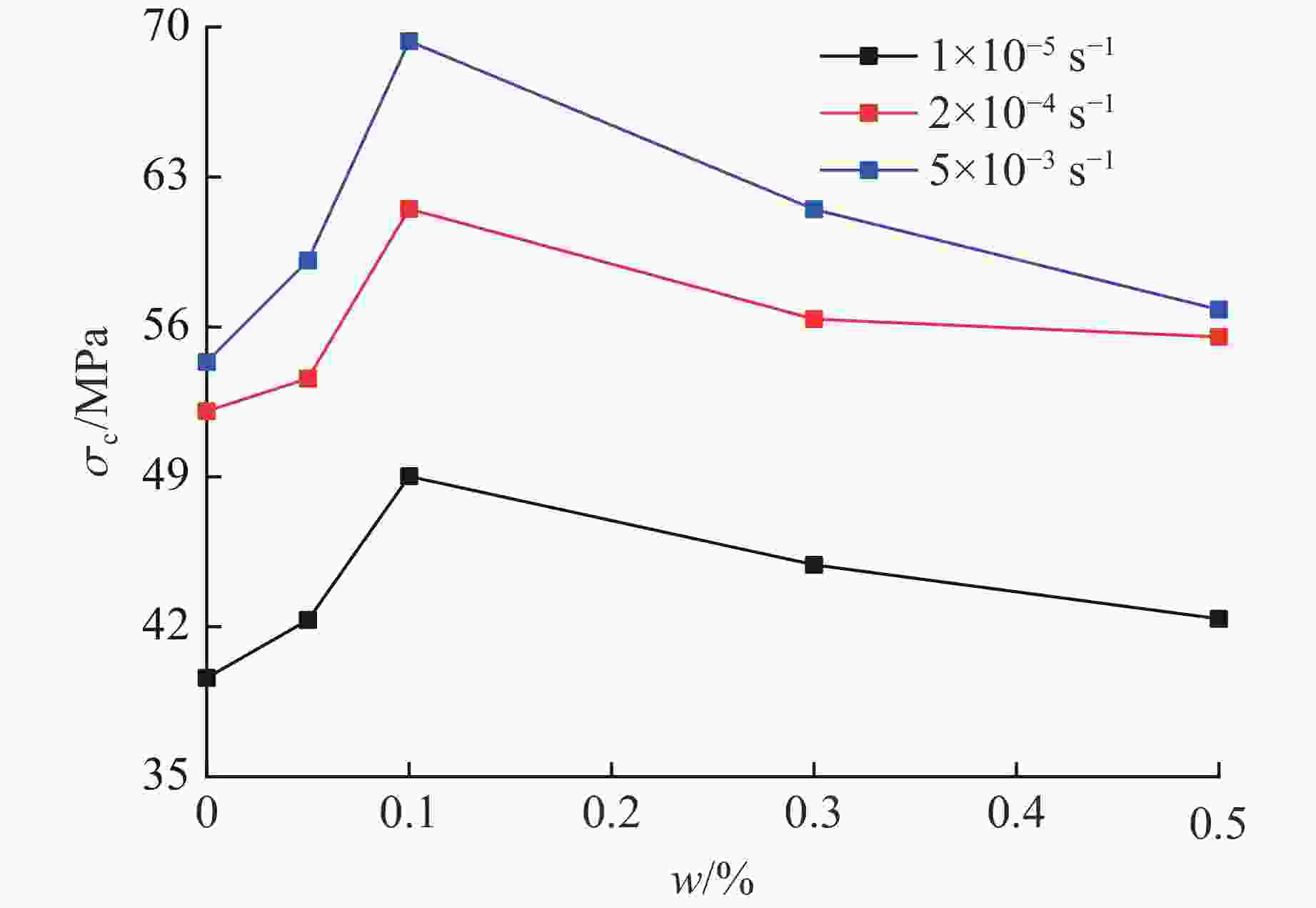

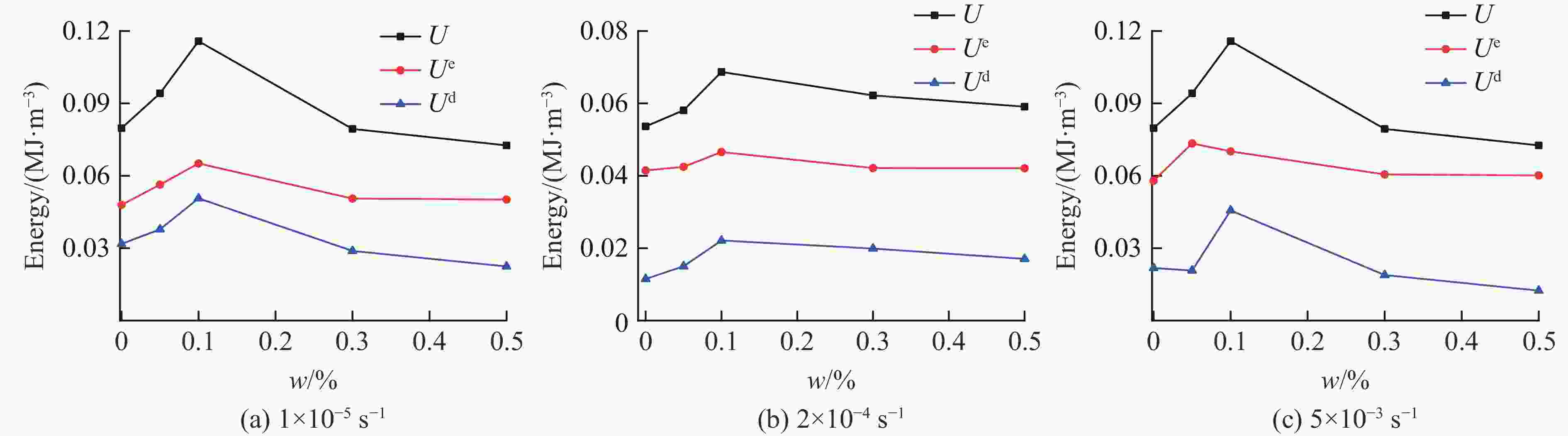

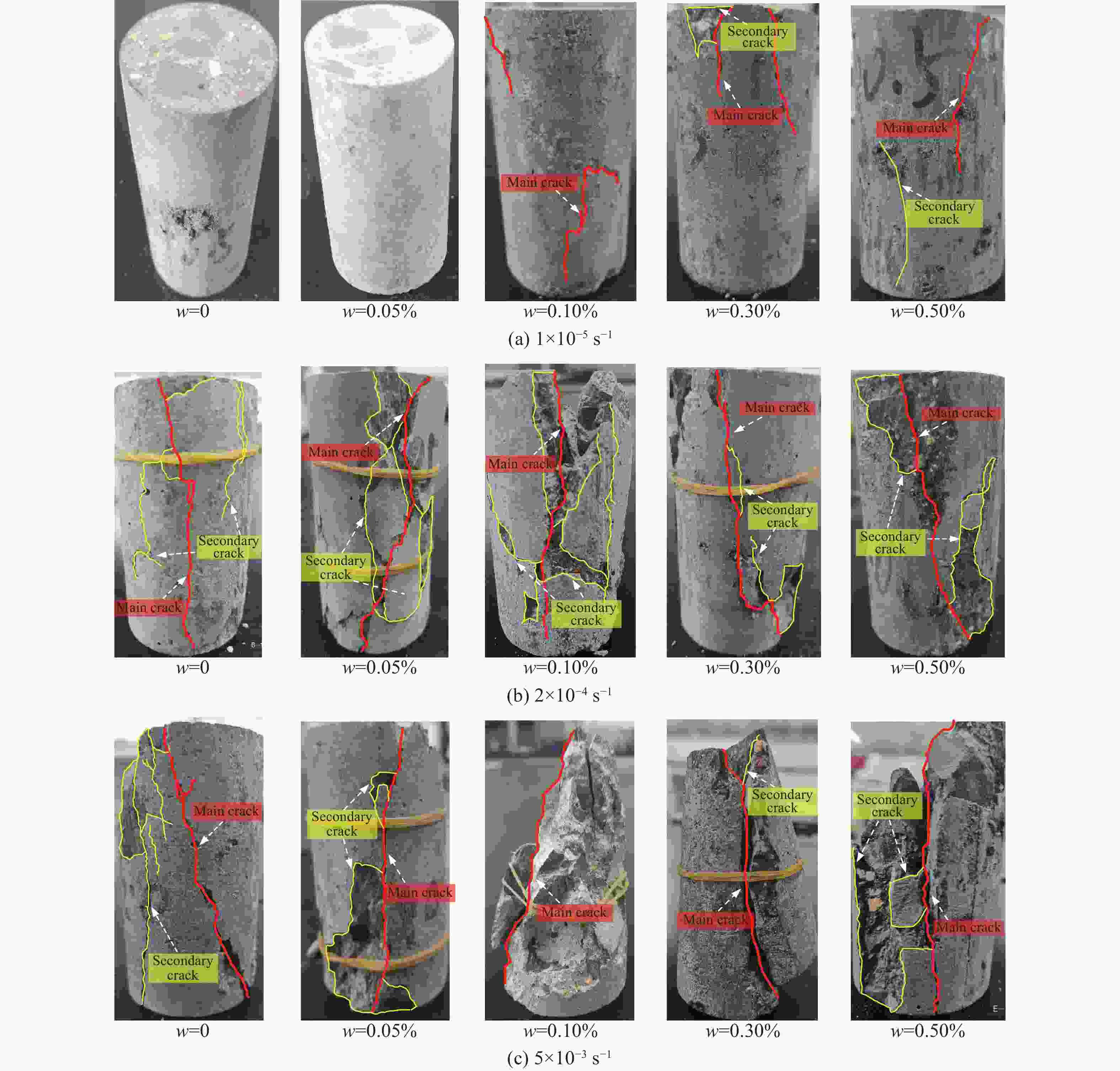

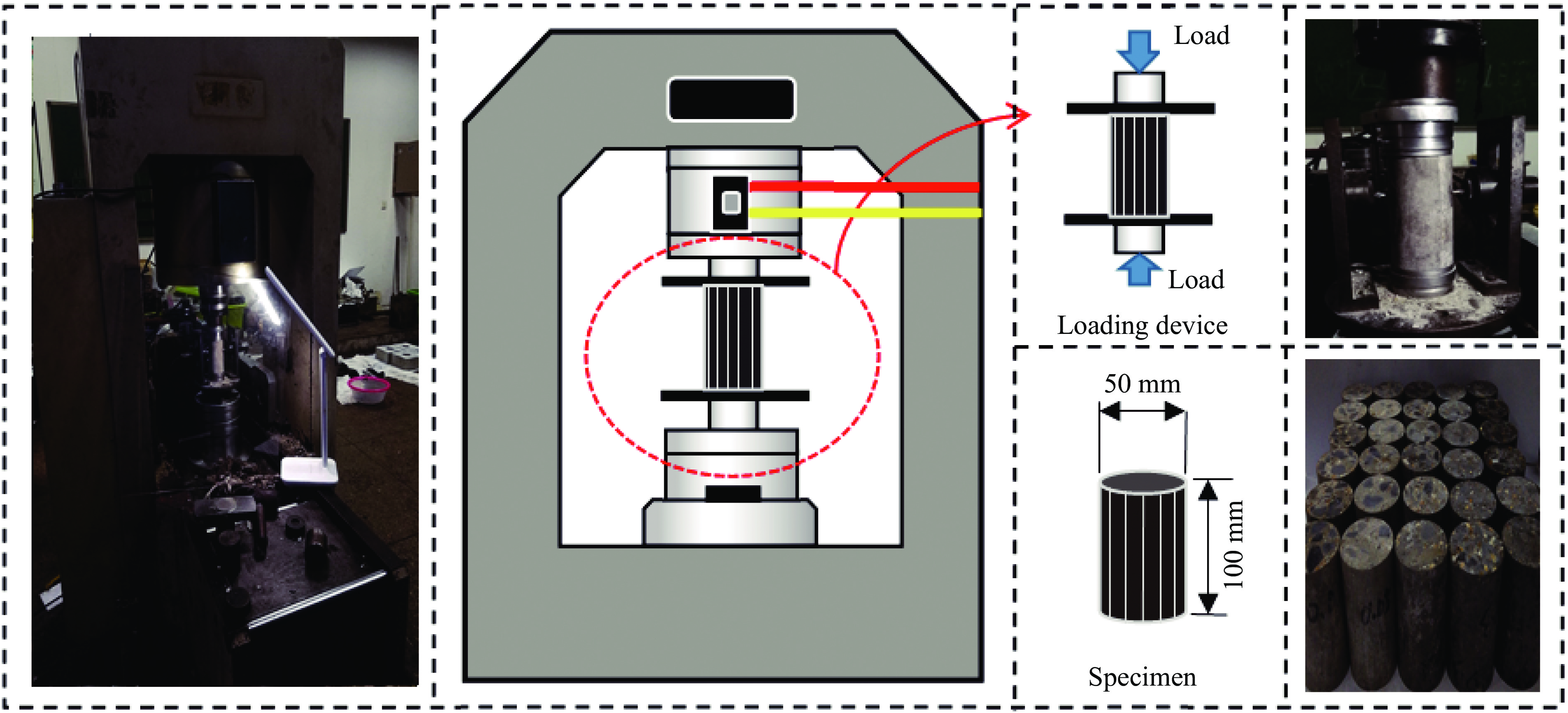

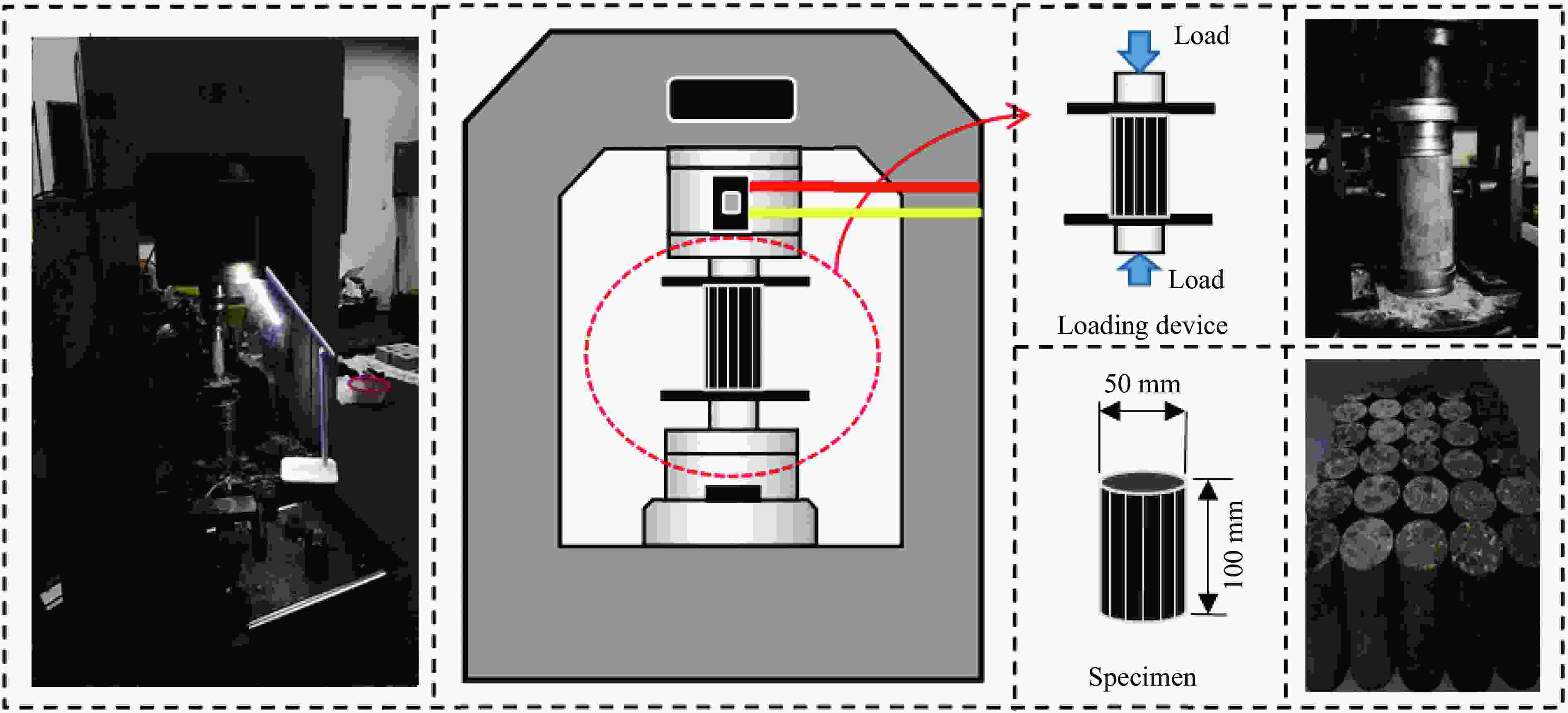

摘要: 为研究应变率(加载速率)和多壁碳纳米管掺量对碳纳米管混凝土试样力学性质、能量演化规律及损伤破坏特征的影响,采用RMT-150B岩石力学试验系统,对不同应变率下不同碳纳米管掺量的混凝土试样开展了系列单轴压缩试验。试验结果表明:碳纳米管混凝土试样的延性随着多壁碳纳米管掺量的增加而增大;当应变率恒定时,多壁碳纳米管掺量为0.1%的改性碳纳米管混凝土的单轴抗压强度最大;当多壁碳纳米管掺量恒定时,应变率为5×10−3 s−1(0.5 mm/s)时碳纳米管混凝土试样的单轴抗压强度最大;当应变率较大时,在试样峰值应力处,碳纳米管混凝土的能量耗散值占总能量的28.29%;当应变率较小时,试样峰前阶段的能量耗散现象显著,峰值应力处耗散能占比平均高达37.34%;当应变率和多壁碳纳米管掺量均较小时,碳纳米管混凝土在破坏前所吸收的能量大量转化为耗散能,峰后试样能量释放率较小,表现为局部张拉与剪切混合破坏特征;当应变率和多壁碳纳米管掺量均较大时,碳纳米管混凝土在破坏前所吸收的能量主要储存为可释放弹性应变能,在破坏时混凝土试样的能量释放速率较高,碳纳米管混凝土试样破坏时较为破碎,一定程度上表现出冲击破坏的特征。Abstract: In order to study the effect of strain rate (loading rate) and multi-walled carbon nanotubes (MWCNTs) content on the mechanical properties, energy evolution law and damage failure characteristics of MWCNTs-reinforced concrete samples, the RMT-150B rock mechanics test system was used to carry out a series of uniaxial compression tests on MWCNTs-reinforced concrete samples with different content of MWCNTs under different strain rates. The results show that the ductility of MWCNTs-reinforced concrete samples increases with the increase of the content of MWCNTs. When the strain rate is constant, the uniaxial compressive strength of the MWCNTs-reinforced concrete with 0.10% MWCNTs content is the highest; when the content of MWCNTs is constant, the uniaxial compressive strength of the MWCNTs-reinforced concrete samples reaches the maximum under strain rate of 5×10–3 s–1 (0.5 mm/s); when the strain rate is large, the mean value of the energy dissipation of MWCNTs-reinforced concrete accounts for 28.29% of the total energy at the peak stress. When the strain rate is small, the energy dissipation phenomenon in the pre-peak stage is significant, and the mean proportion of dissipated energy at the peak stress is as high as 37.34%. When the strain rate and MWCNTs content are small, the energy absorbed by the MWCNTs-reinforced concrete before failure is largely transformed into dissipative energy, and the energy release rate of the samples after peak stress is small, which is characterized by mixed failure of local tension and shear. When the strain rate and MWCNTs content are large, the energy absorbed by the MWCNTs-reinforced concrete before failure is mainly stored as releasable elastic strain energy, and the energy release rate of the concrete samples is faster at failure, and the MWCNTs-reinforced concrete samples are relatively broken at failure, showing the characteristics of impacted damage to a certain extent.

-

Key words:

- concrete /

- carbon nanotubes /

- strain rate /

- mechanical properties /

- energy evolution /

- failure mode

-

表 1 碳纳米管混凝土试样配合比及各原料质量

Table 1. Mixing ratio of MWCNTs-reinforced concrete specimen and mass of each raw material

No. w/% Water-cement ratio Mass/g Water Cement River sand Coarse aggregate MWCNTs A 0 0.4 33.95 84.78 109.51 243.74 0 B 0.05 0.4 33.95 84.78 109.51 243.74 0.0424 C 0.10 0.4 33.95 84.78 109.51 243.74 0.0848 D 0.30 0.4 33.95 84.78 109.51 243.74 0.2543 E 0.50 0.4 33.95 84.78 109.51 243.74 0.4239 -

[1] 陈宝春, 季韬, 黄卿维, 等. 超高性能混凝土研究综述 [J]. 建筑科学与工程学报, 2014, 31(3): 1–24. doi: 10.3969/j.issn.1673-2049.2014.03.002CHEN B C, JI T, HUANG Q W, et al. Review of research on ultra-high performance concrete [J]. Journal of Architecture and Civil Engineering, 2014, 31(3): 1–24. doi: 10.3969/j.issn.1673-2049.2014.03.002 [2] 金伟良, 赵羽习. 混凝土结构耐久性研究的回顾与展望 [J]. 浙江大学学报(工学版), 2002, 36(4): 371–380, 403. doi: 10.3785/j.issn.1008-973X.2002.04.006JIN W L, ZHAO Y X. State-of-the-art on durability of concrete structures [J]. Journal of Zhejiang University (Engineering Science), 2002, 36(4): 371–380, 403. doi: 10.3785/j.issn.1008-973X.2002.04.006 [3] 王彩辉, 蒋金洋, 任春福, 等. 基于无机纳米混凝土的研究进展 [J]. 材料导报, 2011, 25(Suppl 1): 41–44, 67.WANG C H, JIANG J Y, REN C F, et al. The study progress of inorganic nano-concrete [J]. Materials Reports, 2011, 25(Suppl 1): 41–44, 67. [4] 范杰, 熊光晶, 李庚英. 碳纳米管水泥基复合材料的研究进展及其发展趋势 [J]. 材料导报, 2014, 28(11): 142–148.FAN J, XIONG G J, LI G Y. Progress in research and development of carbon nanotubes-reinforced cement-based composite materials [J]. Materials Reports, 2014, 28(11): 142–148. [5] 王建雷, 赵云里, 和晓博, 等. 碳纳米管对混凝土性能的影响研究 [J]. 硅酸盐通报, 2016, 35(7): 2193–2197. doi: 10.16552/j.cnki.issn1001-1625.2016.07.036WANG J L, ZHAO Y L, HE X B, et al. Influence of carbon nanotubes on the properties of concrete [J]. Bulletin of the Chinese Ceramic Society, 2016, 35(7): 2193–2197. doi: 10.16552/j.cnki.issn1001-1625.2016.07.036 [6] IIJIMA S. Helical microtubules of graphitic carbon [J]. Nature, 1991, 354(6348): 56–58. doi: 10.1038/354056a0 [7] 王宝民, 韩瑜, 葛树奎, 等. 碳纳米管在水性体系中的分散性能及机理 [J]. 哈尔滨工程大学学报, 2014, 35(10): 1206–1211. doi: 10.3969/j.issn.1006-7043.201303081WANG B M, HAN Y, GE S K, et al. Research on the dispersibility and mechanism of carbon nanotubes in aqueous solution [J]. Journal of Harbin Engineering University, 2014, 35(10): 1206–1211. doi: 10.3969/j.issn.1006-7043.201303081 [8] 刘巧玲, 李汉彩, 彭玉娇, 等. 多壁碳纳米管增强水泥基复合材料的纳米力学性能 [J]. 复合材料学报, 2020, 37(4): 952–961. doi: 10.13801/j.cnki.fhclxb.20190730.004LIU Q L, LI H C, PENG Y J, et al. Nanomechanical properties of multi-wall carbon nanotubes/cementitious composites [J]. Acta Materiae Compositae Sinica, 2020, 37(4): 952–961. doi: 10.13801/j.cnki.fhclxb.20190730.004 [9] SINDU B S, SASMAL S. Properties of carbon nanotube reinforced cement composite synthesized using different types of surfactants [J]. Construction and Building Materials, 2017, 155: 389–399. [10] 施韬, 朱敏, 李泽鑫, 等. 碳纳米管改性水泥基复合材料的研究进展 [J]. 复合材料学报, 2018, 35(5): 1033–1049. doi: 10.13801/j.cnki.fhclxb.20180328.003SHI T, ZHU M, LI Z X, et al. Review of research progress on carbon nanotubes modified cementitious composites [J]. Acta Materiae Compositae Sinica, 2018, 35(5): 1033–1049. doi: 10.13801/j.cnki.fhclxb.20180328.003 [11] JUNG M, LEE Y S, HONG S G, et al. Carbon nanotubes (CNTs) in ultra-high performance concrete (UHPC): dispersion, mechanical properties, and electromagnetic interference (EMI) shielding effectiveness (SE) [J]. Cement and Concrete Research, 2020, 131: 106017. doi: 10.1016/j.cemconres.2020.106017 [12] 刘洋洋, 孙敏, 冯芳, 等. 改性碳纳米管的掺入对混凝土力学性能的影响 [J]. 混凝土与水泥制品, 2018(2): 26–30. doi: 10.3969/j.issn.1000-4637.2018.02.006LIU Y Y, SUN M, FENG F, et al. Influence of modified carbon nanotubes on mechanical properties of concrete [J]. China Concrete and Cement Products, 2018(2): 26–30. doi: 10.3969/j.issn.1000-4637.2018.02.006 [13] 牛晓伟, 王永维, 李强, 等. 多壁碳纳米管/水性环氧树脂复合改性多孔水泥混凝土性能研究 [J]. 公路, 2017, 62(1): 174–179.NIU X W, WANG Y W, LI Q, et al. Research on multi-walled carbon nanotubes/epoxy resin composite modification of porous cement concrete performance [J]. Highway, 2017, 62(1): 174–179. [14] 刘鹏飞, 范俊奇, 郭佳奇, 等. 三轴应力下花岗岩加载破坏的能量演化和损伤特征 [J]. 高压物理学报, 2021, 35(2): 024102. doi: 10.11858/gywlxb.20200622LIU P F, FAN J Q, GUO J Q, et al. Damage and energy evolution characteristics of granite under triaxial stress [J]. Chinese Journal of High Pressure Physics, 2021, 35(2): 024102. doi: 10.11858/gywlxb.20200622 [15] ZHANG Z Z, GAO F. Experimental investigation on the energy evolution of dry and water-saturated red sandstones [J]. International Journal of Mining Science and Technology, 2015, 25(3): 383–388. doi: 10.1016/j.ijmst.2015.03.009 [16] 李忠友, 刘元雪, 姚志华, 等. 基于能量耗散原理的混凝土力学损伤模型 [J]. 土木工程学报, 2019, 52(Suppl 1): 23–30. doi: 10.15951/j.tmgcxb.2019.s1.004LI Z Y, LI Y X, YAO Z H, et al. Mechanical damage model for concrete based on energy dissipation [J]. China Civil Engineering Journal, 2019, 52(Suppl 1): 23–30. doi: 10.15951/j.tmgcxb.2019.s1.004 [17] 王美英, 郭腾翔. 单轴压缩下混凝土的能量储存和耗散规律研究 [J]. 中国测试, 2022, 48(6): 143–147.WANG M Y, GUO T X. A study of the energy storage and dissipation laws of concrete under uniaxial compression [J]. China Measurement & Test, 2022, 48(6): 143–147. [18] 韩辰悦, 庞建勇. 不同应变率下橡胶混凝土抗压性能及能量特性研究 [J]. 硅酸盐通报, 2022, 41(3): 922–930. doi: 10.16552/j.cnki.issn1001-1625.20220113.001HAN C Y, PANG J Y. Compressive properties and energy characteristics of rubber concrete under different strain rates [J]. Bulletin of the Chinese Ceramic Society, 2022, 41(3): 922–930. doi: 10.16552/j.cnki.issn1001-1625.20220113.001 [19] 袁璞, 朱益胜. 不同龄期碱矿渣陶粒混凝土抗压强度试验与能量特征分析 [J]. 硅酸盐通报, 2022, 41(7): 2292–2298. doi: 10.16552/j.cnki.issn1001-1625.20220510.001YUAN P, ZHU Y S. Compressive strength test and energy characteristics analysis of alkali slag ceramsite concrete at different ages [J]. Bulletin of the Chinese Ceramic Society, 2022, 41(7): 2292–2298. doi: 10.16552/j.cnki.issn1001-1625.20220510.001 [20] 谢和平, 鞠杨, 黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则 [J]. 岩石力学与工程学报, 2005, 24(17): 3003–3010. doi: 10.3321/j.issn:1000-6915.2005.17.001XIE H P, JU Y, LI L Y. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles [J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(17): 3003–3010. doi: 10.3321/j.issn:1000-6915.2005.17.001 [21] SOLECKI R, CONANT R J. Advanced mechanics of materials [M]. London: Oxford University Press, 2003. -

下载:

下载: