| [1] |

PALOMBA G, EPASTO G, CRUPI V. Lightweight sandwich structures for marine applications: a review [J]. Mechanics of Advanced Materials and Structures, 2021: 1–26.

|

| [2] |

汪璇, 裴轶群, 周方宇, 等. 船舶复合材料应用现状及发展趋势 [J]. 造船技术, 2021, 49(4): 74–80. doi: 10.12225/j.issn.1000-3878.2021.04.20210414WANG X, PEI Y Q, ZHOU F Y, et al. Application status and development trend of ship composite materials [J]. Marine Technology, 2021, 49(4): 74–80. doi: 10.12225/j.issn.1000-3878.2021.04.20210414

|

| [3] |

HOSUR M V, MOHAMMED A A, ZAINUDDIN S, et al. Impact performance of nanophased foam core sandwich composites [J]. Materials Science and Engineering: A, 2008, 498(1/2): 100–109. doi: 10.1016/j.msea.2007.11.156

|

| [4] |

ZHU Y F, SUN Y G. Dynamic response of foam core sandwich panel with composite facesheets during low-velocity impact and penetration [J]. International Journal of Impact Engineering, 2020, 139: 103508. doi: 10.1016/j.ijimpeng.2020.103508

|

| [5] |

LONG S C, YAO X, WANG H, et al. Failure analysis and modeling of foam sandwich laminates under impact loading [J]. Composite Structures, 2018, 197: 10–20. doi: 10.1016/j.compstruct.2018.05.041

|

| [6] |

ELAMIN M, LI B, TAN K T. Impact damage of composite sandwich structures in arctic condition [J]. Composite Structures, 2018, 192: 422–433. doi: 10.1016/j.compstruct.2018.03.015

|

| [7] |

LIU D, BAI R X, LEI Z K, et al. Experimental and numerical study on compression-after-impact behavior of composite panels with foam-filled hat-stiffener [J]. Ocean Engineering, 2020, 198: 106991. doi: 10.1016/j.oceaneng.2020.106991

|

| [8] |

刘姗姗, 刘亚军, 张英杰, 等. 碳纤维-泡沫铝夹芯板低速冲击响应 [J]. 高压物理学报, 2020, 34(3): 034202. doi: 10.11858/gywlxb.20190872LIU S S, LIU Y J, ZHANG Y J, et al. Low-velocity impact response of carbon fiber-aluminum foam sandwich plate [J]. Chinese Journal of High Pressure Physics, 2020, 34(3): 034202. doi: 10.11858/gywlxb.20190872

|

| [9] |

刘莹, 王沁宇, 杨博, 等. 湿热老化对亚麻纤维增强泡沫夹芯板冲击力学性能的影响 [J]. 高压物理学报, 2022, 36(4): 044102.LIU Y, WANG Q Y, YANG B, et al. Effect of hygrothermal aging on impact performance of flax fiber-reinforced foam sandwich panels [J]. Chinese Journal of High Pressure Physics, 2022, 36(4): 044102.

|

| [10] |

司海龙, 赵南, 胡嘉骏. 船艏自由落体砰击载荷模型试验研究 [J]. 船舶力学, 2020, 24(4): 445–455. doi: 10.3969/j.issn.1007-7294.2020.04.004SI H L, ZHAO N, HU J J. Experimental study of slamming loads on ship bow during free water entry [J]. Journal of Ship Mechanics, 2020, 24(4): 445–455. doi: 10.3969/j.issn.1007-7294.2020.04.004

|

| [11] |

SHAMS A, ZHAO S, PORIFIRI M. Hydroelastic slamming of flexible wedges: modeling and experiments from water entry to exit [J]. Physics of Fluids, 2017, 29(3): 037107. doi: 10.1063/1.4978631

|

| [12] |

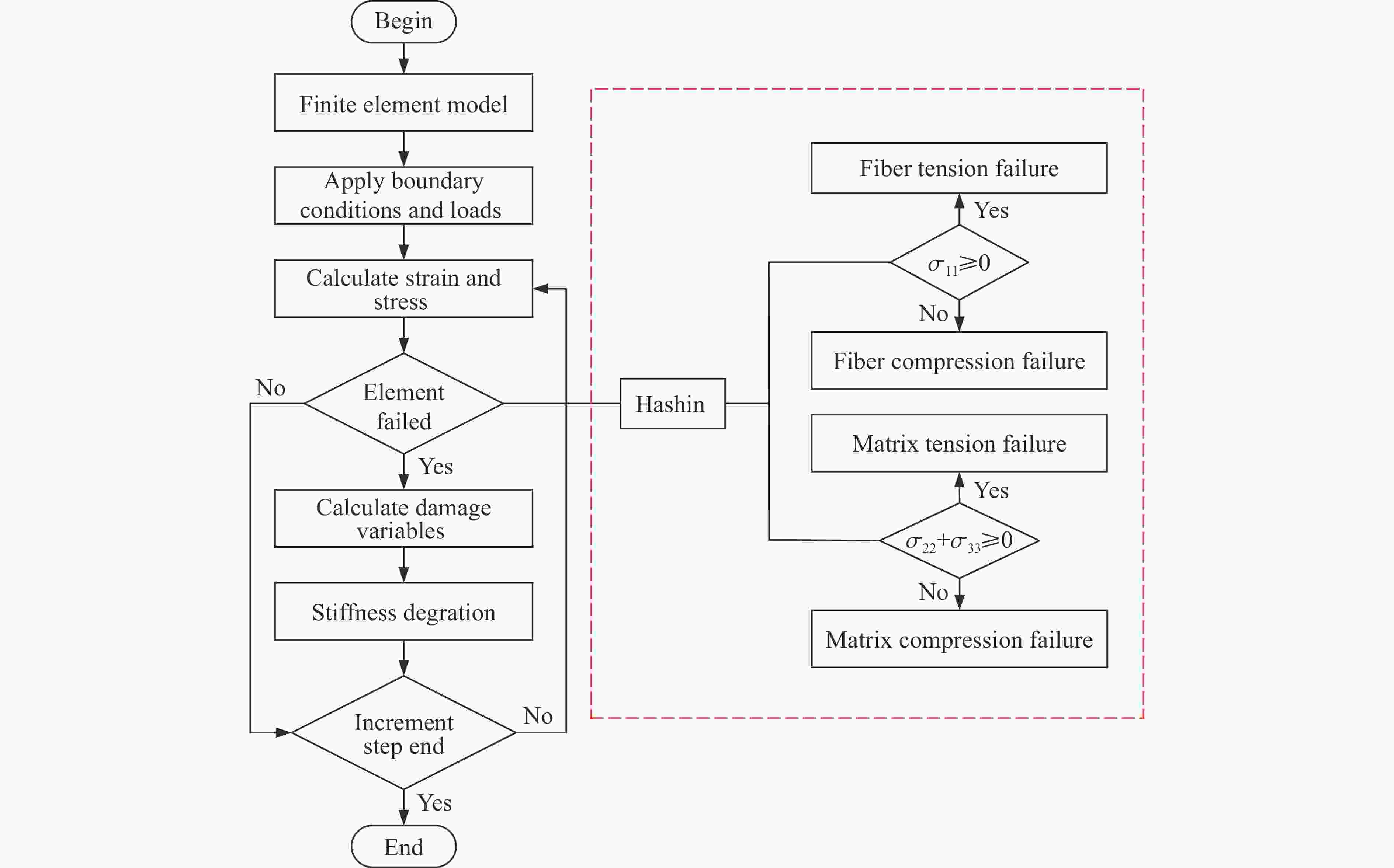

CHANG F K, CHANG K Y. A progressive damage model for laminated composites containing stress concentrations [J]. Journal of Composite Materials, 1987, 21(9): 834–855. doi: 10.1177/002199838702100904

|

| [13] |

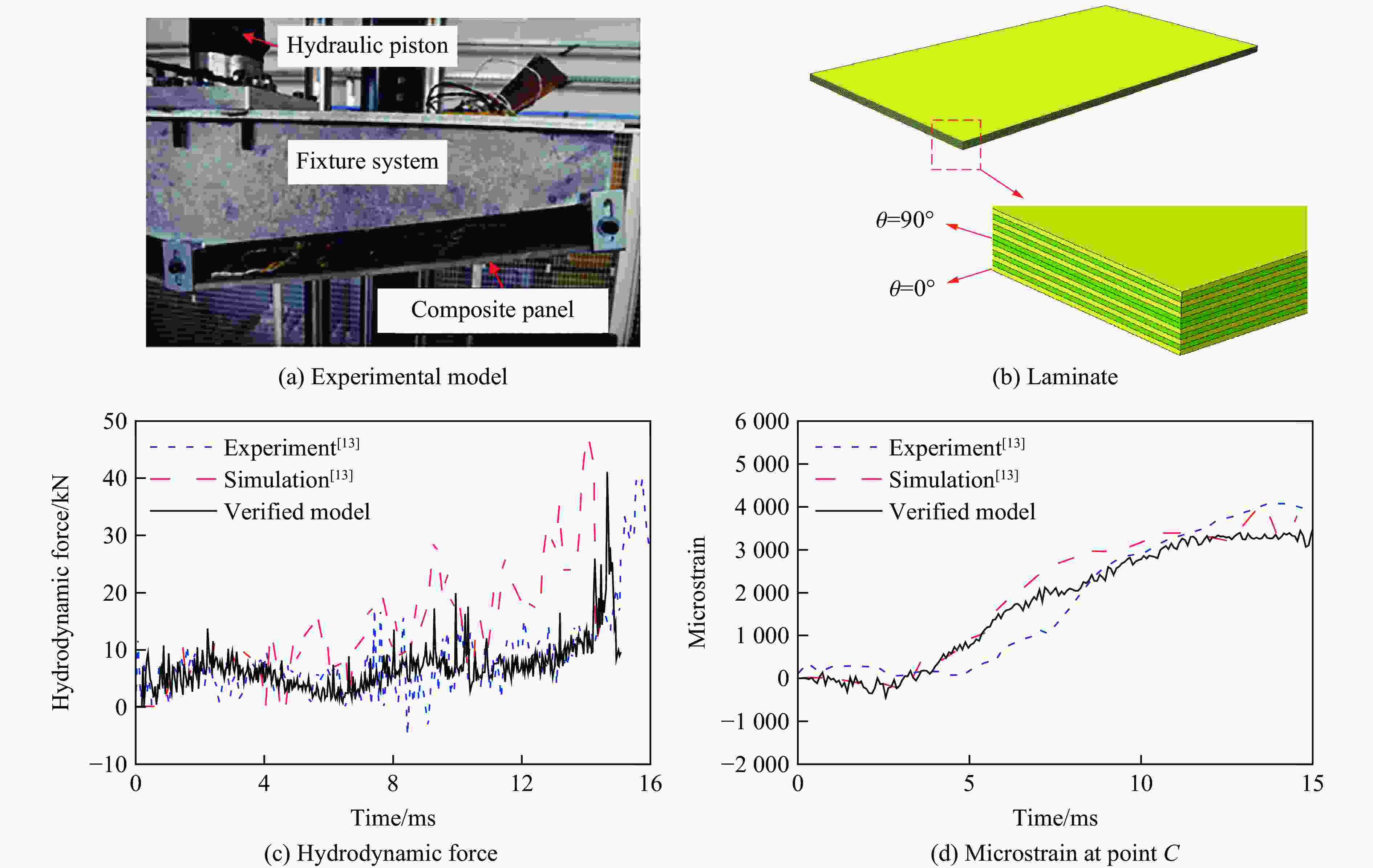

HASSOON O H, TARFAOUI M, El MOUMEN A, et al. Numerical evaluation of dynamic response for flexible composite structures under slamming impact for naval applications [J]. Applied Composite Materials, 2018, 25(3): 689–706. doi: 10.1007/s10443-017-9646-0

|

下载:

下载: