Blast Resistant Performance of Steel/POZD Composite Structures under Close-Range Air Blast Loading

-

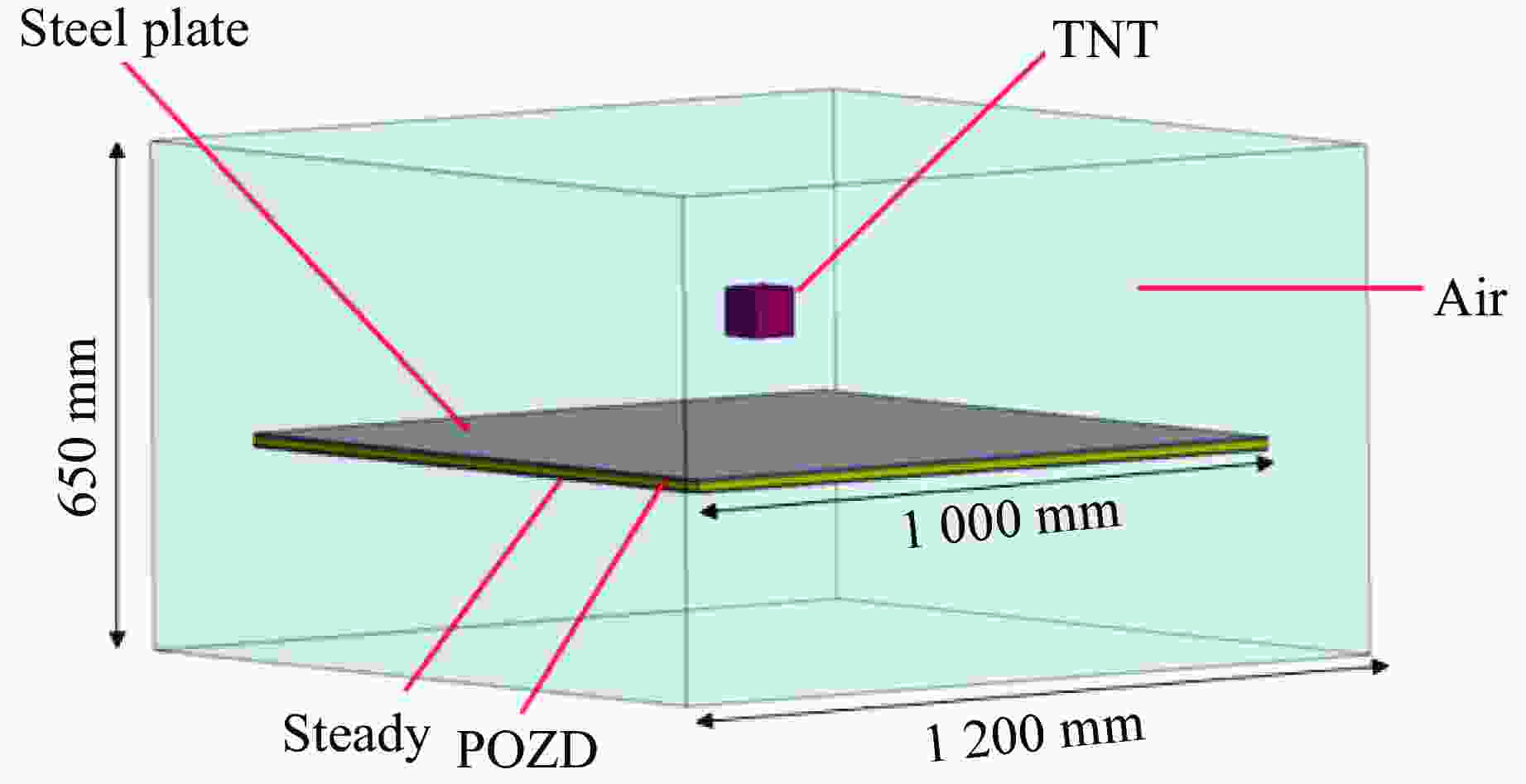

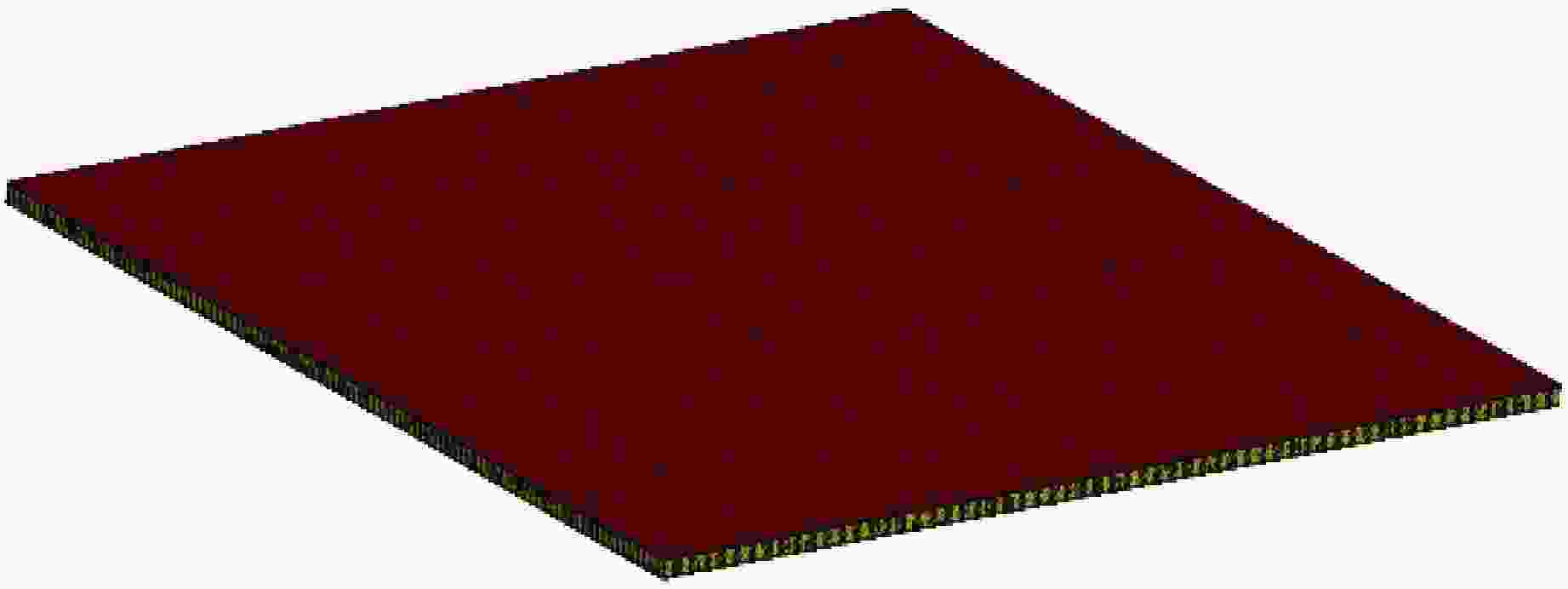

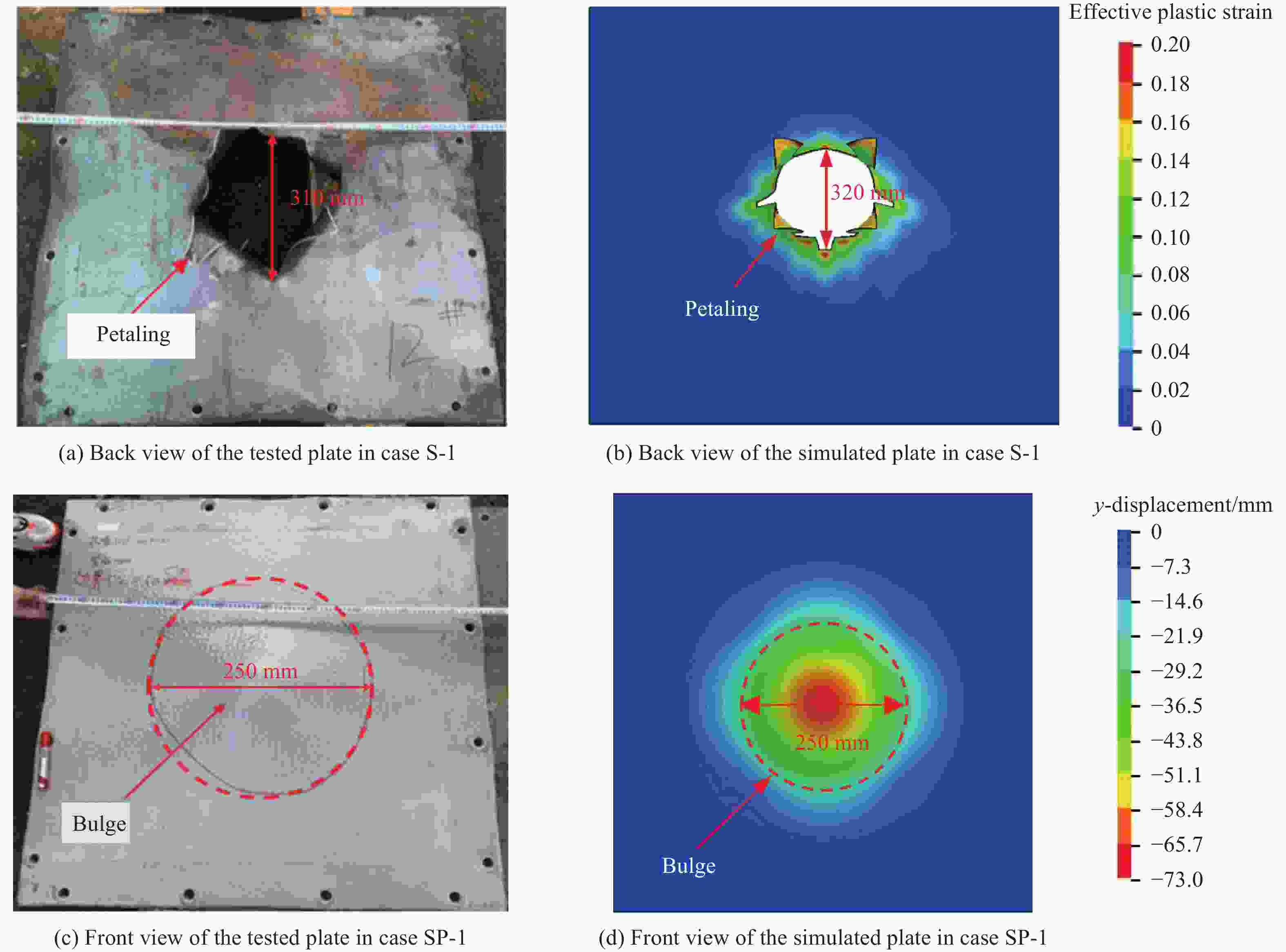

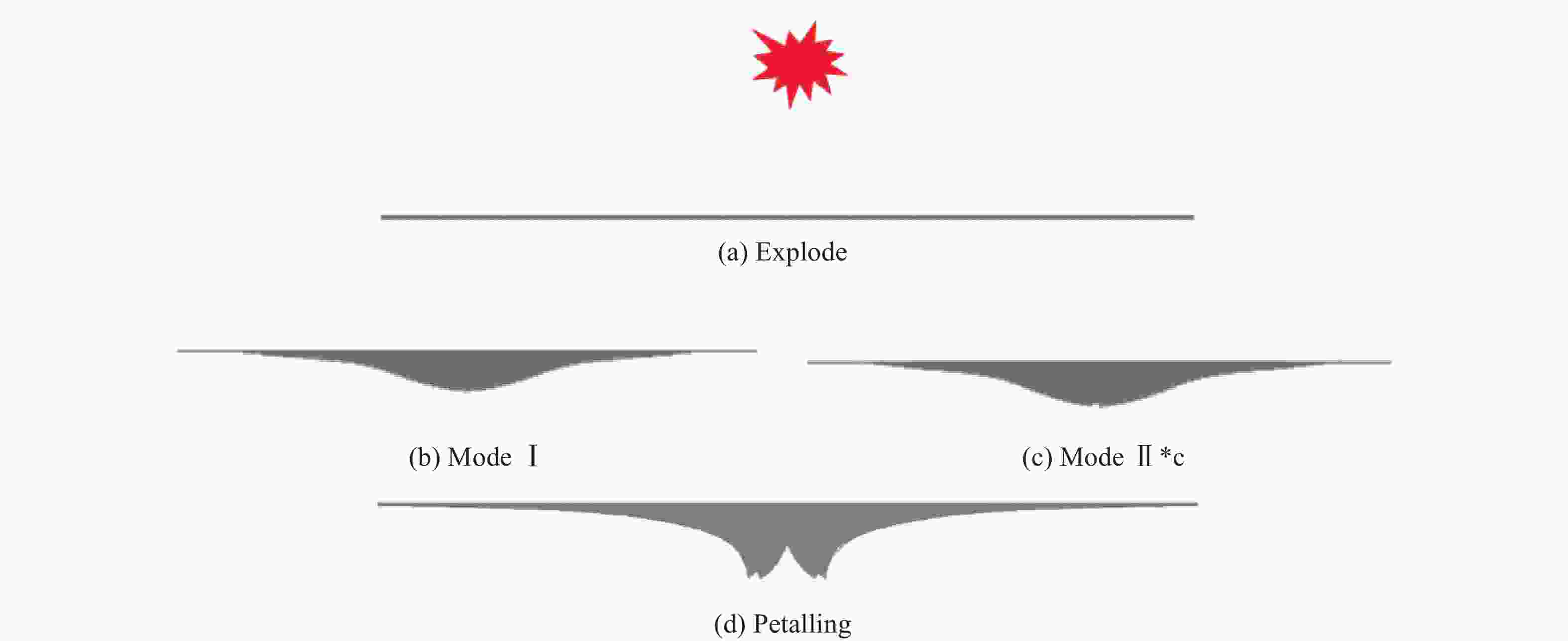

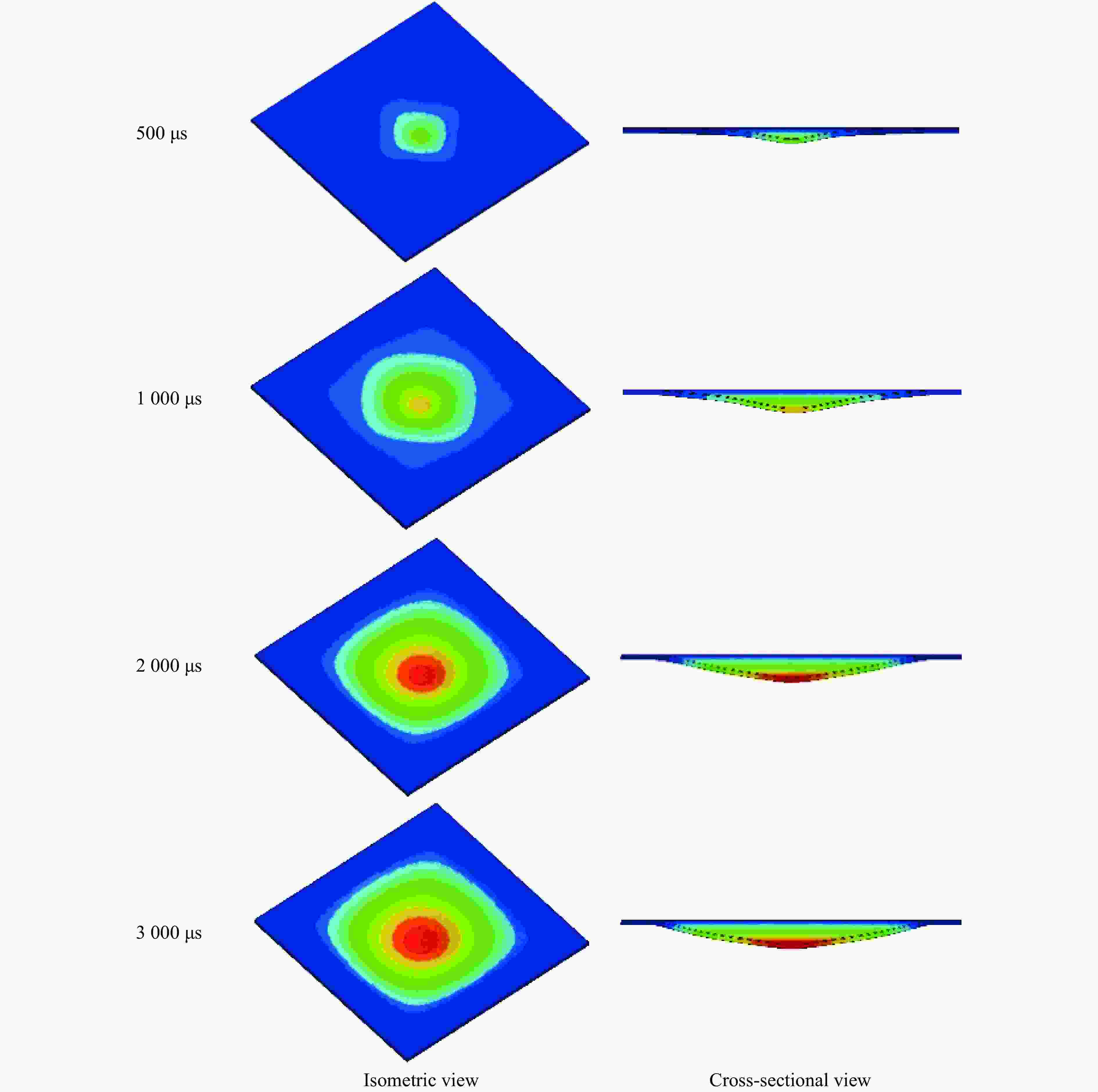

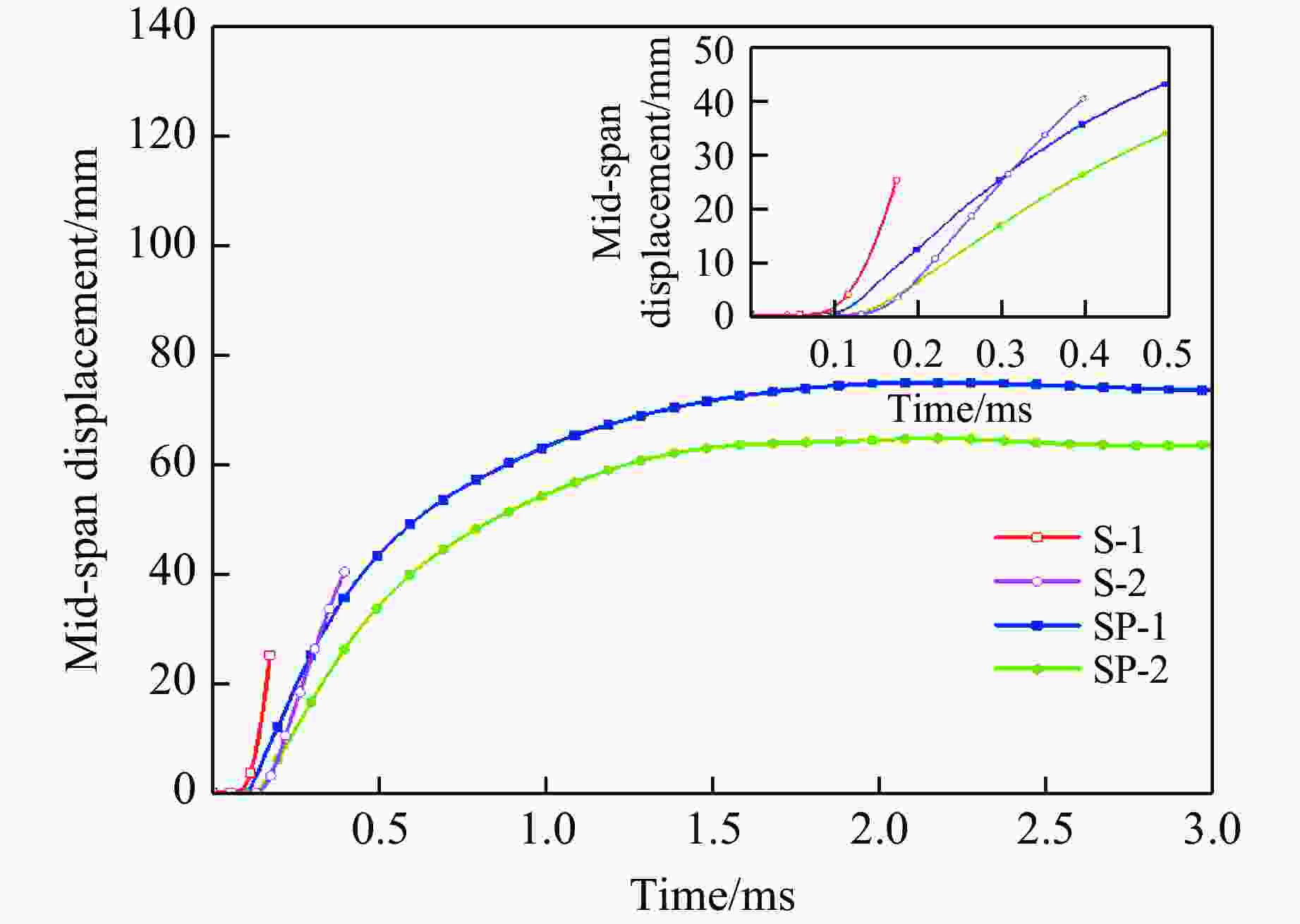

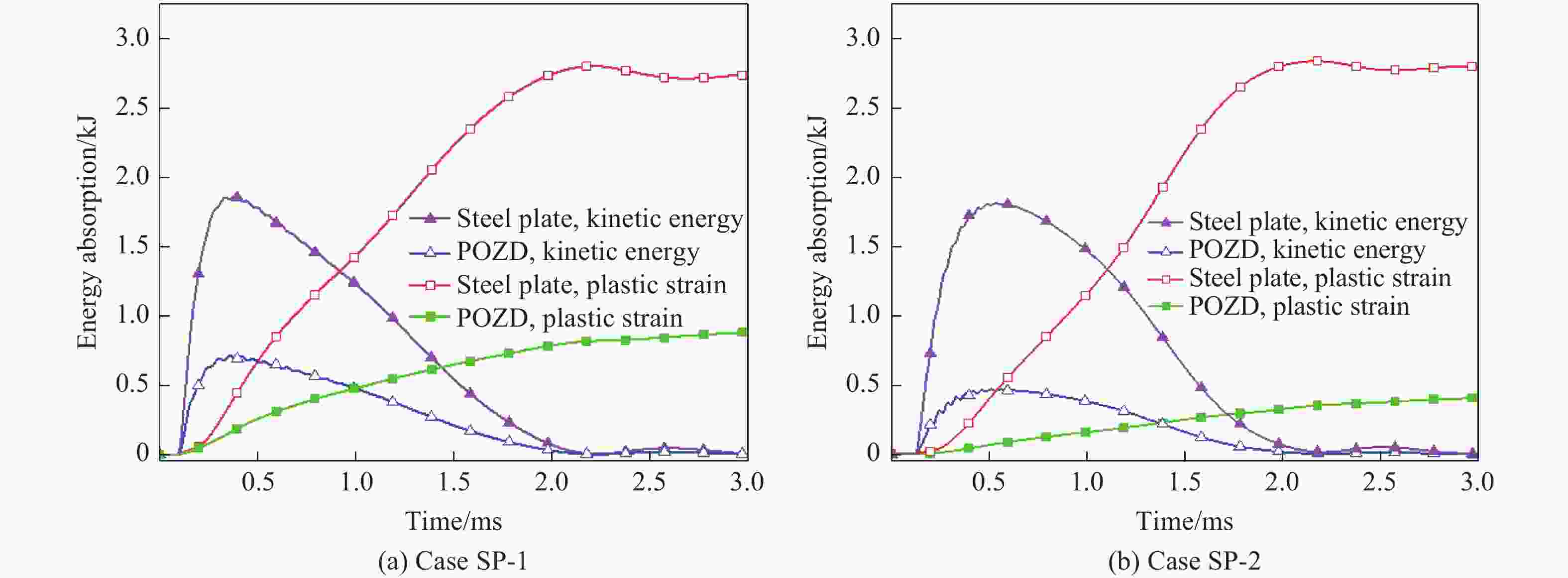

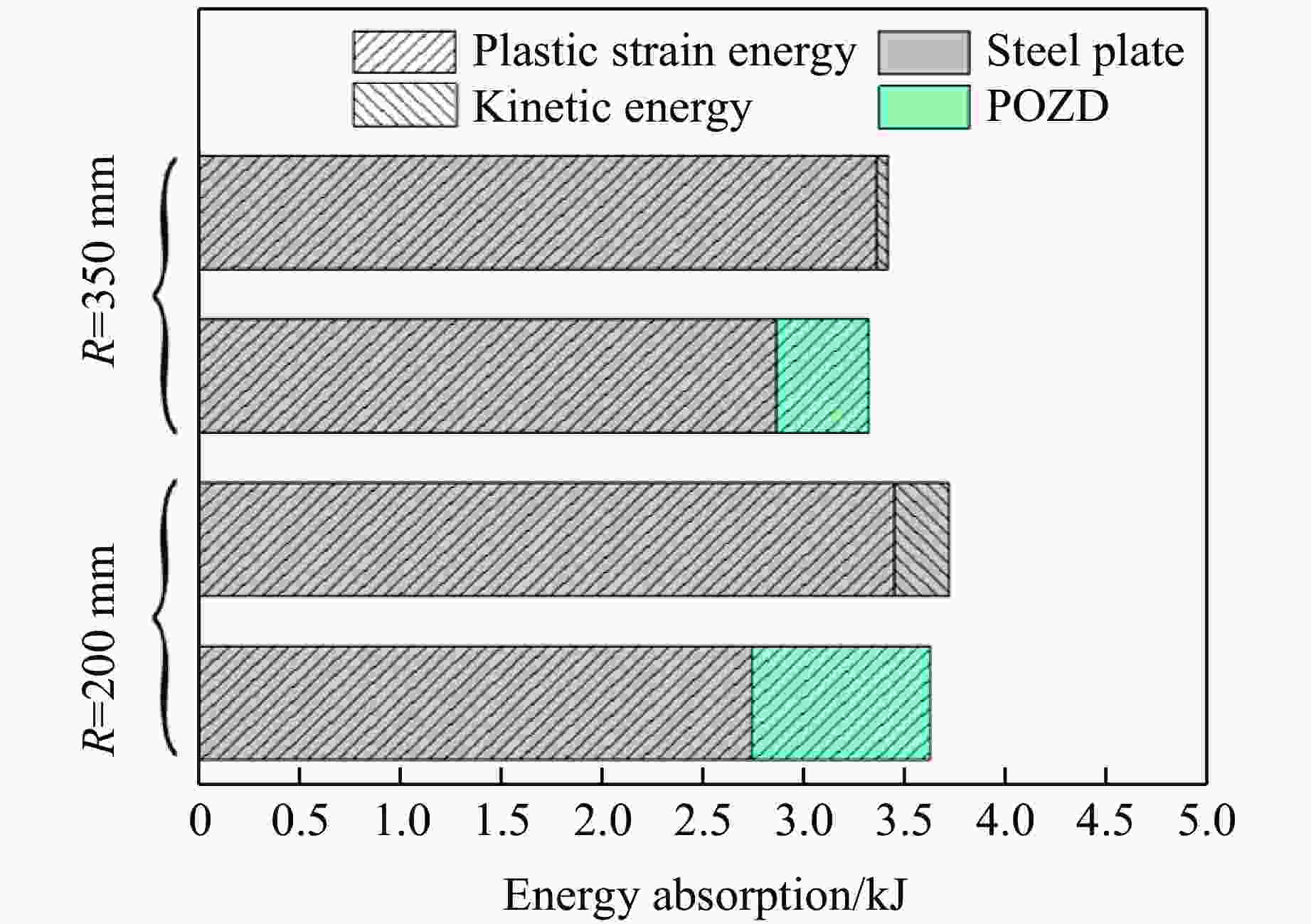

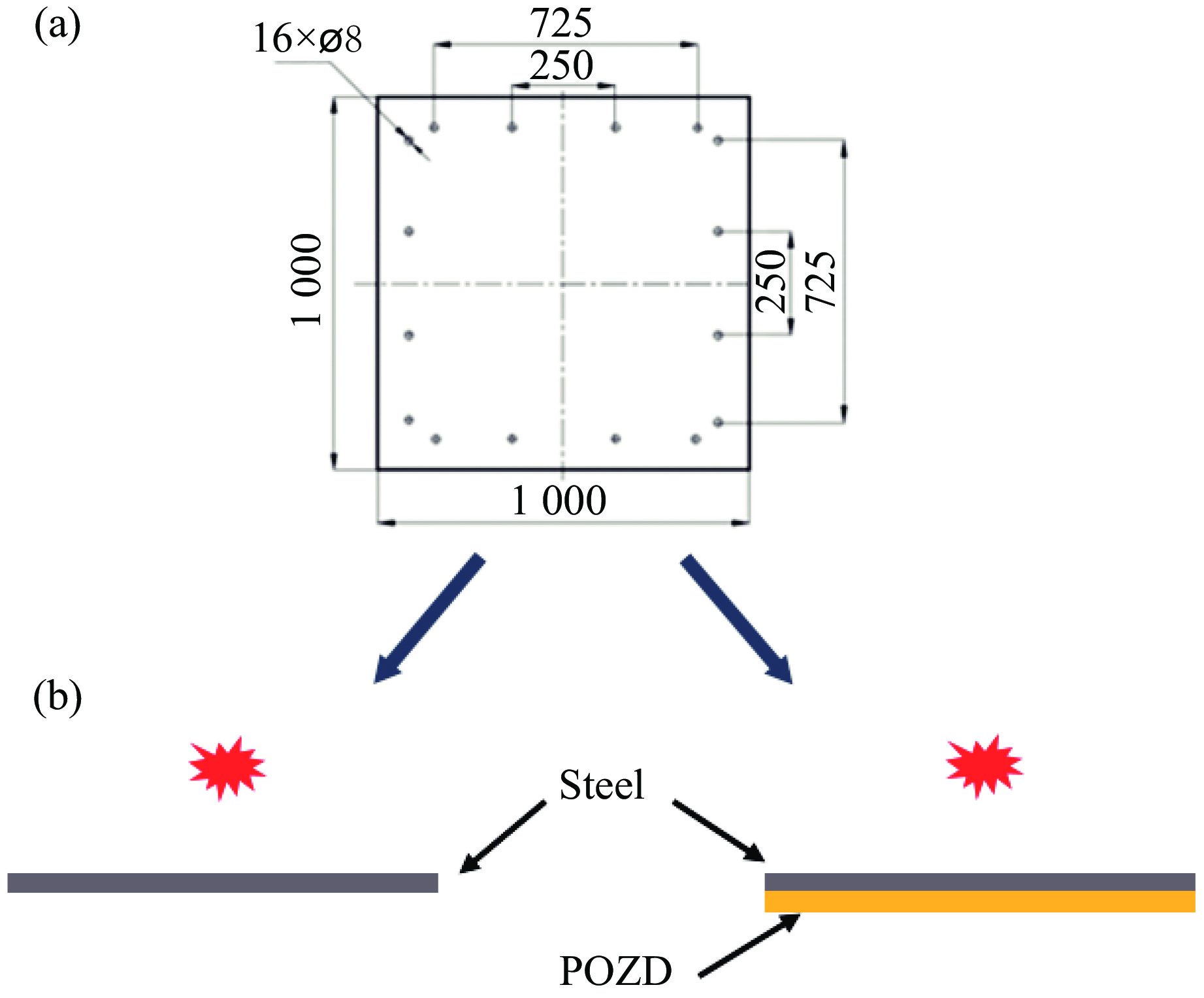

摘要: 为研究钢板/聚异氰氨酸酯噁唑烷(polyisocyanate oxazodone,POZD)聚合物高分子材料复合结构在近距空爆载荷下的抗爆性能,开展了近距空爆试验,通过观察试验模型的损伤以及相关数据统计,分析了钢板/POZD复合结构的变形失效模式。采用LS-DYNA软件进行数值模拟,通过与试验结果进行对比,验证了数值模拟方法的准确性,并进一步分析了钢板/POZD复合结构跨中位移变化和能量吸收特性。结果表明:在相同钢板厚度下,钢板/POZD复合结构较单一钢板具有更优越的抗爆性能,钢板呈现出3种不同的变形失效模式;在钢板/POZD复合结构中,当钢板和POZD均未出现破口时,钢板的塑性应变能占总能量吸收的大部分;钢板/POZD复合结构中心点最大位移逐渐增大,且变形速度先升高后降低。研究结果可为工程中钢板/POZD复合结构的抗爆防护设计提供参考。Abstract: To study the improvement mechanism of polyisocyanate oxazodone (POZD) on the blast resistance of steel plate, and analyze the dynamic response of steel/POZD composite structure, close-range air blast tests and finite element numerical simulations were conducted. Deformation failure modes of steel/POZD composite structures were studied and analyzed by observing the damage of tested structures and dealing with related date statistics. The accuracy of numerical simulation method was verified by comparing the results of numerical simulations with those of tests. The mid-span displacement change and energy absorption characteristics of steel/POZD composite structures were analyzed. Results show that steel/POZD composite structures have better blast resistant performance than single steel plates. Steel plates exhibit three different deformation failure modes. In the case of a steel/POZD composite structure with no crevasse, the plastic strain energy of steel layer gives a most contribution to the total energy absorption. The maximum central displacement of steel/POZD composite structure gradually increases, and meanwhile, its deformation velocity first increases and then decreases. The research results can provide references for the anti-explosion protection design of steel/POZD composite structures in engineering field.

-

表 1 POZD和普通聚脲材料的力学性能

Table 1. Mechanical properties of POZD and ordinary polyurea

Materials Density/

(g·cm−3)Tensile strength/

MPaElastic modulus/

GPaPoisson’s ratio Adhesion (steel plate)/

MPaPOZD 1.02 ≥25 230 0.3 ≥8 Ordinary polyurea 1.02 16 213 0.3 6 表 2 试验工况

Table 2. Test conditions

Case no. Plates Explosive POZD TNT mass/g R/mm Thickness/mm Coating position S-1 Steel plates 500 200 0 S-2 Steel plates 500 350 0 SP-1 Steel/POZD plates 500 200 12 Back SP-2 Steel/POZD plates 500 350 8 Back E/GPa ρ/(kg·m−3) ν σ0/MPa Et/MPa C/s−1 P Fs 210 7850 0.3 235 250 40.4 5 0.28 e/(MJ·kg−1) A/GPa B/GPa R1 R2 ω 6.74 371.2 3.231 4.15 0.95 0.3 表 5 4种工况的破口尺寸和跨中最大位移

Table 5. Break size and maximum displacement in the middle of the four test conditions

Case No. R/mm Thickness/mm Failure mode Break size/

(mm×mm)ymax/mm Steel POZD S-1 200 4 Petalling 330×290 S-2 350 4 Mode Ⅱ*c 90×10 SP-1 200 4 12 Mode Ⅰ 70 SP-2 350 4 8 Mode Ⅰ 65 -

[1] 卢广照, 姜春兰, 毛亮, 等. 薄钢板在CL-20基含铝炸药内爆载荷作用下的变形响应和工程预测 [J]. 兵工学报, 2020, 41(8): 1509–1518. doi: 10.3969/j.issn.1000-1093.2020.08.005LU G Z, JIANG C L, MAO L, et al. Deformation response and its engineering prediction of steel plate subjected to internal blast loading from CL-20-based aluminized explosive charges [J]. Acta Armamentarii, 2020, 41(8): 1509–1518. doi: 10.3969/j.issn.1000-1093.2020.08.005 [2] MOHOTTI D, NGO T, MENDIS P, et al. Polyurea coated composite aluminium plates subjected to high velocity projectile impact [J]. Materials & Design, 2013, 52: 1–16. [3] MOHOTTI D, FERNANDO P L N, WEERASINGHE D, et al. Evaluation of effectiveness of polymer coatings in reducing blast-induced deformation of steel plates [J]. Defence Technology, 2021, 17(6): 1895–1904. doi: 10.1016/j.dt.2020.11.009 [4] 冯加和, 董奇, 张刘成, 等. 聚脲弹性体在爆炸防护中的研究进展 [J]. 含能材料, 2020, 28(4): 277–290.FENG J H, DONG Q, ZHANG L C, et al. Review on using polyurea elastomer for enhanced blast-mitigation [J]. Chinese Journal of Energetic Materals, 2020, 28(4): 277–290. [5] 甘云丹, 宋力, 杨黎明. 弹性体涂覆钢板抗冲击性能的数值模拟 [J]. 兵工学报, 2009, 30(2): 15–19.GAN Y D, SONG L, YANG L M. Numerical simulation for anti-blast performances of steel plate coated with elastomer [J]. Acta Armamentarii, 2009, 30(2): 15–19. [6] LI Y, CHEN C, HOU H L, et al. The influence of spraying strategy on the dynamic response of polyurea-coated metal plates to localized air blast loading: experimental investigations [J]. Polymers (Basel), 2019, 11(11): 1888. doi: 10.3390/polym11111888 [7] 廖瑜, 石少卿, 梁朝科, 等. 聚脲-编织玻璃纤维网格布复合材料加固钢板抗冲击力学性能研究 [J]. 兵工学报, 2018, 39(10): 1988–1996. doi: 10.3969/j.issn.1000-1093.2018.10.015LIAO Y, SHI S Q, LIANG C K, et al. Dynamics performances of polyurea-woven fiberglass mesh composite [J]. Acta Armamentarii, 2018, 39(10): 1988–1996. doi: 10.3969/j.issn.1000-1093.2018.10.015 [8] 王喜梦, 刘均, 陈长海, 等. 近距空爆载荷下钢板/聚脲复合结构动响应特性仿真 [J]. 中国舰船研究, 2021, 16(2): 116–124. doi: 10.19693/j.issn.1673-3185.01833WANG X M, LIU J, CHEN C H, et al. Simulation on dynamic response characteristics of steel/polyurea composite structures under close-range air blast loading [J]. Chinese Journal of Ship Research, 2021, 16(2): 116–124. doi: 10.19693/j.issn.1673-3185.01833 [9] HOU H L, CHEN C H, CHENG Y, et al. Effect of structural configuration on air blast resistance of polyurea-coated composite steel plates: experimental studies [J]. Materials & Design, 2019, 182: 108049. [10] CHEN C H, WANG X, HOU H L, et al. Effect of strength matching on failure characteristics of polyurea coated thin metal plates under localized air blast loading: experiment and numerical analysis [J]. Thin-Walled Structures, 2020, 154: 106819. doi: 10.1016/j.tws.2020.106819 [11] 杨建超, 汪剑辉, 周旺进, 等. POZD涂层钢筋混凝土板抗震塌性能 [J]. 兵工学报, 2020, 42(1): 7–11.YANG J C, WANG J H, ZHOU W J, et al. Anti-collapsing performance of POZD coated reinforced concrete slab [J]. Acta Armamentarii, 2020, 42(1): 7–11. [12] 杨建超, 汪剑辉, 陈力, 等. 喷涂POZD弹性涂层防护门抗爆性能试验研究 [J]. 防护工程, 2021, 42(1): 133–140.YANG J C, WANG J H, CHEN L, et al. Experimental study on blast resistance performance of blast door with POZD elastic coating [J]. Protective Engineering, 2021, 42(1): 133–140. [13] 汪维, 杨建超, 汪剑辉, 等. POZD涂层方形钢筋混凝土板抗接触爆炸试验研究 [J]. 爆炸与冲击, 2020, 40(12): 14–23. doi: 10.11883/bzycj-2020-0180WANG W, YANG J C, WANG J H, et al. Experimental research on anti-contact explosion of POZD coated square reinforced concrete slab [J]. Explosion and Shock Waves, 2020, 40(12): 14–23. doi: 10.11883/bzycj-2020-0180 [14] WANG W, YANG J, WANG J, et al. Experimental investigation of polyisocyanate-oxazodone coated square reinforced concrete slab under contact explosions [J]. International Journal of Impact Engineering, 2021, 149: 103777. doi: 10.1016/j.ijimpeng.2020.103777 [15] 陈长海, 朱锡, 侯海量, 等. 近距空爆载荷作用下双层防爆舱壁结构抗爆性能仿真分析 [J]. 海军工程大学学报, 2012, 24(3): 26–34. doi: 10.3969/j.issn.1009-3486.2012.03.006CHEN C H, ZHU X, HOU H L, et al. Numerical analysis of blast resistance of double-layer bulkhead structures subjected to close-range air blast [J]. Journal of Naval University of Engineering, 2012, 24(3): 26–34. doi: 10.3969/j.issn.1009-3486.2012.03.006 [16] WANG W, HUO Q, YANG J C, et al. Damage analysis of POZD coated square reinforced concrete slab under contact blast [J]. Defence Technology, 2022, 18(9): 1715–1726. doi: 10.1016/j.dt.2021.07.005 [17] WU G, WANG X, JI C, et al. Anti-blast properties of 6063-T5 aluminum alloy circular tubes coated with polyurea elastomer: experiments and numerical simulations [J]. Thin-Walled Structures, 2021, 164: 107842. doi: 10.1016/j.tws.2021.107842 [18] 杨建超, 汪剑辉, 王幸, 等. 聚异氰氨酸脂噁唑烷弹性涂层钢筋混凝土板抗震塌机理 [J]. 科学技术与工程, 2022, 22(4): 1338–1343. doi: 10.3969/j.issn.1671-1815.2022.04.005YANG J C, WANG J H, WANG X, et al. Anti-collapsing mechanism of reinforced concrete slab with polyisocyanate-oxazodone elastic coating [J]. Science Technology and Engineering, 2022, 22(4): 1338–1343. doi: 10.3969/j.issn.1671-1815.2022.04.005 [19] 王礼立. 应力波基础[M]. 北京: 国防工业出版社, 2010: 52−60.WANG L L. Foundation of stress waves [M]. Beijing: National Defense Industry Press, 2010: 52−60. [20] JACOB N, NURICK G N, LANGDON G S. The effect of stand-off distance on the failure of fully clamped circular mild steel plates subjected to blast loads [J]. Engineering Structures, 2007, 29(10): 2723–2736. doi: 10.1016/j.engstruct.2007.01.021 -

下载:

下载: