Experimental Study on Delay Time Optimization of Tunnel Cutting Holes and Caving Holes under Electronic Detonator Initiation Condition

-

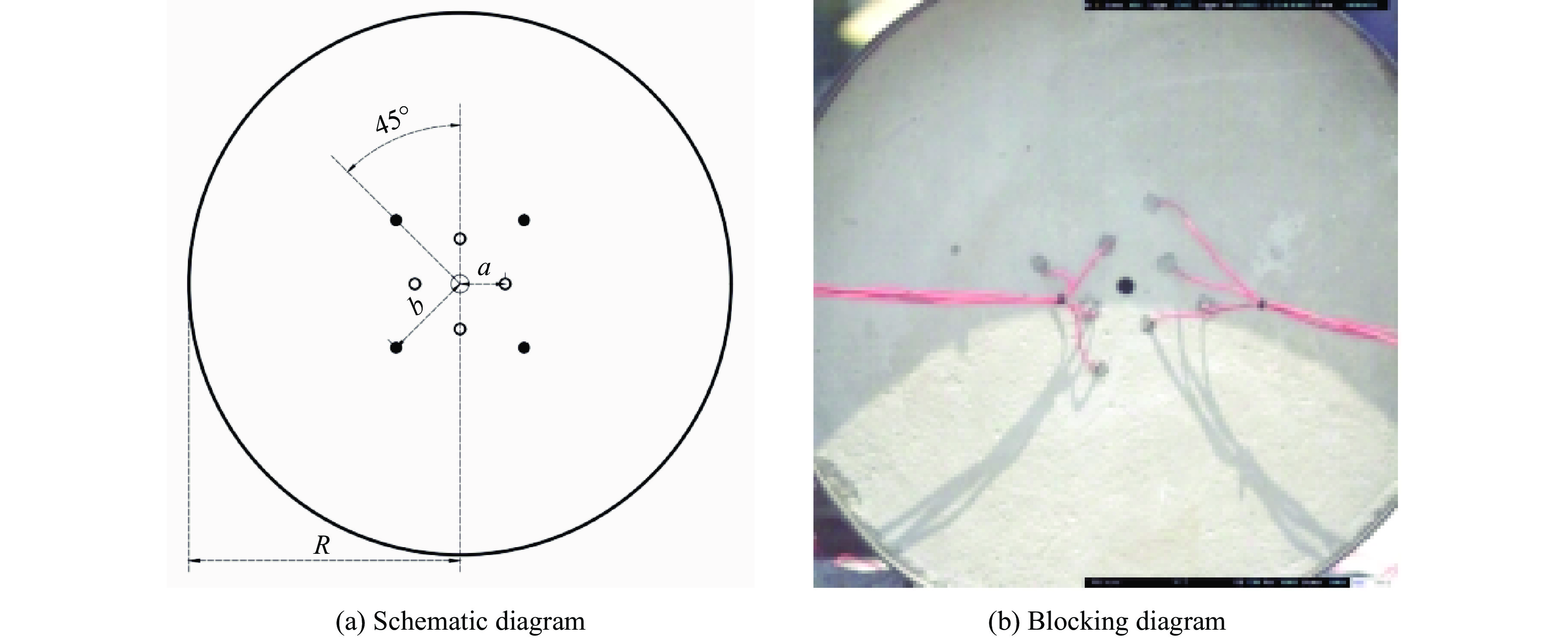

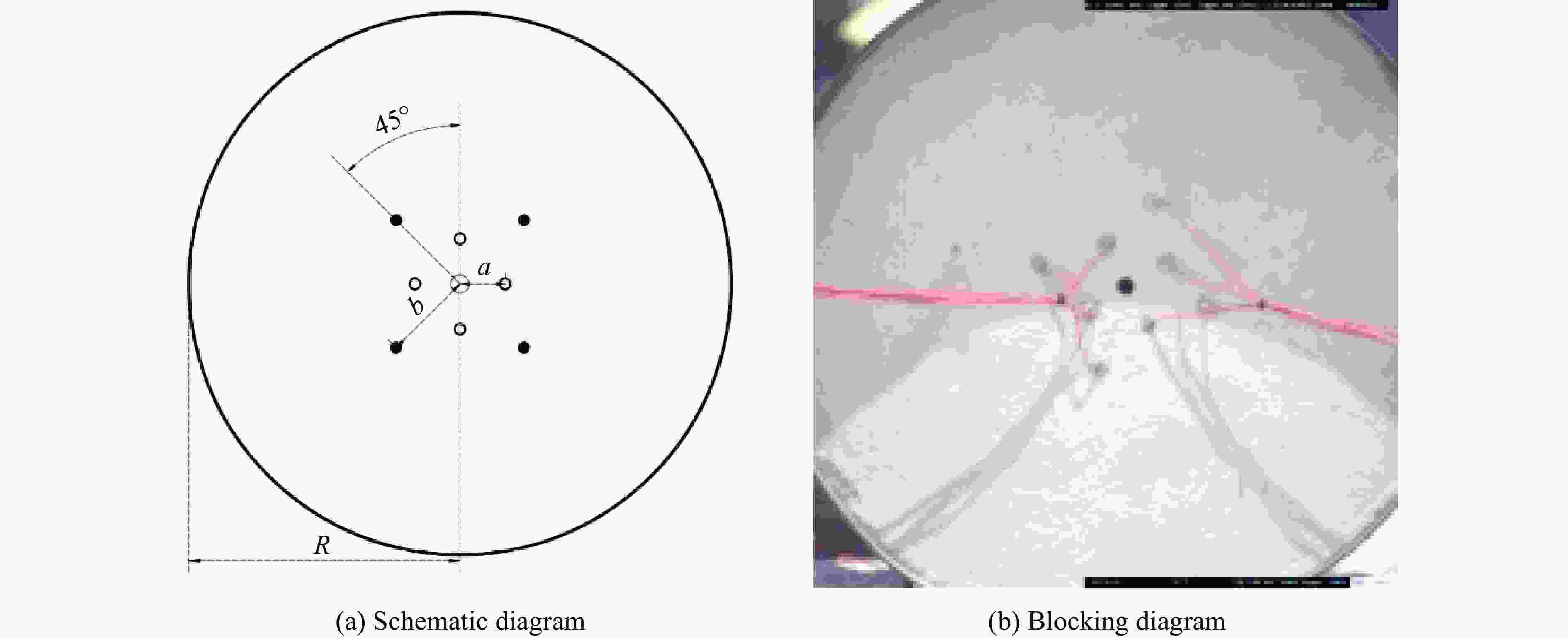

摘要: 起爆延时严重影响隧道爆破掘进效率,研究隧道精确控制爆破中岩石的破碎效果和掘进效率具有重要意义。为此,开展了隧道爆破中掏槽孔与辅助孔之间延时的相似模型试验研究,分析了不同起爆延时情况下岩石的破碎特征。模型试验表明,在隧道爆破中精确延时电子雷管对于提高爆破效果具有明显优势,得到了一定条件下模型试验与现场试验中起爆延时的相似关系。由现场试验可知:掏槽孔与辅助孔之间的最佳延时范围为15~25 ms,此时炮孔的利用率最高。结合相似理论的模型试验,得到最佳延时范围为8~24 ms,与现场试验结果具有较好的一致性,研究结果对隧道爆破掏槽孔与辅助孔之间的延时选取具有指导意义。Abstract: The initiation delay time seriously affects the efficiency of tunnel blasting excavation. It is of great significance to study the improvement of rock fragmentation effect and tunneling efficiency under the electronic detonator initiation condition via precise control blasting. The similarity model test of delay time between the cutting holes and the caving holes in tunnel blasting was conducted, and the rock fragmentation characteristics under different delay time were analyzed. The results show that it can be seen from the model test that the electronic detonator has obvious advantages in improving the blasting effect in tunnel blasting for its precise delay ability. In addition, the similarity relationship of the initiation delay time between the model and field tests was summarized. According to the field test, when the best delay time between the cutting holes and the caving holes is 15−25 ms, the utilization rate of the blast-holes is the highest. Guided by the similarity theory, the optimum delay time drawn from the model test is 8–24 ms, showing a good agreement with the field test. This paper is of reference for the selection of delay time between the cutting holes and the caving holes in tunnel blasting.

-

Key words:

- tunnel blasting /

- electronic detonator /

- delay time /

- millisecond blasting

-

表 1 模型及现场岩石的相关参数

Table 1. Model and field rock-related parameters

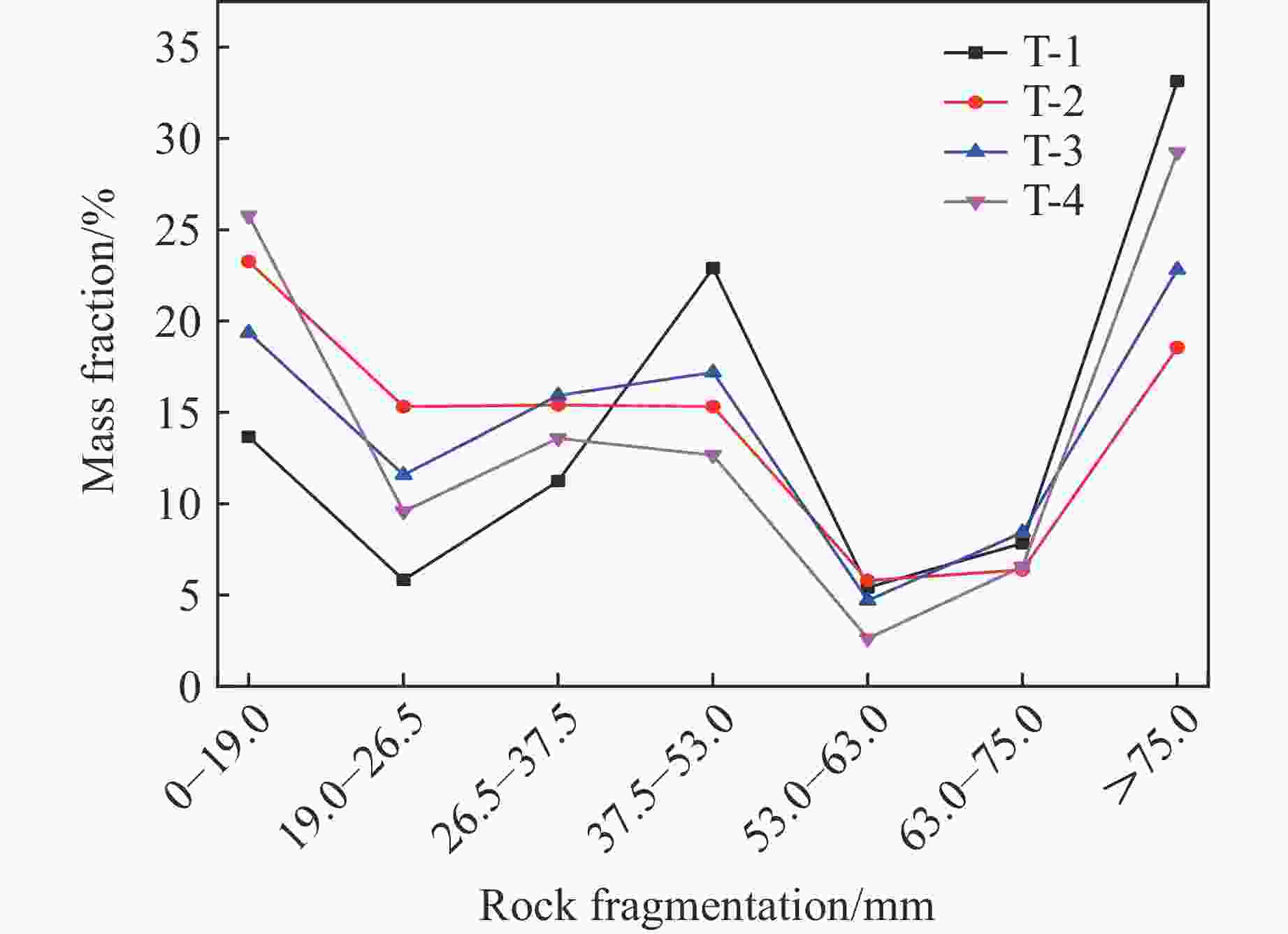

Material $\,\rho$/(kg·m−3) ${\sigma }{_{\mathrm{c} } }$/MPa ${C}{_{\mathrm{p} } }$/(m·s−1) E/GPa $ \mu $ Cast material 2080 20.8 2982.1 17.1 0.177 Rocks on site 2840 121 4900 53 0.21 Scheme $ \tau $/ms a/cm b/cm h1/cm d0/cm d1/cm T-1 0 5.0 10.0 13.0 2.0 1.2 T-2 1 5.0 10.0 13.0 2.0 1.2 T-3 3 5.0 10.0 13.0 2.0 1.2 T-4 5 5.0 10.0 13.0 2.0 1.2 表 3 碎岩统计

Table 3. Rock fragmentation statistics

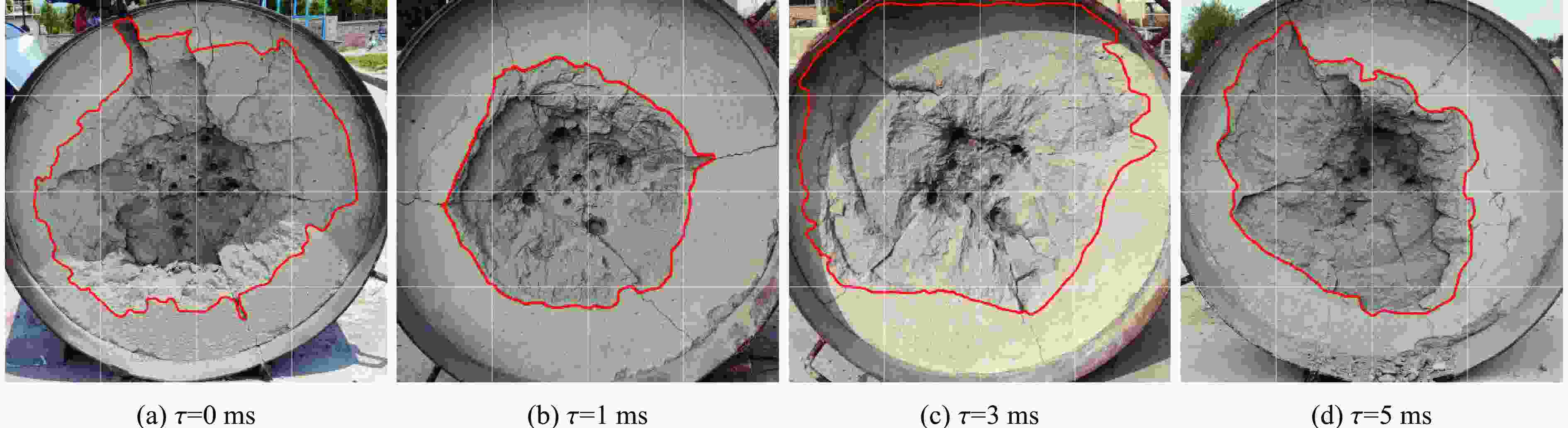

Scheme Mass/kg (Mass fraction/%) 0–19.0 mm 19.0–26.5 mm 26.5–37.5 mm 37.5–53.0 mm 53.0–63.0 mm 63.0–75.0 mm >75.0 mm T-1 1.60(13.66) 0.62(5.83) 1.16(11.24) 1.27(22.90) 0.65(5.41) 0.98(7.83) 3.28(33.14) T-2 1.64(23.26) 0.70(15.31) 1.35(15.41) 2.75(15.31) 0.65(5.79) 0.94(6.38) 3.98(18.55) T-3 2.37(19.37) 1.56(11.58) 1.57(15.93) 1.56(17.19) 0.59(4.70) 0.65(8.42) 1.89(22.81) T-4 2.76(25.77) 1.65(9.57) 2.27(13.58) 2.45(12.65) 0.67(2.62) 1.20(6.56) 3.25(29.24) 表 4 爆腔参数和炮孔利用率

Table 4. Cavity parameters and blast hole utilization rate

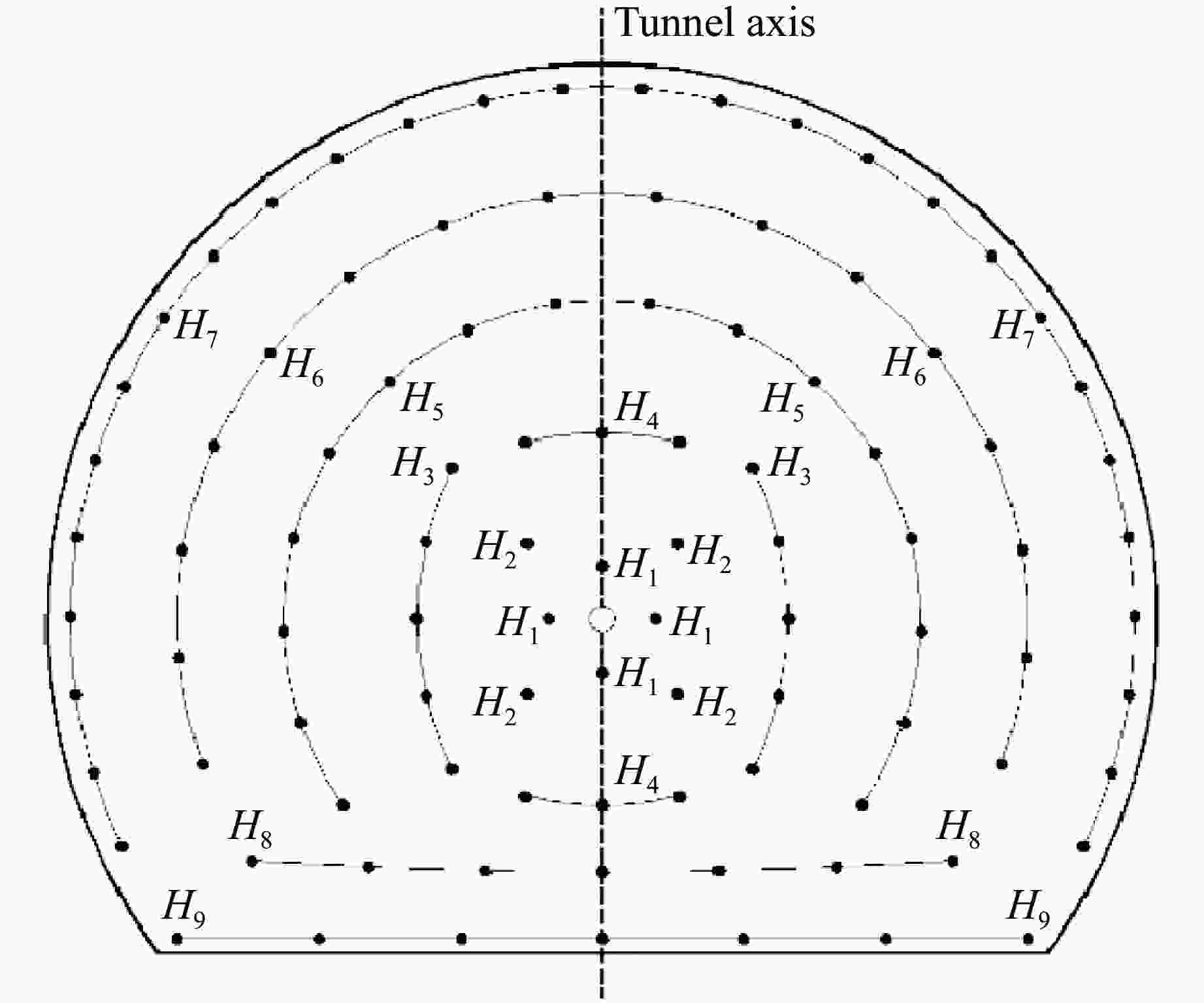

Scheme Blast cavity volume/cm3 Detonation depth/cm Blast hole utilization/% T-1 7960 11.40 87.7 T-2 6760 11.63 89.5 T-3 9450 11.59 89.2 T-4 8595 11.52 88.6 表 5 原隧道爆破参数

Table 5. Original tunnel blasting parameters

Serial number Name of hole $ \tau $/ms d2/mm L1/m a1/cm W/kg d3/mm N Q/kg H0 Holes in the middle 100 2.2 0 0 H1 Kibble hole 0 42 2.2 40 1.5 32 4 6.0 H2 Pilot hole 1 30 42 2.0 80 1.3 32 4 5.2 H3 Pilot hole 2 80 42 2.0 60 1.2 32 10 12.0 H4 Pilot hole 3 130 42 2.0 60 1.2 32 6 7.2 H5 Pilot hole 4 180 42 2.2 70 1.2 32 16 19.2 H6 Pilot hole 5 230 42 2.2 80 1.2 32 16 19.2 H7 Profile accuracy hole 1 280 42 2.2 60 0.4 32 28 11.2 H8 Bottom hole 1 330 42 2.2 90 1.4 32 7 9.8 H9 Bottom hole 2 380 42 2.2 100 1.5 32 7 10.5 表 6 原方案爆破效果

Table 6. Blasting effect of original scheme

Hole la/m Bu/% Hole la/m Bu/% Kibble hole 0.26 88.2 Profile accuracy hole 0.36 83.6 Pilot hole 0.30 85.0 Bottom hole 0.41 81.4 表 7 优化后起爆网路设计方案

Table 7. Optimized initiation network design scheme

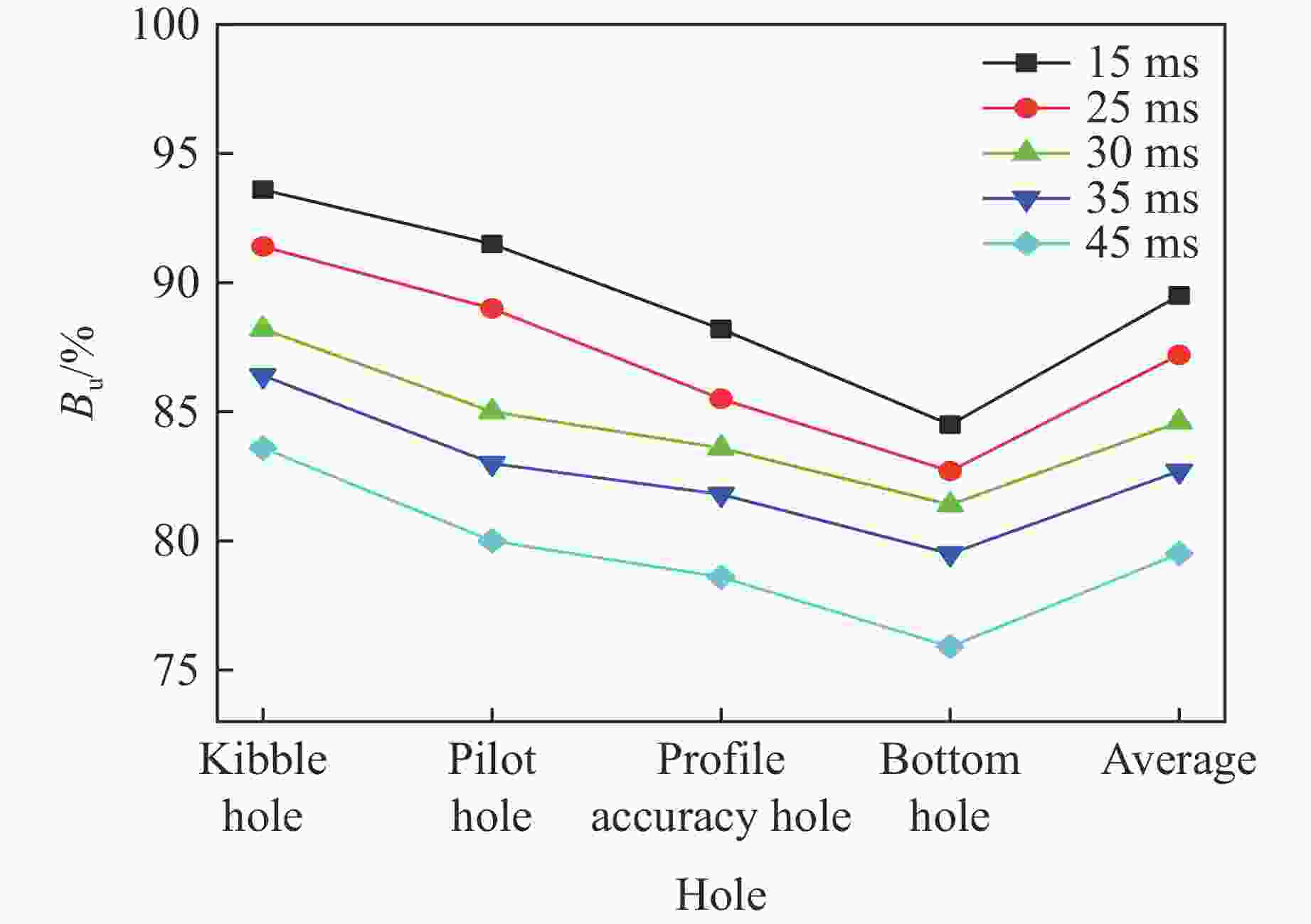

$ \tau / $ms Delay time/ms H1 H2 H3 H4 H5 H6 H7 H8 H9 30 0 30 80 130 180 230 280 330 380 15 0 15 65 115 165 215 265 315 365 25 0 25 75 125 175 225 275 325 375 35 0 35 85 135 185 235 285 335 385 45 0 45 95 145 195 245 295 345 395 表 8 炮孔利用率

Table 8. Blasthole utilization

$ \tau $/ms Hole L1/m la/m Bu/% Bu,ave/% Cycle footage/m 15 Kibble hole 2.2 0.14 93.6 89.5 1.92 Pilot hole 2.0 0.17 91.5 Profile accuracy hole 2.2 0.26 88.2 Bottom hole 2.2 0.34 84.5 25 Kibble hole 2.2 0.19 91.4 87.2 1.87 Pilot hole 2.0 0.22 89.0 Profile accuracy hole 2.2 0.32 85.5 Bottom hole 2.2 0.38 82.7 30 Kibble hole 2.2 0.26 88.2 84.6 1.82 Pilot hole 2.0 0.30 85.0 Profile accuracy hole 2.2 0.36 83.6 Bottom hole 2.2 0.41 81.4 35 Kibble hole 2.2 0.30 86.4 82.7 1.78 Pilot hole 2.0 0.34 83.0 Profile accuracy hole 2.2 0.40 81.8 Bottom hole 2.2 0.45 79.5 45 Kibble hole 2.2 0.36 83.6 79.5 1.71 Pilot hole 2.0 0.40 80.0 Profile accuracy hole 2.2 0.47 78.6 Bottom hole 2.2 0.53 75.9 -

[1] 中华人民共和国工业和信息化部. 关于推进民爆行业高质量发展的意见 [EB/OL]. (2018-11-13) [2022-08-11]. http://www.gov.cn/gongbao/content/2019/content_5366488.htm.Ministry of Industry and Information Technology of the People’s Republic of China. Opinions on promoting high quality development of civil explosion industry [EB/OL]. (2018-11-13)[2022-08-11]. http://www.gov.cn/gongbao/content/2019/content_5366488.htm. [2] 中华人民共和国工业和信息化部. 工业数码电子雷管标准体系建设方案(试行) [EB/OL]. (2021-10-27) [2021-11-02]. https://wap.miit.gov.cn/jgsj/aqs/gzdt/art/2021/art_f93f3384a8444e15b1beecdd7ae4cf6a.html.Ministry of Industry and Information Technology of the People’s Republic of China. Industrial digital electronic detonator standard system construction scheme (Trial) [EB/OL]. (2021-10-27) [2021-11-02]. https://wap.miit.gov.cn/jgsj/aqs/gzdt/art/2021/art_f93f3384a8444e15b1beecdd7ae4cf6a.html. [3] 李创新, 刘仕佳, 常根召, 等. 电子雷管推广使用问题探究 [J]. 煤矿爆破, 2018, 36(2): 14–16. doi: 10.3969/j.issn.1674-3970.2018.02.005LI C X, LIU S J, CHANG G Z, et al. Research on the use of electronic detonators [J]. Coal Mine Blasting, 2018, 36(2): 14–16. doi: 10.3969/j.issn.1674-3970.2018.02.005 [4] 姚华南. 电子雷管在巷道掘进中的应用研究 [J]. 煤矿爆破, 2021, 39(4): 25–28. doi: 10.3969/j.issn.1674-3970.2021.04.008YAO H N. Application of electronic detonator in tunnel excavation [J]. Coal Mine Blasting, 2021, 39(4): 25–28. doi: 10.3969/j.issn.1674-3970.2021.04.008 [5] 吴献明, 李中辉, 张文锡, 等. 数码电子雷管与非电导爆管雷管在露天深孔爆破中的应用对比 [J]. 西部探矿工程, 2021, 33(11): 14–16. doi: 10.3969/j.issn.1004-5716.2021.11.005WU X M, LI Z H, ZHANG W X, et al. Application comparison of digital electronic detonator and non-conductive detonator in open pit deep hole blasting [J]. West-China Exploration Engineering, 2021, 33(11): 14–16. doi: 10.3969/j.issn.1004-5716.2021.11.005 [6] CHO S H, KANEKO K. Influence of the applied pressure waveform on the dynamic fracture processes in rock [J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(5): 771–784. doi: 10.1016/j.ijrmms.2004.02.006 [7] HUANG D, QIU X Y, SHI X Z, et al. Experimental and numerical investigation of blast-induced vibration for short-delay cut blasting in underground mining [J]. Shock and Vibration, 2019(2): 5843516. doi: 10.1155/2019/5843516 [8] 黄宝龙. 岩巷掘进准直眼掏槽爆破试验研究 [D]. 北京: 中国矿业大学(北京), 2011.HUANG B L. Research on quasi-parallel cutting blast in rock drivage [D]. Beijing: China University of Mining and Technology (Beijing), 2011. [9] 单仁亮, 黄宝龙, 蔚振廷, 等. 岩巷掘进准直眼掏槽爆破模型试验研究 [J]. 岩石力学与工程学报, 2012, 31(2): 256–264. doi: 10.3969/j.issn.1000-6915.2012.02.004SHAN R L, HUANG B L, WEI Z T, et al. Model test of quasi-parallel cut blasting in rock drivage [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(2): 256–264. doi: 10.3969/j.issn.1000-6915.2012.02.004 [10] SHAPIRO V Y. Efficiency of cut configuration in driving tunnels with a set of deep blast holes [J]. Soviet Mining Science, 1989, 25(4): 379–386. doi: 10.1007/BF02528560 [11] 龚敏, 文斌, 王华. 掏槽参数对煤矿岩巷爆破效果的影响 [J]. 爆炸与冲击, 2015, 35(4): 576–584. doi: 10.11883/1001-1455(2015)04-0576-09GONG M, WEN B, WANG H. Influences of cut parameters on blasting effect in rock roadway of coal mine [J]. Explosion and Shock Waves, 2015, 35(4): 576–584. doi: 10.11883/1001-1455(2015)04-0576-09 [12] 龚敏, 王灿华, 梁立勋, 等. 硬岩掘进中主要爆破参数的确定与作用 [J]. 煤炭学报, 2015, 40(7): 1526–1533. doi: 10.13225/j.cnki.jccs.2014.1766GONG M, WANG C H, LIANG L X, et al. Function analysis and confirming method of key blasting parameters for excavating in hard rock [J]. Journal of China Coal Society, 2015, 40(7): 1526–1533. doi: 10.13225/j.cnki.jccs.2014.1766 [13] 傅洪贤, 沈周, 赵勇, 等. 隧道电子雷管爆破降振技术试验研究 [J]. 岩石力学与工程学报, 2012, 31(3): 597–603. doi: 10.3969/j.issn.1000-6915.2012.03.018FU H X, SHEN Z, ZHAO Y, et al. Experimental study of decreasing vibration technology of tunnel blasting with digital detonator [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(3): 597–603. doi: 10.3969/j.issn.1000-6915.2012.03.018 [14] 李清, 于强, 张迪, 等. 地铁隧道精确控制爆破延期时间优选及应用 [J]. 振动与冲击, 2018, 37(13): 135–140, 170. doi: 10.13465/j.cnki.jvs.2018.13.021LI Q, YU Q, ZHANG D, et al. Metro tunnel precisely controlled blasting’s delay time optimization and its application [J]. Journal of Vibration and Shock, 2018, 37(13): 135–140, 170. doi: 10.13465/j.cnki.jvs.2018.13.021 [15] 孔祥松, 刘响钟, 周纪军, 等. 岩石工程爆破破碎的机理研究 [J]. 矿业研究与开发, 2013, 33(4): 118–121. doi: 10.13827/j.cnki.kyyk.2013.04.011KONG X S, LIU X Z, ZHOU J J, et al. Study on fragmentation mechanism for rock blasting engineering [J]. Mining Research and Development, 2013, 33(4): 118–121. doi: 10.13827/j.cnki.kyyk.2013.04.011 [16] 马芹永, 袁璞, 张经双, 等. 立井直眼微差爆破模型试验振动测试与分析 [J]. 振动与冲击, 2015, 34(6): 172–176. doi: 10.13465/j.cnki.jvs.2015.06.033MA Q Y, YUAN P, ZHANG J S, et al. Blasting vibration measurement and analyses of millisecond blasting models for vertical shaft blasting [J]. Journal of Vibration and Shock, 2015, 34(6): 172–176. doi: 10.13465/j.cnki.jvs.2015.06.033 [17] 李鹏, 吕良哲, 陈智山, 等. 隧道爆破中合理微差时间的选择 [J]. 采矿技术, 2011, 11(5): 127–128. doi: 10.3969/j.issn.1671-2900.2011.05.048LI P, LYU L Z, CHEN Z S, et al. Selection of reasonable millisecond time in tunnel blasting [J]. Mining Technology, 2011, 11(5): 127–128. doi: 10.3969/j.issn.1671-2900.2011.05.048 [18] 戴俊. 爆破工程 [M]. 2版. 北京: 机械工业出版社, 2015.DAI J. Blasting engineering [M]. 2nd ed. Beijing: China Machine Press, 2015. [19] 周传波. 深孔爆破一次成井模拟优化与应用研究 [D]. 武汉: 中国地质大学, 2004.ZHOU C B. Study on simulation optimization and application of shaft formation by one deep-hole blasting [D]. Wuhan: China University of Geosciences, 2004. [20] 宗琦, 傅菊根, 徐华生. 立井冻土掘进爆破技术的研究与应用 [J]. 岩土力学, 2007, 28(9): 1992–1996. doi: 10.3969/j.issn.1000-7598.2007.09.043ZONG Q, FU J G, XU H S. Study and application of frozen soil blasting technique in shaft [J]. Rock and Soil Mechanics, 2007, 28(9): 1992–1996. doi: 10.3969/j.issn.1000-7598.2007.09.043 [21] 李洪伟, 黄昕旭, 吴立辉, 等. 电子雷管在岩巷爆破中掏槽孔微差时间试验研究及数值模拟 [J]. 金属矿山, 2022(7): 64–72. doi: 10.19614/j.cnki.jsks.202207009LI H W, HUANG X X, WU L H, et al. Experimental study and numerical simulation on micro-difference time of cutting hole of electronic detonator in rock roadway blasting [J]. Metal Mine, 2022(7): 64–72. doi: 10.19614/j.cnki.jsks.202207009 [22] 唐建华, 宗琦, 马长世. 试析筒形直眼掏槽产生大块的机理 [J]. 煤矿爆破, 1995(4): 21–23.TANG J H, ZONG Q, MA C S. Analysis on the mechanism of large block in cylindrical straight eye cutting [J]. Coal Mine Blasting, 1995(4): 21–23. -

下载:

下载: