Mechanical Properties and Failure Analysis of UHMWPE Fiber Composite Laminates under Compressive Loading

-

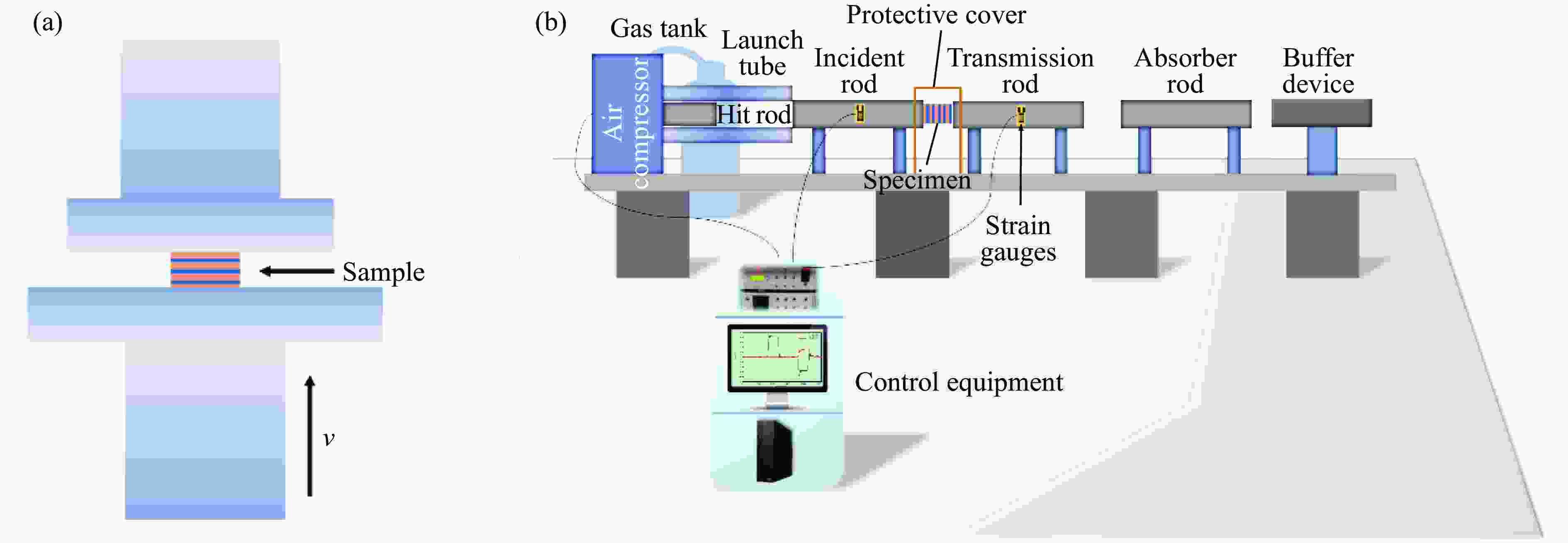

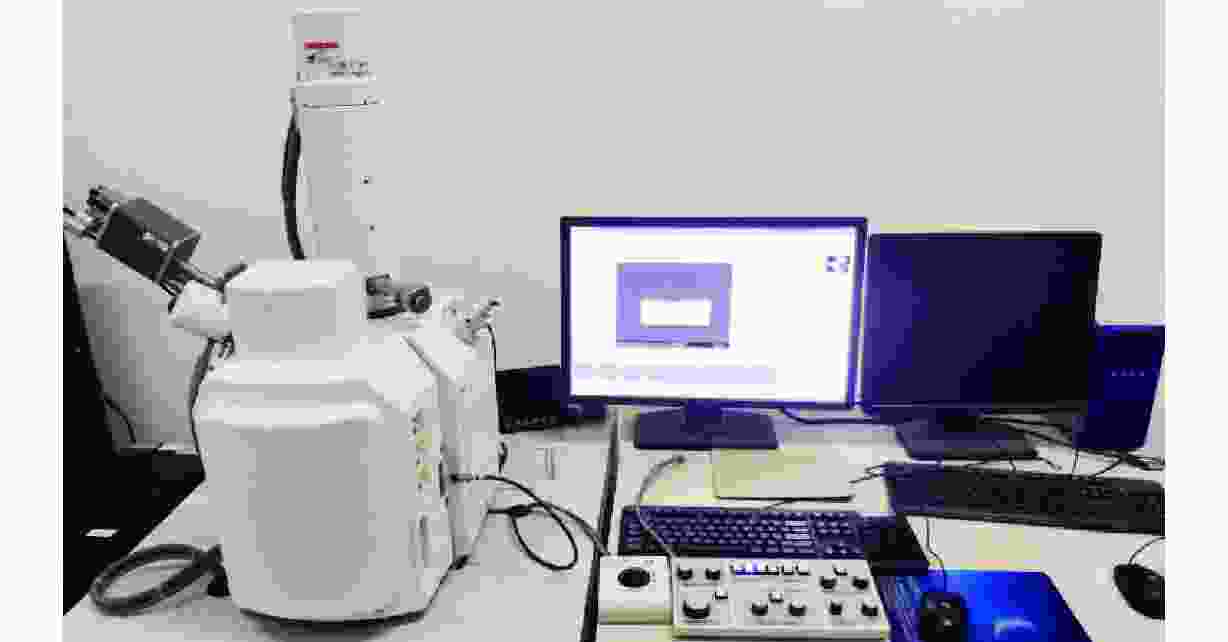

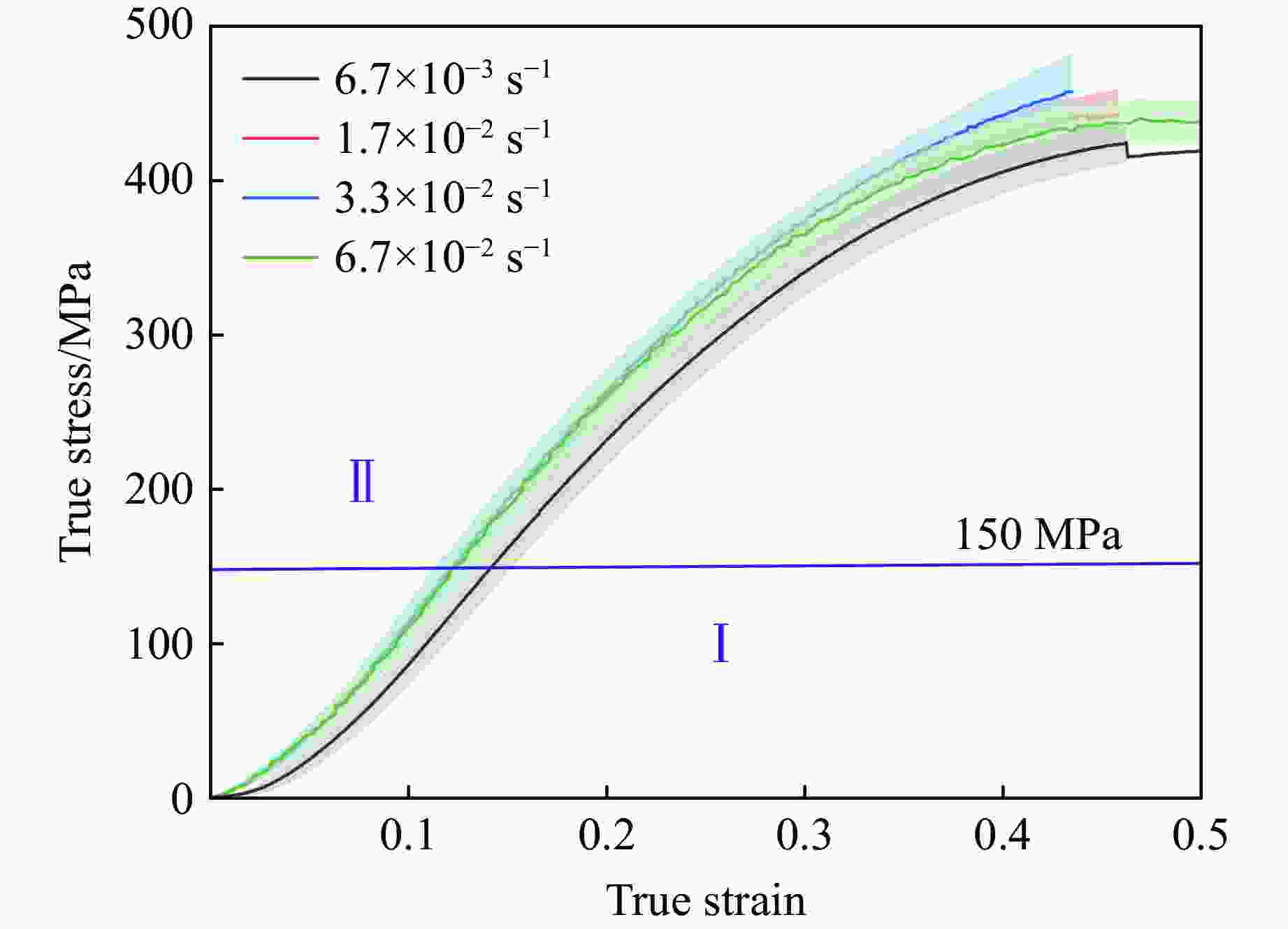

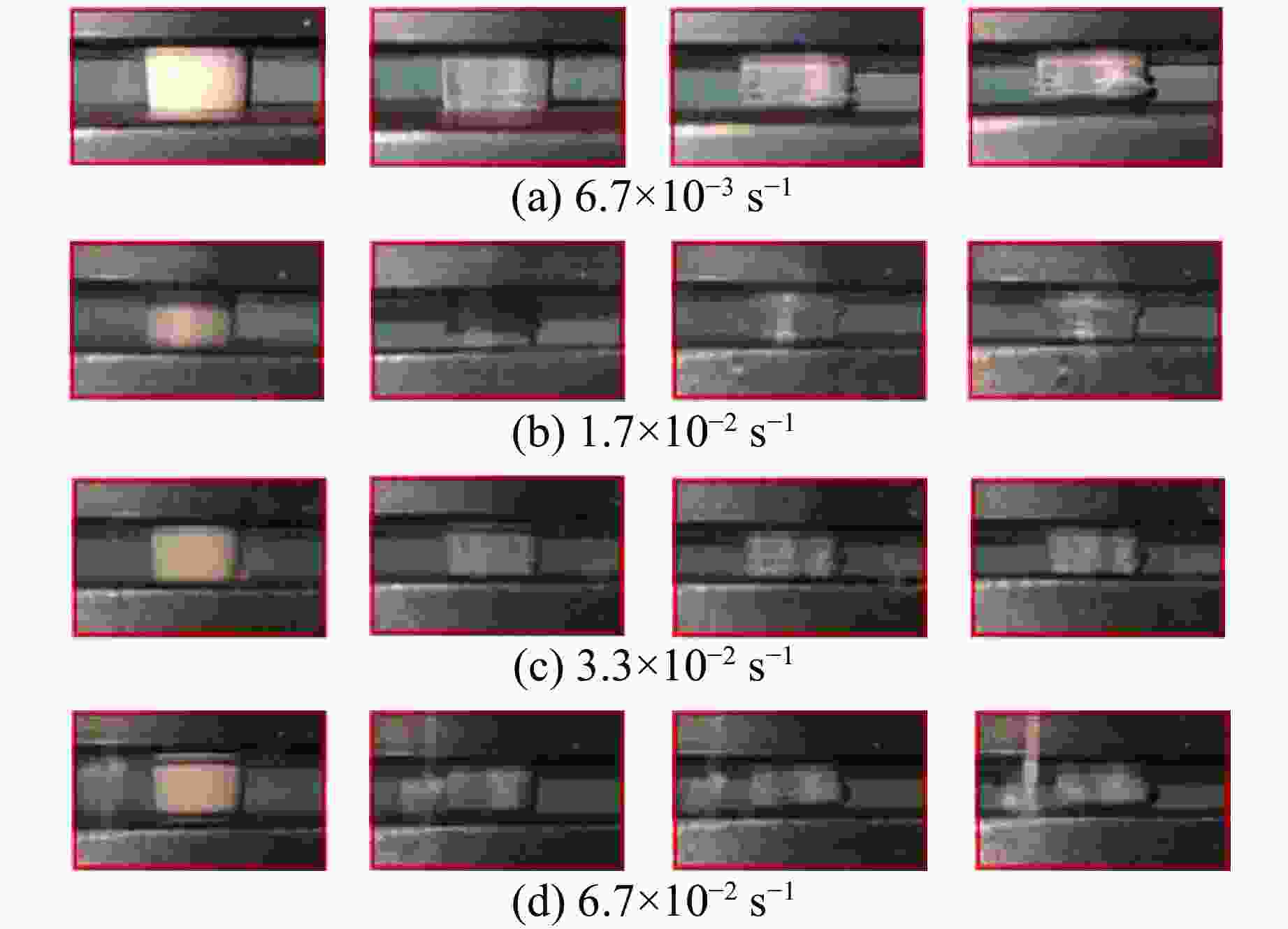

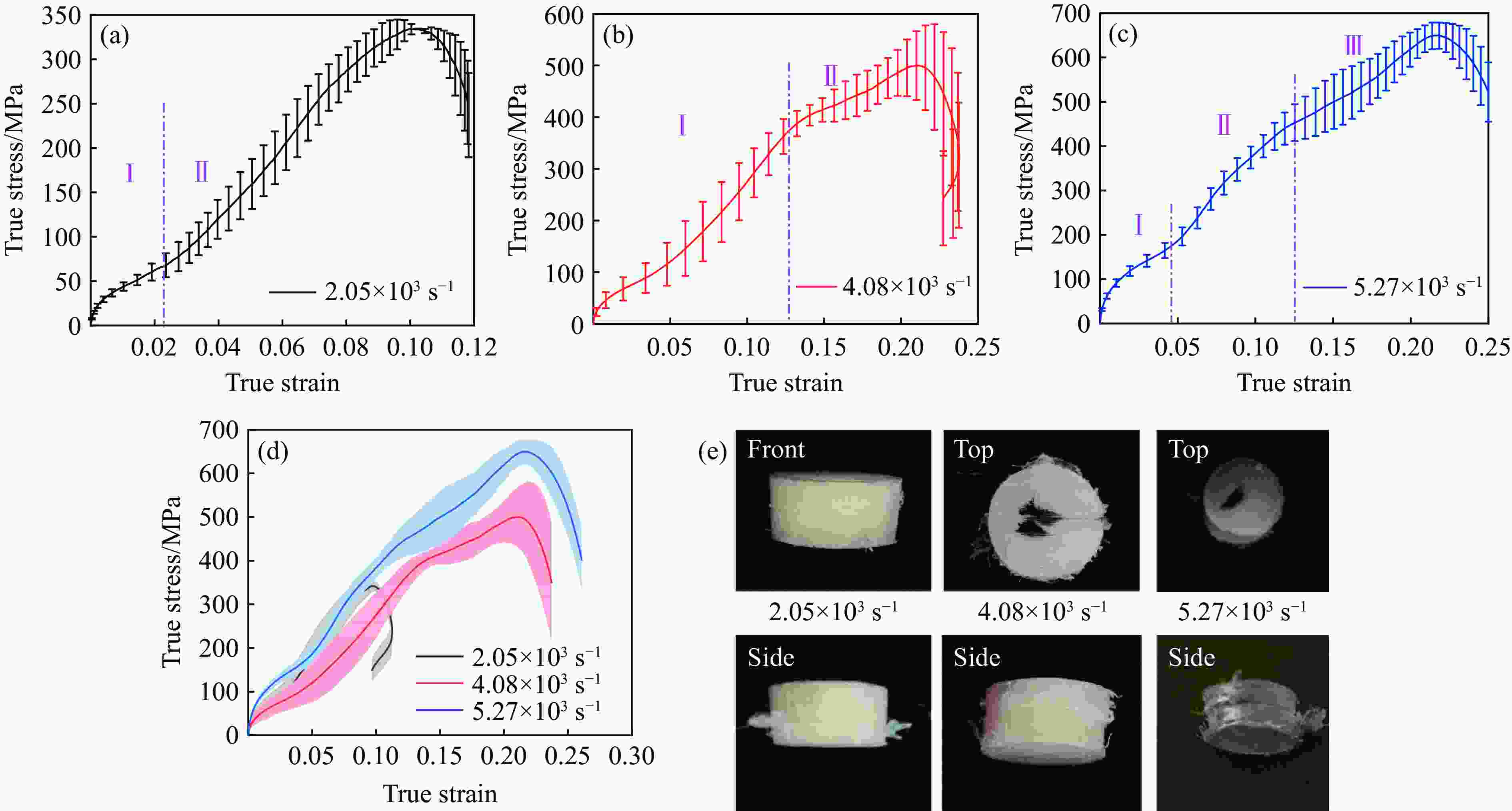

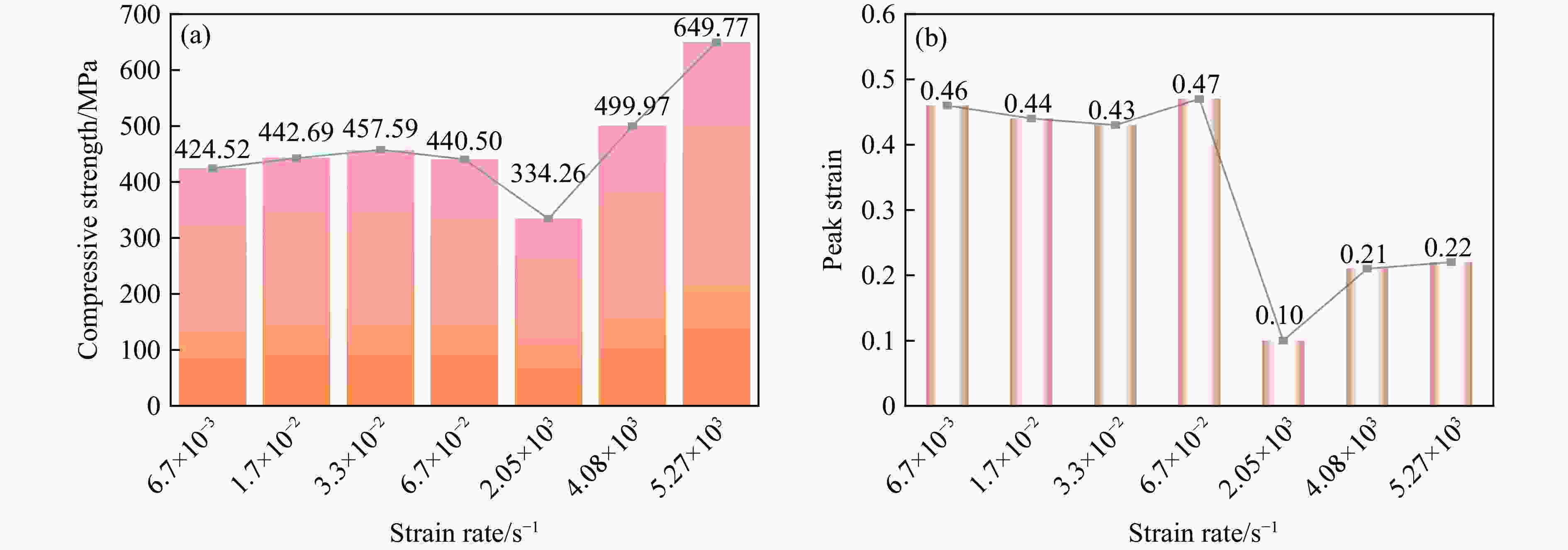

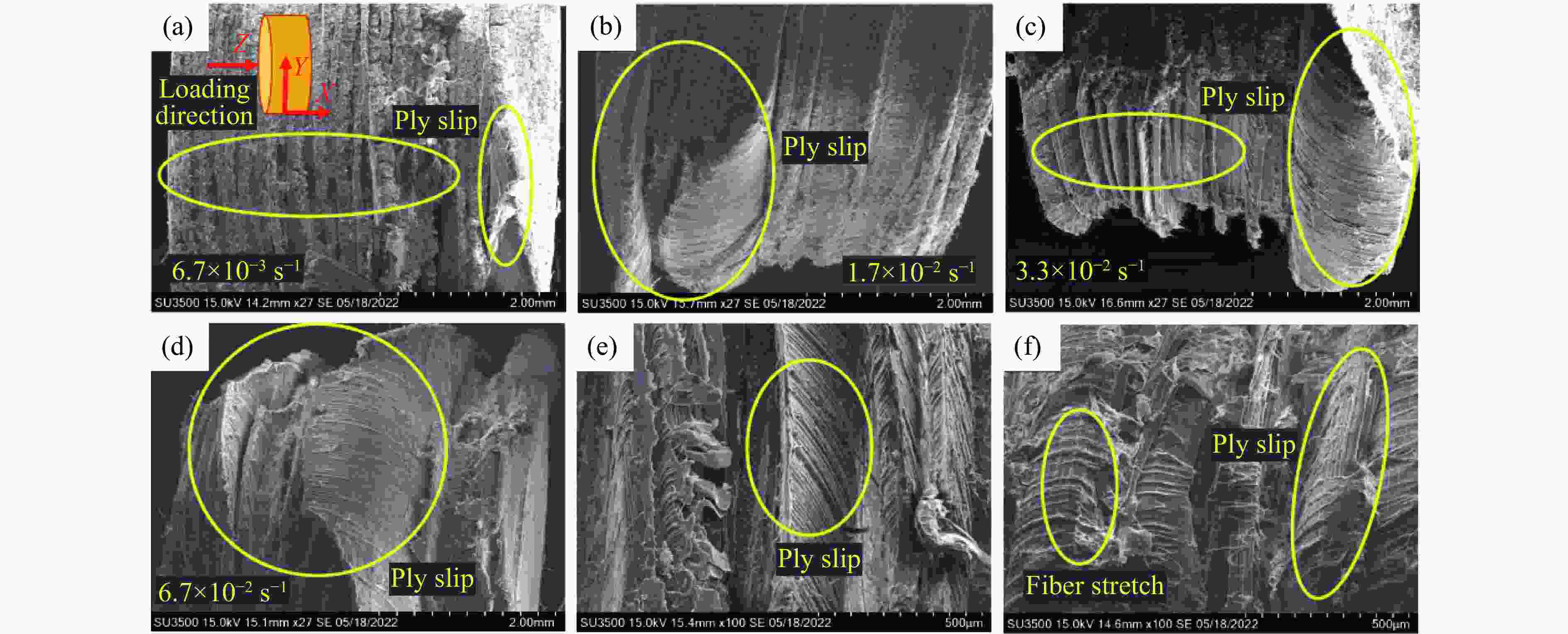

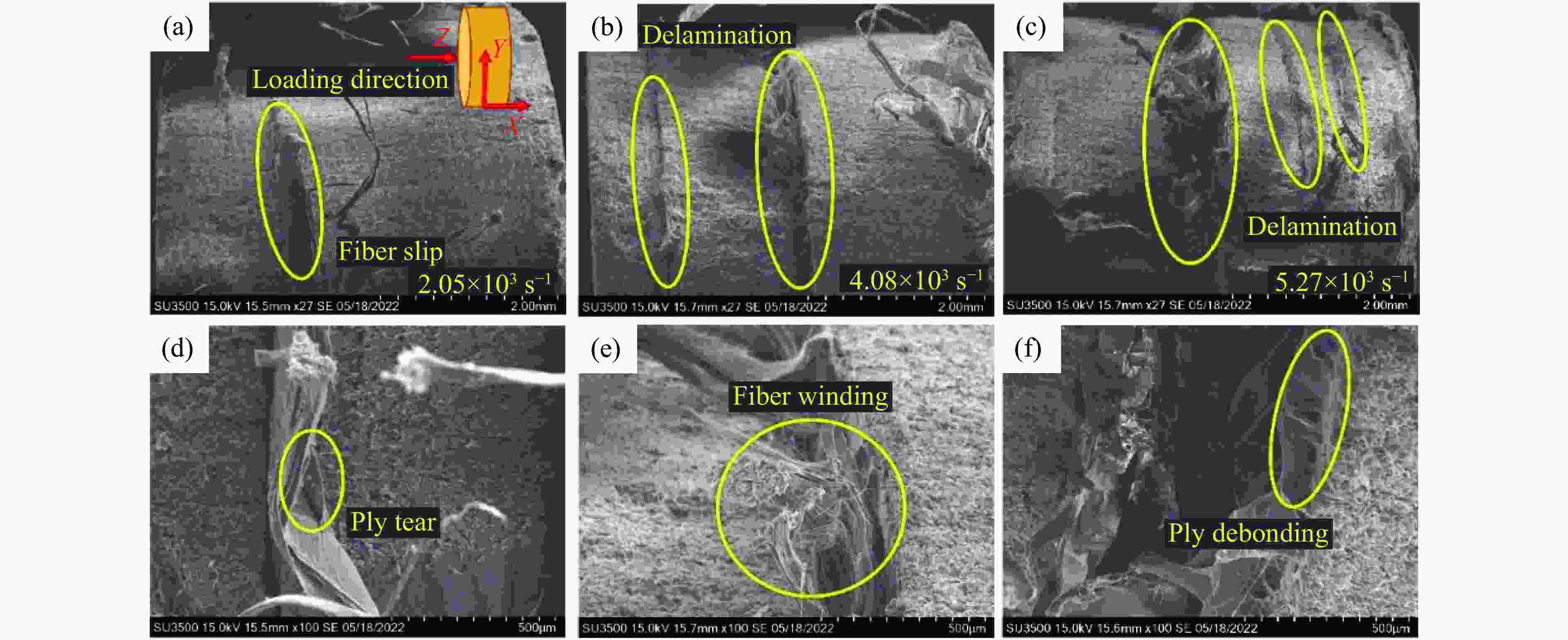

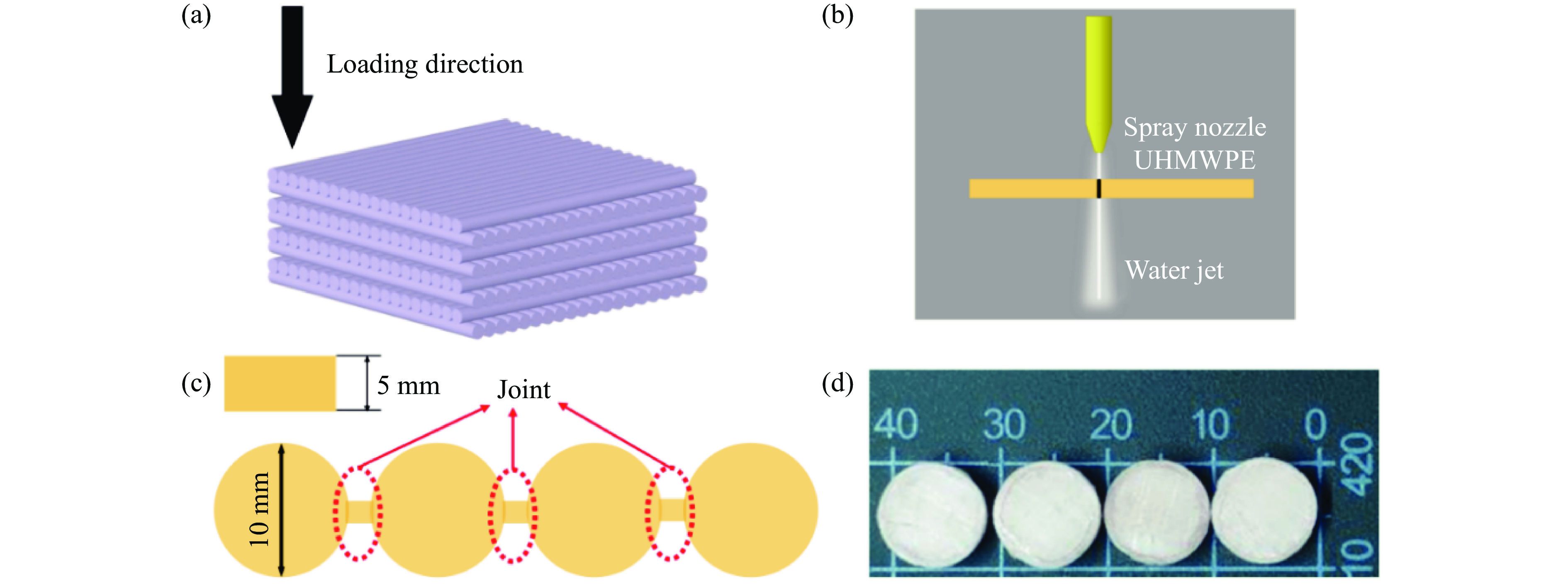

摘要: 为获得超高分子量聚乙烯(ultra-high molecular weight polyethylene,UHMWPE)纤维复合材料层合板在静、动态压缩载荷下的力学性能与失效模式,采用万能材料试验机和分离式霍普金森压杆对材料进行面外方向的压缩实验,获得了不同应变率下材料的应力-应变关系。通过扫描电子显微镜观察材料微观失效形貌,分析了材料的失效模式。结果表明,UHMWPE纤维复合材料层合板在应变率较低(6.7×10−3~6.7×10−2 s−1)且相差较小时,无应变率效应;在高应变率(2.05×103~5.27×103 s−1)下,材料具有明显的应变率效应。压缩强度随应变率的增加而增大,动态增强因子逐渐增大,具有明显的应变率强化效应。静态压缩载荷下,材料的主要破坏模式为纤维的拉伸、断裂;动态压缩载荷下,材料的主要破坏模式为纵向位错分层。Abstract: To determine the mechanical properties and failure modes of ultra-high molecular weight polyethylene (UHMWPE) fiber composite laminates under static and dynamic compressive loading, a universal material testing machine (UTM) and a split Hopkinson pressure bar (SHPB) experimental system were used to obtain the stress-strain relationships of UHMWPE subjected to out-of-plane compression at different strain rate loading. After experiments, the microscopic failure morphology of the material was observed through scanning electron microscopy (SEM), then the failure mode of the material was analyzed. The results show that the UHMWPE fiber composite laminates performs a rate-independent behavior at low strain rates (6.7×10−3 s−1 to 6.7×10−2 s−1); while a rate-dependent at high strain rates (2.05×103 s−1 to 5.27×103 s−1). The compression strength increases with the rising strain rate, and the dynamic enhancement factor gradually increases, with an obvious strain rate strengthening effect. Under static compression, the main damage mode of UHMWPE is the stretching and fracture of the fibers, while at dynamic situation, the main damage mode of the material is the longitudinal dislocation delamination.

-

表 1 动态压缩实验结果

Table 1. Dynamic compression experimental results

Static compressive

strength/MPaLoading air

pressure/MPaStrain rate/s−1 Dynamic compressive

strength/MPaDIF Dynamic peak

strain424.52 0.25 2.05×103 334.26 0.78 100 424.52 0.45 4.08×103 499.97 1.18 210 424.52 0.65 5.27×103 649.77 1.53 220 Note: (1) Static compressive strength is the maximum stress at a loading speed of 2 mm/min;

(2) Dynamic compressive strength is the peak stress achieved by the sample under dynamic compressive loading;

(3) DIF is the dynamic compressive strength divided by the static compressive strength;

(4) Dynamic peak strain is the strain value corresponding to the dynamic compressive strength. -

[1] ROGERS J A, MOTE A, MEAD P T, et al. Hypervelocity impact response of monolithic UHMWPE and HDPE plates [J]. International Journal of Impact Engineering, 2022, 161: 104081. doi: 10.1016/j.ijimpeng.2021.104081 [2] CAI S P, LIU J, ZHANG P, et al. Experimental study on failure mechanisms of sandwich panels with multi-layered aluminum foam/UHMWPE laminate core under combined blast and fragments loading [J]. Thin-Walled Structures, 2021, 159: 107227. doi: 10.1016/j.tws.2020.107227 [3] TANG F, CHENG D, YANG Z, et al. Protective performance and dynamic behavior of composite body armor with shear stiffening gel as buffer material under ballistic impact [J]. Composites Science and Technology, 2022, 218: 109190. doi: 10.1016/j.compscitech.2021.109190 [4] CHANG L J, GUO Y F, HUANG X Y, et al. Experimental study on the protective performance of bulletproof plate and padding materials under ballistic impact [J]. Materials & Design, 2021, 207: 109841. [5] 肖文莹, 李想, 郭万涛, 等. Kevlar/UHMWPE混杂纤维复合材料抗弹性能 [J]. 玻璃钢/复合材料, 2019, 9: 79–84.XIAO W Y, LI X, GUO W T, et al. Resistance performance of Kevlar/UHMWPE fiber hybrid composites [J]. Fiber Reinforced Plastics/Composites, 2019, 9: 79–84. [6] ZHANG T G, SATAPATHY S S, VARGAS-GONZALEZ L R, et al. Ballistic impact response of ultra-high-molecular-weight polyethylene (UHMWPE) [J]. Composite Structures, 2015, 133: 191–201. doi: 10.1016/j.compstruct.2015.06.081 [7] JASON C P, LING Y T T, RAMESH K T. Effect of microstructure on the dynamic behavior of ultra-high-molecular-weight polyethylene (UHMWPE) composites [J]. Composites Part A: Applied Science and Manufacturing, 2022, 156: 106833. doi: 10.1016/j.compositesa.2022.106833 [8] KEDZIERSKI P, MORKA A. A comprehensive approach to the modeling and simulation of ballistic textiles [J]. Composite Structures, 2022, 292: 115643. doi: 10.1016/j.compstruct.2022.115643 [9] O’MASTA M R, CRAYTON D H, DESHPANDE V S, et al. Mechanisms of penetration in polyethylene reinforced cross-ply laminates [J]. International Journal of Impact Engineering, 2015, 86: 249–264. doi: 10.1016/j.ijimpeng.2015.08.012 [10] 苏罗川, 田立智, 宜晨虹, 等. 破片和爆炸波联合加载下UHMWPE纤维复合材料失效行为实验研究 [J]. 复合材料科学与工程, 2021(12): 60–65. doi: 10.19936/j.cnki.2096-8000.20211228.009SU L C, TIAN L Z, YI C H, et al. Experimental investigations on the failure behaviour of UHMWPE composite panel under the loading of fragments and blast [J]. Composites Science and Engineering, 2021(12): 60–65. doi: 10.19936/j.cnki.2096-8000.20211228.009 [11] 付杰, 李伟萍, 黄献聪, 等. 新型超高分子量聚乙烯膜材料防弹性能及机理 [J]. 兵工学报, 2021, 42(11): 2453–2464. doi: 10.3969/j.issn.1000-1093.2021.11.019FU J, LI W P, HUANG X C, et al. Bullet-proof performance and mechanism of new ultra-high molecular weight polyethylene film [J]. Acta Armamentarii, 2021, 42(11): 2453–2464. doi: 10.3969/j.issn.1000-1093.2021.11.019 [12] LASSIG T, NGUYEN L, MAY M, et al. A non-linear orthotropic hydrocode model for ultra-high molecular weight polyethylene in impact simulations [J]. International Journal of Impact Engineering, 2015, 75: 110–122. doi: 10.1016/j.ijimpeng.2014.07.004 [13] ZHU Y H, ZHANG X Y, XUE B Y, et al. High-strain-rate compressive behavior of UHMWPE fiber laminate [J]. Applied Sciences, 2020, 10(4): 1505. doi: 10.3390/app10041505 [14] O’MASTA M R, RUSSELL B P, RONAN W. Inter-ply angle influence on the out-of-plane compressive response of polyethylene fibre laminates [J]. Composites Part A: Applied Science and Manufacturing, 2018, 110: 11–20. doi: 10.1016/j.compositesa.2018.03.032 [15] 孙颖, 王国军, 张典堂, 等. UHMWPE/乙烯基酯2.5D角联锁机织复合材料动态压缩性能实验研究 [J]. 材料工程, 2011(4): 38–42.SUN Y, WANG G J, ZHANG D T, et al. Experimental investigation on dynamic compression properties of UHMWPE/Vinyl Ester 2.5 dimensional angle interlocked woven composites [J]. Journal of Materials Engineering, 2011(4): 38–42. [16] LIU B G, KANDAN K, WADLEY H N G, et al. High strain rate compressive response of ultra-high molecular weight polyethylene fibre composites [J]. International Journal of Plasticity, 2019, 122: 115–134. doi: 10.1016/j.ijplas.2019.04.005 [17] SHARIFPOUR F, MONTESANO J, TALREJA R. Micromechanical assessment of local failure mechanisms and early-stage ply crack formation in cross-ply laminates [J]. Composites Science and Technology, 2022, 220: 109286. doi: 10.1016/j.compscitech.2022.109286 [18] GUO Z R, CASEM D, HUDSPETH M, et al. Transverse compression of two high-performance ballistic fibers [J]. Textile Research Journal, 2016, 86(5): 502–511. doi: 10.1177/0040517515592814 [19] 张羲黄, 李金柱, 武海军, 等. 静、动态压缩下环氧树脂玻璃钢的力学行为和特性 [J]. 高压物理学报, 2021, 35(6): 064105.ZHANG X H, LI J Z, WU H J, et al. Mechanical behavior and failure mechanism of glass fiber reinforced plastics under quasi-static and dynamic compressive loading [J]. Chinese Journal of High Pressure Physics, 2021, 35(6): 064105. [20] 潘月秀, 鲍佳伟, 王凡文, 等. 国产T800炭纤维/环氧树脂单向复合材料动态压缩性能 [J]. 新型炭材料, 2020, 35(6): 785–792. doi: 10.19869/j.ncm.1007-8827.20200128PAN Y X, BAO J W, WANG F W, et al. Dynamic compressive properties of unidirectional composites made of TG800 carbon fiber and epoxy resin [J]. New Carbon Materials, 2020, 35(6): 785–792. doi: 10.19869/j.ncm.1007-8827.20200128 [21] 叶卓然, 罗靓, 潘海燕, 等. 超高分子量聚乙烯纤维及其复合材料的研究现状与分析 [J]. 复合材料学报, 2022, 39(9): 4286–4309.YE Z R, LUO L, PAN H Y, et al. Research status and analysis of ultra-high molecular weight polyethylene fiber and its composites [J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4286–4309. [22] YANG Y F, LING T P, XUE S N, et al. Meso-scale numerical modeling of uni-directional composite panel under ballistic impact [J]. Applied Composite Materials, 2022, 29(1): 205–218. doi: 10.1007/s10443-021-09930-x [23] GILSON L, IMAD A, RABET L, et al. On analysis of deformation and damage mechanisms of DYNEEMA composite under ballistic impact [J]. Composite Structures, 2020, 253: 112791. doi: 10.1016/j.compstruct.2020.112791 [24] WANG H X, WEERASINGHE D, MOHOTTI D, et al. On the impact response of UHMWPE woven fabrics: experiments and simulations [J]. International Journal of Mechanical Sciences, 2021, 204: 106574. doi: 10.1016/j.ijmecsci.2021.106574 [25] MEYER C S, O’BRIEN D J, HAQUE B Z G, et al. Mesoscale modeling of ballistic impact experiments on a single layer of plain weave composite [J]. Composites Part B: Engineering, 2022, 235: 109753. doi: 10.1016/j.compositesb.2022.109753 [26] GREENHALGH E S, BLOODWORTH V M, IANNUCCI L, et al. Fractographic observations on Dyneema® composites under ballistic impact [J]. Composites Part A: Applied Science and Manufacturing, 2013, 44: 51–62. doi: 10.1016/j.compositesa.2012.08.012 [27] NGUYEN L H, LASSIG T R, RYAN S, et al. A methodology for hydrocode analysis of ultra-high molecular weight polyethylene composite under ballistic impact [J]. Composites Part A: Applied Science and Manufacturing, 2016, 84: 224–235. doi: 10.1016/j.compositesa.2016.01.014 [28] 仲越, 徐铭涛, 王萍, 等. 碳纤维-超高分子量聚乙烯纤材料低速冲击性能及失效机制 [J]. 复合材料学报, 2022, 39(7): 3202–3211.ZHONG Y, XU M T, WANG P, et al. Low-velocity impact properties and failure mechanism of carbon fiber-UHMWPE fiber hybrid reinforced epoxy resin composites [J]. Acta Materiae Composites Sinica, 2022, 39(7): 3202–3211. [29] YERRAMALLI C S, SUMANT C, PRUSTY R K, et al. Finite element modelling and experimentation of plain weave glass/epoxy composites under high strain-rate compression loading for estimation of Johnson-Cook model parameters [J]. International Journal of Impact Engineering, 2022, 167: 104262. doi: 10.1016/j.ijimpeng.2022.104262 [30] 赵昌方, 周志坛, 朱宏伟, 等. 锻造/层合碳纤维-环氧树脂复合材料压缩性能实验与仿真 [J]. 材料导报, 2021, 35(12): 12209–12213.ZHAO C F, ZHOU Z T, ZHU H W, et al. Experiments and simulations of compression properties of forged/laminated carbon fiber-epoxy resin composites [J]. Materials Reports, 2021, 35(12): 12209–12213. [31] MEHDIKHANI M, GORBATIKH L, VERPOEST I, et al. Voids in fiber-reinforced polymer composites: a review on their formation, characteristics, and effects on mechanical performance [J]. Journal of Composite Materials, 2019, 53(12): 1579–1669. doi: 10.1177/0021998318772152 [32] CHENG M, CHEN W N, WEERASOORIYA T. Mechanical properties of Kevlar® KM2 single fiber [J]. Journal of Engineering Materials and Technology, 2005, 127(2): 197–203. doi: 10.1115/1.1857937 [33] 何业茂, 焦亚男, 周庆, 等. 热塑性树脂基体对超高分子量聚乙烯纤维复合材料力学性能和抗弹道侵彻性能的影响 [J]. 复合材料学报, 2021, 39(4): 1570–1581.HE Y M, JIAO Y N, ZHOU Q, et al. Effects of thermoplastic resin matrix on mechanical properties and anti-penetration performance of ultra-high molecular weight polyethylene fiber composite [J]. Acta Materiae Compositae Sinica, 2021, 39(4): 1570–1581. [34] 王志航, 白二雷, 许金余, 等. 聚合物改性碳纤维增强混凝土的动态压缩力学性能 [J]. 复合材料学报, 2023, 40(3): 1602–1613.WANG Z H, BAI E L, XU J Y, et al. Dynamic compression mechanical properties of polymer modified carbon fiber reinforced concrete [J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1602–1613. [35] ATTWOOD J P, KHADERI S N, KARTHIKEYAN K, et al. The out-of-plane compressive response of Dyneema® composites [J]. Journal of the Mechanics and Physics of Solids, 2014, 70: 200–226. doi: 10.1016/j.jmps.2014.05.017 -

下载:

下载: