Out-of-Plane Mechanical Behaviors of Intorsion Hierarchical Honeycomb-Like Structures

-

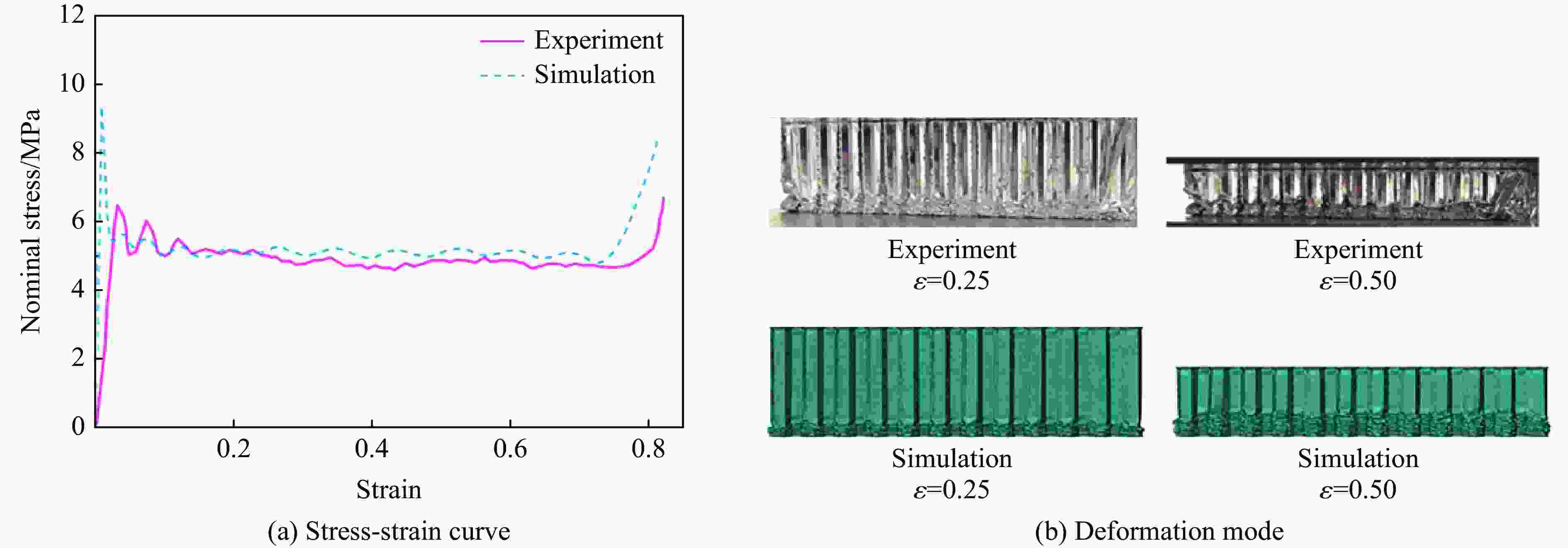

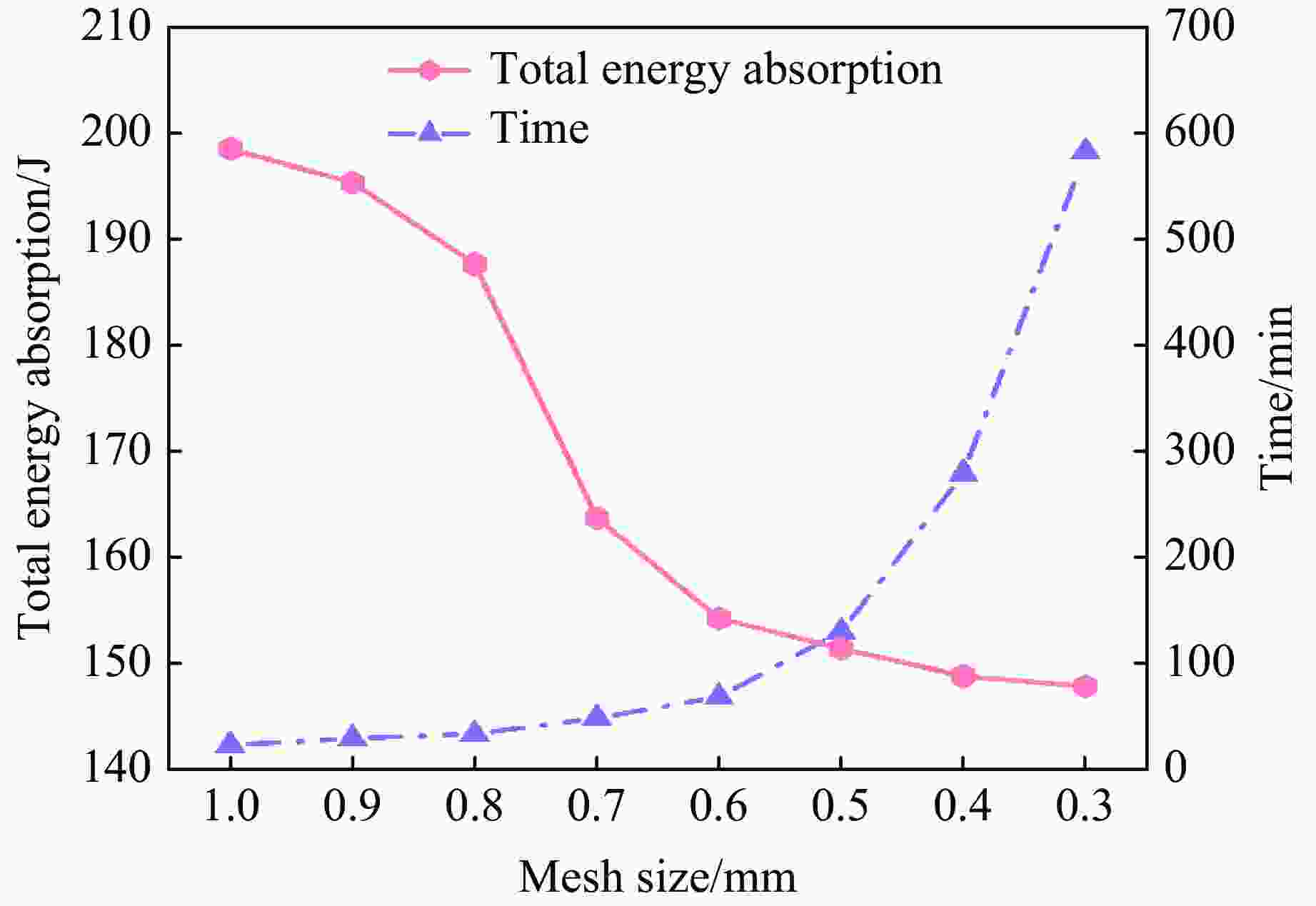

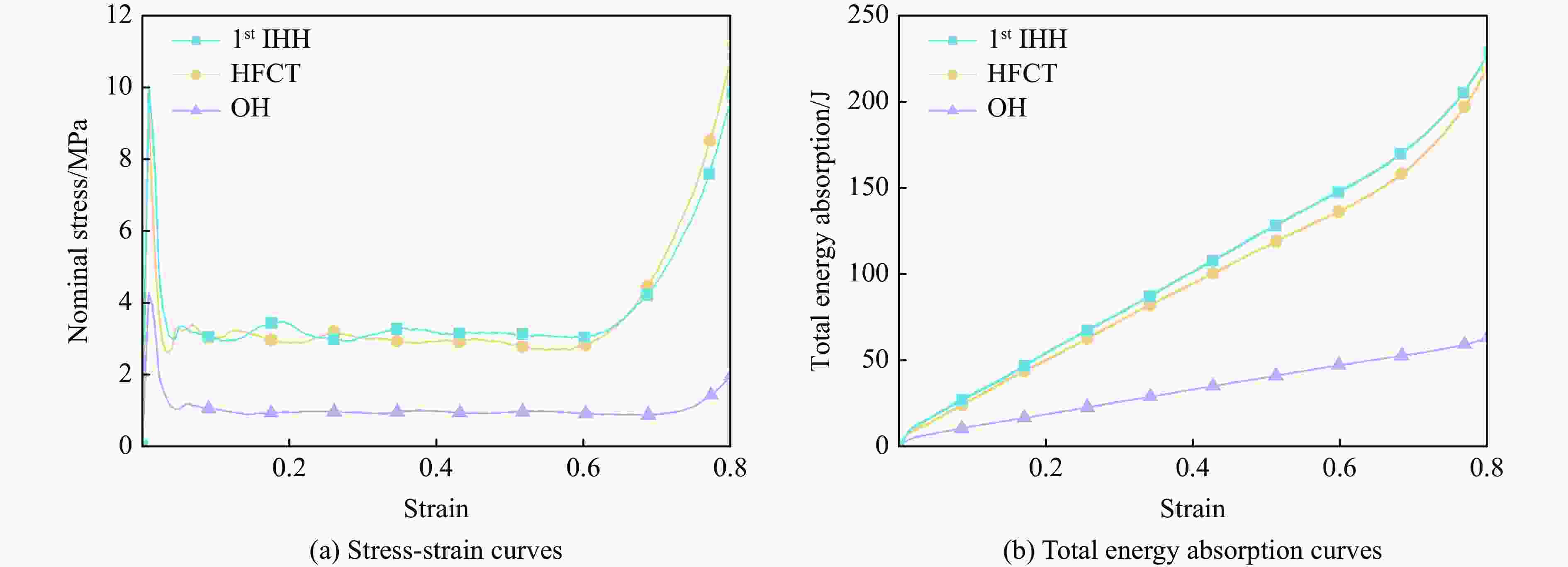

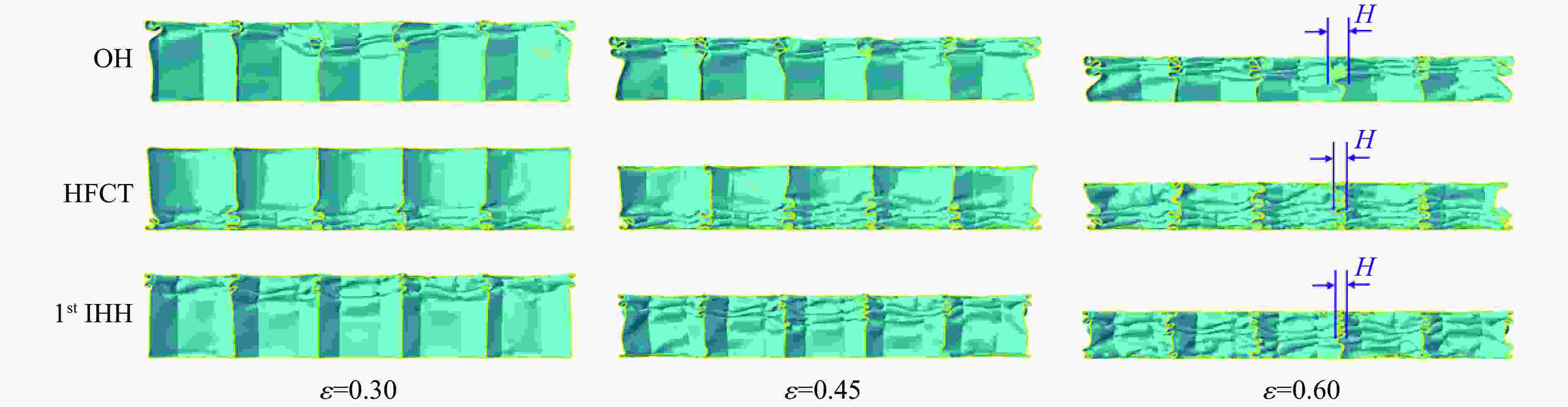

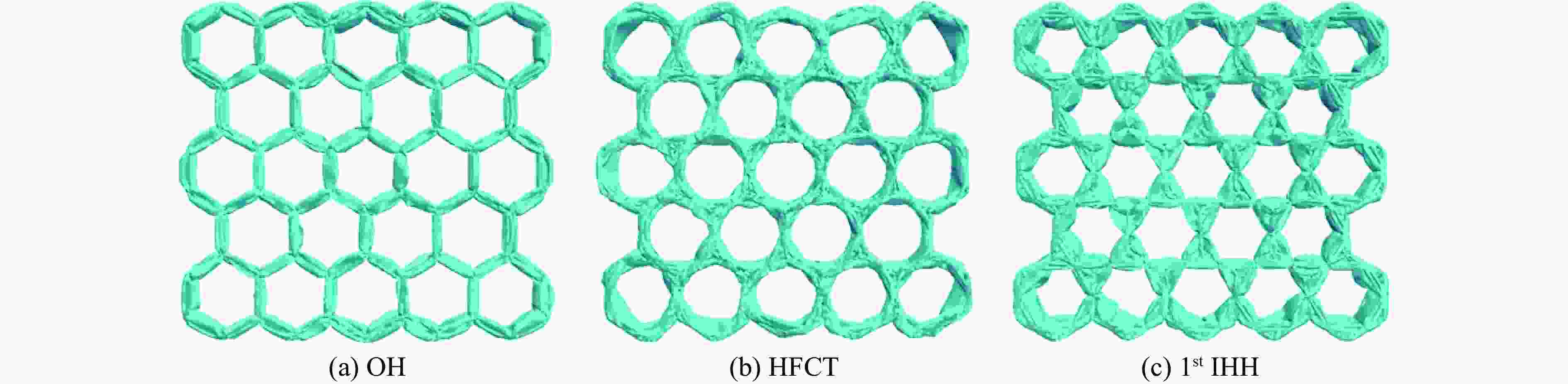

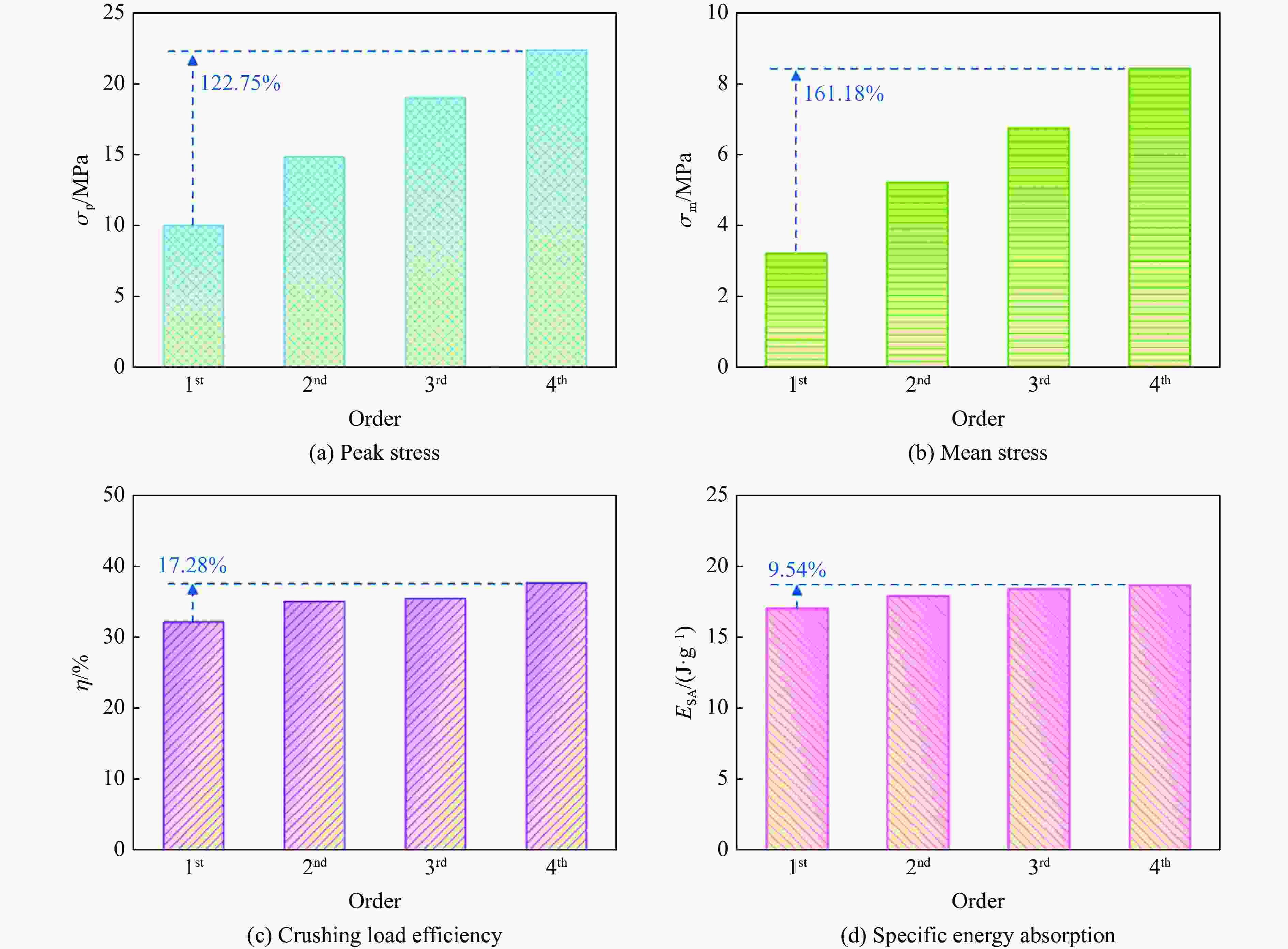

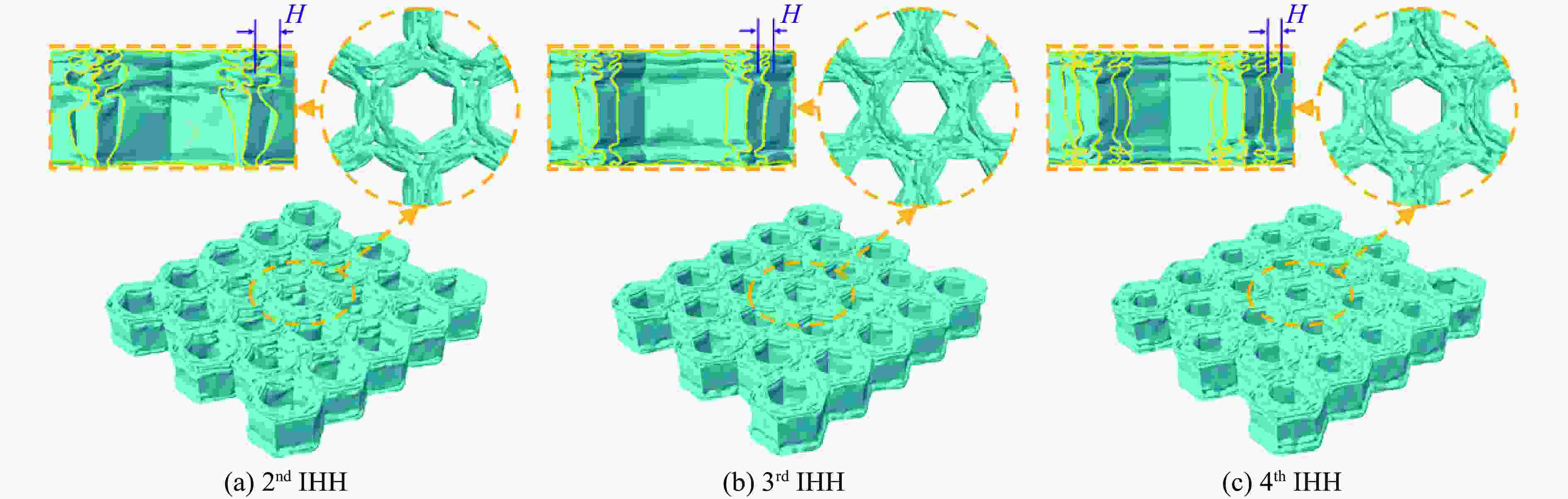

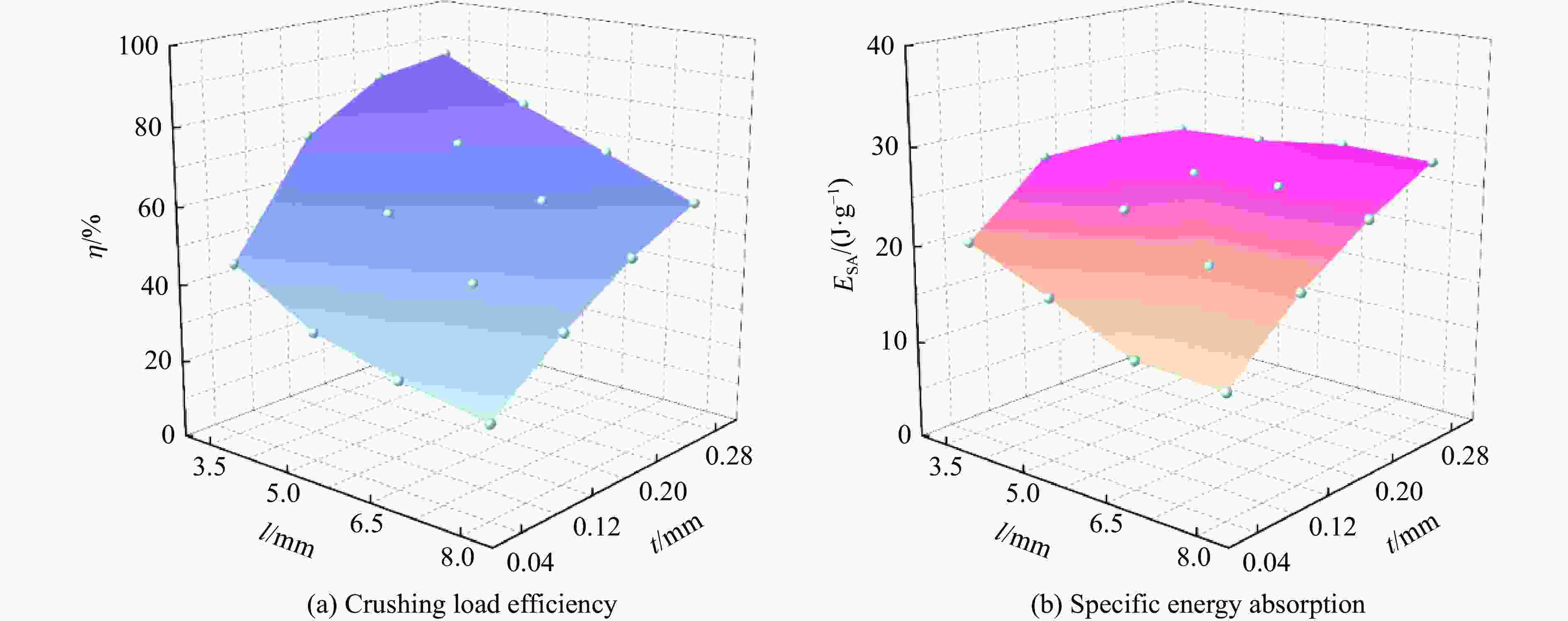

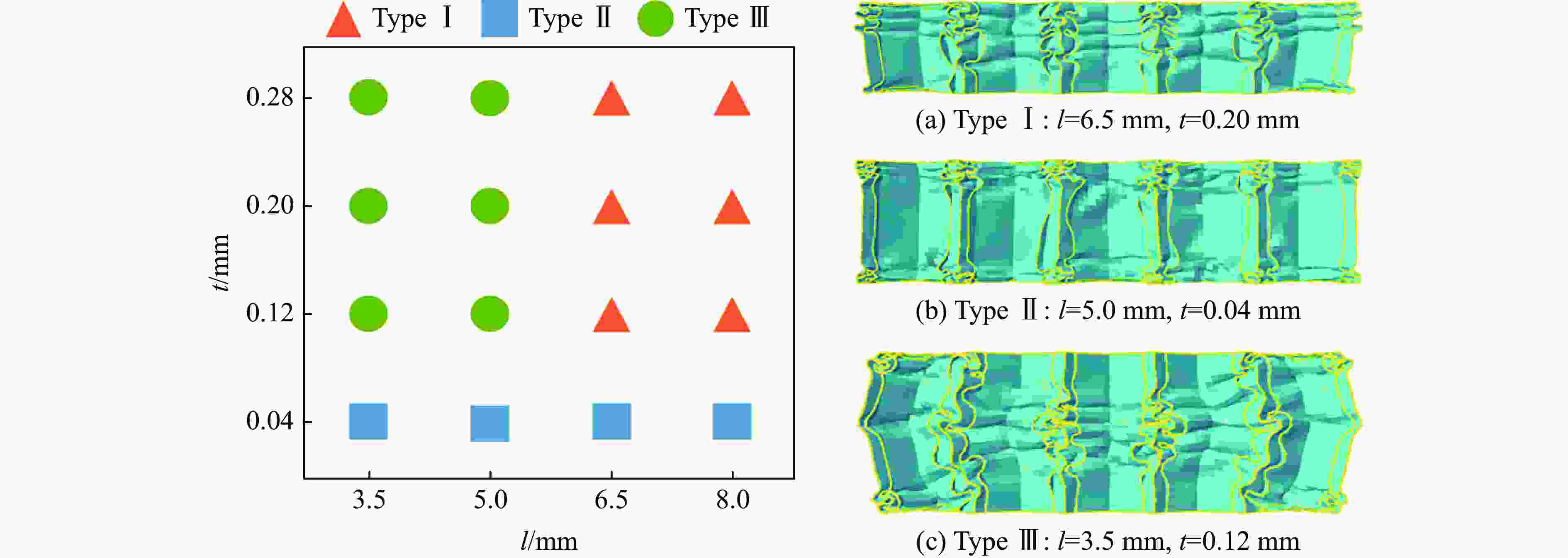

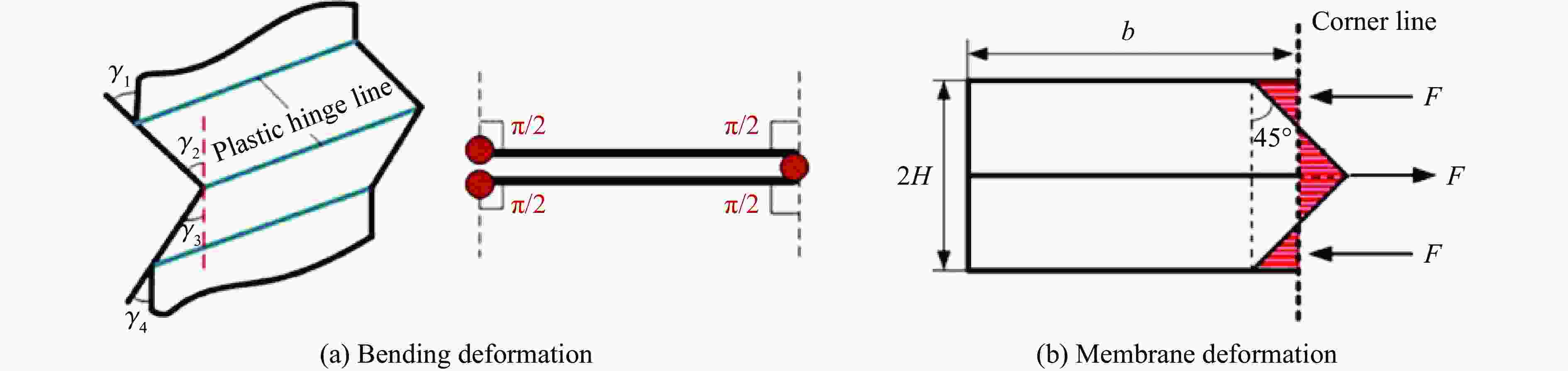

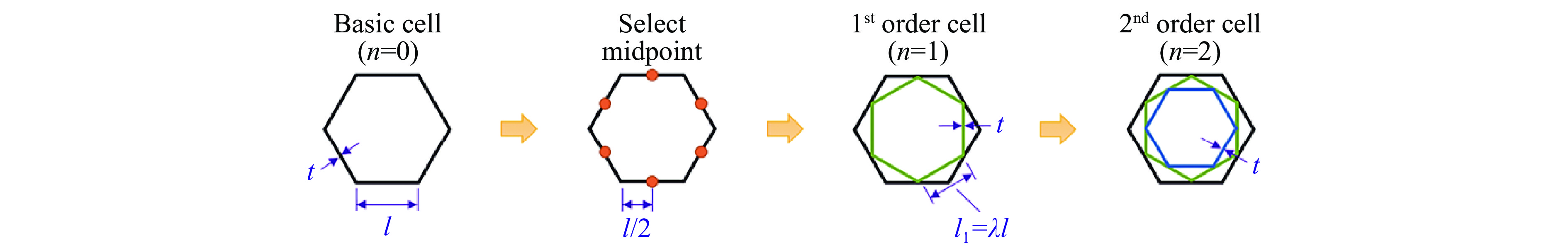

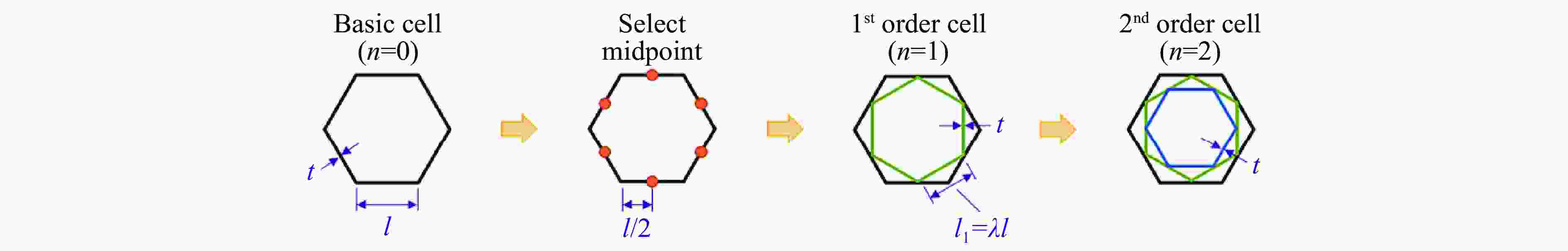

摘要: 结合几何学的胞元设计思路,提出了一种新型多胞结构—内旋层级类蜂窝(intorsion hierarchical honeycomb-like,IHH)结构,通过数值模拟方法对其面外力学性能和变形特征进行深入研究,并与普通蜂窝结构、填充圆管的蜂窝结构进行了比较。研究发现,采用内旋层级设计的多胞结构,其胞元内部产生了独特的约束效果,在多层级设计条件下,可以进一步加强这种约束效果,从而提高结构的力学性能。此外,通过开展参数化研究,以揭示相对密度变化对结构性能的影响;基于简化超级折叠单元理论,建立了内旋层级类蜂窝结构的理论模型。结果表明,内旋层级类蜂窝结构在渐进式折叠变形模式下表现出最佳的吸能效率,理论模型能够有效地预测内旋层级类蜂窝结构的平台应力。研究结果可为多胞结构性能优化设计提供指导。Abstract: In this study, a novel type of the intorsion hierarchical honeycomb-like (IHH) structures was proposed based on the cell geometrical design. The out-of-plane mechanical behaviors and deformation characteristics were studied by numerical simulation, and the results were compared with that of ordinary honeycomb (OH) structure as well as the honeycomb structure filled with circular tube (HFCT). It is found that the intorsion hierarchical design makes the constraint effect inside the cell. Through multi-order hierarchical design, the constraint effect can be further strengthened, so as to improve the mechanical behaviors. In addition, parametric studies were carried out to reveal the influence of the change of relative density on mechanical performance. Based on the simplified super folding element (SSFE) theory, a theoretical model of IHH was established. The results show that the proposed IHH exhibit the progressive folding deformation mode and attain the optimal energy absorption efficiency among all the competitors. The theoretical model can effectively predict the mean stress of IHH. The results in this study can provide guidance for the mechanical performance optimization of multi-cell structure.

-

表 1 3种多胞结构的相对密度

Table 1. Relative density of three multi-cell structures

Structures $ V $ ${V}{_{\mathrm{s} }}$ $ \Delta \rho $ OH $\dfrac{69\sqrt{3} }{2}{l}{^{2}}T$ $ 88ltT $ $\dfrac{176\,t}{69\sqrt{3}\,l}$ HFCT $\dfrac{69\sqrt{3} }{2}{l}{^{2}}T$ $(88+23\sqrt{3}\text{π})ltT$ $\left(\dfrac{176}{69\sqrt{3} }+\dfrac{2\text{π} }{3}\right)\dfrac{t}{l}$ IHH $\dfrac{69\sqrt{3} }{2}{l}{^{2}}T$ $\left(88+138\displaystyle\sum _{i=1}^{n}{\lambda }^{i}\right)ltT$ $\left(\dfrac{176}{69\sqrt{3} }+\dfrac{4}{\sqrt{3} }\displaystyle\sum _{i=1}^{n}{\lambda }^{i}\right)\dfrac{t}{l}$ 表 2 3种多胞结构的力学性能指标

Table 2. Mechanical properties of three multi-cell structures

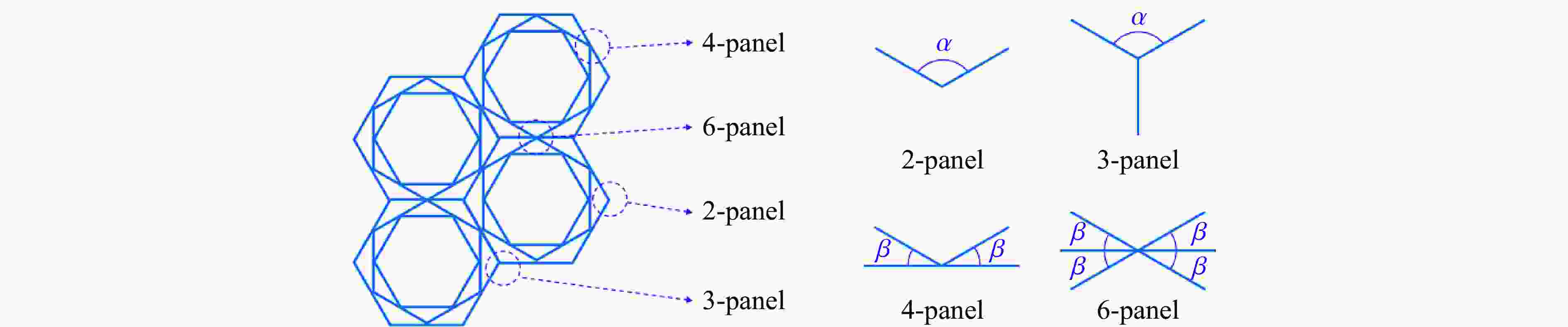

Structures $ \mathrm{\Delta }\rho $ ${E}{_{\mathrm{A} } }$/J ${E}{_{\mathrm{S}\mathrm{A} } }$/(J·g−1) ${\sigma }{_{\mathrm{p} } }$/MPa ${\sigma }{_{\mathrm{m} } }$/MPa $ \eta $/% OH 0.018 4 52.59 13.95 4.27 1.00 23.39 HFCT 0.044 6 133.21 14.57 9.42 2.98 31.66 1st IHH 0.043 4 151.45 17.02 10.04 3.22 32.06 表 3 角单元数量

Table 3. Number of various corner elements

Structure $ {N}_{1} $

(2-panel)$ {N}_{2} $

(3-panel)$ {N}_{3} $

(4-panel)$ {N}_{4} $

(6-panel)IHH 22 44 38+138(n–1) 50 -

[1] CHEN Z H, LIU L W, GAO S L, et al. Dynamic response of sandwich beam with star-shaped reentrant honeycomb core subjected to local impulsive loading [J]. Thin-Walled Structures, 2021, 161: 107420. doi: 10.1016/j.tws.2020.107420 [2] 于鹏山, 刘志芳, 李世强. 新型仿生蜂窝结构的设计与耐撞性能分析 [J]. 高压物理学报, 2022, 36(1): 014204.YU P S, LIU Z F, LI S Q. Design and crashworthiness analysis of new bionic honeycomb structure [J]. Chinese Journal of High Pressure Physics, 2022, 36(1): 014204. [3] LUO H, CHEN F, WANG X, et al. A novel two-layer honeycomb sandwich structure absorber with high-performance microwave absorption [J]. Composites Part A: Applied Science and Manufacturing, 2019, 119: 1–7. doi: 10.1016/j.compositesa.2019.01.015 [4] LI Z D, WANG Z G, WANG X X, et al. Bending behavior of sandwich beam with tailored hierarchical honeycomb cores [J]. Thin-Walled Structures, 2020, 157: 107001. doi: 10.1016/j.tws.2020.107001 [5] QI C, JIANG F, YANG S. Advanced honeycomb designs for improving mechanical properties: a review [J]. Composites Part B: Engineering, 2021, 227: 109393. doi: 10.1016/j.compositesb.2021.109393 [6] YIN H F, LIU Z P, DAI J L, et al. Crushing behavior and optimization of sheet-based 3D periodic cellular structures [J]. Composites Part B: Engineering, 2020, 182: 107565. doi: 10.1016/j.compositesb.2019.107565 [7] LIU J F, CHEN W S, HAO H, et al. Numerical study of low-speed impact response of sandwich panel with tube filled honeycomb core [J]. Composite Structures, 2019, 220: 736–748. doi: 10.1016/j.compstruct.2019.04.023 [8] WANG Z G, LI Z D, ZHOU W, et al. On the influence of structural defects for honeycomb structure [J]. Composites Part B: Engineering, 2018, 142: 183–192. doi: 10.1016/j.compositesb.2018.01.015 [9] WU Y Z, SUN L F, YANG P, et al. Energy absorption of additively manufactured functionally bi-graded thickness honeycombs subjected to axial loads [J]. Thin-Walled Structures, 2021, 164: 107810. doi: 10.1016/j.tws.2021.107810 [10] WANG X W, WEI K, TAO Y, et al. Thermal protection system integrating graded insulation materials and multilayer ceramic matrix composite cellular sandwich panels [J]. Composite Structures, 2019, 209: 523–534. doi: 10.1016/j.compstruct.2018.11.004 [11] LIU J F, CHEN W S, HAO H, et al. In-plane crushing behaviors of hexagonal honeycombs with different Poisson’s ratio induced by topological diversity [J]. Thin-Walled Structures, 2021, 159: 107223. doi: 10.1016/j.tws.2020.107223 [12] WIERZBICKI T. Crushing analysis of metal honeycombs [J]. International Journal of Impact Engineering, 1983, 1(2): 157–174. doi: 10.1016/0734-743X(83)90004-0 [13] TRAN T N, HOU S J, HAN X, et al. Theoretical prediction and crashworthiness optimization of multi-cell triangular tubes [J]. Thin-Walled Structures, 2014, 82: 183–195. doi: 10.1016/j.tws.2014.03.019 [14] TRAN T N, HOU S, HAN X, et al. Crushing analysis and numerical optimization of angle element structures under axial impact loading [J]. Composite Structures, 2015, 119: 422–435. doi: 10.1016/j.compstruct.2014.09.019 [15] PEHLIVAN L, BAYKASOĞLU C. An experimental study on the compressive response of CFRP honeycombs with various cell configurations [J]. Composites Part B: Engineering, 2019, 162: 653–661. doi: 10.1016/j.compositesb.2019.01.044 [16] SAN HA N, LU G X. A review of recent research on bio-inspired structures and materials for energy absorption applications [J]. Composites Part B: Engineering, 2020, 181: 107496. doi: 10.1016/j.compositesb.2019.107496 [17] ZHANG Y, HE N, SONG X Y, et al. On impacting mechanical behaviors of side fractal structures [J]. Thin-Walled Structures, 2020, 146: 106490. doi: 10.1016/j.tws.2019.106490 [18] HUANG W Z, ZHANG Y, XU Y L, et al. Out-of-plane mechanical design of bi-directional hierarchical honeycombs [J]. Composites Part B: Engineering, 2021, 221: 109012. doi: 10.1016/j.compositesb.2021.109012 [19] LI Z D, SHEN L M, WEI K, et al. Compressive behaviors of fractal-like honeycombs with different array configurations under low velocity impact loading [J]. Thin-Walled Structures, 2021, 163: 107759. doi: 10.1016/j.tws.2021.107759 [20] WANG Z G, LIU J F. Numerical and theoretical analysis of honeycomb structure filled with circular aluminum tubes subjected to axial compression [J]. Composites Part B: Engineering, 2019, 165: 626–635. doi: 10.1016/j.compositesb.2019.01.070 [21] WANG Z G, LIU J F. Mechanical performance of honeycomb filled with circular CFRP tubes [J]. Composites Part B: Engineering, 2018, 135: 232–241. doi: 10.1016/j.compositesb.2017.09.048 [22] PIETRAS D, LINUL E, SADOWSKI T, et al. Out-of-plane crushing response of aluminum honeycombs in-situ filled with graphene-reinforced polyurethane foam [J]. Composite Structures, 2020, 249: 112548. doi: 10.1016/j.compstruct.2020.112548 [23] WANG Z G, LIU J F, HUI D. Mechanical behaviors of inclined cell honeycomb structure subjected to compression [J]. Composites Part B: Engineering, 2017, 110: 307–314. doi: 10.1016/j.compositesb.2016.10.062 [24] ZHANG Y, CHEN T T, XU X, et al. Out-of-plane mechanical behaviors of a side hierarchical honeycomb [J]. Mechanics of Materials, 2020, 140: 103227. doi: 10.1016/j.mechmat.2019.103227 [25] WANG Z G, ZHANG J, LI Z D, et al. On the crashworthiness of bio-inspired hexagonal prismatic tubes under axial compression [J]. International Journal of Mechanical Sciences, 2020, 186: 105893. doi: 10.1016/j.ijmecsci.2020.105893 [26] ZHANG D H, FEI Q G, JIANG D, et al. Numerical and analytical investigation on crushing of fractal-like honeycombs with self-similar hierarchy [J]. Composite Structures, 2018, 192: 289–299. doi: 10.1016/j.compstruct.2018.02.082 -

下载:

下载: