Numerical Simulation of Crack Propagation and Damage Behavior of Glass Plates under Impact Loading

-

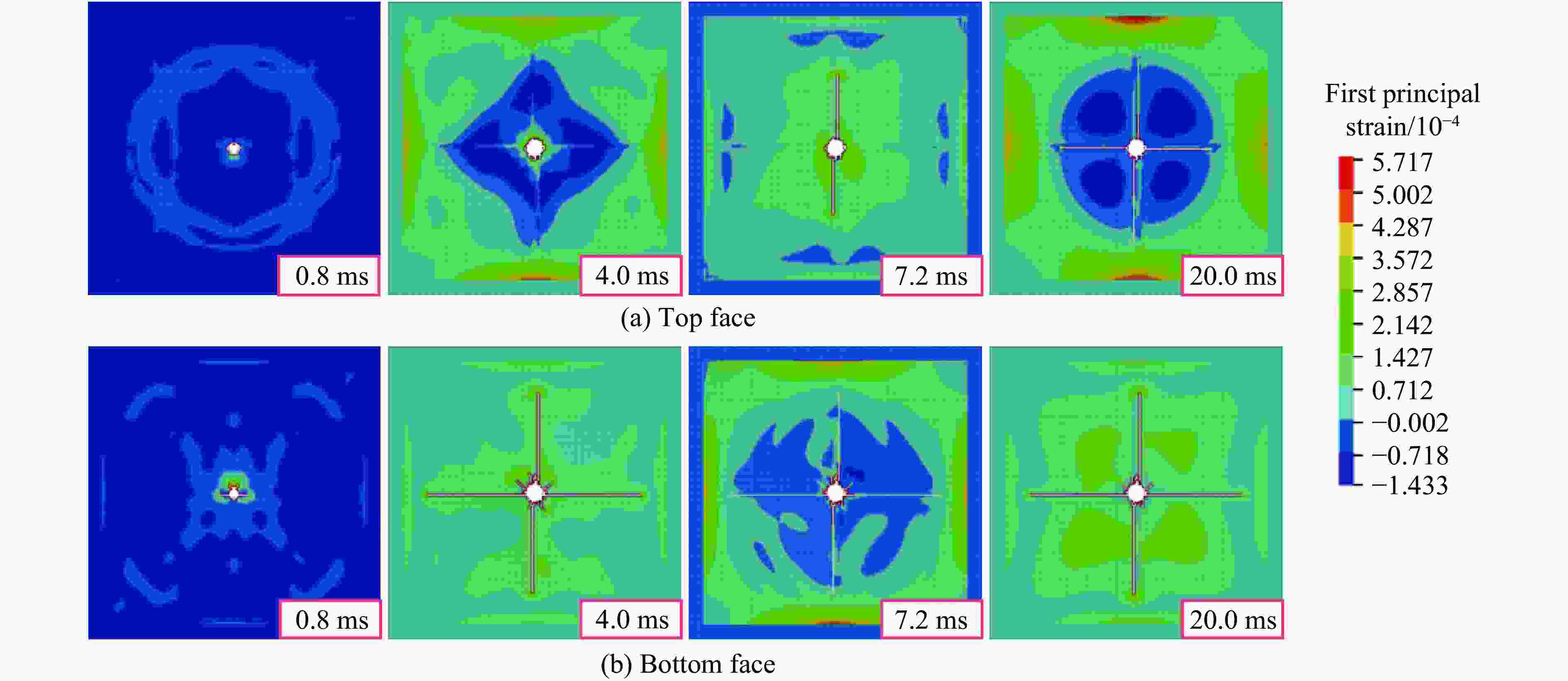

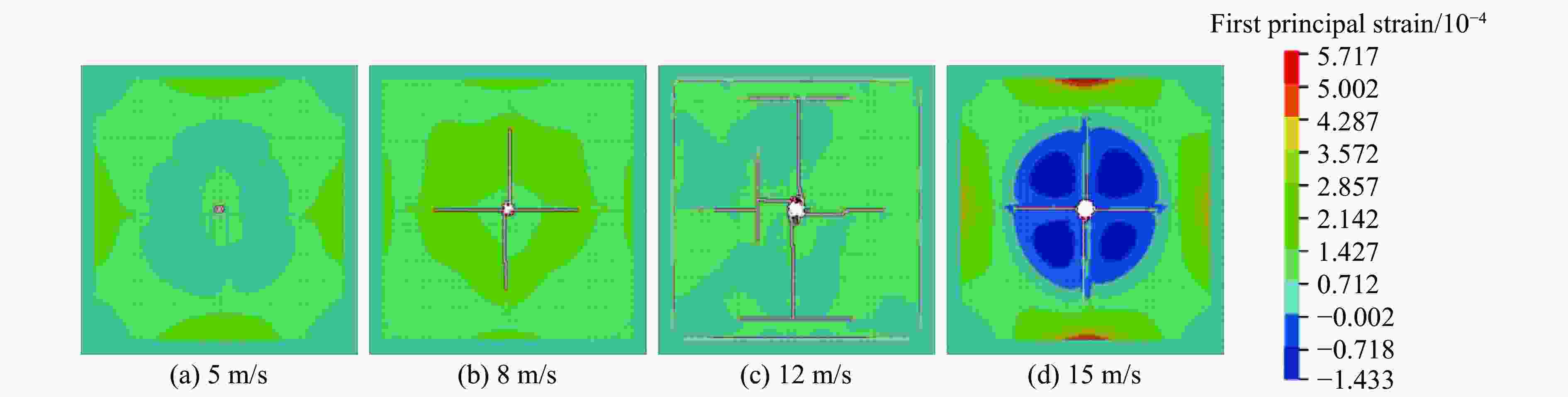

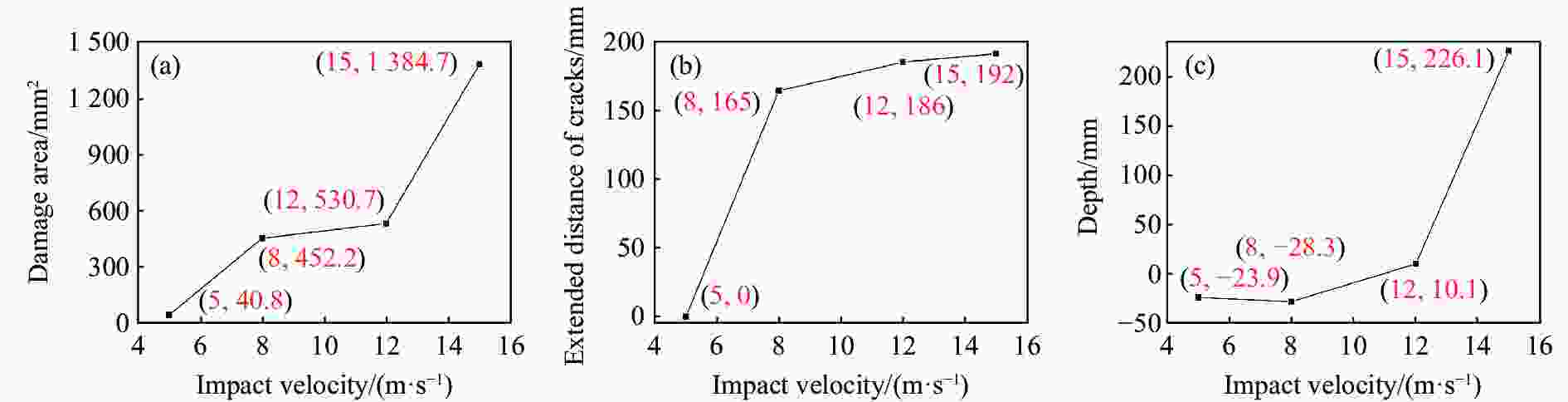

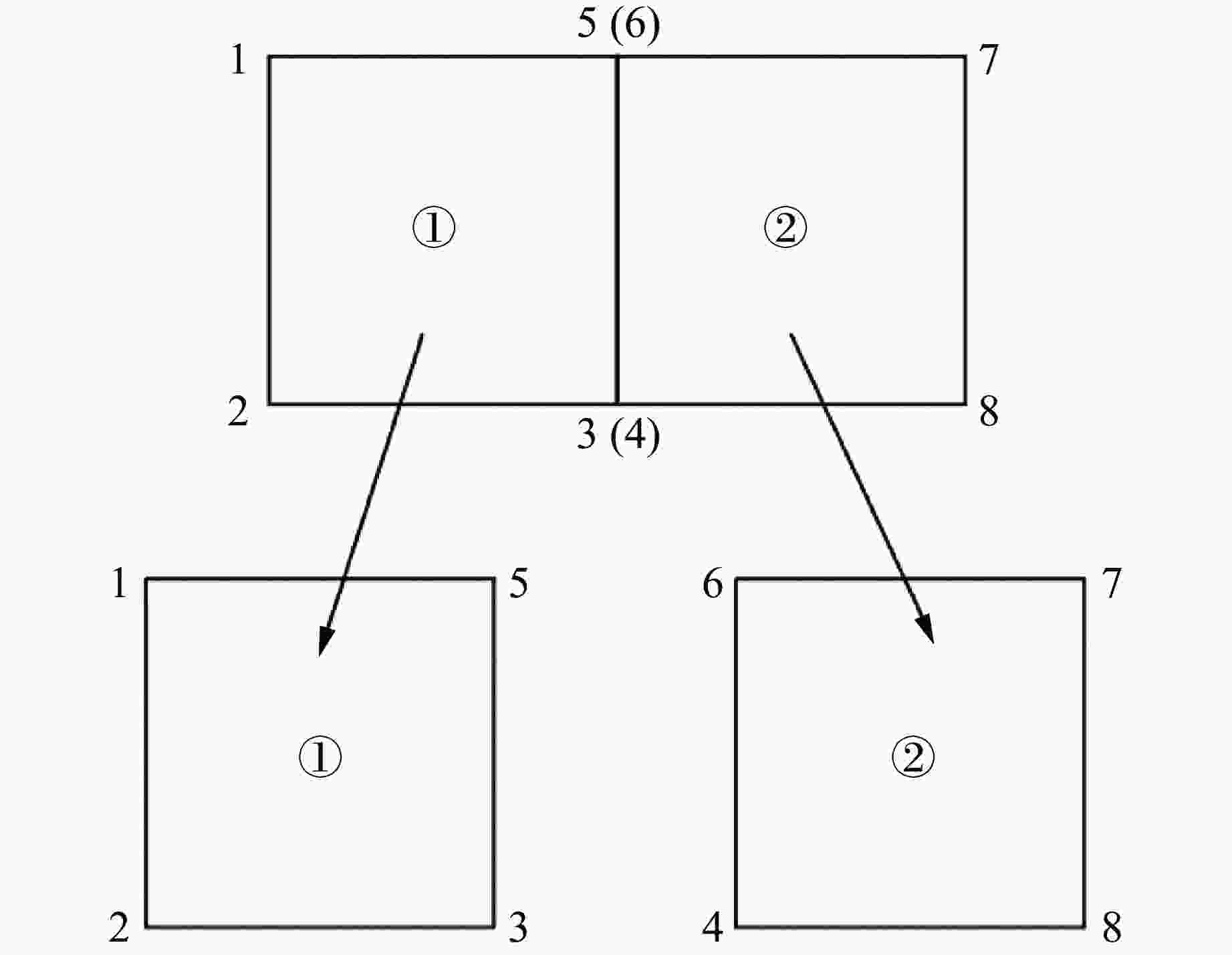

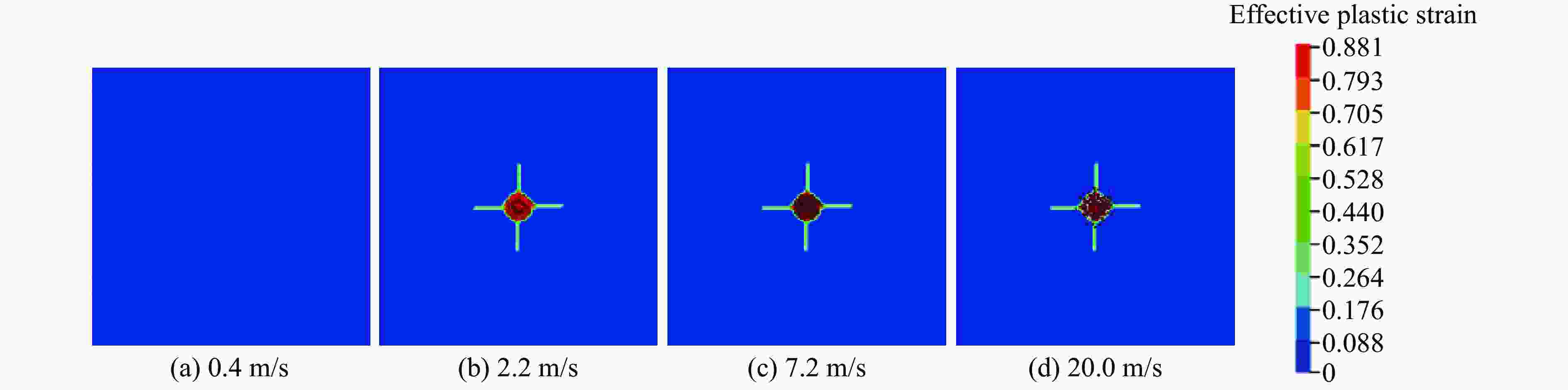

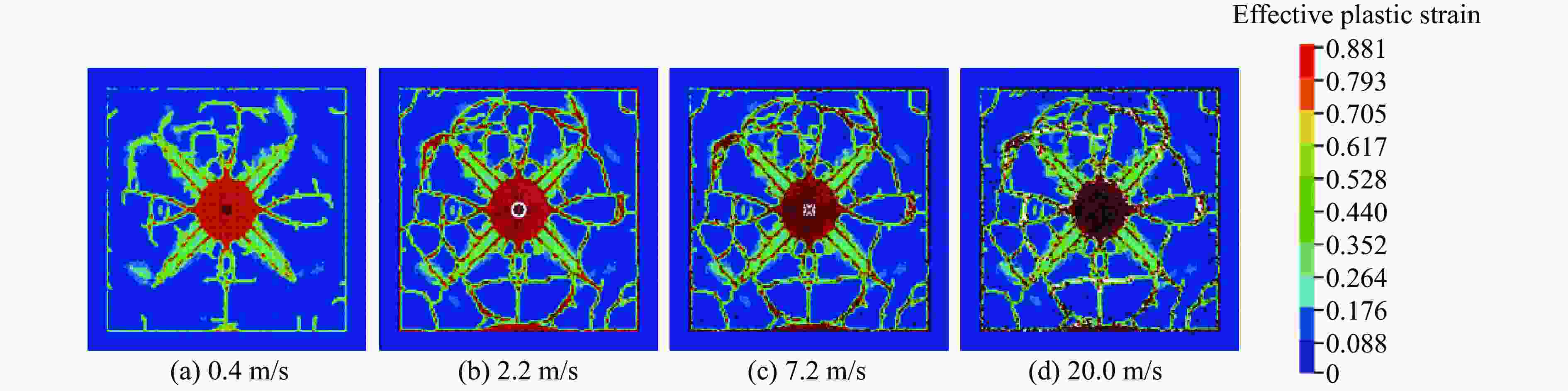

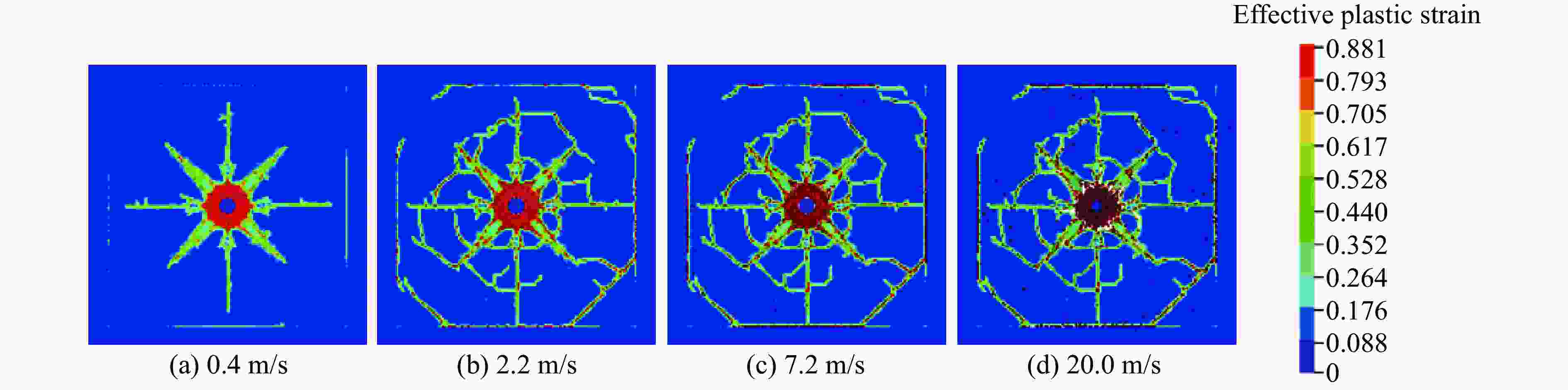

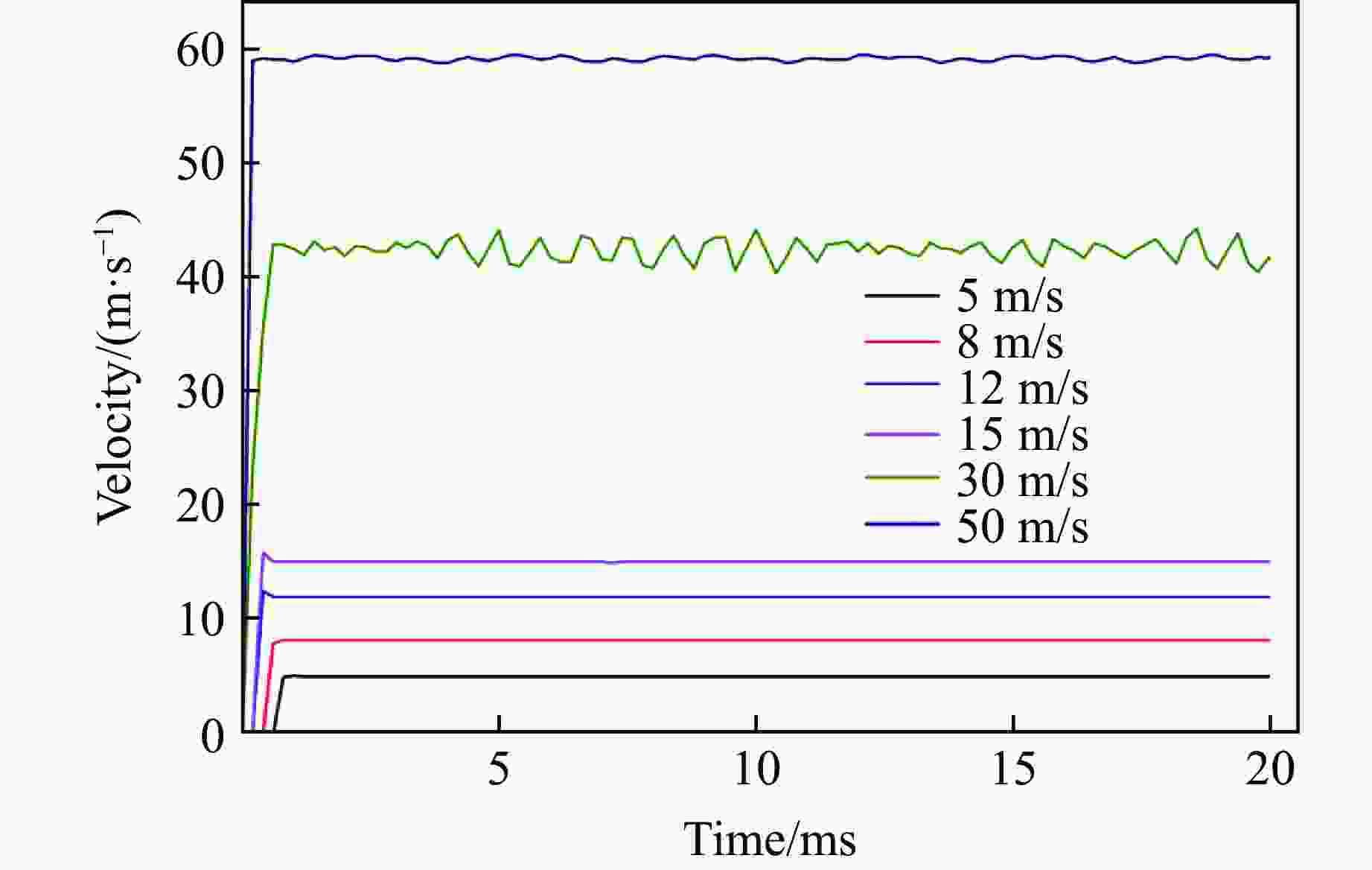

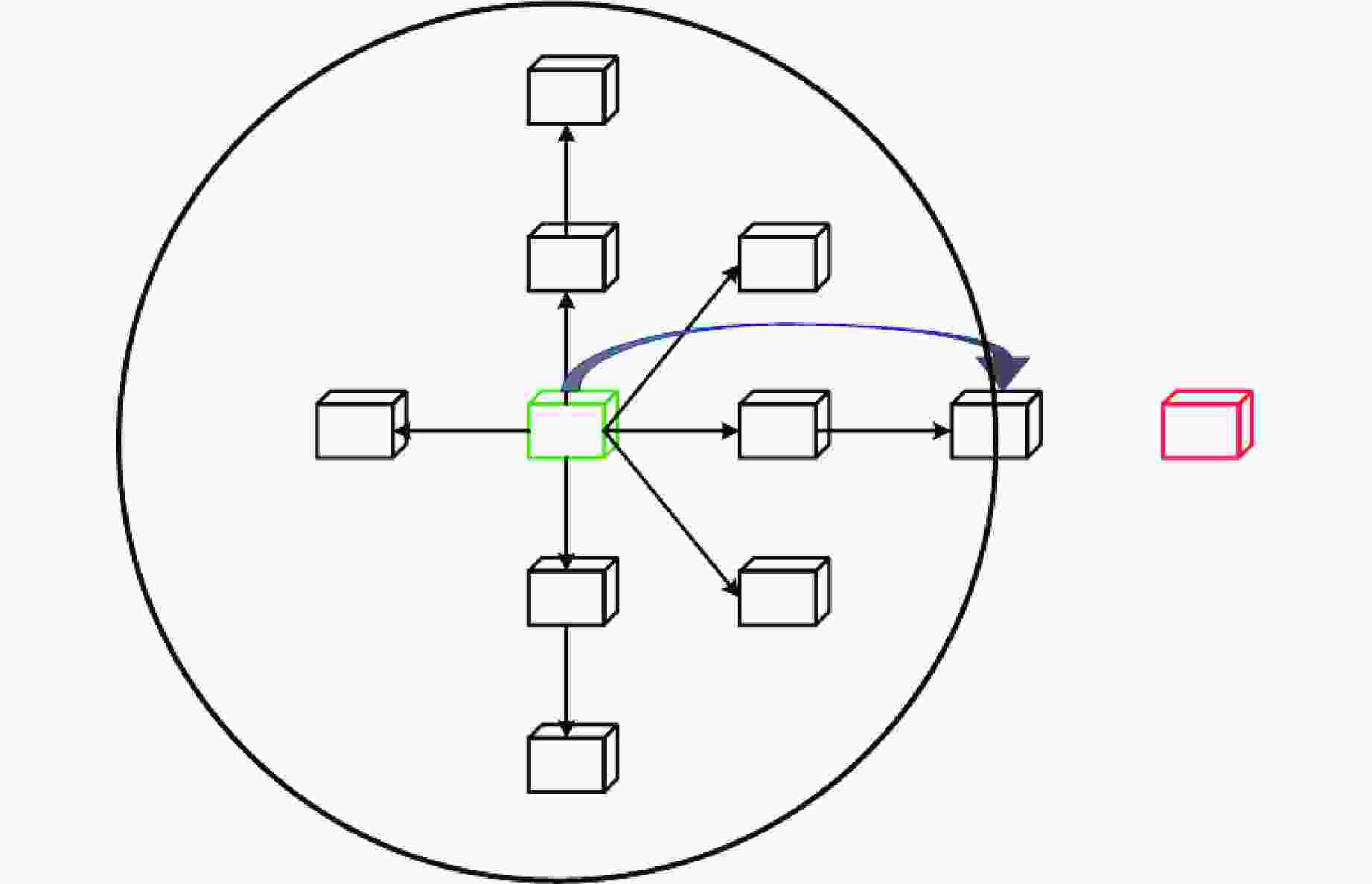

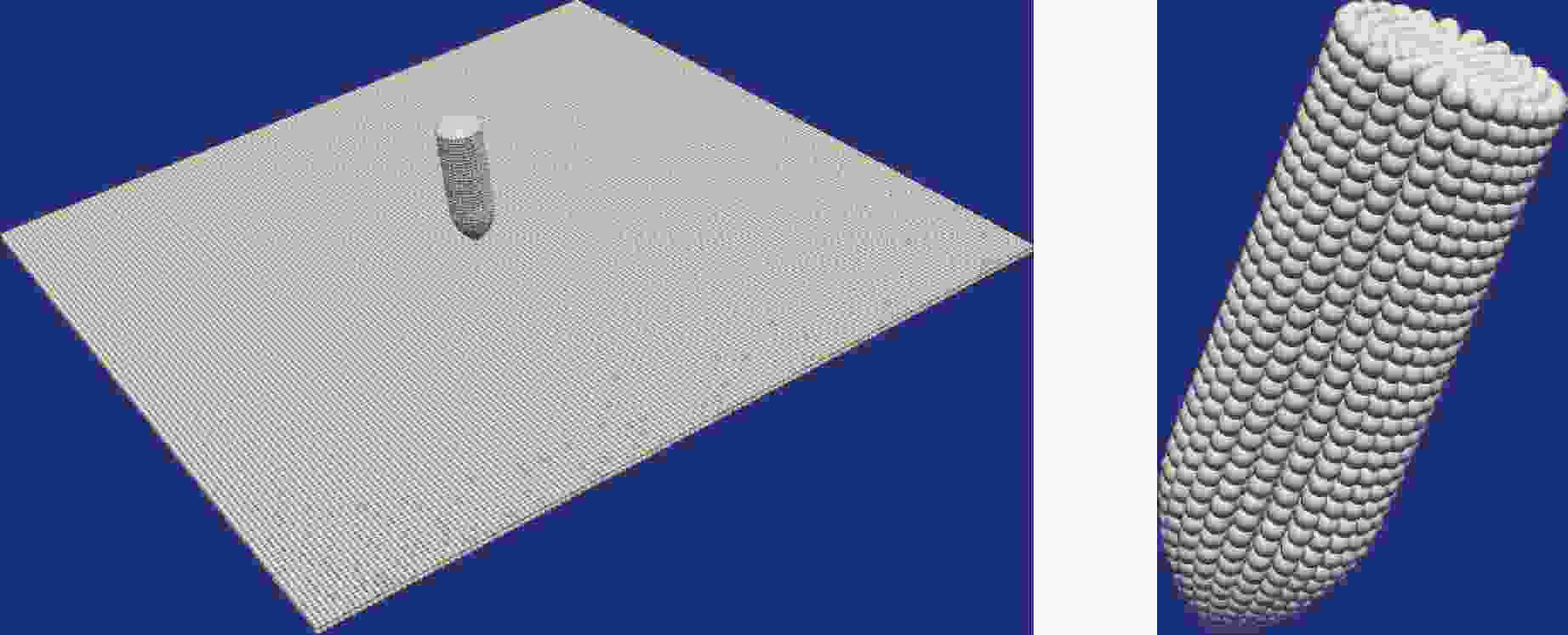

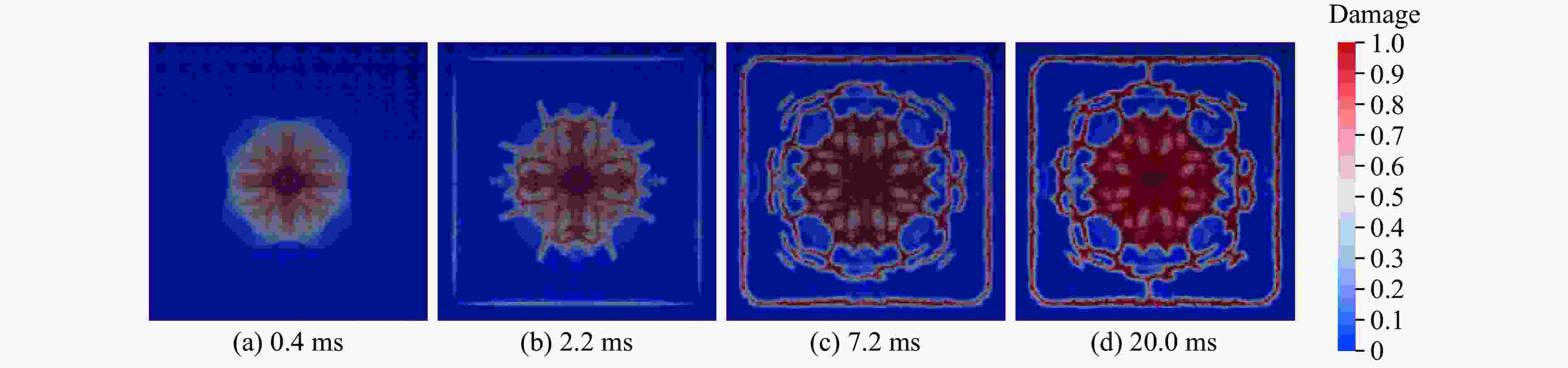

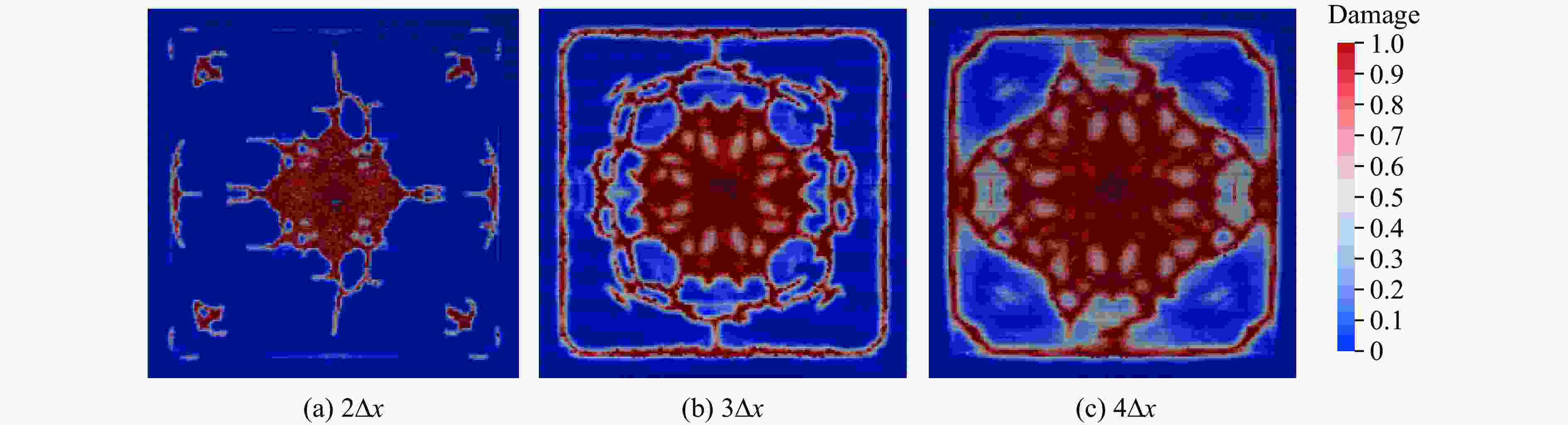

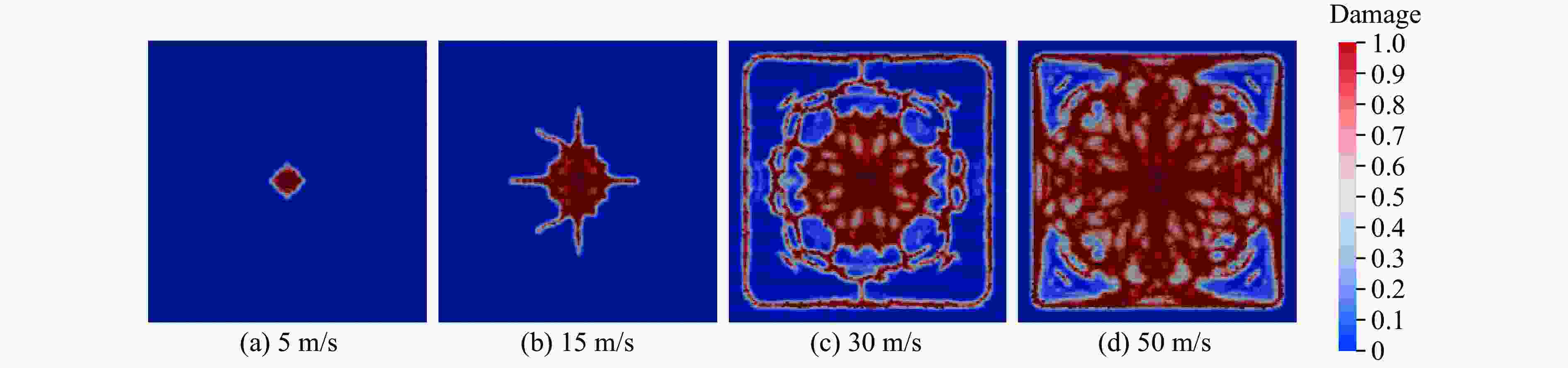

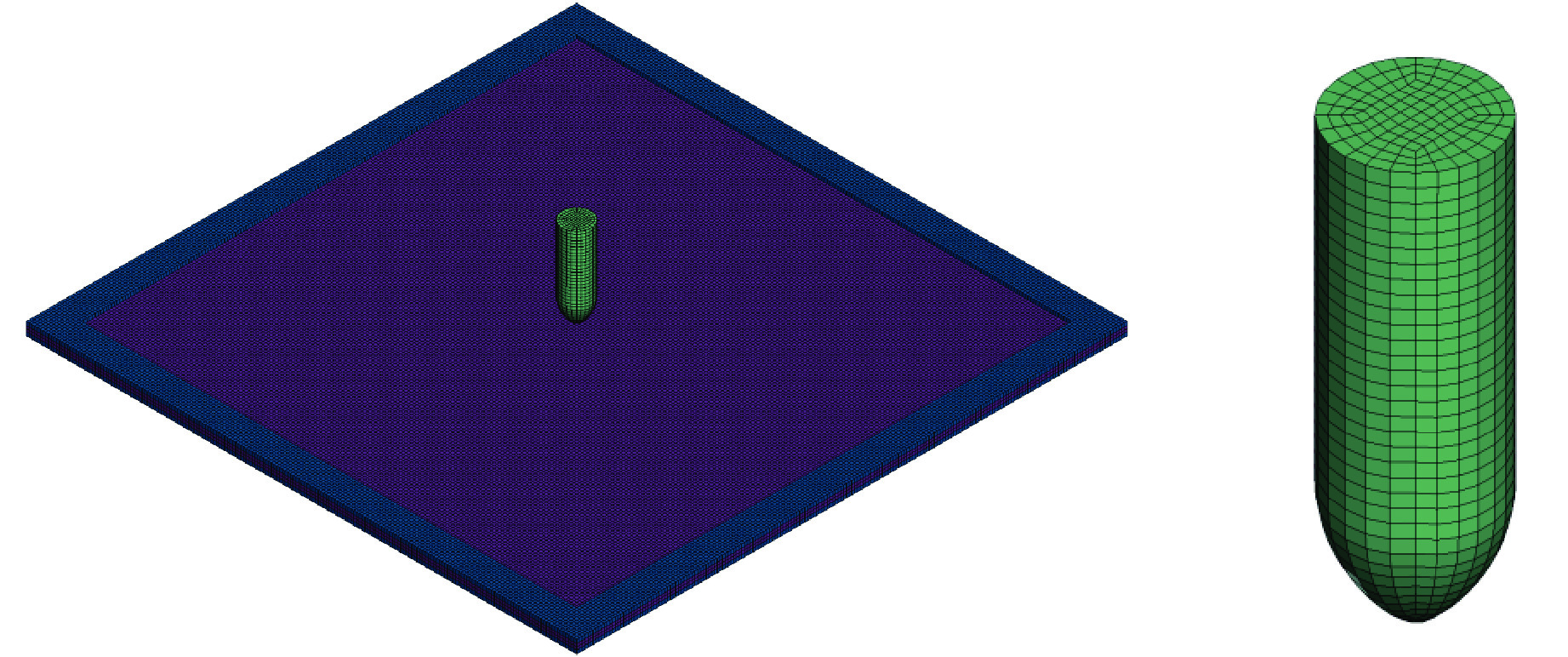

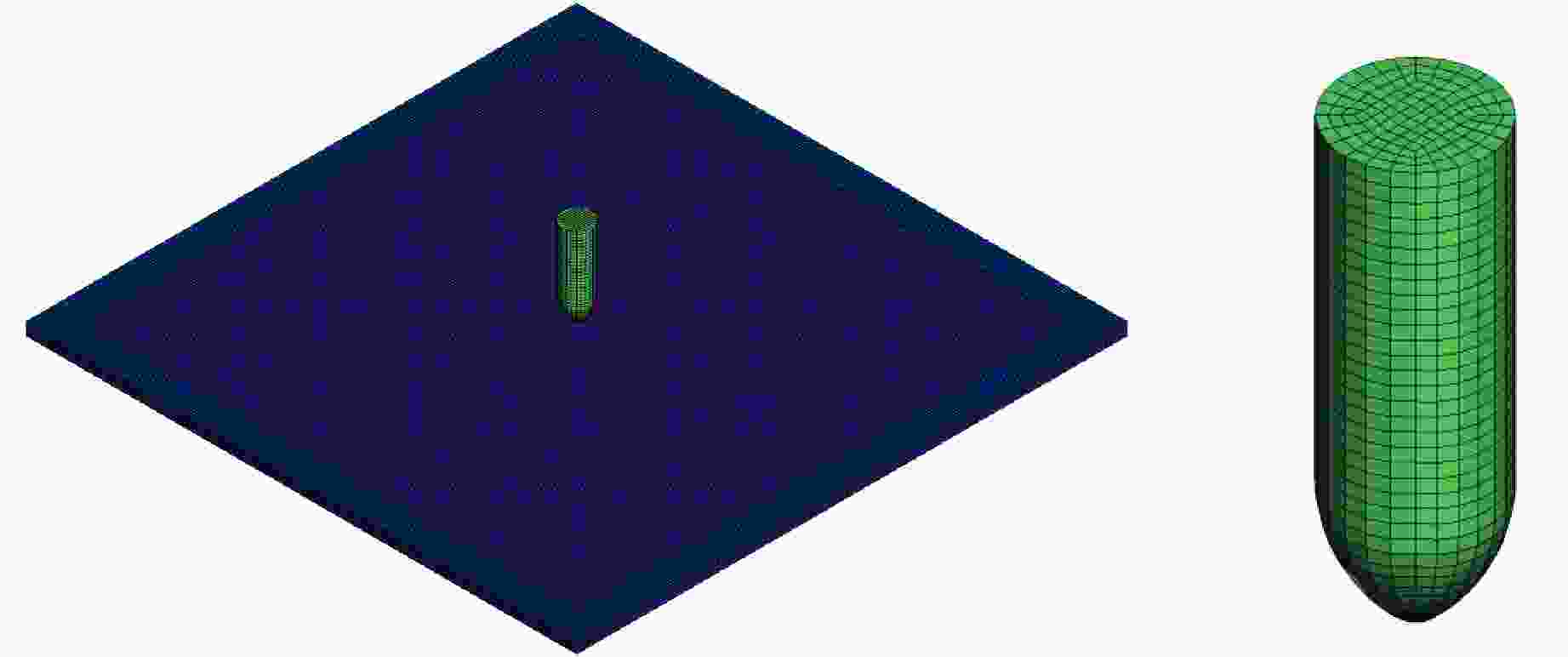

摘要: 裂纹的萌生和扩展是计算力学领域长期存在的难点和热点,也是玻璃、岩石、混凝土等脆性材料中常见的工程实际问题。为了探究冲击载荷下平板钠钙玻璃的损伤破坏行为和细观裂纹扩展规律,分别采用单元删除法、不连续伽辽金近场动力学法(discontinuous Galerkin peridynamic, DG-PD)和无网格粒子近场动力学法(meshless peridynamic, M-PD),研究其裂纹扩展行为。单元删除法采用JH-2材料模型,同时添加最大主应力和最大主应变失效准则;DG-PD法采用节点分离操作,并施加临界能量释放率准则;M-PD法采用自编程序粒子离散方法,选择合适的计算域,并施加临界伸长率准则。模拟结果表明:(1) 单元删除法可大致模拟出玻璃在冲击载荷下的损伤形貌,但在捕捉裂纹分叉和贯通等方面略显不足,未见玻璃碎片的飞溅,无法通过碎片飞溅速度评估其安全性能;(2) DG-PD法中环状裂纹和径向裂纹明显,裂纹具有很高的对称性,冲击点和边框处有大量玻璃碎片飞溅;(3) M-PD法中能捕捉到径向裂纹和环向裂纹,且裂纹的对称性较好,近场域和冲击速度对平板玻璃的动态响应有着重要的影响,就损伤形态而言,M-PD法和DG-PD法具有很高的一致性。Abstract: Crack initiation and propagation is a long-standing difficult problem in solid mechanics, especially for elastic-brittle material. To explore the damage and crack propagation behavior of glass plates under impact loading, the element deletion, discontinuous Galerkin peridynamic (DG-PD), and meshless peridynamic (M-PD) methods are used to conduct numerical simulations, respectively. The JH-2 material model, and the maximum principal stress and maximum principal strain failure criteria are adopted in the element deletion method. The node separation operation and the critical energy release rate criterion are used in the DG-PD method. In the M-PD method, a self-programmed particle discretization method is utilized along with an appropriate computational domain, and a critical elongation criterion is imposed. The simulation results show that: (1) the element deletion method can roughly simulate the damage morphology of glass under impact loading, but it is insufficient in capturing crack bifurcation and penetration. (2) In the DG-PD method, circumferential cracks and radial cracks are observed, and the cracks are of high symmetry. In addition, there are a lot of glass fragments splashing at the impact point and the frame. (3) Radial cracks and circumferential cracks can be captured in the M-PD method, and the symmetry of the cracks is good. The size of horizon and the impact velocity show great influence on the dynamic responses of the glass plates. As far as the damage form is concerned, the M-PD method and the DG-PD method yield consistent results.

-

Key words:

- impact loading /

- glass plates /

- crack propagation /

- element deletion method /

- peridynamic /

- meshless method

-

$ \;\rho $/(kg·m−3) G/GPa A B C M N $ \dot{\varepsilon }_{\rm s} $ T/GPa 2530 24 0.93 0.2 0.003 1 0.77 1 0.05042 σf,max σe/GPa pHEL/GPa β D1 D2 k1/GPa k2/GPa k3/GPa 0.5 5.95 2.92 1 0.043 0.85 45.4 −138 290 表 2 边框和弹头刚体材料模型参数

Table 2. Rigid body material model parameters of frame and bullet

$ \,\rho $/(kg·m−3) $\,\nu$ E/GPa 7850 0.28 200 表 3 玻璃材料DG-PD材料模型参数

Table 3. DG-PD material model parameters of glass material

$ \,\rho $/(kg·m−3) E/GPa Gt/(J·m−2) HSFAC 2530 72 15.47 0.8 表 4 玻璃材料M-PD材料模型参数

Table 4. M-PD model parameters of glass

$ \,\rho $/(kg·m−3) E/GPa G/GPa S0 $ \Delta x $/mm $ \delta $/mm 2530 72 24 $ 7.17\times 1{0}^{-5} $ 3 9.03 -

[1] KRAUTHAMMER T, ALTENBERG A. Negative phase blast effects on glass panels [J]. International Journal of Impact Engineering, 2000, 24: 1–17. doi: 10.1016/S0734-743X(99)00043-3 [2] YUAN Y, TAN P J, LI Y B. Dynamic structural response of laminated glass panels to blast loading [J]. Composite Structure, 2017, 182: 579–589. doi: 10.1016/j.compstruct.2017.09.028 [3] HOLMQUIST T J, JOHNSON G R, LOPATIN C M, et al. High strain rate properties and constitutive modeling of glass: SAND 95-0379C [R]. Albuquerque, NM: Sandia National Laboratories, 1995. [4] DARYADEL S S, MANTENA P R, KIM K, et al. Dynamic response of glass under low-velocity impact and high strain-rate SHPB compression loading [J]. Journal of Non-Crystalline Solids, 2016, 432B: 432–439. [5] 张晓颖, 李胜杰, 李志强. 爆炸载荷作用下夹层玻璃动态响应的数值模拟 [J]. 兵工学报, 2018, 39(7): 1379–1388. doi: 10.3969/j.issn.1000-1093.2018.07.016ZHANG X Y, LI S J, LI Z Q. Numerical simulation of dynamic response of laminated glass subjected to blast load [J]. Acta Armamentarii, 2018, 39(7): 1379–1388. doi: 10.3969/j.issn.1000-1093.2018.07.016 [6] 唐剑. 冲击荷载下建筑玻璃裂纹扩展及破碎的试验与数值模拟研究 [D]. 天津: 天津大学, 2018. [7] DAUX C, MOES N, DOLBOW J, et al. Arbitrary branched and intersecting cracks with the extended finite element method [J]. International Journal for Numerical Methods in Engineering, 2000, 48(12): 1741−1760. [8] SILLING S A. Reformulation of elasticity theory for discontinuities and long-range forces [J]. Journal of Mechanics Physics of Solids, 2000, 48(1): 175–209. doi: 10.1016/S0022-5096(99)00029-0 [9] 徐泳, 孙其诚, 张凌, 等. 颗粒离散元法研究进展 [J]. 力学进展, 2003, 33(2): 251–260. doi: 10.3321/j.issn:1000-0992.2003.02.010XU Y, SUN Q C, ZHANG L, et al. Advances in discrete element methods for particulate materials [J]. Advances in Mechanics, 2003, 33(2): 251–260. doi: 10.3321/j.issn:1000-0992.2003.02.010 [10] 张锁春. 光滑质点流体动力学(SPH)方法(综述) [J]. 计算物理, 1996, 13(4): 2–14.ZHANG S C. Smoothed particle hydrodynamics (SPH) method (a review) [J]. Chinese Journal of Computation Physics, 1996, 13(4): 2–14. [11] SUN X, LIU W. Modeling and characterization of dynamic failure of borosilicate glass under compression/shear loading [J]. International Journal of Impact Engineering, 2009, 36(2): 226–234. doi: 10.1016/j.ijimpeng.2008.01.014 [12] NIE X, CHEN W. Dynamic failure of borosilicate glass under compression/shear loading experiments [J]. Journal of the American Ceramic Society, 2007, 90(8): 2556–2562. doi: 10.1111/j.1551-2916.2007.01819.x [13] ZANG M, CHEN H, LEI Z. Simulation on high velocity impact process of windshield by sph/fem coupling method [C]//2010 WASE International Conference on Information Engineering. Institute of Electrical and Electronics Engineers, 2010: 381–384. [14] DENG R B, JIN X L. Numerical simulation for blast analysis of insulating glass in a curtain wall [J]. International Journal for Computational Methods in Engineering Science and Mechanics, 2010, 11(3): 162–171. doi: 10.1080/15502281003702302 [15] BOBARU F, HA Y D, HU W K, et al. Damage progression from impact in layered glass modeled with peridynamics [J]. Central European Journal of Engineering, 2012, 2(4): 551–561. [16] BLESS S, CHEN T. Impact damage in layered glass [J]. International Journal of Fracture, 2010, 162(1/2): 151–158. doi: 10.1007/s10704-009-9379-7 [17] REN B, WU C T, SELESON P, et al. A peridynamic failure analysis of fiber-reinforced composite laminates using finite element discontinuous Galerkin approximations [J]. International Journal of Fracture, 2018, 214: 49–68. doi: https://doi.org/10.1007/s10704-018-0317-4 [18] 师燕超, 于海涛, 李忠献. 爆炸荷载作用下建筑玻璃的破碎分析 [J]. 天津大学学报(自然科学与工程技术版), 2015, 48(10): 888–893. doi: 10.11784/tdxbz201411025SHI Y C, YU H T, LI Z X. Analysis of architecture glass breaking under explosion load [J]. Journal of Tianjin University (Science and Technology), 2015, 48(10): 888–893. doi: 10.11784/tdxbz201411025 -

下载:

下载: