Dynamic Model of Clamped Elastoplastic Circular Plate under Air Blast Loading

-

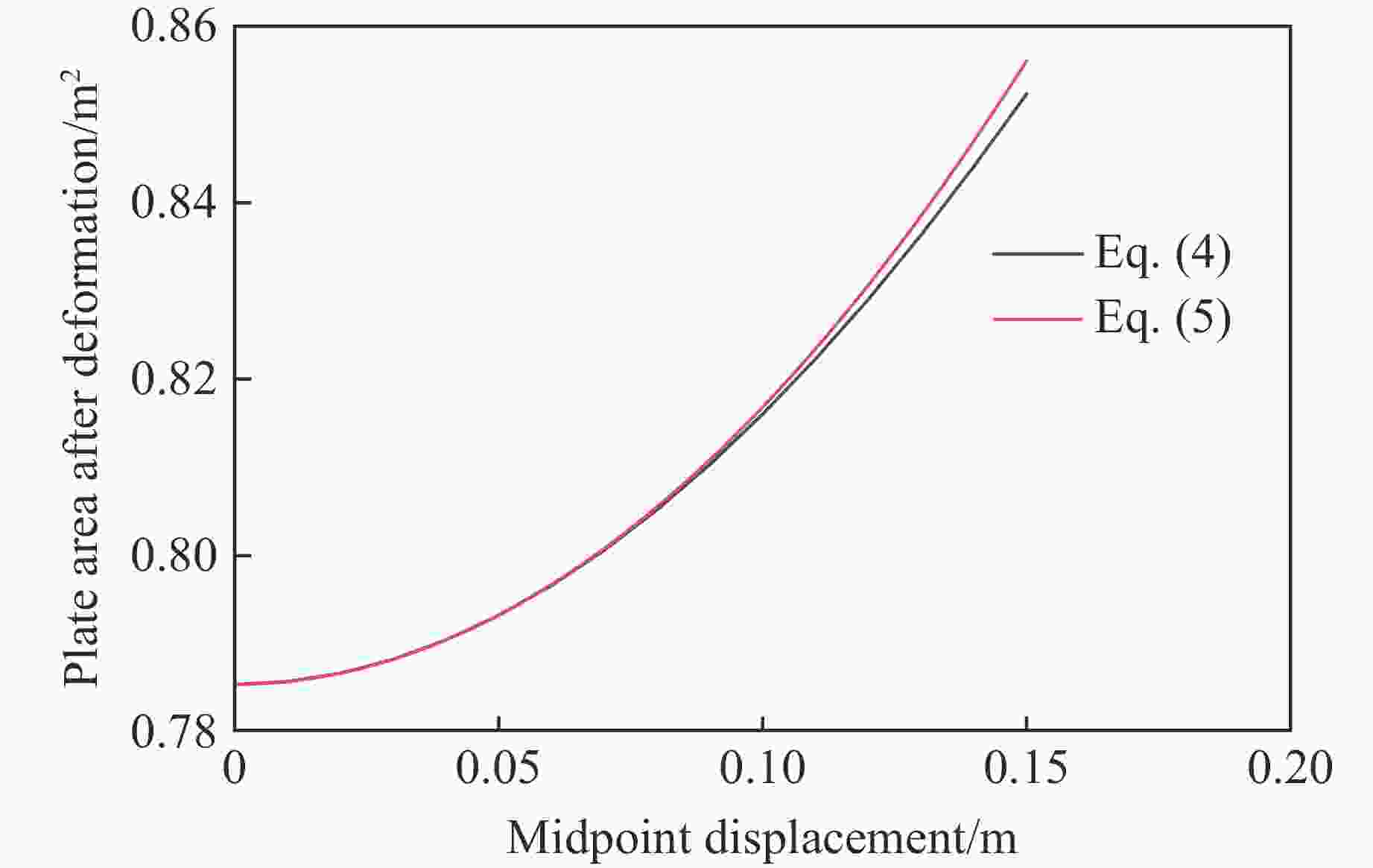

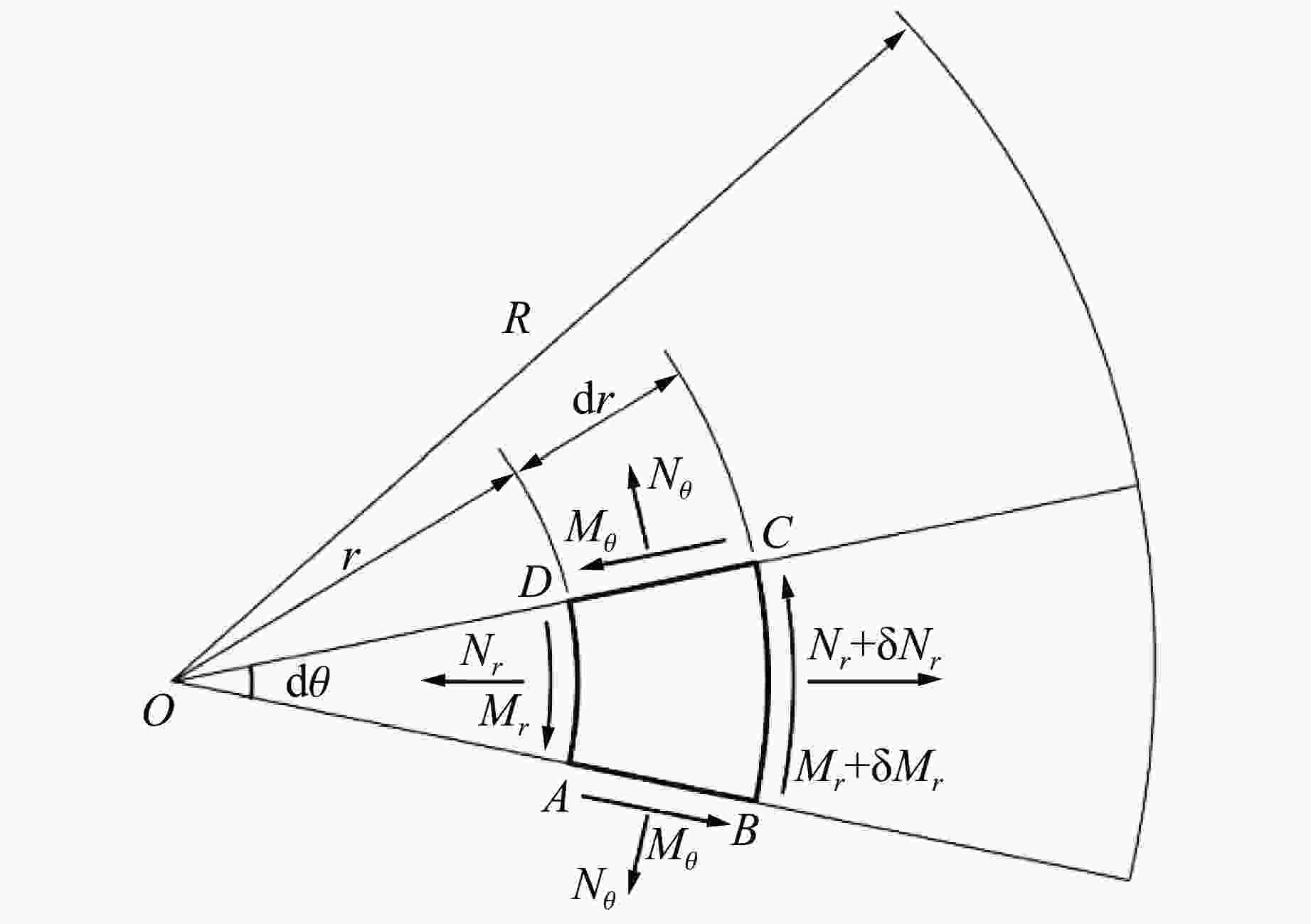

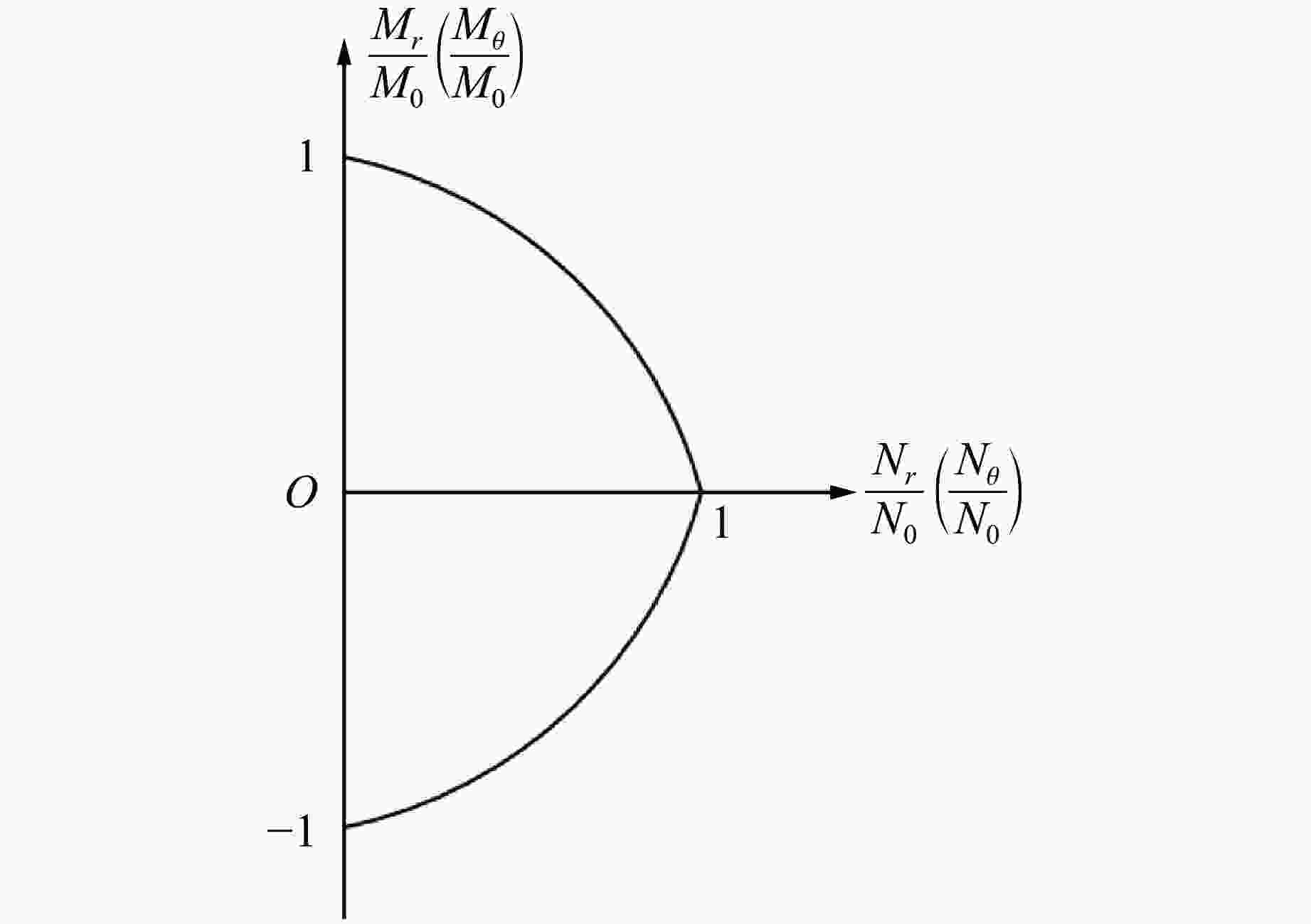

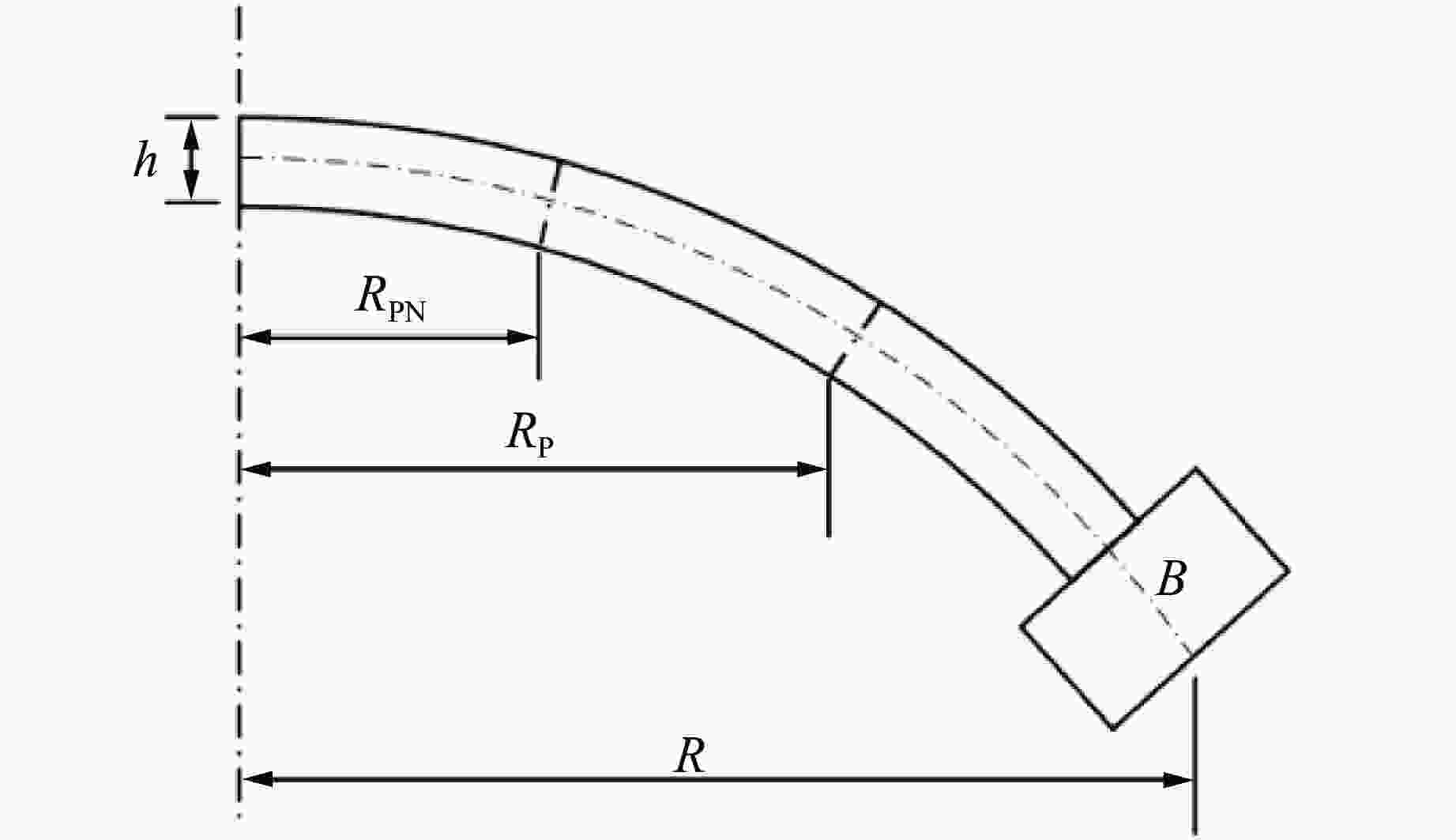

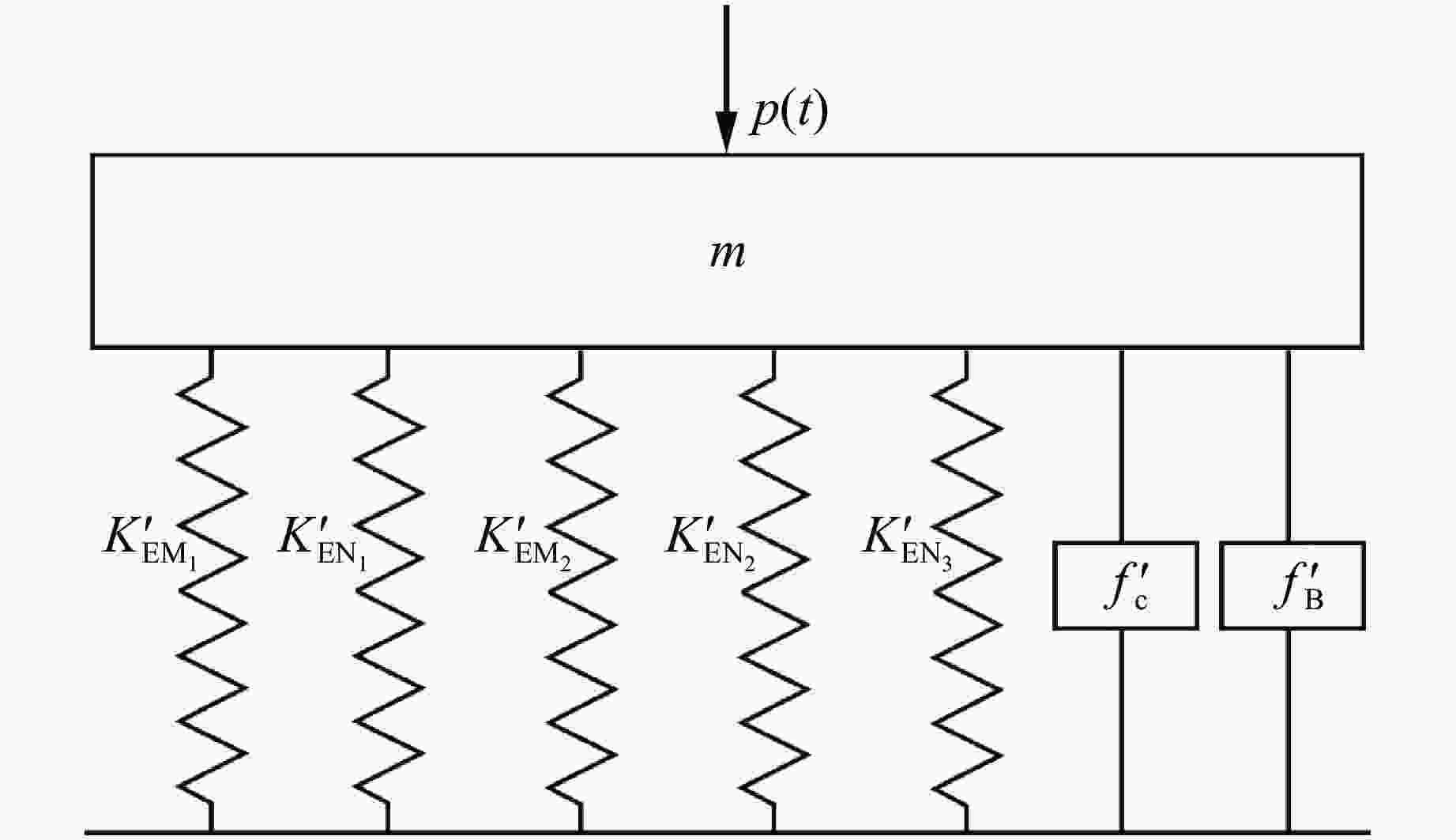

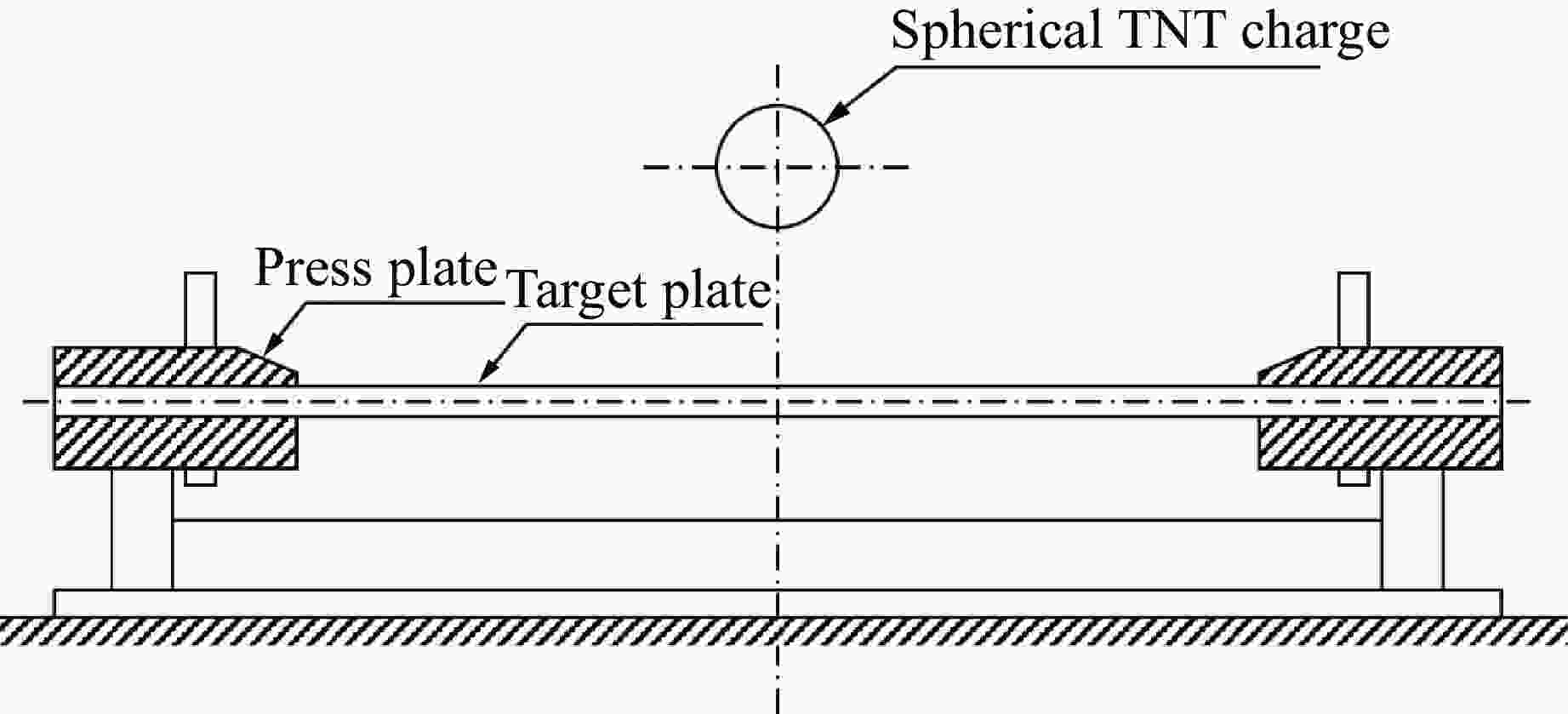

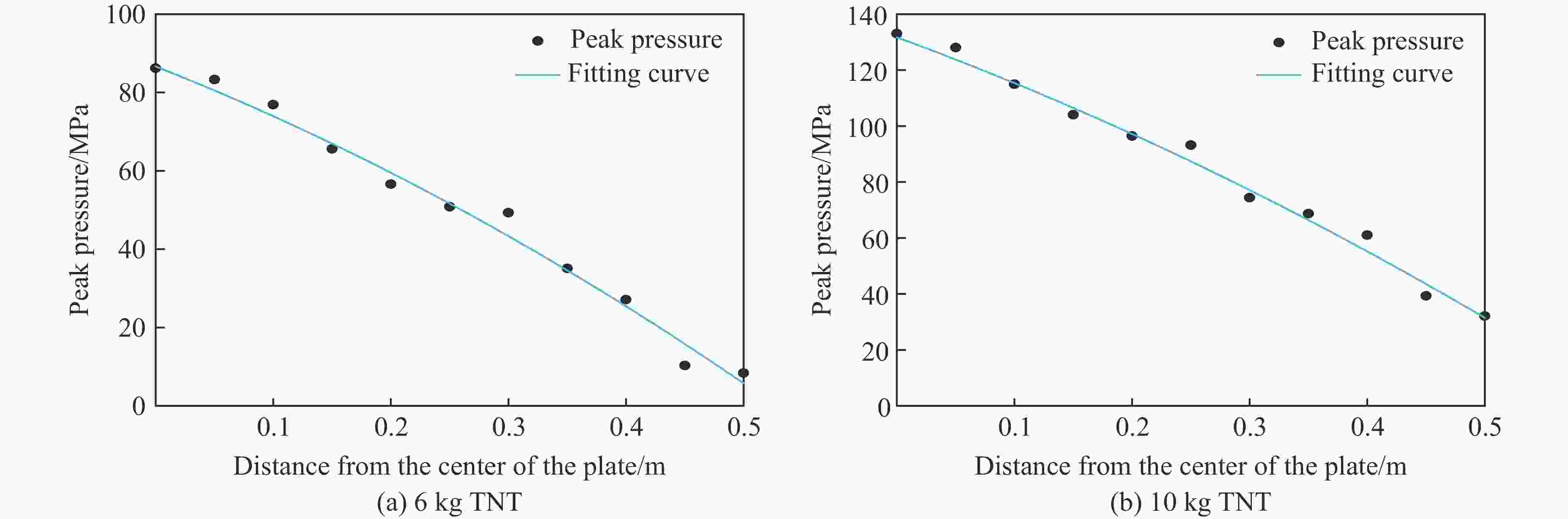

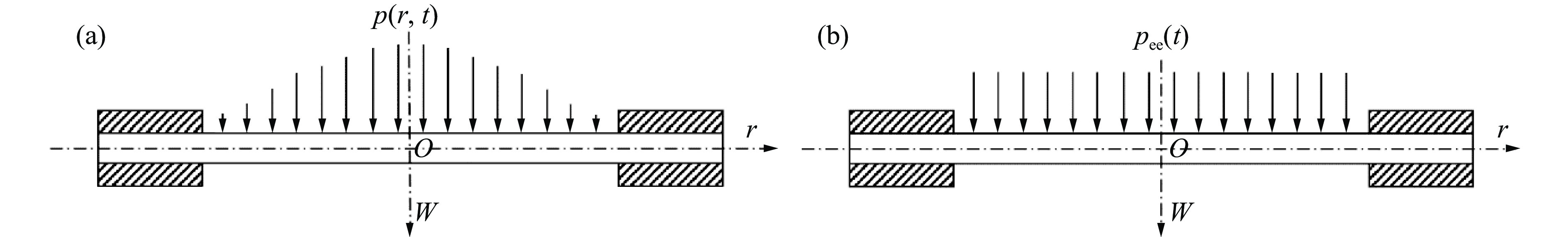

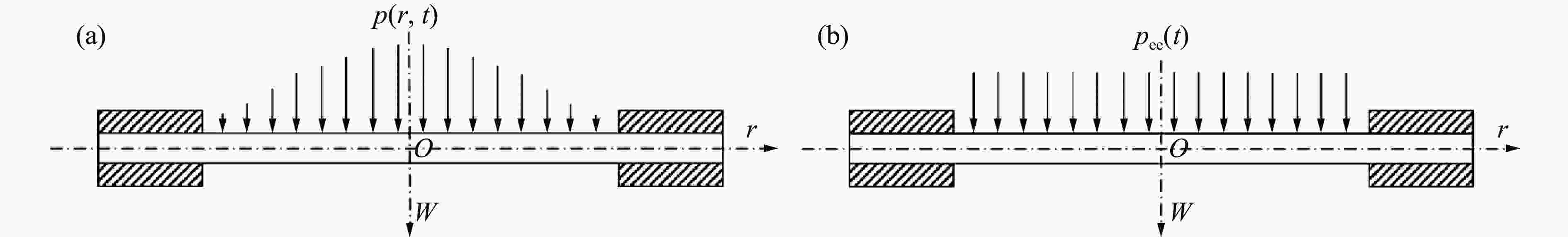

摘要: 基于等效单自由度模型理论,考虑变形过程中弯矩和膜力的联合承载,建立了空中近爆作用下固支弹塑性圆板的动力学模型,实现了圆板加载和卸载的全过程描述。基于文献中的试验工况建立有限元模型,利用有限元数值模拟对空爆作用下固支圆板的动态响应进行分析,并将动力学模型计算结果与试验结果及有限元数值模拟结果进行对比,验证了动力学模型计算结果的准确性。结果表明,理论计算结果与试验结果及数值模拟结果吻合较好,建立的动力学模型可以应用于固支圆板在空中近爆载荷作用下的大变形预测,为结构抗爆提供技术支持。Abstract: Based on equivalent single degree-of-freedom (SDOF) theory, a dynamic model of clamped elastoplastic circular plate under near air blast loading is established by considering the bending moment and the membrane force during the deformation process, and the whole process containing loading and unloading for circular plate is described. The finite element model is established using test parameters in the literature, and the dynamic response of clamped circular plate under air blast loading is analyzed by finite element simulation. After comparing the calculation results of the dynamic model and the finite element simulation results, the accuracy of the calculation results of the dynamic model is verified. The results show that the theoretical calculation results are in good agreement with the test results and the finite element simulation results. The proposed dynamic model can be applied to predict the large deformation of clamped circular plate under near air blast loading, and provides technical support for blast resistant structure.

-

Key words:

- single degree-of-freedom model /

- elastoplastic response /

- air blast loading /

- membraneforce /

- LS-DYNA

-

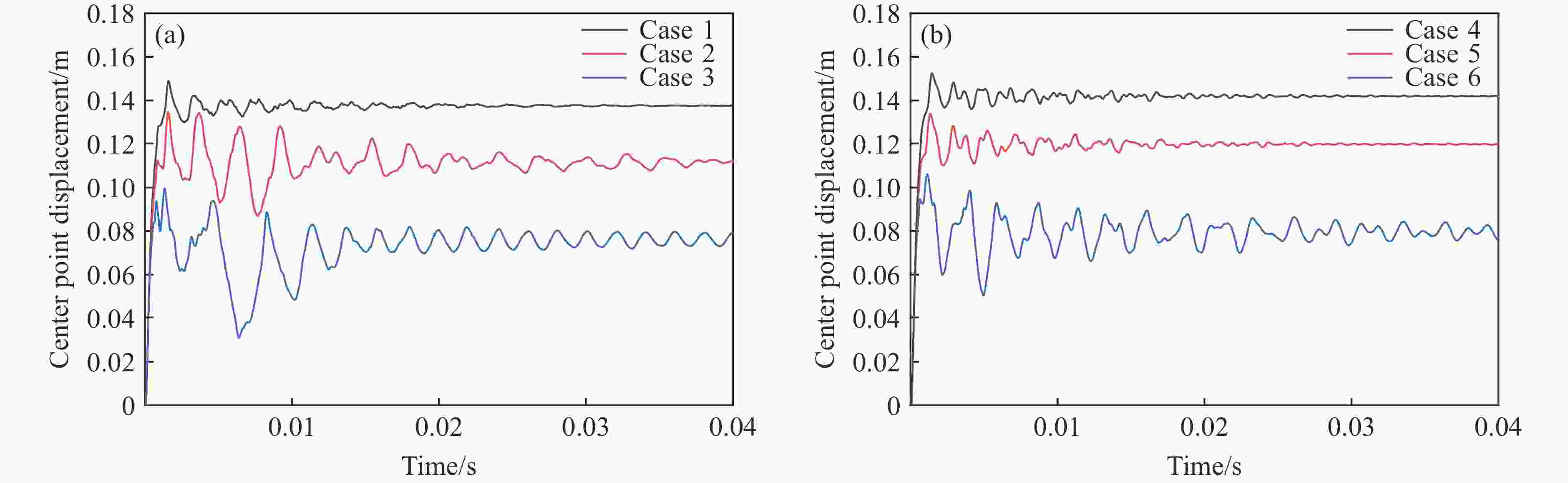

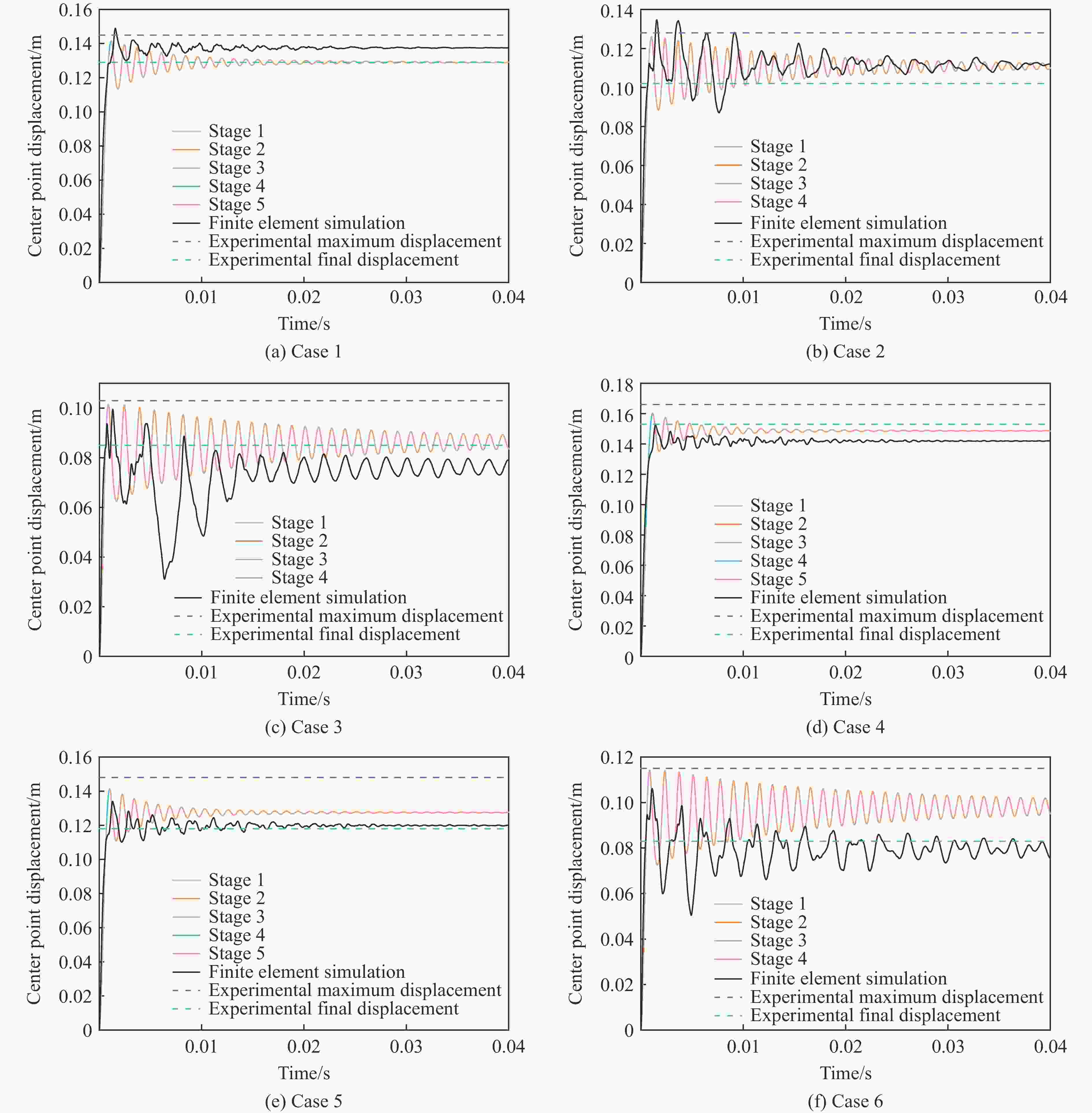

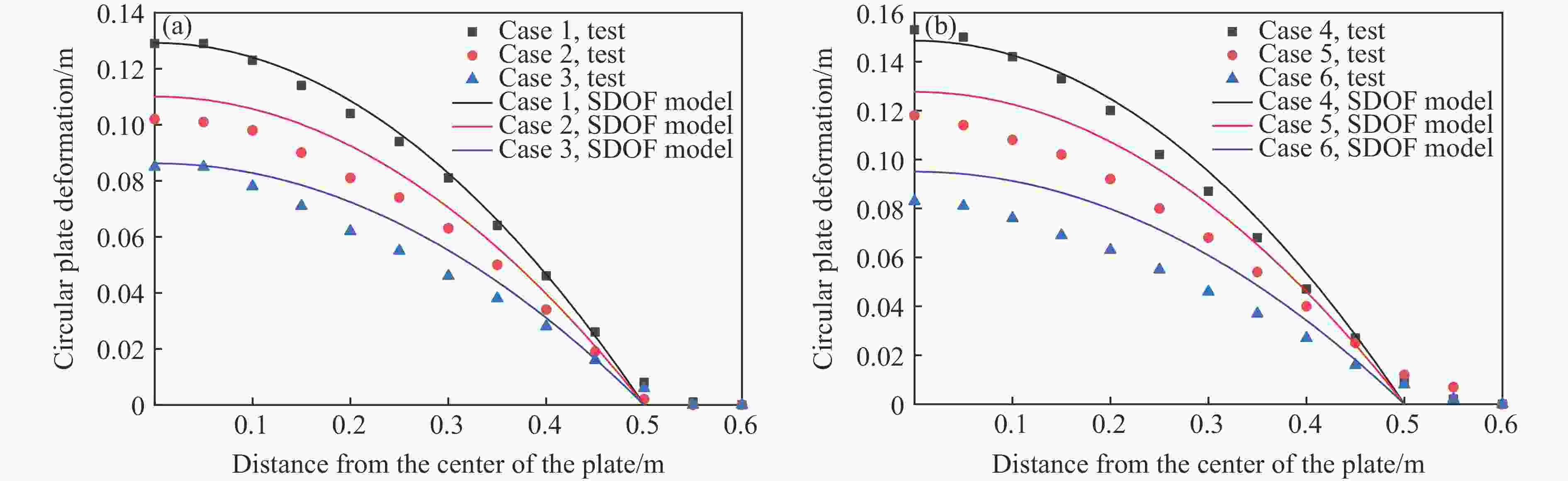

Case Material Thickness/mm Yield strength/MPa Mass of TNT/kg Detonation distance/mm 1 Weldox700E steel 8 800 6 250 2 B1 steel 8 1070 6 250 3 B2 steel 8 1600 6 250 4 Weldox700E steel 12 800 10 250 5 B1 steel 12 1070 10 250 6 B2 steel 12 1600 10 250 表 2 各工况下试验与有限元模拟得到的中心点位移对比

Table 2. Comparison of center point displacements between test and finite element simulation under various calculation cases

Case Maximum displacement of center point Final displacement of center point Test/mm Sim./mm Error/% Test/mm Sim./mm Error/% 1 145 148.84 2.65 129 137.42 6.53 2 128 134.67 5.21 102 111.88 9.69 3 103 99.52 −3.38 85 79.07 −6.98 4 166 152.44 −8.17 153 141.95 −7.22 5 148 133.87 −9.55 118 120.12 1.80 6 115 106.74 −7.18 83 79.28 −4.48 表 3 各工况下动力学模型计算结果与试验结果的对比

Table 3. Comparison between dynamic model results and test results under various cases

Case Maximum displacement Final displacement Test/mm SDOF model/mm Error/% Test SDOF model/mm Error/% 1 145 141.48 −2.43 129 129.22 0.17 2 128 126.03 −1.54 102 110.06 7.90 3 103 101.49 −1.47 85 86.21 1.42 4 166 160.24 −3.47 153 148.57 −2.90 5 148 141.27 −4.55 118 127.66 8.19 6 115 114.19 −0.70 83 95.03 14.49 -

[1] 王芳, 冯顺山, 俞为民. 爆炸冲击波作用下靶板的塑性大变形响应研究 [J]. 中国安全科学学报, 2003, 13(3): 58–61. doi: 10.16265/j.cnki.issn1003-3033.2003.03.016WANG F, FENG S S, YU W M. Study on large plastic deformation response of target plate under explosive blast wave [J]. China Safety Science Journal, 2003, 13(3): 58–61. doi: 10.16265/j.cnki.issn1003-3033.2003.03.016 [2] 吴成, 金俨, 李华新. 固支方板对水中爆炸作用的动态响应研究 [J]. 高压物理学报, 2003, 17(4): 275–282. doi: 10.3969/j.issn.1000-5773.2003.04.006WU C, JIN Y, LI H X. A study on square plate dynamic response under underwater explosion [J]. Chinese Journal of High Pressure Physics, 2003, 17(4): 275–282. doi: 10.3969/j.issn.1000-5773.2003.04.006 [3] 何建, 肖玉凤, 陈振勇, 等. 空爆载荷作用下固支矩形钢板的塑性极限变形 [J]. 哈尔滨工业大学学报, 2007, 39(2): 310–313, 329. doi: 10.3321/j.issn:0367-6234.2007.02.036HE J, XIAO Y F, CHEN Z Y, et al. Plastic limited deformation analysis of the clamped rectangular steel plate subjected to air non-contact explosions [J]. Journal of Harbin Institute of Technology, 2007, 39(2): 310–313, 329. doi: 10.3321/j.issn:0367-6234.2007.02.036 [4] DUFFEY T A. Large deflection dynamic response of clamped circular plates subjected to explosive loading [R]. Albuquerque: Sandia National Laboratories, 1967. [5] NURICK G N, PEARCE H T, MARTIN J B. Predictions of transverse deflections and in-plane strains in impulsively loaded thin plates [J]. International Journal of Mechanical Sciences, 1987, 29(6): 435–442. doi: 10.1016/0020-7403(87)90004-X [6] JONES N. Impulsive loading of a simply supported circular rigid plastic plate [J]. Journal of Applied Mechanics, 1968, 35(1): 59–65. doi: 10.1115/1.3601174 [7] FLORENCE A L. Circular plate under a uniformly distributed impulse [J]. International Journal of Solids and Structures, 1966, 2(1): 37–47. doi: 10.1016/0020-7683(66)90005-9 [8] CLOETE T J, NURICK G N. On the influence of radial displacements and bending strains on the large deflections of impulsively loaded circular plates [J]. International Journal of Mechanical Sciences, 2014, 82: 140–148. doi: 10.1016/j.ijmecsci.2014.02.026 [9] CAMPBELL T I, CHARLTON T M. Finite deformation of a fully fixed beam comprised of a non-linear material [J]. International Journal of Mechanical Sciences, 1973, 15(5): 415–422. doi: 10.1016/0020-7403(73)90040-4 [10] KARAGIOZOVA D, YU T X, SHI S Y, et al. On the influence of elasticity on the large deflections response of circular plates to uniform quasi-static pressure [J]. International Journal of Mechanical Sciences, 2017, 131/132: 894–907. doi: 10.1016/j.ijmecsci.2017.07.032 [11] BIGGS J M. Introduction to structural dynamics [M]. New York: McGraw-Hill, 1964. [12] 钟贤哲. 高强度钢Weldox700E的动态本构关系及其抗爆特性 [D]. 北京: 北京理工大学, 2019.ZHONG X Z. Dynamic constitutive relations and explosion resistance properties of high strength steel Weldox700E [D]. Beijing: Beijing Institute of Technology, 2019. [13] RIGBY S E, TYAS A, BENNETT T. Single-degree-of-freedom response of finite targets subjected to blast loading: the influence of clearing [J]. Engineering Structures, 2012, 45: 396–404. doi: 10.1016/j.engstruct.2012.06.034 [14] TAYLOR G I. The distortion under pressure of diaphragm which is clamped along its edge and stressed beyond the elastic limit [J]. Underwater Explosion Research, 1950. [15] KYOHEI K, PIAN T H H. Large deformations of rigid-plastic circular plates [J]. International Journal of Solids and Structures, 1981, 17(11): 1043–1055. doi: 10.1016/0020-7683(81)90012-3 [16] WANG X D, YU T X. Parkes revisited: effect of elastic deformation at the root of a cantilever beam [J]. International Journal of Impact Engineering, 1991, 11(2): 197–209. doi: 10.1016/0734-743X(91)90006-2 [17] 汤安民, 许明达, 赵蕾. 自由变形结构弹塑性分析的新方法 [J]. 广西大学学报(自然科学版), 2009, 34(1): 36–39. doi: 10.13624/j.cnki.issn.1001-7445.2009.01.008TANG A M, XU M D, ZHAO L. New method for elasto-plastic analysis of free-form deformation structure [J]. Journal of Guangxi University (Natural Science Edition), 2009, 34(1): 36–39. doi: 10.13624/j.cnki.issn.1001-7445.2009.01.008 [18] 许明达. 自由变形结构弹塑性分析的新方法及应用 [D]. 西安: 西安理工大学, 2009.XU M D. The structure of free-form deformation elasto-plastic analysis and application of new method [D]. Xi’an: Xi’an University of Technology, 2009. -

下载:

下载: