Crashworthiness Optimization of Horsetail-Bionic Thin-Walled Structures

-

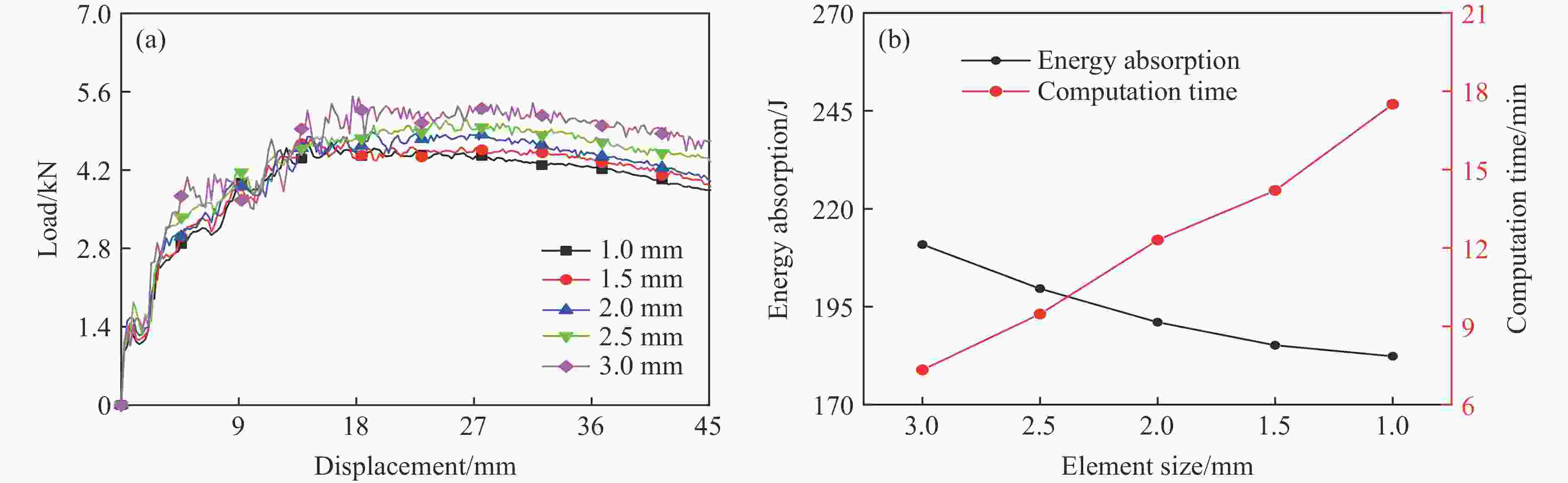

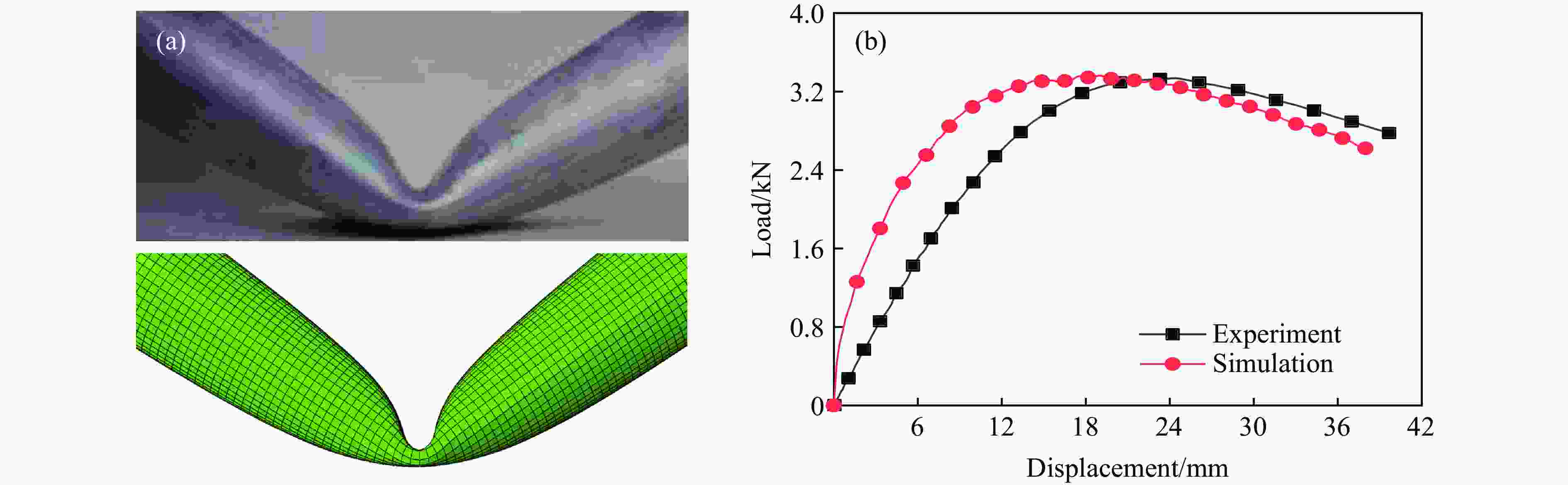

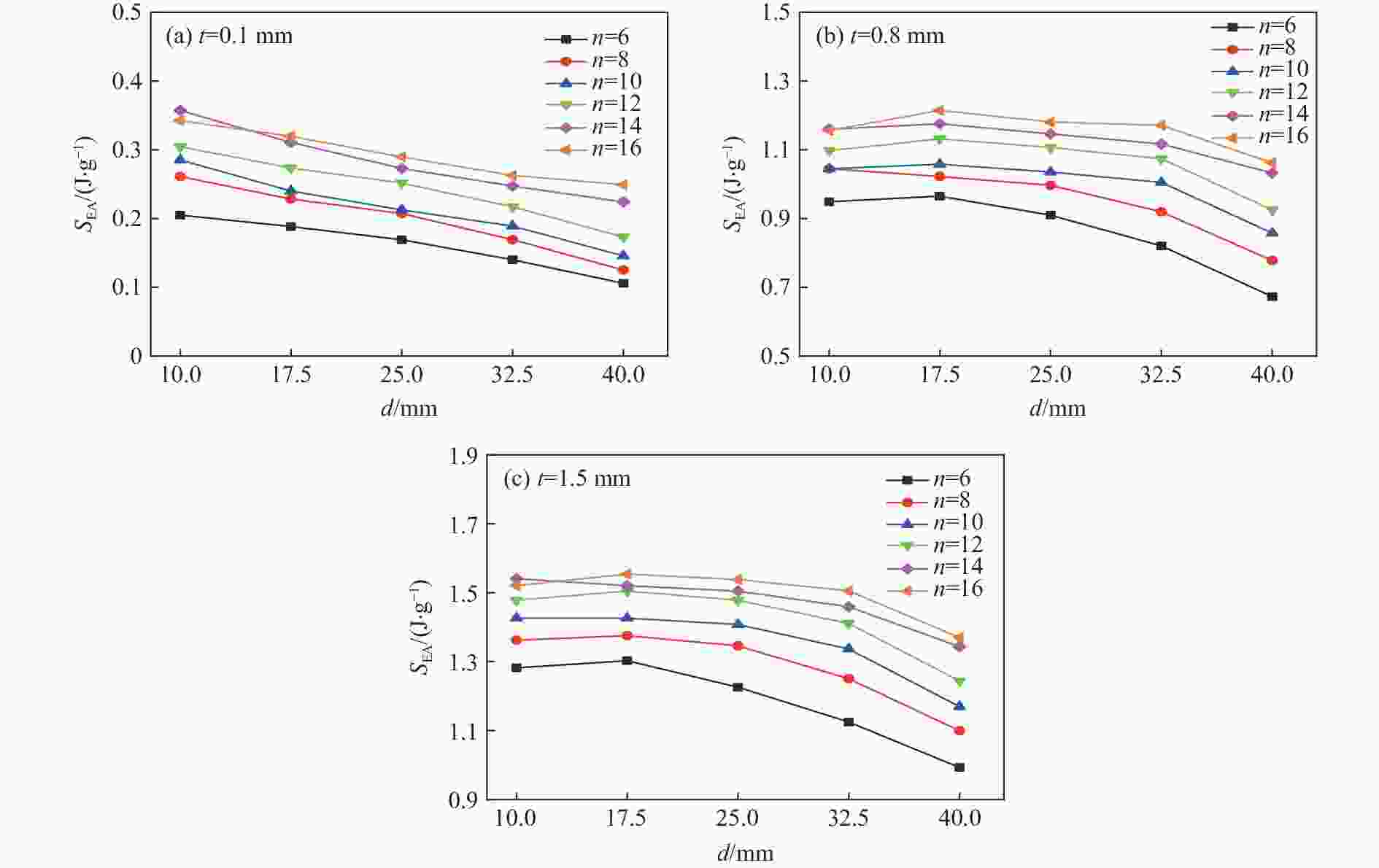

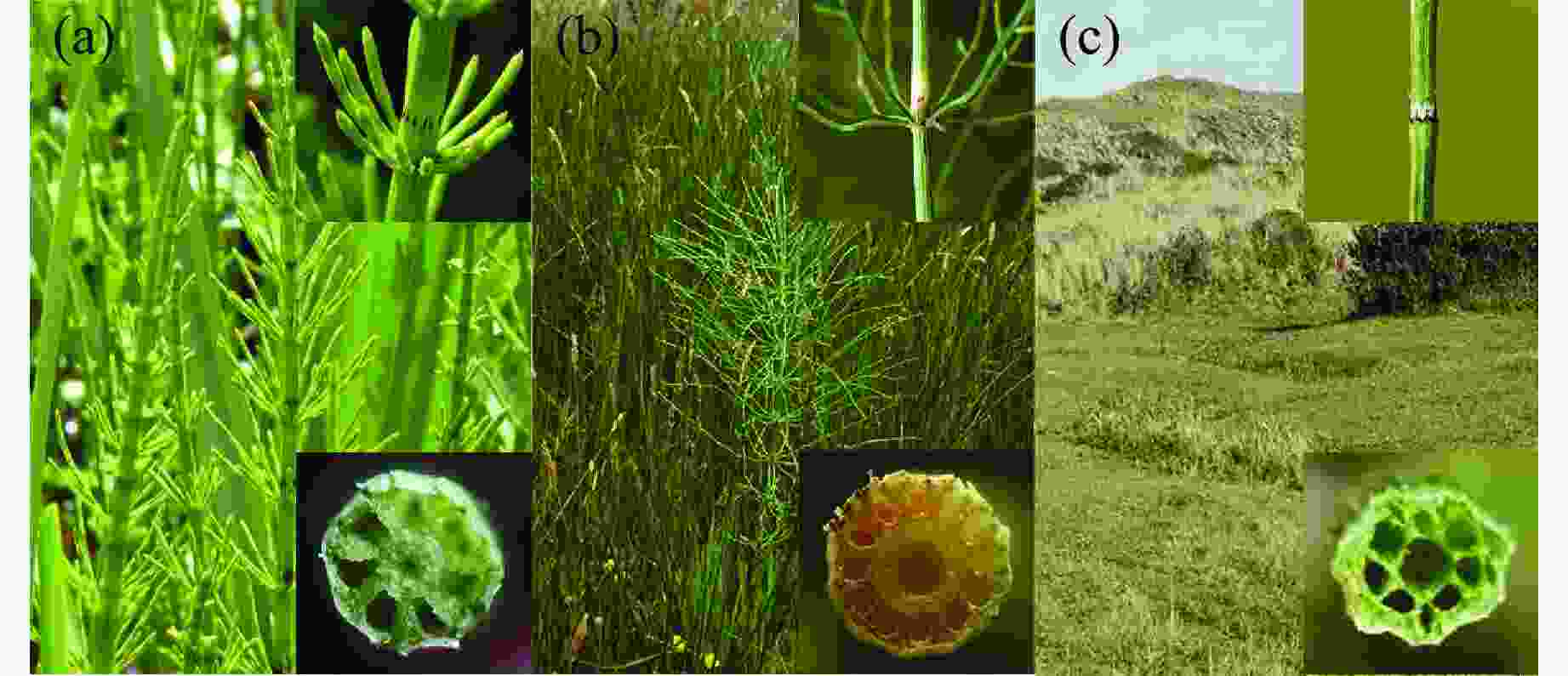

摘要: 利用ABAQUS有限元软件构建木贼属植物仿生薄壁结构(horsetail-bionic thin-walled structure,HBTS)在侧向冲击下的数值模型,分析了结构的壁厚、内径和肋骨数对其耐撞性能和变形模态的影响。结果表明:肋骨数和整体壁厚的增加会明显提高HBTS的比吸能和最大峰值载荷,HBTS不同部分的壁厚变化显著影响其变形模态和耐撞性能。为了综合考虑HBTS各部分的壁厚、肋骨数、内径5个参数对耐撞性能的影响,集成modeFRONTIER优化软件与ABAQUS软件,通过参数化建模在设计空间上构建有限元模型,建立比吸能和最大峰值载荷的Kriging代理模型。使用基于Kriging代理模型的多目标优化方法获取Pareto前沿,以同时实现比吸能最大化和峰值载荷最小化。最后分析了Pareto前沿面上各HBTS的设计参数分布情况,并验证了优化结果,该方法可为薄壁结构的优化设计提供新思路。

-

关键词:

- 仿生薄壁结构 /

- 多目标优化 /

- modeFRONTIER /

- Pareto前沿

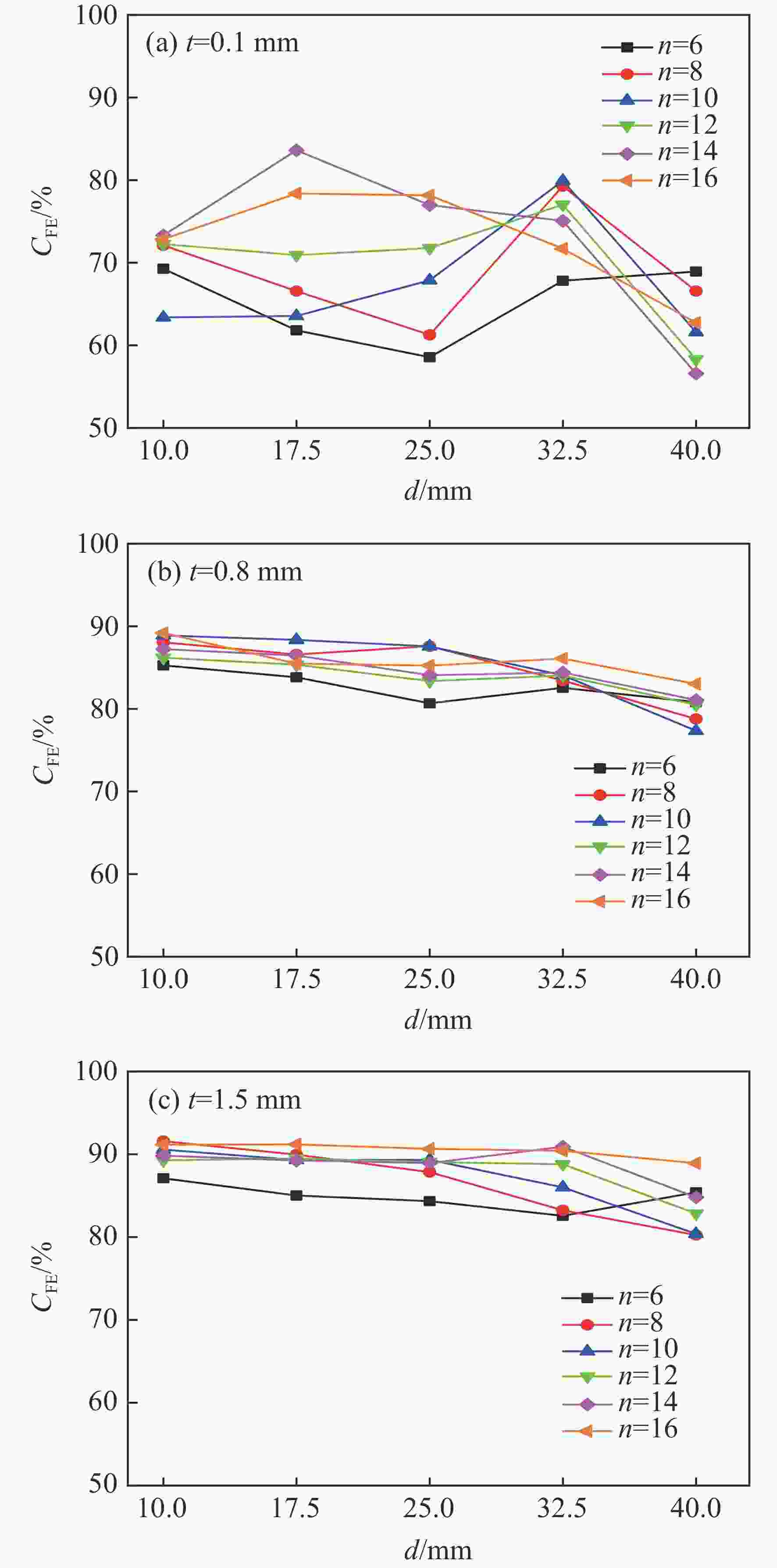

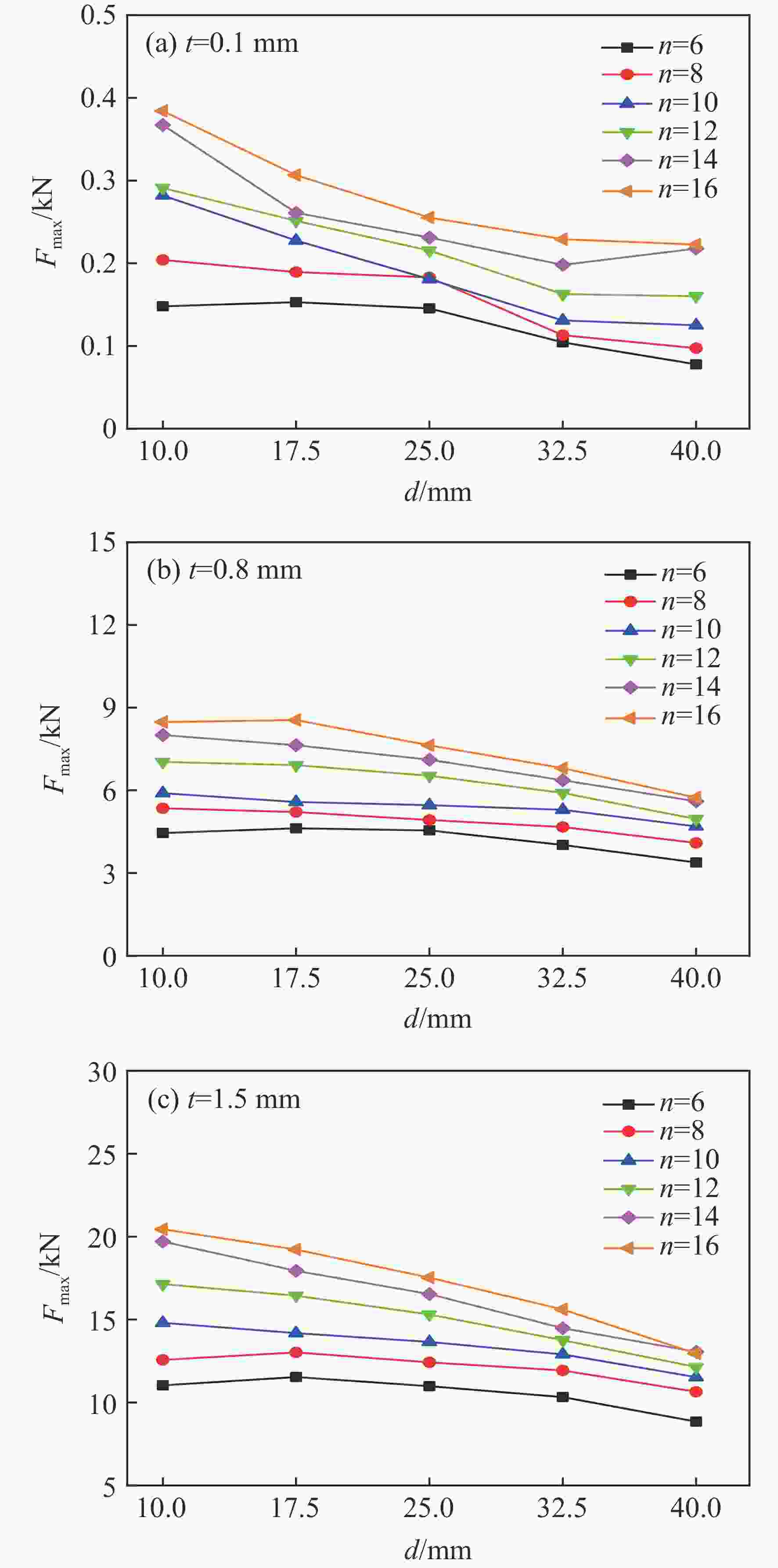

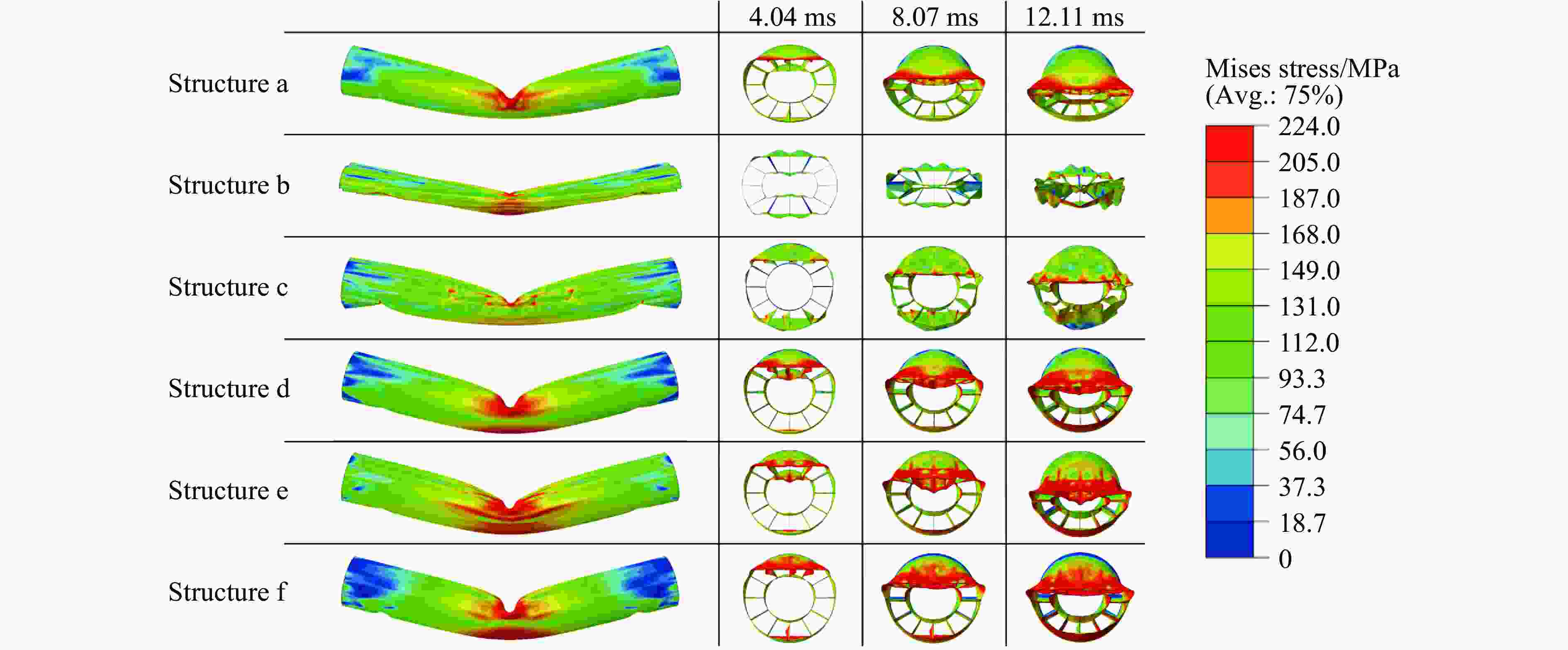

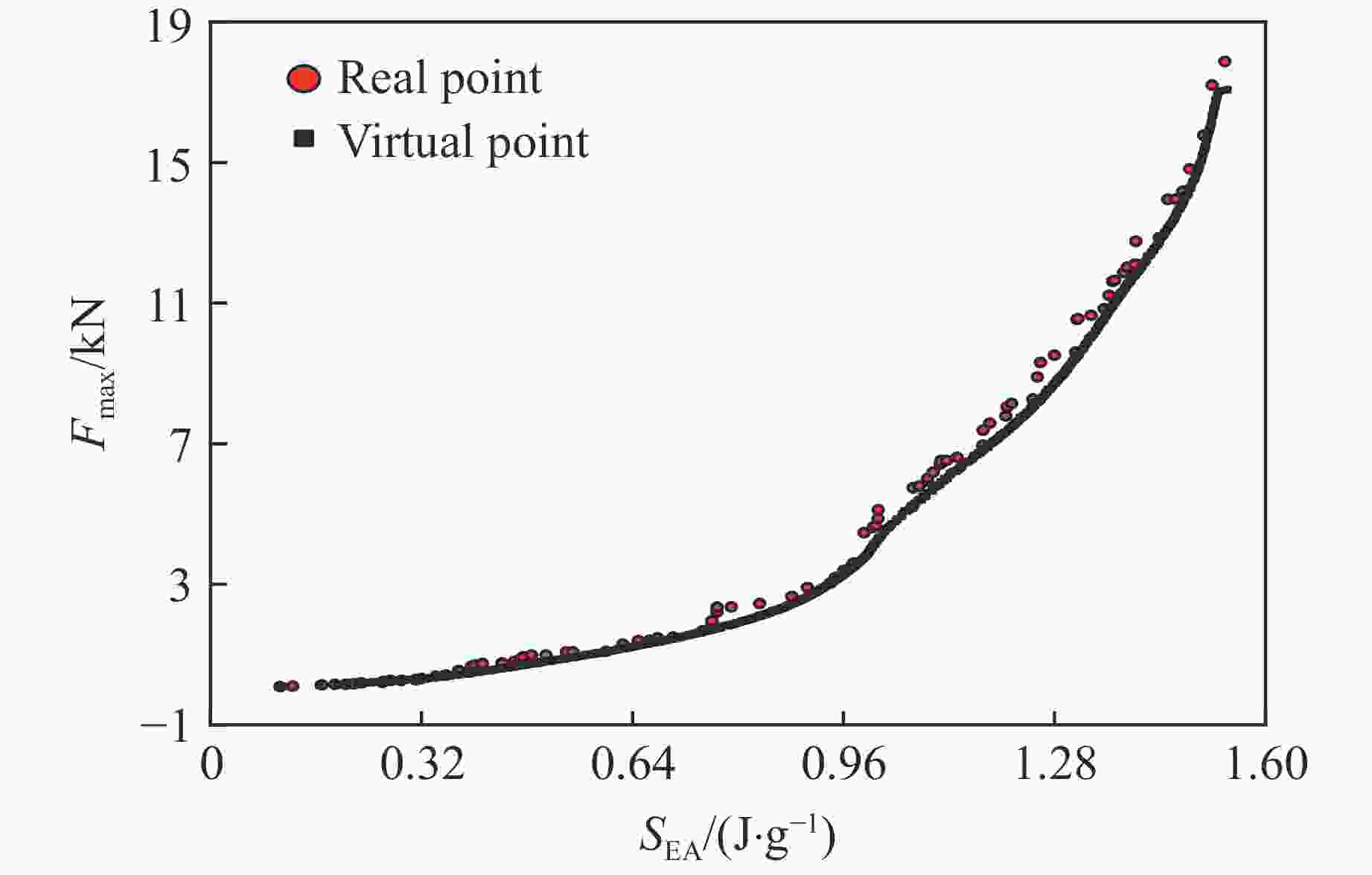

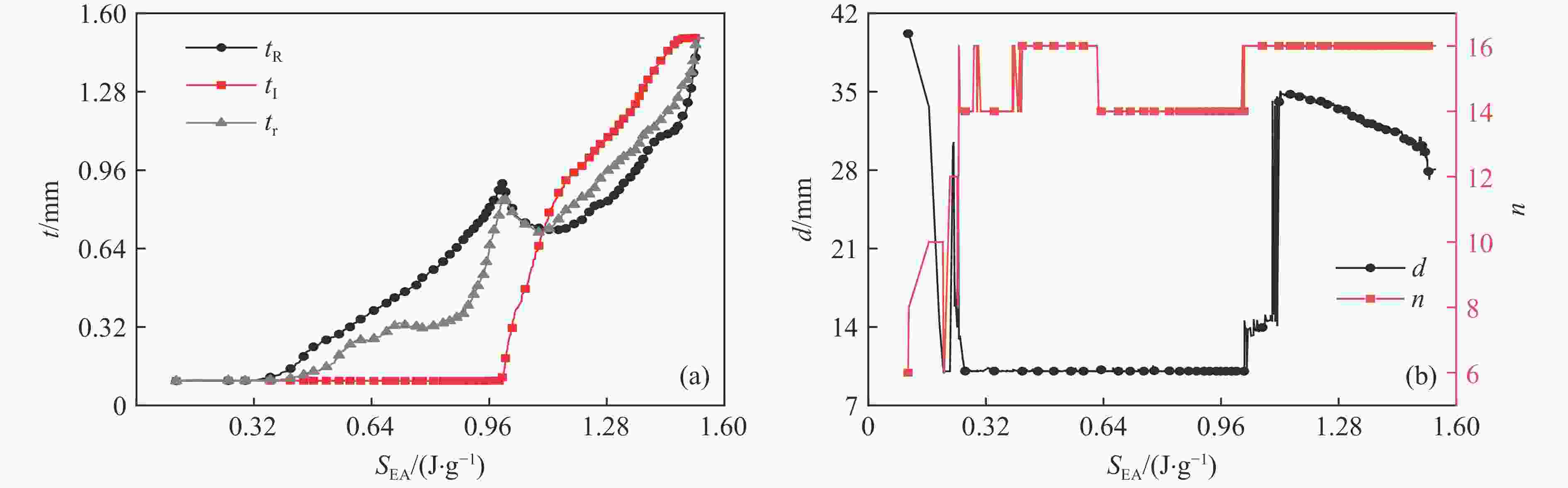

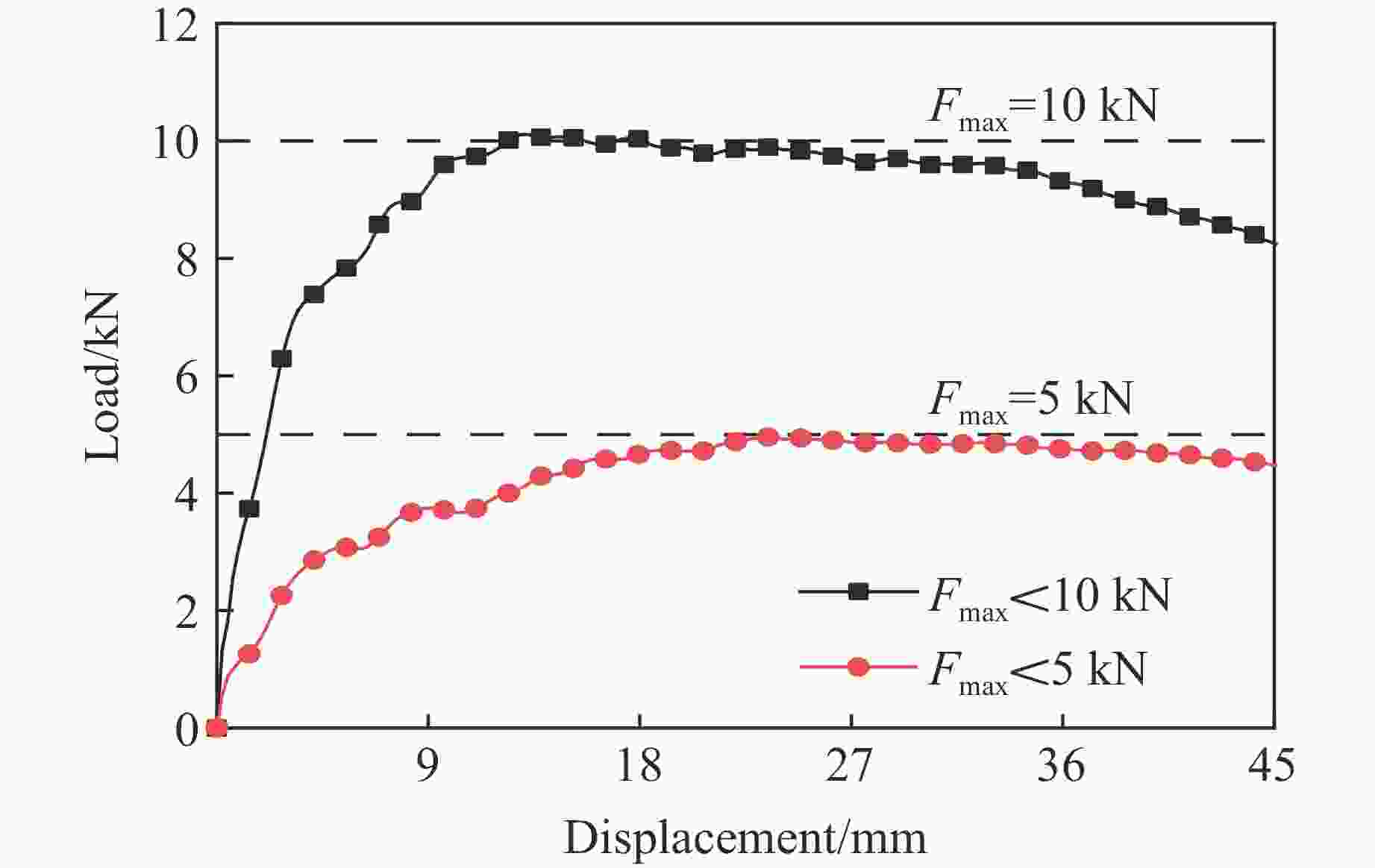

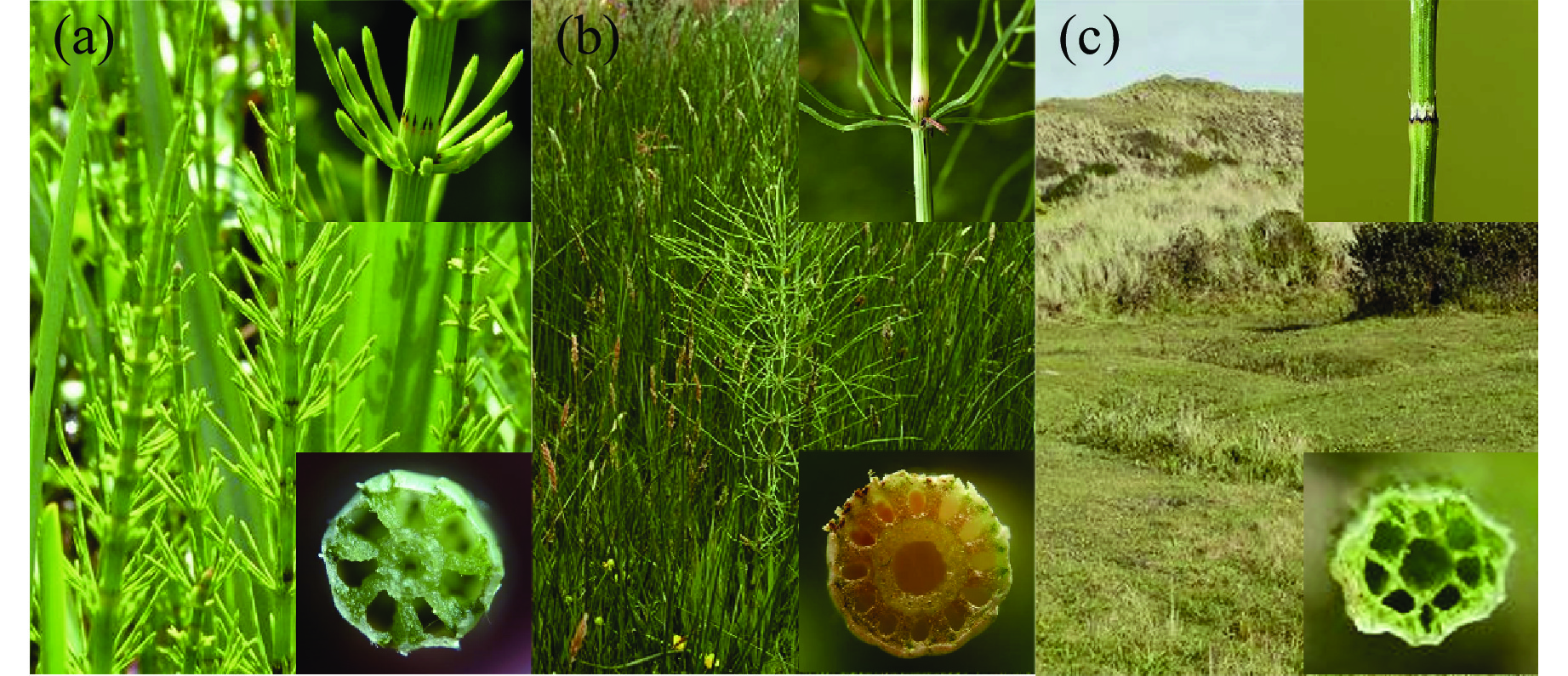

Abstract: Numerical model of horsetail-bionic thin-walled structure (HBTS) under the lateral impact was constructed using ABAQUS. The effects of wall thickness, inner diameter and number of ribs on the crashworthiness performance and deformation modes were analyzed. The results indicate that the specific energy absorption and peak load of HBTS can be significantly enhanced with the increase of the number of ribs and the overall wall thickness. The changes in the wall thickness of each part significantly affects its deformation mode and crashworthiness performance. Based on the above results, the optimization software modeFRONTIER and the finite element analysis software ABAQUS were integrated to explore the influence of five design parameters, in terms of wall thickness, number of ribs, inner diameter and so on. Finite element models were uniformly distributed on the design space through parametric modeling method, hence the Kriging surrogate models for the specific energy absorption and peak load were established. Then, Pareto front was obtained using Kriging surrogate model-based multi-objective optimization method for the specific energy absorption maximization and peak load minimization simultaneously in one model. Finally, the distribution of each HBTS’s design parameters on Pareto front was analyzed and the optimization results were verified. The method is expected to provide new thoughts for the optimization design of the thin-walled structure.-

Key words:

- bionic thin-walled structure /

- multi-objective optimization /

- modeFRONTIER /

- Pareto front

-

表 1 铝合金AA6061的材料参数

Table 1. Parameters of aluminum alloy AA6061

Density/(g∙cm−3) Poisson’s ratio Elastic modulus/GPa Yield stress/MPa Ultimate strength/MPa 2.70 0.3 70.0 137.03 223.53 表 2 HBTS的耐撞性比较

Table 2. Comparison of crashworthiness of HBTS

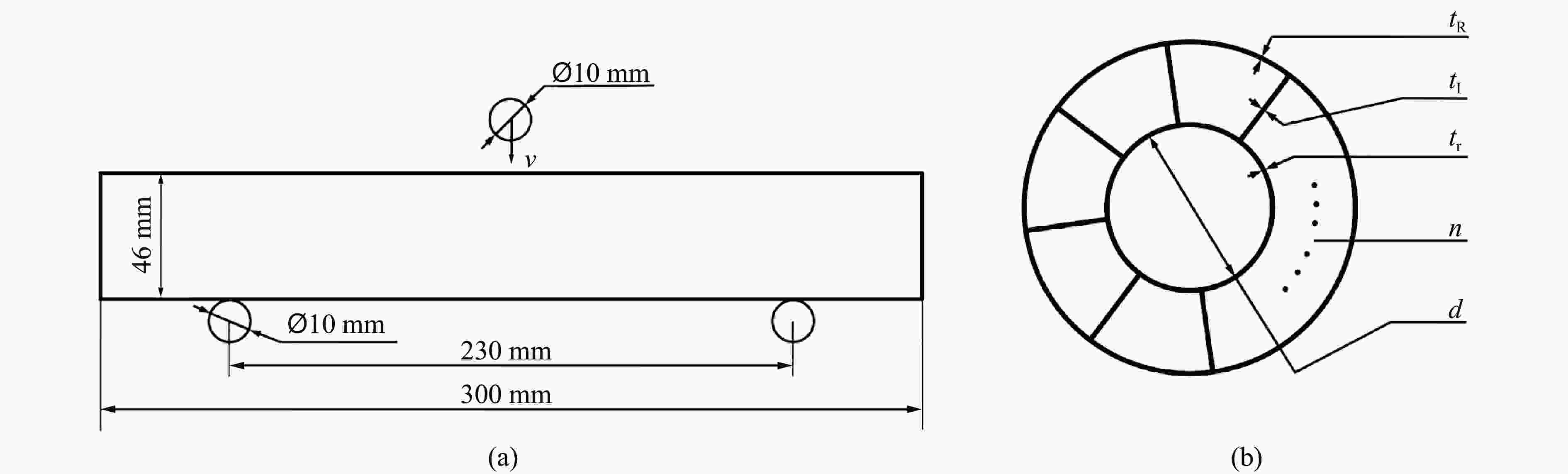

Structure ${ {t} }{_{\text{R} }}$/mm ${ {t} }{_{\text{I} }}$/mm ${ {t} }{_{\text{r} }}$/mm M/g ${ {E} }{_{\text{A} }}$/J ${ {S} }{_{ \text{EA} } }$/(J∙g−1) ${ {F} }{_{\text{max} }}$/kN ${ {C} }{_{\text{FE} }}$/% a 0.800 0.100 0.100 110.2 70.16 0.637 1.841 82.8 b 0.158 0.800 0.158 110.2 28.02 0.254 1.125 54.1 c 0.271 0.271 0.800 110.2 49.11 0.446 1.401 76.2 d 1.500 0.800 0.800 308.1 361.61 1.174 9.095 86.4 e 0.858 1.500 0.858 308.1 390.85 1.268 9.691 87.7 f 0.971 0.971 1.500 308.1 315.82 1.025 8.110 84.7 表 3 壁厚与内径水平

Table 3. Wall thickness and inner diameter level

Level ${ {t} }{_{\mathrm{R} }}$/mm ${ {t} }{_{\text{I} }}$/mm ${ {t} }{_{\text{r} }}$/mm d/mm 1 0.10 0.10 0.10 10.0 2 0.45 0.45 0.45 17.5 3 0.80 0.80 0.80 25.0 4 1.15 1.15 1.15 32.5 5 1.50 1.50 1.50 40.0 表 4 Kriging代理模型精度

Table 4. Accuracy assessment of the Kriging surrogate models

${ {S} }{_{ \text{EA} } }$ ${ {F} }{_{\text{max} } }$ ${ {R} }{^{\text{2} }}$ δARE/% δRAAE/% ${ {R} }{^{\text{2} }}$ δARE/% δRAAE/% 0.989 1.52 1.33 0.996 1.68 0.67 表 5 不同

$F_{\text{max}}$ 限制下的最优HBTSTable 5. Optimal HBTSs with different

$F_{\text{max}}$ limitsType Design parameters ${ {S} }{_{ \text{EA} } }$/(J∙g−1) $\delta_{S_{\rm EA}} $/% ${ {F} }{_{\text{max} }}$/(J∙g−1) $\delta_{F_{\max}}$/% ${ {t} }{_{\text{R} }}$/mm ${ {t} }{_{\text{I} } }$/mm ${ {t} }{_{\text{r} } }$/mm n d/mm Kriging FE Kriging FE ${ {F} }{_{\text{max} }}$<5 kN 0.759 0.413 0.775 16 13.9 1.054 1.026 2.73 4.994 4.953 0.83 ${ {F} }{_{\text{max} } }$<10 kN 0.954 1.221 1.064 16 31.9 1.347 1.348 −0.07 9.952 10.111 −1.57 -

[1] 武和全, 毛鸿锋, 侯海彬. 复合材料仿竹薄壁管耐撞性和可靠性研究 [J]. 南京理工大学学报, 2017, 41(2): 186–190, 197.WU H Q, MAO H F, HOU H B. Study on crashworthiness and reliability of composite bamboo-like thin-walled tube [J]. Journal of Nanjing University of Science and Technology, 2017, 41(2): 186–190, 197. [2] ZHAO Z, HUANG W, LI B, et al. Synergistic effects of chiral morphology and reconfiguration in cattail leaves [J]. Journal of Bionic Engineering, 2015, 12(4): 634–642. doi: 10.1016/S1672-6529(14)60153-0 [3] LIU Q, MA J, HE Z, et al. Energy absorption of bio-inspired multi-cell CFRP and aluminum square tubes [J]. Composites Part B: Engineering, 2017, 121: 134–144. doi: 10.1016/j.compositesb.2017.03.034 [4] 范晓文, 杨欣, 许述财, 等. 仿骨单位薄壁结构轴向和斜向耐撞性研究 [J]. 载人航天, 2020, 26(2): 142–151. doi: 10.3969/j.issn.1674-5825.2020.02.002FAN X W, YANG X, XU S C, et al. Study on crashworthiness of thin-walled structure based on osteon under axial and oblique loads [J]. Manned Spaceflight, 2020, 26(2): 142–151. doi: 10.3969/j.issn.1674-5825.2020.02.002 [5] TSANG H H, RAZA S. Impact energy absorption of bio-inspired tubular sections with structural hierarchy [J]. Composite Structures, 2018, 195: 199–210. doi: 10.1016/j.compstruct.2018.04.057 [6] 黄晗, 许述财, 杜雯菁, 等. 基于虾螯结构的仿生薄壁管吸能特性分析及优化 [J]. 北京理工大学学报, 2020, 40(3): 267–274.HUANG H, XU S C, DU W J, et al. Energy absorption analysis and optimization of a bionic thin-walled tube based on shrimp chela [J]. Transactions of Beijing Institute of Technology, 2020, 40(3): 267–274. [7] 于鹏山, 刘志芳, 李世强. 新型仿竹薄壁圆管的设计与吸能特性分析 [J]. 高压物理学报, 2021, 35(5): 054205. doi: 10.11858/gywlxb.20210710YU P S, LIU Z F, LI S Q. Design and energy absorption characteristic analysis of a new bio-bamboo thin-walled circular tube [J]. Chinese Journal of High Pressure Physics, 2021, 35(5): 054205. doi: 10.11858/gywlxb.20210710 [8] HUANG J L, DENG X L, LIU W Y. Bionic design of bend-twist coupled thin-walled beam based on the structure of rice stem [J]. Mechanics of Advanced Materials and Structures, 2021: 1–14. [9] 霍鹏, 许述财, 范晓文, 等. 鹿角骨单位仿生薄壁管斜向冲击耐撞性研究 [J]. 爆炸与冲击, 2020, 40(11): 124–135.HUO P, XU S C, FAN X W, et al. Oblique impact resistance of a bionic thin-walled tube based on antles osteon [J]. Explosion and Shock Waves, 2020, 40(11): 124–135. [10] 白芳华, 张林伟, 白中浩, 等. 基于甲虫鞘翅的客车八边形仿生多胞薄壁管耐撞性研究 [J]. 振动与冲击, 2019, 38(21): 24–30.BAI F H, ZHANG L W, BAI Z H, et al. Crashworthiness of coach’s octagonal bionic mult-cell thin-walled tubes based on beetle elytra [J]. Journal of Vibration and Shock, 2019, 38(21): 24–30. [11] YIN H F, XIAO Y Y, WEN G L, et al. Crushing analysis and multi-objective optimization design for bionic thin-walled structure [J]. Materials & Design, 2015, 87: 825–834. [12] XIAO Y Y, YIN H F, FANG H B, et al. Crashworthiness design of horsetail-bionic thin-walled structures under axial dynamic loading [J]. International Journal of Mechanics and Materials in Design, 2016, 12(4): 563–576. doi: 10.1007/s10999-016-9341-6 [13] YIN H F, XIAO Y Y, WEN G L, et al. Multi-objective robust optimization of foam-filled bionic thin-walled structures [J]. Thin-Walled Structures, 2016, 109: 332–343. doi: 10.1016/j.tws.2016.10.011 [14] SUN G Y, TIAN X Y, FANG J G, et al. Dynamical bending analysis and optimization design for functionally graded thickness (FGT) tube [J]. International Journal of Impact Engineering, 2015, 78: 128–137. doi: 10.1016/j.ijimpeng.2014.12.007 [15] 尹华伟, 王陈凌, 段金曦, 等. 新型薄壁管耐撞性分析及优化设计 [J]. 高压物理学报, 2021, 35(3): 034202. doi: 10.11858/gywlxb.20200624YIN H W, WANG C L, DUAN J X, et al. Crashworthiness analysis and optimization design of new thin-walled tube [J]. Chinese Journal of High Pressure Physics, 2021, 35(3): 034202. doi: 10.11858/gywlxb.20200624 [16] 郝文乾, 卢进帅, 黄睿, 等. 轴向冲击载荷下薄壁折纹管的屈曲模态与吸能 [J]. 爆炸与冲击, 2015, 35(3): 380–385. doi: 10.11883/1001-1455-(2015)03-0380-06HAO W Q, LU J S, HUANG R, et al. Buckling and energy absorption properties of thin-walled corrugated tubes under axial impacting [J]. Explosion and Shock Waves, 2015, 35(3): 380–385. doi: 10.11883/1001-1455-(2015)03-0380-06 [17] MEGUID S A, ATTIA M S, MONFORT A. On the crush behaviour of ultralight foam-filled structures [J]. Materials & Design, 2004, 25(3): 183–189. [18] 穆雪峰, 姚卫星, 余雄庆, 等. 多学科设计优化中常用代理模型的研究 [J]. 计算力学学报, 2005, 22(5): 608–612.MU X F, YAO W X, YU X Q, et al. A survey of surrogate models used in MDO [J]. Chinese Journal of Computational Mechanics, 2005, 22(5): 608–612. [19] FANG J G, GAO Y K, SUN G Y, et al. Dynamic crashing behavior of new extrudable multi-cell tubes with a functionally graded thickness [J]. International Journal of Mechanical Sciences, 2015, 103: 63–73. doi: 10.1016/j.ijmecsci.2015.08.029 [20] FU J, LIU Q, LIU-FU K, et al. Design of bionic-bamboo thin-walled structures for energy absorption [J]. Thin-Walled Structures, 2019, 135: 400–413. doi: 10.1016/j.tws.2018.10.003 -

下载:

下载: