Numerical Study on Wave Effect of the Frictional Interface

-

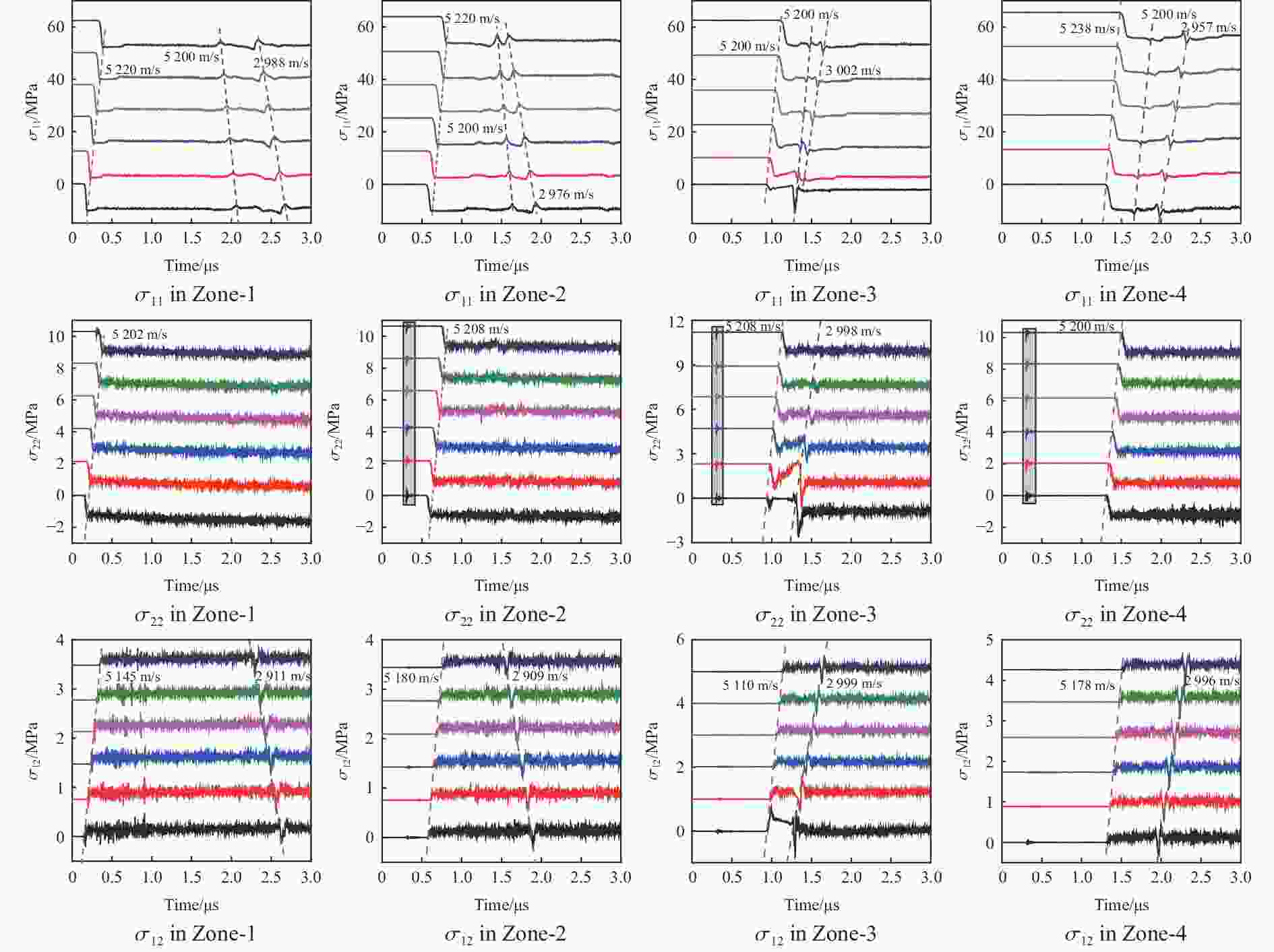

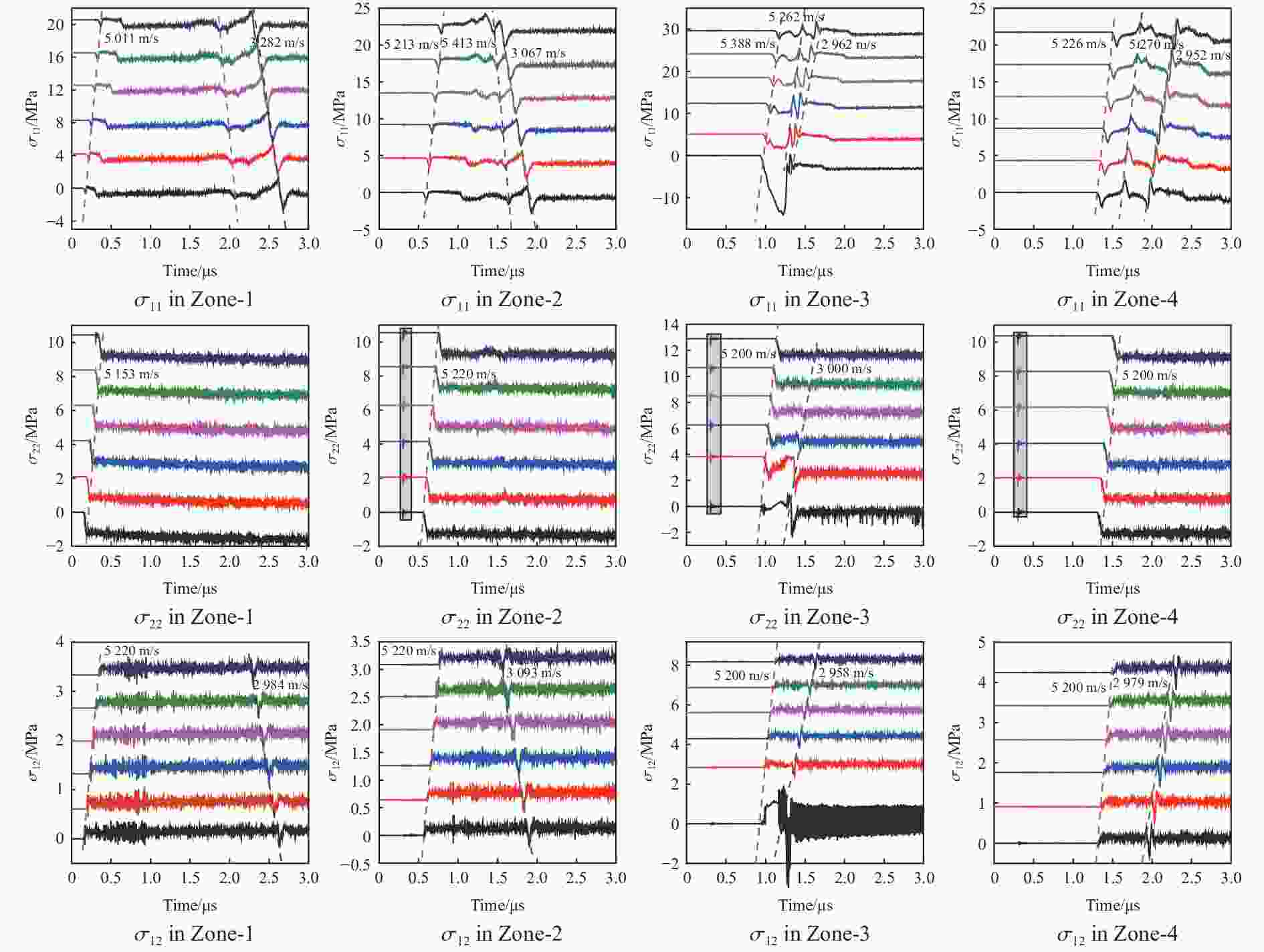

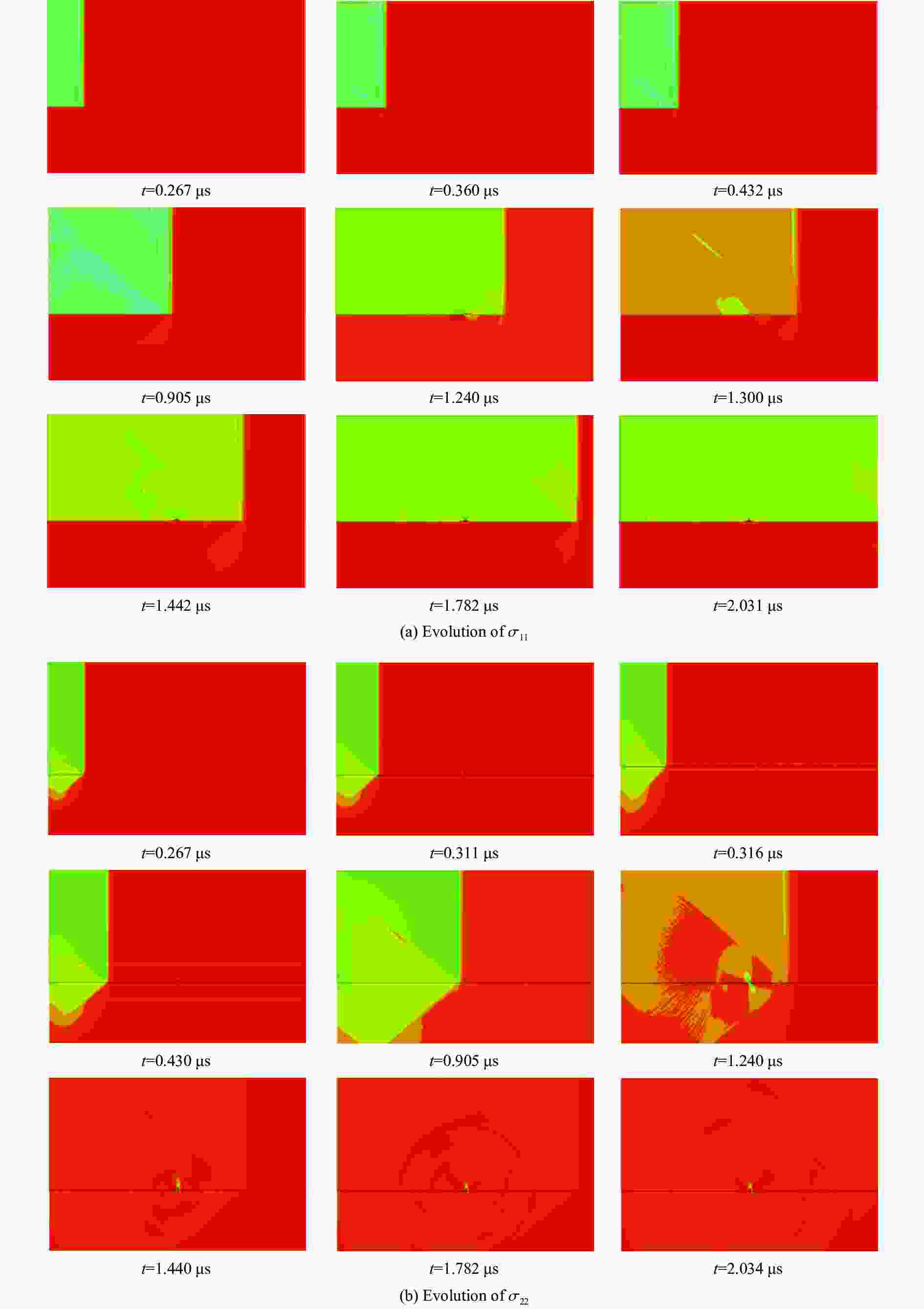

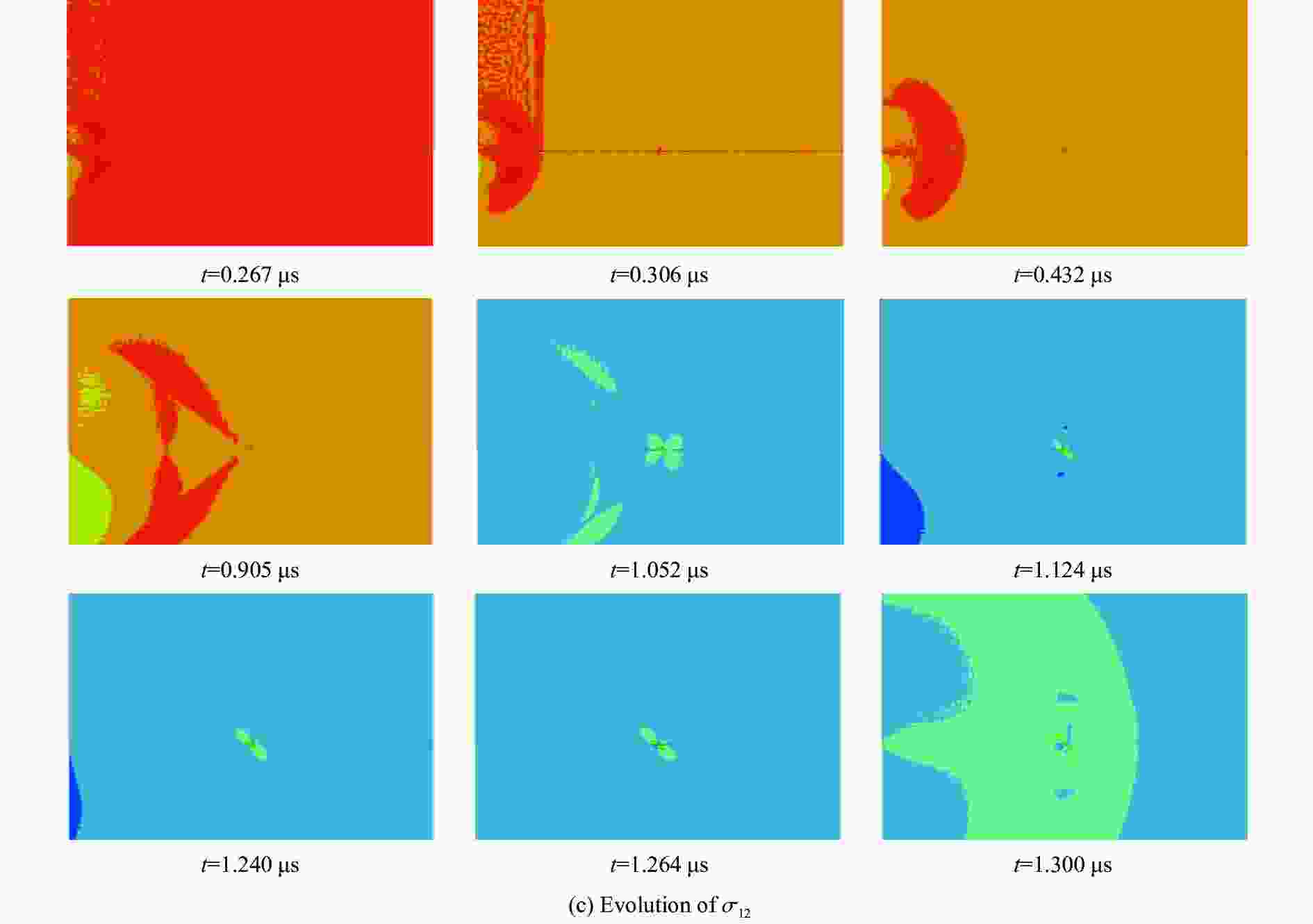

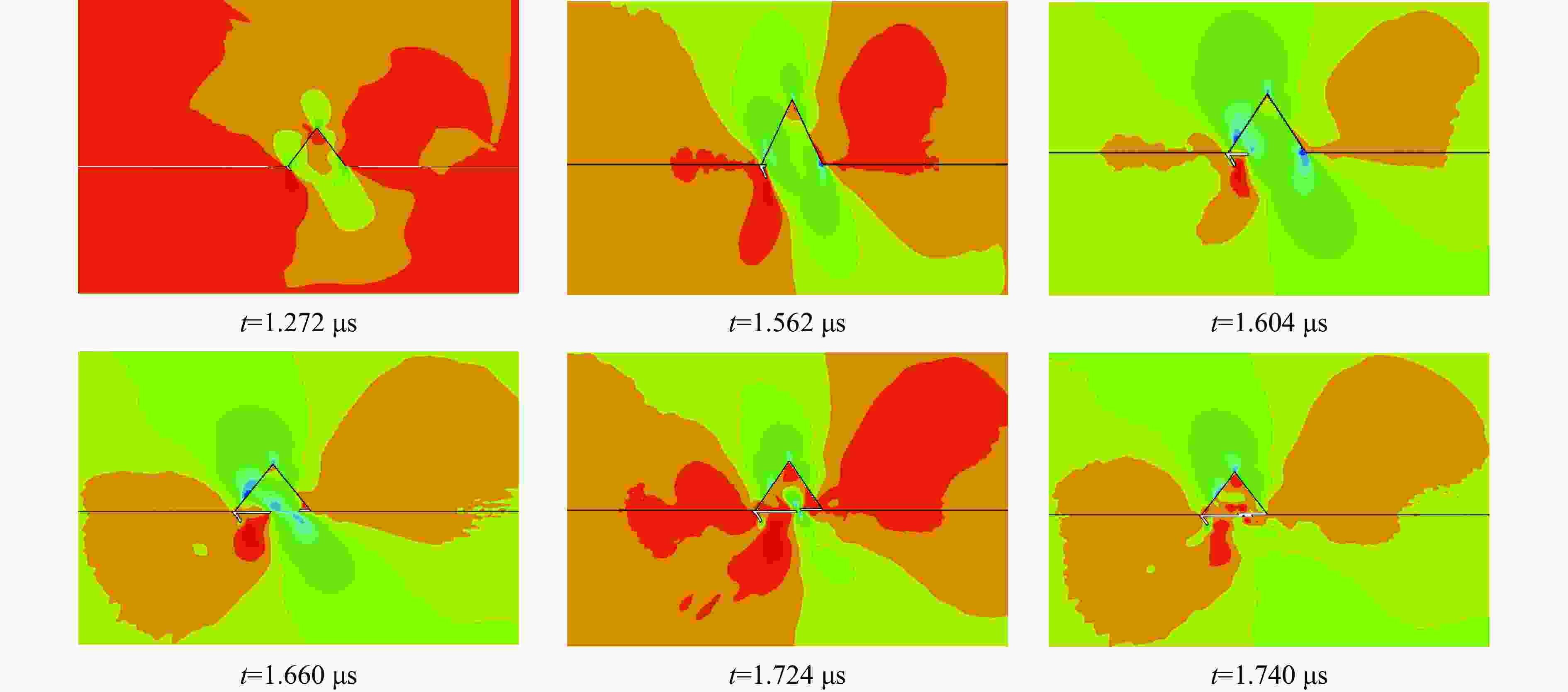

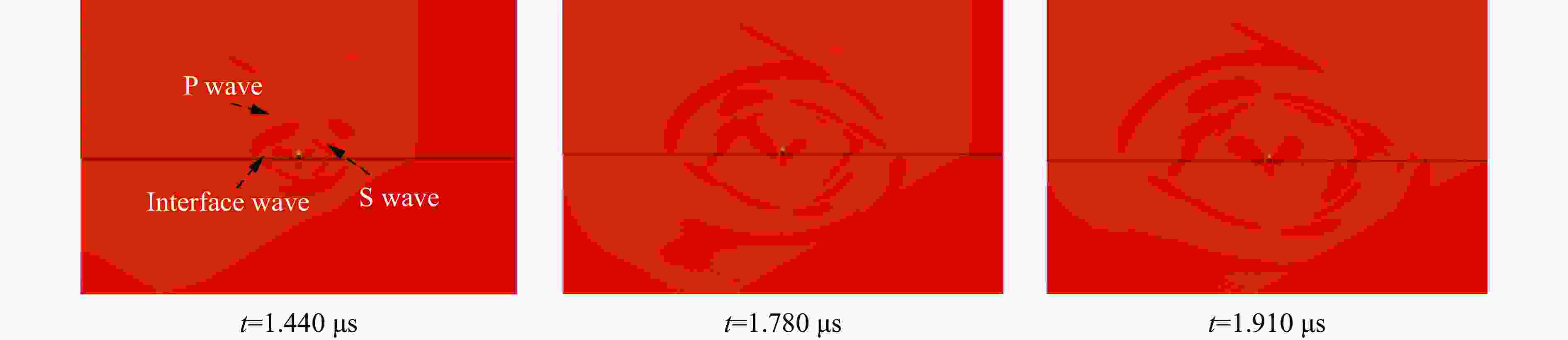

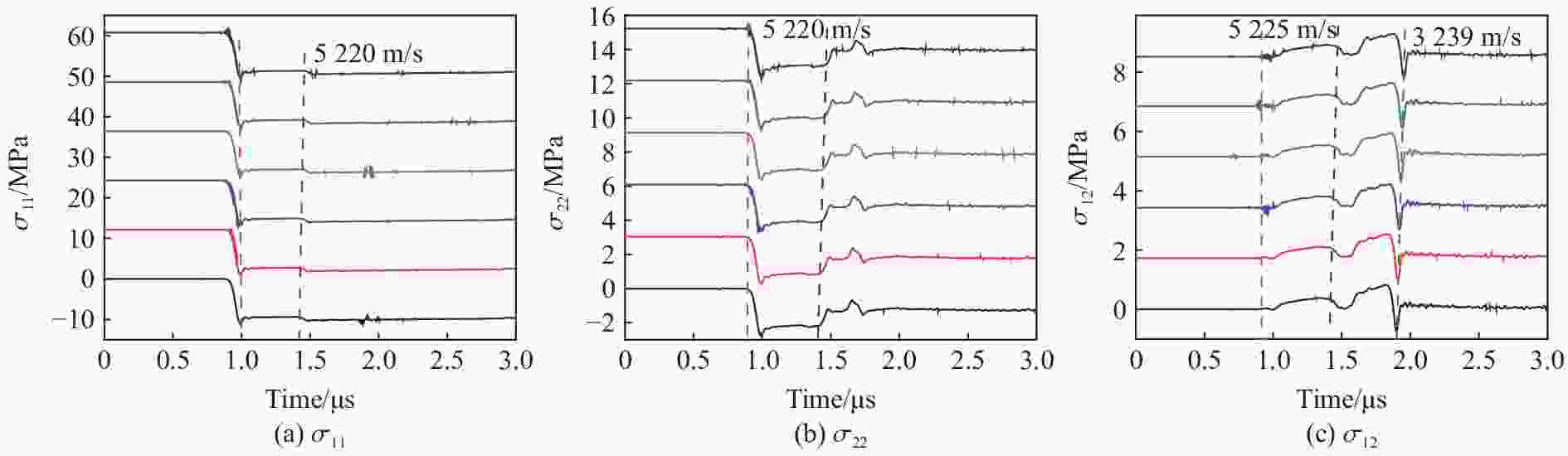

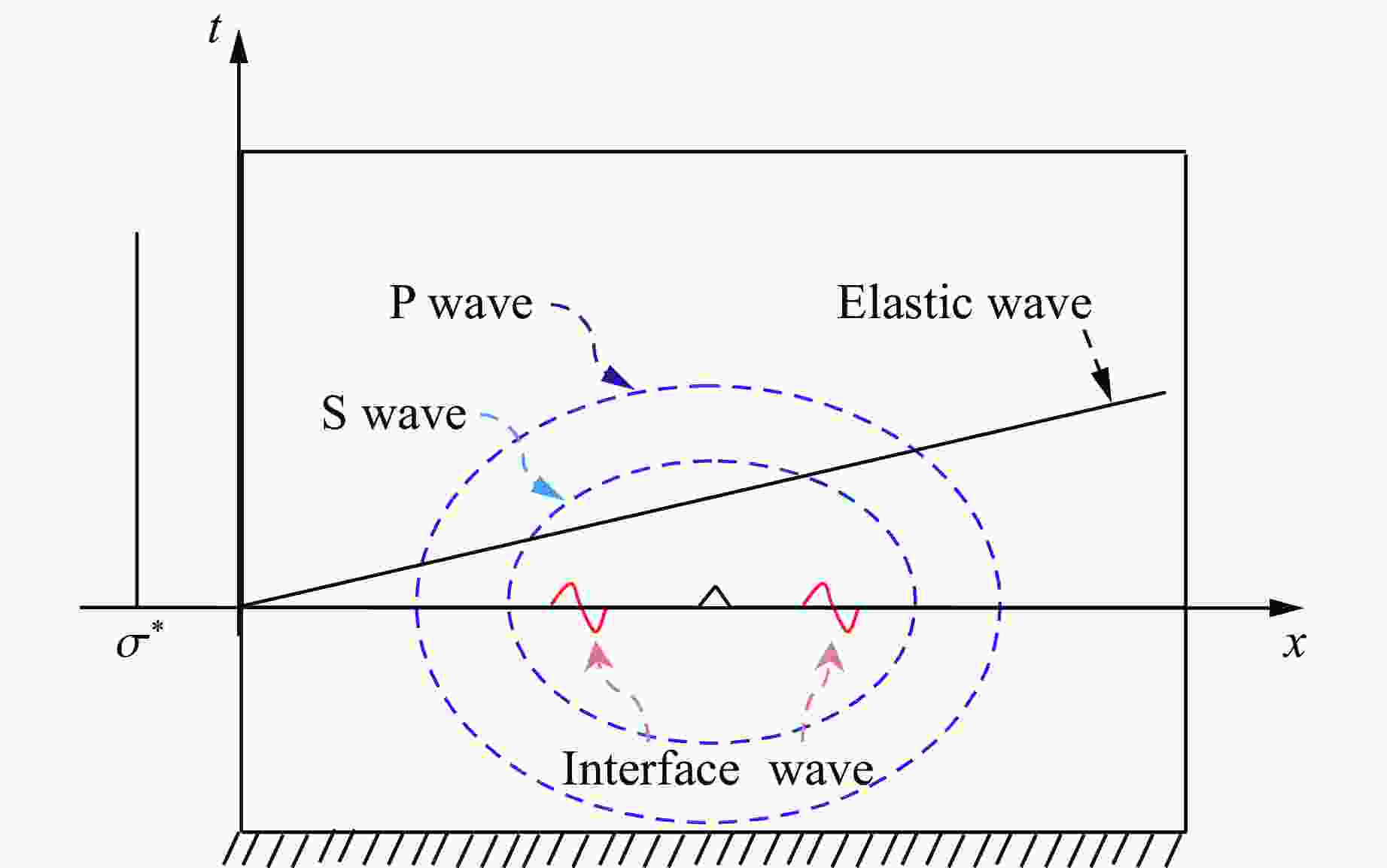

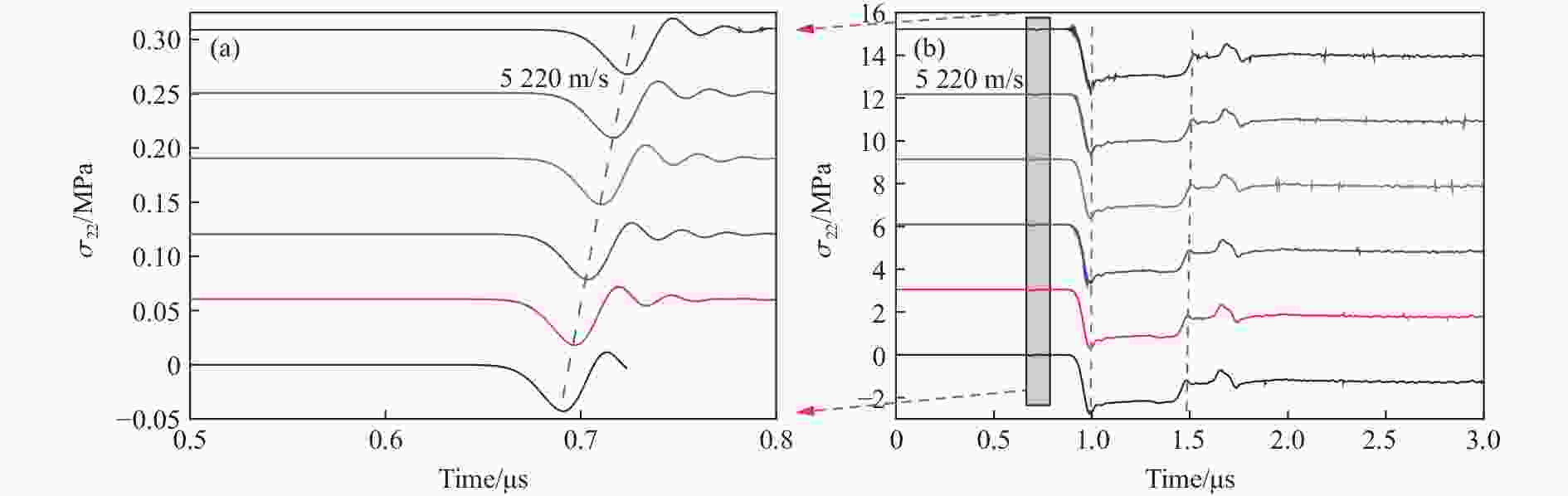

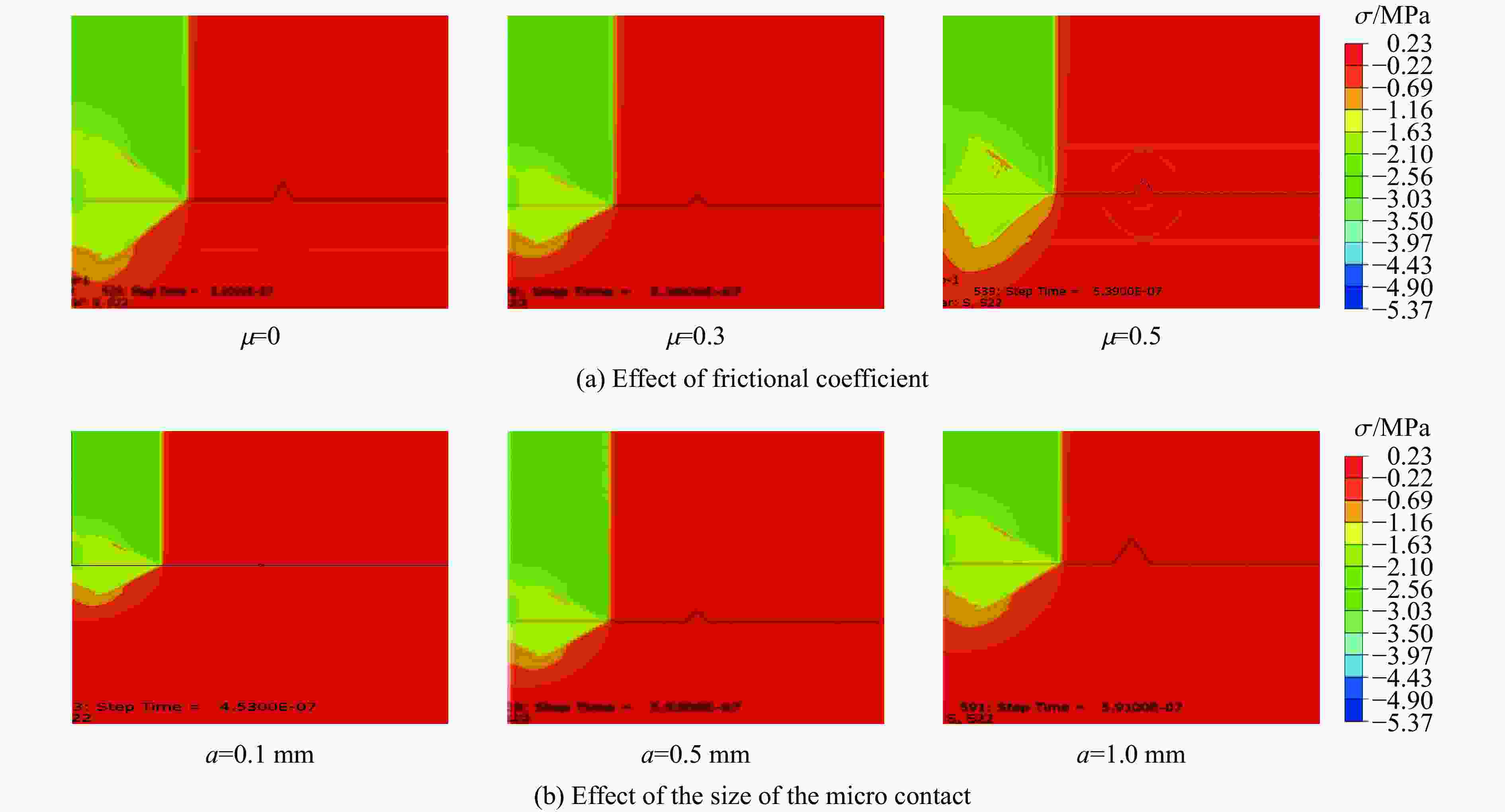

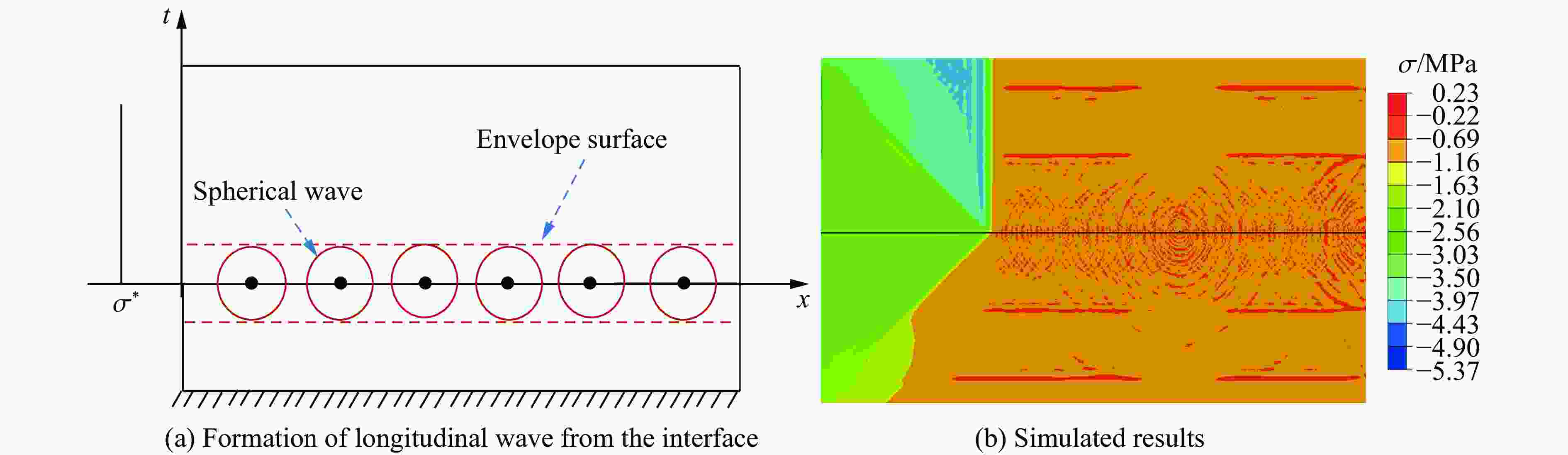

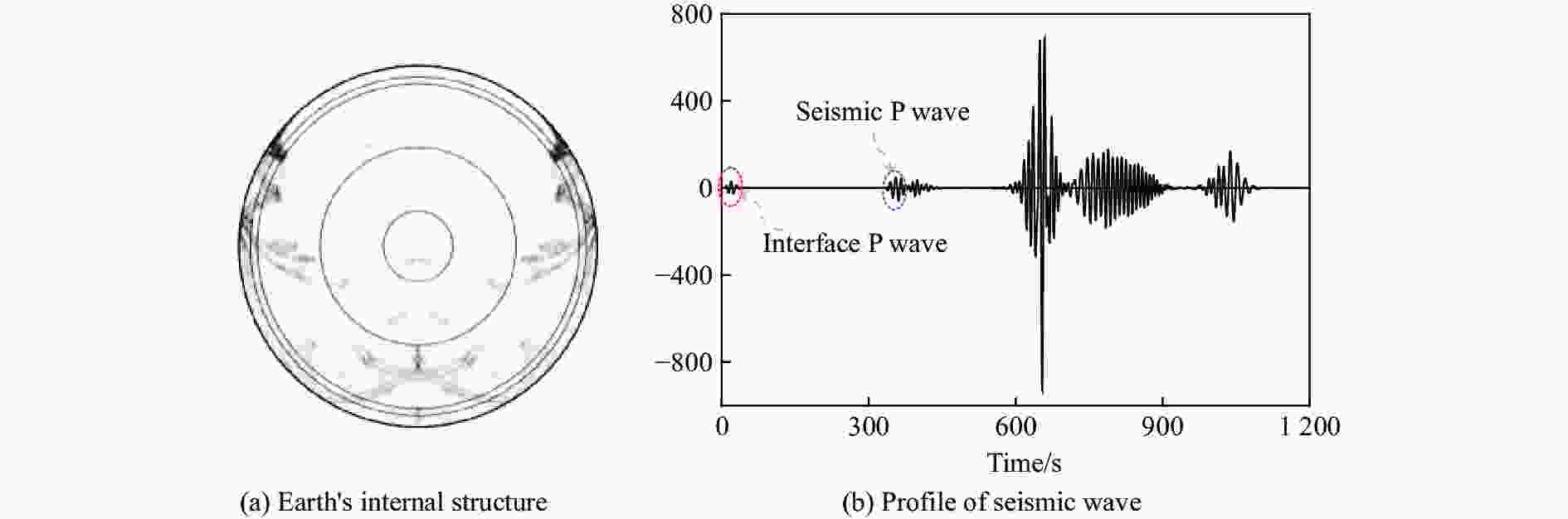

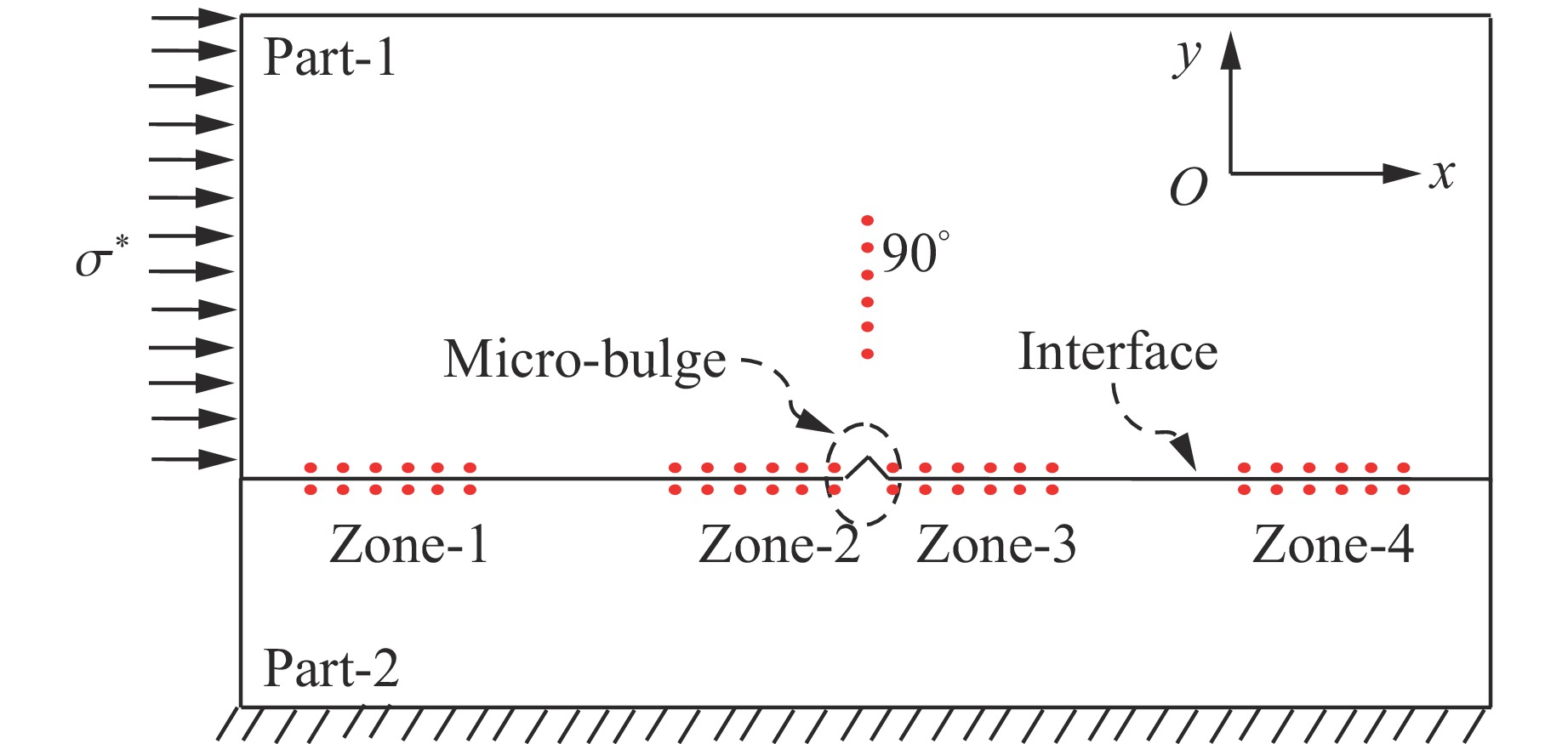

摘要: 界面摩擦是一种普遍的自然现象。基于摩擦的界面微接触断裂机制,采用线弹性本构关系和D-P破坏准则,建立了包含三角形微凸起的二维界面摩擦模型,采用有限元分析对入射波和摩擦界面的相互作用进行数值模拟。结果表明:在主动加载的微过程中,界面存在显著的应力波动及精细结构特征,波阵面在界面近区域内的演化具有对称扩散性,应力扰动作用于界面微凸起可诱发其断裂,从而以断裂面为中心形成纵波、横波和界面波结构。一个有趣的现象是,在加载的瞬间,界面几乎同步产生了微应力扰动,以纵波形式向基体内传播,更多比较算例和分析证实该扰动产生的物理机制同作用在界面的整体重力微调整有关。该工作揭示了摩擦早期的界面波动效应及其微断裂机制,有望为地震预测提供新的有效途径,从而实现将地震预测时间提前。Abstract: Interface friction is a common natural phenomenon. Based on the micro-contact fracture mechanism of friction, a two-dimensional interface friction model including a triangular micro bulge is established with linear elastic constitutive relationship and D-P failure criterion. The early dynamic behavior of the interface under transient loading is numerically calculated and analyzed by the finite element simulation method. The research shows that in the micro process of loading, there exist significant stress fluctuations and fine structure characteristics at frictional interfaces. The evolution of the wavefront in the near region of the interface has symmetrical diffusion. The interaction of the incoming stress disturbance and the micro bulge will induce the fracture of the bulge, resulting in a three-wave profile centered on the fracture surface: longitudinal wave, transverse wave, and interface wave. A new interesting phenomenon is that at the moment of loading, a micro stress disturbance is generated synchronously from the interface and propagates to the substrate in the form of longitudinal waves. More comparative examples and analysis show that the mechanism of this disturbance is related to the overall gravity micro-adjustment acting on the interface. This work reveals the early wave effect of interface friction and its micro fracture mechanism, which is expected to provide an effective way for earthquake prediction and to advance the earthquake prediction time.

-

Key words:

- wave mechanics /

- interface friction /

- simulation /

- fracture /

- earthquake prediction

-

表 1 计算材料参数

Table 1. Material parameters for calculation

Density/

(kg·m−3)Elastic modulus/GPa Shear modulus/GPa P wave velocity/(m·s–1) S wave velocity/(m·s–1) Friction coefficient Internal friction angle/(°) 2300 62.8 24.1 5225 3237 0.1 44 Expansion angle/(°) Hardening coefficient Fracture strain Tensile

strength/MPaCohesion strength/MPa Shear stress ratio Absolute plastic strain 0 6.98 0.0075 3.5 8 0.33 0 -

[1] 许金泉. 界面力学 [M]. 北京: 科学出版社, 2006.XU J Q. The mechanics of interface [M]. Beijing: Science Press, 2006. [2] RUBINSTEIN S M, COHEN G, FINEBERG J. Detachment fronts and the onset of dynamic friction [J]. Nature, 2004, 430(7003): 1005–1009. doi: 10.1038/nature02830 [3] RUBINSTEIN S M, COHEN G, FINEBERG J. Dynamics of precursors to frictional sliding [J]. Physical Review Letters, 2007, 98(22): 226103. doi: 10.1103/PhysRevLett.98.226103 [4] BEN-DAVID O, COHEN G, FINEBERG J. The dynamics of the onset of frictional slip [J]. Science, 2010, 330(6001): 211–214. doi: 10.1126/science.1194777 [5] ZHU Y D, ZHENG Z J, ZHANG Y L, et al. Adhesion of elastic wavy surfaces: interface strengthening/weakening and mode transition mechanisms [J]. Journal of the Mechanics and Physics of Solids, 2021, 151: 104402. doi: 10.1016/j.jmps.2021.104402 [6] PERSSON B N J. Sliding friction: physical principles and applications [M]. 2nd ed. Berlin: Springer, 2000. [7] TA W R, QIU S M, WANG Y L, et al. Volumetric contact theory to electrical contact between random rough surfaces [J]. Tribology International, 2021, 160: 107007. doi: 10.1016/j.triboint.2021.107007 [8] GERDE E, MARDER M. Friction and fracture [J]. Nature, 2001, 413(6853): 285–288. doi: 10.1038/35095018 [9] BAUMBERGER T, BERTHOUD P, CAROLI C. Physical analysis of the state- and rate-dependent friction law. Ⅱ. dynamic friction [J]. Physical Review B, 1999, 60(6): 3928–3939. doi: 10.1103/PhysRevB.60.3928 [10] BRAUN O M, MANINI N, TOSATTI E. Size scaling of static friction [J]. Physical Review Letters, 2013, 110(8): 085503. doi: 10.1103/PhysRevLett.110.085503 [11] BARRAS F, AGHABABAEI R, MOLINARI J F. Onset of sliding across scales: how the contact topography impacts frictional strength [J]. Physical Review Materials, 2021, 5(2): 023605. doi: 10.1103/PHYSREVMATERIALS.5.023605 [12] SHAO R L, WAHLE M, ZIMMERMANN M. A model for the dynamic friction behaviour of rubber-like materials [J]. Tribology International, 2021, 164: 107220. doi: 10.1016/j.triboint.2021.107220 [13] 张磊, 王文帅, 苗春贺, 等. 花岗岩粗糙表面动摩擦形态演化 [J]. 高压物理学报, 2021, 35(3): 031201. doi: 10.11858/gywlxb.20200640ZHANG L, WANG W S, MIAO C H, et al. Rough surface morphology of granite subjected to dynamic friction [J]. Chinese Journal of High Pressure Physics, 2021, 35(3): 031201. doi: 10.11858/gywlxb.20200640 [14] BERMAN N, COHEN G, FINEBERG J. Dynamics and properties of the cohesive zone in rapid fracture and friction [J]. Physical Review Letters, 2020, 125(12): 125503. doi: 10.1103/PhysRevLett.125.125503 [15] WANG P F, JIANG H B, XU S L, et al. Dynamic plastic instability of ring-shaped aluminum alloy with different interface behaviors [J]. International Journal of Impact Engineering, 2021, 155: 103898. doi: 10.1016/j.ijimpeng.2021.103898 [16] 赵剑衡, 孙承纬, 段祝平, 等. 玻璃样品表面对失效波萌生的影响 [J]. 力学学报, 2001, 33(6): 834–838. doi: 10.3321/j.issn:0459-1879.2001.06.014ZHAO J H, SUN C W, DUAN Z P, et al. Effect of impacted surface of K9 glass sample on formation of failure wave [J]. Acta Mechanica Sinica, 2001, 33(6): 834–838. doi: 10.3321/j.issn:0459-1879.2001.06.014 [17] 刘均伟, 张先锋, 刘闯, 等. 考虑摩擦因数变化的弹体高速侵彻混凝土质量侵蚀模型研究 [J]. 爆炸与冲击, 2021, 41(8): 083301. doi: 10.11883/bzycj-2020-0250LIU J W, ZHANG X F, LIU C, et al. Study on mass erosion model of projectile penetrating concrete at high speed considering variation of friction coefficient [J]. Explosion and Shock Waves, 2021, 41(8): 083301. doi: 10.11883/bzycj-2020-0250 [18] POCHIRAJU K V, TANDON G P, PAGANO N J. Analyses of single fiber pushout considering interfacial friction and adhesion [J]. Journal of the Mechanics and Physics of Solids, 2001, 49(10): 2307–2338. doi: 10.1016/S0022-5096(01)00045-X [19] 王蕉, 楚锡华. 冲击载荷下颗粒材料临边界区域的波动行为及变形特征分析 [J]. 力学学报, 2021, 53(9): 2395–2403. doi: 10.6052/0459-1879-21-242WANG J, CHU X H. Analysis of wave behavior and deformation characteristics of granular materials in pro-border zone under impact load [J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(9): 2395–2403. doi: 10.6052/0459-1879-21-242 [20] ZHENG W, ZHANG S Y, XU N. Jamming of packings of frictionless particles with and without shear [J]. Chinese Physics B, 2018, 27(6): 066102. doi: 10.1088/1674-1056/27/6/066102 [21] SCHOLZ C H. Earthquakes and friction laws [J]. Nature, 1998, 391(6662): 37–42. doi: 10.1038/34097 [22] KANAMORI H, ANDERSON D L, HEATON T H. Frictional melting during the rupture of the 1994 Bolivian earthquake [J]. Science, 1998, 279(5352): 839–842. doi: 10.1126/science.279.5352.839 [23] RUBINO V, ROSAKIS A J, LAPUSTA N. Understanding dynamic friction through spontaneously evolving laboratory earthquakes [J]. Nature Communications, 2017, 8: 15991. doi: 10.1038/ncomms15991 [24] PYRAK-NOLTE L J, XU J P, HALEY G M. Elastic interface waves propagating in a fracture [J]. Physical Review Letters, 1992, 68(24): 3650–3653. doi: 10.1103/PhysRevLett.68.3650 [25] XIA K W, ROSAKIS A J, KANAMORI H. Laboratory earthquakes: the sub-Rayleigh-to-supershear rupture transition [J]. Science, 2004, 303(5665): 1859–1861. doi: 10.1126/science.1094022 [26] FERRER C, SALAS F, PASCUAL M, et al. Discrete acoustic emission waves during stick-slip friction between steel samples [J]. Tribology International, 2010, 43(1/2): 1–6. doi: 10.1016/j.triboint.2009.02.009 [27] BRAUN O M, BAREL I, URBAKH M. Dynamics of transition from static to kinetic friction [J]. Physical Review Letters, 2009, 103(19): 194301. doi: 10.1103/PhysRevLett.103.194301 [28] SVETLIZKY I, FINEBERG J. Classical shear cracks drive the onset of dry frictional motion [J]. Nature, 2014, 509(7499): 205–208. doi: 10.1038/nature13202 [29] DI BARTOLOMEO M, MASSI F, BAILLET L, et al. Wave and rupture propagation at frictional bimaterial sliding interfaces: from local to global dynamics, from stick-slip to continuous sliding [J]. Tribology International, 2012, 52: 117–131. doi: 10.1016/j.triboint.2012.03.008 [30] KAMMER D S, MUÑOZ D P, MOLINARI J F. Length scale of interface heterogeneities selects propagation mechanism of frictional slip fronts [J]. Journal of the Mechanics and Physics of Solids, 2016, 88: 23–34. doi: 10.1016/j.jmps.2015.12.014 [31] 李永池. 波动力学 [M]. 合肥: 中国科学技术大学出版社, 2015.LI Y C. Wave mechanics [M]. Hefei: University of Science and Technology of China Press, 2015. -

下载:

下载: