Polyvinylidene Fluoride (PVDF) Phase Transitions under In-Situ High Pressure

-

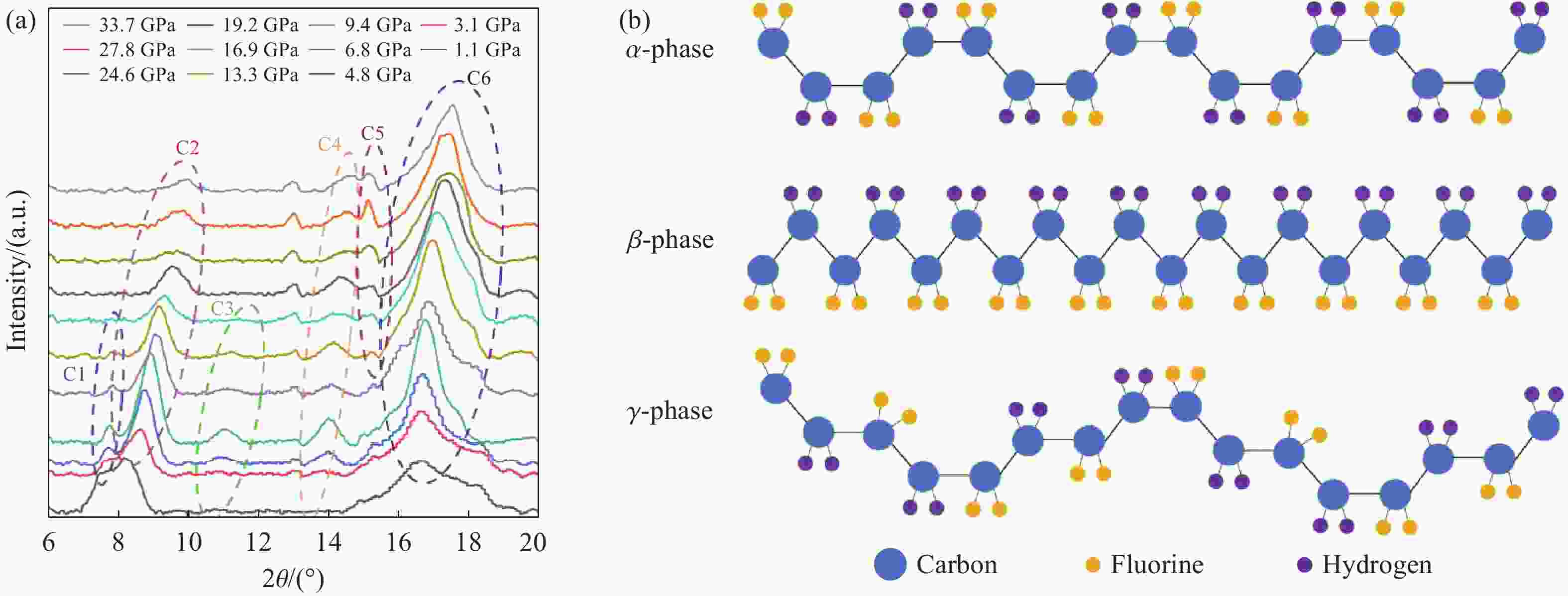

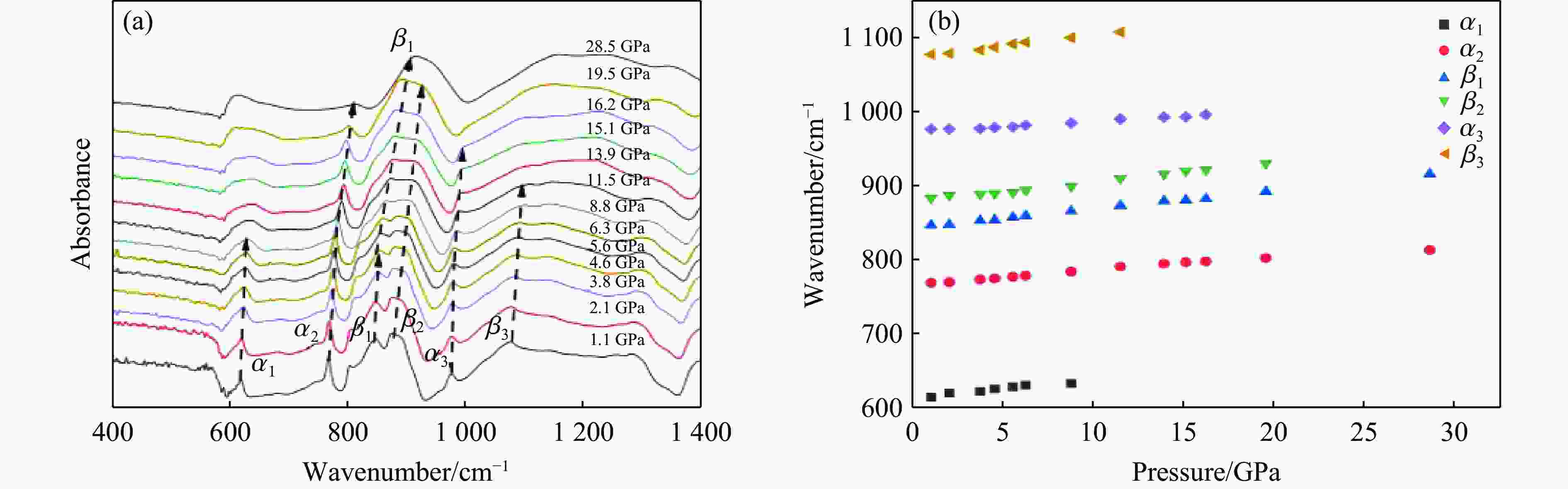

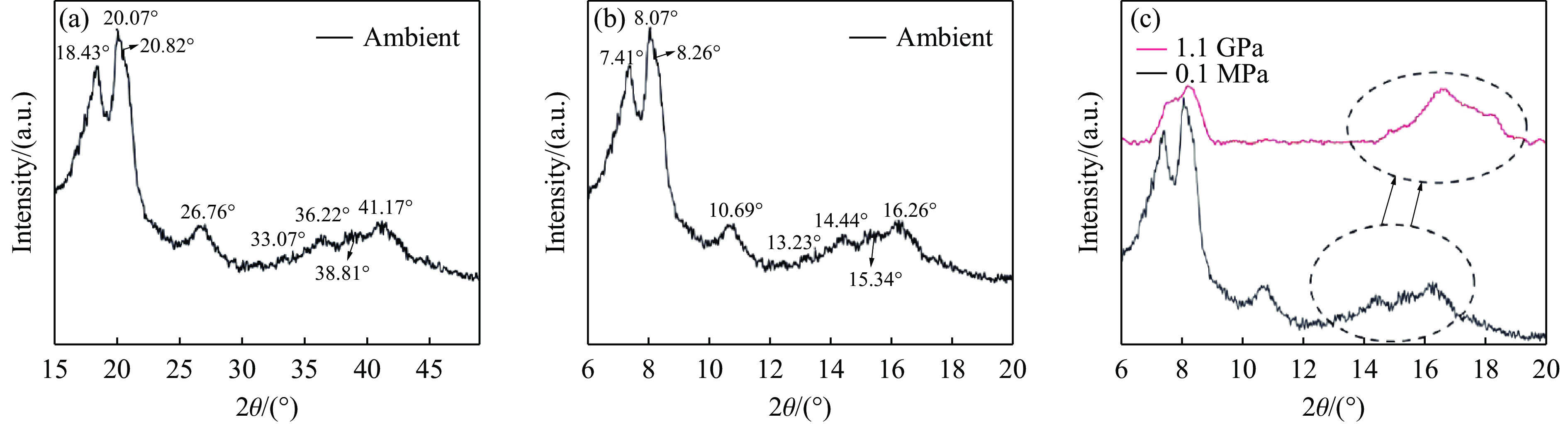

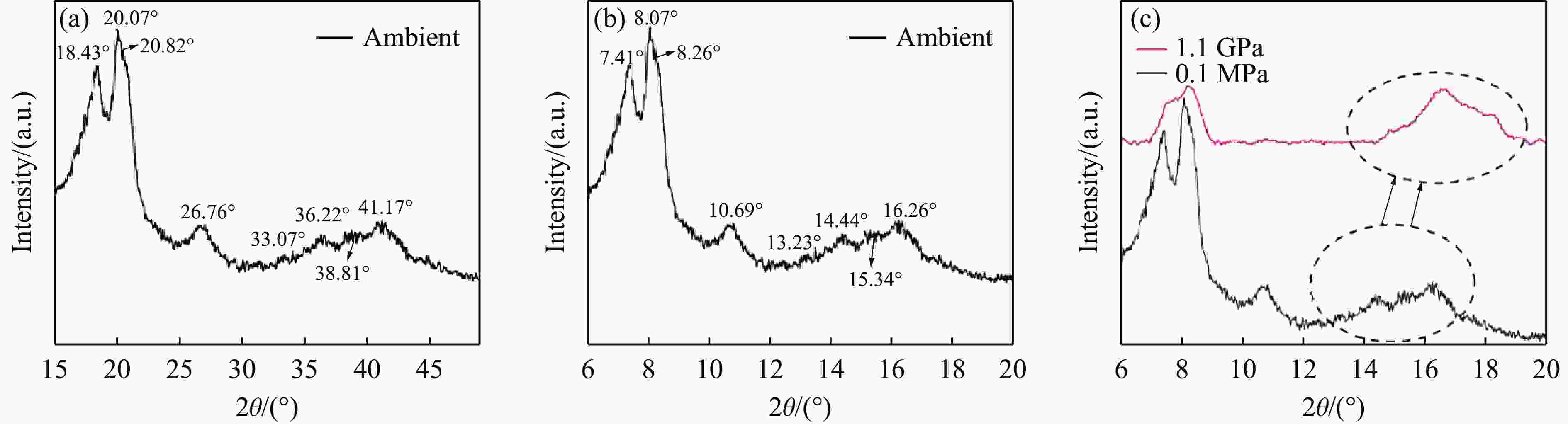

摘要: 聚偏二氟乙烯(polyvinylidene fluoride,PVDF)是一种多用途的半结晶聚合物,具有优异的压电、热释电和介电性能,被广泛应用于传感器、能源设备和生物医学等领域。PVDF的性能受结晶度和多晶结构(α、β、γ、δ、ε)的影响,其中,极性β相比非极性α相具有更优异的机电性能。然而,α相仍然是热力学最稳定和最容易获得的形式。利用原位X射线衍射和傅里叶红外光谱技术,研究了PVDF在高压下的结构演变。在常压条件下,PVDF粉体主要以 α相存在,并伴有少量β相。随着压力不断升高(0~20 GPa),α相逐渐减少,新的衍射峰和振动带位移表明发生了α→β 和β→γ相变,β相含量显著增加,γ相随之生成。当压力进一步升高至20 GPa以上时,晶格发生严重畸变,晶体长程有序结构被破坏,导致衍射峰展宽并最终非晶化。研究结果揭示了压力诱导下 PVDF分子链重排与多晶型转化之间的复杂相互作用,阐明了其高压相变路径与结构演化规律,不仅深化了对PVDF结构-性能关系的理解,也为其在极端环境下的性能调控与高压技术应用提供了理论依据。Abstract: Polyvinylidene fluoride (PVDF) is a versatile semi-crystalline polymer exhibiting outstanding piezoelectric, pyroelectric and dielectric properties, and is therefore widely employed in sensors, energy devices and biomedical applications. Its performance is governed by crystallinity and the polymorphic constitutiona (α, β, γ, δ, ε), among which the polar β-phase possesses superior electromechanical characteristics compared with the non-polar α-phase. Nevertheless, the α-phase remains the most stable and the most readily obtained thermodynamical form. The structural evolution of PVDF under high pressure is investigated by means of in situ X-ray diffraction and Fourier-transform infrared spectroscopy. At ambient conditions the powder consists primarily of the α-phase with a minor fraction of β. Upon compression to 0–20 GPa, the α phase gradually diminishes; the emergence of new diffraction peaks and band shifts indicates sequential α→β and β→γ transformations, accompanied by a pronounced increase in β content and concomitant formation of γ. When the pressure exceeds 20 GPa, severe lattice distortion destroys long-range crystalline order, resulting in peak broadening and eventual amorphization. The study unveils the intricate interplay between pressure-induced chain rearrangement and polymorphic transitions, clarifies the high-pressure phase-transformation pathway and structural evolution of PVDF, and thereby deepens the structure–property understanding of this polymer. The findings also provide a theoretical basis for tailoring its performance under extreme conditions and for designing high-pressure technologies.

-

Key words:

- PVDF /

- high pressure /

- structural phase transition /

- in-situ X-ray diffraction

-

图 1 (a) λ=1.541 8 Å 时PVDF粉末的XRD谱,(b) 使用布拉格方程(nλ=2dsin θ)计算得到的λ=0.619 9 Å 时PVDF粉末的XRD谱,(c) 常压和1.1 GPa下PVDF粉末的XRD谱对比

Figure 1. (a) XRD spectrum of powdered PVDF (λ=1.541 8 Å); (b) XRD spectrum of powdered PVDF calculated using the Bragg equation (nλ=2dsin θ) for λ=0.619 9 Å; (c) comparison of XRD spectra of powdered PVDF at atmospheric pressure and 1.1 GPa

表 1 PVDF主要晶型的结构和性能参数

Table 1. Structure and performance parameters of the main crystalline forms of PVDF

Crystal phase Crystal system Molecular chain conformation Polarity Space group Lattice parameters α Monoclinic TGTG´ Nonpolar P21/c a=4.96 Å, b=9.64 Å, c=4.62 Å, α0=β0=γ0=90° β Orthorhombic TTTT Strongly polar Cm2m a=8.58 Å, b=4.91 Å, c=2.56 Å, α0=β0=γ0=90° Unoriented-γ Monoclinic TTTGTTTG´ Weakly polar P21/c a=4.97 Å, b=9.66 Å, c=2.58 Å, α0=γ0=90°, β0=97° Oriented-γ Orthorhombic TTTGTTTG´ Weakly polar P21/c a=4.97 Å, b=9.66 Å, c=9.18 Å, α0=γ0=90°, β0=92.9° -

[1] DUAN B Y, WU K F, CHEN X Y, et al. Bioinspired PVDF piezoelectric generator for harvesting multi-frequency sound energy [J]. Advanced Electronic Materials, 2023, 9(8): 2300348. doi: 10.1002/aelm.202300348 [2] FAN W, LEI R X, DOU H, et al. Sweat permeable and ultrahigh strength 3D PVDF piezoelectric nanoyarn fabric strain sensor [J]. Nature Communications, 2024, 15(1): 3509. doi: 10.1038/S41467-024-47810-7 [3] MU J L, XIAN S, YU J B, et al. Synergistic enhancement properties of a flexible integrated PAN/PVDF piezoelectric sensor for human posture recognition [J]. Nanomaterials, 2022, 12(7): 1155. doi: 10.3390/NANO12071155 [4] ZOU X X, ZHU R J, CHEN X, et al. PVDF piezoelectric sensor based on solution blow spinning fibers for structural stress/strain health monitoring [J]. Smart Materials and Structures, 2024, 33(4): 045006. doi: 10.1088/1361-665X/ad2d6a [5] ZHOU H J, ZHANG Z J, SUN C X, et al. Biomimetic approach to facilitate the high filler content in free-standing and flexible thermoelectric polymer composite films based on PVDF and Ag2Se nanowires [J]. ACS Applied Materials & Interfaces, 2020, 12(46): 51506–51516. doi: 10.1021/acsami.0c15414 [6] KUMAR A, KUMAR R, SATAPATHY D K. Bi2Se3-PVDF composite: a flexible thermoelectric system [J]. Physica B: Condensed Matter, 2020, 593: 412275. doi: 10.1016/j.physb.2020.412275 [7] PAI Y H, XU C, ZHU R Y, et al. Piezoelectric-augmented thermoelectric ionogels for self-powered multimodal medical sensors [J]. Advanced Materials, 2025, 37(6): 2414663. doi: 10.1002/adma.202414663 [8] FERREIRA A, COSTA C M, CORREA M A, et al. Thermoelectric study of Co2FeAl thin films grown onto flexible P(VDF-TrFE-CFE) terpolymer [J]. Journal of Alloys and Compounds, 2023, 956: 170333. doi: 10.1016/J.JALLCOM.2023.170333 [9] TIWARI V, SRIVASTAVA G. Effect of thermal processing conditions on the structure and dielectric properties of PVDF films [J]. Journal of Polymer Research, 2014, 21(11): 587. doi: 10.1007/s10965-014-0587-0 [10] WANG Z, XUE W Q, YANG Y Z, et al. PMMA brush-modified graphene for flexible energy storage PVDF dielectric films [J]. Composites Communications, 2023, 37: 101411. doi: 10.1016/j.coco.2022.101411 [11] PADURARIU L, BRUNENGO E, CANU G, et al. Role of microstructures in the dielectric properties of PVDF-based nanocomposites containing high-permittivity fillers for energy storage [J]. ACS Applied Materials & Interfaces, 2023, 15(10): 13535–13544. doi: 10.1021/acsami.2c23013 [12] CHEN X L, SHI Y H, ZHANG K, et al. Synergistically depressed dielectric loss and elevated breakdown strength in core@double-shell structured Cu@CuO@MgO/PVDF nanocomposites [J]. Polymer, 2024, 307: 127321. doi: 10.1016/j.polymer.2024.127321 [13] CHEN Y X, CAO L L, SU Y L, et al. Enhancement of dielectric properties in flexible Ti3C2Tx/PVDF composite films [J]. Ceramics International, 2024, 50(3): 4323–4331. doi: 10.1016/J.CERAMINT.2023.11.016 [14] LOVINGER A J. Annealing of poly(vinylidene fluoride) and formation of a fifth phase [J]. Macromolecules, 1982, 15(1): 40–44. doi: 10.1021/ma00229a008 [15] 陈雨晴, 周峻, 吴锴, 等. 聚偏二氟乙烯(PVDF)多晶型特征的研究进展 [J]. 绝缘材料, 2022, 55(4): 1–12. doi: 10.16790/j.cnki.1009-9239.im.2022.04.001CHEN Y Q, ZHOU J, WU K, et al. Research progress in polyvinylidene fluoride (PVDF) polycrystalline characteristics [J]. Insulating Materials, 2022, 55(4): 1–12. doi: 10.16790/j.cnki.1009-9239.im.2022.04.001 [16] GREGORIO JR R, UENO E M. Effect of crystalline phase, orientation and temperature on the dielectric properties of poly(vinylidene fluoride) (PVDF) [J]. Journal of Materials Science, 1999, 34(18): 4489–4500. doi: 10.1023/A:1004689205706 [17] WANG W J, FAN H Q, YE Y X. Effect of electric field on the structure and piezoelectric properties of poly(vinylidene fluoride) studied by density functional theory [J]. Polymer, 2010, 51(15): 3575–3581. doi: 10.1016/j.polymer.2010.05.021 [18] LI L, ZHANG M Q, RONG M Z, et al. Studies on the transformation process of PVDF from α to β phase by stretching [J]. RSC Advances, 2014, 4(8): 3938–3943. doi: 10.1039/C3RA45134H [19] MAO H K, BELL P M, SHANER J W, et al. Specific volume measurements of Cu, Mo, Pd, and Ag and calibration of the ruby R1 fluorescence pressure gauge from 0.06 to 1 Mbar [J]. Journal of Applied Physics, 1978, 49(6): 3276–3283. doi: 10.1063/1.325277 [20] CHAUHAN A, CHAUHAN P. Powder XRD technique and its applications in science and technology [J]. Journal of Analytical & Bioanalytical Techniques, 2014, 5(5): 212. doi: 10.4172/2155-9872.1000212 [21] CAI X M, LEI T P, SUN D H, et al. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR [J]. RSC Advances, 2017, 7(25): 15382–15389. doi: 10.1039/c7ra01267e -

下载:

下载: