Discrete Element Simulation of Axially Compressed Energy Constitutive Relations in Defective Sandstone

-

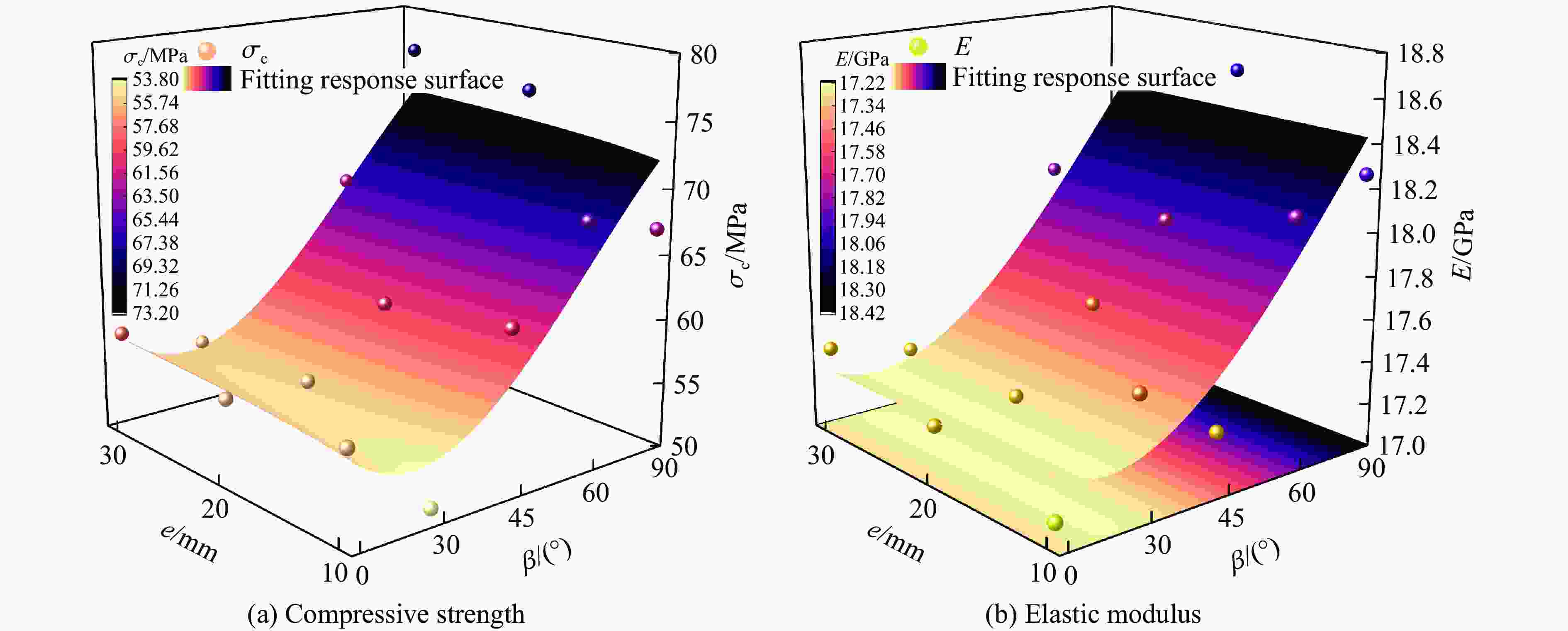

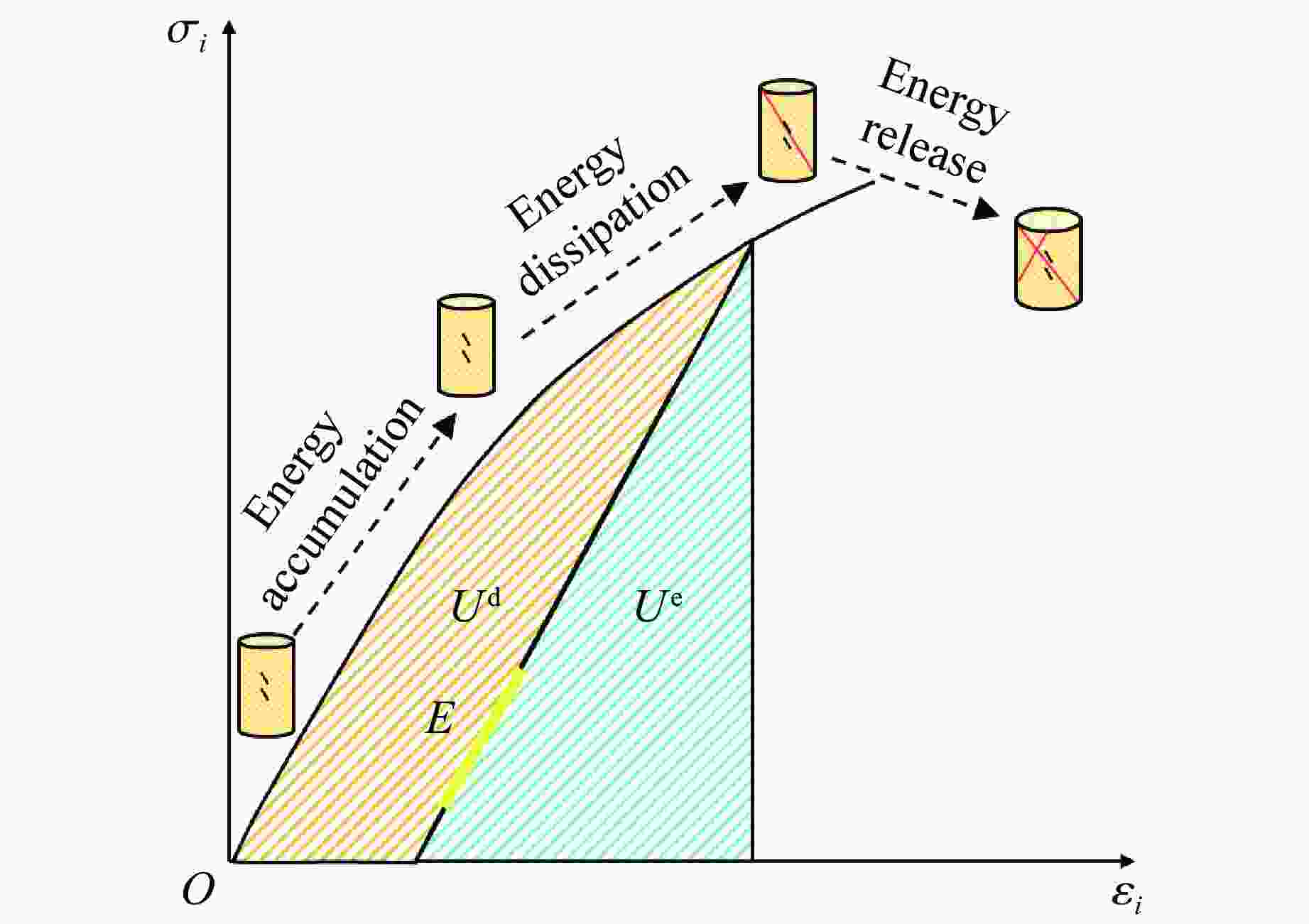

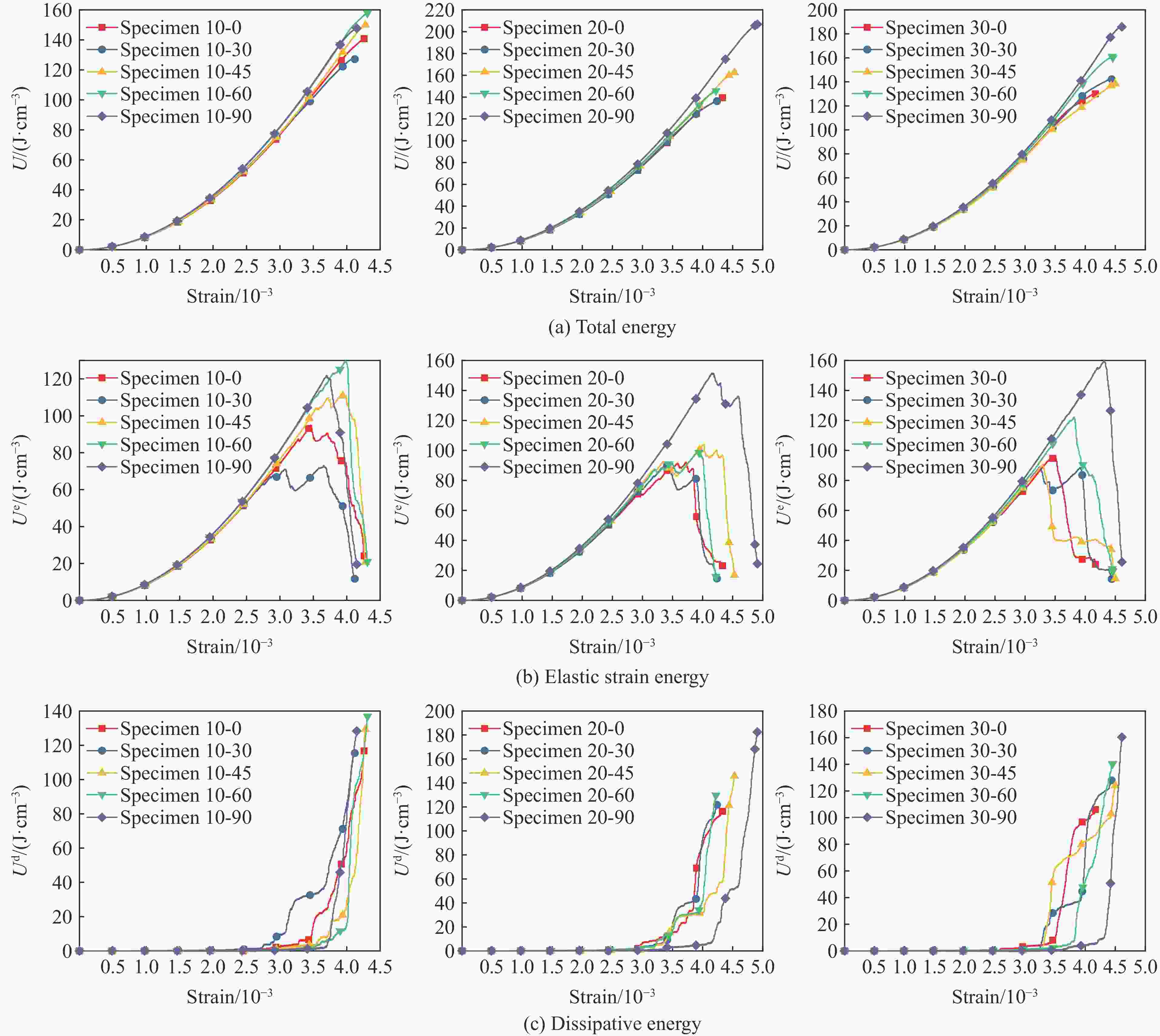

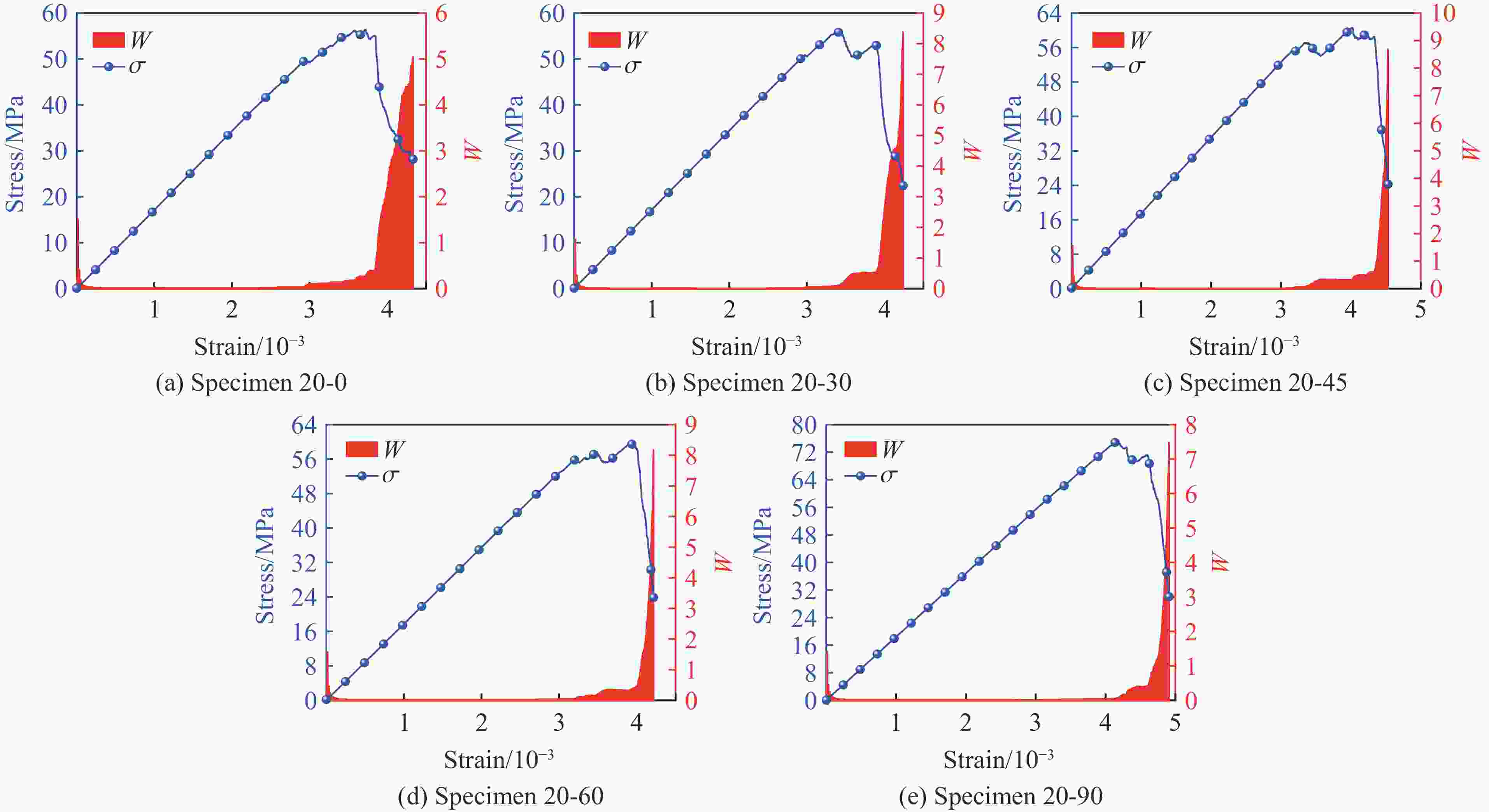

摘要: 为探究单轴压缩下缺陷砂岩的能量演化和力学行为,通过离散元法数值模拟,分析了不同岩桥倾角和岩桥距离对缺陷砂岩的影响,结合能量耗散建立了损伤本构方程。结果表明:岩桥倾角和岩桥距离显著影响缺陷砂岩的力学响应和破坏机制,大倾角(60°、90°)促进裂纹沿最大主应力方向扩展,而小倾角(0°、30°)增加剪切裂纹比例,导致不同的破坏形态;弹性模量和抗压强度随岩桥倾角和岩桥距离的变化呈“U”形非线性特征。能量演化规律对岩桥倾角具有依赖性,总能量和耗散能量随岩桥倾角的增加先降低后升高,并在90°时达到最大。岩桥距离对能量的影响随岩桥倾角的变化而变化,当岩桥倾角小于45°时,能量随岩桥距离的增加而减少,当岩桥倾角大于45°时,能量随岩桥距离的增加先增加后减少。弹性能耗比的三阶段特征可作为缺陷砂岩失稳的预测指标。基于耗散能理论构建的能量耗散损伤本构模型能够准确地描述不同岩桥参数下缺陷砂岩的变形和破坏行为。该模型在实际工程中具有重要的应用潜力,但需要针对具体应力条件进行调整以优化预测准确性。研究结果可为岩土工程的灾害防治提供理论参考。Abstract: In order to investigate the energy evolution and mechanical behavior of defective sandstone under uniaxial compression, the discrete element method (DEM) is employed. Effects of different rock bridge inclination angles and distances on the mechanical behavior of defective sandstone are systematically studied by DEM, and established a damage constitutive equation based on energy dissipation. The results indicate that the rock bridge inclination angle and distance significantly affect the mechanical response and failure modes of defective sandstone. Large inclination angles (60°, 90°) facilitate crack propagation along the direction of maximum principal stress, while small inclination angles (0°, 30°) increase the proportion of shear cracks, leading to different failure patterns. Additionally, the elastic modulus and compressive strength exhibit a “U” -shaped nonlinear characteristic with the variation of inclination angle and distance. Moreover, the energy evolution pattern depends on the rock bridge inclination angle. The total energy and dissipated energy first decrease and then increase with increasing rock bridge inclination angle, and peaking at 90°. The influence of rock bridge distance on energy varies with inclination angle. For angles less than 45°, the two types of energy decrease with increasing distance. For angles greater than 45°, the two types of energy first increase and then decrease. The three-stage characteristic of the elastic energy dissipation ratio can serve as a predictive indicator of the instability of defective sandstone. Furthermore, the energy dissipation damage constitutive model constructed based on dissipated energy can accurately describe the deformation and failure behavior of defective sandstone under different rock bridge parameters. This model has significant application potential in practical engineering, but it needs to be adjusted according to specific stress conditions to optimize prediction accuracy. The research results can provide theoretical references for disaster prevention in geotechnical engineering.

-

Key words:

- uniaxial compression /

- defective sandstone /

- discrete element method /

- crack evolution /

- energy ontology

-

表 1 试验[19]与数值模拟得到的力学参数对比

Table 1. Comparison of mechanical parameters between test[19] and simulation

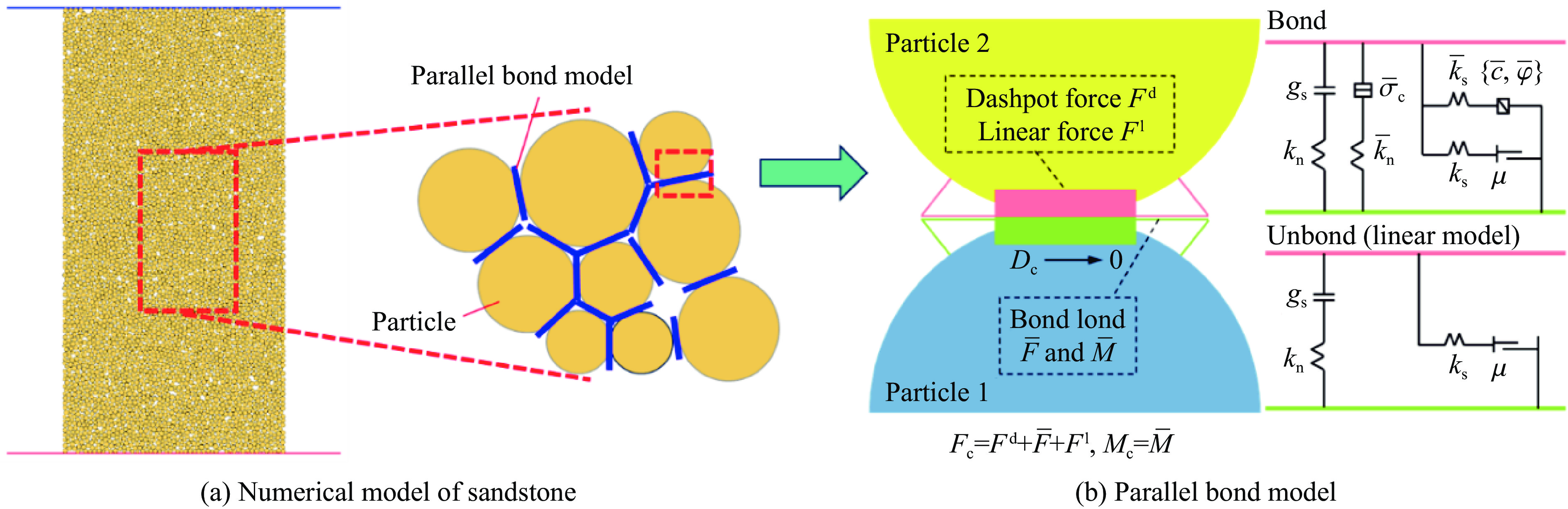

σmax εmax E Test/MPa Sim./MPa Error/% Test/10−3 Sim./ 10−3 Error/% Test/GPa Sim./GPa Error/% 84.96 85.68 0.8 4.62 4.71 1.9 20.01 18.84 5.8 表 2 砂岩的细观参数

Table 2. Microscopic parameters of sandstone

Ec/GPa $ {\overline{E}}_{\rm c} $/GPa k σb/MPa τb/MPa Damp value $ \overline{\varphi } $/(°) μ 15 15 1.33 10 9 0.7 70 0.2 表 3 数值模拟方案

Table 3. Numerical simulation scheme

Specimen No. e/mm β/(°) Specimen No. e/mm β/(°) Specimen No. e/mm β/(°) 10-0 10 0 20-0 20 0 30-0 30 0 10-30 10 30 20-30 20 30 30-30 30 30 10-45 10 45 20-45 20 45 30-45 30 45 10-60 10 60 20-60 20 60 30-60 30 60 10-90 10 90 20-90 20 90 30-90 30 90 表 4 含缺陷砂岩的力学参数

Table 4. Mechanical parameters of defective sandstone

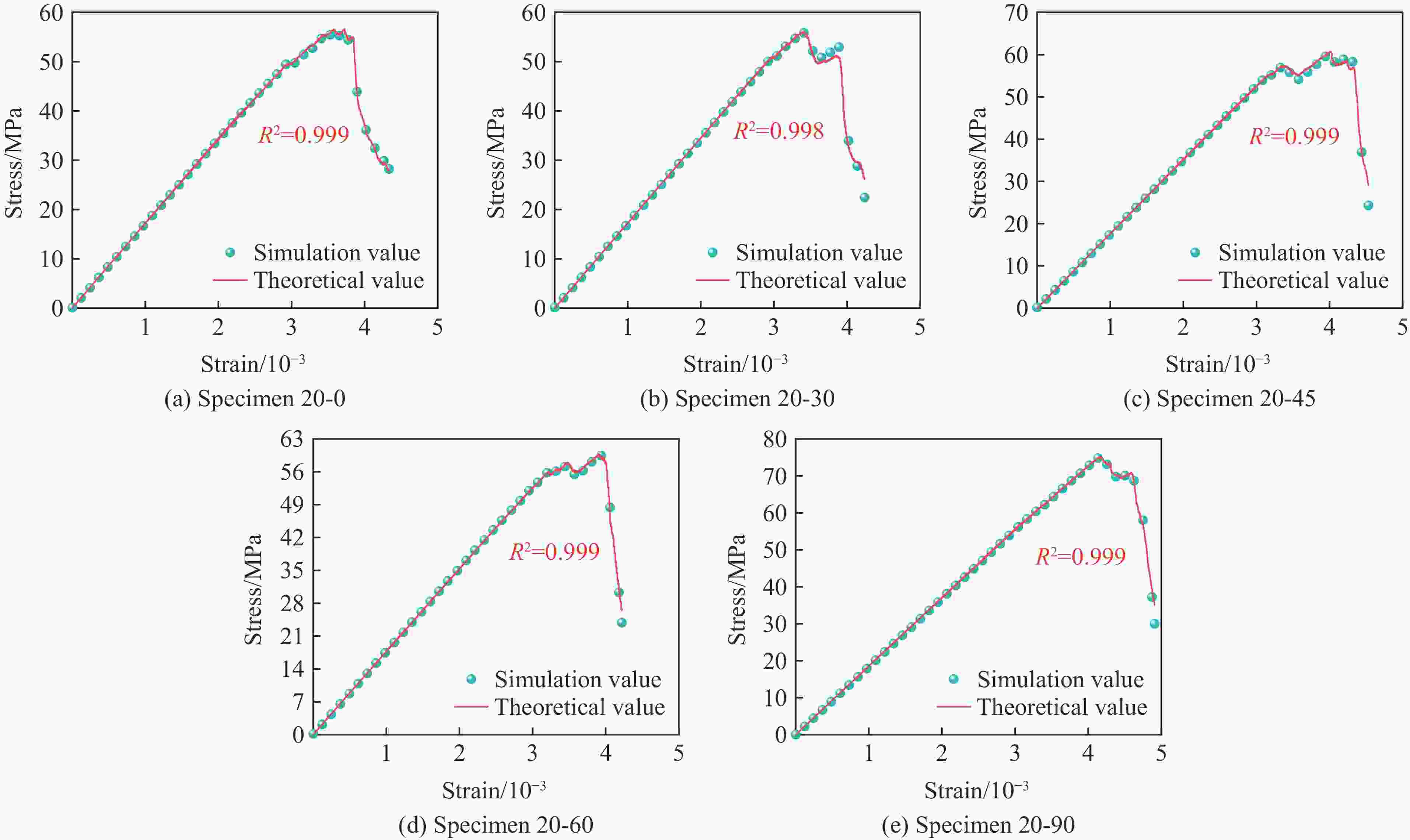

Specimen No. β/(°) σc/MPa E/GPa Specimen No. β/(°) σc/MPa E/GPa 10-0 0 56.9959 17.10 20-60 60 59.6775 17.95 10-30 30 50.6317 17.54 20-90 90 75.0862 18.60 10-45 45 62.1072 17.26 30-0 0 57.7452 17.39 10-60 60 68.5561 18.13 30-30 30 55.4792 17.29 10-90 90 66.7174 18.25 30-45 45 55.6131 17.06 20-0 0 56.3965 17.26 30-60 60 66.3709 18.04 20-30 30 56.0322 17.29 30-90 90 76.4695 18.31 20-45 45 60.5541 17.63 表 5 本构方程参数及拟合精度

Table 5. Constitutive equation parameters and fitting accuracy

Specimen No. m ω λ ϕ R2 10-0 0.001 −0.364 78.839 −0.242 0.999 10-30 −0.632 −0.145 29.205 −0.116 0.999 10-45 −1.021 −0.374 108.360 −0.460 0.999 10-60 −0.032 −0.027 6.610 −0.018 0.999 10-90 −0.515 −0.322 89.375 −0.381 0.999 20-0 −0.212 −0.066 15.181 −0.062 0.999 20-30 −0.016 −0.040 7.050 −0.019 0.998 20-45 −0.290 −0.225 53.109 −0.139 0.998 20-60 −4.647 −1.272 316.756 −1.196 0.999 20-90 −0.060 −0.020 7.033 −0.017 0.999 30-0 −0.672 −0.496 103.613 −0.432 0.999 30-30 −0.933 −0.785 168.428 −0.640 0.999 30-45 1.174 −3.509 547.213 −1.085 0.998 30-60 0.001 −0.025 6.504 −0.020 0.999 30-90 0.065 −0.082 28.310 −0.089 0.999 -

[1] MA W Q, MA Y H, CUI C. Critical instability characteristics and crack propagation process of sandstone containing two non-connected fissures under uniaxial compression [J]. Physics of Fluids, 2025, 37(6): 067158. doi: 10.1063/5.0274346 [2] CUI J, HU C X, CAI K J, et al. Experiment on progressive failure mechanism and anisotropic mechanical properties of differentially brittle-fractured sandstone under uniaxial compression [J]. Theoretical and Applied Fracture Mechanics, 2025, 139: 105024. doi: 10.1016/j.tafmec.2025.105024 [3] WEI S J, WANG W Y, REN D H, et al. Deformation, failure, and crack propagation characteristics of fissured red sandstone under uniaxial compression condition [J]. Scientific Reports, 2025, 15(1): 12254. doi: 10.1038/s41598-025-96552-z [4] SU G S, HUANG J W, LIU Y N. Crack propagation mechanism of fissured sandstone subjected to uniaxial cyclic compression test [J]. Theoretical and Applied Fracture Mechanics, 2025, 139: 105049. doi: 10.1016/j.tafmec.2025.105049 [5] YU M L, WANG Z W, XU Y, et al. The failure behavior of prefabricated fractured sandstone with different rock bridge inclination angles under freeze-thaw cycles [J]. Unconventional Resources, 2025, 6: 100152. doi: 10.1016/j.uncres.2025.100152 [6] SHI S, WANG G F, ZHU F J, et al. Investigation on fracture mechanism of rock containing pre-existing fissures subjected to freeze-thaw cycles under different stress conditions [J]. Theoretical and Applied Fracture Mechanics, 2025, 138: 104948. doi: 10.1016/j.tafmec.2025.104948 [7] CHEN J, YANG C Z, PAN X K, et al. Crack evolution behaviors and AE-DIC characteristics of double fractured sandstone considering the influence of high temperature [J]. Theoretical and Applied Fracture Mechanics, 2025, 139: 104990. doi: 10.1016/j.tafmec.2025.104990 [8] LIU Q, PAN C, YAN L, et al. Acoustic emission characteristics and damage constitutive model of fractured sandstone under uniaxial compression [J]. Scientific Reports, 2025, 15(1): 3128. doi: 10.1038/s41598-025-85257-y [9] BAO X K, JIANG B, CUI G Q, et al. Study on the crack propagation morphology and initiation law of coal rock under the action of underwater electric pulse [J]. Scientific Reports, 2025, 15(1): 2013. doi: 10.1038/s41598-025-86299-y [10] PENG C, DU X T, LIU W R, et al. Experimental and simulation study of fissure and hole effect on sandstone failure [J]. Alexandria Engineering Journal, 2025, 118: 579–590. doi: 10.1016/j.aej.2025.01.100 [11] ZHU W X, GUO Q B, HUA X, et al. Particle flow simulation experiments on the influence of non-penetrating random fractures on the deformation and failure characteristics of sandstone [J]. Results in Engineering, 2025, 27: 106025. doi: 10.1016/J.RINENG.2025.106025 [12] LIU G, ZAN Y L, WANG D W, et al. Numerical simulation of fracture failure propagation in water-saturated sandstone with pore defects under non-uniform loading effects [J]. Water, 2025, 17(12): 1725. doi: 10.3390/w17121725 [13] YANG S Q, LI H, DU S G, et al. Experiment and peridynamics simulation on failure mechanical behavior of cylindrical sandstone containing two persisting fissures under conventional triaxial compression [J]. Rock Mechanics and Rock Engineering, 2025, 58(3): 3129–3157. doi: 10.1007/s00603-024-04252-3 [14] FENG F, ZHANG T, ROSTAMI J, et al. Crack propagation and strength characteristic of sandstone with structural defects under extensive true triaxial tests by using DEM simulation [J]. Theoretical and Applied Fracture Mechanics, 2025, 138: 104971. doi: 10.1016/j.tafmec.2025.104971 [15] LIU J, PENG R, SHEN C Y, et al. Microfracture mechanism and fractal characteristics of sandstone with various prefabricated cracks [J]. Geotechnical and Geological Engineering, 2025, 43(5): 169. doi: 10.1007/s10706-025-03114-1 [16] QIN Z, LI Z W, SUN J H, et al. Study on the evolution law of fracture of sandstone under cyclic water intrusion based on particle-cement coupling damage [J]. Bulletin of Engineering Geology and the Environment, 2025, 84(6): 320. doi: 10.1007/s10064-025-04305-z [17] YU H, JIA H S, LI B Y. Macro-micro mechanical behavior and crack propagation mechanism of sandstone samples containing intermittent cracks [J]. KSCE Journal of Civil Engineering, 2025, 29(8): 100162. doi: 10.1016/J.KSCEJ.2025.100162 [18] PAN C, LIU W R, WANG X, et al. Mechanics and fracture behavior of rocks with triangular holes: experimental and numerical studies [J]. Computational Particle Mechanics, 2025, 12(1): 693–707. doi: 10.1007/s40571-024-00832-w [19] 张新春, 邹有云, 王敬德, 等. 不同岩性脆性岩石的单轴压缩力学特性及破坏规律 [J]. 科学技术与工程, 2025, 25(12): 5141–5150. doi: 10.12404/j.issn.1671-1815.2404995ZHANG X C, ZOU Y Y, WANG J D, et al. Uniaxial compression mechanical behaviors and failure rules of brittle rocks with different lithologies [J]. Science Technology and Engineering, 2025, 25(12): 5141–5150. doi: 10.12404/j.issn.1671-1815.2404995 [20] LI Q W, LI W X, PAN C C, et al. Influence of CFRP jackets stiffness on the performance of coal cylinders: 3D PFC-FLAC coupled numerical investigation [J]. Construction and Building Materials, 2025, 481: 141538. doi: 10.1016/j.conbuildmat.2025.141538 [21] 谭强, 胡朝赟, 张松涛, 等. 非贯通型充填节理对岩体力学特性影响的颗粒流模拟研究 [J]. 材料导报, 2025, 39(Suppl 1): 328–334.TAN Q, HU C Y, ZHANG S T, et al. Particle flow simulation study on the influence of non-through filling joints to mechanical properties of rock masses [J]. Materials Reports, 2025, 39(Suppl 1): 328–334. [22] 李庆文, 才诗婷, 李涵静, 等. 单裂隙岩石-混凝土组合体断裂特征颗粒流模拟 [J]. 高压物理学报, 2024, 38(5): 054202. doi: 10.11858/gywlxb.20240723LI Q W, CAI S T, LI H J, et al. Particle flow simulation of fracture characteristics of rock-concrete combination with single crack [J]. Chinese Journal of High Pressure Physics, 2024, 38(5): 054202. doi: 10.11858/gywlxb.20240723 [23] 张保勇, 王楠楠, 沈爽, 等. 非均匀性对含瓦斯水合物煤体力学特性影响: 试验与数值模拟研究 [J/OL]. 煤炭学报 [2025-07-25]. https://doi.org/10.13225/j.cnki.jccs.2025.0390.ZHANG B Y, WANG N N, SHEN S, et al. Impact of heterogeneity on mechanical properties of gas hydrate-bearing coal: experimental and numerical simulation study [J/OL]. Journal of China Coal Society [2025-07-25]. https://doi.org/10.13225/j.cnki.jccs.2025.0390. [24] 刘新喜, 李玉, 王玮玮, 等. 干湿循环作用下预制裂隙炭质页岩力学特性及强度准则研究 [J]. 岩石力学与工程学报, 2022, 41(2): 228–239. doi: 10.13722/j.cnki.jrme.2021.0730LIU X X, LI Y, WANG W W, et al. Research on mechanical properties and strength criterion of carbonaceous shale with pre-existing fissures under drying-wetting cycles [J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(2): 228–239. doi: 10.13722/j.cnki.jrme.2021.0730 [25] 陈光波, 唐薇, 李谭, 等. 裂隙煤岩组合体单轴压缩力学响应及失稳机制 [J]. 岩土力学, 2024, 45(9): 2633–2652. doi: 10.16285/j.rsm.2023.1677CHEN G B, TANG W, LI T, et al. Mechanical response and instability model of fractured coal-rock combined body [J]. Rock and Soil Mechanics, 2024, 45(9): 2633–2652. doi: 10.16285/j.rsm.2023.1677 [26] LI Q W, PAN C C, LI L, et al. Study on mechanical response and failure mechanism of fracture roof and coal pillar combined body: experiments and numerical simulations [J]. Materials Today Communications, 2025, 44: 111928. doi: 10.1016/j.mtcomm.2025.111928 [27] LI Q W, PAN C C, ZHONG Y Q, et al. Study on the damage constitutive characteristics of coal-rock composites under uniaxial compression: influence of prefabricated crack angle and geometric dimensions [J]. PLoS One, 2025, 20(3): e0316586. doi: 10.1371/journal.pone.0316586 [28] 张亮, 王桂林, 雷瑞德, 等. 单轴压缩下不同长度单裂隙岩体能量损伤演化机制 [J]. 中国公路学报, 2021, 34(1): 24–34. doi: 10.19721/j.cnki.1001-7372.2021.01.003ZHANG L, WANG G L, LEI R D, et al. Energy damage evolution mechanism of single jointed rock mass with different lengths under uniaxial compression [J]. China Journal of Highway and Transport, 2021, 34(1): 24–34. doi: 10.19721/j.cnki.1001-7372.2021.01.003 [29] 李庆文, 潘创创, 张学磊, 等. 基于颗粒流软件探究不同CFRP布层数对轴压煤圆柱能量演化的影响 [J]. 高压物理学报, 2025, 39(4): 045302. doi: 10.11858/gywlxb.20240931LI Q W, PAN C C, ZHANG X L, et al. Effect of CFRP layers on the energy evolution of axial compressed cylindrical coal based on particle flow software [J]. Chinese Journal of High Pressure Physics, 2025, 39(4): 045302. doi: 10.11858/gywlxb.20240931 [30] CAI W, BAI X X, SI G Y, et al. A monitoring investigation into rock burst mechanism based on the coupled theory of static and dynamic stresses [J]. Rock Mechanics and Rock Engineering, 2020, 53(12): 5451–5471. doi: 10.1007/s00603-020-02237-6 [31] 许文松, 张金栋, 赵光明, 等. 不同加载刚度砂岩失稳破坏特征及能量演化规律 [J]. 岩石力学与工程学报, 2024, 43(12): 2908–2923. doi: 10.13722/j.cnki.jrme.2024.0299XU W S, ZHANG J D, ZHAO G M, et al. Failure characteristics and energy evolution of sandstone with different loading stiffnesses [J]. Chinese Journal of Rock Mechanics and Engineering, 2024, 43(12): 2908–2923. doi: 10.13722/j.cnki.jrme.2024.0299 [32] LOU P J, JI P H, SUN L C, et al. Case study on the failure characteristics and energy evolution of three types of hole-fissured sandstone under wetting-drying cycles [J]. Applied Sciences, 2025, 15(5): 2318. doi: 10.3390/app15052318 [33] MA Q, TAN Y L, LIU X S, et al. Experimental and numerical simulation of loading rate effects on failure and strain energy characteristics of coal-rock composite samples [J]. Journal of Central South University, 2021, 28(10): 3207–3222. doi: 10.1007/s11771-021-4831-6 [34] 李子运, 吴光, 黄天柱, 等. 三轴循环荷载作用下页岩能量演化规律及强度失效判据研究 [J]. 岩石力学与工程学报, 2018, 37(3): 662–670. doi: 10.13722/j.cnki.jrme.2017.0927LI Z Y, WU G, HUANG T Z, et al. Variation of energy and criteria for strength failure of shale under traixial cyclic loading [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(3): 662–670. doi: 10.13722/j.cnki.jrme.2017.0927 [35] 孟庆彬, 王从凯, 黄炳香, 等. 三轴循环加卸载条件下岩石能量演化及分配规律 [J]. 岩石力学与工程学报, 2020, 39(10): 2047–2059. doi: 10.13722/j.cnki.jrme.2020.0208MENG Q B, WANG C K, HUANG B X, et al. Rock energy evolution and distribution law under triaxial cyclic loading and unloading conditions [J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(10): 2047–2059. doi: 10.13722/j.cnki.jrme.2020.0208 [36] 杜彬. 酸性环境干湿循环作用下红砂岩动态力学特性研究 [D]. 徐州: 中国矿业大学, 2019.DU B. Study on dynamic mechanical properties of red-sandstone under wet-dry cycle in acidic environment [D]. Xuzhou: China University of Mining and Technology, 2019. [37] LEMAITRE J. A continuous damage mechanics model for ductile fracture [J]. Journal of Engineering Materials and Technology, 1985, 107(1): 83–89. doi: 10.1115/1.3225775 [38] DHAR S, DIXIT P M, SETHURAMAN R. A continuum damage mechanics model for ductile fracture [J]. International Journal of Pressure Vessels and Piping, 2000, 77(6): 335–344. doi: 10.1016/S0308-0161(00)00019-3 [39] 傅强, 赵旭, 何嘉琦, 等. 基于能量转化原理的混杂纤维混凝土本构行为 [J]. 硅酸盐学报, 2021, 49(8): 1670–1682. doi: 10.14062/j.issn.0454-5648.20200047FU Q, ZHAO X, HE J Q, et al. Constitutive response of hybrid basalt-polypropylene fiber-reinforced concrete based on energy conversion principle [J]. Journal of the Chinese Ceramic Society, 2021, 49(8): 1670–1682. doi: 10.14062/j.issn.0454-5648.20200047 [40] 柏耀宗, 李波波, 任崇鸿, 等. 不同层理倾角煤岩损伤破裂机制及能量响应 [J]. 采矿与岩层控制工程学报, 2025, 7(1): 013028. doi: 10.13532/j.jmsce.cn10-1638/td.2024-1243BAI Y Z, LI B B, REN C H, et al. Damage and fracture mechanism and energy response of coal and rock with different bedding dip angles [J]. Journal of Mining and Strata Control Engineering, 2025, 7(1): 013028. doi: 10.13532/j.jmsce.cn10-1638/td.2024-1243 [41] 刘文博, 张树光, 陈雷, 等. 基于统计损伤原理的岩石加速蠕变模型研究 [J]. 岩土工程学报, 2020, 42(9): 1696–1704. doi: 10.11779/CJGE202009014LIU W B, ZHANG S G, CHEN L, et al. Accelerated creep model for rock based on statistical damage principle [J]. Chinese Journal of Geotechnical Engineering, 2020, 42(9): 1696–1704. doi: 10.11779/CJGE202009014 -

下载:

下载: