Machine Learning Potential Construction and Compressive Mechanical Properties of Al-Cu Intermetallic Compounds

-

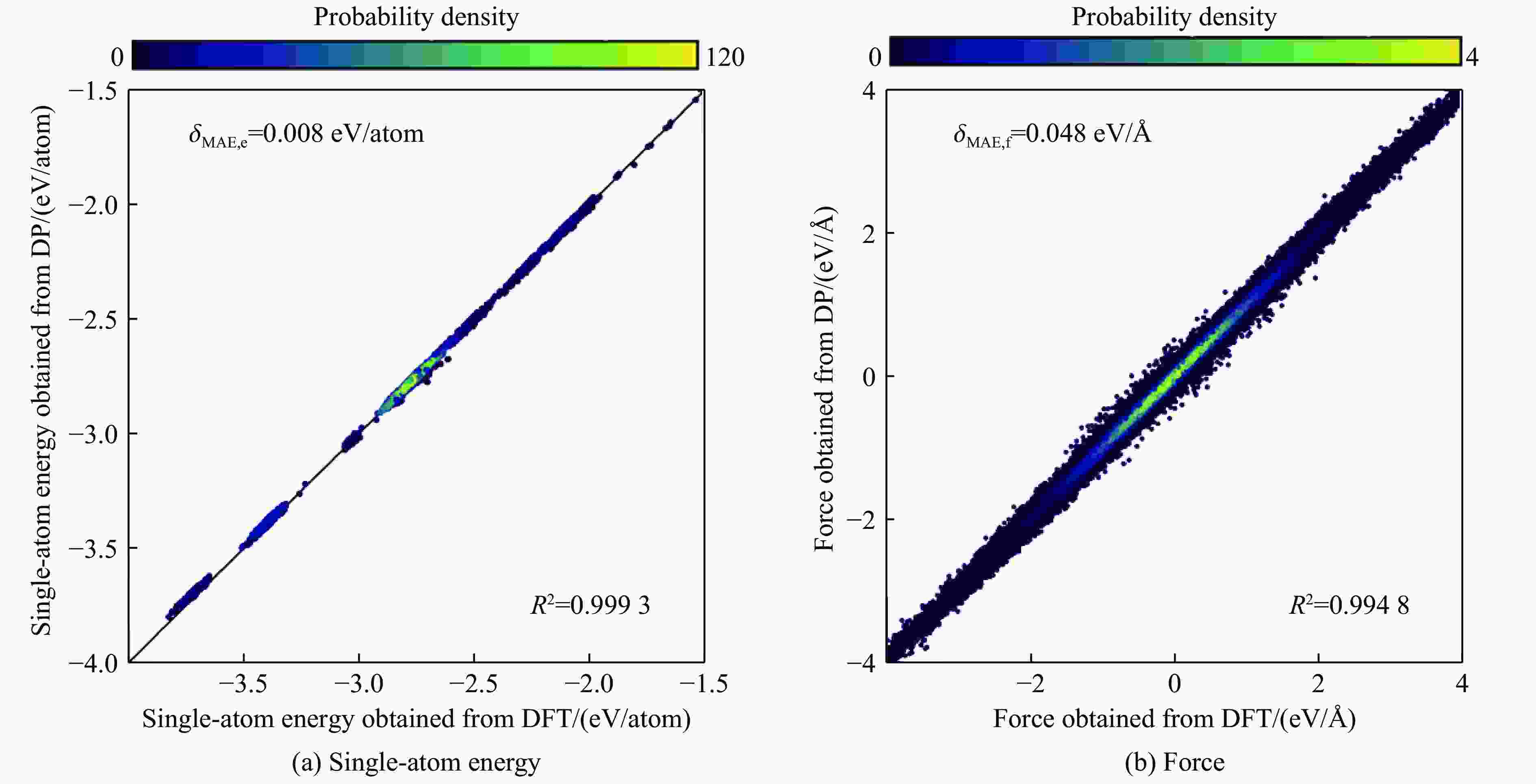

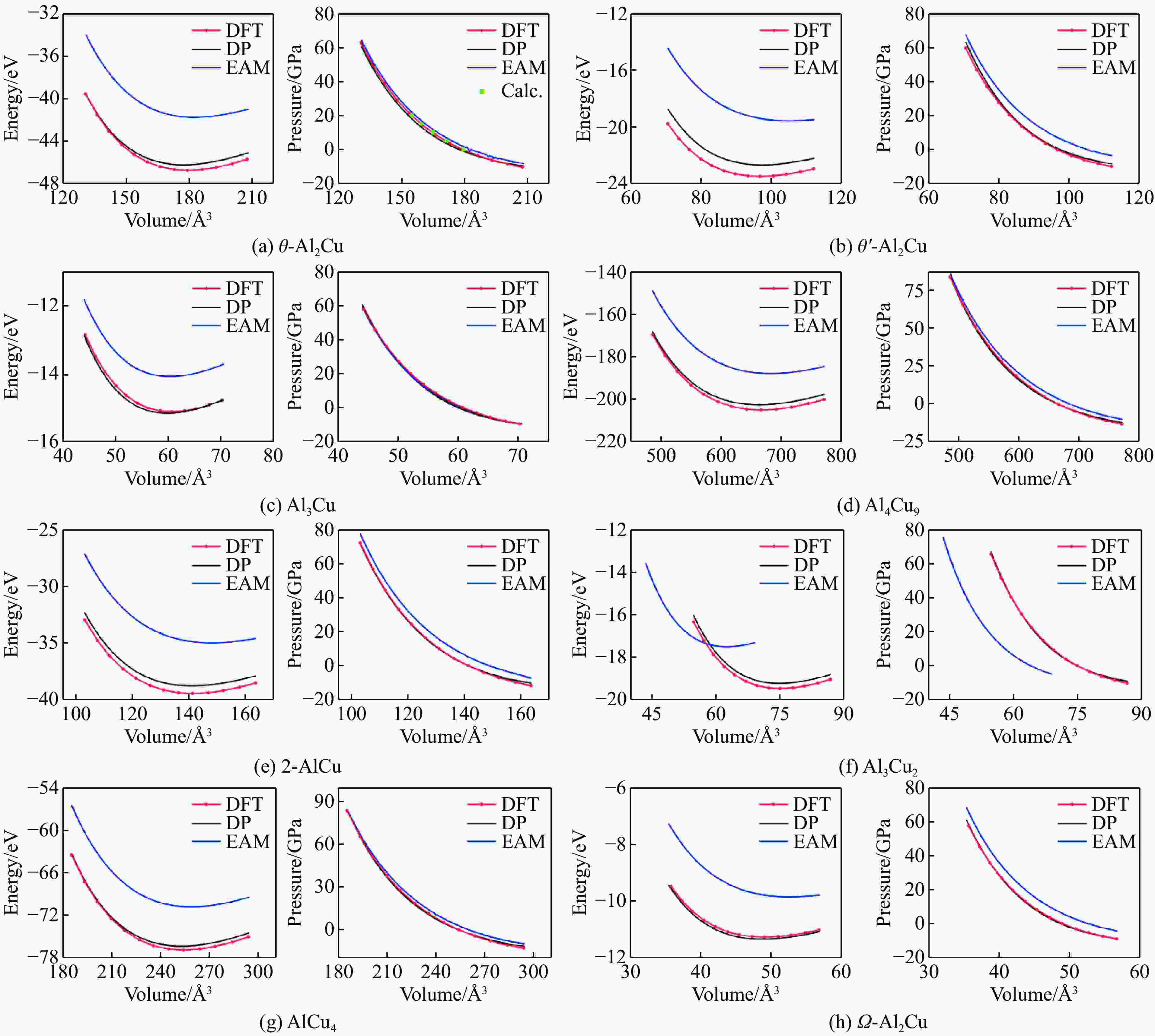

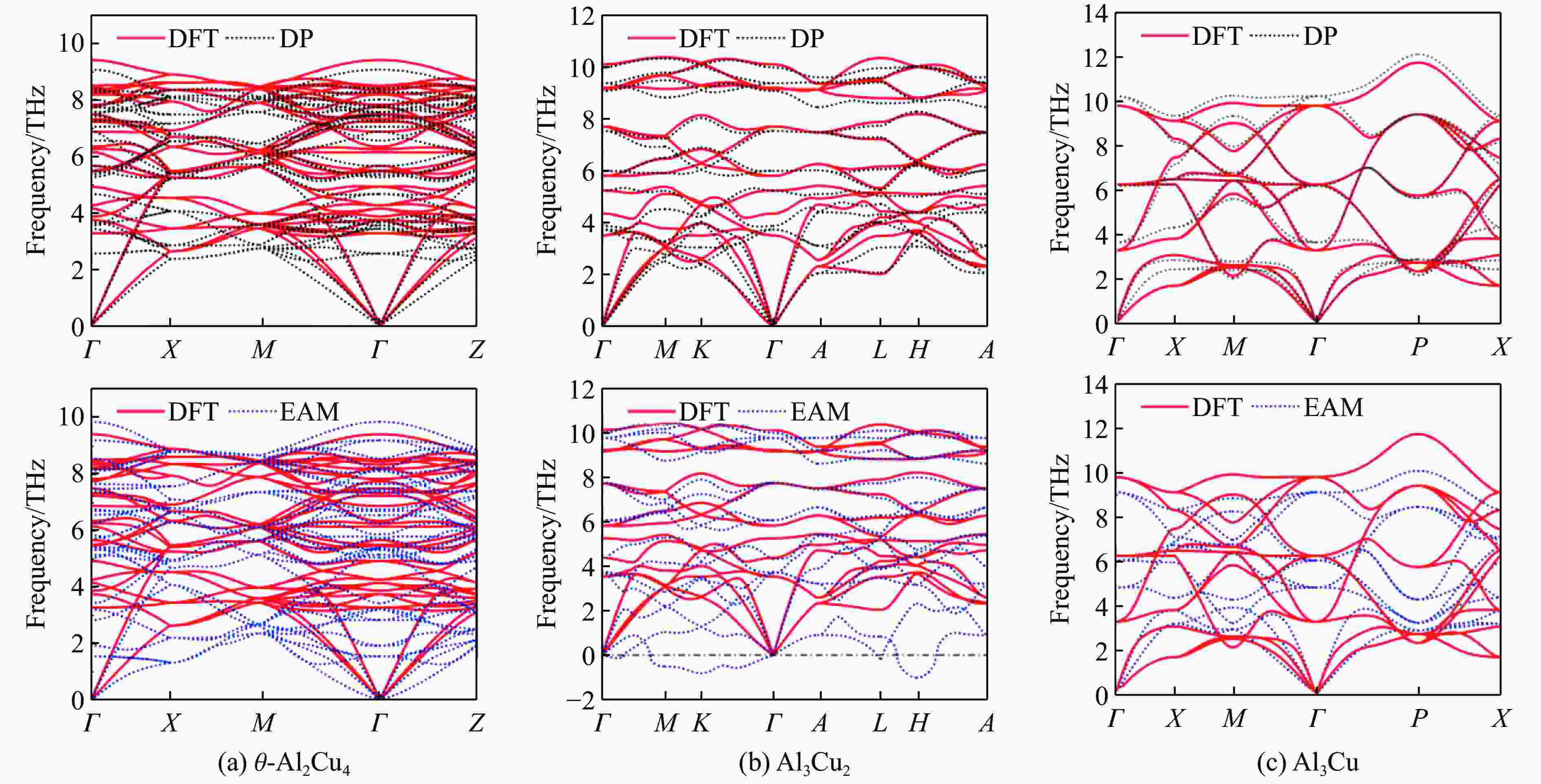

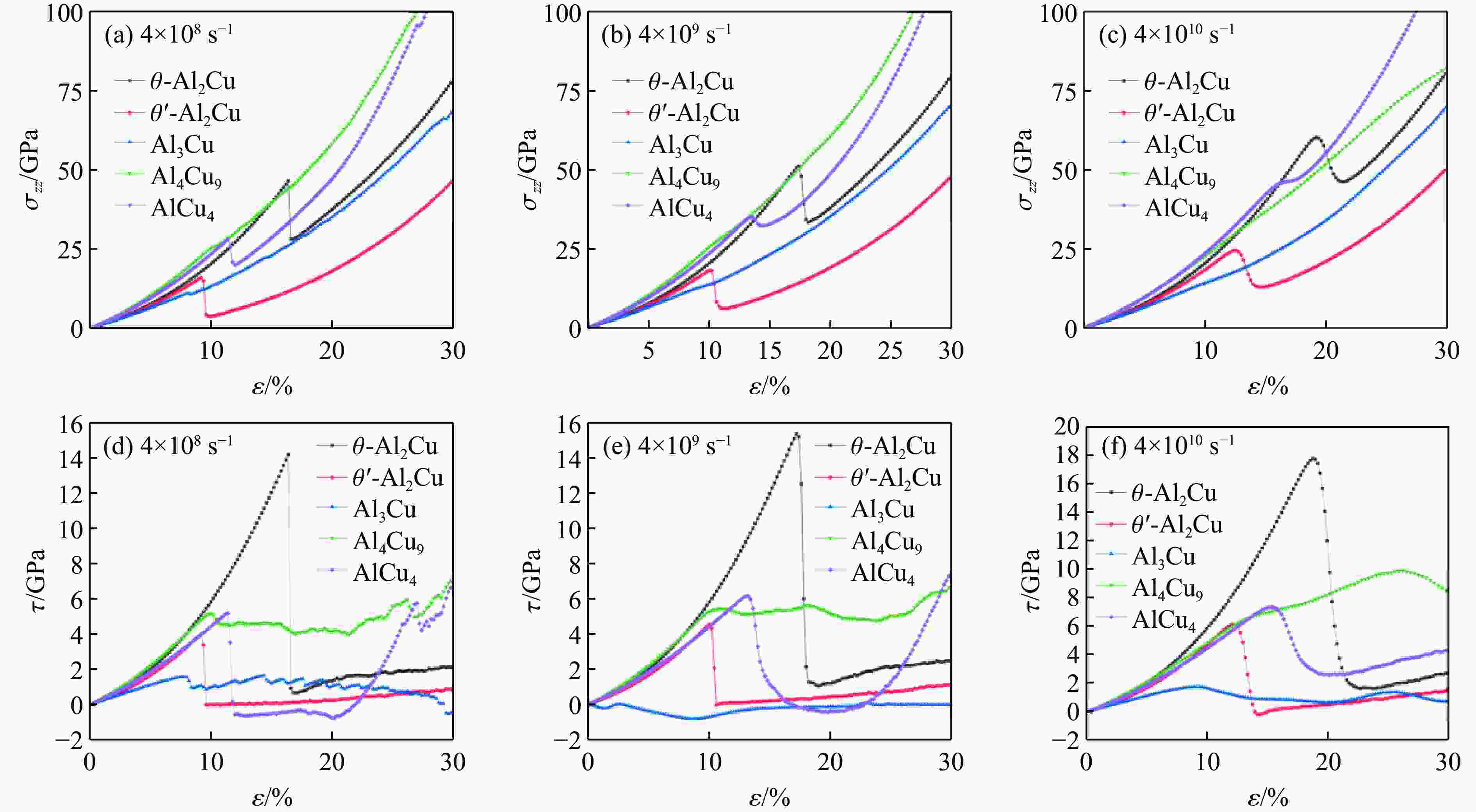

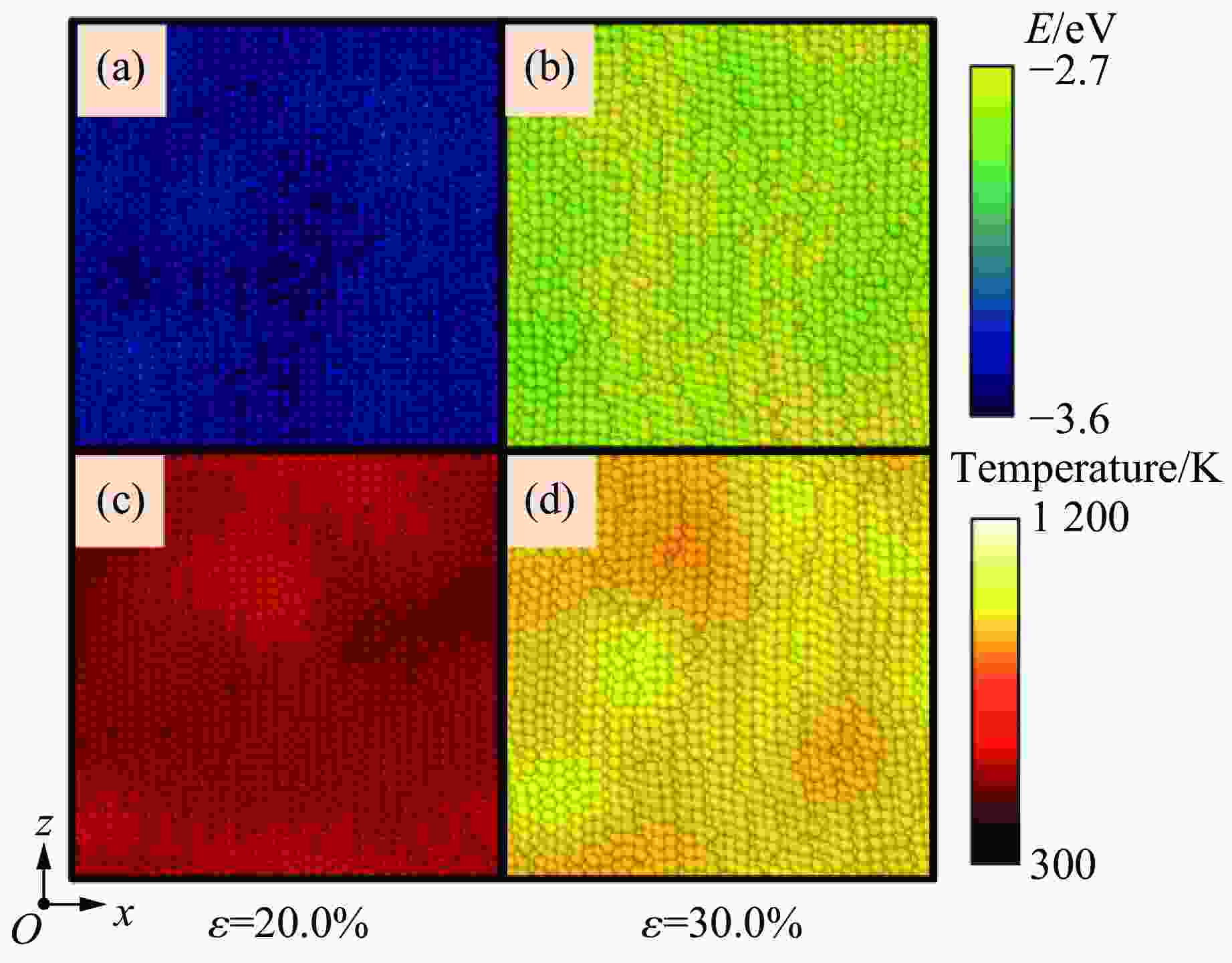

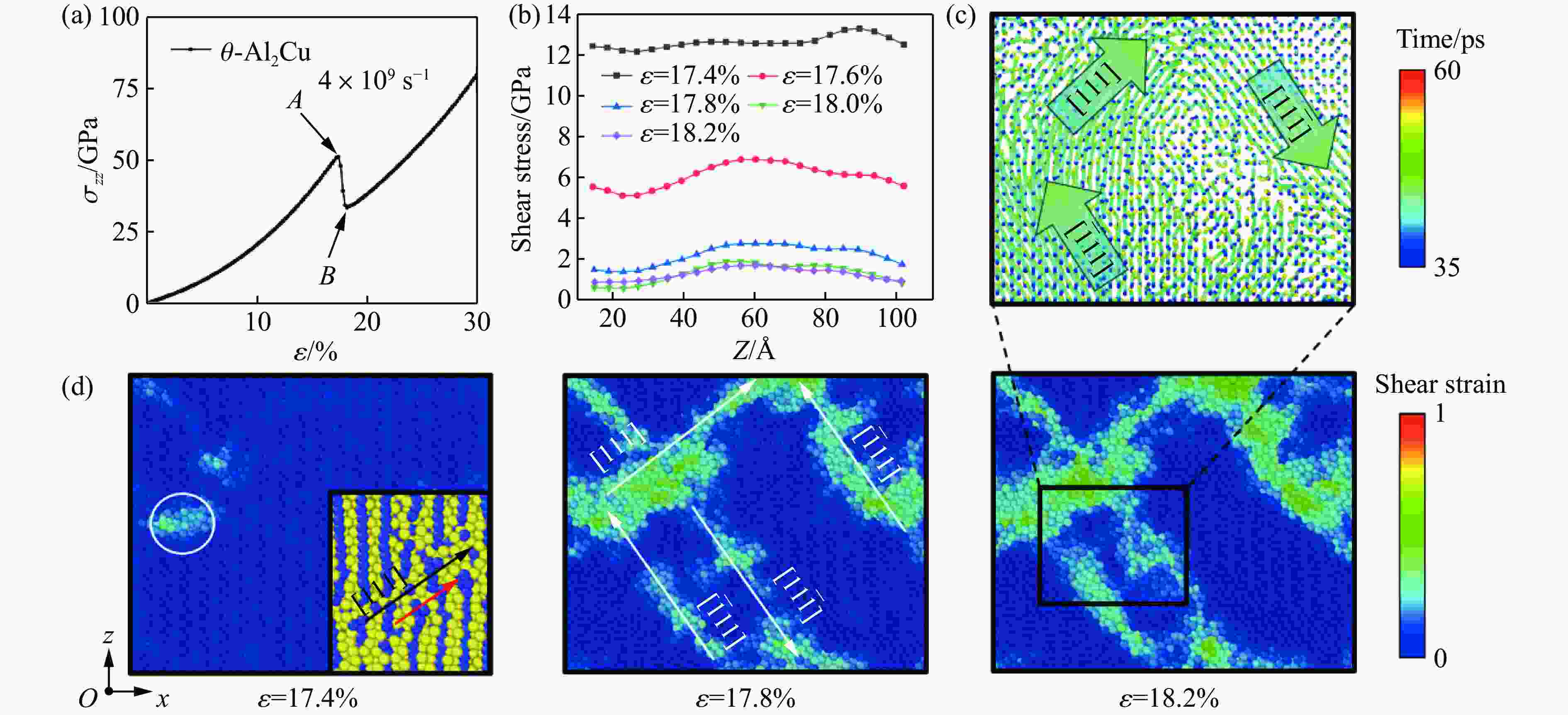

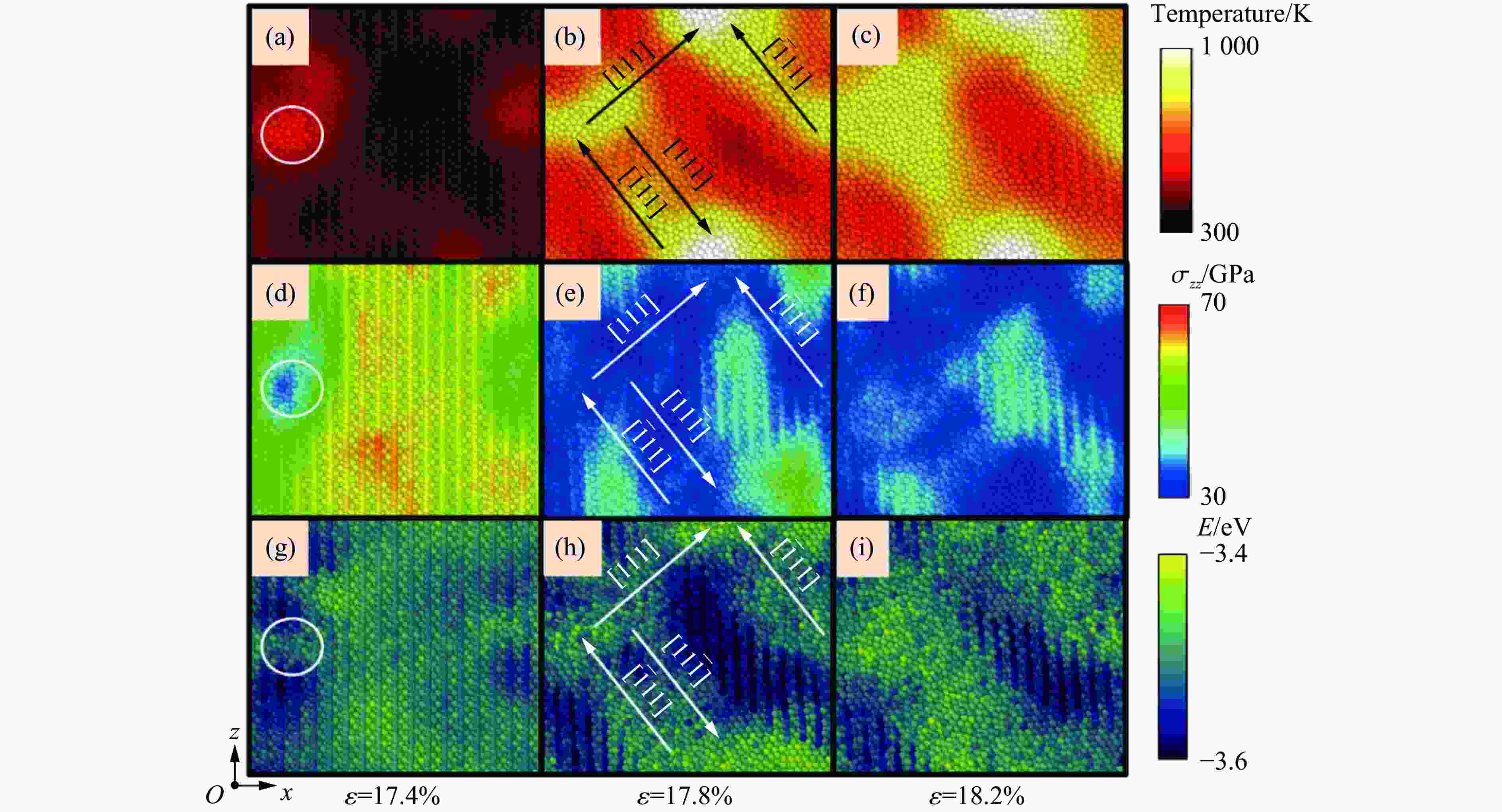

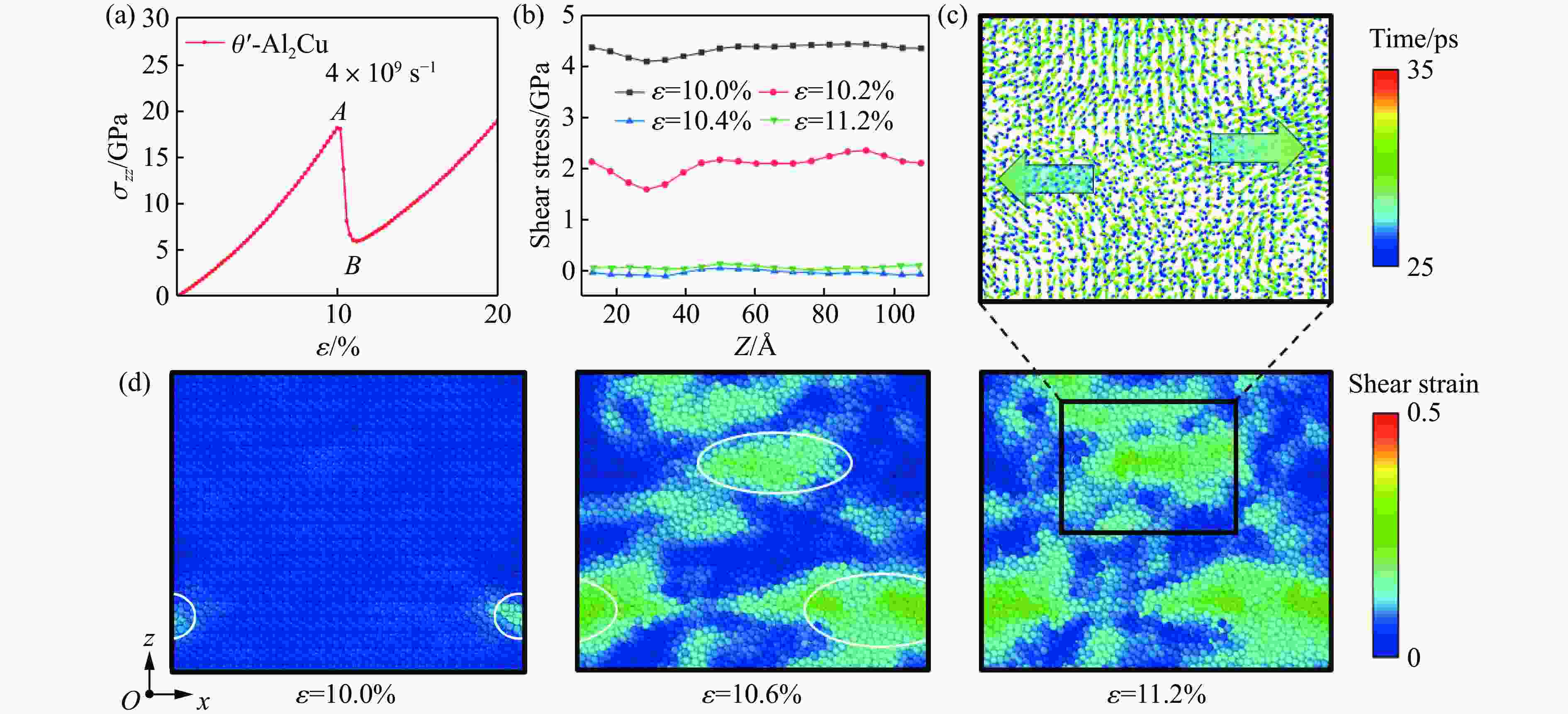

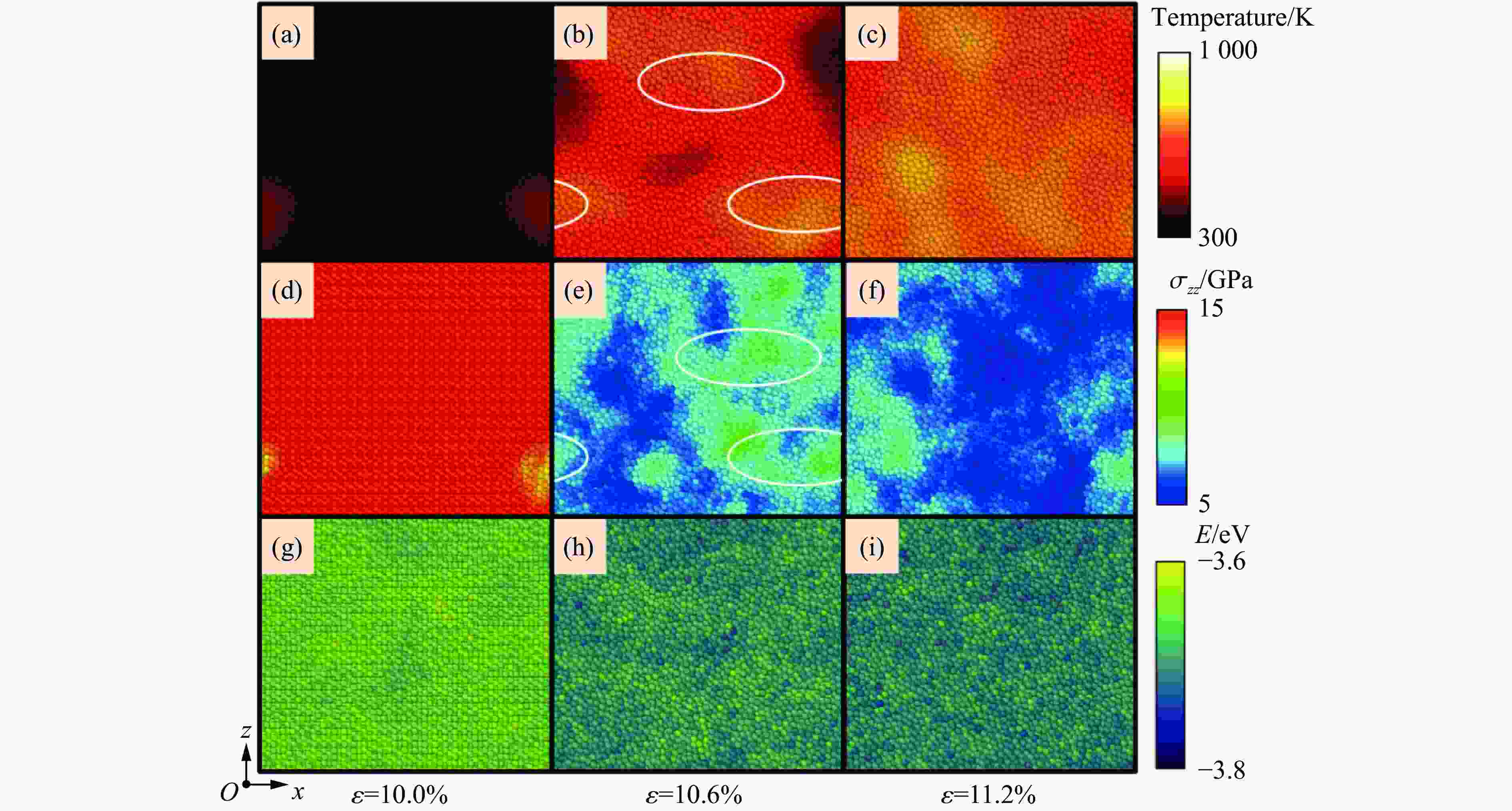

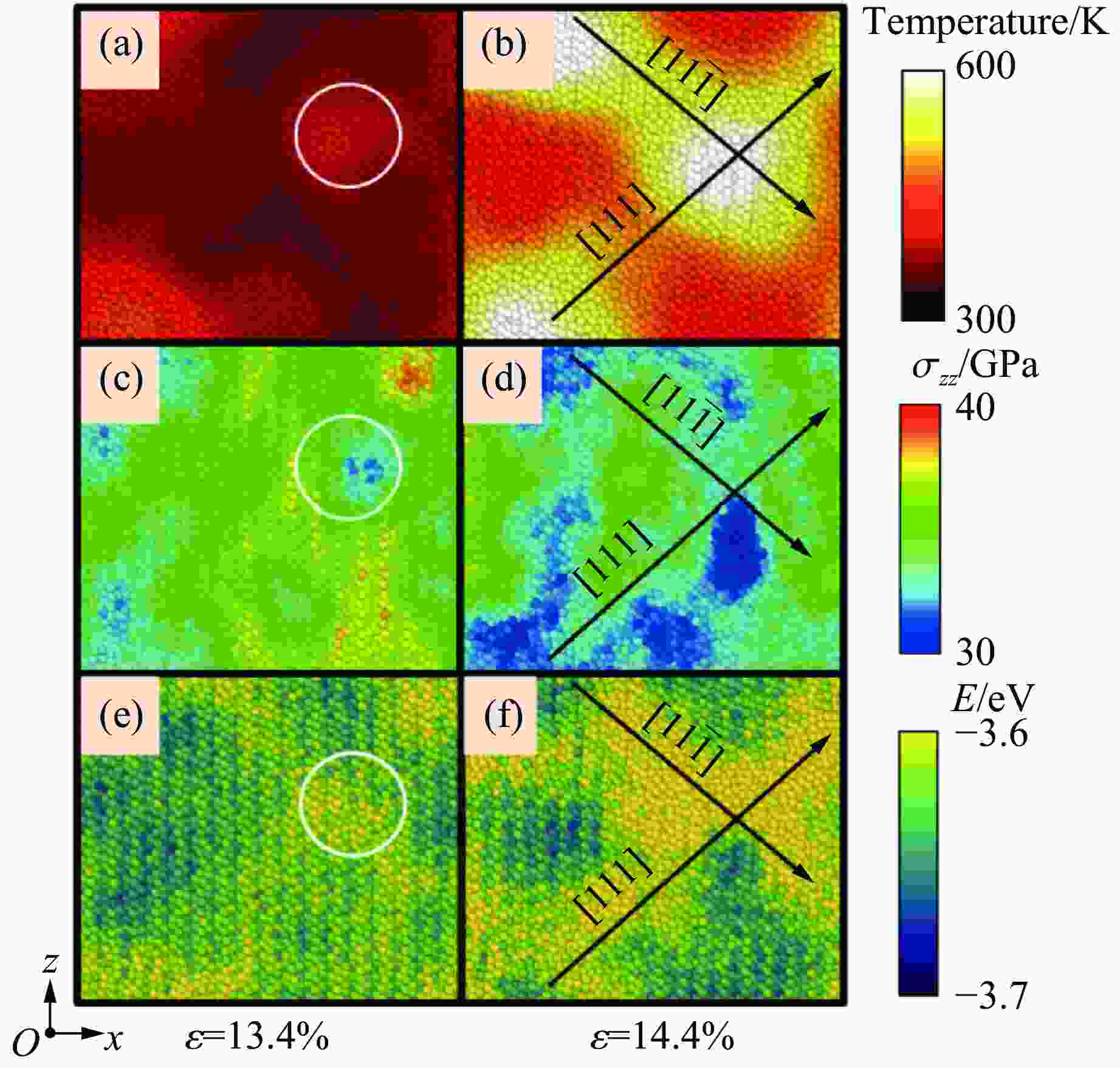

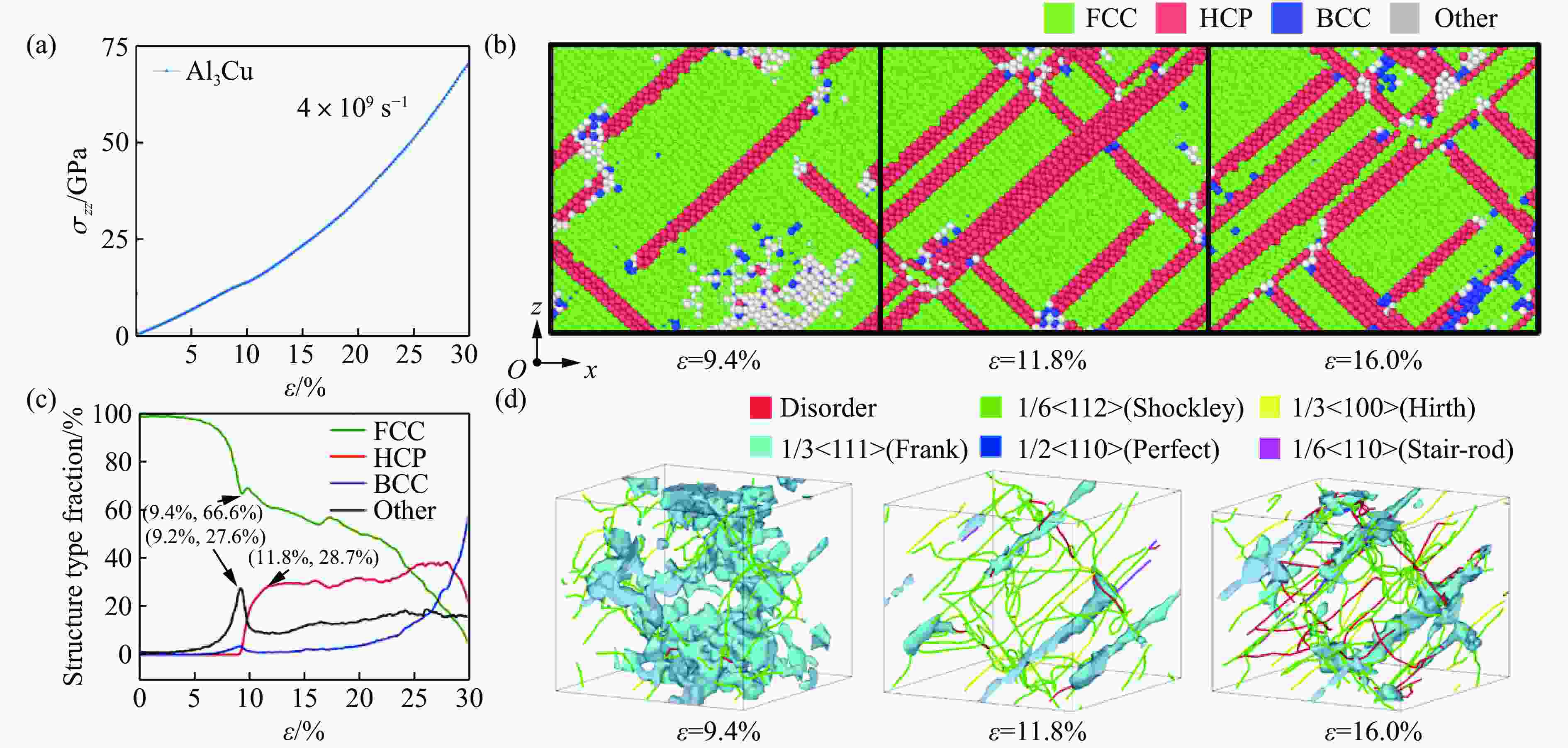

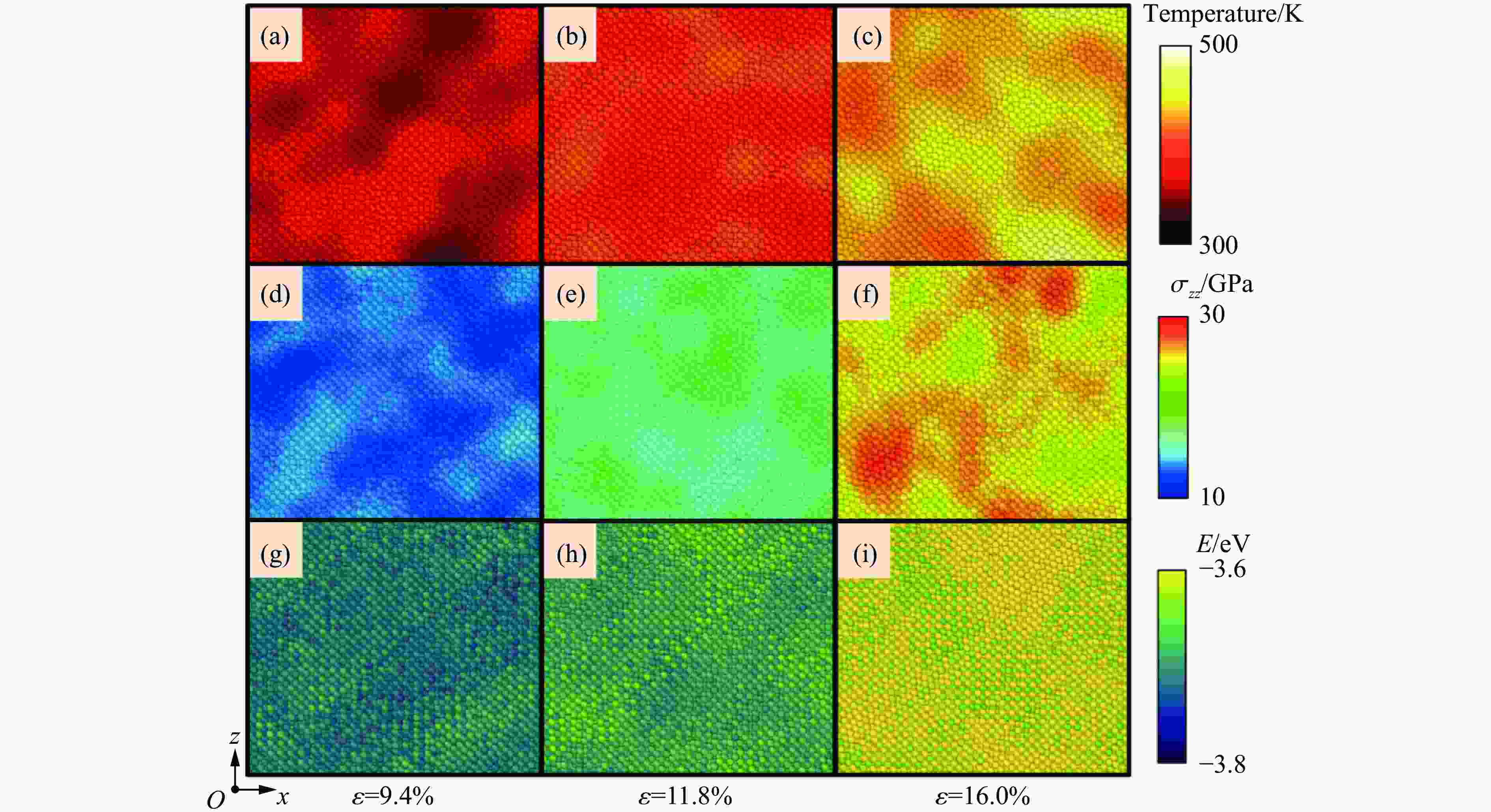

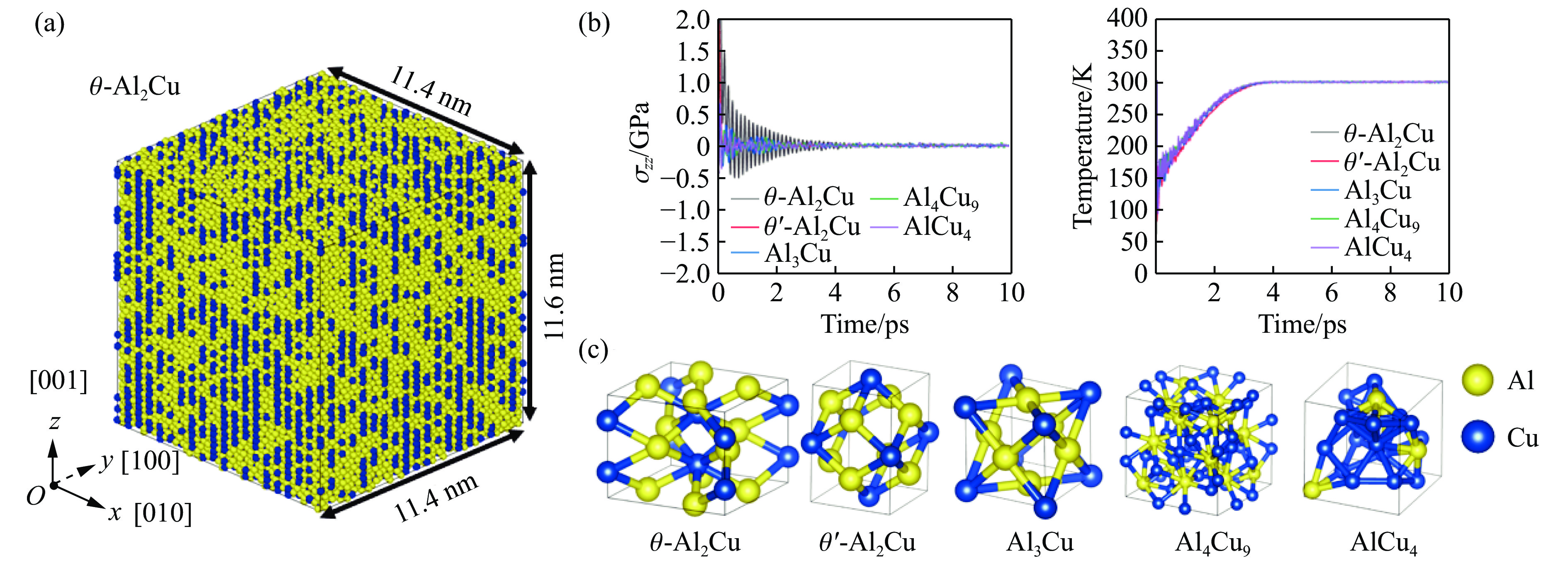

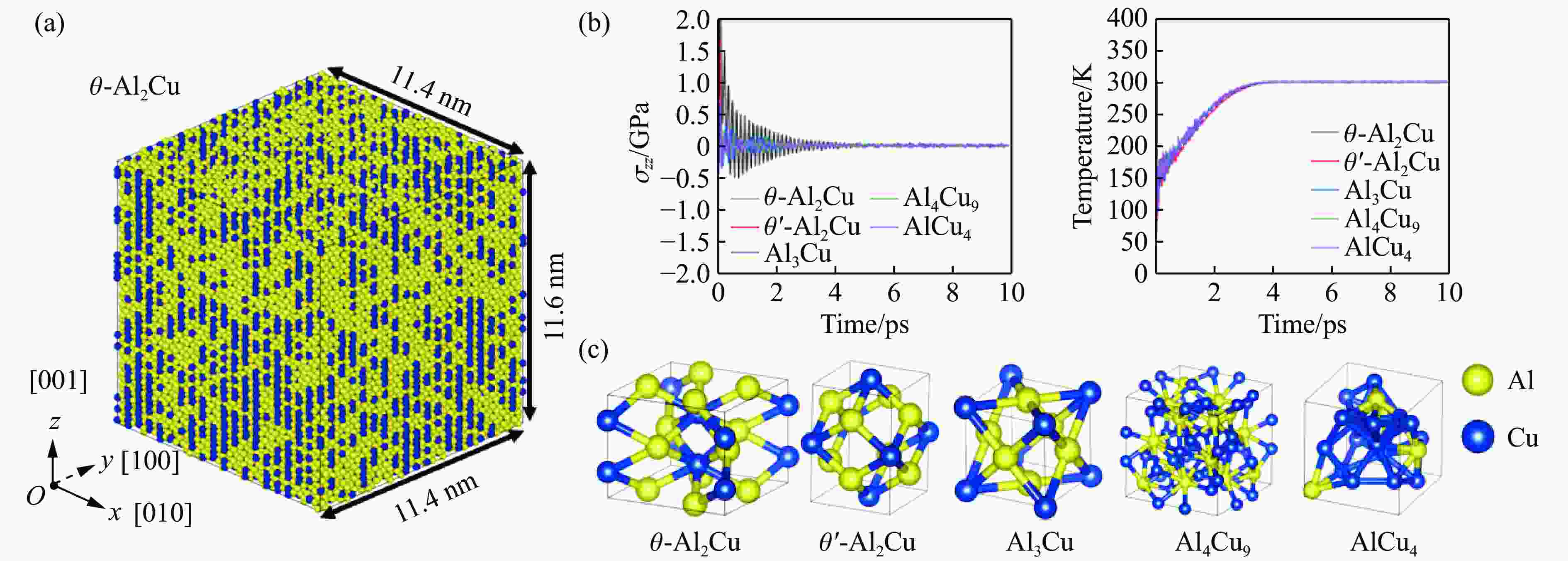

摘要: 研究Al-Cu金属间化合物对于Al-Cu合金的优化设计至关重要。分子动力学(molecular dynamics,MD)模拟可以给出Al-Cu合金力学行为的微观过程,而原子间作用势是保证模拟可靠性的关键物理基础。基于第一性原理计算数据构建了Al-Cu体系的深度势(deep potential,DP)函数,并将DP预测的物理性质(晶体结构、能量-体积曲线、压力-体积曲线和声子谱)与密度泛函理论(density functional theory,DFT)和嵌入原子势(embedded atom method,EAM)结果进行了对比分析,验证了DP模型的泛化能力和准确性。基于该DP模型,对5种Al-Cu金属间化合物(θ-Al2Cu、θ′-Al2Cu、Al3Cu、Al4Cu9和AlCu4相)进行了压缩过程MD模拟,给出了θ-Al2Cu、θ′-Al2Cu和AlCu4等结构屈服时的特征规律:θ-Al2Cu、θ′-Al2Cu和AlCu4的屈服应力和剪应力随应变率的升高而增大,屈服应变也相应提高。这一现象源于声子拖曳对原子滑移的阻碍增强。其中,θ-Al2Cu的抗压缩性能最好,在4×109 s−1应变率下压缩到17.4%时屈服,屈服强度为51.15 GPa,并产生螺位错,原子沿着[$ \overline{1}11 $]、[111]和[$11 \overline{1} $]方向滑移;θ′-Al2Cu压缩到10.0%时屈服,原子在垂直于压缩方向的平面内滑移;AlCu4相压缩到13.4%时屈服,原子沿着[401]和[$40 \overline{1} $]方向滑移。Abstract: The optimization design of Al-Cu intermetallic compounds is crucial for the mechanical properties of Al-Cu alloys. Molecular dynamics (MD) simulation can provide microscopic processes of the mechanical behavior of Al-Cu alloys, and the interatomic potential is the key physical basis to ensure the reliability of the MD simulation. This work constructed a depth potential (DP) function for the Al-Cu system based on first-principles calculations, and compared the physical properties predicted by DP (crystal structure, energy-volume curve, pressure-volume curve, and phonon spectrum) with density functional theory (DFT) and embedded atom method (EAM) results. The generalization ability and accuracy of the DP model were verified. Based on the DP potential, MD simulations were conducted on the compression process of five Al-Cu intermetallic compounds (θ-Al2Cu, θ′-Al2Cu, Al3Cu, Al4Cu9, and AlCu4 phases). The characteristics and laws of yielding phenomena in structures such as θ-Al2Cu, θ′-Al2Cu and AlCu4 were presented. The yield stress and shear stress of θ-Al2Cu, θ′-Al2Cu and AlCu4 increase with the increase of strain rate, and the yield strain also increases correspondingly. This phenomenon arises from the enhancement of phonon drag obstruction to atomic slip. Among them, θ-Al2Cu has the best compressive performance, yielding at a strain rate of 4×109 s−1 when compressed to 17.4%, with a yield strength of 51.15 GPa. Screw dislocations are produced, and the atoms slip along the [$ \overline{1} 11$], [111] and [$11 \overline{1} $] directions. θ′-Al2Cu yields when compressed to 10.0%, and the atoms slip in the plane perpendicular to the compression. Yielding occurs when the AlCu4 phase is compressed to 13.4% and the atoms slip along the [401] and [$40 \overline{1} $] directions.

-

Key words:

- Al-Cu alloy /

- machine learning /

- molecular dynamics /

- mechanical properties /

- uniaxial compression

-

表 1 Al-Cu二元金属间化合物基态下的晶格常数、形成焓和结合能

Table 1. Lattice constants, enthalpy of formation, and binding energy of Al-Cu binary intermetallic compounds in the ground state

Compound Space group a/Å b/Å c/Å ΔH/(eV/atom) ΔE/eV Source θ-Al2Cu I4/mcm 6.075 6.075 4.870 −0.133 −3.146 This work I4/mcm 6.073 6.073 4.879 −0.163 −3.850 Ref. [46] θ′-Al2Cu I4/mmm 4.061 4.061 5.702 −0.159 −3.173 This work I4/mmm 4.087 4.087 5.822 −0.149 −3.836 Ref. [46] Al3Cu Pm3m 3.924 3.924 3.924 −0.019 −2.953 This work Pm3m 3.938 3.938 3.938 −0.029 −3.715 Ref. [46] Ω-Al2Cu P4/mmm 4.105 4.105 2.891 −0.010 −3.024 This work P4/mmm 4.137 4.137 2.875 −0.016 −3.704 Ref. [46] 1-AlCu3 Pm3m 3.637 3.637 3.637 −0.168 −3.582 This work Pm3m 3.692 3.692 3.692 −0.170 −3.865 Ref. [46] Pm3m 3.641 3.641 3.641 Ref. [47] 1-AlCu Pm3m 2.998 2.998 2.998 −0.136 −3.310 This work Pm3m 2.998 2.998 2.998 −0.136 −3.826 Ref. [46] Al3Cu2 Pm3m1 4.092 4.092 4.993 −0.137 −3.215 This work Pm3m1 4.147 4.147 5.059 −0.145 −3.834 Ref. [46] Pm3m1 4.122 4.122 5.114 Ref. [48] AlCu4 P213 6.244 6.244 6.244 −0.111 −3.573 This work P213 6.331 6.331 6.331 −0.109 −3.804 Ref. [46] 2-AlCu3 P63/mmc 5.138 5.138 4.206 −0.175 −3.590 This work P63/mmc 5.223 5.223 4.250 −0.178 −3.872 Ref. [46] Al4Cu15 P4/mmm 3.609 3.609 18.456 −0.095 −3.548 This work P4/mmm 3.677 3.677 18.034 −0.093 −3.788 Ref. [46] 3-AlCu3 Fm3m 5.776 5.776 5.776 −0.154 −3.568 This work Fm3m 5.858 5.858 5.858 −0.163 −3.857 Ref. [46] Fm3m 5.798 5.798 5.798 Ref. [49] 4-AlCu3 Pmmn 4.173 4.512 5.107 −0.180 −3.594 This work 2-AlCu C12/m1 4.056 6.315 6.325 −0.199 −3.373 This work Al4Cu9 P43m 8.618 8.618 8.618 −0.202 −3.561 This work P43m 8.738 8.738 8.738 −0.203 −3.896 Ref. [46] 2-Al3Cu P4/mmm 2.778 2.778 7.513 −0.062 −2.995 This work P4/mmm 2.802 2.802 7.732 −0.082 −3.768 Ref. [46] 表 2 Al-Cu二元金属间化合物基态弹性模量

Table 2. Elastic modulus of Al-Cu binary intermetallic compounds in ground state

Compound Space group B/GPa Em/GPa G/GPa ν B/G θ-Al2Cu I4/mcm 76.10 119.43 48.22 0.24 1.58 θ′-Al2Cu I4/mmm 85.39 142.68 58.40 0.22 1.46 Al3Cu Pm3m 86.15 133.73 53.87 0.24 1.60 Ω-Al2Cu P4/mmm 88.10 93.80 35.46 0.32 2.48 2-AlCu C12/m1 48.31 136.59 66.43 0.03 0.73 Al3Cu2 P3ml 77.21 104.28 40.90 0.27 1.89 AlCu4 P213 80.98 112.41 44.30 0.27 1.83 Al4Cu9 P43m 106.51 191.91 79.98 0.20 1.33 -

[1] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys [J]. Materials & Design (1980–2015), 2014, 56: 862–871. doi: 10.1016/j.matdes.2013.12.002 [2] ZHANG X S, CHEN Y J, HU J L. Recent advances in the development of aerospace materials [J]. Progress in Aerospace Sciences, 2018, 97: 22–34. doi: 10.1016/j.paerosci.2018.01.001 [3] LI S S, YUE X, LI Q Y, et al. Development and applications of aluminum alloys for aerospace industry [J]. Journal of Materials Research and Technology, 2023, 27: 944–983. doi: 10.1016/j.jmrt.2023.09.274 [4] DE SOUSA ARAUJO J V, MILAGRE M X, FERREIRA R O, et al. Microstructural characteristics of the al alloys: the dissimilarities among the 2XXX alloys series used in aircraft structures [J]. Metallography, Microstructure, and Analysis, 2020, 9(5): 744–758. doi: 10.1007/s13632-020-00688-5 [5] HE S, CHEN S, ZHAO Y Q, et al. Study on the intelligent model database modeling the laser welding for aerospace aluminum alloy [J]. Journal of Manufacturing Processes, 2021, 63: 121–129. doi: 10.1016/j.jmapro.2020.04.043 [6] SETTLES G S, KEANE B T, ANDERSON B W, et al. Shock waves in aviation security and safety [J]. Shock Waves, 2003, 12(4): 267–275. doi: 10.1007/s00193-002-0162-1 [7] THORPE J. Fatalities and destroyed aircraft due to bird strikes, 1912–2002 [J]. Modern Language Journal, 2003, 9(6): 375–376. doi: 10.1530/endoabs.37.EP326 [8] CORNMAN L B, MORSE C S, CUNNING G. Real-time estimation of atmospheric turbulence severity from in-situ aircraft measurements [J]. Journal of Aircraft, 2012, 32(1): 171–177. doi: 10.2514/3.46697 [9] BRAMBERGER M, DÖRNBRACK A, WILMS H, et al. Vertically propagating mountain waves—a hazard for high-flying aircraft? [J]. Journal of Applied Meteorology and Climatology, 2018, 57(9): 1957–1975. doi: 10.1175/JAMC-D-17-0340.1 [10] YANG P P, YUE W H, LI J, et al. Review of damage mechanism and protection of aero-engine blades based on impact properties [J]. Engineering Failure Analysis, 2022, 140: 106570. doi: 10.1016/j.engfailanal.2022.106570 [11] SUN D Q, WANG Y X, ZHANG X Y, et al. First-principles calculation on the thermodynamic and elastic properties of precipitations in Al-Cu alloys [J]. Superlattices and Microstructures, 2016, 100: 112–119. doi: 10.1016/j.spmi.2016.09.012 [12] WOLVERTON C. First-principles prediction of equilibrium precipitate shapes in Al-Cu alloys [J]. Philosophical Magazine Letters, 1999, 79(9): 683–690. doi: 10.1080/095008399176724 [13] GUINIER A. Structure of age-hardened aluminium-copper alloys [J]. Nature, 1938, 142(3595): 569–570. doi: 10.1038/142569b0 [14] NAYAK S K, HUNG C J, HEBERT R J, et al. Atomistic origins of Guinier-Preston zone formation and morphology in Al-Cu and Al-Ag alloys from first principles [J]. Scripta Materialia, 2019, 162: 235–240. doi: 10.1016/j.scriptamat.2018.11.031 [15] ZHOU Q, WANG J, MISRA A, et al. Atomistic study of fundamental character and motion of dislocations in intermetallic Al2Cu [J]. International Journal of Plasticity, 2016, 87: 100–113. doi: 10.1016/j.ijplas.2016.09.005 [16] WADA M, KITA H, MORI T. FIM observation of GP zones in an Al-4%Cu alloy [J]. Acta Metallurgica, 1985, 33(9): 1631–1636. doi: 10.1016/0001-6160(85)90158-0 [17] WANG R H, WEN Y, CHEN B A. Sn microalloying Al-Cu alloys with enhanced fracture toughness [J]. Materials Science and Engineering: A, 2021, 814: 141243. doi: 10.1016/j.msea.2021.141243 [18] GUO C C, ZHANG R Z, LI L, et al. Multiscale analysis of Al4Cu9 intermetallic compounds on shock Hugoniot of Al-Cu composites: experiments and simulations [J]. Composite Structures, 2025, 355: 118866. doi: 10.1016/j.compstruct.2025.118866 [19] DOBROMYSLOV A V, TALUTS N I, KOZLOV E A, et al. Influence of spherical converging shock waves on the structure of Al-2.4% Mg-5.5% Zn alloy [J]. Journal de Physique Ⅳ, 2006, 134: 1003–1008. doi: 10.1051/jp4:2006134153 [20] SINGH C V, WARNER D H. Mechanisms of Guinier-Preston zone hardening in the athermal limit [J]. Acta Materialia, 2010, 58(17): 5797–5805. doi: 10.1016/j.actamat.2010.06.055 [21] KRASNIKOV V S, MAYER A E. Modeling of plastic localization in aluminum and Al-Cu alloys under shock loading [J]. Materials Science and Engineering: A, 2014, 619: 354–363. doi: 10.1016/j.msea.2014.09.105 [22] YANILKIN A V, KRASNIKOV V S, KUKSIN A Y, et al. Dynamics and kinetics of dislocations in Al and Al-Cu alloy under dynamic loading [J]. International Journal of Plasticity, 2014, 55: 94–107. doi: 10.1016/j.ijplas.2013.09.008 [23] POGORELKO V V, MAYER A E. Propagation of shock waves and fracture in the Al-Cu composite: numerical simulation [J]. Journal of Physics: Conference Series, 2015, 653: 012046. doi: 10.1088/1742-6596/653/1/012046 [24] MOJUMDER S. Molecular dynamics study of plasticity in Al-Cu alloy nanopillar due to compressive loading [J]. Physica B: Condensed Matter, 2018, 530: 86–89. doi: 10.1016/j.physb.2017.10.119 [25] TIAN X, CUI J Z, YANG M, et al. Molecular dynamics simulations on shock response and spalling behaviors of semi-coherent {111} Cu-Al multilayers [J]. International Journal of Mechanical Sciences, 2020, 172: 105414. doi: 10.1016/j.ijmecsci.2019.105414 [26] CAI J, YE Y Y. Simple analytical embedded-atom-potential model including a long-range force for fcc metals and their alloys [J]. Physical Review B, 1996, 54(12): 8398–8410. doi: 10.1103/PhysRevB.54.8398 [27] APOSTOL F, MISHIN Y. Interatomic potential for the Al-Cu system [J]. Physical Review B, 2011, 83(5): 054116. doi: 10.1103/PhysRevB.83.054116 [28] JOHNSON R A. Alloy models with the embedded-atom method [J]. Physical Review B, 1989, 39(17): 12554–12559. doi: 10.1103/PhysRevB.39.12554 [29] JORDAN M I, MITCHELL T M. Machine learning: trends, perspectives, and prospects [J]. Science, 2015, 349(6245): 255–260. doi: 10.1126/science.aaa8415 [30] LEE K, YOO D, JEONG W, et al. SIMPLE-NN: an efficient package for training and executing neural-network interatomic potentials [J]. Computer Physics Communications, 2019, 242: 95–103. doi: 10.1016/j.cpc.2019.04.014 [31] STANLEY K O, CLUNE J, LEHMAN J, et al. Designing neural networks through neuroevolution [J]. Nature Machine Intelligence, 2019, 1(1): 24–35. doi: 10.1038/s42256-018-0006-z [32] WANG H, ZHANG L F, HAN J Q, et al. DeePMD-kit: a deep learning package for many-body potential energy representation and molecular dynamics [J]. Computer Physics Communications, 2018, 228: 178–184. doi: 10.1016/j.cpc.2018.03.016 [33] ZHANG L F, WANG H, CAR R, et al. Phase diagram of a deep potential water model [J]. Physical Review Letters, 2021, 126(23): 236001. doi: 10.1103/PhysRevLett.126.236001 [34] WANG F, SUN Y, CHENG J. Switching of redox levels leads to high reductive stability in water-in-salt electrolytes [J]. Journal of the American Chemical Society, 2023, 145(7): 4056–4064. doi: 10.1021/jacs.2c11793 [35] JIANG W R, ZHANG Y Z, ZHANG L F, et al. Accurate deep potential model for the Al-Cu-Mg alloy in the full concentration space [J]. Chinese Physics B, 2021, 30(5): 050706. doi: 10.1088/1674-1056/abf134 [36] KRESSE G, FURTHMÜLLER J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set [J]. Physical Review B, 1996, 54(16): 11169–11186. doi: 10.1103/PhysRevB.54.11169 [37] KRESSE G, FURTHMÜLLER J. Efficiency of ab initio total energy calculations for metals and semiconductors using a plane-wave basis set [J]. Computational Materials Science, 1996, 6(1): 15–50. doi: 10.1016/0927-0256(96)00008-0 [38] PERDEW J P, BURKE K, ERNZERHOF M. Generalized gradient approximation made simple [J]. Physical Review Letters, 1998, 77(18): 3865–3868. doi: 10.1103/PhysRevLett.77.3865 [39] KRESSE G, JOUBERT D. From ultrasoft pseudopotentials to the projector augmented-wave method [J]. Physical Review B, 1999, 59(3): 1758–1775. doi: 10.1103/PhysRevB.59.1758 [40] TOGO A, TANAKA I. First principles phonon calculations in materials science [J]. Scripta Materialia, 2015, 108: 1–5. doi: 10.1016/j.scriptamat.2015.07.021 [41] ZHANG Y Z, WANG H D, CHEN W J, et al. DP-GEN: a concurrent learning platform for the generation of reliable deep learning based potential energy models [J]. Computer Physics Communications, 2020, 253: 107206. doi: 10.1016/j.cpc.2020.107206 [42] PLIMPTON S. Fast parallel algorithms for short-range molecular dynamics [J]. Journal of Computational Physics, 1995, 117(1): 1–19. doi: 10.1006/jcph.1995.1039 [43] STUKOWSKI A. Visualization and analysis of atomistic simulation data with OVITO—the open visualization tool [J]. Modelling and Simulation in Materials Science and Engineering, 2010, 18(1): 015012. doi: 10.1088/0965-0393/18/1/015012 [44] STUKOWSKI A. Structure identification methods for atomistic simulations of crystalline materials [J]. Modelling and Simulation in Materials Science and Engineering, 2012, 20(4): 045021. doi: 10.1088/0965-0393/20/4/045021 [45] STUKOWSKI A, BULATOV V V, ARSENLIS A. Automated identification and indexing of dislocations in crystal interfaces [J]. Modelling and Simulation in Materials Science and Engineering, 2012, 20(8): 085007. doi: 10.1088/0965-0393/20/8/085007 [46] 孙凤儿. 铝铜合金金属间化合物及界面性能的第一性原理研究 [D]. 太原: 中北大学, 2021: 34−38.SUN F E. First principles study on intermetallic compounds and interfacial properties of aluminum-copper alloys [D]. Taiyuan: North University of China, 2021: 34−38. [47] ZHOU W, LIU L J, LI B L, et al. Structural, elastic, and electronic properties of Al-Cu intermetallics from first-principles calculations [J]. Journal of Electronic Materials, 2009, 38(2): 356–364. doi: 10.1007/s11664-008-0587-0 [48] YANG C D, LI W, ZHI W. Study on mechanical behavior and electronic structures of Al-Cu intermetallic compounds based on first-principles calculations [J]. Solid State Communications, 2011, 151(18): 1270–1274. doi: 10.1016/j.ssc.2011.05.040 [49] CHEN H C, YANG L J, LONG J P. First-principles investigation of the elastic, Vickers hardness and thermodynamic properties of Al-Cu intermetallic compounds [J]. Superlattices and Microstructures, 2015, 79: 156–165. doi: 10.1016/j.spmi.2014.11.005 [50] WANG C, CHEN J, LIANG S H, et al. First-principles calculations to investigate pressure effect on structural, elastic and thermodynamic properties of AlCu, Al2Cu and Al4Cu9 [J]. Vacuum, 2022, 203: 111279. doi: 10.1016/j.vacuum.2022.111279 -

下载:

下载: